It is always helpful to use a familiar yarn when testing techniques and to have some idea what baseline tensions produce each desired fabric before combining fabric types, structures, and techniques. This will ensure that the knit result will be both manageable to produce, and will match your desired concept.

Any time an empty needle is brought in to work, the first knit pass will create a loop on the empty needle; the second pass will form a full stitch, resulting in a hole. This is seen in lace transfers or when bringing empty needles into work closes single ladder spaces.

Use garment yarn double thickness in the EON needle rib if the aim is to produce DBJ, which will yield a different thickness knit. Test for other fabrics ie patterned English rib, etc. Swatching is worth the effort, avoids producing whole pieces where combined results are disappointing.

EON rib set up for your brand machine

Knit 20+ rows

End and begin the test with COR; trim off one yarn end, to be woven in using your favorite method

Racking handle at half pitch

Bring all needles into work both beds

Observe the needle rule appropriate for your double bed fabric Set both carriages or locks to tuck

Reduce stitch size tensions by one whole number, knit one row, which will produce a “zigzag” across all needles, with a loop on each needle, both beds

Set both carriages to knit circular; this will be a slipstitch, tension may need to be loosened by one number to accommodate the added yarn, knit 2 or 4 rows

Set both carriages to knit, enlarge stitch size one or 2 numbers if needed, knit one row

Proceed as required for pattern

Depending on which direction your first row of “garment” fabric needs to be selected if using a color changer, planning for that may affect which side of the machine needs to be your final location before knitting the first row of pattern.

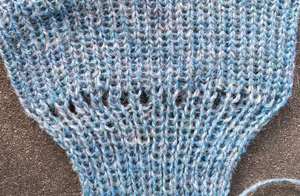

The swatches below illustrate the transitions, are in their “just off the machine” state. I used the same tension throughout. The EOR rib was knit single strand, the resulting difference in width is easily seen, though the density difference is obviously not observable in a photo. The yarn used is one of my “throw-away” acrylic/ wool blends.

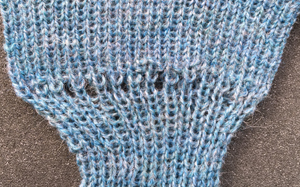

side 1 “holes”

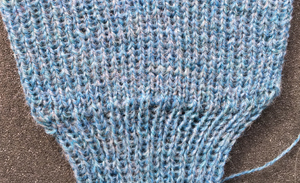

side 1 “no holes”

side 1 “no holes” side 2 “holes”

side 2 “holes” side 2 “no holes”

side 2 “no holes”