In the past, I knit several shawls using the alpaca and silk blend mentioned in my posts. The colors purchased in the latest shipment for some reason, however, have refused to knit without creating enough problems in dropping stitches that I gave up on each of the projects attempted using them.

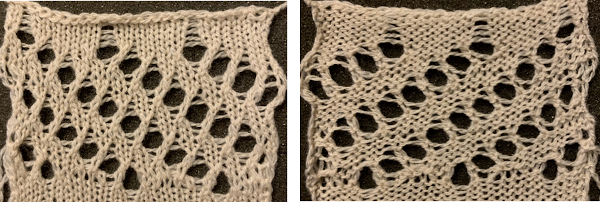

My latest two shawls proved to be one of those instructive cases where the knit behaves just fine in smaller samples and is cranky and hard to manage when a larger number of needles is in use, resulting in switching fiber content to get the piece made

space-dyed that was unsuccessful

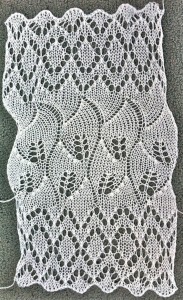

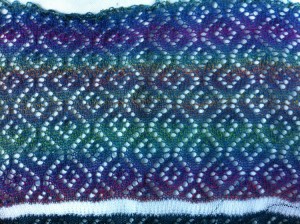

the finished shawl in wool/rayon blend

one disadvantage in deeply colored space-dyed is that some of the surface texture I lost, and patterns may become less evident

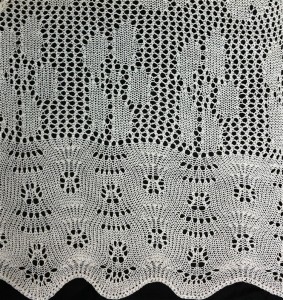

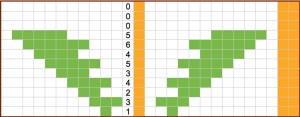

here is another version in wool crepe in what I am now calling my “firecracker” pattern

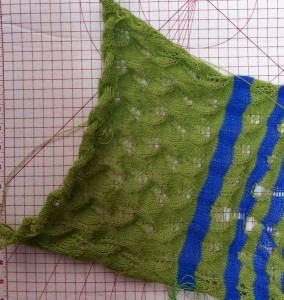

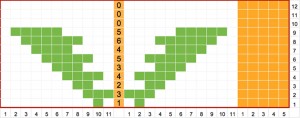

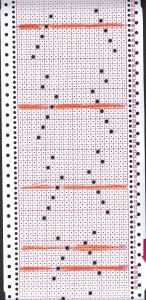

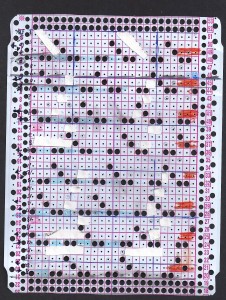

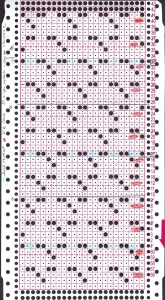

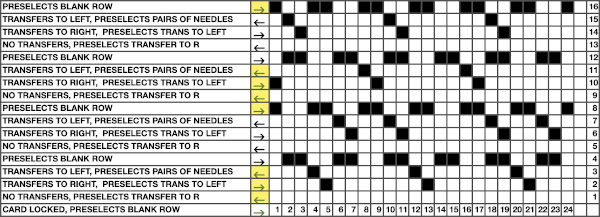

Below is my latest effort. The card that produces it is 90 rows in length and 22 knit rows are completed at the end of each of its rotations. The blue yarn is actually a multi-strand rayon, thicker than the alpaca/silk, was knitting pretty well until the individual thin strands began to break frequently and the partial shawl got added to the future “do something else with” stash of UFOs. There are many rows where 2 or 3 stitches are moved together onto the adjacent needle. I have some Tencel blends that are lovely colors, that when swatched consistently dropped stitches in areas of those transfers, probably because of lack of any “give” in the fiber. Going back to a wool rayon blend, I was able to actually complete a piece, which now awaits blocking.

the rayon multi-strand rayon swatch

the blocked, completed piece in wool crepe, 20X76 inches

With the huge supply of alpaca/silk and other yarns that will not transfer well, I am now considering taking a break from transfer lace and returning to tuck, tuck lace with NOOW, and similar fabrics for a “break” from the routine of this past year.

A brief return in 2020 analyzing the actions of the lace carriage a different way

A brief return in 2020 analyzing the actions of the lace carriage a different way  and a new test swatch

and a new test swatch