I am including notes on my working through the process and some of my stumbles at the start of this post. More specific how-tos are found toward the bottom of it.

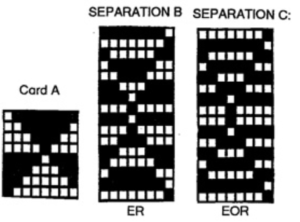

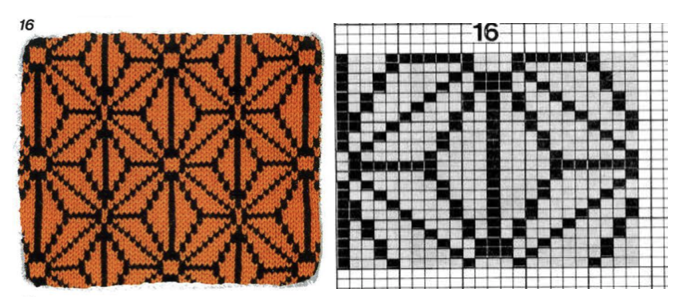

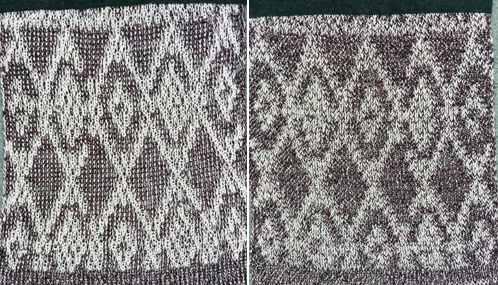

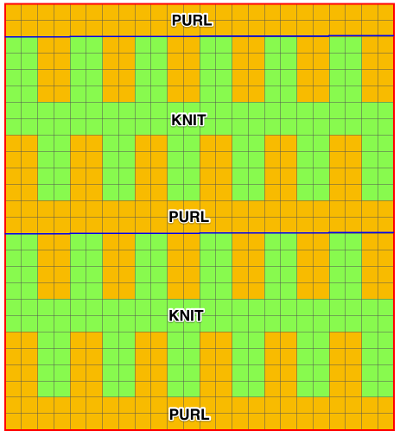

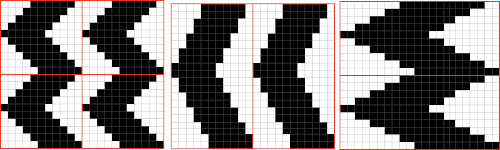

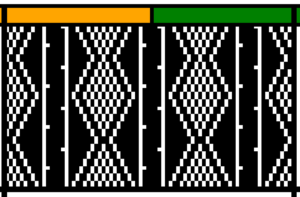

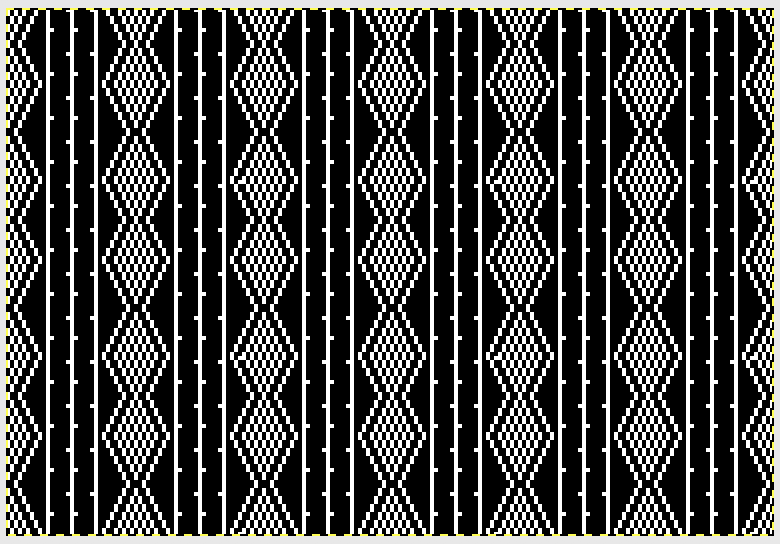

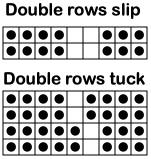

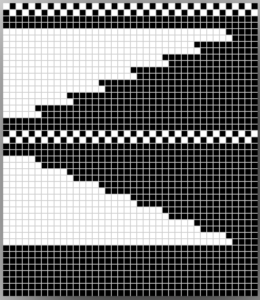

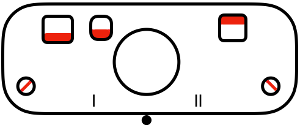

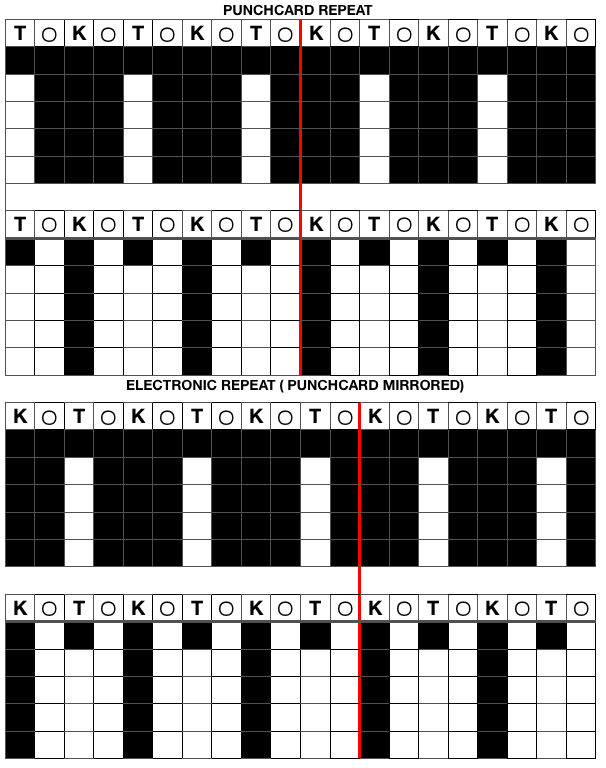

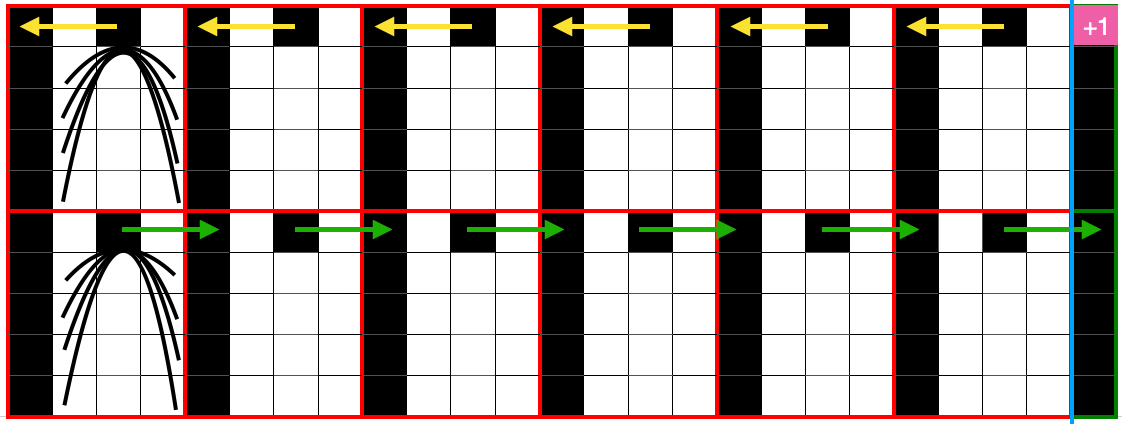

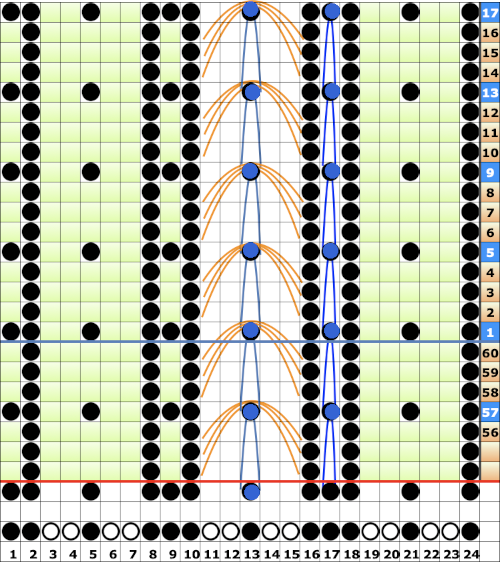

Such fabrics may be created with both the KRC built-in function or with the color separations that knit each color for each design row for 2 consecutive, identical rows. Punchcard knitters are not excluded. The starting side is on the left for the KRC setting (B in this illustration), on the right side for the alternate color separation (C, double length, or drawn with each row repeating X 2). I am still testing my 930, for my samples I began by using the built-in pattern #16 in the Stitchworld Pattern Book I.

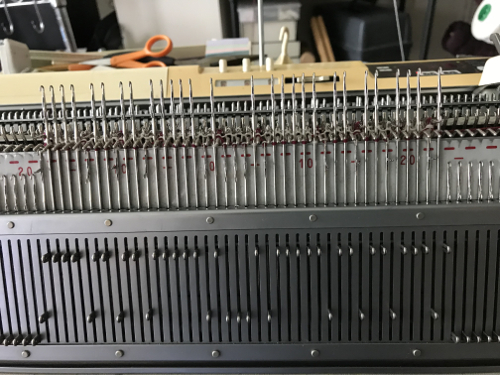

I am still testing my 930, for my samples I began by using the built-in pattern #16 in the Stitchworld Pattern Book I.  In the absence of a jac40, the fabrics are knit by manually selecting stitches to the upper working position (E on Brother) on the ribber bed every row. Preselection for the next row to be knit on the main bed makes the process far easier.

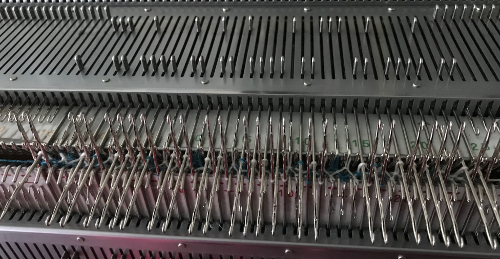

In the absence of a jac40, the fabrics are knit by manually selecting stitches to the upper working position (E on Brother) on the ribber bed every row. Preselection for the next row to be knit on the main bed makes the process far easier.

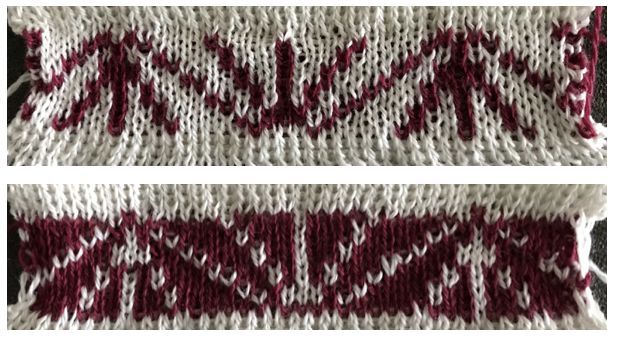

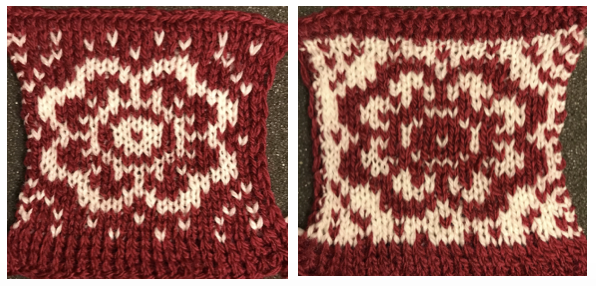

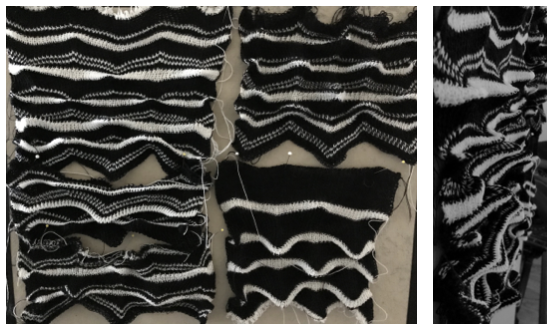

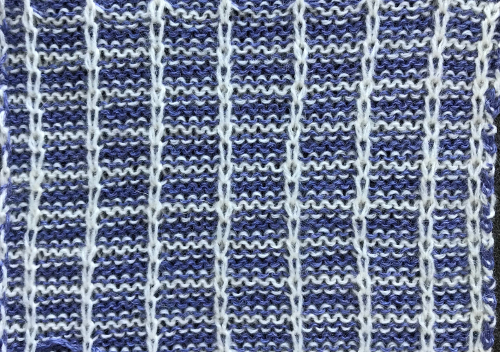

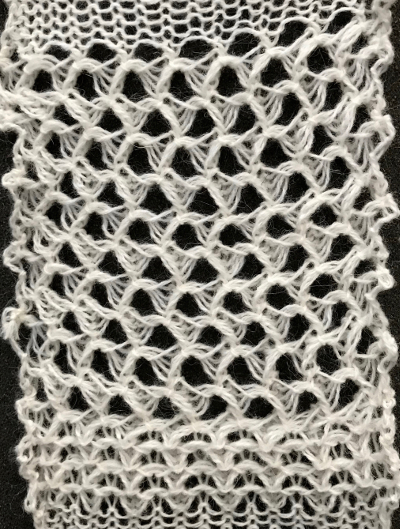

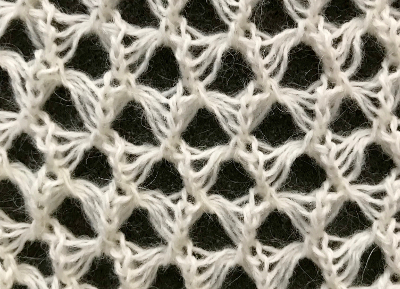

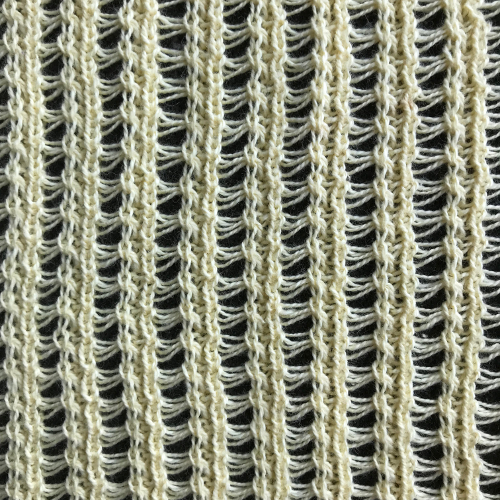

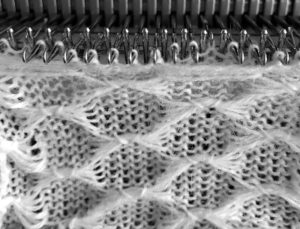

In my first sample, the colors are the same on each face. Since the same number of needles are selected for both design and ground, both sides of the fabric will be exactly alike. There will be floats, enclosed by knit stitches of the opposite color. Beds are set at half-pitch. Consistency makes any process easier and more predictable. My ribber set up was also with an extra needle on the ribber at either end of those in work on the main bed. I found I had less issue with the long floats in my design when I made certain the needle selection began with needles to the left of those in work on the opposite bed rather than to the right, allowing for the color in use to knit first on the ribber, then in turn on the main bed. It may not matter with patterns with shorter spans worked between the 2 colors. The dropped stitch issues below were resolved by using different yarns, no other changes.

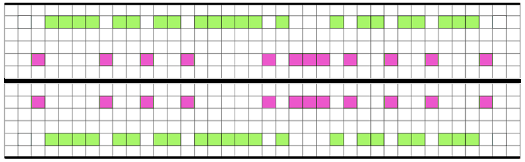

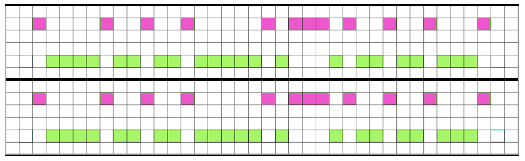

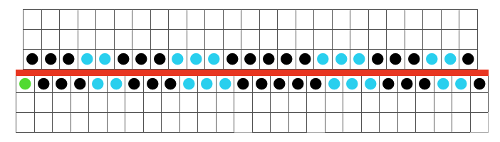

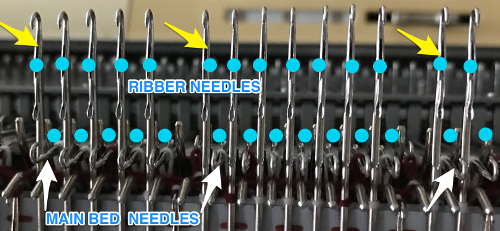

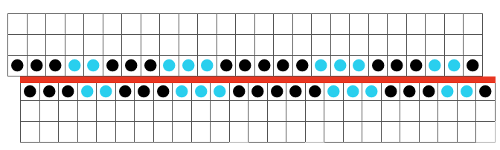

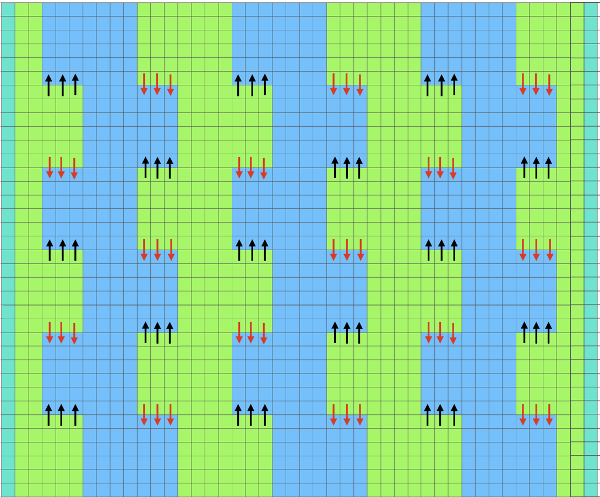

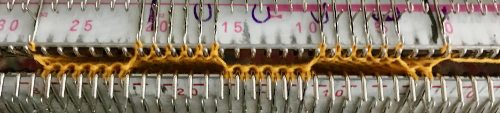

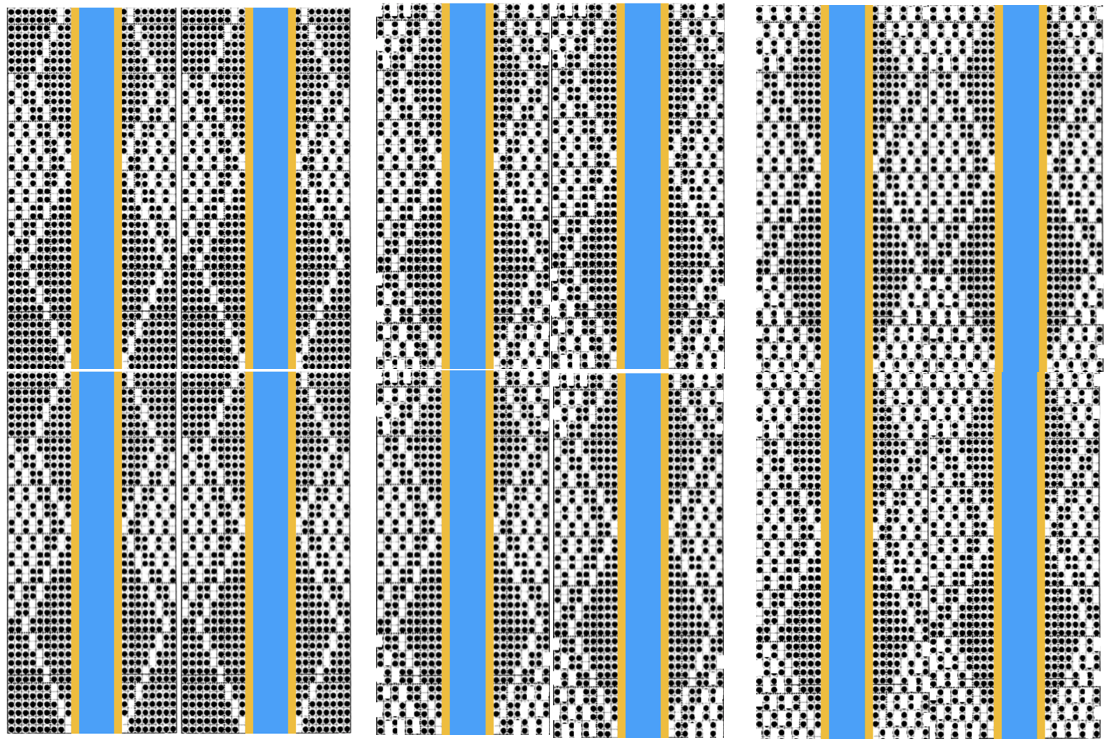

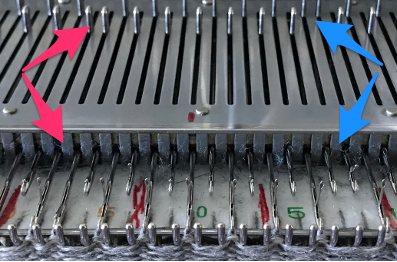

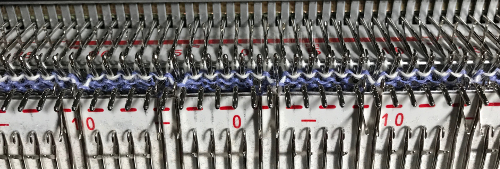

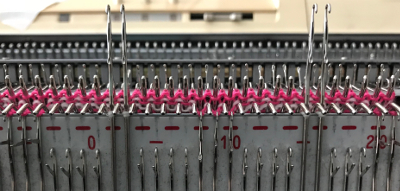

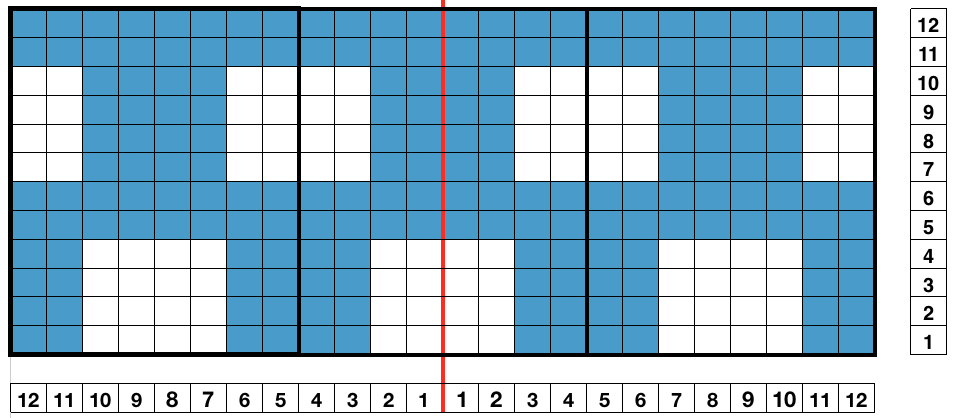

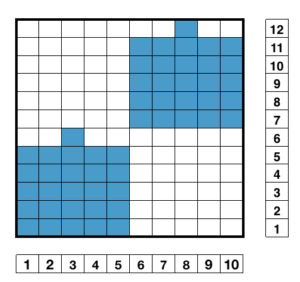

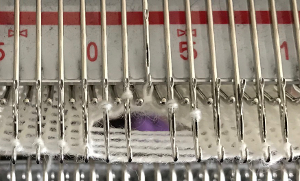

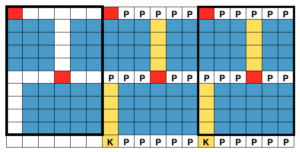

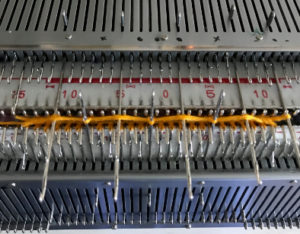

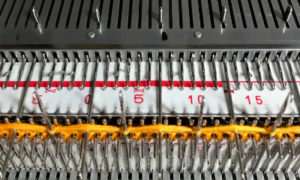

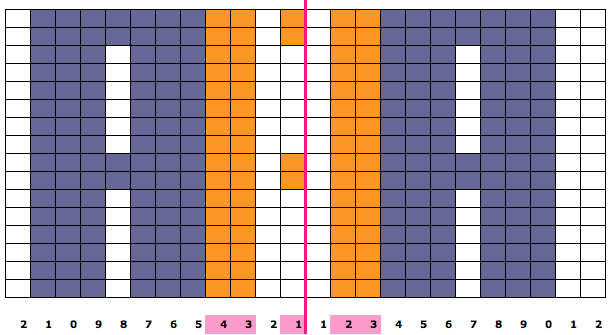

The needle set up in colored squares and on my needle beds showing matching selections on both beds (different design rows). Some of the floats may be seen created by the blue yarn in the bottom photo. If the first and last needle on each side were not selected on the main bed, the needles at each end on the ribber were added to hand selections for the next row (blue squares)

The needle set up in colored squares and on my needle beds showing matching selections on both beds (different design rows). Some of the floats may be seen created by the blue yarn in the bottom photo. If the first and last needle on each side were not selected on the main bed, the needles at each end on the ribber were added to hand selections for the next row (blue squares)

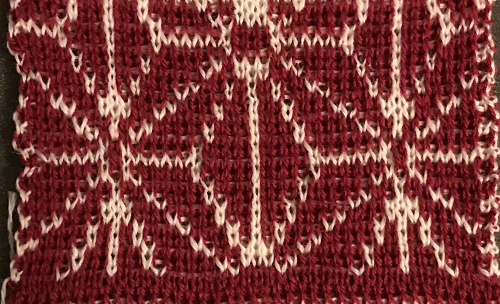

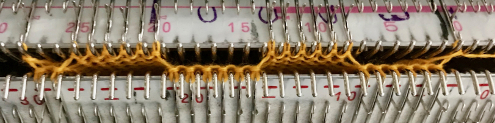

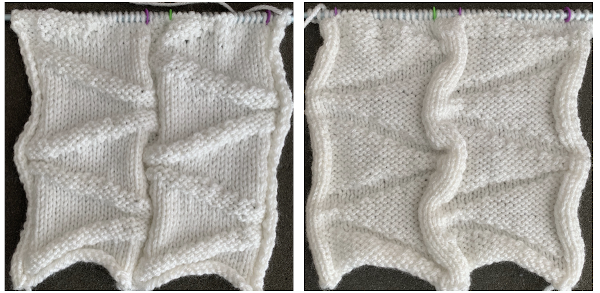

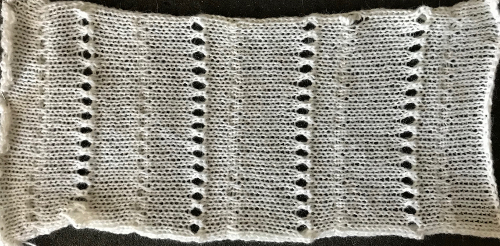

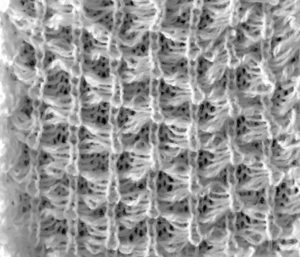

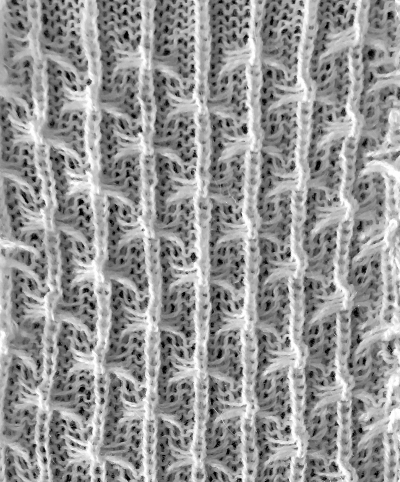

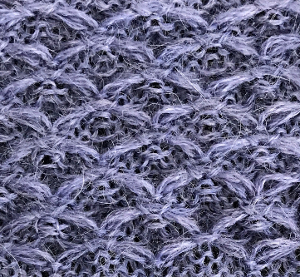

better results with the different yarn choice

better results with the different yarn choice

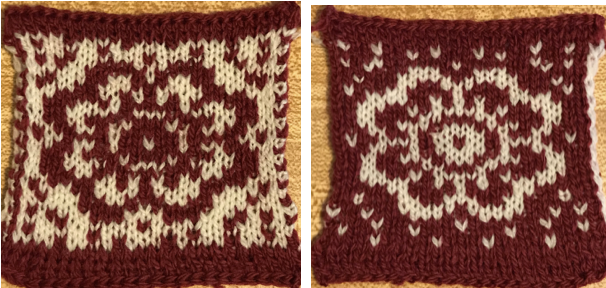

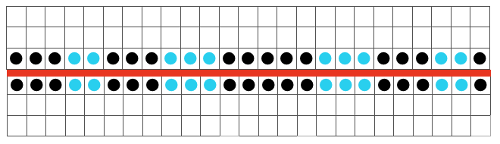

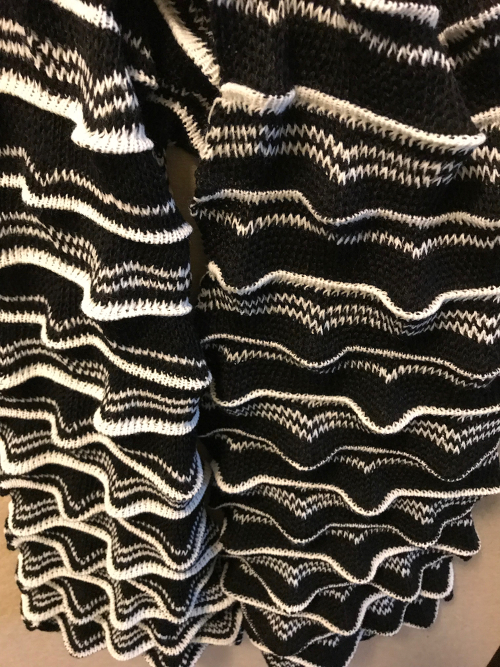

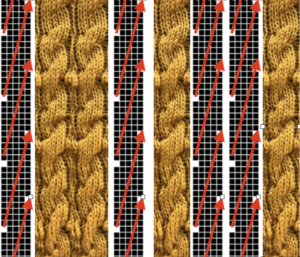

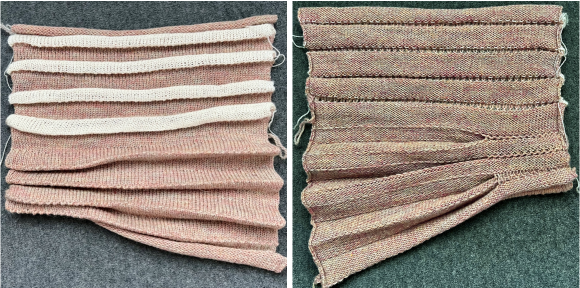

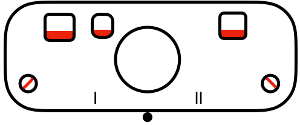

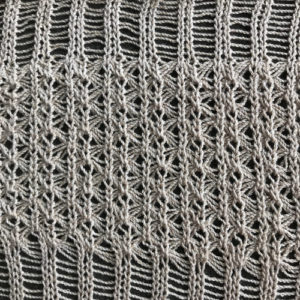

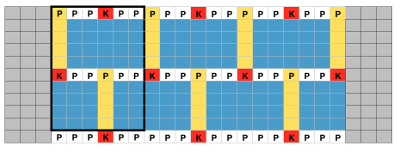

For DBJ that reverses ground and pattern colors, opposite needles are selected on each bed. Color 1 knits the design on one bed and the background on the other at the same time, while color 2 knits the reverse. There are no floats. I knit this fabric as well at half-pitch. The ground color created pockets (white squares), with the pattern color (black squares) locking the layers of fabric together. Here again, first and last needles on the ribber were worked on each row. I began pushing needles up on the ribber beginning to the right of each needle in work on the main bed. Needle selection on ribber matches unselected needles on the main bed (pink). All needle positions in each bed are mirrored.

needles actually selected on both beds (pink), different design row

needles actually selected on both beds (pink), different design row One design row, 2 different angles

One design row, 2 different angles

Since ribber fabrics are not visible for a large number of rows, I frequently scrap off after short distances to proof technique before committing to longer pieces as well as to assess whether the effort is worth it in order to produce the fabric in that particular technique or yarn.

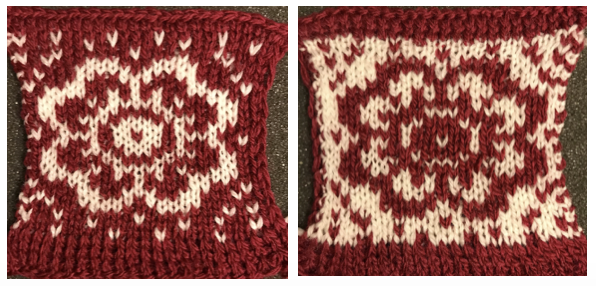

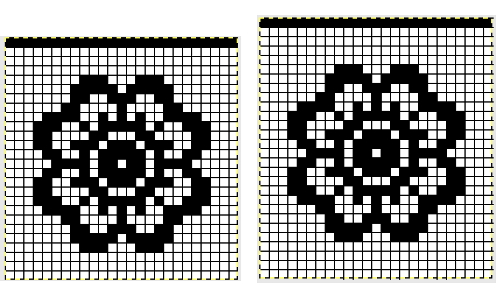

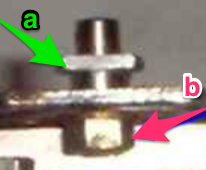

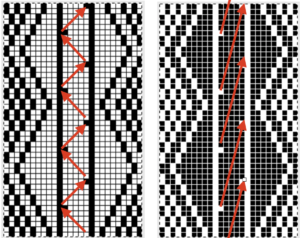

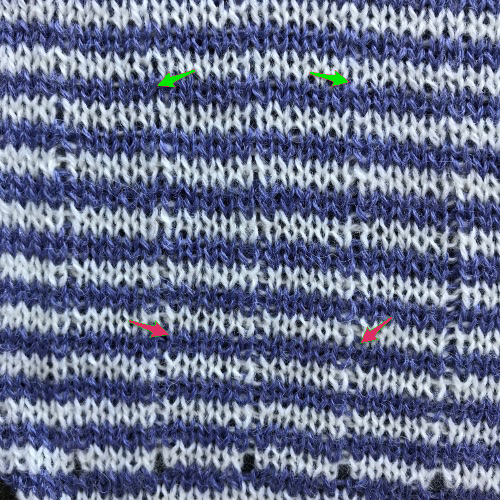

Moving on to a self-drawn pattern, the technique proved to be sound. On inspection, however, I saw I was actually missing a pixel in the .bmp I downloaded, and on the reverse, the green arrow is most likely operator error in needle selection. The orange dots highlight the missing pixel/contrast color stitch, and on the color changer side, I had a really sloppy edge that needs sorting out (red dots). A possible added factor: I knit the motif using KCI, and later recalled end needle selection does not always work with the carriage I am using.

Moving on to a self-drawn pattern, the technique proved to be sound. On inspection, however, I saw I was actually missing a pixel in the .bmp I downloaded, and on the reverse, the green arrow is most likely operator error in needle selection. The orange dots highlight the missing pixel/contrast color stitch, and on the color changer side, I had a really sloppy edge that needs sorting out (red dots). A possible added factor: I knit the motif using KCI, and later recalled end needle selection does not always work with the carriage I am using.  Here I filled in the missing pixel, and drew a single-pixel black line along each side, testing a “border”. The first and last needles on each side were now cast on and in work on the main bed.

Here I filled in the missing pixel, and drew a single-pixel black line along each side, testing a “border”. The first and last needles on each side were now cast on and in work on the main bed.

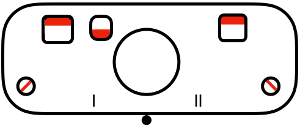

That single stitch solid color line does not add to the design in my opinion, so back to the drawing board: side “border” pixels are eliminated. The first and last stitch are now in work on the ribber. This fabric is the best by far, at the very start I forgot to cancel end needle selection (KCI), then switched to canceling it, KCII on electronic.  The how-to in summary: first and last needle are on the ribber.

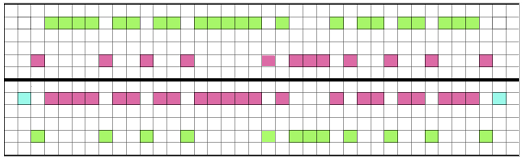

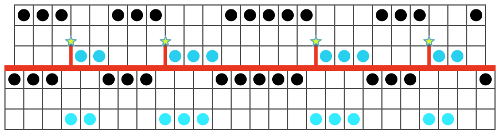

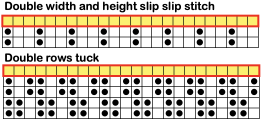

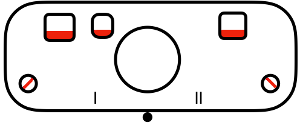

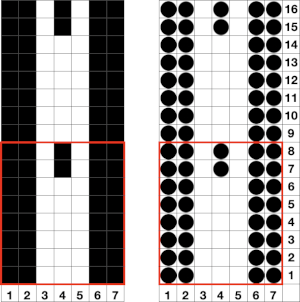

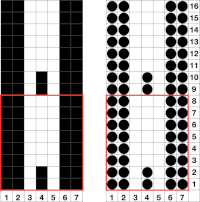

The how-to in summary: first and last needle are on the ribber. On the electronic choose KRC for the built-in color separation for the fabric to be worked in DBJ. KCII (no end needle selection). With a free pass to the right, both carriages set to slip <– –>, select for the first row of knitting to be worked in color represented by white squares in the design chart. Both carriages remain set to slip in both directions throughout. On the ribber bed, bring up to E/hold position first needle on the right of any needle selected on the top bed, then continue to push needles up into work to match the number of not selected needles on the knit bed. As needles are arranged, there will be a space between the last hand selected needle on the ribber, and the next needle in work on the main bed

On the electronic choose KRC for the built-in color separation for the fabric to be worked in DBJ. KCII (no end needle selection). With a free pass to the right, both carriages set to slip <– –>, select for the first row of knitting to be worked in color represented by white squares in the design chart. Both carriages remain set to slip in both directions throughout. On the ribber bed, bring up to E/hold position first needle on the right of any needle selected on the top bed, then continue to push needles up into work to match the number of not selected needles on the knit bed. As needles are arranged, there will be a space between the last hand selected needle on the ribber, and the next needle in work on the main bed  Now that there is that extra needle in work on the ribber on the color changer side, to match selection as seen above, needles are hand-selected to E beginning on the far left, still keeping that space just before the next needle selected by the pattern reader. Remaining selections began to right of needles on the main bed as described above.

Now that there is that extra needle in work on the ribber on the color changer side, to match selection as seen above, needles are hand-selected to E beginning on the far left, still keeping that space just before the next needle selected by the pattern reader. Remaining selections began to right of needles on the main bed as described above. when selection begins on the main bed on the left

when selection begins on the main bed on the left

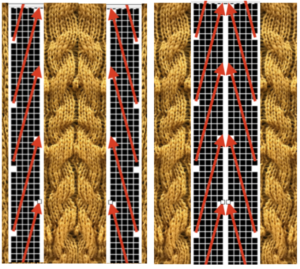

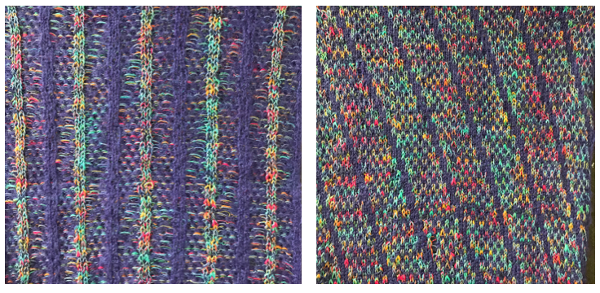

Getting back to working the same pattern on both sides of the knit: the first needle on the left is on the ribber, the one on the far right on the main bed. On the electronic select KRC for the fabric to be worked in DBJ. KCII. With a free pass to the right, both carriages set to slip <– –>, select for the first row of knitting to be worked in color represented by white squares in the design chart. Both carriages remain set to slip in both directions throughout. On the ribber bed, bring up to E/hold position first needle on the left of any needle selected on the top bed, then continue to push needles up into work to match the number of selected needles on the knit bed.

Getting back to working the same pattern on both sides of the knit: the first needle on the left is on the ribber, the one on the far right on the main bed. On the electronic select KRC for the fabric to be worked in DBJ. KCII. With a free pass to the right, both carriages set to slip <– –>, select for the first row of knitting to be worked in color represented by white squares in the design chart. Both carriages remain set to slip in both directions throughout. On the ribber bed, bring up to E/hold position first needle on the left of any needle selected on the top bed, then continue to push needles up into work to match the number of selected needles on the knit bed.

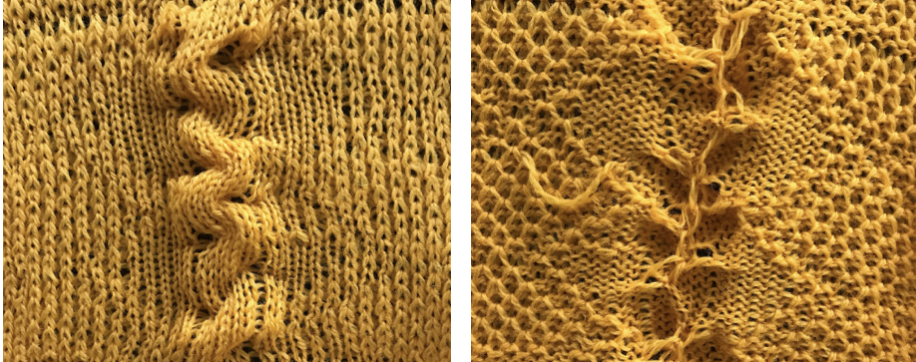

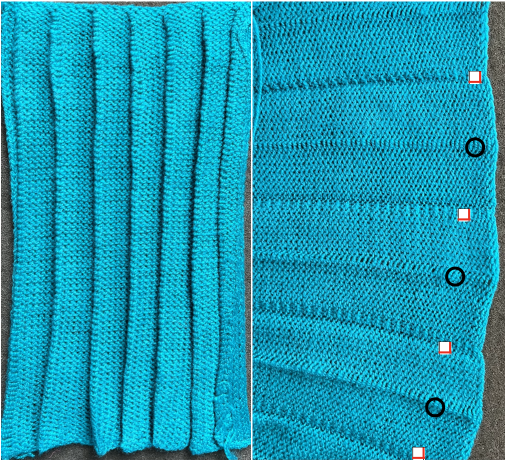

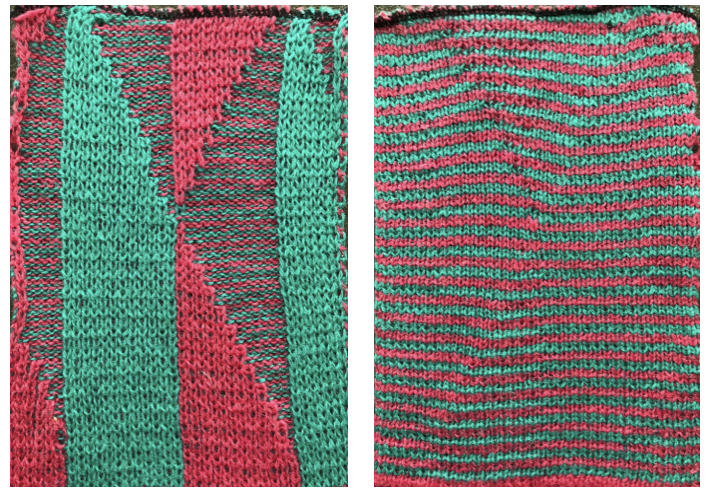

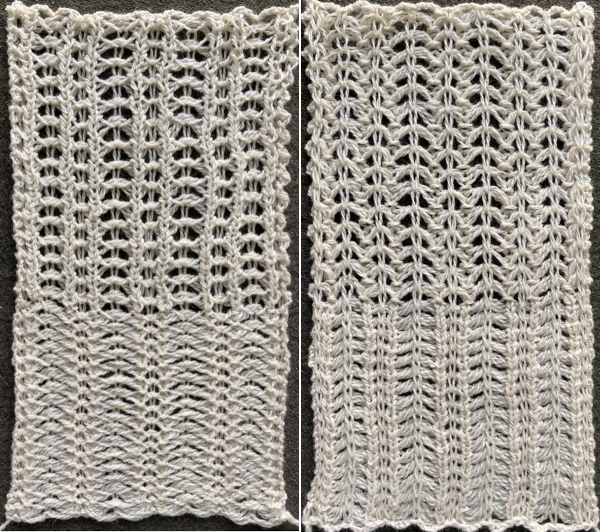

Small selection errors are seen on the left image, ie on the second row on its right, may be easily repaired by duplicate stitching. The stitching yarn may be fed easily through layers of double knit for short distances before and after the “mistake”. With all settings and yarn being equal, there is a difference in size between this fabric (larger of the 2) and the one with color reverse on its other side

Small selection errors are seen on the left image, ie on the second row on its right, may be easily repaired by duplicate stitching. The stitching yarn may be fed easily through layers of double knit for short distances before and after the “mistake”. With all settings and yarn being equal, there is a difference in size between this fabric (larger of the 2) and the one with color reverse on its other side

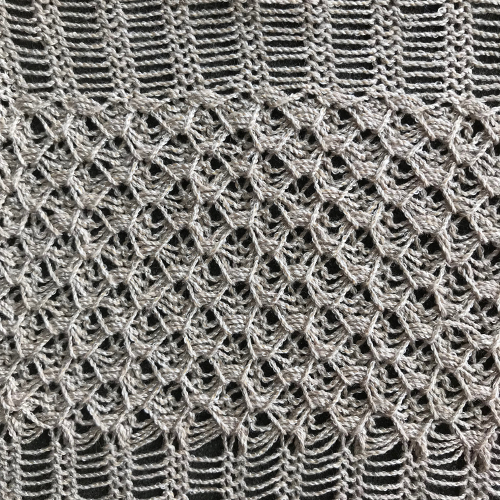

A similar setup, working in full pitch. Here needles line up directly below each other. If the wrong needle is selected it will be point to point with the needle immediately above it and is an added clue the wrong needle is being pushed up into hold/ E position. My first swatch had a distinctly different side / vertical edges. Cast on was for every needle, half-pitch (top image), the first needle on left on the main bed, last needle on right on the ribber. When completed, it was followed by a change to full-pitch prior to pattern knitting, lining up needles point to point, directly below each other (bottom image).

I prefer the edge obtained on the half-pitch throughout, seen in the previous sample

I prefer the edge obtained on the half-pitch throughout, seen in the previous sample

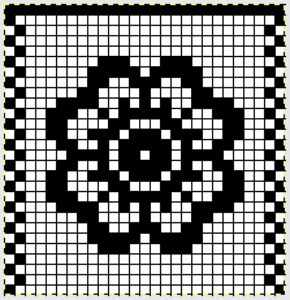

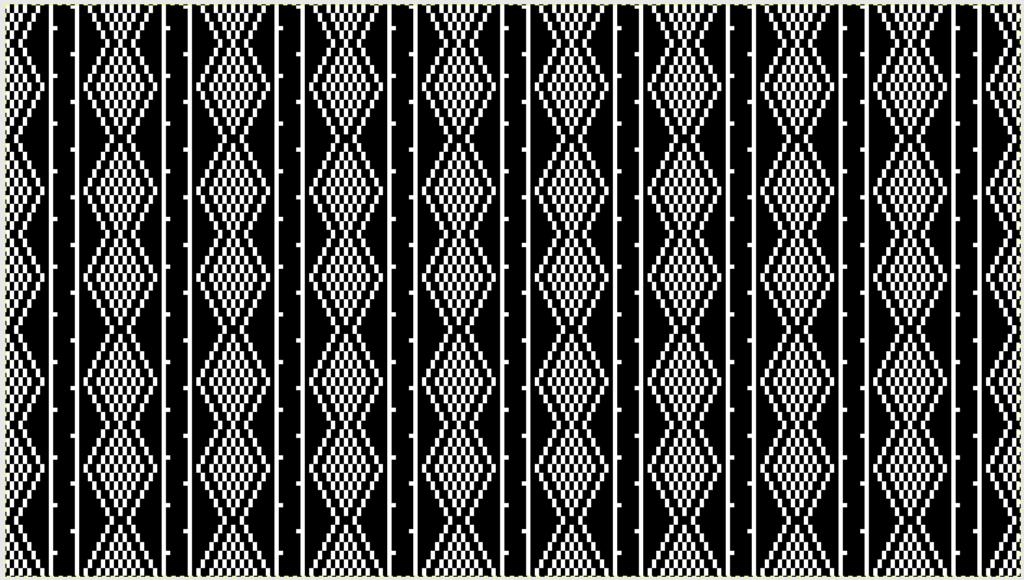

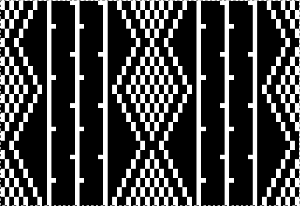

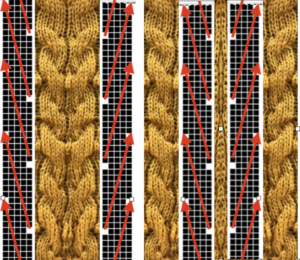

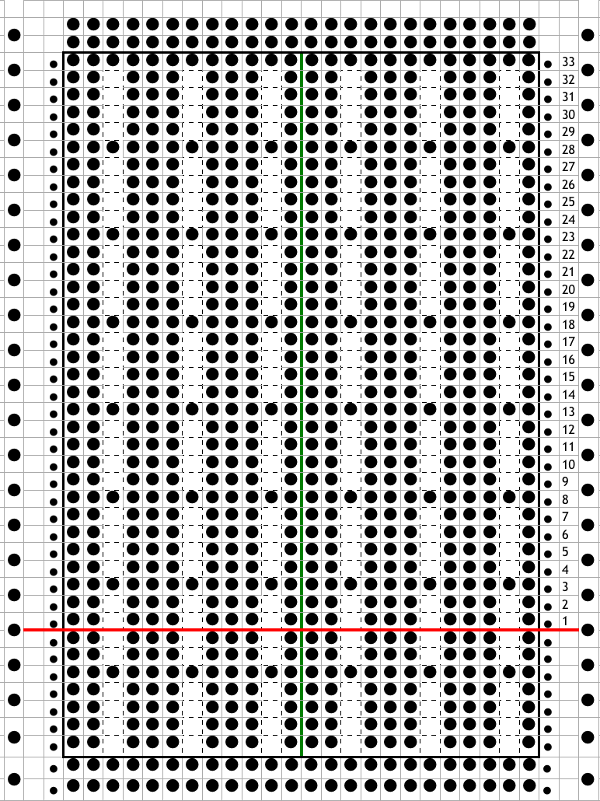

Still, pondering those edges, and what about repeats with large areas of a solid color? The image on the left is 25X26 rows in height, the one on the right adjusted for an even number of solid color rows, and a total row repeat divisible by 4, 25X28. The single black line at the top is a marker for returning the carriage to all knit when the top of the repeat is reached. When using full pitch, solid areas remained open at both edges with carriage set to KCII. A wooden tool handle is actually inserted through from one side to the other at the bottom of the swatch. Because the needles are point to point, no extra needles could be brought to work on both ends as a workaround. KCI will select end needles on the main bed. I tried that as the first workaround to seal the edges. I paid no attention to whether needles were selected at each end every row, and got another creative pair of edges.

Returning to half-pitch I brought up to work the first needle on the left every row (too many rows at seen at R top edge compared to the other side) and pushed the last needle on right up to work if it was not part of the group to be brought up to E.

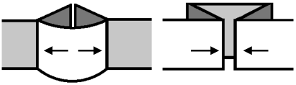

Returning to half-pitch I brought up to work the first needle on the left every row (too many rows at seen at R top edge compared to the other side) and pushed the last needle on right up to work if it was not part of the group to be brought up to E. Analyzing the fabric structure in those areas of solid colors on alternating beds: at first full pitch makes sense if one has knit tubular stripes or solids which have closed edges, with the yarn making a single pass on each bed, traveling back to the color changer, with the option to stripe every X, even number of rows. Such stripes occur evenly spaced and identical on both fabric sides. Here the goal is to knit the fabric with large blocks of solid, alternate colors on each side. The main bed knits color 1 on selected needles on the top bed only, the alternate color is knit with the ribber needles being hand-selected up to E while the main bed is slipping, with none of its needles selected. Other than that first set up row with preselection from the left, 2 rows are knit in color A, followed by 2 rows in color B. There are no stitches traveling between the beds to seal the fabric together in those areas, creating open sides, so if the goal is to have the edges seal. other steps need to be taken. A single-pixel solid line along either edge of the repeat did not create a good edge. Full pitch is easier than half pitch to manage. One possible solution to both issues is to alter the side edges of the design repeat so there will be alternating needle selection along those side edges, thus sealing the fabric.

Analyzing the fabric structure in those areas of solid colors on alternating beds: at first full pitch makes sense if one has knit tubular stripes or solids which have closed edges, with the yarn making a single pass on each bed, traveling back to the color changer, with the option to stripe every X, even number of rows. Such stripes occur evenly spaced and identical on both fabric sides. Here the goal is to knit the fabric with large blocks of solid, alternate colors on each side. The main bed knits color 1 on selected needles on the top bed only, the alternate color is knit with the ribber needles being hand-selected up to E while the main bed is slipping, with none of its needles selected. Other than that first set up row with preselection from the left, 2 rows are knit in color A, followed by 2 rows in color B. There are no stitches traveling between the beds to seal the fabric together in those areas, creating open sides, so if the goal is to have the edges seal. other steps need to be taken. A single-pixel solid line along either edge of the repeat did not create a good edge. Full pitch is easier than half pitch to manage. One possible solution to both issues is to alter the side edges of the design repeat so there will be alternating needle selection along those side edges, thus sealing the fabric.

I decided to cast on with white and to continue with white as the first color used in the pattern (white squares in the chart). This swatch was knit in full pitch. Edges are sealed throughout. The only hitch was when the top was reached and that all black squares row was reached. I was on the right at that point, with my dark color in the feeder. The row toward the left would have knit in the dark color instead of the white on the top bed. I cut the dark yarn, made a free pass to the left, continued in plain knit in white to right, and then transferred stitches and bound off. Top and bottom edges /borders in terms of the number of rows, whether to add pattern there as well, are all subject to personal preferences and taste.

For an off-topic reversible double bed fabric using thread lace setting, see post

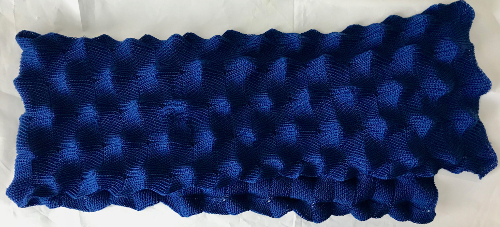

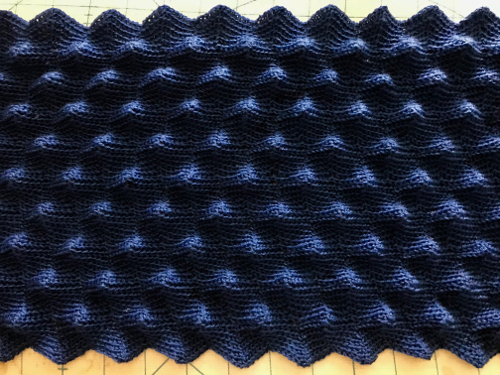

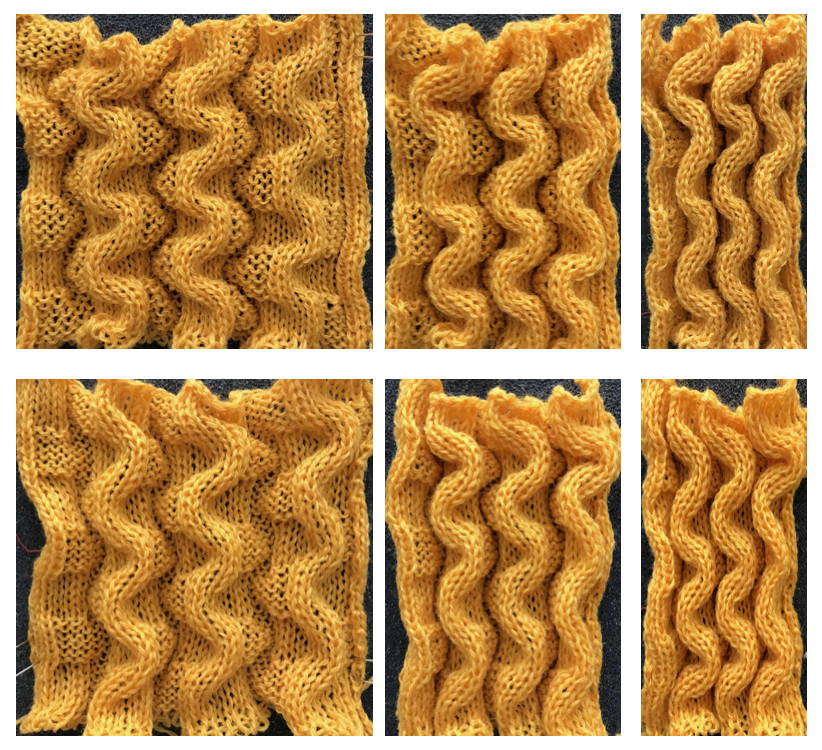

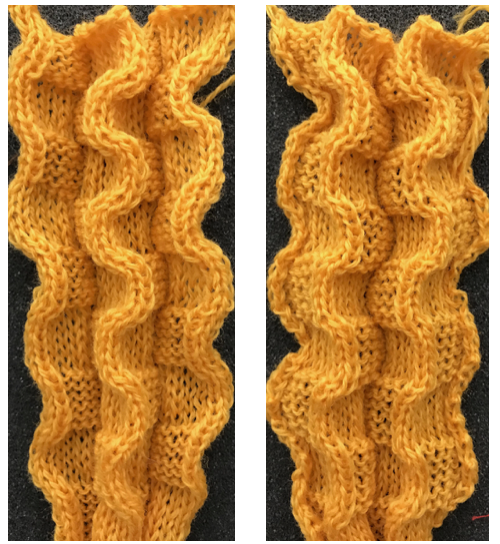

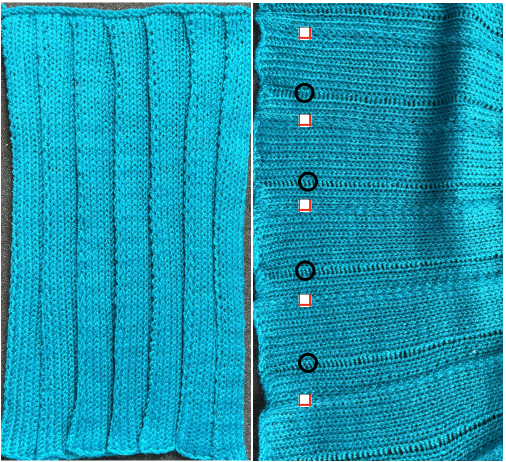

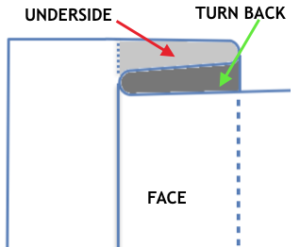

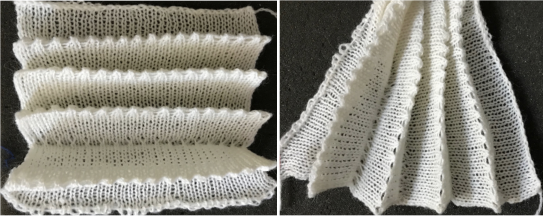

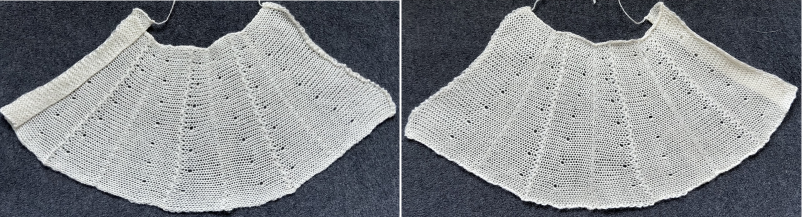

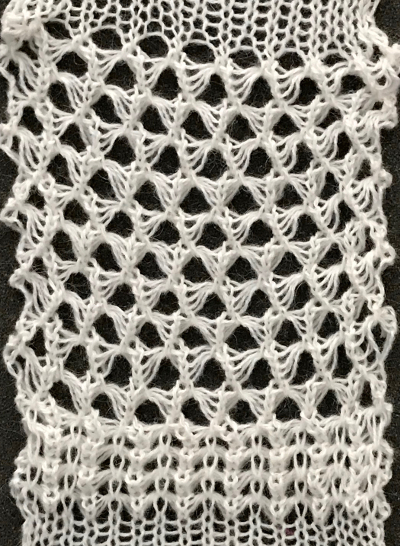

and my small test swatch. The fold on each side and the swing in the pattern appear crisper and better defined to me

and my small test swatch. The fold on each side and the swing in the pattern appear crisper and better defined to me

an attempt at a side view

an attempt at a side view  an earlier

an earlier  Another handknit swatch in worsted weight, perhaps suitable for G carriage

Another handknit swatch in worsted weight, perhaps suitable for G carriage

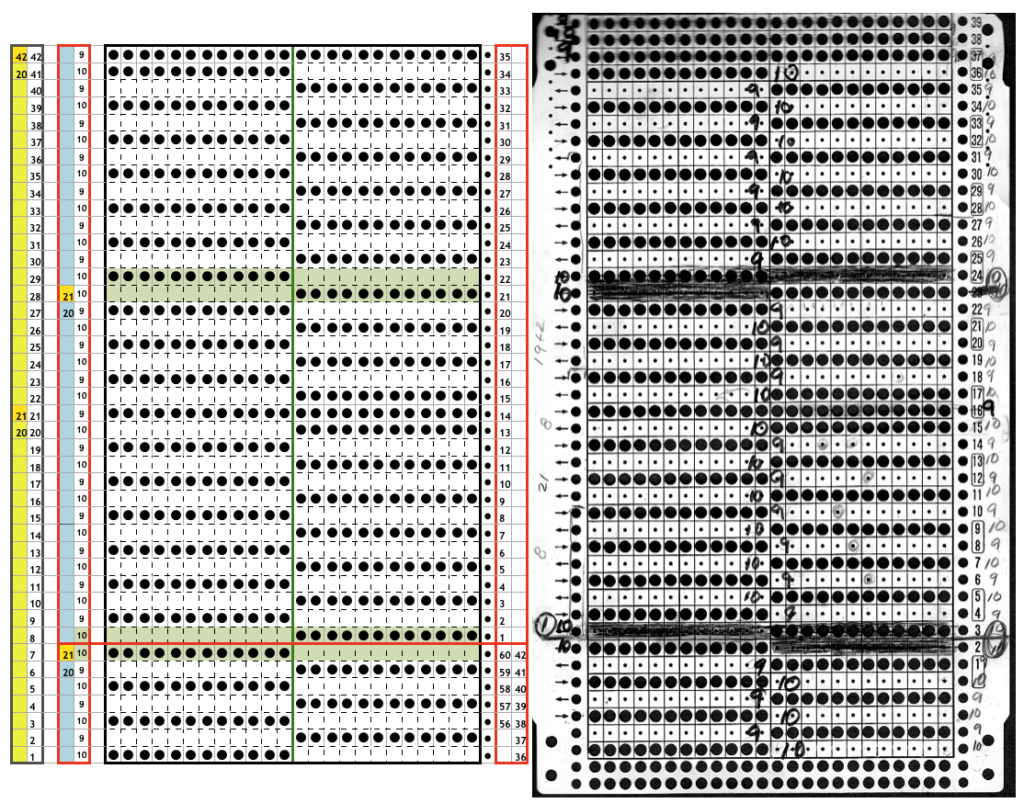

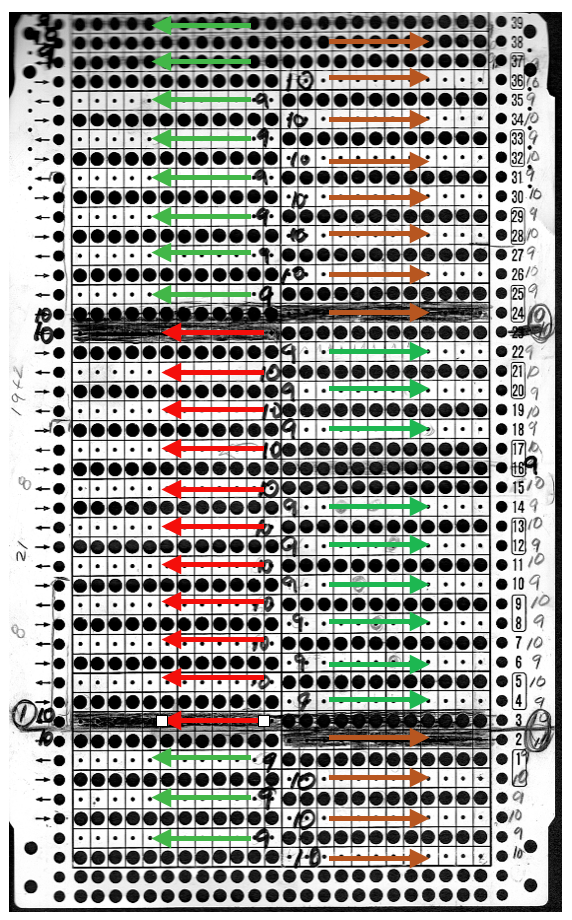

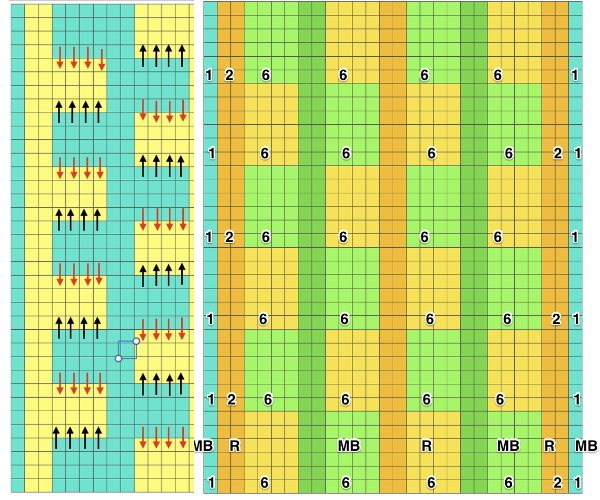

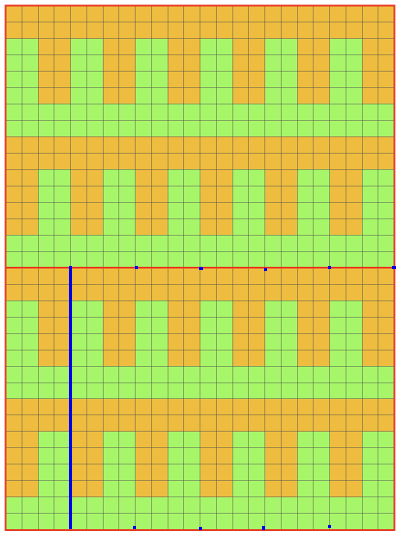

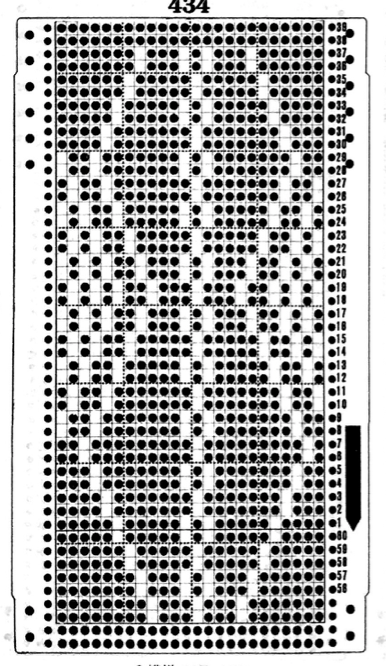

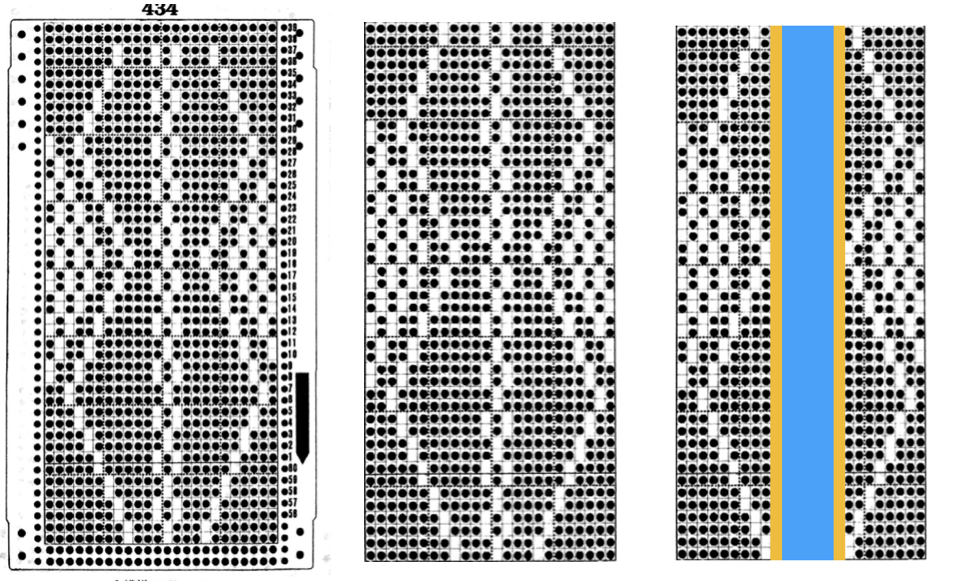

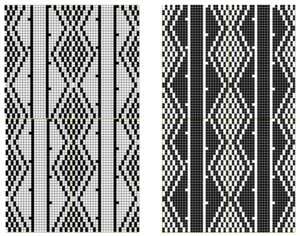

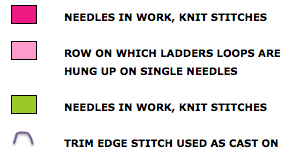

The card is cropped to the 24 X 44 stitch in width and height for the repeat to be worked in electronics. The area colored blue on the far right indicates possible all knit rows for hooking up “cables” during knitting, mustard color indicates ladders created by an out of work needle on each side of the central, all knit column. The ladders make it easier to identify each all knit column. The tape over holes idea does not work for masking a punchcard since that blue area would need to be all punched holes. The tape over would result in “unpunched” ones.

The card is cropped to the 24 X 44 stitch in width and height for the repeat to be worked in electronics. The area colored blue on the far right indicates possible all knit rows for hooking up “cables” during knitting, mustard color indicates ladders created by an out of work needle on each side of the central, all knit column. The ladders make it easier to identify each all knit column. The tape over holes idea does not work for masking a punchcard since that blue area would need to be all punched holes. The tape over would result in “unpunched” ones. This takes the revised card single repeat and indicates some quick possibilities for altering it

This takes the revised card single repeat and indicates some quick possibilities for altering it

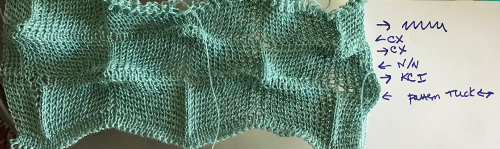

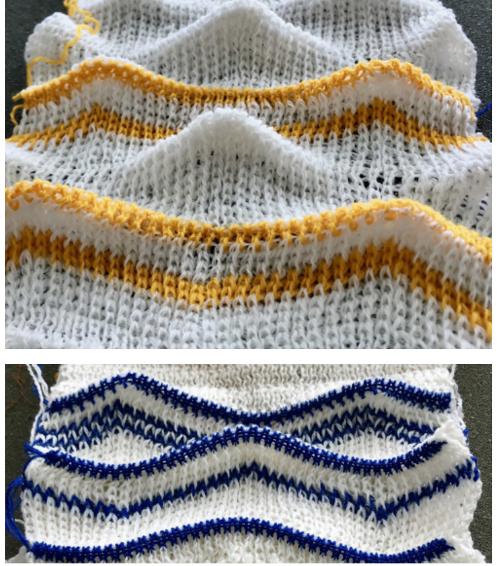

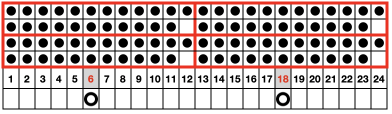

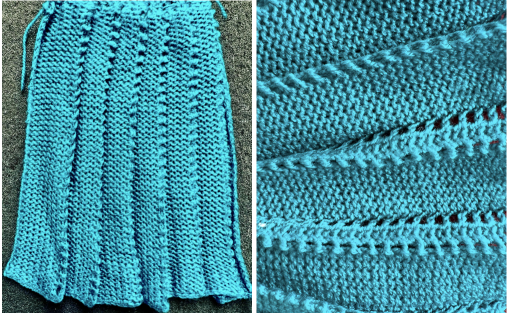

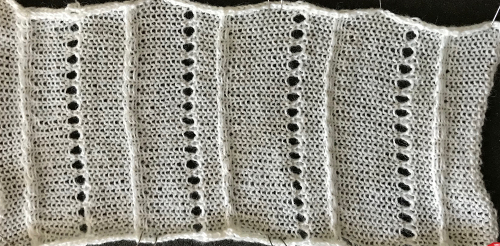

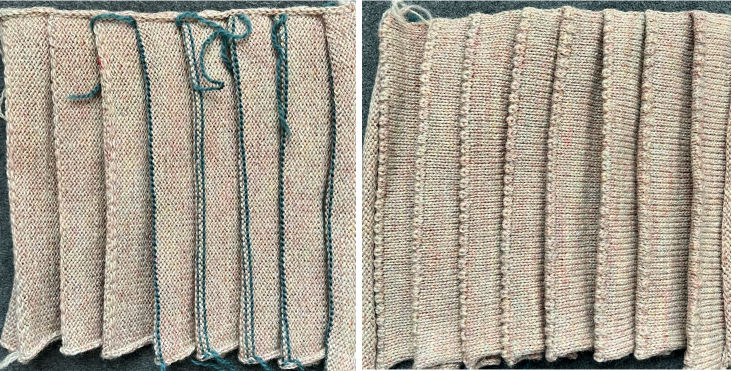

The fabric narrows considerably as it is stretched lengthwise to set the stitches. Several panels would be required for a garment such as a skirt. Such an item would need to be pulled into shape, pinned, and hot pressed. Fiber content will determine the crispness of the pleats after blocking, and their retention after cleaning. The swatch below is turned sideways for the sake of space.

The fabric narrows considerably as it is stretched lengthwise to set the stitches. Several panels would be required for a garment such as a skirt. Such an item would need to be pulled into shape, pinned, and hot pressed. Fiber content will determine the crispness of the pleats after blocking, and their retention after cleaning. The swatch below is turned sideways for the sake of space.  More variations with folds can be made by varying the “rules” commonly recognized for creases. Working sideways once more: on a punchcard machine, using card # 1 locked, cast on making certain every other needle as well as the first and last are selected.

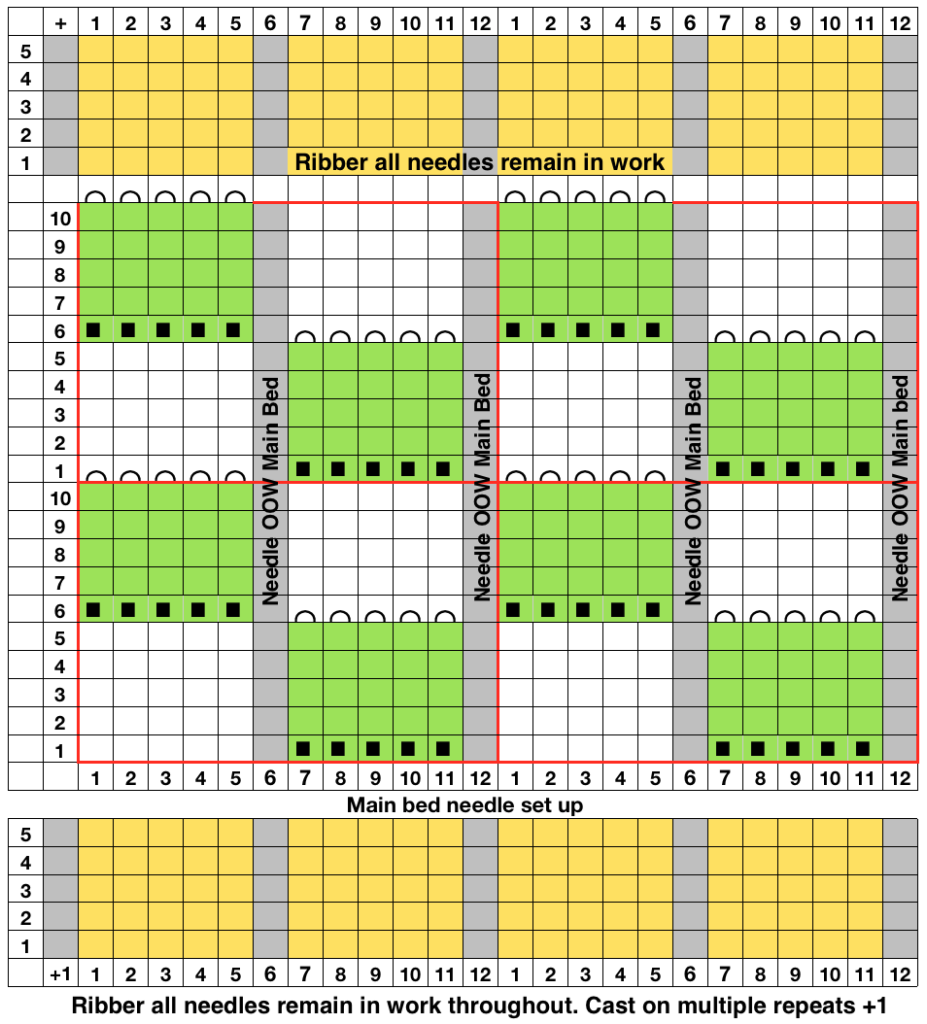

More variations with folds can be made by varying the “rules” commonly recognized for creases. Working sideways once more: on a punchcard machine, using card # 1 locked, cast on making certain every other needle as well as the first and last are selected. Cancel the slip setting, complete the next knit section, and transfer every other needle to the adjacent one on either the right or left.

Cancel the slip setting, complete the next knit section, and transfer every other needle to the adjacent one on either the right or left.  The needles holding 2 stitches may be brought out to the hold position as each transfer is made, or pushed out to hold after the fact to insure the stitches have been transferred and will knit off properly. The number of needles in work remains constant.

The needles holding 2 stitches may be brought out to the hold position as each transfer is made, or pushed out to hold after the fact to insure the stitches have been transferred and will knit off properly. The number of needles in work remains constant.

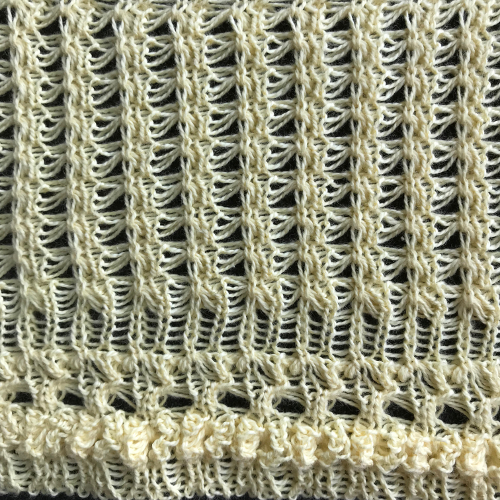

The slipped stitches form the inside folds in the pressed swatch, while eyelets and tuck stitches fold a picot edge to the outside.

The slipped stitches form the inside folds in the pressed swatch, while eyelets and tuck stitches fold a picot edge to the outside.

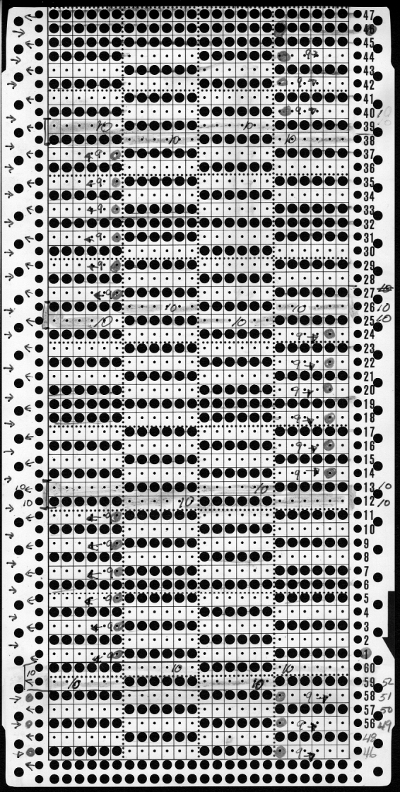

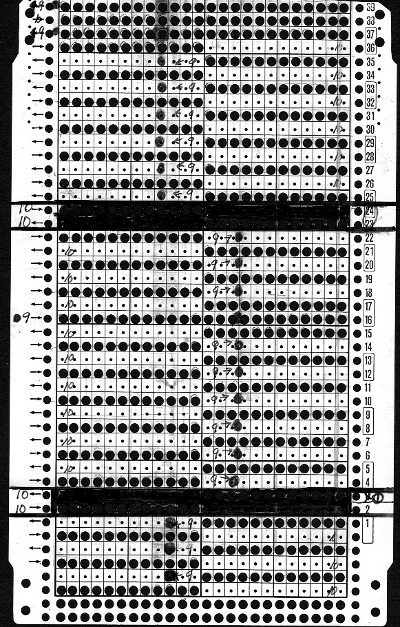

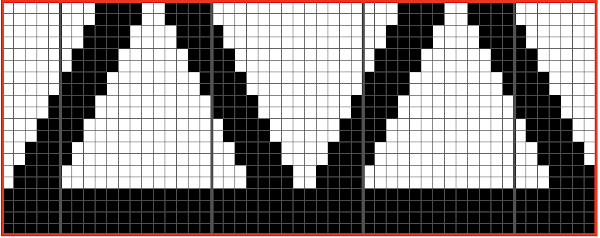

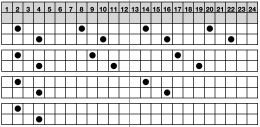

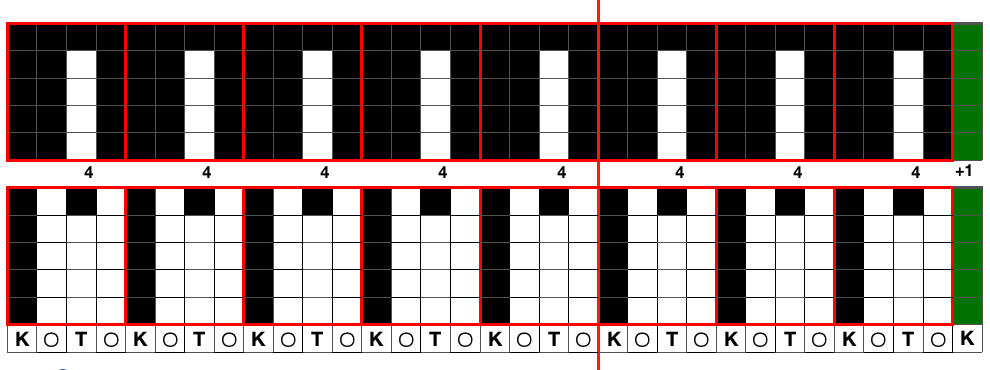

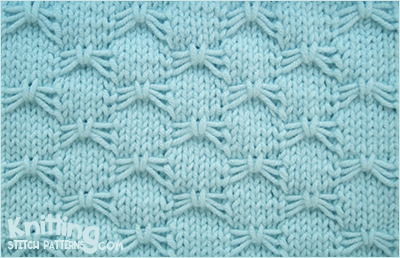

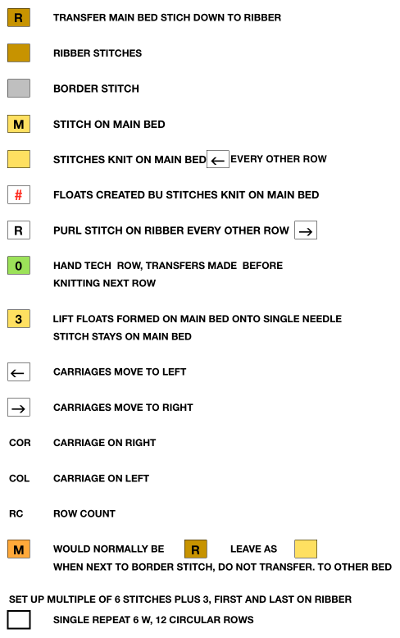

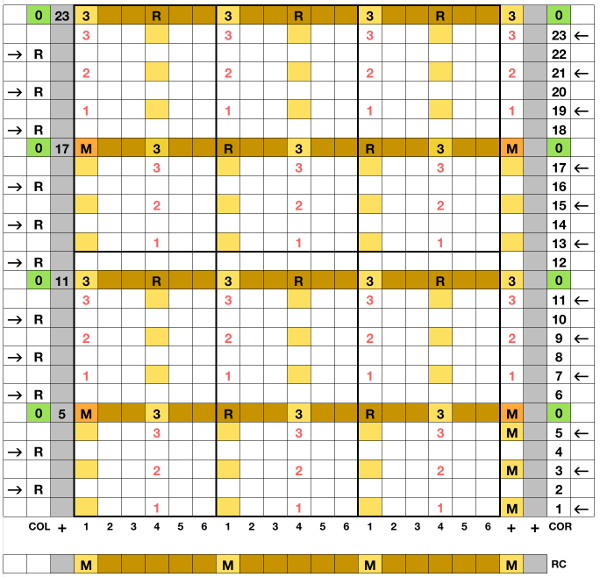

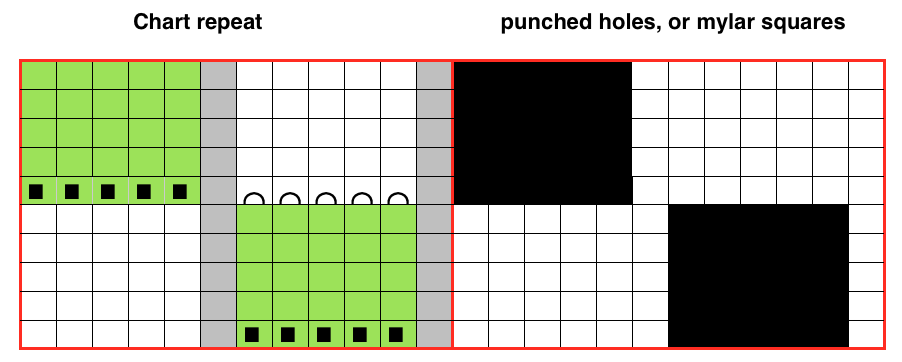

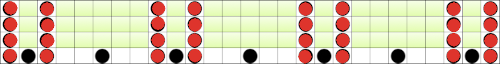

This is my first experiment with gathered slip stitch floats on the purl side of the knit. To begin, this chart indicates one punchcard pattern’s full repeat in width. Four repeats in length would be required (the punchcard minimum repeat in length to achieve smooth continuous card feeding is 36 rows). Punch out blue squares, leaving white ones unpunched. A single repeat (outlined in black, 8 stitches by 12 rows) is for use in electronic patterning, where one may alternately draw or program white squares, then use color reverse. The red line represents 0 needle position in Brother KM

This is my first experiment with gathered slip stitch floats on the purl side of the knit. To begin, this chart indicates one punchcard pattern’s full repeat in width. Four repeats in length would be required (the punchcard minimum repeat in length to achieve smooth continuous card feeding is 36 rows). Punch out blue squares, leaving white ones unpunched. A single repeat (outlined in black, 8 stitches by 12 rows) is for use in electronic patterning, where one may alternately draw or program white squares, then use color reverse. The red line represents 0 needle position in Brother KM

result with color reverse

result with color reverse  working out a mylar, electronic (unless DM 80 40 stitch width is in use) repeat for a variation of the fabric knit single bed. The stitch count is odd, allowing for a center stitch manipulation. KCI is used to make certain the first and last needles knit on each side. Floats created close to edges may be left without hooking them up. The fabric separates slightly along the “bowknot” edges

working out a mylar, electronic (unless DM 80 40 stitch width is in use) repeat for a variation of the fabric knit single bed. The stitch count is odd, allowing for a center stitch manipulation. KCI is used to make certain the first and last needles knit on each side. Floats created close to edges may be left without hooking them up. The fabric separates slightly along the “bowknot” edges

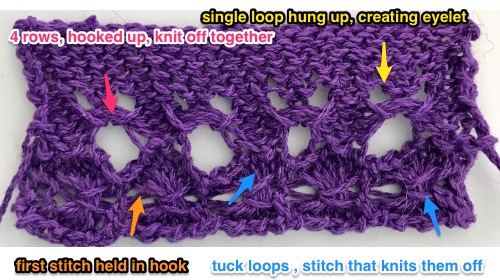

lift them up and onto that single non selected needle, push that needle out to hold

lift them up and onto that single non selected needle, push that needle out to hold with the next pass the single needle and loops knit off together and become part of the alternating all knit block in the design

with the next pass the single needle and loops knit off together and become part of the alternating all knit block in the design the swatches are knit in a 2/15 wool, the fabric might be better served using a thicker yarn. Here the “blocks” creating “floats” are side by side

the swatches are knit in a 2/15 wool, the fabric might be better served using a thicker yarn. Here the “blocks” creating “floats” are side by side

adding border stitches, and more theory on the placement of stitch type

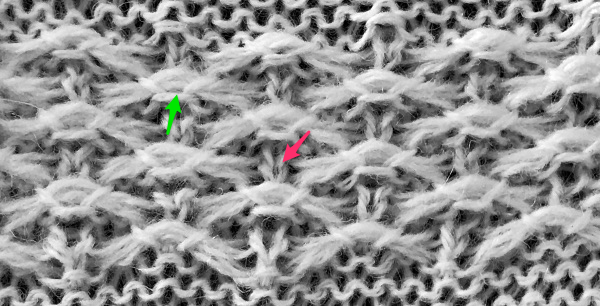

adding border stitches, and more theory on the placement of stitch type the result places “knit” stitches in the center of butterfly (magenta arrow), not at its sides, and I see and extra purl stitch (green arrow). Multiple stitch-wide borders create unwanted floats on one side

the result places “knit” stitches in the center of butterfly (magenta arrow), not at its sides, and I see and extra purl stitch (green arrow). Multiple stitch-wide borders create unwanted floats on one side back to the drawing board and working things out first as a hand technique

back to the drawing board and working things out first as a hand technique

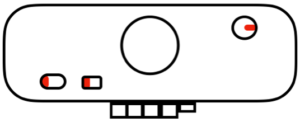

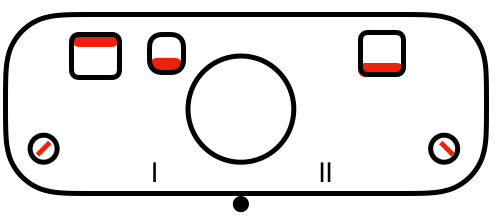

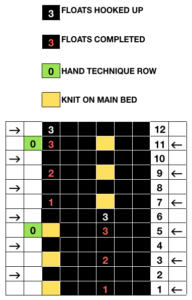

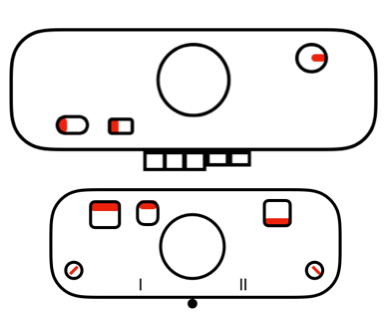

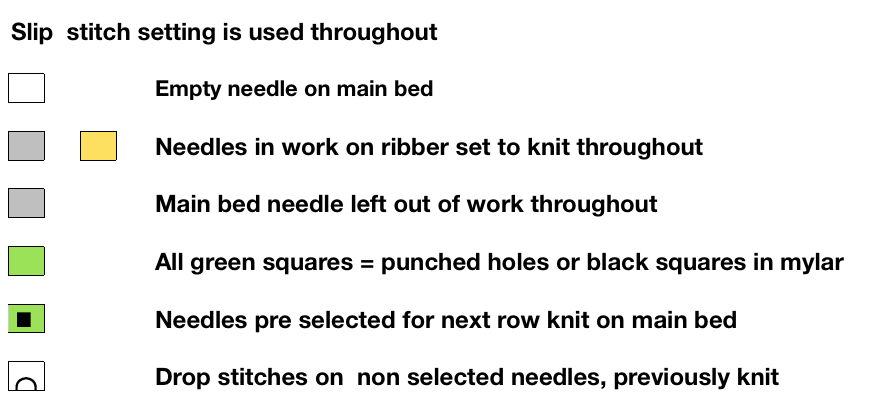

I began with my carriage on the right (COR), after setting up the repeat on a multiple of 6 stitches +3 as indicated above. The last stitch on either side on both beds is never transferred, and the short loops of every other set (rows 5 and 17 in the chart) are not hooked up. This will produce a slightly rolled edge on each side. The larger number of border stitches becomes problematic. The photos were taken while knitting 2 different swatches, so needle tape markings are not the same in all photos. To produce the circular knit, opposite part buttons are pushed in so with carriage on the right (COR), the settings would be

I began with my carriage on the right (COR), after setting up the repeat on a multiple of 6 stitches +3 as indicated above. The last stitch on either side on both beds is never transferred, and the short loops of every other set (rows 5 and 17 in the chart) are not hooked up. This will produce a slightly rolled edge on each side. The larger number of border stitches becomes problematic. The photos were taken while knitting 2 different swatches, so needle tape markings are not the same in all photos. To produce the circular knit, opposite part buttons are pushed in so with carriage on the right (COR), the settings would be

after the three floats have been hooked up, with COL each time, the in-between main bed stitches are transferred back down to ribber

after the three floats have been hooked up, with COL each time, the in-between main bed stitches are transferred back down to ribber

reducing main bed count so only one needle is left on either side of a selected one

reducing main bed count so only one needle is left on either side of a selected one  that needle (green arrow, gets transferred down to ribber

that needle (green arrow, gets transferred down to ribber  now the number of needles involved on both beds is evident on both beds

now the number of needles involved on both beds is evident on both beds While knitting in the pattern the ribber pitch is set on P (point to point) to keep stitches on opposing beds centered (P pitch also makes it easier to transfer directly from one bed to the other). If the cast-on is for every other needle rib with stitches then transferred between beds for pattern knitting set up, the cast-on and all rib rows need to be knit in H pitch, with a switch to P for transfers and knitting in pattern to be completed. With the first row set up on the selected segment of the needle bed, there are additional steps to take.

While knitting in the pattern the ribber pitch is set on P (point to point) to keep stitches on opposing beds centered (P pitch also makes it easier to transfer directly from one bed to the other). If the cast-on is for every other needle rib with stitches then transferred between beds for pattern knitting set up, the cast-on and all rib rows need to be knit in H pitch, with a switch to P for transfers and knitting in pattern to be completed. With the first row set up on the selected segment of the needle bed, there are additional steps to take.

Hand techniques will now also occur when carriages are on the left, on RC 5, 11, etc as described in the hand technique chart, on rows with no needle selection. As in hand tech, transfers and multiple loops containing needles are brought out to hold before moving the carriages from left to right and selecting the needles for the next set of floats with that same pass.

Hand techniques will now also occur when carriages are on the left, on RC 5, 11, etc as described in the hand technique chart, on rows with no needle selection. As in hand tech, transfers and multiple loops containing needles are brought out to hold before moving the carriages from left to right and selecting the needles for the next set of floats with that same pass.

Working in multiple of repeat -1 on the top bed, plus one needle in work at each end on the ribber. Considerations need to be made to align the design properly. The markings on my metal bed are from a different project.

Working in multiple of repeat -1 on the top bed, plus one needle in work at each end on the ribber. Considerations need to be made to align the design properly. The markings on my metal bed are from a different project.  The goal is this needle arrangement

The goal is this needle arrangement

the first selection row

the first selection row  a needle on either side of the groups of 7 is pushed back to A position, remain there throughout the piece

a needle on either side of the groups of 7 is pushed back to A position, remain there throughout the piece

the ribber has now been set up for knitting every needle, every row, with the caston and desired edging completed. The first row is selected on the main bed for pattern knitting.

the ribber has now been set up for knitting every needle, every row, with the caston and desired edging completed. The first row is selected on the main bed for pattern knitting.

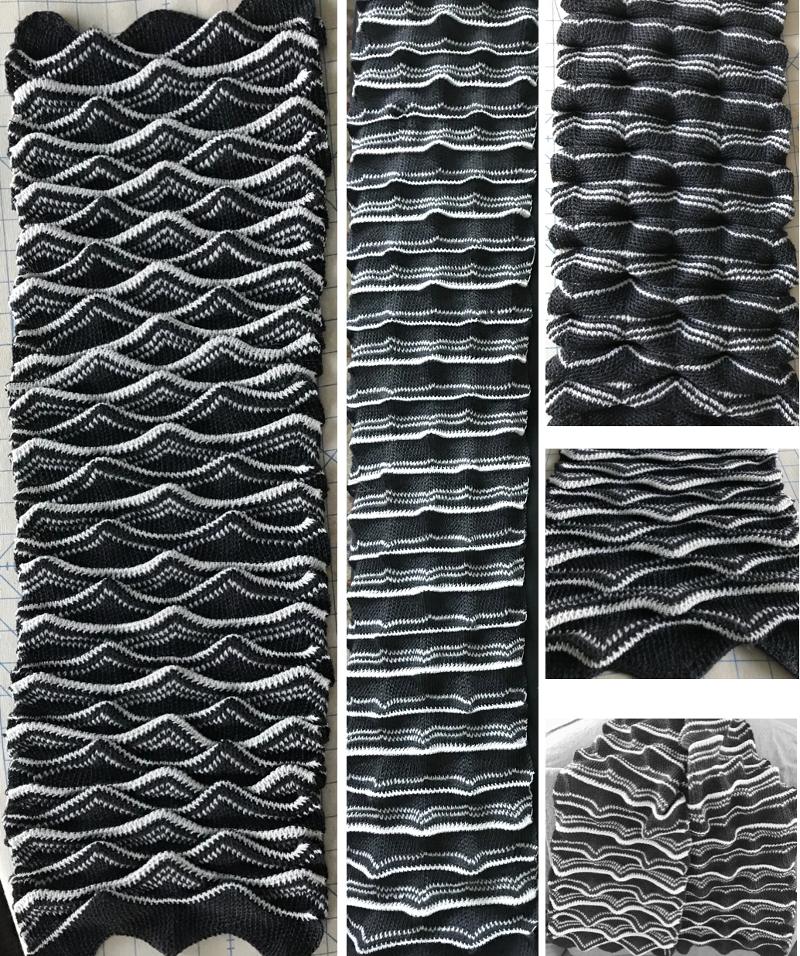

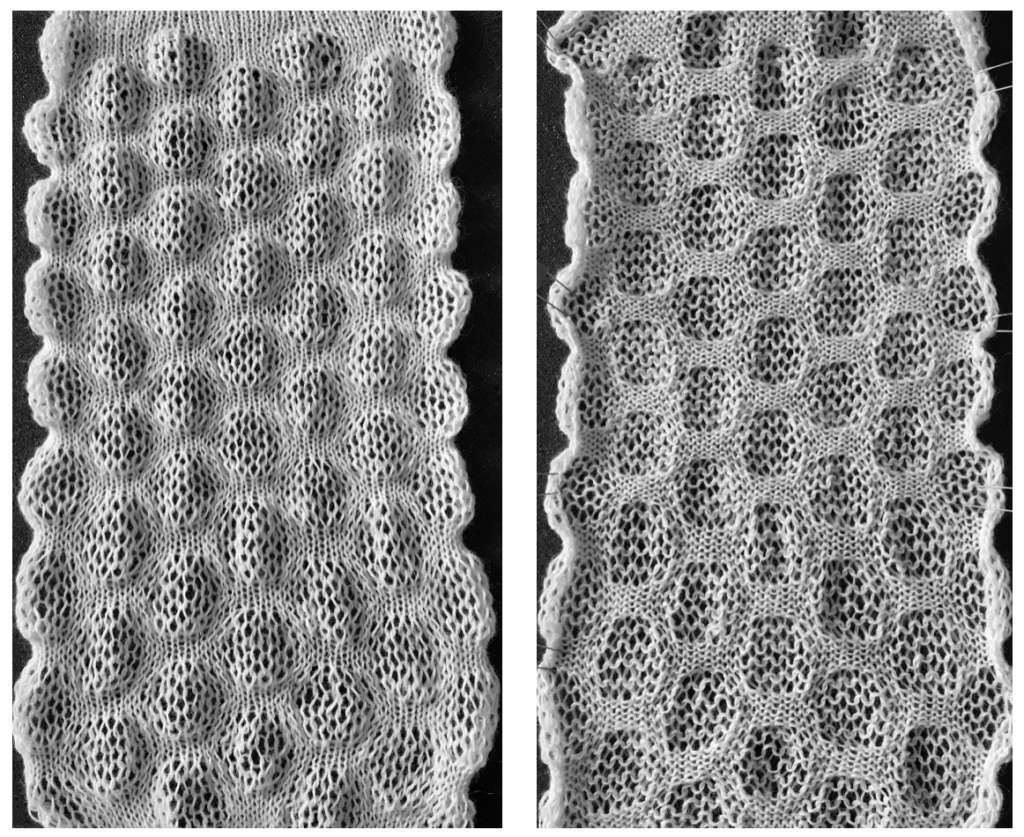

the variation in width is due to adjustments in tension, the swatch folded over itself shows the difference in another way

the variation in width is due to adjustments in tension, the swatch folded over itself shows the difference in another way

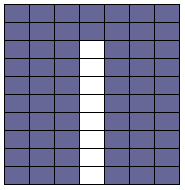

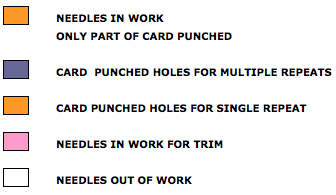

Since the above is seven stitches wide, if punched accordingly it would occupy 21 out of 24 stitch units on a punchcard. As is unless those extra needles on the far right or left are left out of work for ladders or transferred down to the ribber, it would not be suitable for an all-over fabric. It can, however, be used for a trim. If the latter is the intent, only one series of vertical repeats as seen in the chart needs to be punched. The numbers below the image indicate Brother needle tape markings. The Brother needled tape has a center O position marking, with numbers beginning count with one and radiating out marked in groups of 5 in both directions.

Since the above is seven stitches wide, if punched accordingly it would occupy 21 out of 24 stitch units on a punchcard. As is unless those extra needles on the far right or left are left out of work for ladders or transferred down to the ribber, it would not be suitable for an all-over fabric. It can, however, be used for a trim. If the latter is the intent, only one series of vertical repeats as seen in the chart needs to be punched. The numbers below the image indicate Brother needle tape markings. The Brother needled tape has a center O position marking, with numbers beginning count with one and radiating out marked in groups of 5 in both directions.

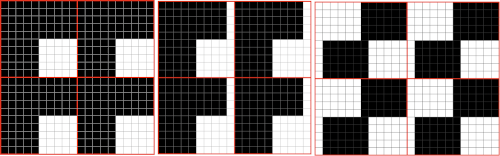

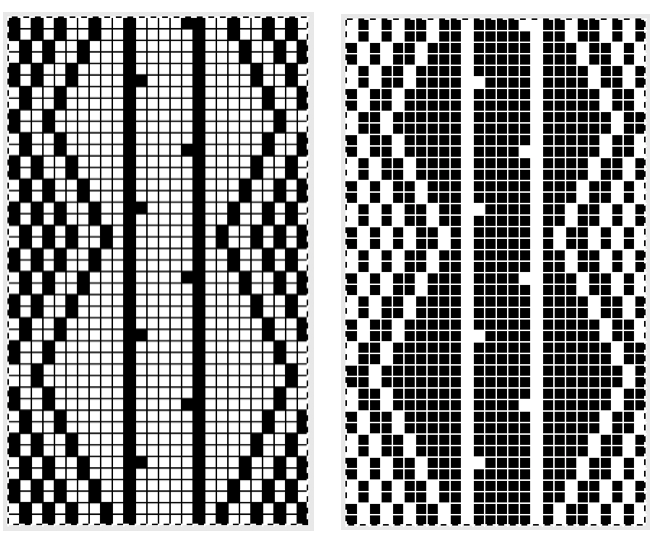

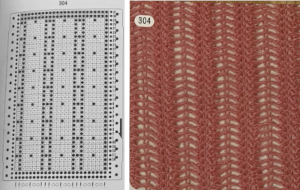

The single-width repeat may be programmed as pixels, on left, or punched holes on right. In electronics a single 8-row repeat is adequate, punchcard knitters repeat 5 times to 40 pattern rows punched.

The single-width repeat may be programmed as pixels, on left, or punched holes on right. In electronics a single 8-row repeat is adequate, punchcard knitters repeat 5 times to 40 pattern rows punched.  I prefer starting such designs on a knit row. To do that, the design repeat start may be shifted

I prefer starting such designs on a knit row. To do that, the design repeat start may be shifted  Using the trim as the cast on edge for a garment: determine the length required after a technique test. Knit a bit extra and remove on waste yarn, so more may be added or some be unraveled if needed or you wish to change the configuration using it as your cast on. Rehang and cast on later when it is completed. The flared-out portions of the trim will be used to “cast on” the edge of the piece, continuing with some needles out of work. An attempt at a line drawing of the “trim” sideways

Using the trim as the cast on edge for a garment: determine the length required after a technique test. Knit a bit extra and remove on waste yarn, so more may be added or some be unraveled if needed or you wish to change the configuration using it as your cast on. Rehang and cast on later when it is completed. The flared-out portions of the trim will be used to “cast on” the edge of the piece, continuing with some needles out of work. An attempt at a line drawing of the “trim” sideways  Using the curved out edge of the trim, hang half stitches if possible, or one full stitch away from its edge as illustrated below. Knit 4 rows. With a tool pick up all ladder loops created by NOOW (RC 1-4) and hang them on the center empty needle. Knit rows (RC 5, 6), hang ladder loops on still empty needles, knit across all needles, continue with garment

Using the curved out edge of the trim, hang half stitches if possible, or one full stitch away from its edge as illustrated below. Knit 4 rows. With a tool pick up all ladder loops created by NOOW (RC 1-4) and hang them on the center empty needle. Knit rows (RC 5, 6), hang ladder loops on still empty needles, knit across all needles, continue with garment

The yarn used is cotton and appears to have a tendency toward biasing on knit rows as seen in the tendency to lean in one direction in the above photos. It has no stretch, so stitches that knit off several tuck loops remain elongated. A look at the structure on the purl side:

The yarn used is cotton and appears to have a tendency toward biasing on knit rows as seen in the tendency to lean in one direction in the above photos. It has no stretch, so stitches that knit off several tuck loops remain elongated. A look at the structure on the purl side:  For more trims in this family, please see later post

For more trims in this family, please see later post  If using the pattern on electronic machines, the needle selection needs to match on the top bed. Depending on the model electronic, the pattern may have to be reversed for accurate needle selection.

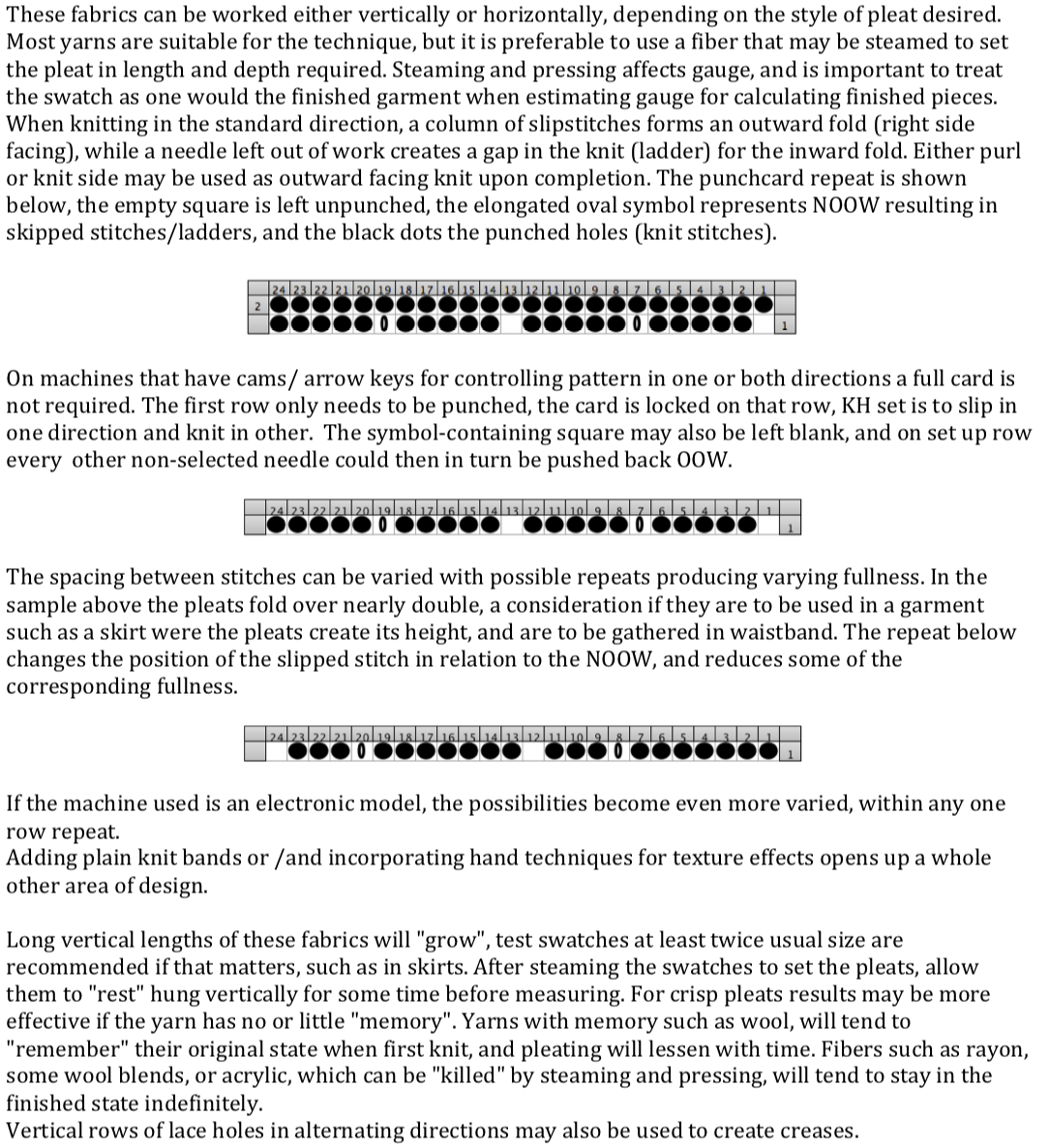

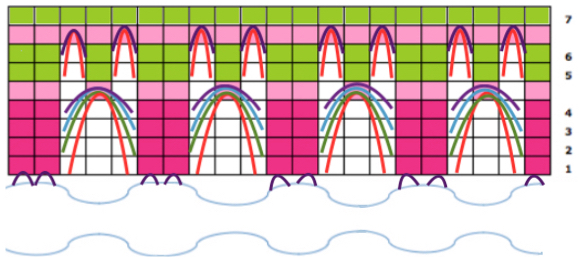

If using the pattern on electronic machines, the needle selection needs to match on the top bed. Depending on the model electronic, the pattern may have to be reversed for accurate needle selection. When using card 304, tucking happens for 3 rows forming loops that span across needles out of work, then all stitches on needles on rows with numbered markings on blue cells knit for one row. Orange gradient-filled cells represent rows on which tuck loops are being formed on the held single stitches, which in turn grow in length.

When using card 304, tucking happens for 3 rows forming loops that span across needles out of work, then all stitches on needles on rows with numbered markings on blue cells knit for one row. Orange gradient-filled cells represent rows on which tuck loops are being formed on the held single stitches, which in turn grow in length.  The full 24 stitch repeat, shifted for my preference, with the smallest electronic 8 stitch repeats outlined with red border

The full 24 stitch repeat, shifted for my preference, with the smallest electronic 8 stitch repeats outlined with red border

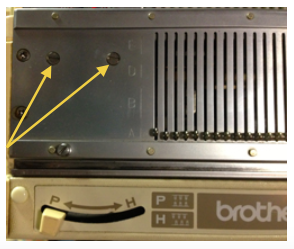

On the 930: the odd number of needles are automatically placed on the left, with the pattern used in the isolated design setting.

On the 930: the odd number of needles are automatically placed on the left, with the pattern used in the isolated design setting.

the tuck loops still form on the main bed, the ribber is set to knit every needle in both directions.

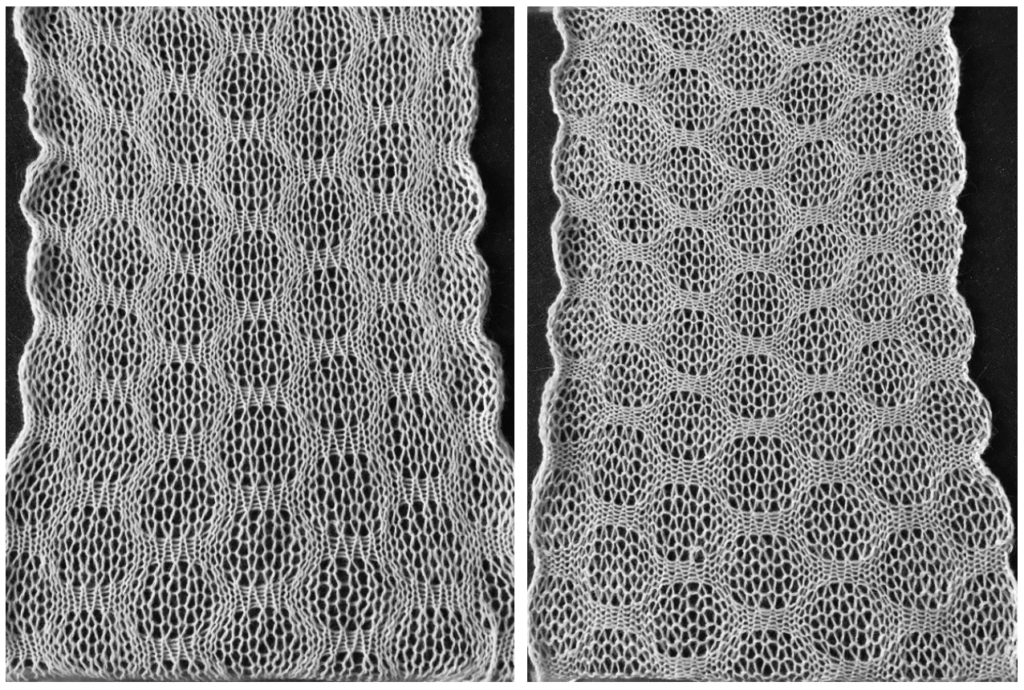

the tuck loops still form on the main bed, the ribber is set to knit every needle in both directions.  The resulting knit, very different in appearance and in width than the previous sample, using the same tensions

The resulting knit, very different in appearance and in width than the previous sample, using the same tensions