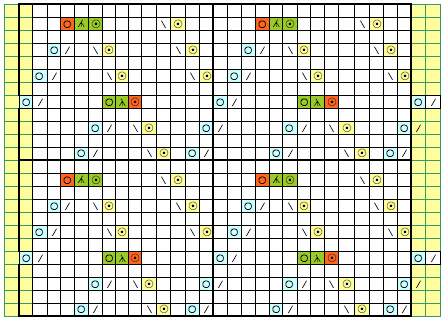

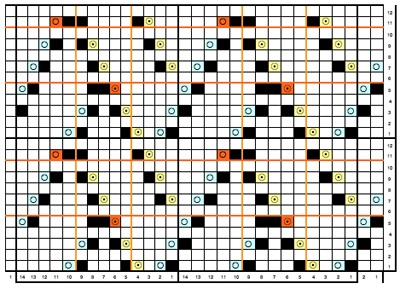

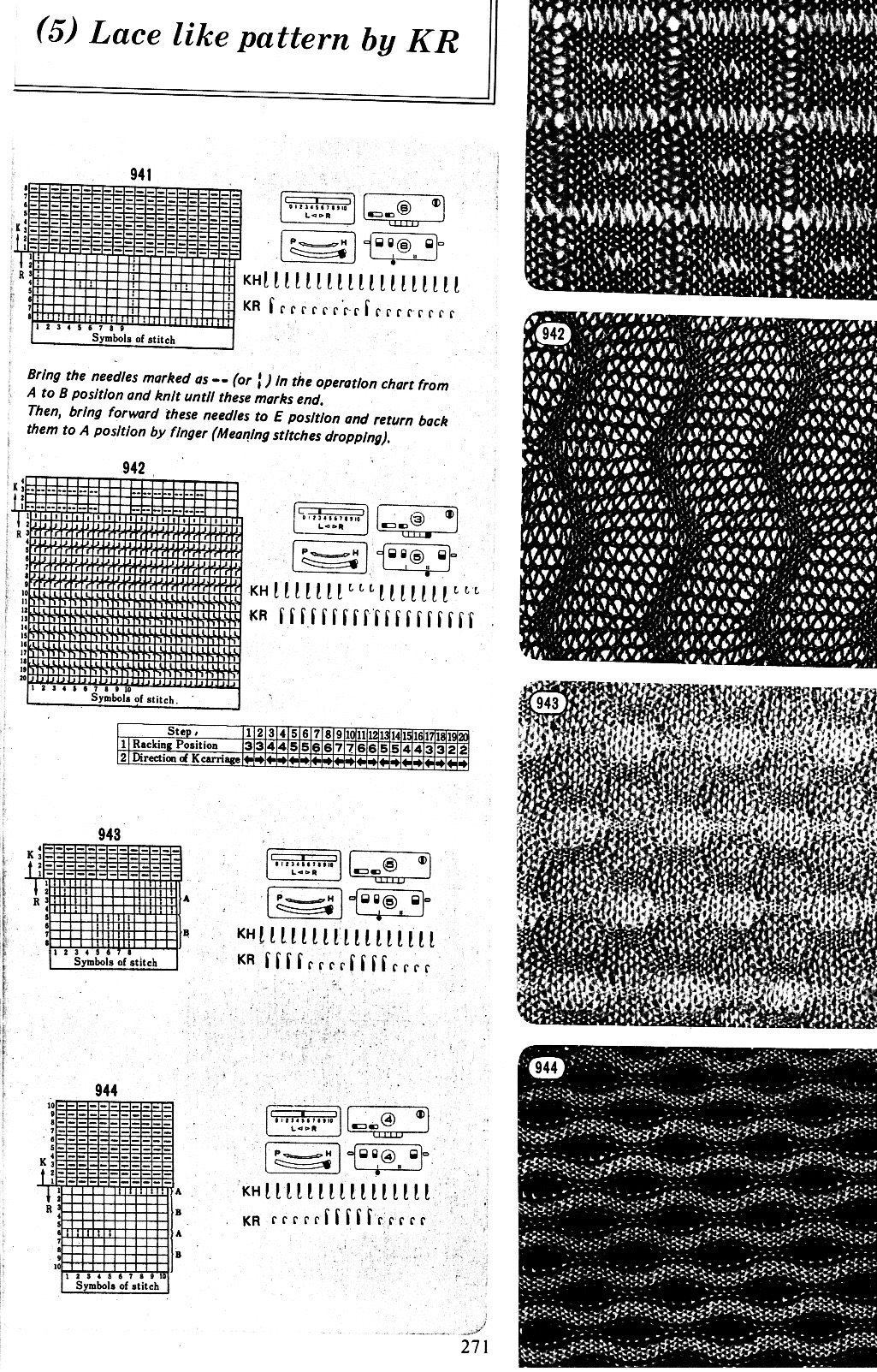

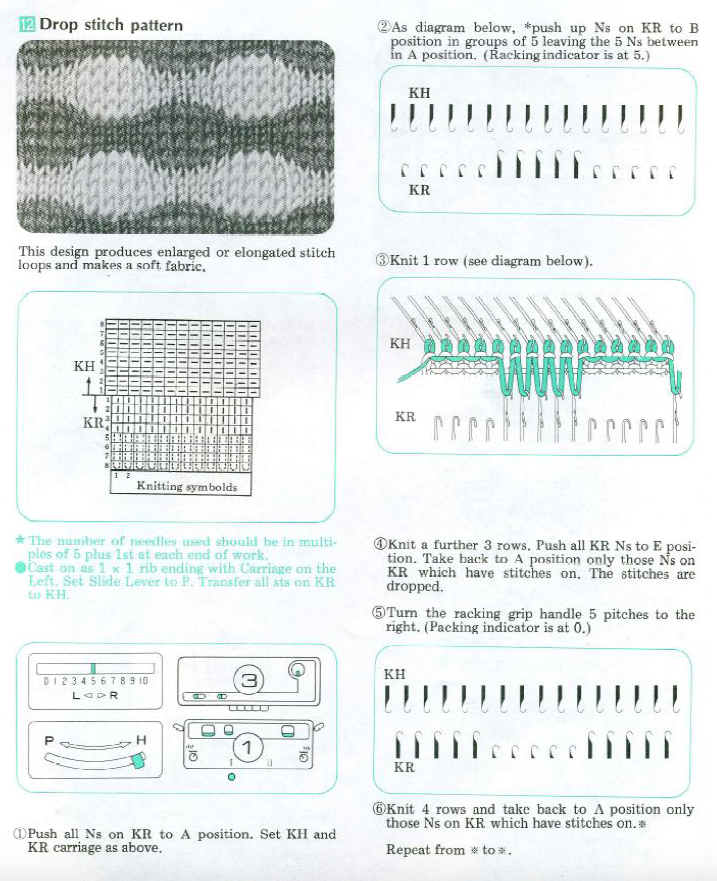

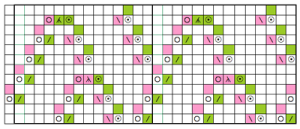

Occasionally I do play with hand knitting and charting for it. A couple of years ago I wrote on the topic of illusion / shadow knitting. The repeat is 24 stitches wide, so it is suitable for use on punchcard machines as well.

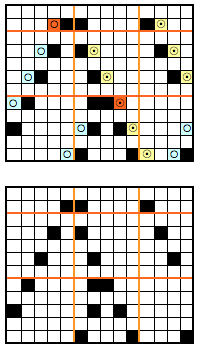

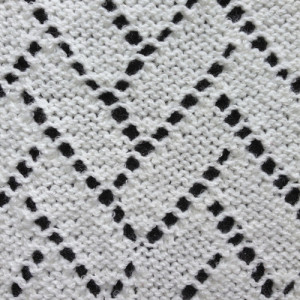

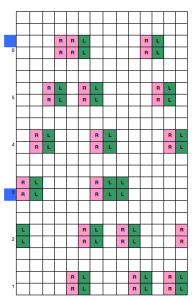

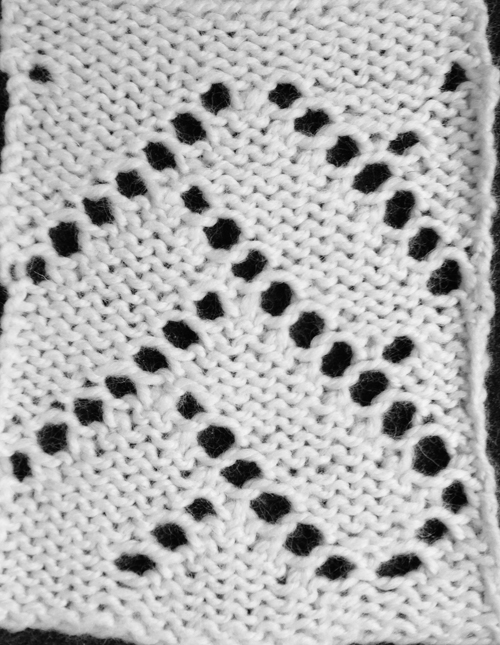

the resulting hand knit, on the purl side

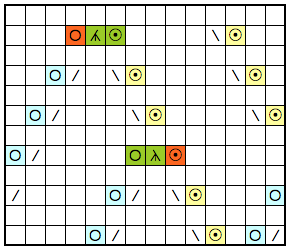

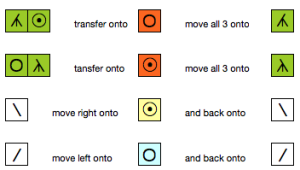

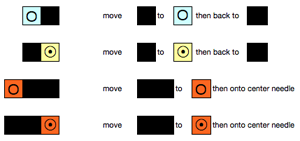

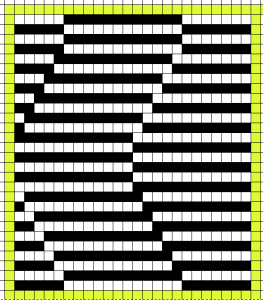

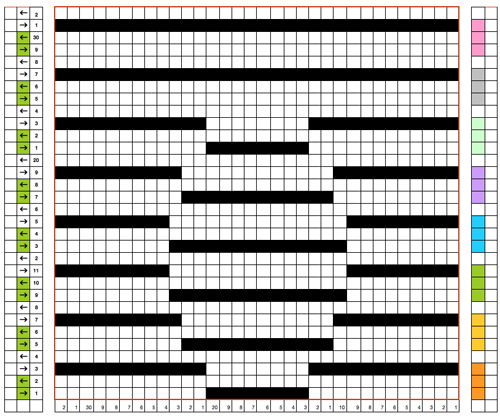

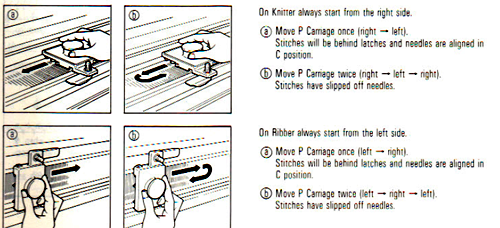

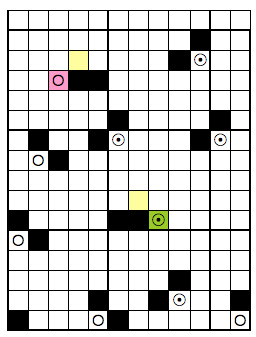

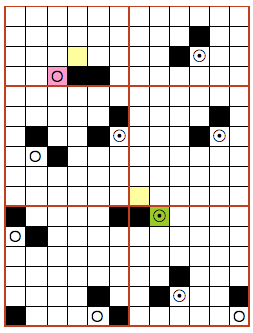

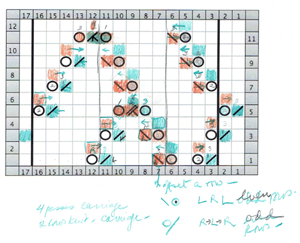

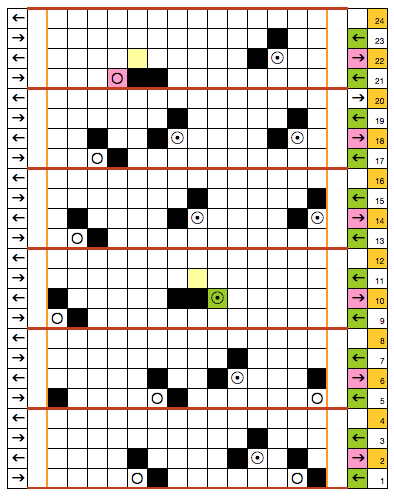

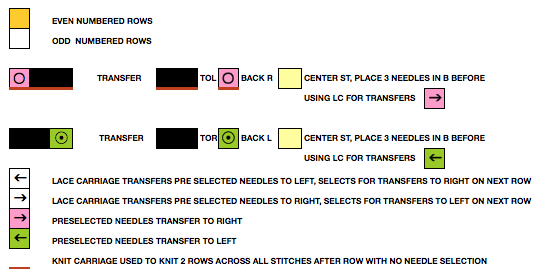

While working out the circle in the previous post it occurred to me that the results were quite similar to shadow knits, where depending on the angle from which the fabric is viewed, images begin to appear in the striped fabric. The above chart is missing those all blank rows that result in no needle selection. The solution for using this type of color separation for drop stitch on the machine is to use double length. Other KM settings remain the same as in the previous post. The first selection row is from left to right. The big difference is that once again, there will be the same needle selection on the next row. With some needles in B and some in D, a slider or pusher will not move across the needle bed. In the past, I tried to drop stitches selectively on the main bed with rulers or whatever was handy. Now, instead, I found pushing the whole row back to B, allowed me to use my new tool to move back and forth across the needle bed, making faster work of the process, and returning needles in position for the next main bed row to be selected on the first pass, knit on the second. The swatch was casually steamed

purl side, viewed as it would appear in a sideways knit

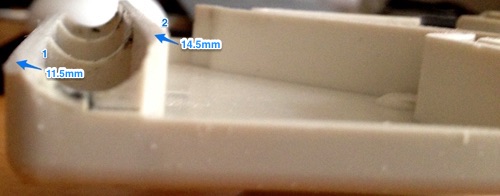

Without the “tool”, all stitches can be brought to E and back to B with a ruler, piece of garter bar, ribber cast on comb, or another handy toy. Dropping stitches is done while carriages are on the right, they return to the left knitting only on the ribber. In the previous post, the ribber only knit first, both beds knit on the second row, and stitches were, in turn, dropped with carriages and yarn on the color changer side (L), after no needle pre-selection across the main bed.

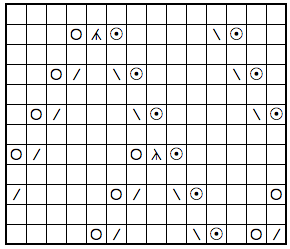

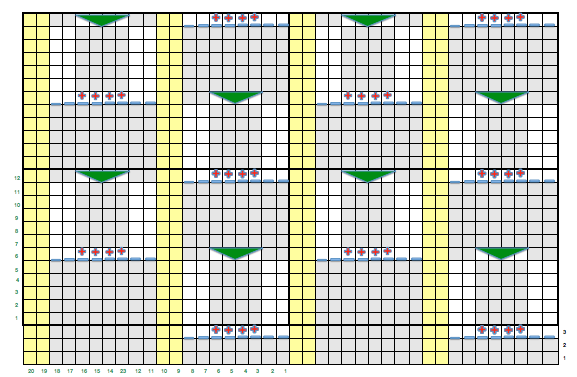

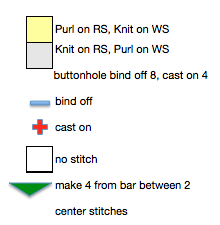

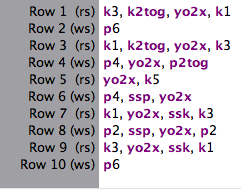

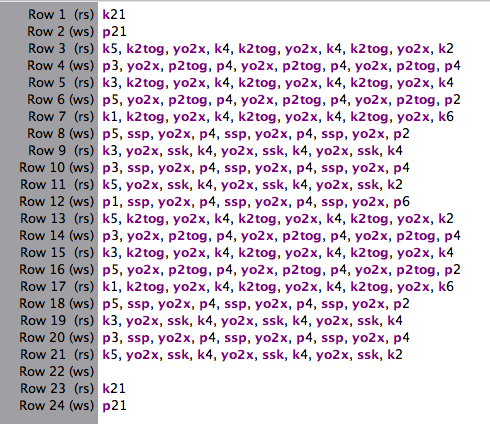

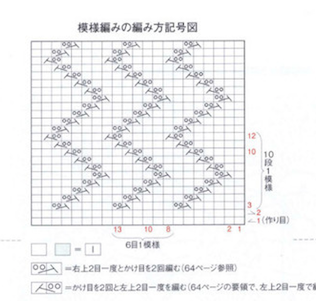

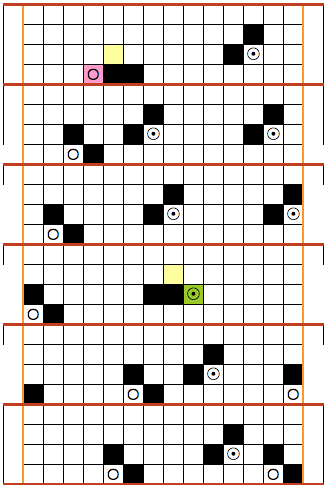

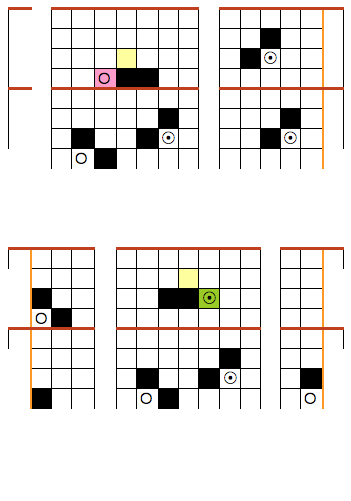

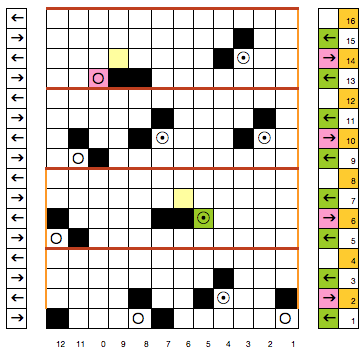

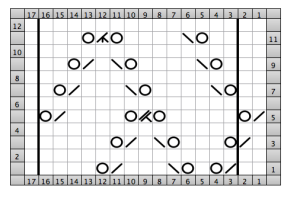

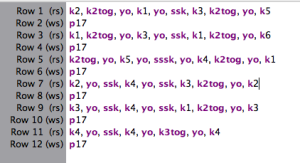

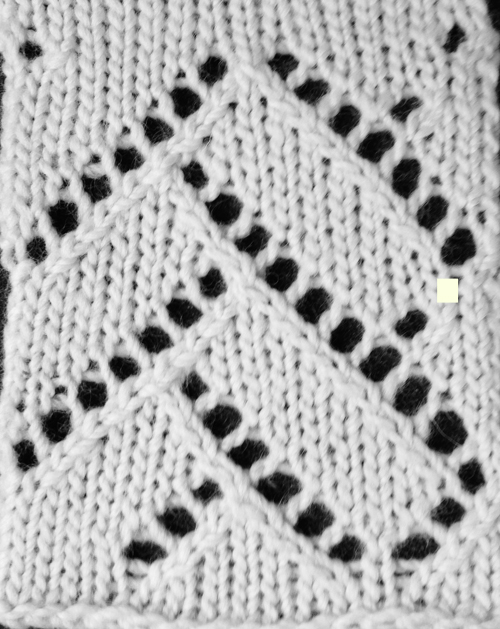

charting things out

charting things out

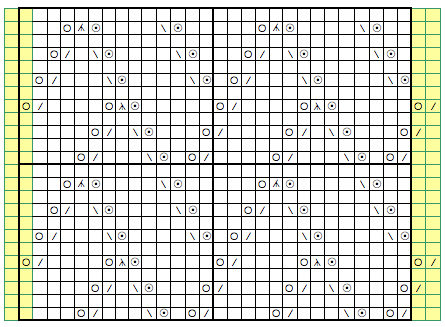

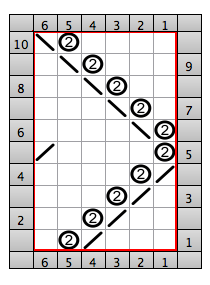

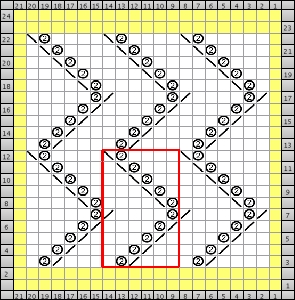

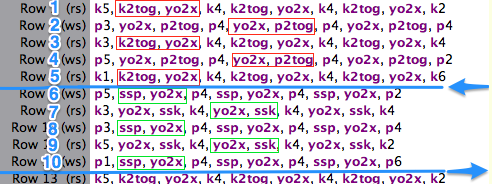

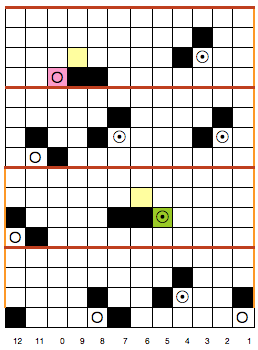

looking at charting differently, back to Excel: single repeat

looking at charting differently, back to Excel: single repeat