During my early morning surfing, I recently came across a pattern knit as fair isle that I thought might work well in slip stitch

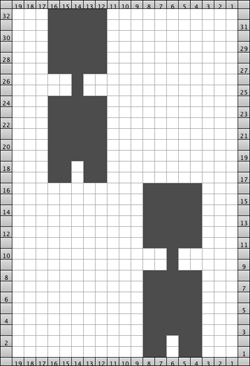

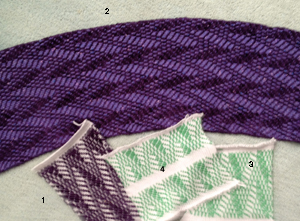

the repeat

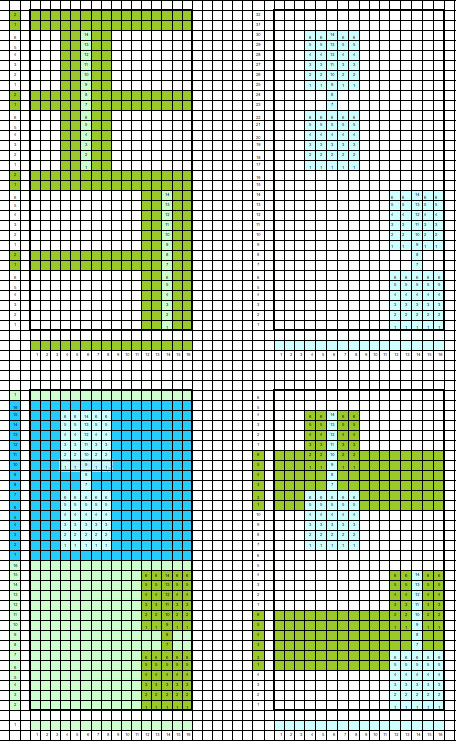

the first sample knit side

its purl side, showing the typical slip “floats”

The light color is a 2/8 wool, the green a rayon/nylon blend, thinner in weight; the rayon flattened considerably after steaming (something to consider if the maximum texture is the desired aim); the first wide band of green is 32 rows high (full repeat), the narrower stripes occur with changes every 16 rows. Slip stitch striping can vary a pattern greatly, sometimes more successfully than others. My sample was knit on a 910, using color reverse. In the first repeat chart the white squares are intended to be what knits, the dark grey the slipped areas (Passap use same repeat, tech 129, each black square is a slipped stitch with lock set to LX rather than KX). This repeat is too wide as-is for use on a punchcard but was it usable, all but the dark squares would be punched.

The obvious color changes may take place every 32 rows, every 16, every 8, every 4, 2 followed by 6, and more. The pattern may also be knit with the same color rotation, but beginning striping sequences on a different row. The purl side of this particular pattern helps make it easy to track the location of color changes, but with many slip patterns the same may not be so obvious, and good note keeping of sequences and starting rows for the design can be a time saver when one wants to reproduce particular pleasing or successful “random” segments.

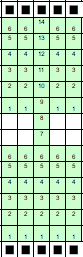

more variations

the top section here begins with the first design row KC–>

these are done with beginning the pattern on row 2, KC<–

swatch is not pressed, resulting in a more pronounced texture

Re_editing the repeat can help change/ plan the areas for solid color blocks to occur on the knit side. Slipped stitches become elongated ones on the front, knit side of the fabric, and the color they assume has to do with the last row knit before the needles with that color yarn. If a color changer is in use, the repeats must be an even number of rows in height. The repeat below is a variation of the one above. The slipped stitches are numbered, with the assumption that in this case, the fabric will be all one color, or with changes at the start and end of each repeat (now 16 rows)

Below are some of the options for color changes, with slip stitch areas renumbered as any of the colors create knit stitches on the face of the fabric, the bar at bottom of the chart indicates starting color prior to the first needle selection row toward color changer. Only 2 colors are in use in the actual knitting, the other color blocks in slipped areas are to help visualize what stitches are being slipped and for how many rows, in each color

Personal fabric and surface preferences may vary greatly between individuals. The swatch below shows variations in the above, including some dropped stitches that were “missed”

My personal preference is for the top of the swatch, where the difference in yarn weight also results in an interesting dimensional effect

a couple of the many sources on this particular stitch type

…

Assuming one uses a crochet cast on and binds off around gate pegs at the top, a chain is created at both ends, akin to that created in crochet, and one can identify a front loop, a back loop, and the whole chain. Any of the 3 may be “rehung” onto the KM, and the options are to knit a row and bind off again, or simply bind off again, for different looks that start to emulate single crochet a bit and can help stabilize edges or decorate them. It is helpful to keep notes as to the sequence used and which side is facing with each re-hanging. Audrey Palmer at one point authored the Empisal book of linked edgings ISBN 0969485905. Intended for use with the Empisal (later = Studio) linker, there are lots of interesting uses for combinations of essentially find off techniques, and some resurfaced when she published her books on knit weaving.

Assuming one uses a crochet cast on and binds off around gate pegs at the top, a chain is created at both ends, akin to that created in crochet, and one can identify a front loop, a back loop, and the whole chain. Any of the 3 may be “rehung” onto the KM, and the options are to knit a row and bind off again, or simply bind off again, for different looks that start to emulate single crochet a bit and can help stabilize edges or decorate them. It is helpful to keep notes as to the sequence used and which side is facing with each re-hanging. Audrey Palmer at one point authored the Empisal book of linked edgings ISBN 0969485905. Intended for use with the Empisal (later = Studio) linker, there are lots of interesting uses for combinations of essentially find off techniques, and some resurfaced when she published her books on knit weaving.