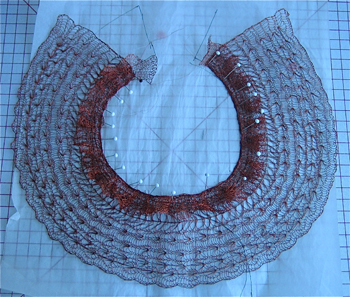

Blocking is one of those topics open to endless debate both as to method and necessity. In most of the items I produce using conventional yarns, I restrict it pretty much to washing/pressing/ironing as needed, thus avoiding all those blocking wires, pins, etc. In this instance, however, the wire item is in need of some help in changing into and retaining the desired shape: my partial solution is seen in the photo above.

For the curious: Magnet wire or enameled copper wire is a copper or aluminum wire covered with thin insulation. It is used in the construction of transformers, inductors, motors, headphones, loudspeakers, hard drive head positioners, potentiometers, and electromagnets, among other applications. However, it is not usually magnetic itself. Magnet wire insulating films used (in order of increasing temperature range) include polyurethane, polyamide, polyester, polyester-polyimide, polyamide-polyimide (or amide-imide), and polyimide. Kynar wire is an instance of a color-coated member of these families and is used in my “colored” jewelry items. For knitting on a loom, I prefer 32 gauge or thinner (higher numbers), which can be plied successfully for more drape but are nearly invisible singly; 30 gauge or less(lower numbers) moves into the hand crochet/knit coil domain for me.

I enjoy using materials designed for uses other than those for which they were designed, the inherent challenge, surprises, and problem-solving.