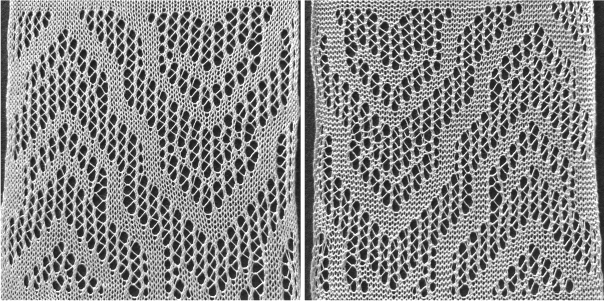

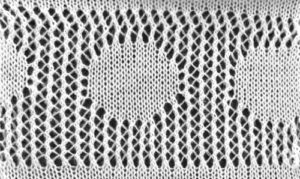

Mock filet crochet machine knit lace has surfaced in a Ravelry blog of late. The sample in question was made by Tanya Cunningham, using a hacked knitting machine and software to download the repeat. Sometimes punchcard machines or early electronic users feel left out of creating particular fabrics. If one can settle for working with simpler and far smaller repeats, however, one can achieve interesting results on that scale.

Several years ago I wrote a series of posts on lace meshes and lace patterns inspired by filet crochet. They are interspersed in the mesh category. There also has been a thread lace Ravelry “thread”, and today’s avoidance of housework led me to think about pre-drawn thread lace patterns to create a filet-like mesh.

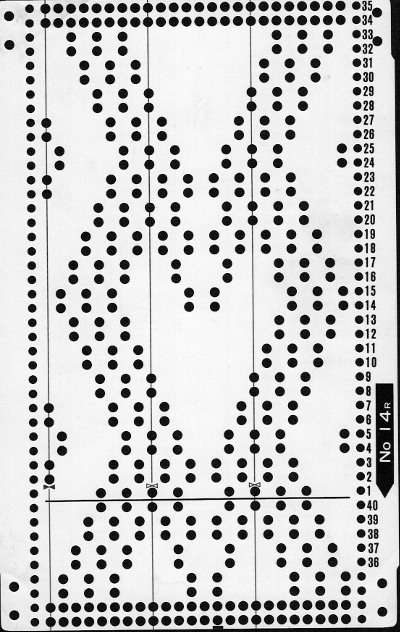

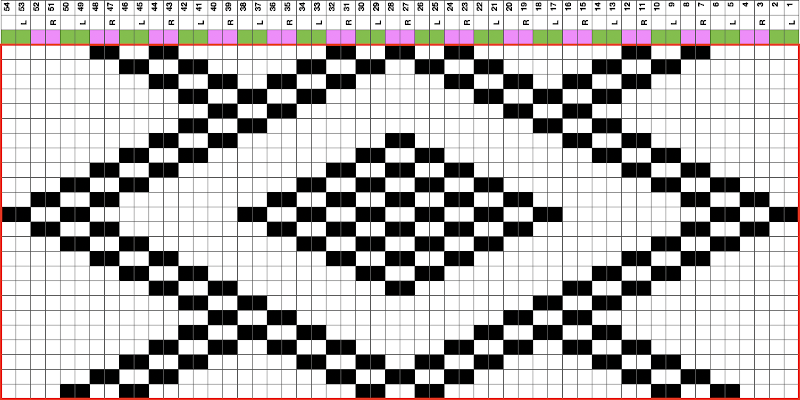

What to look for a first experiment (Brother punchcard machines only): large unpunched areas creating motifs, with no side-by-side punched holes, and no more than 2 consecutive punched rows. Some samples are provided in-stock cards that come with machine purchases. One such  The lace carriage (LC) selects on the first pass, transfers on the second. It advances the card with each pass of the carriage if it is operated consistently from the same side.

The lace carriage (LC) selects on the first pass, transfers on the second. It advances the card with each pass of the carriage if it is operated consistently from the same side.

If 2 knit carriages (KC) set to select needles for any technique are in use in punchcard machines, as one is put to rest and the other one begins to move from the opposite side, the card does not advance on the first pass, so selection for the previous row is repeated one more time.

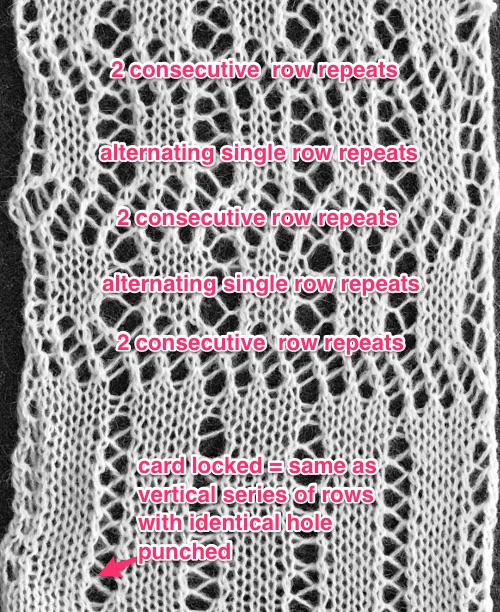

If all lace transfers are made in the same direction the resulting fabric will bias. For balanced lace fabrics, the direction of the transfers needs to be reversed, whether in alternating series of rows or with every other set of transfers. In a situation such as this, the LC makes one set of transfers operating from the left, with the next set of transfers operating from the right.

For the correct setup, the first-row selection with the card is made on the row just below the one marked #1 (in this instance that would be row #40), then the card is set to advance as usual.

If the first selection row is made with the card set to below the #1 line, the card needs to be already joined with snaps into a drum or the card reader will be selecting the all-punched row which is normally part of the overlap that sits over the last 2 rows of the pattern repeat.

I began with my LC on the left for transfers to the left and alternately placed it on the right after knit row(s) for transfers to the right.

A “simple” lace is produced with only one-row knit between transfers, and a more complex lace if 2 rows are knit between them.

The LC moves left to right and transfers back to left. If the knit carriage is used for one pass only, it stays on left. The LC is now taken off the machine and moved to the right, used for 2 rows, and will be removed from the bed to ready it for its return to the left side.

The KC follows with one pass from left to right.

The LC is returned to left and operated for 2 rows, starting the sequence over again. The LC is always moving toward the KC to select, and away from it to transfer.

Brother knitters are used to knitting 2 rows after lace transfers.

It may be done with this card as well. The problem here is that when knitting for 2 rows, the knit carriage consistently returns to the same side so that when transfers need to be made from its starting side with the LC, the KC needs to come off the machine until after transfers are made.

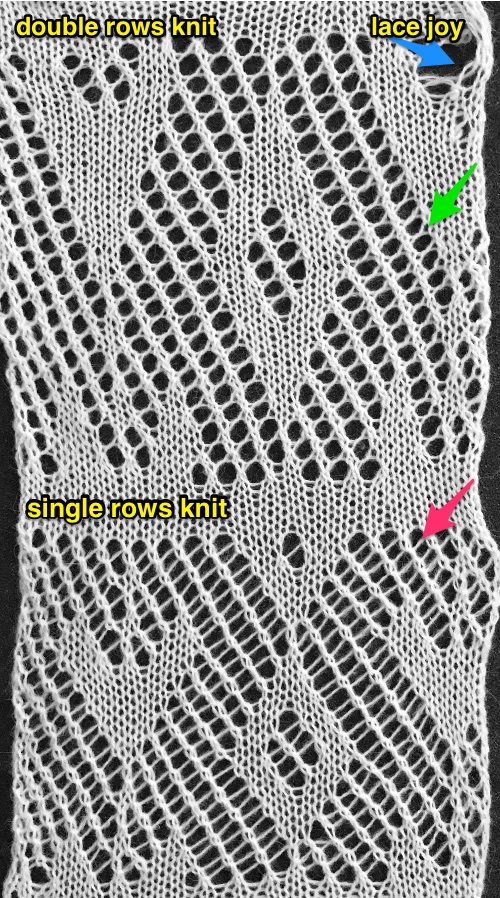

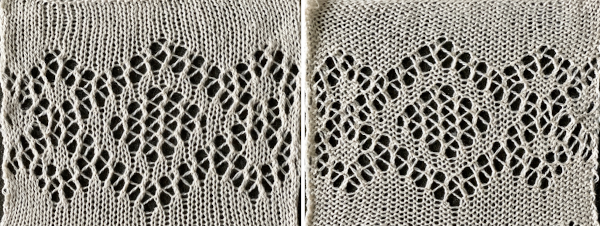

There is a lot more juggling of carriages and keeping track of what needs to be where. The elongation that occurs with 2 rows knit after each set of transfers, and the differences in the appearance of the yarn forming the eyelets (single/magenta arrow vs crossed/glow green arrow strands) for the respective methods are shown below.  Three more candidates for experimenting with the technique.

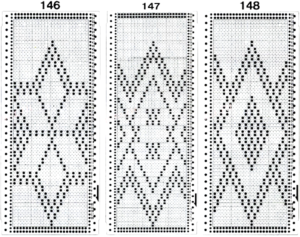

Three more candidates for experimenting with the technique.  Working the fabric on an electronic, the repeat used:

Working the fabric on an electronic, the repeat used:  The single knit row between repeats is fairly easy and rhythmic to produce. The first preselection row is made with the lace carriage, beginning on the left, the design is used as given in the punchcard.

The single knit row between repeats is fairly easy and rhythmic to produce. The first preselection row is made with the lace carriage, beginning on the left, the design is used as given in the punchcard.

LCOL preselects for transfers to the left as it moves to the right

LCOR transfers preselected needles to the left and preselects the same needles, now empty, a good time to check for any dropped stitches or split yarn. Remove LC from the bed to place it on the right before transfers in the reverse direction

KCOR knit one row to the left, leave it there

LCOR preselects for transfer to the right as it moves to the left, transfers on its return to the right, and preselects the same needles, now empty of any yarn. Again, remove it from the bed in order to place it on the left before transfers in the reverse direction

KCOL knit one row to the right, leave it in that position

LCOL begin the sequence again

preselection with the LC is always toward the knit carriage, and transfers are always away from it  If working the same repeat as transfer lace, the knit carriage moves to and from the right with every 2 rows knit, so in order to make transfers with the LC to the right, the knit carriage needs to be moved off the needle bed for the LC to be able to operate from that side.

If working the same repeat as transfer lace, the knit carriage moves to and from the right with every 2 rows knit, so in order to make transfers with the LC to the right, the knit carriage needs to be moved off the needle bed for the LC to be able to operate from that side.

The process is a tad fiddly, if the technique is to be used for an all-over design, converting the design to the traditional transfer lace format would be worth the effort. Barring that, some sort of note-taking to serve as a reminder of which side the LC carriage should operate from is also helpful.

The BMP for the full repeat including blank rows at the top

The BMP for the full repeat including blank rows at the top ![]() Returning to another Brother punch card, more possibilities in ways to experiment

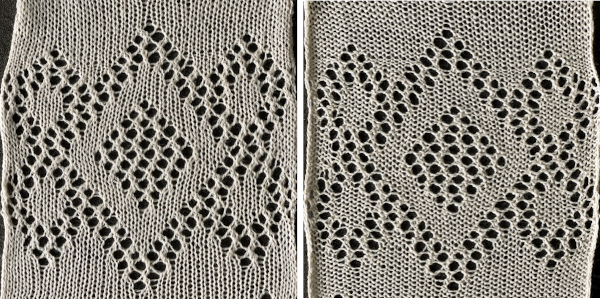

Returning to another Brother punch card, more possibilities in ways to experiment

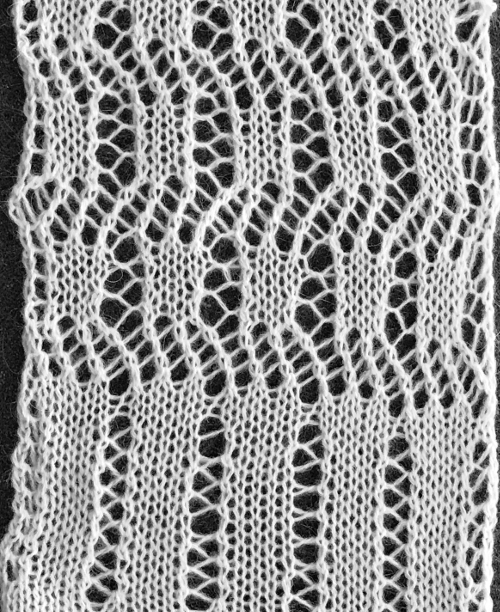

The above shows long vertical lines of transfers are possible in design motifs (punched holes).

The above shows long vertical lines of transfers are possible in design motifs (punched holes).

Adding shapes to all over mesh may require some editing along edges where the shapes meet the mesh. Varying size swatches are recommended before committing to any large piece.

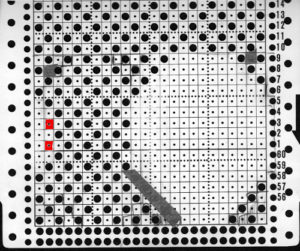

As always punched errors may be taped over. Red squares in the image below reflect holes missing in the card if the goal is to achieve a smoother circular shape.

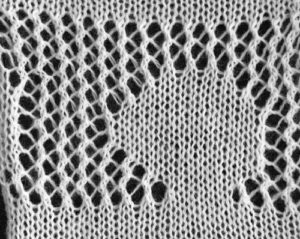

When this technique is used, selection, transfers, and knitting occur in each single, completed row of the design.  note the differences in circle sides

note the differences in circle sides  a wider, amended repeat

a wider, amended repeat  The slight bias zig zag at the top of the swatch results from a missing reverse direction transfer before continuing with plain knitting and binding off. Ultimately whether the final fabric is worth the effort in making it is a personal choice.

The slight bias zig zag at the top of the swatch results from a missing reverse direction transfer before continuing with plain knitting and binding off. Ultimately whether the final fabric is worth the effort in making it is a personal choice.

Sometimes small swatches work like a dream, and when large pieces are produced, problems multiply or the result is disappointing.

In the past, I have also tried to use thread lace-inspired patterns for drop stitch lace (ribber fabric), but have found the result far more subtle than expected.

As always yarn and color choice make a significant difference. The yarn used in these samples is a 2/15 wool blend, knit at tension 6.

BTW: Studio pattern books have multiple sections of published 24-stitch thread lace patterns. Not all Brother machines have the capacity for knitting this type of fabric, so not all of their publications include “suitable patterns”. If one understands what punched holes vs unpunched do, some of the Brother weaving and “pick rib” perhaps another post’s topic) can be used as-is or adapted.

punchcard http://machineknittingetc.com/pattern-library-for-punchca…

previous blog notes on thread lace 2016/11/03/thread-lace-on-brother-km/

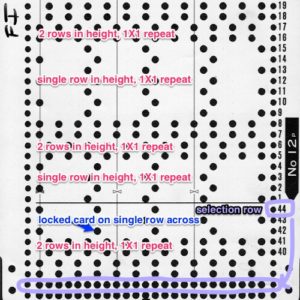

2023 Brother electronic 930, the image is automatically mirrored

Using StitchWorld #545 ![]() Use a yarn that has previously worked well in lace transfer knitting.

Use a yarn that has previously worked well in lace transfer knitting.

On the 930, the Knit Carriage ends On the Left, after casting on. As in any standard transfer lace, it knits stocking stitch rows, does not advance the pattern.

The Lace Carriage begins On the Right, selects needles as it moves to the Left

LCOL the LC transfers to the right, slide it off the machine

KCOL the Knit Carriage makes a pass to the right, knitting a single row, stops and stays there

LCOL returned to the knit bed, the LC preselects as it moves to the right

LCOR transfers as it moves to the left, slide it off the machine

KCOR knits a single row as the carriage returns to the left and stays, knitting a single row

LCOR the LC is returned to the knit bed, preselects moving to the left and the process continues.

At times patterns are best executed with hand transfers as opposed to using the convenience of automating them. In instances such as them, begin the same way, with KCOL

LCOR make a pass toward the knit carriage, transfers stitches manually away from the lace carriage

LCOL make a pass away from the knit carriage, the same needles preselect, they should have no stitches on them now, this is a good time to check all transfers have been made properly and that there are no dropped stitches, slide LC off the machine

KCOL makes a pass to the right, knitting a single row, stops there

LCOL the LC is returned to the knit bed, preselects needles as it moves to the right, hand transfer selected needles away from the LC

LCOR the same needles will be selected on the way back to the left, and are now empty, slide the LC off the needle bed

KCOR knits a single row as it makes a pass returning the the right, and the process begins again

In both automated and hand technique, the LC always moves toward the KC, transfers are always made away from it.

The final mesh is quite different than the standard meshes produced with LC performing all selection and transfers, followed by the KC knitting 2 rows