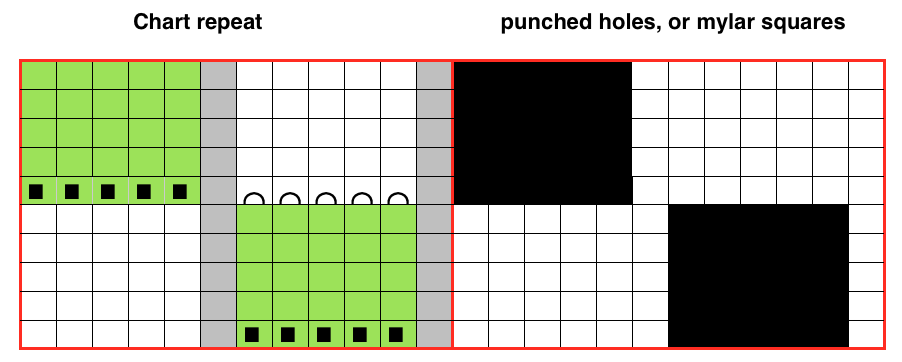

Sometimes months or even years go by before I revisit previous posts. As I review the information, it may occur to me to think about it further, and /or to present it in a slightly different way. I find it hard to believe how much time has passed since 2013/09/06/more-knit-bubbles/ got published. Here is another way to look at the fabric on Brother KM. Since I knit on a punchcard model or a 910 electronic one, I will refer to pattern repeats in terms of punched holes or black squares.

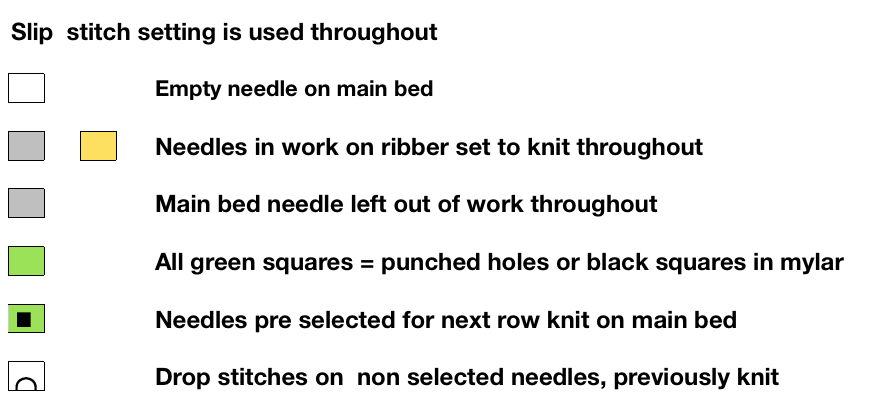

Bubbles and drop stitch lace share some of the same principles, the effect is created by stitches that are larger than others. Slip stitch setting can be used to automate needle selection. Black squares or punched holes will knit, unpunched areas or white squares will not, with needles left in the B position. Brother preselects needles for the next row of knitting, so when combining hand techniques with needle selection, one has the option to intervene before the next row in the design is knit. Using the card or mylar to read row 1 of the design helps determine where on the needle bed to set up your repeats. In this instance, the ribber knits every stitch, every row, with one extra needle on the left (or more on each end if preferred) in addition to repeats # required to achieve the desired width. All needles are in work every row on both beds. Main bed knits in response to programming.

Working in multiple of repeat -1 on the top bed, plus one needle in work at each end on the ribber. Considerations need to be made to align the design properly. The markings on my metal bed are from a different project.

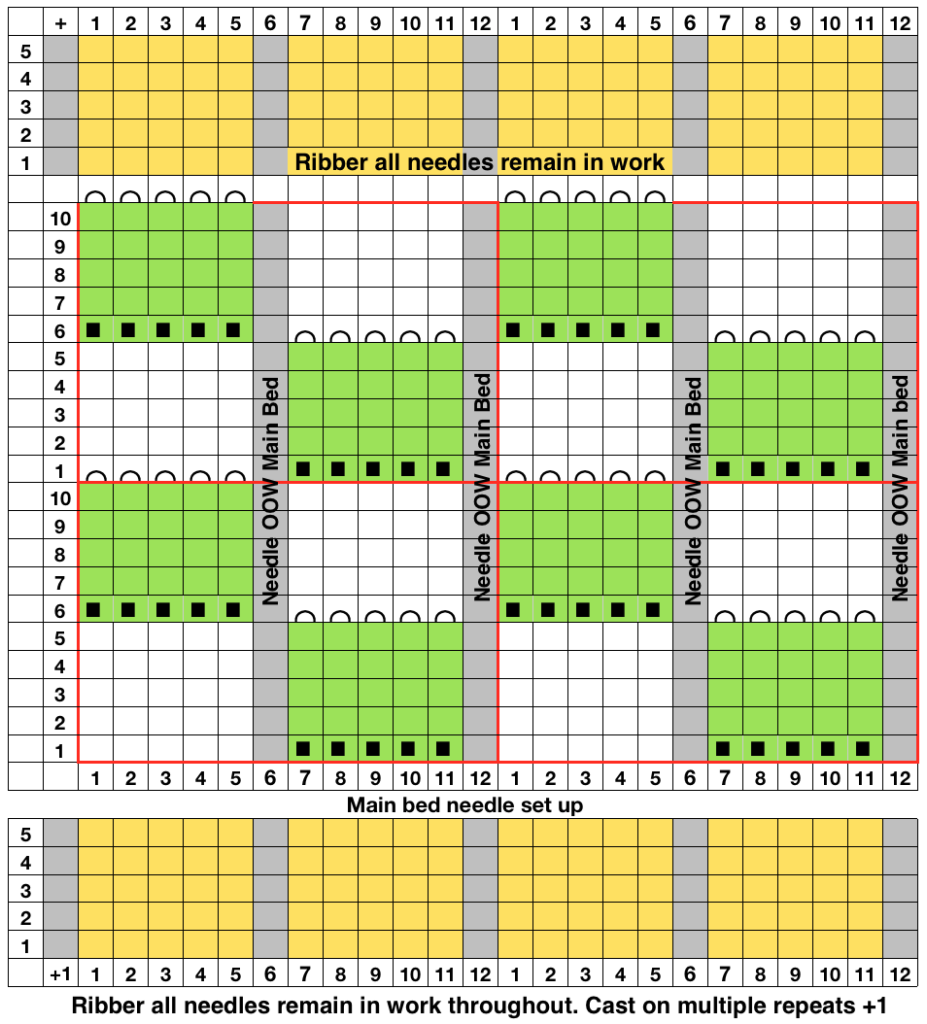

Working in multiple of repeat -1 on the top bed, plus one needle in work at each end on the ribber. Considerations need to be made to align the design properly. The markings on my metal bed are from a different project.  The goal is this needle arrangement

The goal is this needle arrangement  “air knitting” with carriage set to KC will help identify patterning repeats. Groups of 7 include a needle on each end which will be pushed back to A position in the body of the knit/ NOOW (needle out of work) indicated in the chart for the main bed needle setup

“air knitting” with carriage set to KC will help identify patterning repeats. Groups of 7 include a needle on each end which will be pushed back to A position in the body of the knit/ NOOW (needle out of work) indicated in the chart for the main bed needle setup  the first selection row

the first selection row  a needle on either side of the groups of 7 is pushed back to A position, remain there throughout the piece

a needle on either side of the groups of 7 is pushed back to A position, remain there throughout the piece an extra needle is brought into work on the ribber on either side of repeat ends. Machine settings: main bed set to slip <->, ribber set to normal knit

an extra needle is brought into work on the ribber on either side of repeat ends. Machine settings: main bed set to slip <->, ribber set to normal knit

the ribber has now been set up for knitting every needle, every row, with the caston and desired edging completed. The first row is selected on the main bed for pattern knitting.

the ribber has now been set up for knitting every needle, every row, with the caston and desired edging completed. The first row is selected on the main bed for pattern knitting.  since there are needles out of work and pattern knitting is involved, if KCI is used or end needle selection is not canceled, the end needles on the areas being slipped will be selected to the knitting position, so patterning errors will occur. The first row knit on both beds is shown on the remaining needles

since there are needles out of work and pattern knitting is involved, if KCI is used or end needle selection is not canceled, the end needles on the areas being slipped will be selected to the knitting position, so patterning errors will occur. The first row knit on both beds is shown on the remaining needles Brother knits a row while preselecting for the next one. Here the needles in B would slip/ not knit on the next row, and needles out to D (Brother skipped the letter C in needle positions) will knit. Before knitting that next row, stitches on the now non-selected needles should be dropped across the bed

Brother knits a row while preselecting for the next one. Here the needles in B would slip/ not knit on the next row, and needles out to D (Brother skipped the letter C in needle positions) will knit. Before knitting that next row, stitches on the now non-selected needles should be dropped across the bed  this shows those stitches have been dropped, their needles are now empty, and returned to B position

this shows those stitches have been dropped, their needles are now empty, and returned to B position

end knitting with the same treatment as it bottom (swatch was simply dropped off).

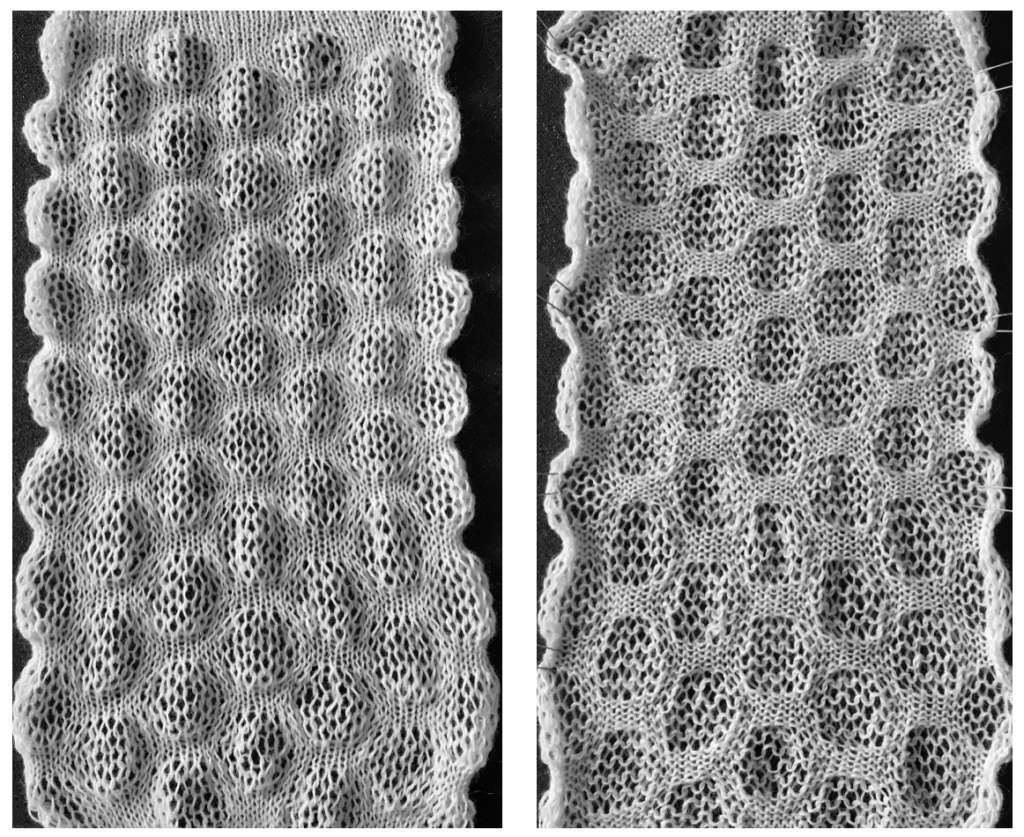

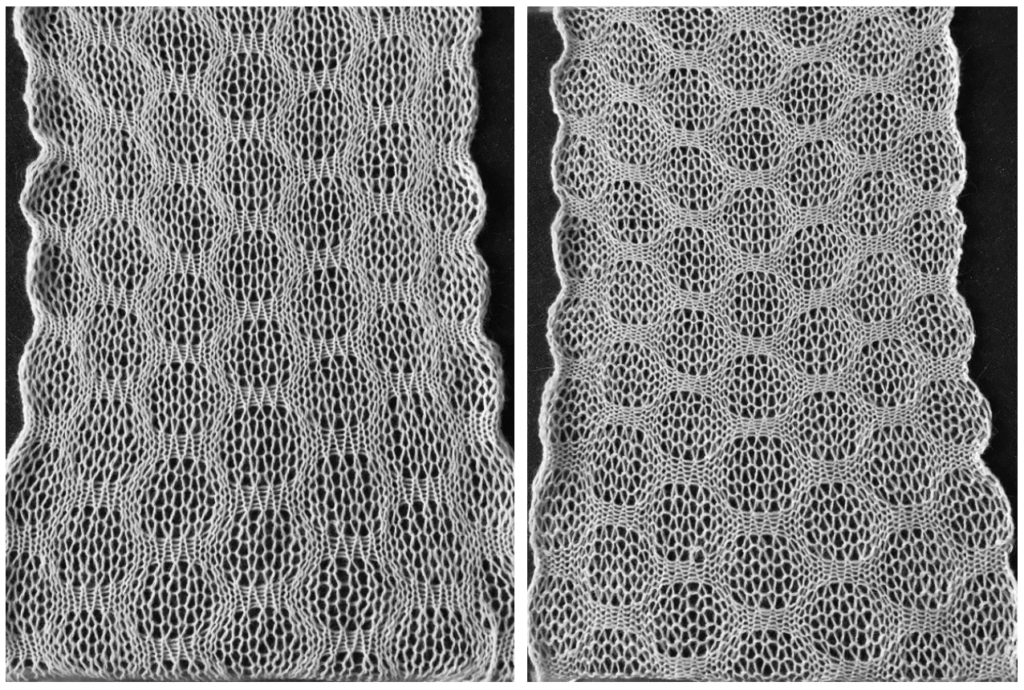

It is possible with solid geometric shapes such as these to release stitches after each shape. The type of yarn used and loop behavior upon dropping stitches are variables that influence success in doing so (other swatches ).

An acrylic yarn was used: the first image is the fabric’s “relaxed view”. after steaming and pressing

after steaming and pressing

the variation in width is due to adjustments in tension, the swatch folded over itself shows the difference in another way

the variation in width is due to adjustments in tension, the swatch folded over itself shows the difference in another way