In browsing through old photos I came across one of this swatch knit on the Passap eons ago, in a slightly textured unknown fiber, and a thin white one on a small cone with lost fiber markings.  The find led me to attempt a similar knit using my 930.

The find led me to attempt a similar knit using my 930.

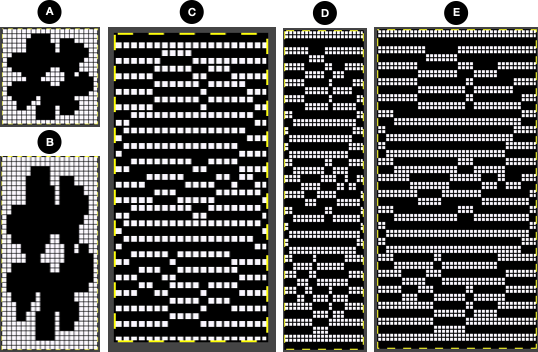

The flower image # 1228

![]()

![]()

is usable as published in variations for single bed knitting on the Passap ie using Tech 179, or on the Japanese knitting machines using the built-in KRC separation for 2-colors DBJ.

is usable as published in variations for single bed knitting on the Passap ie using Tech 179, or on the Japanese knitting machines using the built-in KRC separation for 2-colors DBJ.

The double bed fair-isle techniques on the Passap use a default color separation where each color in each design row knits twice.

The console performs the separation, but to achieve the same result in Brother models, the manual color separation can be performed using Gimp without any other software.

A: the chosen file, 20X20![]() B: scaled in length X2, to 20X40

B: scaled in length X2, to 20X40

C: color inverting every other row beginning with an all-white pixel row ![]() D: scaling the file X2 in length to 20X80

D: scaling the file X2 in length to 20X80![]() choosing a black row start planned in the background color by color inverting the png

choosing a black row start planned in the background color by color inverting the png ![]() E: taking into consideration that the planned DBJ settings will elongate the design, the 20X80 file is scaled in width X2 to 40X80

E: taking into consideration that the planned DBJ settings will elongate the design, the 20X80 file is scaled in width X2 to 40X80 ![]()

Knitting the swatch:

Knitting the swatch:

the thin white yarn simply refused to knit on the 930 without breaking. The problem can sometimes be solved by adding a second thread, which in this case, is a 3,000-yard monofilament serger thread, both are hard to see and slippery.

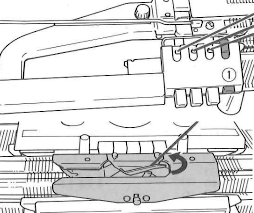

The way the yarn is picked up and carried varies with the knitting machine models’ color changers.

The yarn when using the Brother double bed color changer is picked up and swapped out in the ribber arm,  while in Passap models, the colors are threaded into individual feeding eyelets which are swapped out in any sequence needed in the front lock.

while in Passap models, the colors are threaded into individual feeding eyelets which are swapped out in any sequence needed in the front lock.  Some of the yarn-feeding issues in small or large cones can be solved by “putting a sock” on the cones, no matter their size. The manufacturer sometimes supplies the latter, but DIY versions can be segments of pantyhose, foam sleeves used to protect some of the exotic fruits in supermarkets, covers for flowers until they are used in arrangements, and at times simply a plastic bag.

Some of the yarn-feeding issues in small or large cones can be solved by “putting a sock” on the cones, no matter their size. The manufacturer sometimes supplies the latter, but DIY versions can be segments of pantyhose, foam sleeves used to protect some of the exotic fruits in supermarkets, covers for flowers until they are used in arrangements, and at times simply a plastic bag.

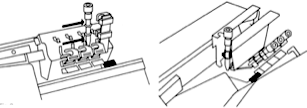

My arrangement, with the threads on top of the machine table, and fed through the same side of the yarn mast.  The first preselection row is from right to left

The first preselection row is from right to left

The ribber is set to knit in both directions throughout

The first and last needles are in work on the ribber

Colors are changed every two rows

The backing will be striped, with each color knitting for 2 rows, referred to as striper backing in many pubs.

Pattern knitting begins COL, set the knit carriage to slip in both directions

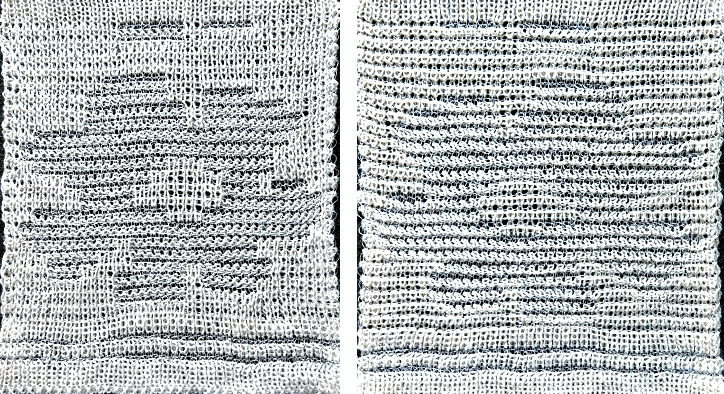

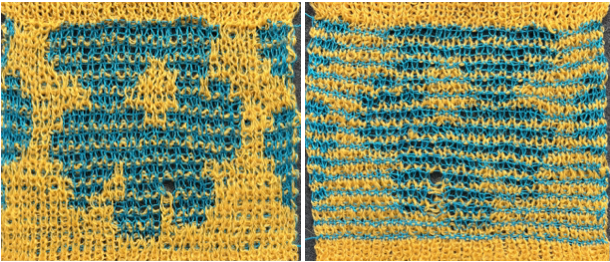

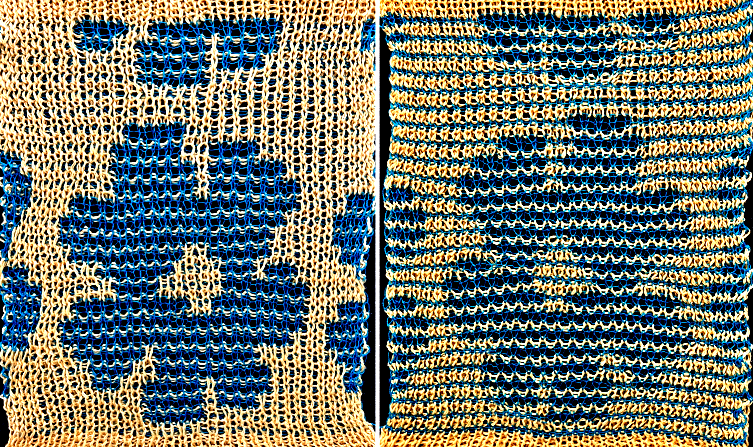

The proof of concept:  The matching technique using the settings for knitting (N) on the back lock and slip (LX) on the front lock, for striper backing is 183:

The matching technique using the settings for knitting (N) on the back lock and slip (LX) on the front lock, for striper backing is 183:  knit on 30 stitches, but less than full repeat in height.

knit on 30 stitches, but less than full repeat in height.

With some understanding of the pattern selection method for the front lock, different Technique numbers may be used for the same knit result simply by changing pusher arrangements and lock settings on either or even both beds.

With some understanding of the pattern selection method for the front lock, different Technique numbers may be used for the same knit result simply by changing pusher arrangements and lock settings on either or even both beds.

This test was knit on 30 stitches and for 100 rows after changing the ground yarn, adjusting the tension, and programming Tech 180, but disregarding the pusher set up for the back bed, and setting the back lock to N

The fabric is stable and reversible with interesting peek-through that reminded me of drop stitch lace.

The fabric is stable and reversible with interesting peek-through that reminded me of drop stitch lace.