Any repeat suitable for a 2 color 24 stitch DBJ separation published or self-drawn for a 4.5mm machine is suitable for DBJ on the bulky.

At times yarns ie 2/8 to 3/8 wools that knit stocking stitch at tension 8-10 on the main bed and are too thick for every needle rib on the standard may produce a fabric that is not too dense, and still has some drape at the lower tension settings on both beds on the bulky.

Electronic standard knitters can double the size of the repeat prior to separating the 2 colors and then work on every other needle on both beds, proceeding as usual for DBJ.

Thicker yarns begin to make too thick a fabric for wearables but may work well for other uses.

If some drape is required, the ladder-back method becomes the preferred one in bulky KM DBJ.

I no longer have available the bulky dbj samples from my teaching days, my 260 KM is not set up, so, for now, this post will not include swatch photos.

As always swatching is a necessity to determine whether the resulting knit is one that meets our expectations, preferences, and often, patience.

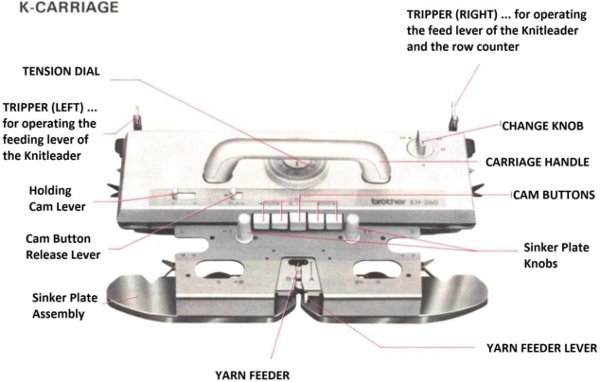

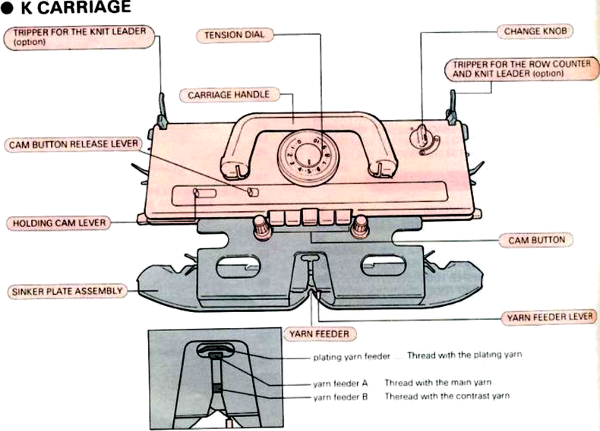

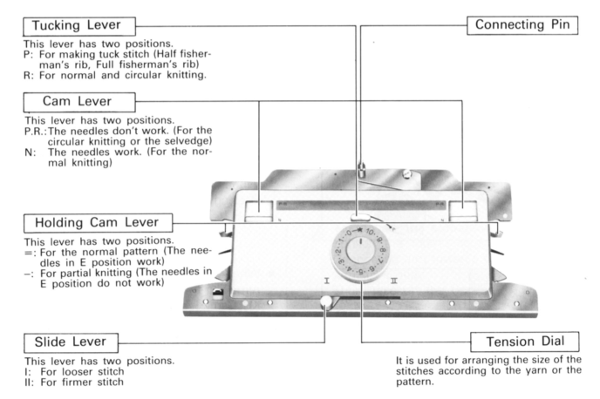

To review: the 260 KH carriage will be familiar to Brother punchcard 4.5 mm machine users and has the option for creating thread lace (“split” cam button in center position), which is not commonly available in Brother models.

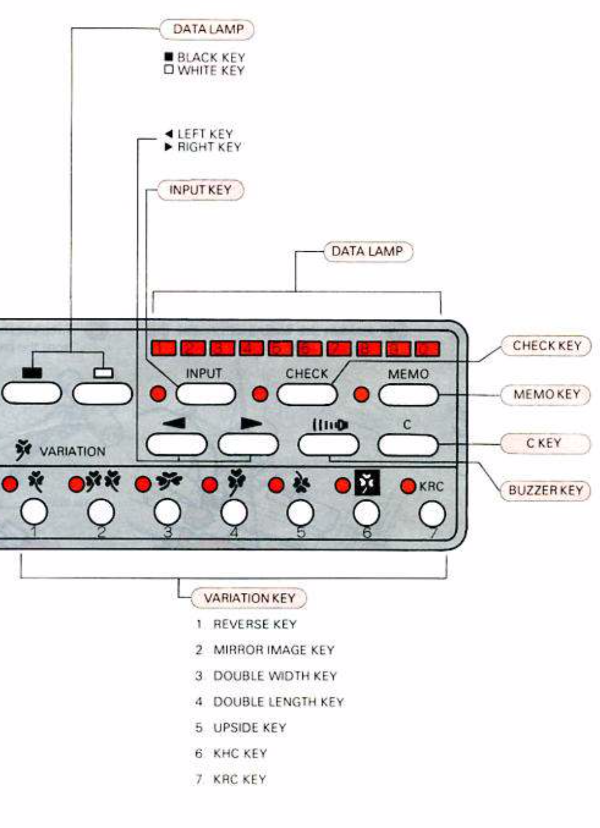

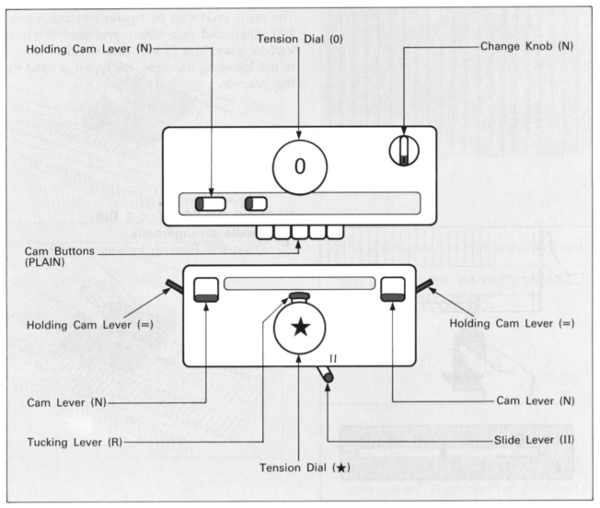

The Brother 270 electronic knit carriage offers similar settings

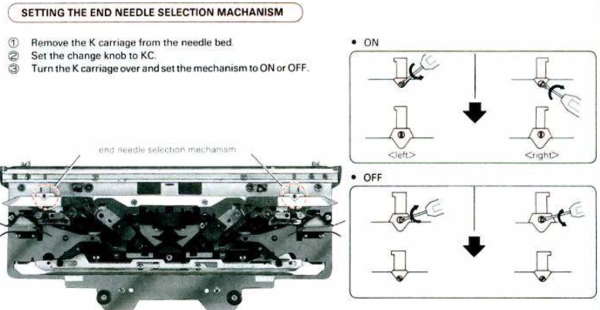

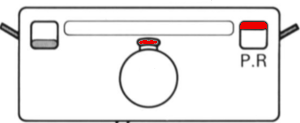

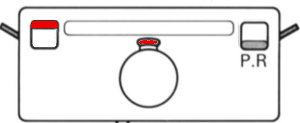

There is no automatic method for eliminating end needle selection ie KCII, rather, adjustments for it are made on the underside of the carriage, as in other punchcard machines  in terms of DBJ, the electronics allow for the familiar KRC 2 color separation

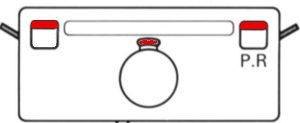

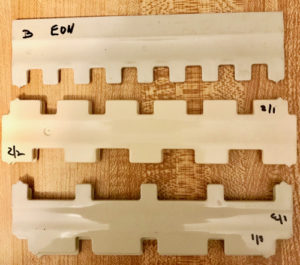

in terms of DBJ, the electronics allow for the familiar KRC 2 color separation  KR 260 parts as described in the ribber manual, followed by possible settings for cam levers are illustrated below. The absence of lili buttons is immediately noticeable. There is no automatic every-other needle selection on the bulky ribber carriage shown, as opposed to that choice being available on the standard KM.

KR 260 parts as described in the ribber manual, followed by possible settings for cam levers are illustrated below. The absence of lili buttons is immediately noticeable. There is no automatic every-other needle selection on the bulky ribber carriage shown, as opposed to that choice being available on the standard KM.

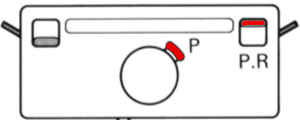

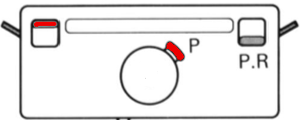

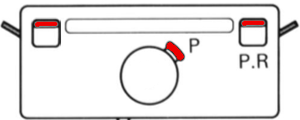

slip to right  slip to left

slip to left  slip both directions

slip both directions  tuck to right

tuck to right  tuck to left

tuck to left  tuck both directions

tuck both directions

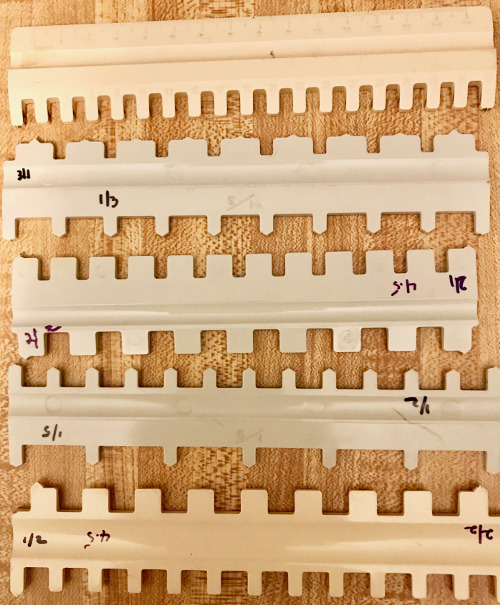

hand selection tools for either bed, 4.5mm on top, sometimes interchangeable

every needle selector for standard, operates similar to Jac 40, EON here for use bulky, adjustable

every needle selector for standard, operates similar to Jac 40, EON here for use bulky, adjustable

17.5-inch workshop cut model in plastic for 2X2 selection on bulky

17.5-inch workshop cut model in plastic for 2X2 selection on bulky  nowadays 3D printed custom options are also beginning to be available

nowadays 3D printed custom options are also beginning to be available

The DBJ setting that requires the least intervention on either standard or bulky machines is the one produced with the separated motif being knit with the ribber set to slip all needles in one direction, and to knit every needle in the other. Reproducing the lili effect is accomplished on the KR 260 is achieved with hand needle selection. For birdseye, where every needle is in use on an even number of needles in work on the ribber, select every other needle on the ribber beginning with the second needle on the right for the preselection row, and push up to the holding position. The ribber carriage is set to slip both ways and will knit hand-selected needles as it makes its way to the opposite side. Now select every other needle on the ribber beginning with the first needle on the right, bringing those needles up to hold. Stitches on those needles will knit on the ribber as the carriage makes its way back to the left and to the color changer. Colors continue to be changed every 2 rows as in any standard 2 colors birdseye fabric.

Ladderback or modified Jacquard is at times used on standard machines specifically for the effect created on the fabric reverse side, and most often used with bulkier yarns to be able to make a garment with more drape than it may have in regular jacquard, or to knit large designs with no long floats.

This technique on the KR 260 ribber involves hand manipulation of the ribber stitches to reduce the number of stitches formed on the ribber as well.

Ribbing is often set up to produce a band that is not hugely different in stretch and width than the body of a garment, with further transfers for the ladder back configuration when it is completed.

No more than one needle is usually in work on the main bed beyond needles in work on the ribber bed. If an additional needle on the main bed is required, it should be on the left-hand side.

The rib is knit as tightly as possible, tension is loosened as one progresses into the jacquard portion of the piece.

Common arrangements are 1X1, 1X3, 2X2, etc.

When needles are arranged in “even groups” ie 2X2, 2X4, 4X2, etc, the lili setting or manual needle selection to emulate it on the 260 may be used.

Tuck settings may be experimented with as well, but tend to create a more noticeable vertical line between ribbed repeats on the knit face.

The larger the number of needles in work on the main bed between ribber needles in work, the more the main bed tension needs to approach that used for the yarn when it is knit single bed.

In the EON ladder back tension increases are usually necessary to accommodate the number of stitches knitting plain on either or both beds.

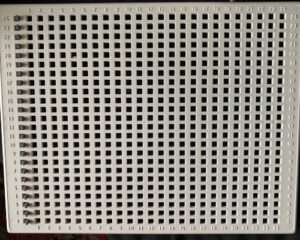

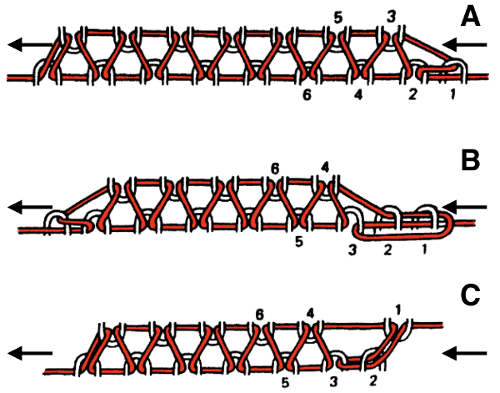

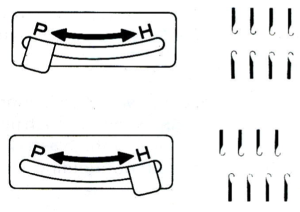

The hand needle selection must remain constant throughout the piece to maintain the birdseye backing or any of its variants, which are based on pairs of needles alternating functions every 2 rows. This is the illustration for the lili actions from one of the Brother ribber manuals:  The second needle on the carriage side knits with each pass, and the last needle away from the carriage knits. When hand-selecting the rule may be reversed.

The second needle on the carriage side knits with each pass, and the last needle away from the carriage knits. When hand-selecting the rule may be reversed.

Striper backing is achieved by selecting the same needle for each of the 2 colors used, slipping the opposite color needle locations. The first needle selection on the right is easier to track by marking the location of the first needle used on that side on the needle tape or needle bed as a guide for subsequent rows.

The row counter will show double the number of rows than if the fabric were produced in Fair Isle. Four passes of the carriages complete one design row. The motif will appear elongated to a degree depending on the yarn and techniques used. Ladderback and vertical stripe backings may produce vertical separation lines in the fabric that may be quite noticeable depending on color, tension, and yarn used. Watch closely for dropped stitches or split ones. Splices and knots in yarn may tend to break due to the use of added weights and tension. Plan on adding new yarn at the sides and using the yarn ends to seam up, or use Russian join before the point at which a new yarn end is required, and continue knitting. The latter has become my favorite even in lace knitting on the standard machine. A recent tutorial on the technique may be found here https://www.mybluprint.com/article/this-method-of-joining-yarn-ends-is-pure-magic

Check the alignment and oiling requirements of machines frequently.

Other backings: one color backing. The main bed is set as normal for DBJ, but the ribber is set to knit for 2 rows of one color and to slip for 2 rows with the other color. This means on any machine (unless using 2 electronic carriages as described in another post) the operator has to change ribber settings every 2 rows. It will now take 4 carriage passes to complete 2 rows of knitting. Floats will be formed in the non-backing color and may be caught on the ribber on slip rows, so check frequently, begin with small repeats, and always test new yarns, or even a different color or dye lot in the same yarn on swatches before committing to larger pieces.

Patterned backing: selection of ribber needles in blocks of alternate colors, or selecting ribber needles in between those selected on the main bed applies here as well. Yarn thickness and end product serve as guides as to whether the fabric serves one’s purpose or preference.

In large areas of solid color on the garment face, if bleed-through is noticeable, a pattern of 2 black rows alternating 2 white ones may need to be programmed, with color changes continuing as in pattern areas. If the goal is simply to match density or drape, then continue in settings used for the design area without color changing. Most punchcard double jacquard separations and “rules” apply to both standard and bulky machines.

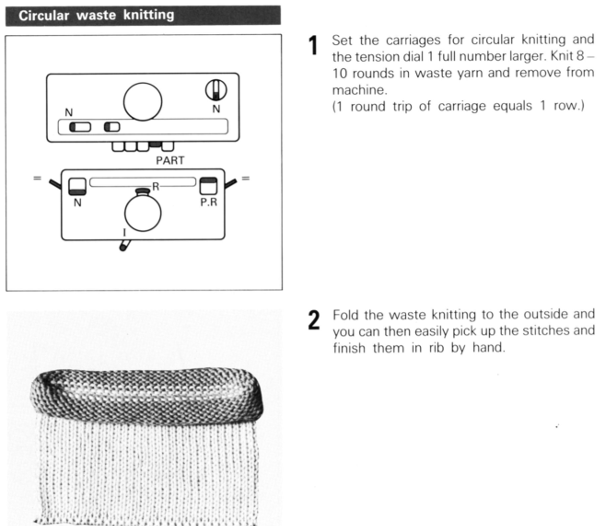

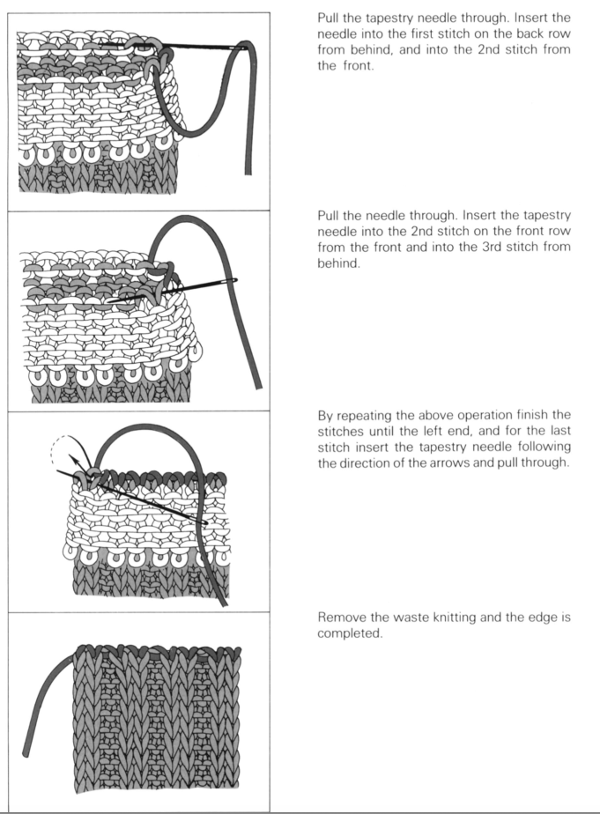

Later posts: ribber bind-offs at first, and casting on. I was never quite content with ribbed edgings on my bulky knits. There are always several options for achieving a look that pleases us more, or a technique that will alter the unwanted results. In this instance, one is to knit a row on the main bed after several rows of waste yarn, continue with the body of the garment piece, rehang that first knit row, knit the rib upside down, and bind off. The latter can happen on the machine, by hand, off on waste yarn with a “sewing” needle, or removing the work onto hand knitting needles and going that route. The 260 ribber manual recommends the following method.

Having the waste yarn U style with an opening on the right with the bind-off beginning on that side, or finding a way to mark the first needle on the ribber in the sequence may make finding that needle position easier when the knit is off the machine.

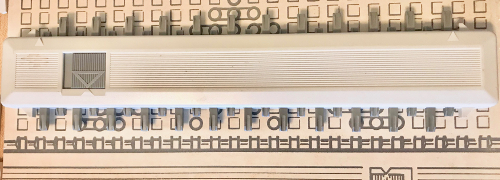

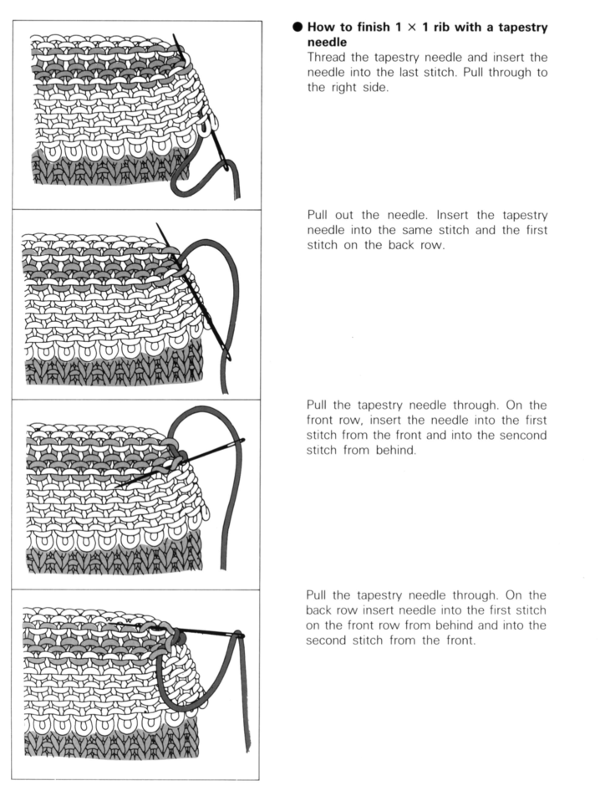

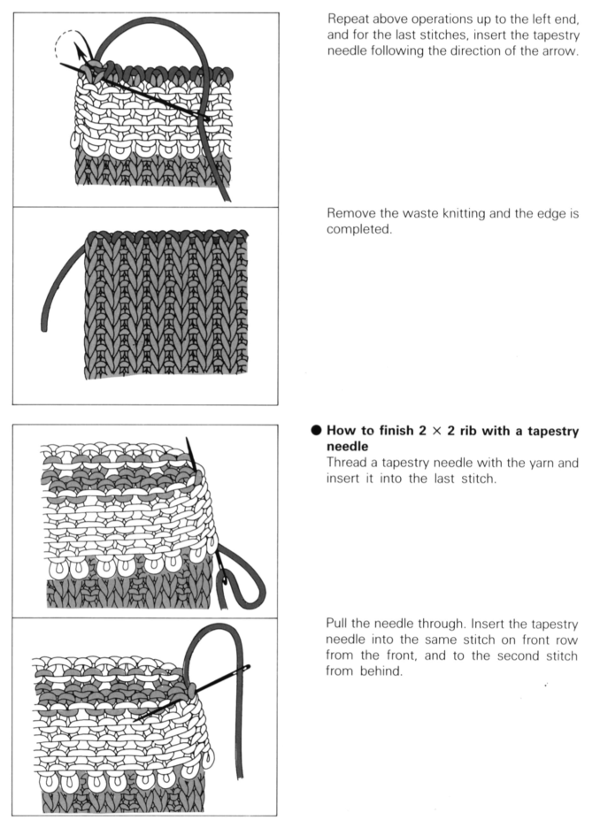

This illustration, also from a Brother manual, slightly edited, shows the sequence for how the yarn is threaded through the stitches in numbered sequence according to stitch configuration for the ribbed fabric

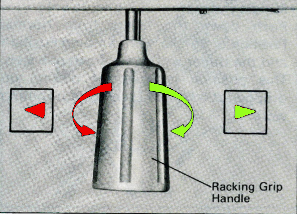

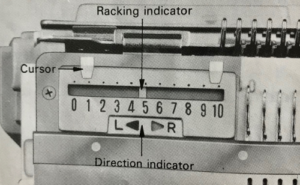

The ribber is then racked back to its original position (6). The first needle on the left will once again be on the top bed, and the first needle on the ribber to its right

The ribber is then racked back to its original position (6). The first needle on the left will once again be on the top bed, and the first needle on the ribber to its right

“zigzag” row, normal needle position: work slowly, make certain all needles have picked up yarn

“zigzag” row, normal needle position: work slowly, make certain all needles have picked up yarn