I have recently been asked about DBJ on the bulky machine, ribber setting options are offered at the bottom of this post. More to follow.

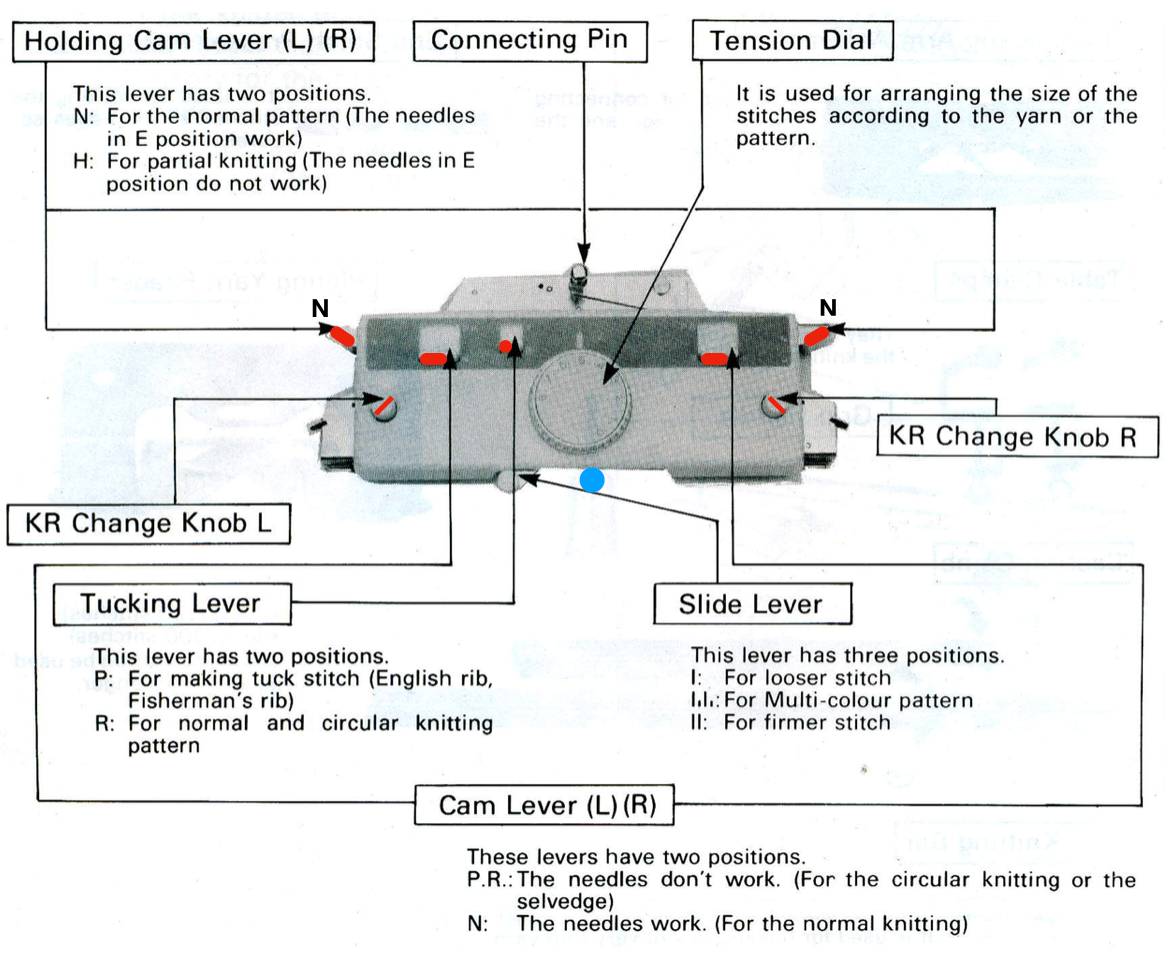

Ribber settings vary from one brand of machine to another. Here is a review of the Brother carriage features

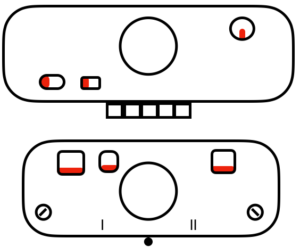

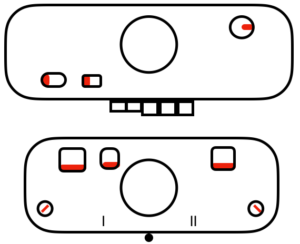

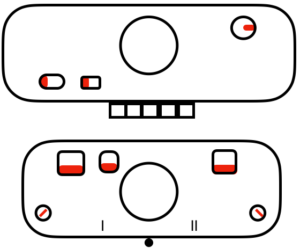

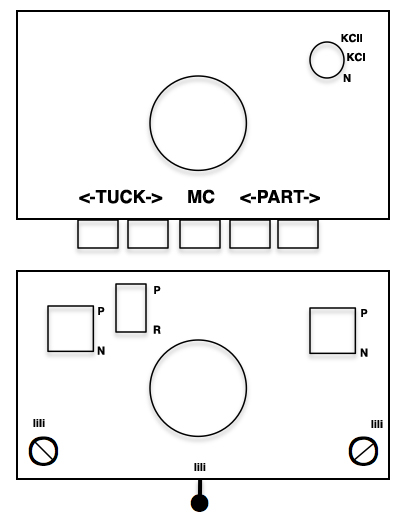

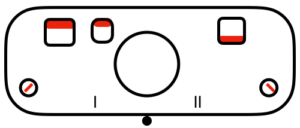

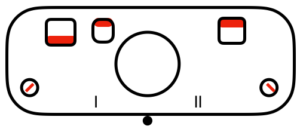

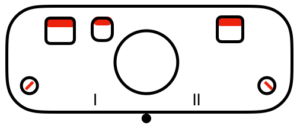

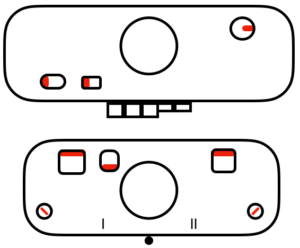

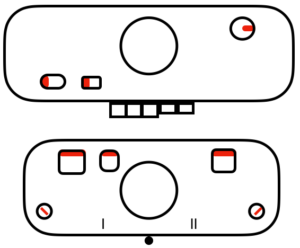

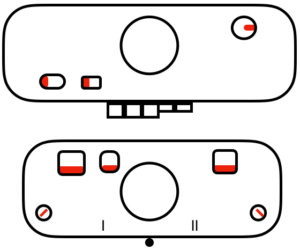

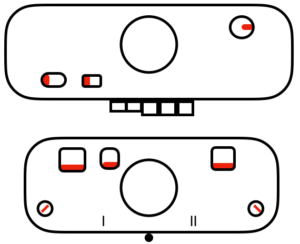

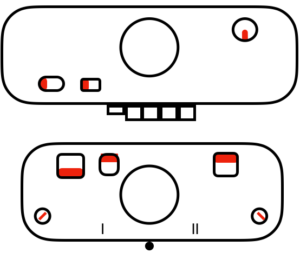

Back in 2015, I wrote on quilting on the machine, using the carriage representation below. Here lili buttons are positioned for use

Back in 2015, I wrote on quilting on the machine, using the carriage representation below. Here lili buttons are positioned for use

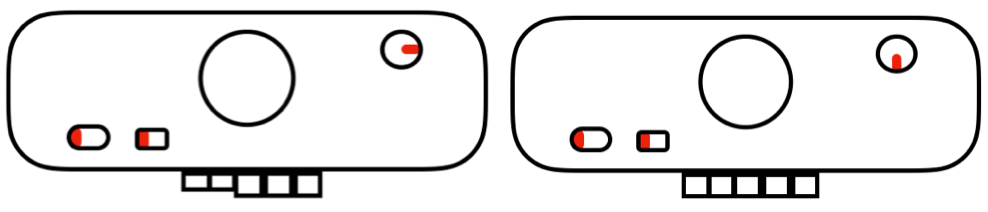

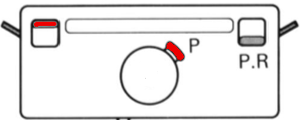

I no longer have Adobe programs available to me, for this post my images were created in Mac Pages. I have simplified the illustrated button and cam settings in red.

I tend to knit most if not all my rib fabrics with the slide lever in the center position (marked lili on the carriage, blue dot). This avoids accidental changes when altering the settings for sections of garments or forgetting to reset it ie. if one uses a ribbed band in a sweater front on one setting and accidentally uses a different one in the back, there will be a difference in width and height between the 2 bands that can be quite noticeable, and is not apparent until the garment pieces are completed and ready for seaming.

If you prefer to start with a 2 X 2 industrial rib, arrange needles to give a neat join at seams, plying yarns may again be required to give the rib more body. racking cast on may be used, avoiding transfers between beds after an every needle cast on Diana Sullivan shows one method of working and illustrates needle arrangement and transitions to main bed knitting well. Alternative needle setups:![]()

I personally never do 3 circular rows after the first cast-on row: it will produce floats on one side of the rib, which may be noticeable in your final fabric on one of the 2 garment sides.

To close holes when transitioning to garment pieces in other than every needle ribs, rack the beds one full turn, knit 2 rows, rack back again, and proceed as needed for the desired fabric

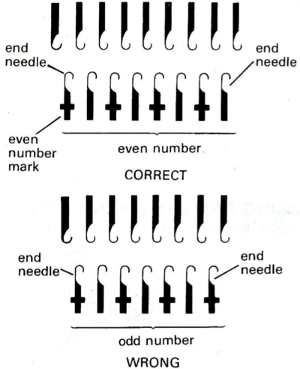

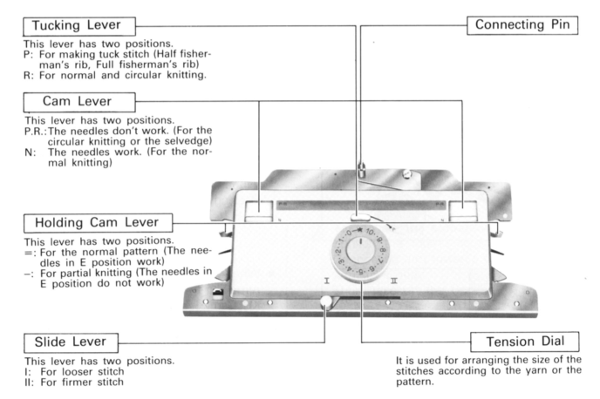

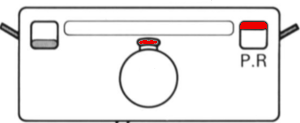

The lili buttons on the ribber are representations of every other needle set up, akin to the 1X1 card use on the main bed. It is essential for an even number of needles to be in use when the lili buttons are in use (pushed in, and turned toward the lili markings on each side of the ribber carriage, R to R, L to L). An easy way to ensure the even number is to look at the needle tape markings, which alternate between dashes and blank spaces between them. A line/ dash and space make a pair, so if you start with a needle on a line, the last needle on the opposing side needs to be on a blank space or vice versa. The holding cam lever remains in N position throughout these illustrations.

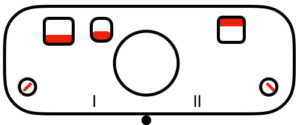

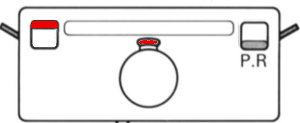

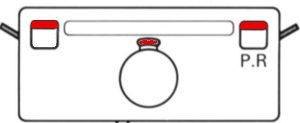

Setting for slip stitch: raising levers to P position will result in stitches slipping when the ribber carriage moves in that direction

slip to right  slip to left

slip to left  slip in both directions

slip in both directions

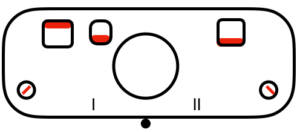

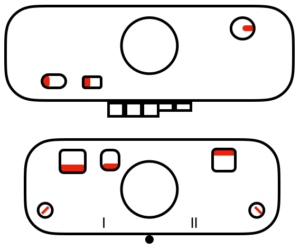

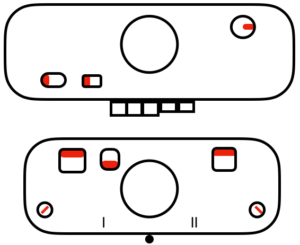

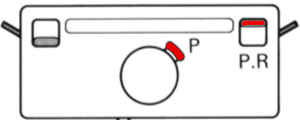

Setting for tucking on ribber: it is possible to tuck on every needle on either bed when knitting every needle rib, as long as the needle on each side of the stitch forming the tuck loop on the opposing bed is creating a knit stitch, anchoring down those tuck loops on each side.

tuck to left  tuck to right

tuck to right  tuck in both directions

tuck in both directions

Double bed patterning DBJ

The most balanced fabrics are achieved when no more than 2 colors on any single design row are used, and the number of rows knit on the ribber total the same as the number of rows knit on the main bed. It is possible to knit designs with 3 or more colors per row. With Japanese standard machines, this would require a color separation, automatic ones are limited to 2 colors per row (Passap built-in techniques have a range of other options). The more strands of yarn, the thicker and heavier the fabric, with distortion in the aspect ratio of the design. As with single bed fabrics, double bed slip stitch creates knits that are short and skinny, tuck creates short and wide ones. As stitches slip, tuck, or get longer there will also be “bleed-through” of the alternate color on the front, “knit” face of the fabric. In small, balanced repeats this can create a color mix that may make the result either interesting or confusing. Garment swatches need to be larger than usual for when knitting single bed. I tend to use at least 80 or 100 stitches/rows on both beds to calculate garments.

When using no more than 2 colors per row, Japanese machines offer the option of a color separation that knits one design row per row, which is an added way to reduce motif elongations in the finished knit. Passap knitters may use tech 179 to achieve the same result. For different separation methods for double-bed fabrics, see color separation posts on them.

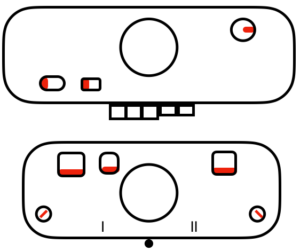

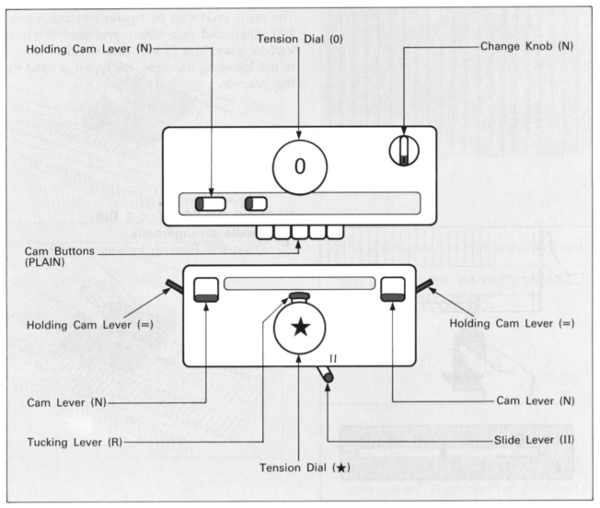

Brother lili buttons: illustrations found in brother manuals for their actions, an even number of needles in work on ribber is required

bird’s eye (lili <- ->): this is a common type of slip stitch. One pass of the carriage causes every other needle to knit. As the ribber carriage moves back to the starting side, the alternate needles knit, producing a single row of color. This helps double-check on the color used on the last row knit when knitting is interrupted on the color changer side. When knitting in 2 colors per row the fabric is fairly well balanced

tucked bird’s eye backing (lili <- ->) with slip pattern on MB: if no cam buttons are pushed in on the Main bed, and the carriage is set to normal knit with no pattern selection, lili buttons on ribber will behave as though the 1X1 card is in use, no elongation or other changes are possible without changing levers manually as often as needed

tucked bird’s eye backing (lili <- ->) as above, with main bed set to tuck the main color and slip the contrast, requires manually resetting cam buttons with each color change, or alternately tucking the main color, knitting the contrast

color 1 color 2

striper (double) backing: fabric is unbalanced, twice as many rows of ribber stitches as main bed ones, the design is elongated, but the fabric is softer and more flexible

single (half) striper backing: fairly well balanced. The ribber knits only one row for each 2 passes of the carriages, so for 2 colors again, there are no extra rows knit. Part button on ribber may be engaged on either side  tubular: either pair of opposite part buttons used

tubular: either pair of opposite part buttons used  tucked half Milano: when using tuck/slip combinations opposite cam buttons are used i.e. if right tuck cam button is pushed in, then the left slip button is also

tucked half Milano: when using tuck/slip combinations opposite cam buttons are used i.e. if right tuck cam button is pushed in, then the left slip button is also  main bed <–> tucked jacquard: each needle on the ribber knits every row. Needles on the main bed knit in pattern according to punched holes, black squares on mylar, or programmed pixels. Non selected needles tuck. The patterns produced on the backside of the fabric are almost the reverse images of the front. Because so many tuck loops are formed the fabric is “short” and very wide, so cast ons and bind offs need to be planned accordingly

main bed <–> tucked jacquard: each needle on the ribber knits every row. Needles on the main bed knit in pattern according to punched holes, black squares on mylar, or programmed pixels. Non selected needles tuck. The patterns produced on the backside of the fabric are almost the reverse images of the front. Because so many tuck loops are formed the fabric is “short” and very wide, so cast ons and bind offs need to be planned accordingly

variation: tucking the main color, knitting the contrast, manual cam button reset every 2 rows

variation: tucking the main color, knitting the contrast, manual cam button reset every 2 rows

solid backing: the part buttons on the ribber are reversed manually on the left side of the machine when the color changes are made. The solid backing color knits on the ribber when both part buttons are down (N<–>N), the second color will be slipped with both the part buttons in the up position. For an interesting effect use wool for solid back color 2, other fiber for color 1, and felt the result.

2 rows color 1 2 rows color 2 (solid back color)

2 rows color 2 (solid back color)

See altering a sinker plate for producing this fabric using a second KC to knit rows only on the top bed, no ribber setting changes required.

tuck/plain combo: requires manually changing cam button settings on the main bed every 2 rows, change knob remains on pattern selection setting

no automatic patterning on the main bed, change knob on N for English or half fisherman rib: tuck every needle either direction on ribber only

full fisherman rib: tuck every needle alternately on both beds, in opposite carriage directions (below = L/R, or use R/L)

full fisherman rib: tuck every needle alternately on both beds, in opposite carriage directions (below = L/R, or use R/L)

Vertical striper backing and “ladder-back” variations involving some hand manipulation and selection of needles in work are also alternatives for DBJ backing.

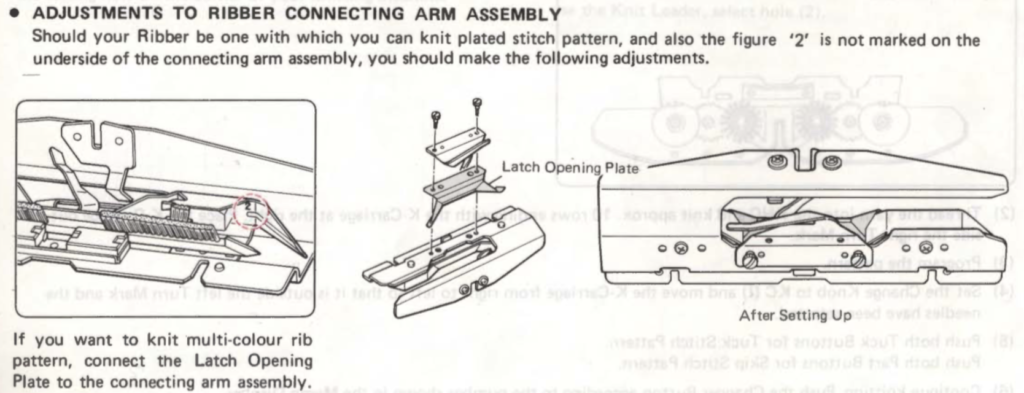

I have for decades and in my posts referred to this part as the ribber sinker plate; technically it is called the connecting arm in the Brother literature. There were slight differences between model years for them as well. Later connecting arms were branded with the number 2, earlier ones were not.

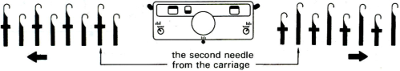

For knitting DBJ with the unmarked connecting arm, it was suggested in later manuals that an accessory be used:  the result with the plate in place is a change in the height of the metal from the needles with stitches in work as seen below with the plate secured in place

the result with the plate in place is a change in the height of the metal from the needles with stitches in work as seen below with the plate secured in place

more on non-repetitive dbj images and ribber parts and settings:

two-color-dbj-non-repetitive-images/

ribber-fabrics-produced-with-2-knit-carriages-selecting-needles/

geometric-shapes-on-ribber-fabrics-with-tuck-stitches-2-knitting-with-4-carriages/

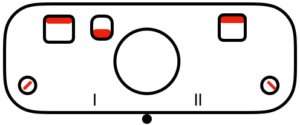

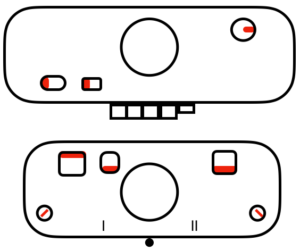

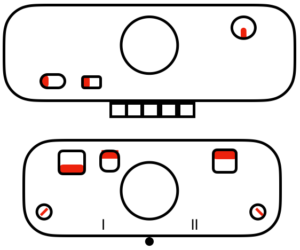

DBJ on bulky KR 260: parts as described in the ribber manual, followed by possible settings

slip to right

slip to right  slip to left

slip to left  slip both directions

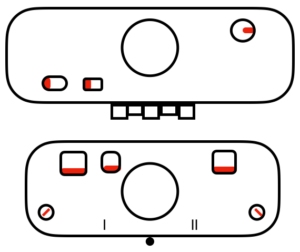

slip both directions  tuck to right

tuck to right  tuck to left

tuck to left  tuck both directions

tuck both directions