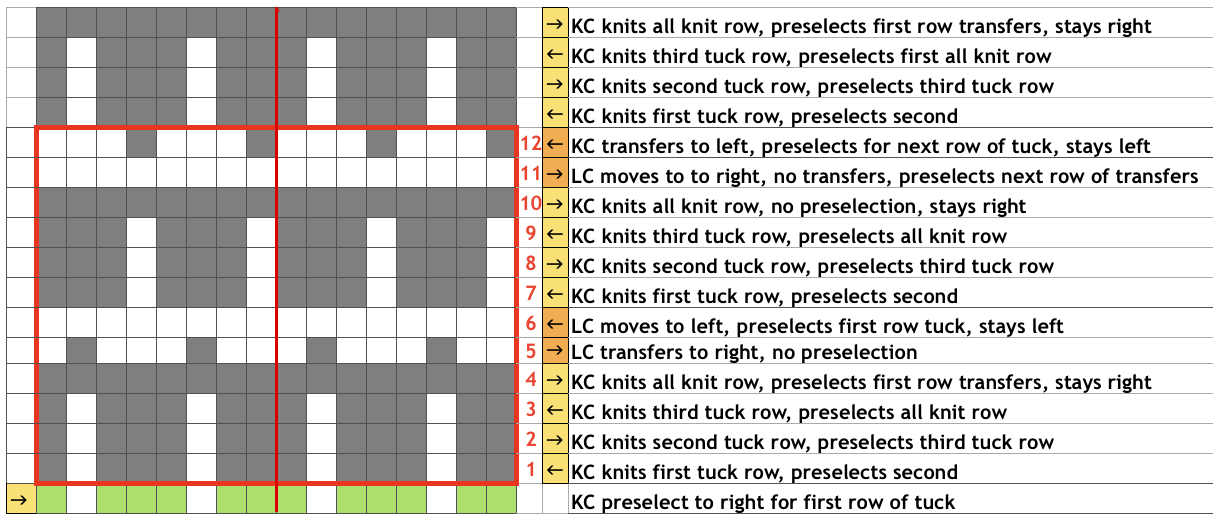

The question has often been asked as to why knit with 2 carriages. For me, it became a personal favorite for knitting fabrics requiring color changes every even number of rows. I tend to push the limit with materials and found the Brother single bed color changer to be quirky. When using 2 KCs there is no pushing the wrong button for the proper color in the sequence, or accidental choosing of an empty slot and dropping the knitting. Some of the loops at the color changer side edge or yarn getting caught in wheels or hooks are also eliminated. Each carriage can be set for a completely different function from the other with no manual cam button changes ie single color knitting vs FI, its own tension depending on desired effect or fiber (ie striped shadow pleats), etc. Floats along the vertical edges of the knit as a result of the striping happen on both sides rather than all on the color changer side. The principles apply when using the lace carriage and combining it with tuck, slip, or FI settings in the KC. If one is following a published punchcard pattern for such fabrics, frequently there are guidelines as to when to change colors, but no explanation as to why the cards are punched the way they are, so understanding what happens enables one to interpret directions for electronics. When going from published 2 carriage punchcard machine repeats to electronic, the repeat needs to be adjusted to compensate for the change to row by row selection. In punchcard machines, the needle selection does not advance when you switch to operating the carriages from the opposite sides, so the pattern for those rows knits twice.

Many of the stitch world books seemed more concerned with larger repeats than with some of the more labor-intensive, specialty fabrics. The punchcard books, now downloadable for free are worth having and studying no matter what your machine. They do need to be brand specific. Studio and Toyota ones may be used, but adjustments may have to be made in terms of starting rows or even flipping the card over vertically. Download links for punchcard patterns, with symbols used and pattern samples, can be found in my previous post

I have added a new category to my sidebar to make this topic search easier: Patterning with 2 knit carriages. Included are color separations for some fabrics suitable for this method of knitting.

I am presently knitting my samples on an altered 910, using an EMS kit purchased last December. I have had selection problems related to my hardware, but some of the 2 carriage operation or lack thereof has been evaluated and duplicated by others. My successful experiments with 2 single bed carriages selecting so far:

Lace and slip stitch: both carriages selecting in their usual positions

2018/03/05/lace-edgings-on-brother-machines/

Start with 2 knit rows in a programmed pattern

with KC on left, preselect to right, set to slip <€” €”>, knit first 2 all knit rows, ending with KC on right, proceed with selection with LC on left

Will not work if the pattern is adjusted so KC knits the first 2 rows and parks on left, with attempted use of LC from the right. LC will not select.

Operating LC with KC plain knitting (no pattern selection) may be done with LC selecting from either side, with repeat adjustment 2018/03/05/lace-edgings-on-brother-machines/

Lace and weaving:

2018/01/02/lace-punchcards-meet-ayab/

both carriages selecting in their usual positions

Lace and tuck stitch: the fabric worked out for use with mylar sheet

Ayab actions for carriages, use LC on left, KC / tuck <– –> on right

a charted ayab repeat for my swatch

a charted ayab repeat for my swatch

I came across this image on a pinboard, and imagining the possibility of knitting it led me back to a previous post illustrating a similar stitch structure, knit on an unaltered 910. The pin:

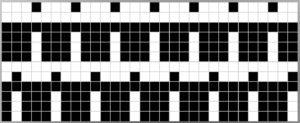

working out the first repeat in the blog post

working out the first repeat in the blog post

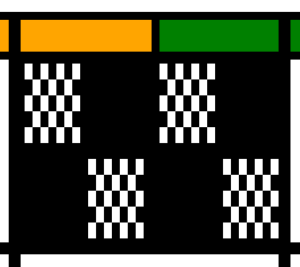

The swatch (sideways view) shows the repeat as illustrated in the upper segment of the above chart, and then lengthened X 2, with color changes every 4 rows (the length X2 is not presently an available action in Ayab)

In the past, when I tried to knit with 2 KCs, one on the left and one on the right, both selecting needles, I was unsuccessful, but in light of the above experiments, I decided to test the idea with the RKC (the one that would operate from the right) selecting and then knitting the first 2 rows of color, in turn resting on the right side. I then operated the second KC from the left, alternating carriages every 2 rows. Knitting at a slower speed and moving each carriage perilously far out on the extension rails did the trick.

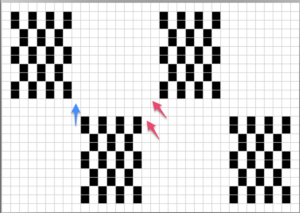

To use the repeat in Ayab, in order to keep the proper color sequence, the last design row is shifted down to row 1 position. There is an error in the repeat, marked by arrows I did not notice until I had completed the swatch. The repeat may be used as is, and color reversed via action inverse in Ayab, or color reversed prior to loading the image, which I chose to do personally.

This is grabbed from the ayab screen: the knitting is actually mirrored automatically by the software, so what is shown onscreen is what appears on the knit side of the finished piece. Something to keep in mind in situations where placement and direction might have some importance.

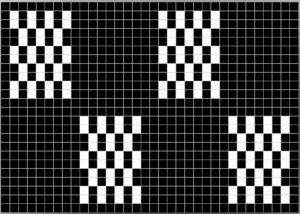

Things to notice in swatch: as already mentioned, there is an error in the repeat in terms of my intention. Placement for the slip stitch blocks could certainly be planned for an asymmetrical effect, varied in size, and more. Slip stitch produces a significantly narrower knit than the stocking stitch. That would need to be allowed for were the stitch to be used in a garment or gauge dependent knit.

Examining the purl side of the knit, which is facing as one machine knits: the intentionally dropped stitches at the start on both sides are there because I had cast on extra stitches that were outside the parameters of the programmed repeat width. The left side edge, next to LKC (left knit carriage) is visibly shorter than the right. The two yarns used were of different thicknesses but knit at the same tension. The LKC would have merited from a looser tension, and an edge weight on the very last stitch on that side would help with adjusting the length the white edge €œfloats€ from one color change to the other as stripes are created. The handling of side floats in striped knitting is dependent on the row height of such stripes.

There are a great number of interesting ribber fabrics that can only be knit by manually changing the ribber settings to slip in both directions, so that the main bed only knits for X # of rows, with the ribber carriage periodically set to knit again. If the function happens for an even number of rows at a time and in both directions, the sinker plate for the KC may be altered for use with the ribber in the up position, to knit the main bed stitches only. Its change knob should be set to KC I to ensure that the first and last stitch is knit. I knit this sample using the altered KC selecting from the right, the KC engaged with the ribber sinker plate selecting from the left. I will address the altering process and steps involved in the knitting in a separate post.

The first repeat is 8 stitches wide, can be used as is in terms of motif width. The slip stitch repeat is 16 stitches wide, so you would have to eliminate 2 columns from each repeat half to reduce the total width to 12, and punch out white squares since color reverse is not an option. That said, you cannot knit patterns possible on the electronic machines with 2 carriages selecting needles on punchcard ones because as has been explained in other posts, electronic machines advance the repeat with every pass to the opposite side. With punchcard machines when you swap to knitting from the opposite side the pattern row does not advance on the first pass, thus knitting the previous row a second time, changing the overall design. See previous posts https://alessandrina.com/2017/05/01/knitting-in-pattern-with-2-carriages-brother-punchcard-kms-2/ and https://alessandrina.com/2016/08/25/knitting-in-pattern-with-2-carriages-brother-punchcard-kms1/ for more information, including a link to a post using slip stitch combined with lace patterning.

This is really interesting. Could one do similar testing with a punchcard machine?