Just about a decade ago, I began one of my many temporary technique obsessions by finally attempting transfer lace knitting, and it continued for a few years during which I produced scarves and shawls for gifts and sale in galleries and craft shows.

Leaf shapes held a particular attraction for me.

That long ago I was not sharing the pattern repeats used in my production items, and my note-keeping was not what could be defined as consistent or compulsive, so in looking at yet another pin sharing a lace leaf pattern in the present time, I went looking for some of my early repeats and let us say I did not immediately locate them.

My lace production pieces were worked on a 910 with mylar or a Brother 892 punchcard model, long before I entered the world of spreadsheet tables, downloads from Mac with Ayab to the 910, and later owning and favoring to a 930 with img2track.

A review of previous shares:

Beginnings, 2/11, adapted from a design published by Susanna Lewis

In progress, 2/11

In progress, 2/11  On the blocking board 2/11

On the blocking board 2/11 Back to lace/ 2/12, hand knit

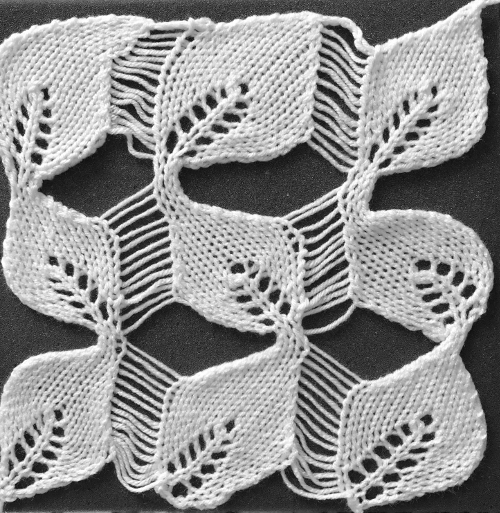

Back to lace/ 2/12, hand knit  More on those slanting lace leaves 2/12 hand knit, pattern graph available for download

More on those slanting lace leaves 2/12 hand knit, pattern graph available for download  Back to leaf lace, add rib, and take it to the Passap, hand transfer, E6000 with console assist 3/12, added punchcard unrelated design

Back to leaf lace, add rib, and take it to the Passap, hand transfer, E6000 with console assist 3/12, added punchcard unrelated design

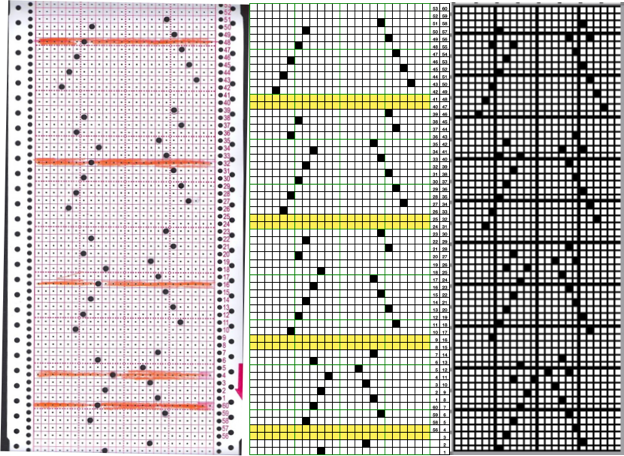

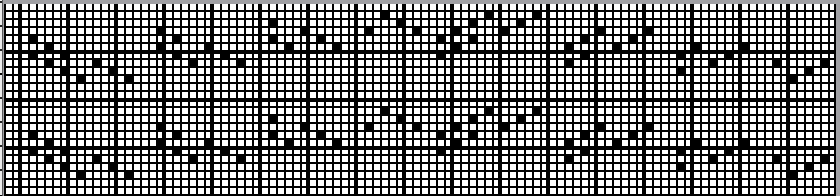

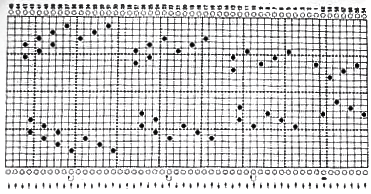

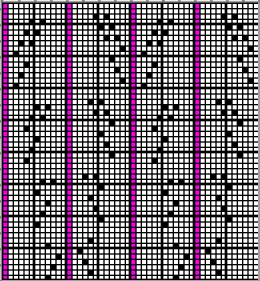

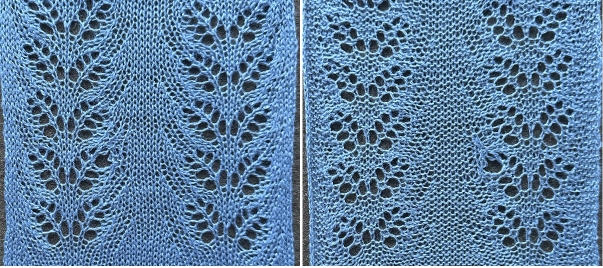

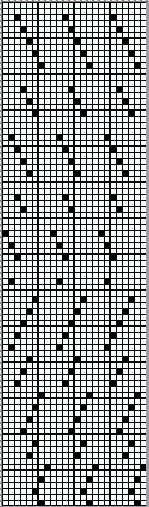

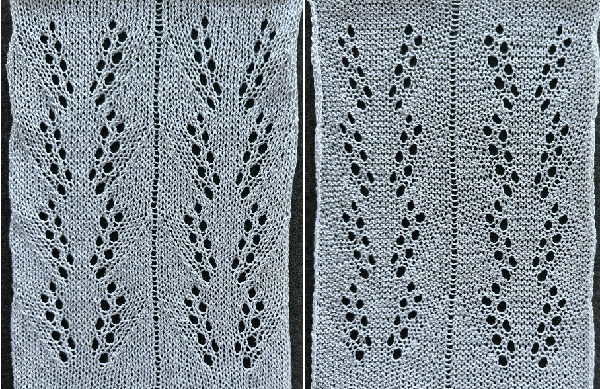

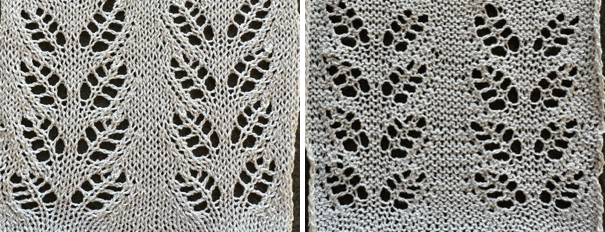

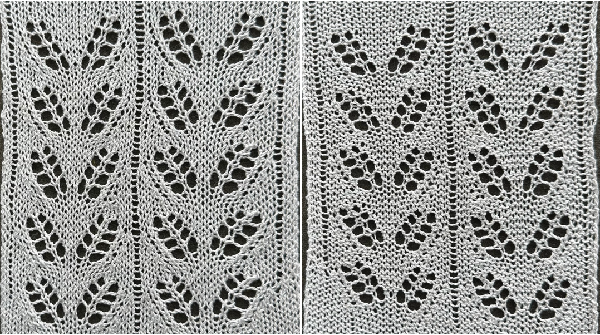

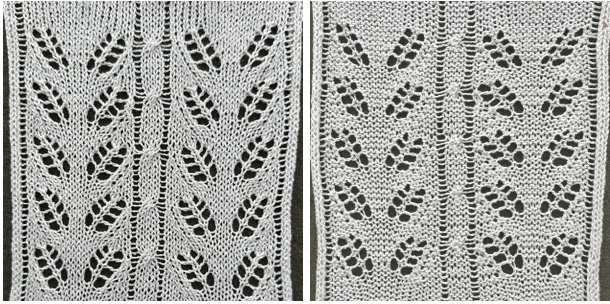

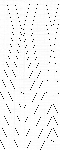

The post punchcard, reconstructed in 2024 using Mac Numbers, Gimp, and ArahPaint, with similarities to the design that evolved in later explorations producing the more successful 24X64 repeat reproduced on the right.

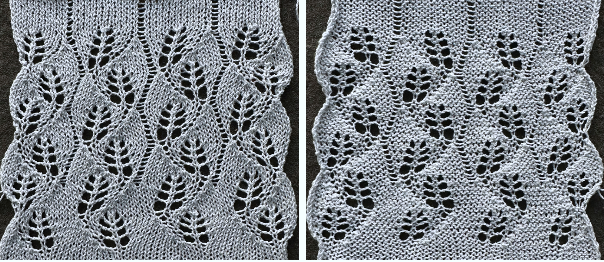

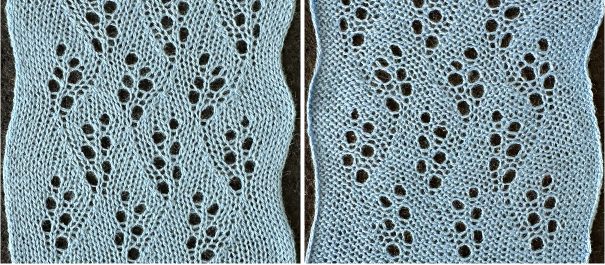

The post punchcard, reconstructed in 2024 using Mac Numbers, Gimp, and ArahPaint, with similarities to the design that evolved in later explorations producing the more successful 24X64 repeat reproduced on the right.  Comparing the knitted results:

Comparing the knitted results:  Getting there hand transfer tech with card assist 3/12

Getting there hand transfer tech with card assist 3/12  The joys of lace on the KM 3/12, dropped knitting, or too many dropped stitches can happen.

The joys of lace on the KM 3/12, dropped knitting, or too many dropped stitches can happen.  Getting there leaf motifs, adding borders 3/12, goal: find the related punchcard

Getting there leaf motifs, adding borders 3/12, goal: find the related punchcard

2024 the punchcard was located.

2024 the punchcard was located.

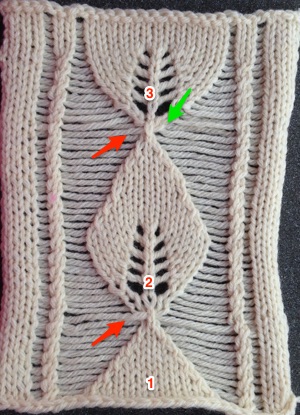

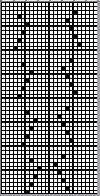

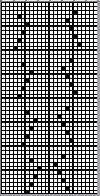

A punch card roll was used. When purchased, it was advertised for Brother but factory number markings on the right are for Studio machines, with row 1 on row 5 from the bottom all punched rows as opposed to row 7 for Brother. Keeping the use of the roll continuous, the factory markings become irrelevant in such DIY long repeats.

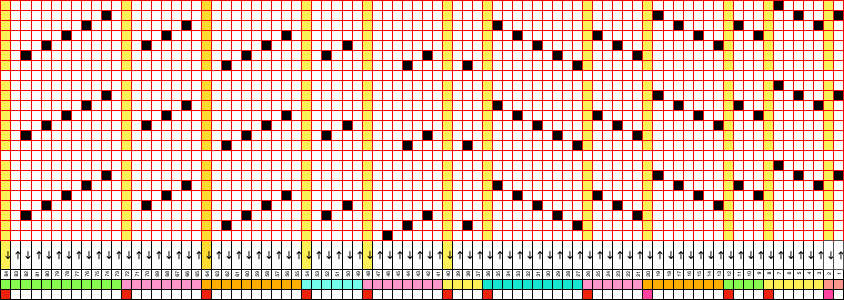

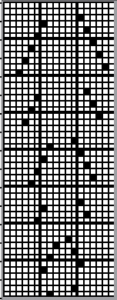

In this instance, the card is 104 rows in length.  Using Mac Numbers, Gimp, and ArahPaint, for easier reproduction, here it is shown with 6X6 grid block markings typical of Brother factory cards

Using Mac Numbers, Gimp, and ArahPaint, for easier reproduction, here it is shown with 6X6 grid block markings typical of Brother factory cards  The card begins with a blank row, and the first transfers will be made to the right rather than to the typical left

The card begins with a blank row, and the first transfers will be made to the right rather than to the typical left

In the swatch, only two knit rows were knit after each series of transfers occurring after 19, 22, 36, 52, 62,74, 88, 104.

Needles were taken out of work beginning with needle 1 on the right of 0, and 13 on the left, continuing every 12 stitches on wider knits.

The earlier swatch has extra rows knit between shapes

The earlier swatch has extra rows knit between shapes  A quick test on 24 stitches with 4 rows knit after 52 and 104 passes of the LC respectively

A quick test on 24 stitches with 4 rows knit after 52 and 104 passes of the LC respectively  Yes, a punchcard is possible leaf motifs 3/12, card, find repeat

Yes, a punchcard is possible leaf motifs 3/12, card, find repeat  the card, also finally found

the card, also finally found  exploring detail options ie adding knit rows, where to place the repeat for side edge variations, using ladders between motifs, latching the ladder to reproduce single row tuck stitches, applying the choices to a long-ago final shawl.

exploring detail options ie adding knit rows, where to place the repeat for side edge variations, using ladders between motifs, latching the ladder to reproduce single row tuck stitches, applying the choices to a long-ago final shawl.

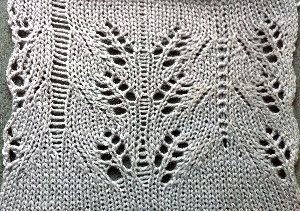

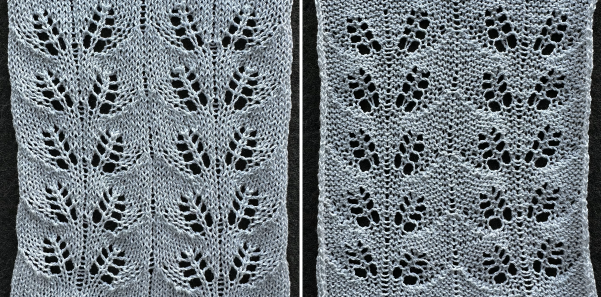

The repeat shortened for swatching 2024: 24X52

The repeat shortened for swatching 2024: 24X52  needles out of work help define the leaf shapes

needles out of work help define the leaf shapes  the png

the png ![]() proof of concept with 4 rows knit after the 52 LC passes that complete one pair of leaves.

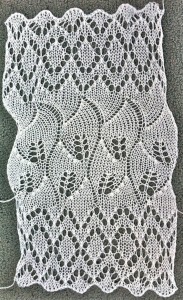

proof of concept with 4 rows knit after the 52 LC passes that complete one pair of leaves.  With so many transfers between knit rows on a long piece like a shawl or scarf, knitting 4, 6, or more rows upon completion of each full repeat is an option. Six appears to have been my choice in that work on the machine

With so many transfers between knit rows on a long piece like a shawl or scarf, knitting 4, 6, or more rows upon completion of each full repeat is an option. Six appears to have been my choice in that work on the machine

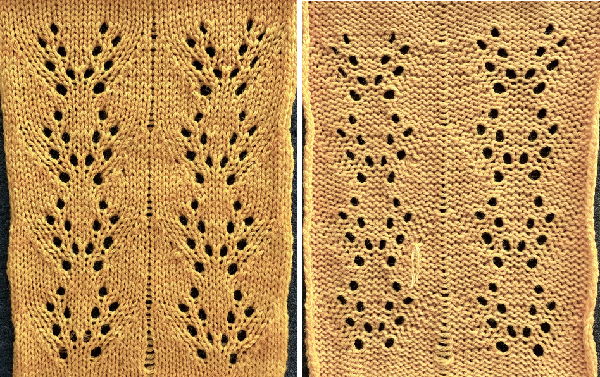

This repeat is composed of 24X64 cells, there are 16 rows of LC transfers followed by 2 rows of knit stitches throughout, after 64 LC passes only 8 rows of actual knitting have taken place.

This repeat is composed of 24X64 cells, there are 16 rows of LC transfers followed by 2 rows of knit stitches throughout, after 64 LC passes only 8 rows of actual knitting have taken place.

Remember to oil the LC as well as the KC, and look out for dropped stitches, like the one in the swatch followed by a lazy “repair” that is particularly noticeable on the purl side.

![]()

The evolution of a simpler and easier-to-execute pattern with similar movement can be found at the bottom of this post.

The evolution of a simpler and easier-to-execute pattern with similar movement can be found at the bottom of this post.

Ladders with lace, (leaf) “making things work” 1 3/15

Ladders with lace, (leaf) “making things work” 2 3/15

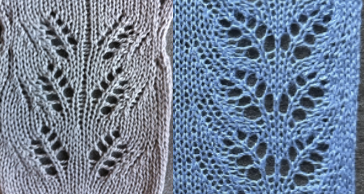

A new “leaf” lace 4/17, chart provided

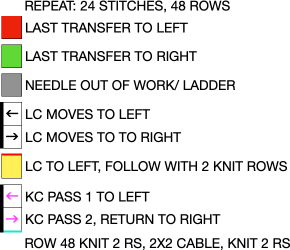

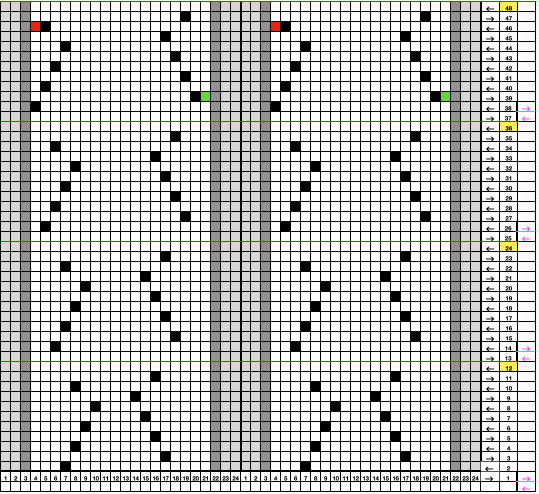

A new “leaf” lace 4/17, chart provided  The start of a new series aiming for DIY: this repeat is 24 stitches wide, suitable for punchcard models, but tested on a 930 where it was necessary to mirror it horizontally, and is knit using 2/18 wool.

The start of a new series aiming for DIY: this repeat is 24 stitches wide, suitable for punchcard models, but tested on a 930 where it was necessary to mirror it horizontally, and is knit using 2/18 wool.

Plotted on a spreadsheet with LC passes and direction of movement marked on the left side, knit rows after LC passes 2, 8, 12, 20, 26, 36, 40, 48, 54, 64, 72, 84

the 24X84 png

the 24X84 png ![]()

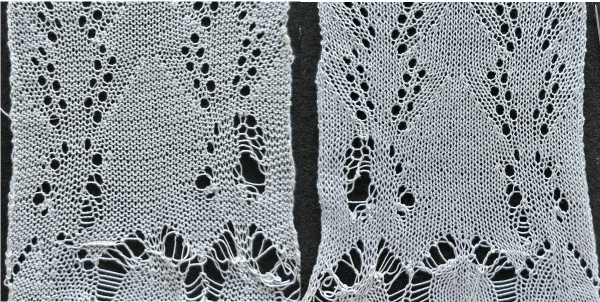

Playing with more variations does not always lead to results worth pursuing, but they provide learning experiences that inform future choices. Anyone familiar with lace knitting, particularly where so many transfer rows occur between knit rows, has experienced a lot of this from time to time.

Playing with more variations does not always lead to results worth pursuing, but they provide learning experiences that inform future choices. Anyone familiar with lace knitting, particularly where so many transfer rows occur between knit rows, has experienced a lot of this from time to time.  Lace can only be described as temperamental.

Lace can only be described as temperamental.

I am perennially in awe of videos where some knitters appear able to knit lace yardage with a motor with no dropped stitches to be seen anywhere. That has not been my experience, though for a while I did manage to produce a line of one-off scarves and shawls knit in a variety of lace patterns. I got good at unraveling down to knit rows and rehanging.

Avoiding dropped stitches, and managing dropped ones have avid advocates for different methods, a topic for a different discussion.

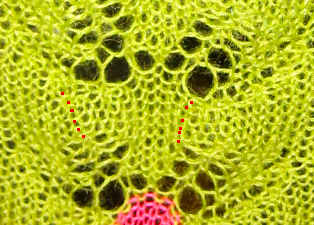

It helps to have a needle retainer bar that is in really good condition, needles with latches that operate properly, tension and suitable weight of yarn based on the number of needles used, and begin testing with yarn colors that make it easy to identify transfer issues as they are happening as opposed to after the fact when large holes seem to magically appear.

Unless the goal is to create a large mesh, if side-by-side needles are preselected in most designs including these, the causes may be punching or drawing errors, or simply that in the specific machine model, or software used, the pattern needs to be mirrored horizontally, as in my 930.

New to me now: the assumption is made that the LC will be slipped off the belt when the other carriage is in use. That is not necessary if the knit carriage does not also select needles, locking onto the belt.

Generally, the patterns are advanced by any carriage set to select needles as it moves past the center of the needle bed.

If the lace carriage does not clear the set mark on the left side of the machine, the pattern may not advance sporadically, which is evocative of needle selection fails, but it will resume doing so when the LC is moved far enough to the left before making its next pass to the right.

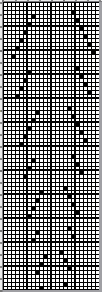

In this repeat, the knit rows are easy to track. They happen after there is no needle preselection as the LC moves from right to left, ie. after 4, 8, 6, 10 carriage passes, etc.

The blank number of rows between black pixels is not always even and can be odd when a reversal of the direction of transfers is required with a Lace Carriage that operates only from the left.

If needles out of work are used, care should be taken not to accidentally bring them back into work during knitting. If several rows have been knit, the stitch is dropped, and the needle is brought out of work again, the resulting ladder will be wider than the one in the space below it.

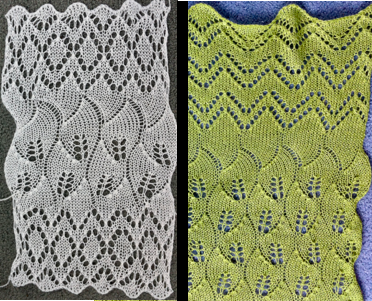

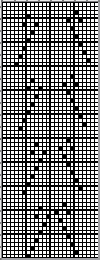

Maintaining the goal of producing a design suitable for punchcard models as well, this new repeat is composed of 24X72 cells  the png.

the png. ![]() adding needles out of work helps define the shapes which can also change appearance depending on yarn and color choices.

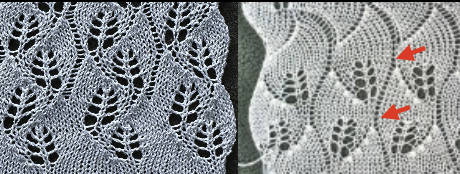

adding needles out of work helps define the shapes which can also change appearance depending on yarn and color choices. ![]() A more successful swatch, knit in wool rayon:

A more successful swatch, knit in wool rayon:  Modifying the design for use on electronic models only, an 18X48 repeat, knit in a 2/8 wool that really wanted to split upon being transferred, adding a ladder between repeats as above, and 4 knit rows rather than 2 upon the completion of each design segment

Modifying the design for use on electronic models only, an 18X48 repeat, knit in a 2/8 wool that really wanted to split upon being transferred, adding a ladder between repeats as above, and 4 knit rows rather than 2 upon the completion of each design segment

![]() Three would-be runaway stitch spots are visible.

Three would-be runaway stitch spots are visible.  Wanting to shift eyelets, changing the repeat:

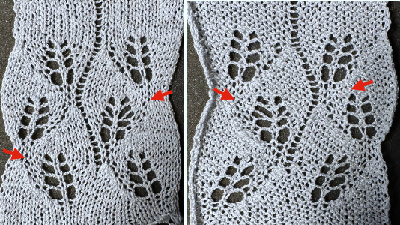

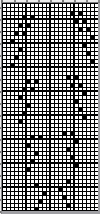

Wanting to shift eyelets, changing the repeat:  The first try, 20X48 pixels repeat proved to be quicker and easier to knit, with only single transfers at any one time, two rows were knit after every 12 LC passes.

The first try, 20X48 pixels repeat proved to be quicker and easier to knit, with only single transfers at any one time, two rows were knit after every 12 LC passes. ![]()

A shift to a 19X48 row repeat, planning to add ladders between each of the repeats

A shift to a 19X48 row repeat, planning to add ladders between each of the repeats

![]() I like to program repeats taking into consideration the number of stitches required for the project, which offers the opportunity of adding extra blank columns for knit borders on either side and avoids any confusion with positioning when returning to the design at some future time.

I like to program repeats taking into consideration the number of stitches required for the project, which offers the opportunity of adding extra blank columns for knit borders on either side and avoids any confusion with positioning when returning to the design at some future time.

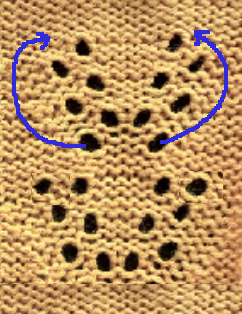

The swatch on the machine, beginning with needle one on the right side of 0 taken out of work, followed by every 19th in either direction, 4 rows were knit after every 12 LC passes.

![]()

Widening the repeat to 24 cells wide makes it suitable for use on punchcard models

Widening the repeat to 24 cells wide makes it suitable for use on punchcard models  The extra columns of knit stitches allow for placements of twisted stitches upon completion of each row of shapes:

The extra columns of knit stitches allow for placements of twisted stitches upon completion of each row of shapes:

In the final swatch 2 rows were knit after every 12 LC passes. Upon completion of a full row of shapes, 48 LC passes, 2 rows were knit again, the 2X2 cable crossings were made, followed by 2 more knit rows before returning to the use of the LC.

In the final swatch 2 rows were knit after every 12 LC passes. Upon completion of a full row of shapes, 48 LC passes, 2 rows were knit again, the 2X2 cable crossings were made, followed by 2 more knit rows before returning to the use of the LC.

Having a ladder on each side and vertical columns of 3 stitches aside them will form a roll to the purl side that may in many instances be a satisfactory side edge.

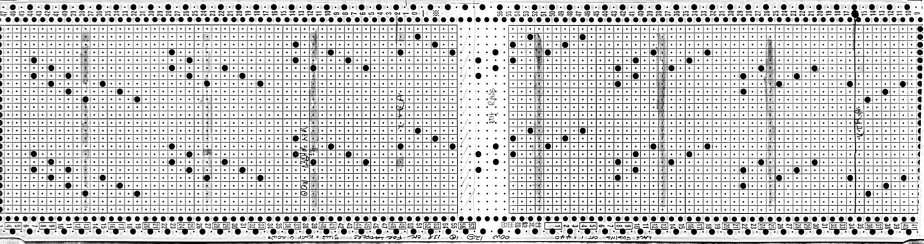

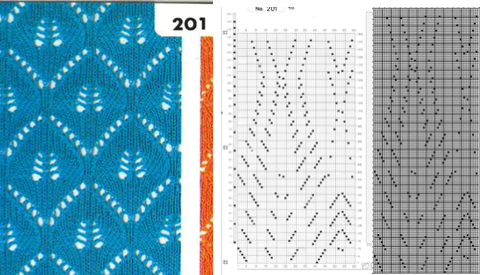

An untested converted design from  pattern 201

pattern 201  the locations of knit rows marked with black cells on the far left of the mylar

the locations of knit rows marked with black cells on the far left of the mylar  the 60X150 png

the 60X150 png

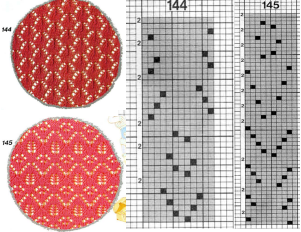

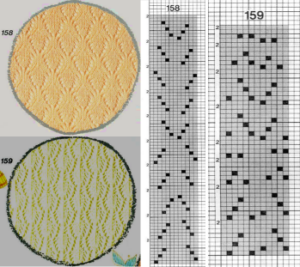

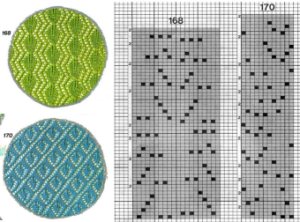

Some to try: from Stitchworld

12 stitch repeats are also suitable for punchcard models

12 stitch repeats are also suitable for punchcard models

144, 12X36![]() 159, 12X52

159, 12X52 ![]() 170, 12X60

170, 12X60 ![]() 158, 12X80

158, 12X80 ![]() 145, 10X56

145, 10X56 ![]() 168, 20X56

168, 20X56![]()