WORK IN PROGRESS

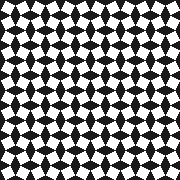

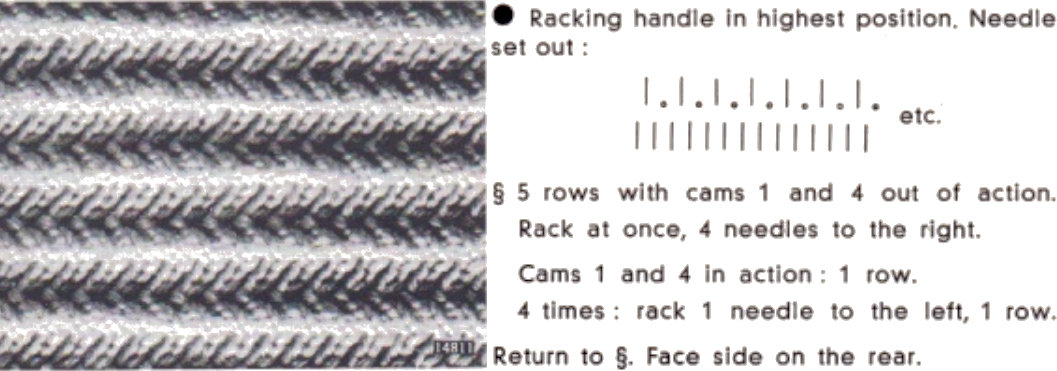

From Dubied pattern books,

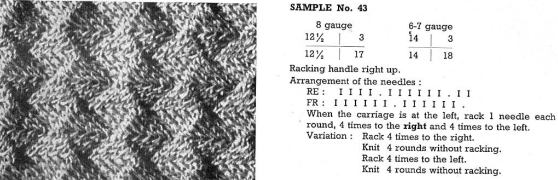

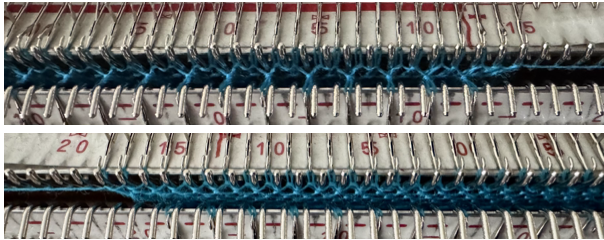

1: matching needle set up

1: matching needle set up

2: stitch positions after racking to the right

3: stitch positions after racking to the left

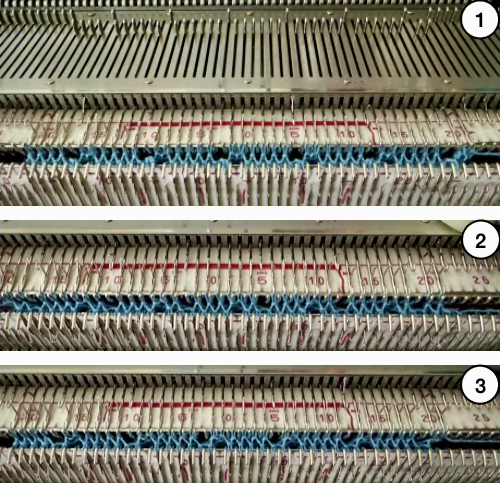

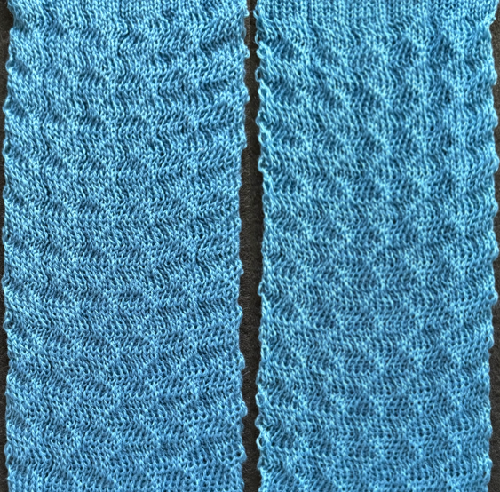

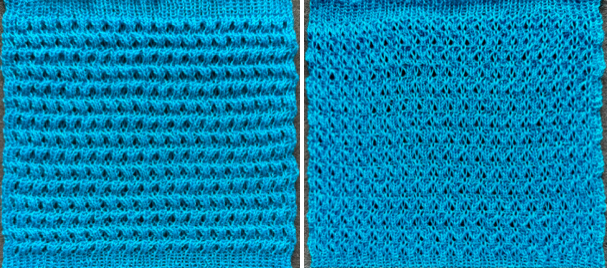

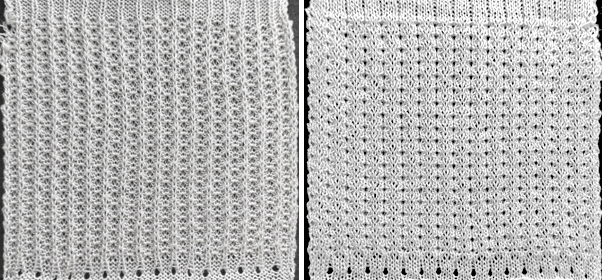

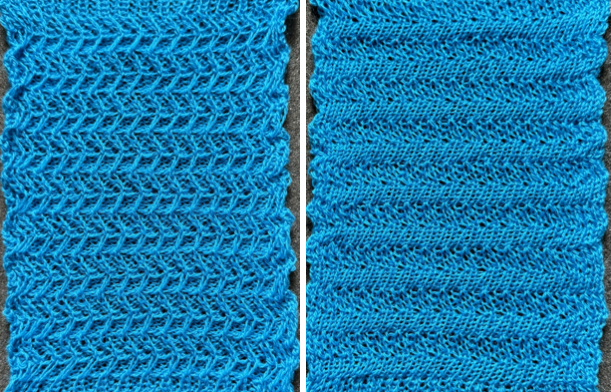

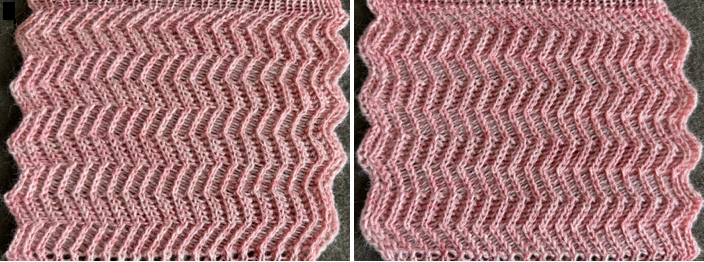

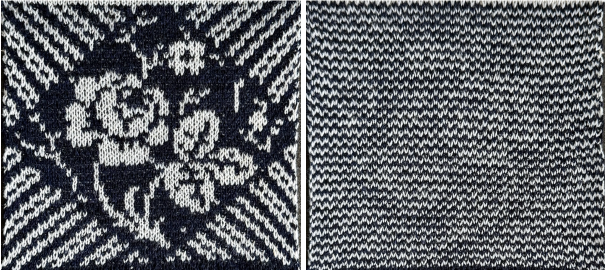

These images illustrate the differences produced depending on the number of rows knit without racking: four on the left and 2 on the right. The knit is reversible, is lightly pleated, and lies flat.

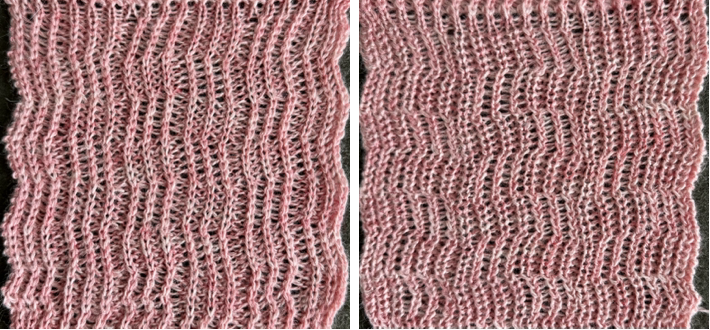

These images illustrate the differences produced depending on the number of rows knit without racking: four on the left and 2 on the right. The knit is reversible, is lightly pleated, and lies flat.  In this swatch, no rows were knit between racking sequences.

In this swatch, no rows were knit between racking sequences.  A pattern that requires no cam changes

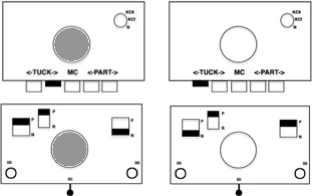

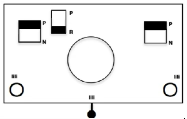

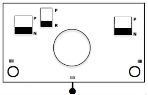

A pattern that requires no cam changes  is knit in tubular tuck stitch, using opposite buttons on the knit bed and ribber. The starting size matters in this case to allow for the use of the color changer every 2 rows. Knitting begins on the left, using the settings shown on the left.

is knit in tubular tuck stitch, using opposite buttons on the knit bed and ribber. The starting size matters in this case to allow for the use of the color changer every 2 rows. Knitting begins on the left, using the settings shown on the left.  My third color, white, was knit in plain ribbing, would be too narrow if used in a final project, and, if used, should be knit using the same settings as the remainder of the knitting.

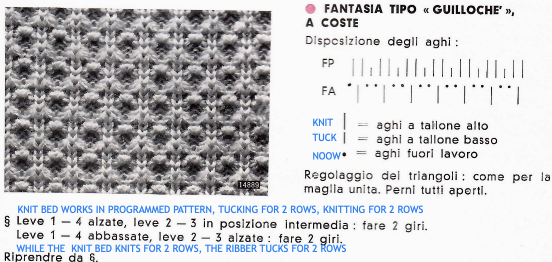

My third color, white, was knit in plain ribbing, would be too narrow if used in a final project, and, if used, should be knit using the same settings as the remainder of the knitting.  This pattern requires more interpretation, as seen in the blue text notes.

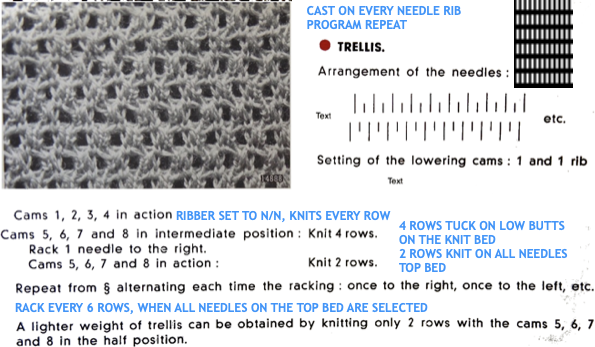

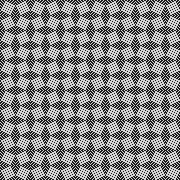

This pattern requires more interpretation, as seen in the blue text notes.  The knit bed may be programmed, thus automating its functions. The repeat as suitable for punchcard models, 24X36

The knit bed may be programmed, thus automating its functions. The repeat as suitable for punchcard models, 24X36  the corresponding PNG

the corresponding PNG![]() and proof of concept, knit on 40 stitches, testing a one stitch knit vertical border on the left side, and 2 stictch one on the other. The 930 automatically mirrors the design.

and proof of concept, knit on 40 stitches, testing a one stitch knit vertical border on the left side, and 2 stictch one on the other. The 930 automatically mirrors the design.![]()

The needle arrangement

The needle arrangement ![]() the program for the top bed, 24X36, usable on punchcard models

the program for the top bed, 24X36, usable on punchcard models

![]() the swatch repeat, 53X36

the swatch repeat, 53X36![]() the starting setup on the machine

the starting setup on the machine The knit bed is set to tuck in both directions, all black pixel rows will form knit stitches. When pairs of rows with non-selected needles occur on the top bed, the ribber is set to knit, the tuck lever may be left in the up position.

The knit bed is set to tuck in both directions, all black pixel rows will form knit stitches. When pairs of rows with non-selected needles occur on the top bed, the ribber is set to knit, the tuck lever may be left in the up position.  When all needles are selected on the top bed, the ribber is set to tuck

When all needles are selected on the top bed, the ribber is set to tuck

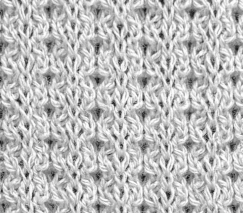

A closer look at the structure on the knit side

A closer look at the structure on the knit side

Slip stitch designs, beginning with “ripple stitch” sample

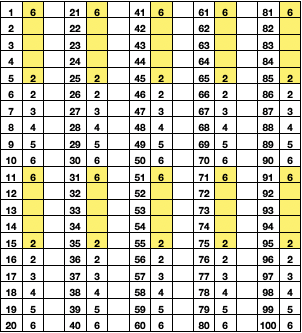

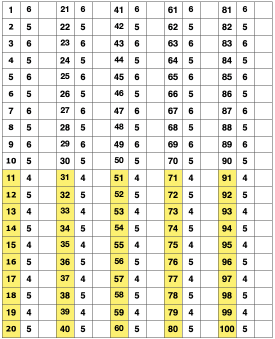

Slip stitch designs, beginning with “ripple stitch” sample Using a spreadsheet to plan racking sequences and respective row numbers:

Using a spreadsheet to plan racking sequences and respective row numbers: the repeat is 10 rows in height

the repeat is 10 rows in height

1-5 the knit carriage is set to knit, the ribber carriage is set to slip in both directions for 5 rows, marked with yellow cells

for 5 rows, marked with yellow cells

rack by four positions at once. The yarn and tension will need testing to allow for that much movement and for knitting the next row without yarn breakage or carriage jams

6-10 set the ribber to knit,  knit one row

knit one row

rack by one position every row X4, returning to the original position

set the ribber to slip in both directions again, repeat the 10 rows.

Following the charted sequence, set up with 3 needles only on the main bed on the right. As the sequence is completed there will be three needles on the knit bed on the left. The original needle setup is restored with return to the original racking position.  The proof of concept knit in a 2/20 wool

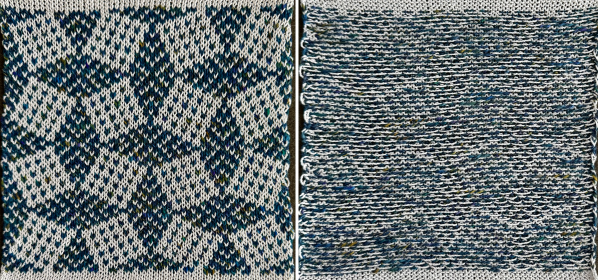

The proof of concept knit in a 2/20 wool  An easy racked pattern in 2 versions and with slightly different needle arrangements began with

An easy racked pattern in 2 versions and with slightly different needle arrangements began with

the planned sequences in series with change in direction every 10 rows. A punchcard machine can be marked with the row # to help track positions.

A punchcard machine can be marked with the row # to help track positions.

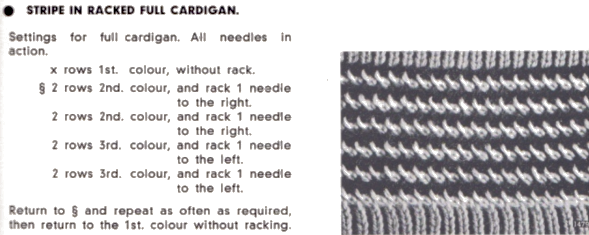

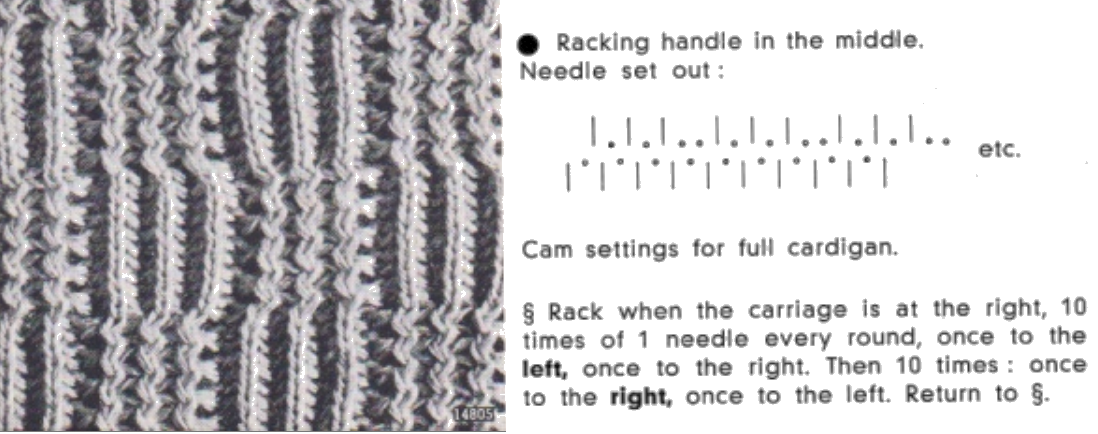

The inspiration: Full cardigan is a tubular tuck, using opposite tuck/knit buttons. As one bed knits every stitch, the opposite bed will form loops on every stitch.

Full cardigan is a tubular tuck, using opposite tuck/knit buttons. As one bed knits every stitch, the opposite bed will form loops on every stitch.

The yarn used is a 2/8 wool. The first test was knit on an every other needle rib

The second test matched the needle set up in the manual, but was knit in half cardigan, not full, with only the knit carriage set to tuck in one direction

The second test matched the needle set up in the manual, but was knit in half cardigan, not full, with only the knit carriage set to tuck in one direction

A version of Brother block racked designs from the Ribber Techniques book uses the top bed to knit every row, with the ribber set to tuck to the right and knit to the left.

A version of Brother block racked designs from the Ribber Techniques book uses the top bed to knit every row, with the ribber set to tuck to the right and knit to the left.

Reversing the racking sequence in direction results in some biasing of the stitches, not as evident in the swatch photo in the manual. That feature can actually be used to produce 3D projections.

Reversing the racking sequence in direction results in some biasing of the stitches, not as evident in the swatch photo in the manual. That feature can actually be used to produce 3D projections.

Cumulative racking references

Cross-brand pattern interpretations: Dubied to Brother

Double bed embossed patterns

Origami-inspired 2: more pleats and folds using ribber

Racking on EON rib: some considerations

Racking mechanical handle repair saga

Racked patterns 5: Passap/Brother 2

More dragon scales and chevrons in ribbed, racked (4) fabrics

Racking: Passap/Brother 3

Fisherman and English rib checks patterns, Brother and Passap

Ribber fabrics produced with 2 knit carriages selecting needles

Combining knit carriage needle selection with racking

Vertical racking 3: automating half fisherman in pattern (2)

Racking 2: vertical chevrons/ herringbone +

Ribber pitch, a bit on racking 1: chevrons/ horizontal herringbone

Unconventional uses for punchcards 1: tracking racking positions

Racked ribber cast on

DBJ based on repeats in my previous posts:

Combining patterns referenced in previous blog posts

60X58 180X174

180X174 a single knit block

a single knit block Another striped block variation and the corresponding swatch can be found in the post on Developing tiled repeats suitable for multiple stitch types, including tuck

Another striped block variation and the corresponding swatch can be found in the post on Developing tiled repeats suitable for multiple stitch types, including tuck

in the same post, knit as single bed FI but also suitable for DBJ, 30X30![]()

with all those dots removed, knit as DBJ

with all those dots removed, knit as DBJ

![]()