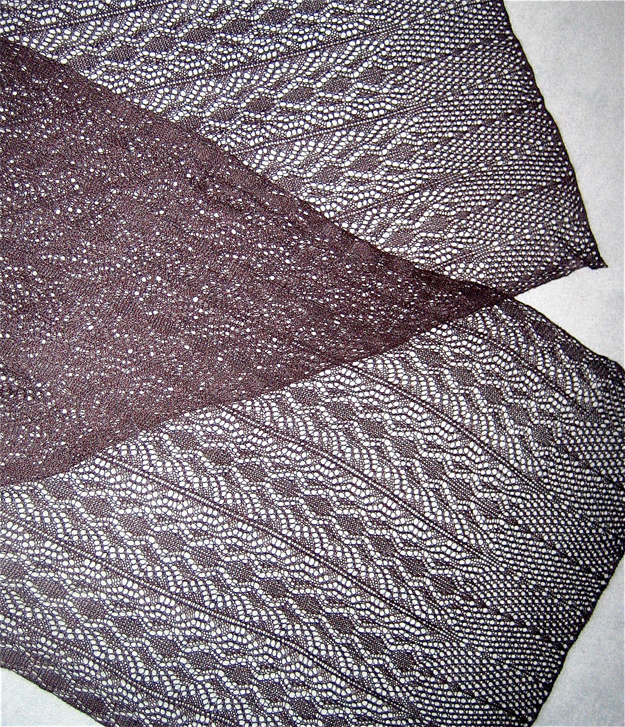

The finished black shawl

The now finished white shawl with a 2 gate peg bind off and a longer border after some pressing, in need of final blocking. Shawls measure approximately 25 X 80 inches.

I am trying to knit a shawl in the latest lace scarf pattern repeat. Using most of the needle bed is making it necessary to take KH far off the end of the KM, ergo the bungee cord (which may keep the extension rail from going out the window with the KM if I reach the appropriate frustration level).

Knitting in black is great on aging eyeballs! My studio is my attic space, and as can be seen, this punchcard machine is nestled at the moment in a very “neat” corner of it. I own 2 lace carriages for Bro punchcard machines, one is appropriate for this KM, the other for a later model. The usual mantra is not to exchange carriages between models without cautious evaluation, it is sometimes simply not workable. For lace, I found the “correct” carriage drops stitches easily, the “incorrect” one is harder to push, but drops far less often.

Knitting in black is great on aging eyeballs! My studio is my attic space, and as can be seen, this punchcard machine is nestled at the moment in a very “neat” corner of it. I own 2 lace carriages for Bro punchcard machines, one is appropriate for this KM, the other for a later model. The usual mantra is not to exchange carriages between models without cautious evaluation, it is sometimes simply not workable. For lace, I found the “correct” carriage drops stitches easily, the “incorrect” one is harder to push, but drops far less often.

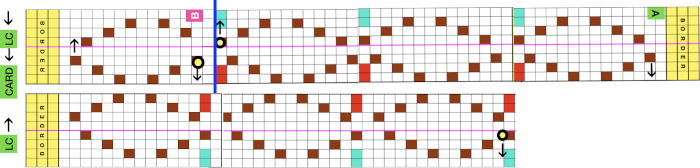

I mark the punchcard rows on which the arrow markings occur/ need to be placed by drawing across that row with a colored pencil; in addition to serving as a reminder for when the knit rows with the opposing carriage need to happen, this gives me reference points for the beginning of each transfer sequence for correcting mistakes when unraveling back to last knit row. Because this lace is much more labor-intensive than that used in the previous shawls the plan is to knit in a border at its top rather than on rehung open stitches, one at a time, sideways (this can take several hours and a lot of patience).

More lace thoughts: lace repeats don’t necessarily have to begin on row 1 of any repeat. Here I chose to begin on RC 33 of my card so as to “go” for complete diamond shapes centered on the bottom and top. If the first knit row of the scarf/shawl is rehung at half of the desired finished length, a vertical mirror pivot for the lace pattern is created. When this is the plan, a contrasting thread may be placed where the 0 marking is on the needle tape, between the 2 needle ones (one of the brother oddities is the 2 needle one positions, R and L of 0) on the first row knit after the waste knitting; marking the needle tape with water-soluble markers along easily identified repeat points can also assure proper placement on the needle bed. When the knit is rehung for mirroring, the loop where the marker sits is placed on needle 1L, rehanging away from the center, every needle will be “filled”. Those needle tape markings may spare the grief of missing any stitches after rehanging, before removing waste yarn. On the standard KM single-width may max out at 18-20 inches. Steaming the edge that will be rehung helps make stitches more stable and visible prior to doing so. This is an image of a small border test with dropped stitches along with the mirror point, and a 2 gate peg bind off

Part of half a scarf on the machine, there are added temporary markings on the needle tape for needles with specific vertical areas in pattern repeat,

Part of half a scarf on the machine, there are added temporary markings on the needle tape for needles with specific vertical areas in pattern repeat,

My new production line of lace scarves, of varying fiber content, after pressing. There is an average of 10 lace carriage passes for every one row knit. Though a bit daunting for production, I am considering knitting some shawls in the same pattern and am in the process of exploring repeats for shawl borders.

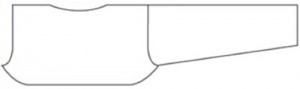

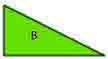

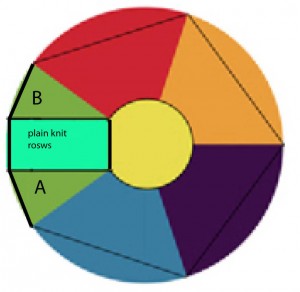

A large gauge swatch is important: I suggest 100 sts by 100 rows. For a bolero style garment with a “shawl” collar, a place to start is with bottom and top sections measuring at least 6 inches in height, and for the middle rectangle to measure 22in W by 23in L. Again, a muslin in a purchased knit of the center section will help decide how much of it needs to be seamed to allow for an armhole opening, keeping in mind that the opening in the machine knit may have less stretch than the test muslin knit. The number of stitches cast on is based on those required for section B, with adjustments made to allow for lining up pattern repeats in seaming up the finished piece.

Beginning the knit with a cast on that allows for maximum stretch, test out rib pattern (A), transfer to a mostly single bed for (B), bind off, and treat the swatch in the same way the finished garment will be: ie. steam, wash, etc. Testing the stretch in the cast-on edge and its immediate fabric neighbor will define how the large a “shawl collar”may be achieved. A more “circular” shape when worn may be obtained by adjusting height while keeping in mind that a true circle would have a circumference approximately 3 times its diameter which in this test would be based on the stitch count obtained in knitting the width of the swatch in the B pattern.

If a significantly larger “donut” is required in the design, every needle rib can be ended in a row of stocking stitch after transferring stitches to the main knitting bed, taken off the machine, and rehung on fewer stitches prior to knitting B. Same step is taken when joining the last section.

Trial basting side seams will ensure armhole fitting comfortably. If more of a cap sleeve is desired, stitches may be added in the location of armholes during knitting B, or bands may be knit onto or stitched onto armhole after completion of the piece. Suggestions for cast on will follow.

Entrelacs abound in knitting at the moment. In thinking about perhaps composing my thoughts for a post on the subject, I searched online and found some very good sources on this subject. One is found at howtoknitasweater.com. The author, Cheryl Brunette also shares an article on lace . Here are 2 of my teaching samples, executed on 4.5 mm machine

front view

a rearview with ends woven in

Removing a circle from the center of our pie yields the “donut”. The purpose and size of the “donut hole” can vary from the size needed to apply a central motif whether in knit, crochet, or other forms, to one large enough to allow for insertion of a “back piece” that can be anything from a “square” to one that included a bit of shoulder, armhole, even neck shaping and an optional curve at the waist/hip area.  Additional rows of plain knitting in the “donut” itself alter the final forms. Seaming can occur where preferred; the direction of pattern repeats if in use further influence choice of seam placement.

Additional rows of plain knitting in the “donut” itself alter the final forms. Seaming can occur where preferred; the direction of pattern repeats if in use further influence choice of seam placement.

If miter shapes are created in the knitting method, the corners of the triangles will want to “poke out”. This can be a purposeful design feature. If they are not wanted one way to soften them is to have stitches for at least an inch at the outer circumference of the circle knitting with no shaping in that area, adding a border, going the spiral route. Swatching helps determine preference in creating personal designs. Small scale paper collages sorting out geometric shapes and joins can inspire the large form variations.

Vests and sweaters built on circular shapes offer some challenges. Shawls and shoulder wraps are much more forgiving, but garments, particularly if sleeves are added, can provide sizing and fitting challenges. Making a muslin in disposable knit yardage prior to the actual knitting allows for trial placement of armholes and testing of overall measurements prior to charting out garment and sleeve shaping. Slits for the armholes can easily be taped or stitched closed to suit, and in turn, trial cut in a different location. Trimming or adding borders to circumference allows for visualizing size grading. This process helps spare the knitter regrets upon completion of the piece.

Drawing large circles is easy and accurate with a “yardstick compass”. Trammel points are available online and at many woodworking supply stores, etc. They convert any standard size yardstick for drawing arcs and circles up to 72 inches dia. Use a longer stick the same width and thickness as a yardstick and draw circles as large as you like. They are usually made of aluminum except for the steel point, measure about 3-1/2 inches in length.

Some beginning guidelines for drafting:

1. Use your bust measurement as the circle’s diameter and draw the corresponding shape. Two or more strips of freezer paper may be used as the drawing surface, temporarily fused onto the knit yardage, becoming the paper “pattern” for the piece and stabilizing the knit for cutting.

2. Measure your back from arm to arm to determine how far apart to place armholes or obtain this measurement from any well-fitting favorite.

3. Measure armhole depth from the top of the shoulder to 2-3 inches below the armpit.

4. Draw lines for armholes and center horizontally within the body of the circle, shoulder measurement apart. Commercially written patterns are bountiful online and in magazines and tend to center the armholes vertically as well. I prefer them shifted up for a less bulky “collar”, and for placement of sleeves with raglan or traditional caps. Binding off a few stitches at the base and casting them on at the top of the slit create a slightly shaped for easing in the sleeve top.

5. Cut “armholes”, remove freezer paper if used, try on for fit, adjust as needed. 6. Back to more math!

I made a series of long-sleeved circular sweaters for sale in 2008. Discovered problems with photos in my photo library (new computer). These are an attempt at “restored” shots of one of the first such sweaters. The yarn was fine Italian mohair.

close up

Holding/ short-rowing is used to knit each wedge. The basic rule for holding is followed: stitches are brought in to work on the carriage side, and into hold opposite the carriage to avoid floats. The greater the number of sections, for either the full circle or a donut, the smoother the curves at the outer circumference, as can be imagined in the form below, which divided into more sections than those 5 in our original calculation.

The pie slices” begin and end on open stitches, ultimately requiring a join where the radii meet, using whatever method is preferred by the knitter. Assuming the knit carriage is on left and set for hold in the diagrams below if all stitches are brought into hold except 1 on the carriage side (or number required by calculations for the individual piece), 2 rows are knit, and action is repeated until all needles are in work, the following shape starts to fill in and a miter with pointed edges is created.

If all the needles are in work, and one begins to bring them into hold opposite the carriage, one begins to fill in the shape creating the form below, and a spiral is created, with circumference edges more rounded.

Like shapes may be stacked sequentially. If shaping at the top of the initial triangle wedge is reversed, however, the following begins to occur.

Knit rows in between the triangles begin to create larger holes in the center of the pie, and a donut occurs. The donut center can be varied, the knit rows between triangles increased to suit. The illustration below shows some of the variables. The plain knit rows are another factor in smoothing that outer circumference.

There are many knitting programs that will perform the necessary calculations, as well as a variety of knit calculators. The diophantine formula is the basis for what is known to some knitters as the “magic formula”. In the early 1980s, Alles Hutchinson authored a small book on the subject. There is a bit of personal leeway in the results, and the formula may be used in calculating even complex shapes with the proviso that one has the patience to break such shapes into series of simpler ones.

There are many online resources for information and calculators to sort out the math, including a triangle calculator. The original website’s offerings are now closed, but the info remains available here

https://web.archive.org/web/20200224005535/http://www.getknitting.com/ak_0603triangle.aspx

Using the gauge to match the previous post of 4S and 6R per inch the calculation for the pie divided into five triangles breaks down into the web calculator result pictured below:

The longhand method for the same calculation follows and also translates to: bring into hold 2 stitches for 4 times, 1 stitch for 80 times. Stitches in shaping are proofed as above: 88 stitches shaped over 84 rows.

The longhand method for the same calculation follows and also translates to: bring into hold 2 stitches for 4 times, 1 stitch for 80 times. Stitches in shaping are proofed as above: 88 stitches shaped over 84 rows.

Math is not always fun and is downright dreaded by some. One instance in knitting wherein basic calculations are required is in obtaining stitch and row gauges. I have known one hand knitter who would purchase yarn (not necessarily the one used in pattern), knit happily away, and try the finished product on everyone she knew until she found an accommodating body shape and size. If a large number of family and friends did not oblige, sweaters were stored until such a correct body appeared. Predictable results require careful measurements and some basic formula calculations.

Using home knitting machines to produce circular forms one resorts to breaking down the round object into pie wedges, which in turn are knit as triangles with straight line outer edges. The outer final circumference curve is controlled in a number of ways, one is by creating a far greater number of pie slices. For this exercise, I will work with 5 segments.

There are some math constants. One example: to find the circumference of a circle its diameter is multiplied by pi = 3.14. If the diameter of our knit is 44 inches, its circumference will measure 44 X 3.14 = 138.16 inches. Using the rule of 5 or less than 5, this measurement is rounded to 138 inches.

The radius becomes the width of the pie wedge. In this instance, it would measure 22 inches. Let us assume our gauge is 4 stitches and 6 rows per inch. The radius is converted to stitches: 22 X 4 = 88 sts. The circumference becomes rows: 138 X 6 = 828 rs. If subdivided into 5 slices, each slice would be composed of 166 rows.

To knit the pie slice, short rows are used; since they happen every 2 rows, our row number for outer edge is divided by 2, yielding the total of now 83, which in this exercise I will round off to the even # 84.