This post was originally written intended for punchcard machines only, with the passage of time electronic pattern tracking, samples and associated repeats were shared.

Links to some later posts including cable manipulation and patterning

2023/05/30/a-return-to-plaiting-and-double-bed-hand-transfers/

2021/03/11/slip-stitch-patterns-with-hand-transferred-stitches-double-bed/

2021/02/01/slip-stitch-patterns-with-hand-transferred-stitches/

2021/05/09/double-bed-embossed-patterns/

2012/01/19/using-punchcards-to-track-small-cables-in-pattern-1/

2011: Cables seem to be in vogue once again in myriad permutations. They pose some interesting issues when created in machine knitting. Interweave Knits Winter 2011 published an article on “Cables 101” that includes a way to color code and graph cable crossings. “Back in the day” of regular, worldwide machine knitting seminars, several authors provided collections of machine-knit cables including George Le Warre at Passap universities (copyrighted, George presently in England).

Simple crossings are a good place to begin and produce texture. If one is not interested in freeform but rather constant, recurring patterns it is possible to use punchcards to produce visual cues when stitch twists and crossings are to occur. This is not an option in Studio Machines, easy on Brother because of the fact that needles pre-select, and Passap pushers may be used for a similar set of clues with a bit more fiddling.

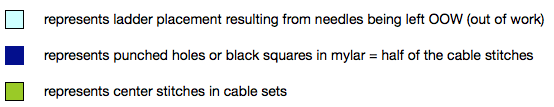

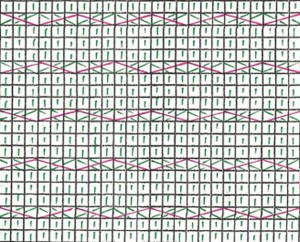

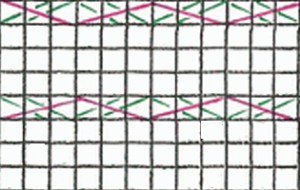

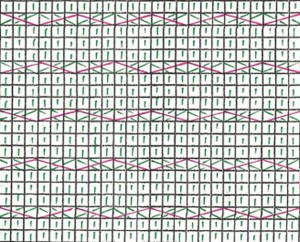

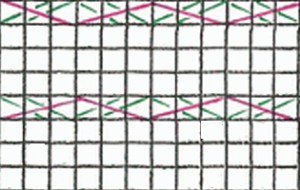

When color-coding information for referencing as one knits, it is possible to be generous with symbols or edit down to bare elements. For example, one way to approach a schematic follows below, where knit stitches are illustrated as well as cable crossings. Red indicates stitches moved to the front, and the green indicates those traveling to the back in each cable set. In hand knitting, vertical or horizontal bars would represent knit and purl stitches. Since these are identical in this HK graph, they could all be eliminated

A

B the isolated repeat

The choice then remains whether or not to revert the crossings to match the HK pattern. One way to do that is simply to reverse positions for colors. The mantra becomes “red moves first, green moves second and over red”.

With all machines, if the knit carriage is left set for normal knit, even if the patterning option is engaged (KCI or KCII if there are any needles out of work) needles will be selected, but the fabric produced is stocking stitch. The usual considerations are in order: the number viewed on the card outside the machine corresponds to the design row being read by the reader, but the punchcard holes in view are not necessarily the same as the design row selected. Because one is producing the cables on the purl side of the knit, if hand knitting charts are used the cables themselves will be mirrored. In many instances, this may not matter, but if one is using the twists for representational crosses ie. in trees, owls, diamonds, and other geometric shapes, it is a good idea to scan the repeat, mirror the image vertically, and then begin translating it into machine knit interpretations. Relatively easy with simple scanning and printing software (ie. the flip horizontal function in Preview, a bit harder by hand.

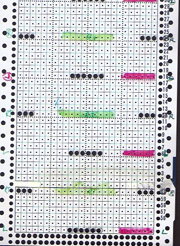

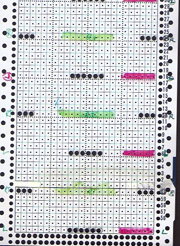

When I can I color code my cards: ie. with lace I draw a line across the card when I reach each knit row sequence with a color pencil. This provides me with an easy-to-follow visual cue as to when the rows must occur, and also facilitates returning to the previous selection sequence when mistakes in patterning occur.

Some basics: with a punchcard, there is no row length limitation, but repeats are limited to 24 or a factor thereof. In this particular use wherever needles are selected, one has a visual reminder to move those needles in the desired direction.

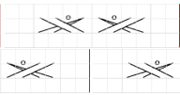

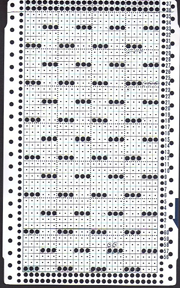

I used the cards below to illustrate the idea in my intro to knitting classes. When needle selection occurs in the first, remove the selected stitches off the machine with a 3 prong tool in each desired location, then insert a second 3 prong tool back through the front of those same stitches, in turn removing from the initial tool used. Rotate the twice transferred stitches 180 degrees consistently either clockwise or counter-clockwise throughout, and return them to their original position on the needle bed. The result is a consistently textured fabric with no counting stitches or rows between repeats.

a swatch using it

This card begins to address regular cable crossings, mine was punched in repeat the full 60 rows. Color may be assigned to help with opposing twists’ directions ie. to left (pink) or to right (green) when the corresponding color bar appears just above the card reader.

With tubular knit cord in addition to hooking up, anchoring may require some stitching, “seaming as you knit” at planned intervals would make the joins “invisible ”

With tubular knit cord in addition to hooking up, anchoring may require some stitching, “seaming as you knit” at planned intervals would make the joins “invisible ”  Strips using holding techniques or stitches hooked onto the knit to create texture, in turn, joined in the “seam as you knit method”

Strips using holding techniques or stitches hooked onto the knit to create texture, in turn, joined in the “seam as you knit method” Cording may also be inserted into single stitch lace “holes”

Cording may also be inserted into single stitch lace “holes” or larger holes created through holding techniques

or larger holes created through holding techniques Knit i-cords, ribbon, twisted cording, etc. may also be threaded/woven through holes created at cable crossing as a way to add color and dimension to standard cables, mimicking their movement on the fabric. A recent foreign magazine cover including a variant of the above technique

Knit i-cords, ribbon, twisted cording, etc. may also be threaded/woven through holes created at cable crossing as a way to add color and dimension to standard cables, mimicking their movement on the fabric. A recent foreign magazine cover including a variant of the above technique