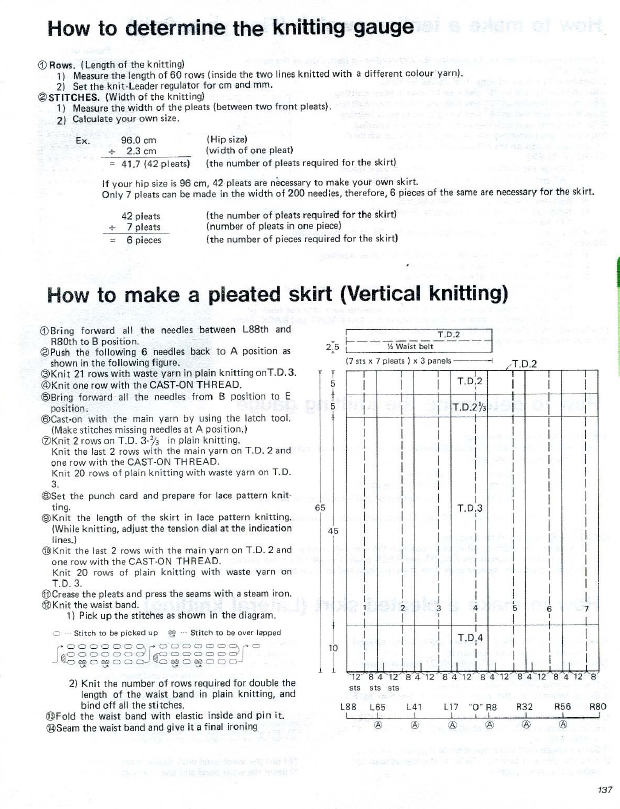

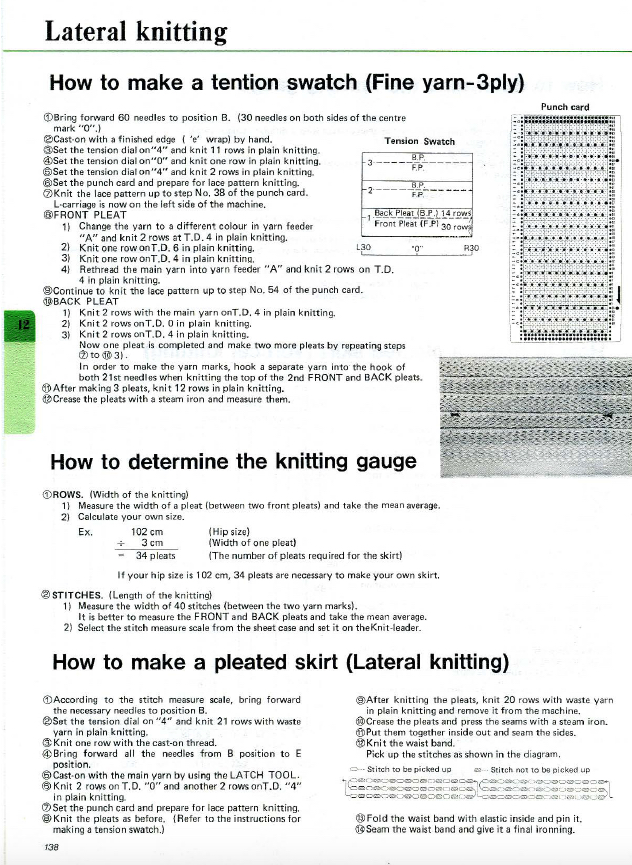

I previously posted on both single and double bed pleats. In light of the recent thread on mesh, I am sharing some of the information on pleats created using lace transfers, working out gauges for knitting predictable size fabric using them, and published in the Brother techniques book

A lace mesh series: using GIMP

Eons ago I owned a BitKnitter for my Passap machine, and to this day I miss it and some of the other Cochenille software that is no longer available, especially when working with multiple colors for color separations of any sort. When using it for downloading the resulting motif, picking the same exact color for each “square” on the grid was a necessity for accuracy. If “only” black was involved, the same guide applied. Working in GIMP one can set the color mode to fewer colors to start with, reducing the palette. This can limit your editing ability sometimes, and switching between modes may be required. I tend to go autopilot when I work on color separations for any purpose and work with built-in colors rather than custom.

It is helpful to have previous experience with any program as well as with basic knitting before tackling and combining large scale designs and fabrics such as lace. This is not a step by step how to use GIMP (search for my other posts on the topic), merely an illustration of my experiment in working with superimposing an image onto a mesh grid.

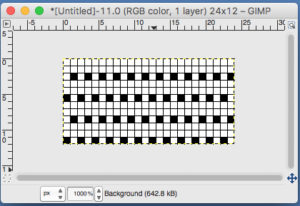

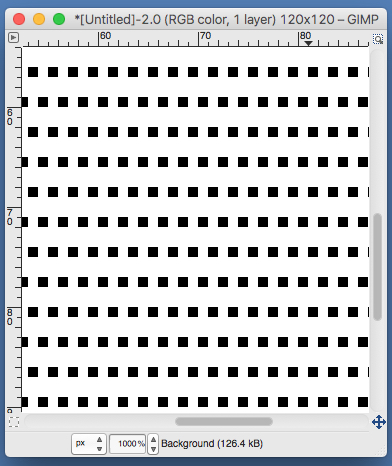

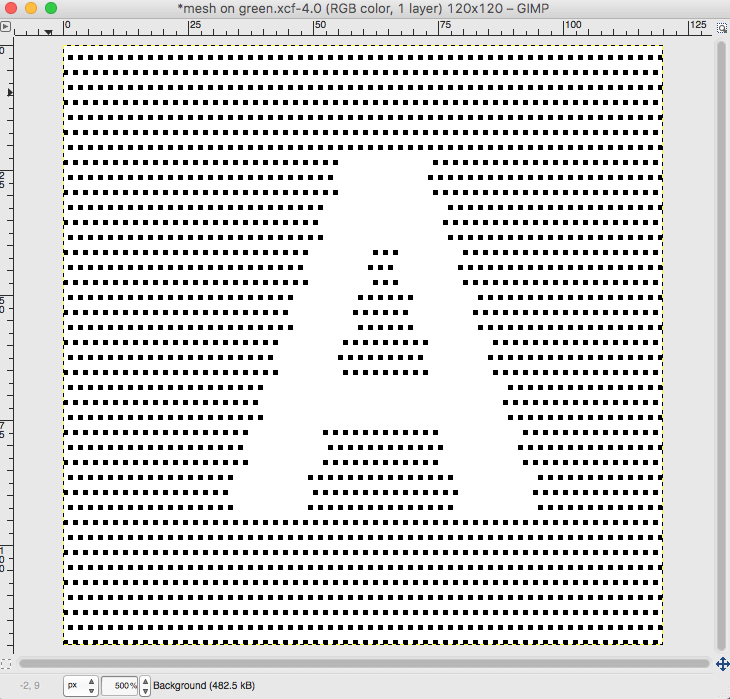

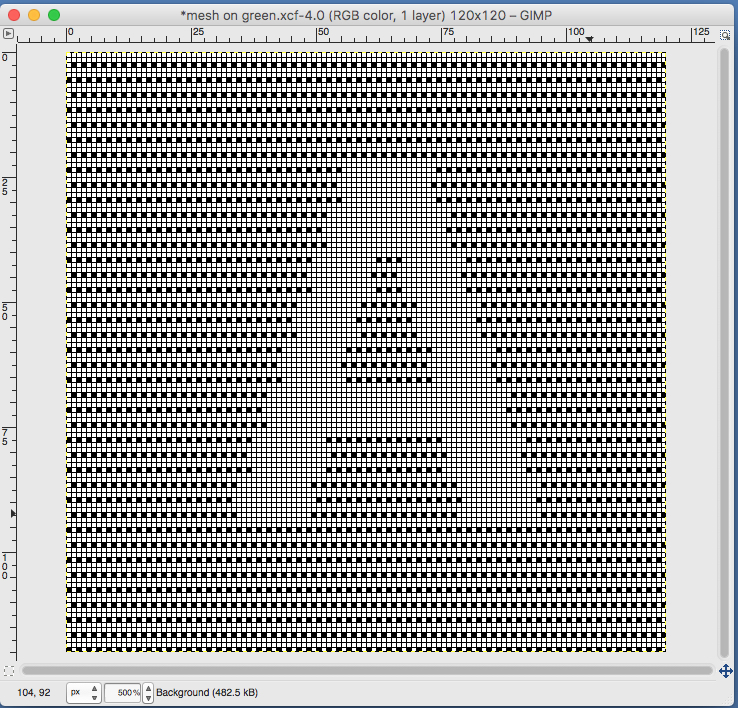

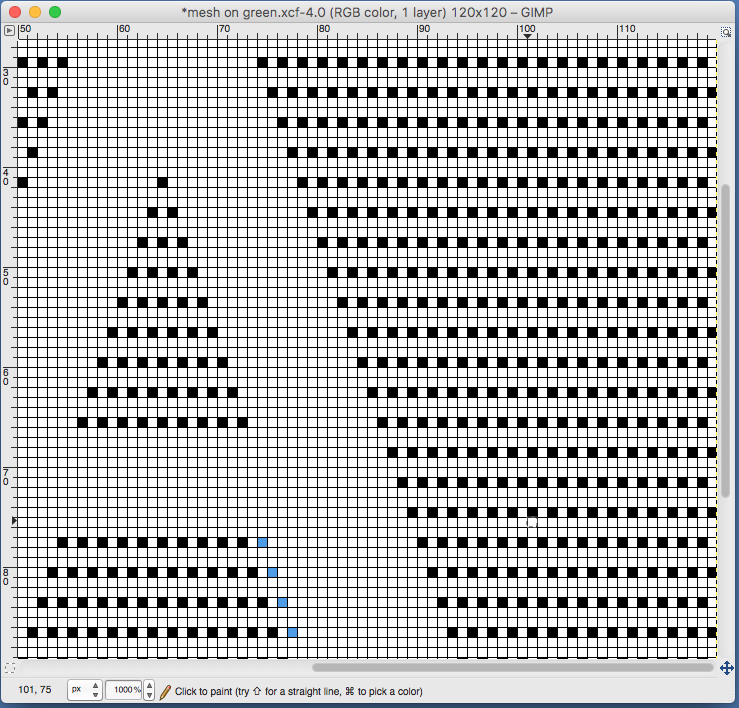

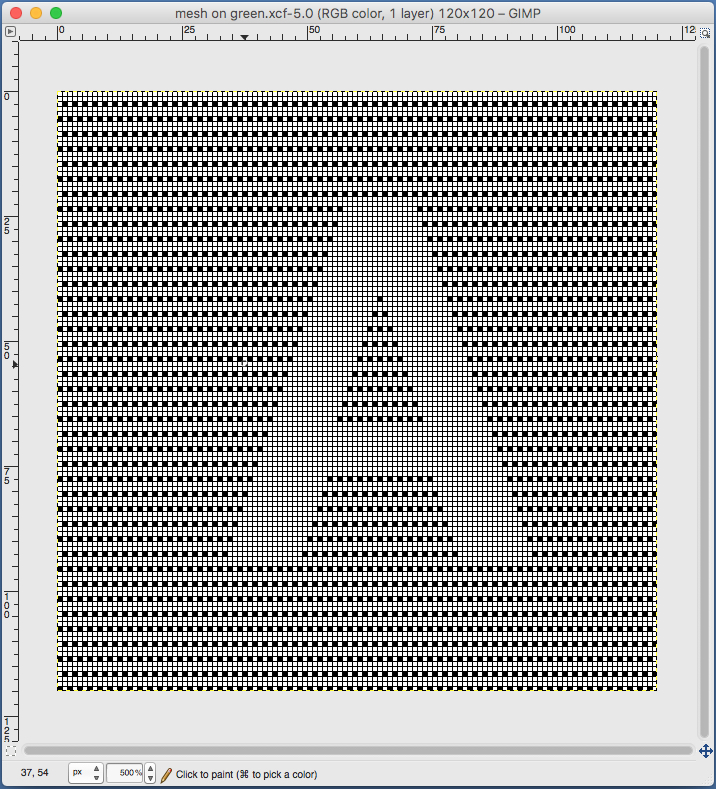

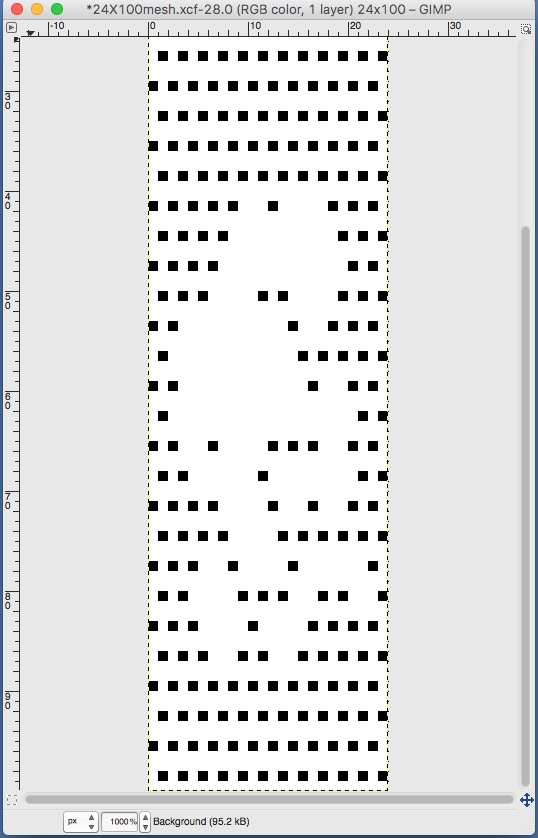

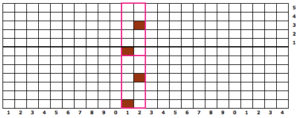

To start with: a 1 X 1 grid is set up. “Black squares” become single pixels in downloads. For the single stitch 1 X 1 grid to be visible, I prefer to work in at least a 500X magnification. Because I do not own a hacked machine I am unable to provide a corresponding test swatch to the final chart.

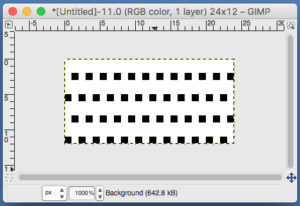

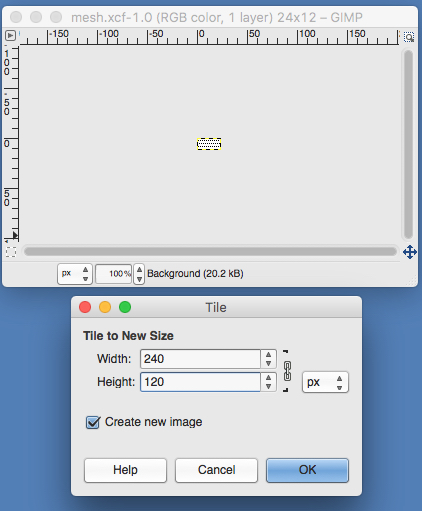

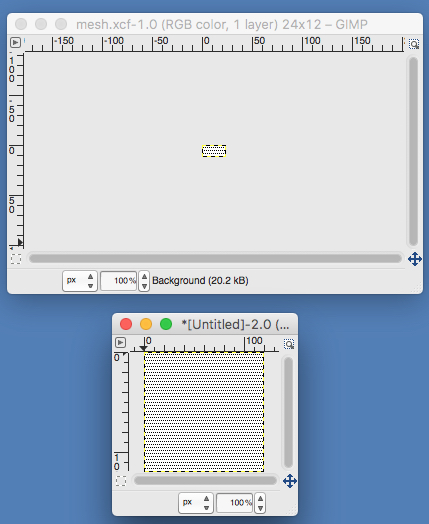

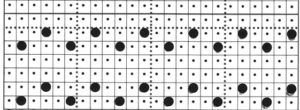

The resulting image may be tiled to produce a large enough mesh ground, the grid needs to be turned off for this step

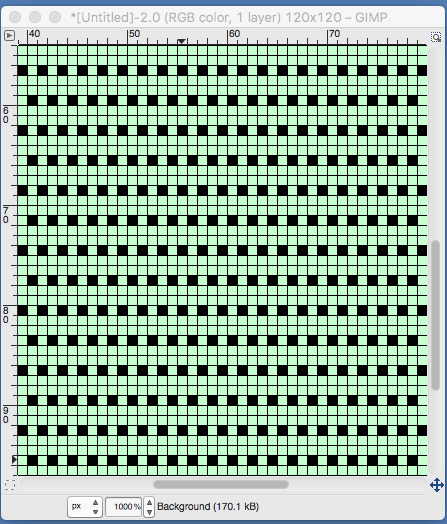

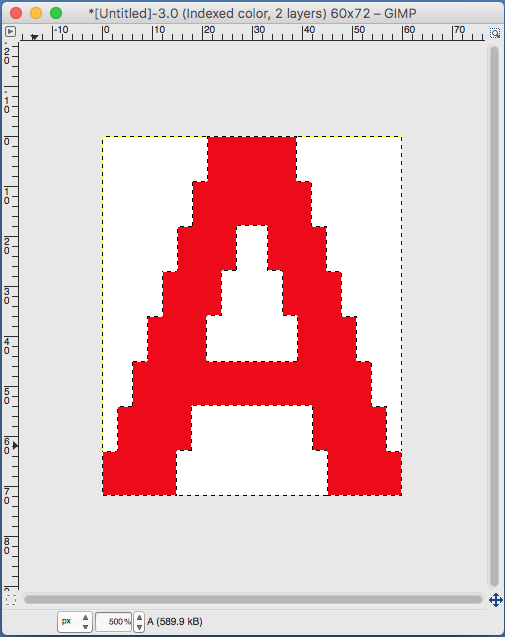

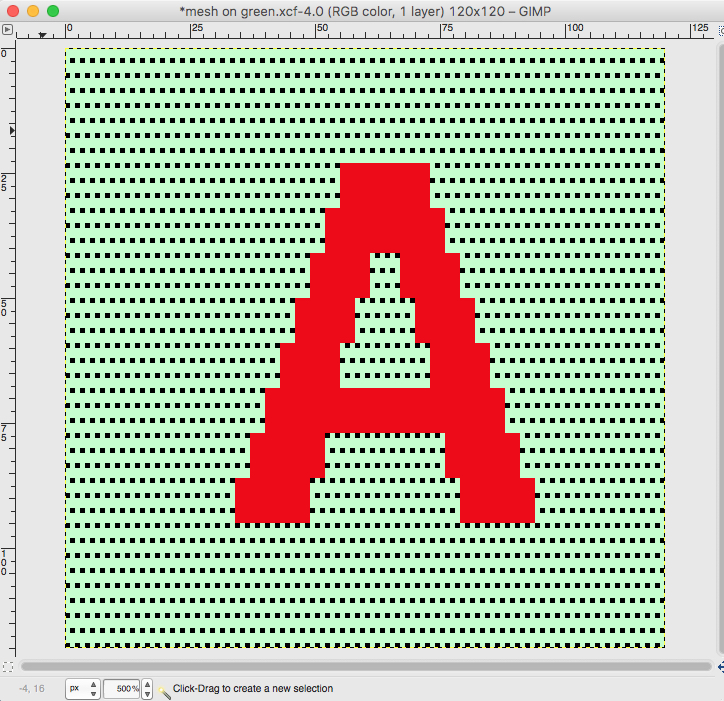

The tiled image will appear on a different part of the screen, shown in both versions below, I realized reviewing the above that the width was for more pixels than could be programmed on a 200 needle machine, I resized its width to 120 pixels

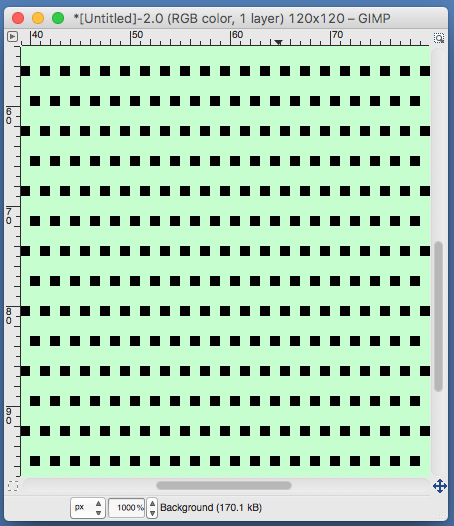

here the grid is removed for further processing

the goal is to retain the black squares for the end bmp, so the ground is filled with a color that will later be removed  gridded again if and when needed

gridded again if and when needed

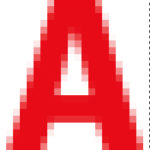

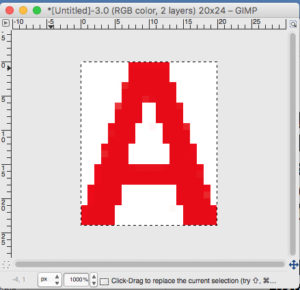

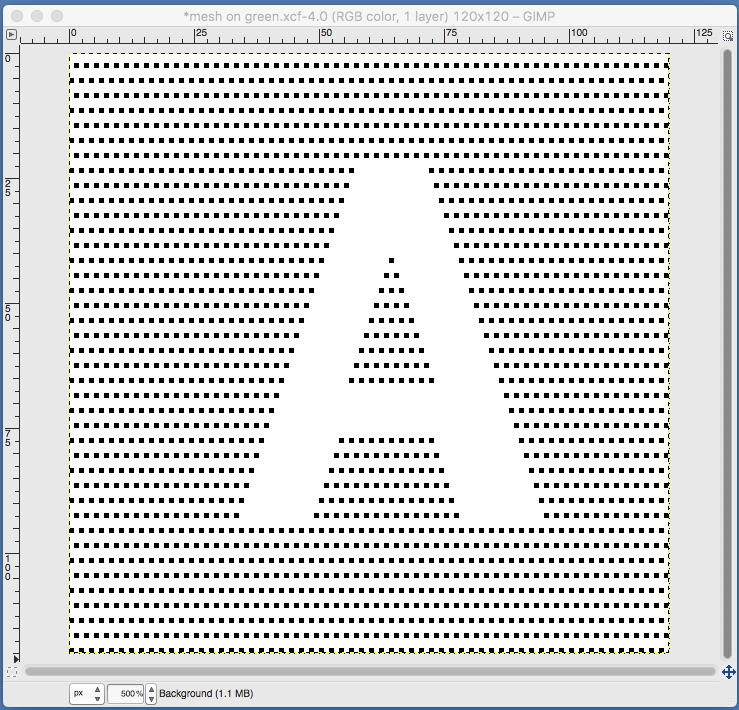

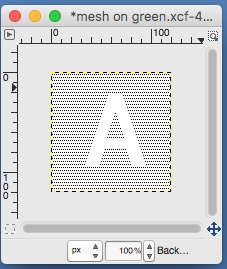

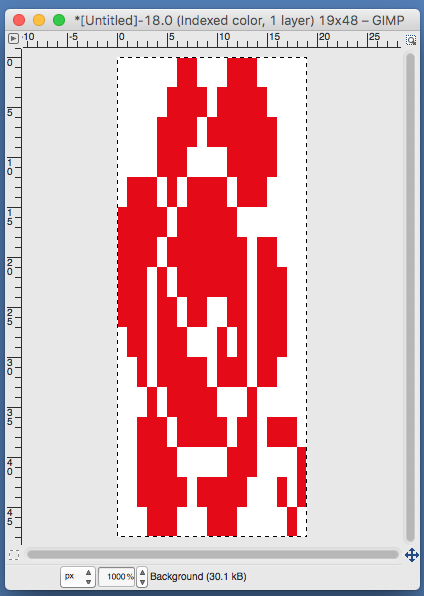

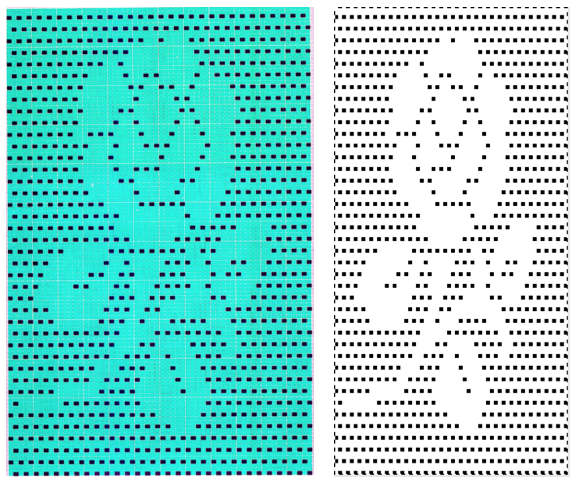

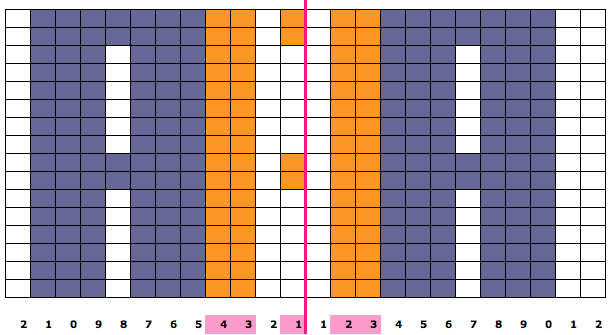

Today’s image is a letter (20 pixels by 24), produced in a new file with text from one of my built-in computer fonts. I happened to be working in RGB mode  the same image as it would appear in indexed mode

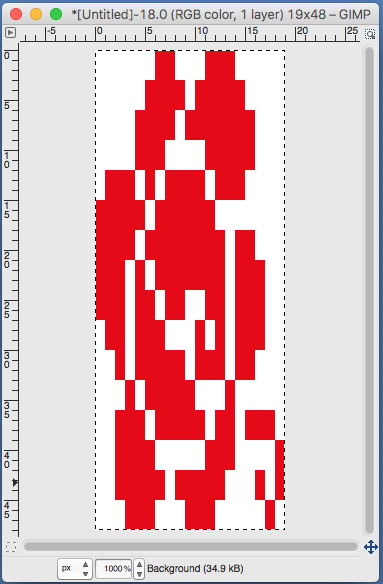

the same image as it would appear in indexed mode  Here some edges “clean up” has been worked with the grid on, then removed for tripling the motif length (now 72 pixels) and pasting on the “mesh” ground

Here some edges “clean up” has been worked with the grid on, then removed for tripling the motif length (now 72 pixels) and pasting on the “mesh” ground

Switching to indexed colors (6) if you have worked in RGB to this point, it may make cleaning up of edges easier. I flood filled the A to insure only one red was in use. Below the A is selected (fuzzy selection tool) and copied for paste onto the “mesh”. Magnification reduction to 500X makes the whole file more easily viewed on my mac

the A pasted in place

the A pasted in place white color fill leaving only black squares of letter and ground

white color fill leaving only black squares of letter and ground

Superimposing may be used in some machines, but eliminates the choice of editing when one is “not happy with edges” until after sampling the knit, has several parameters and limitations. Above image gridded for editing:

feeling better, with the exception of the left side bottom of right leg of A

feeling better, with the exception of the left side bottom of right leg of A one last bit of clean up, switching between magnification as needed

one last bit of clean up, switching between magnification as needed happier

happier  grid removed, image magnification reduction to 100X for export as bmp and download to KM

grid removed, image magnification reduction to 100X for export as bmp and download to KM

When downloading a large image that constitutes the width of your piece, programming an extra square or 2 vertically for the height of the pattern in “white” on each side will insure that stitches in those areas are not selected for transfer by the lace carriage, and a knit border will be created.

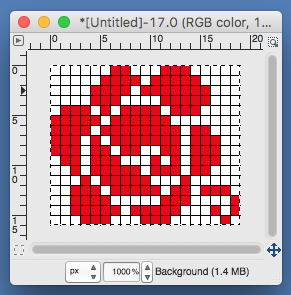

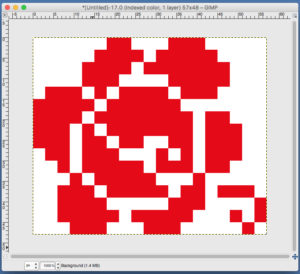

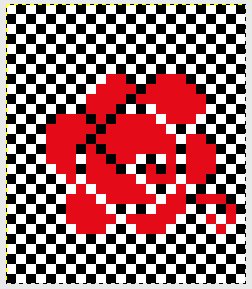

Things become more complicated with more complex shapes. This is part of a filet crochet chart, and a rose now becomes my goal

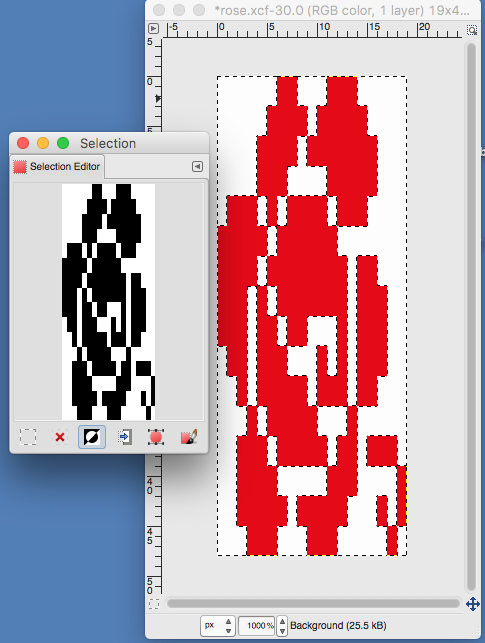

use selection editor or fuzzy select

use selection editor or fuzzy select paste and move to “best” spot

paste and move to “best” spot  not quite a rose

not quite a rose

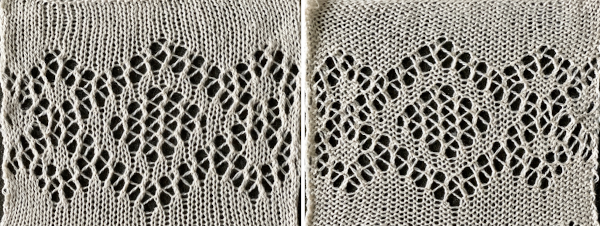

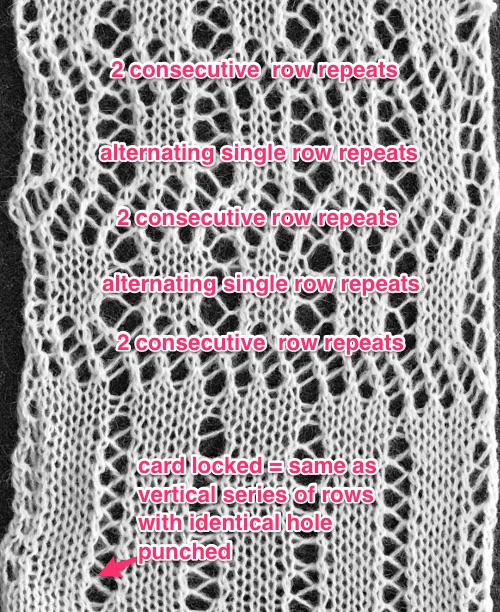

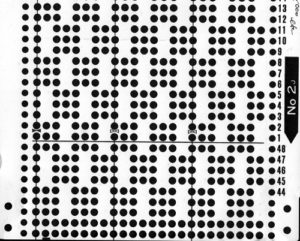

8/9/18. From the Brother electronic lace pattern book, worked out in a much larger repeat

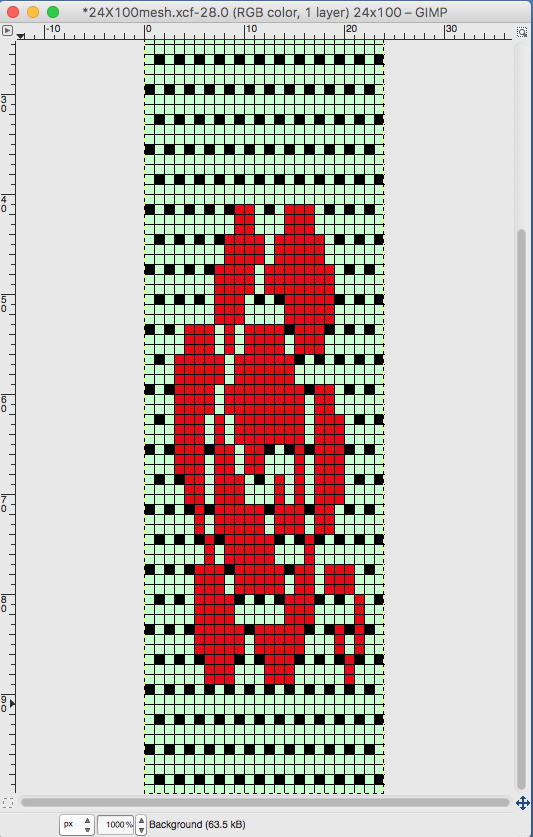

Back to the drawing board: the mesh and knitting method are altered. For a possible knitting method option see https://alessandrina.com/2017/07/28/unconventional-uses-for-punchcards-2-thread-lace-cards-for-filet-mesh/ The ground “mesh” is now composed of every other stitch, alternating every other row. The “rose is not lengthened. “Stitches” need to be “cleaned up” to approximate a more recognizable shape.

When satisfied, export in format for download.

When satisfied, export in format for download.

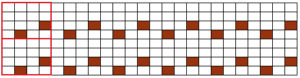

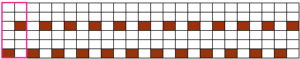

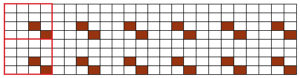

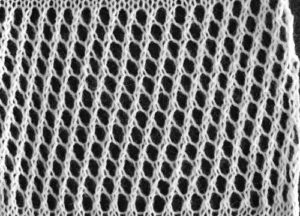

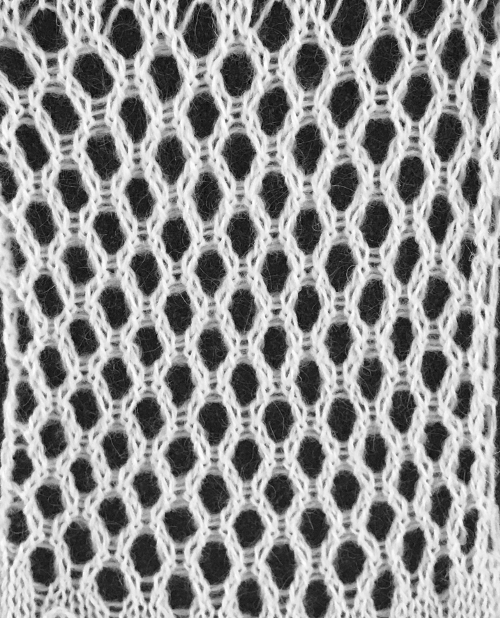

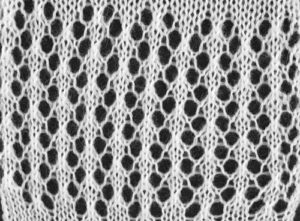

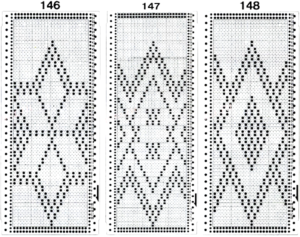

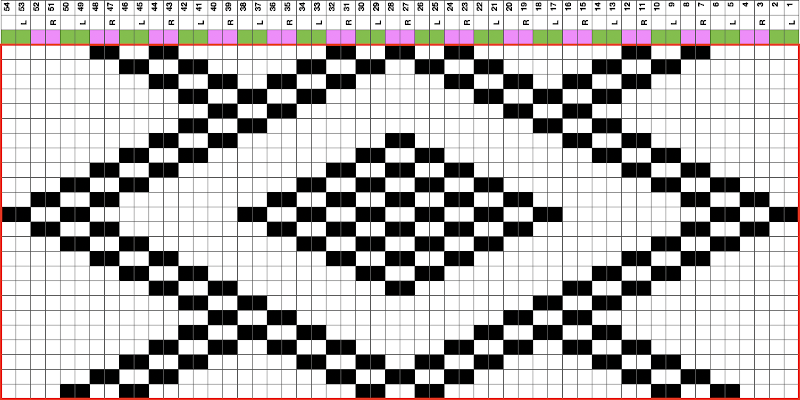

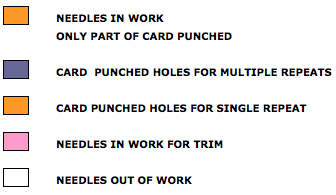

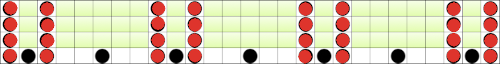

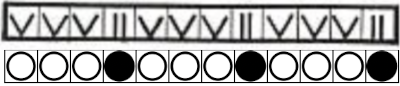

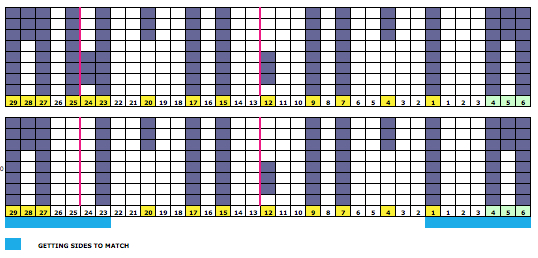

To mesh or not to mesh 5- design repeats

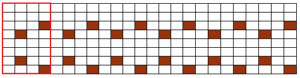

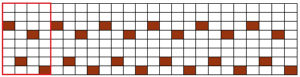

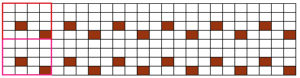

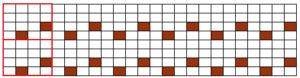

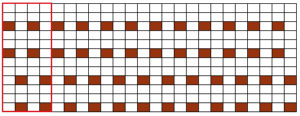

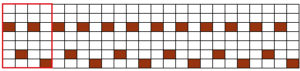

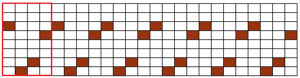

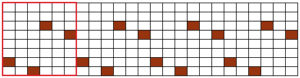

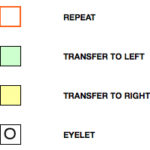

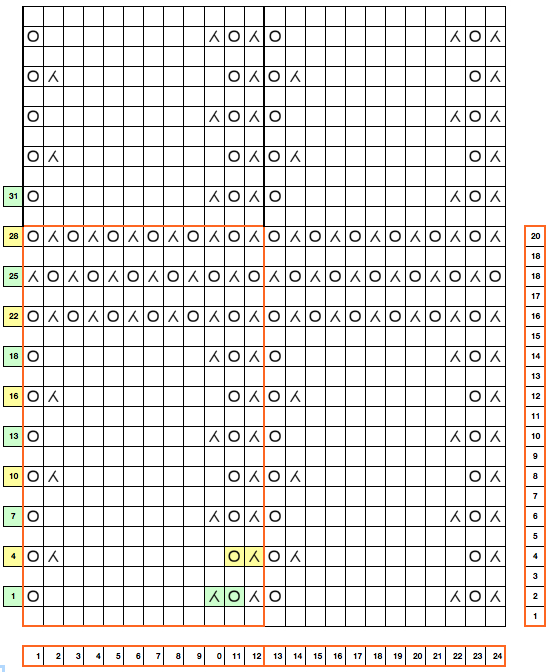

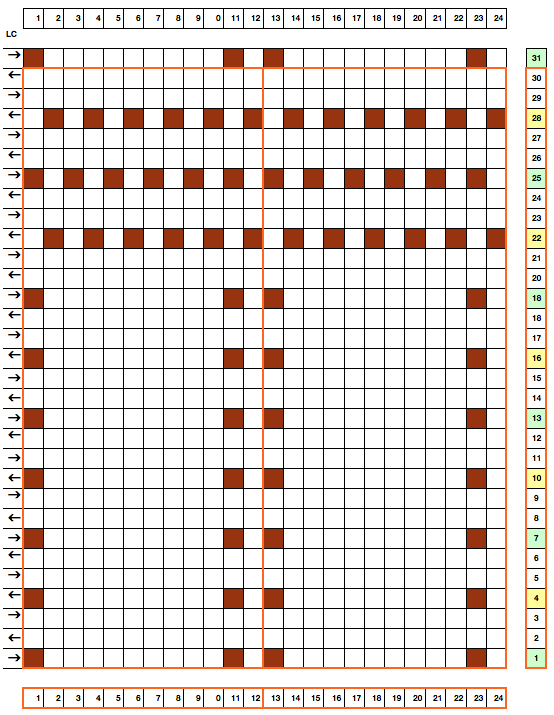

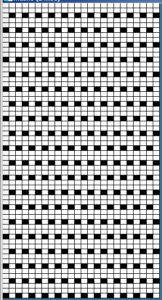

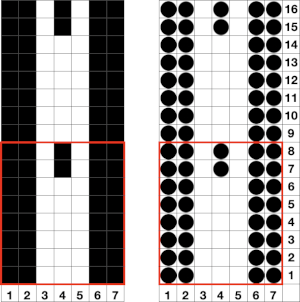

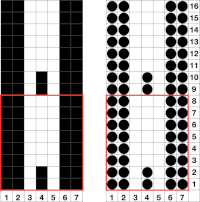

These patterns are suitable for punchcard machines. Individual repeats in excel illustrations are outlined in red. They in turn are the minimal repeat information for electronic machines. The lace carriage always begins on left, transfers are made during either 2 or 4 LC pass rows. In the first repeat below the LC operates for 4 rows, KC follows for 2 rows knit. For a fabric using it see post

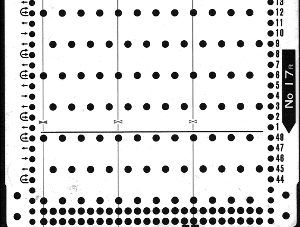

This repeat appears in my pre-punched factory basic packs as both #17 and #20. The lace carriage is used for 2 passes and then for 4 alternately, as indicated on the left side of the punchcard. The 2 passes will make transfers to the left, the 4 make transfers to the right. See previous lace posts for further info on lace selection methods and accompanying charting.

This repeat appears in my pre-punched factory basic packs as both #17 and #20. The lace carriage is used for 2 passes and then for 4 alternately, as indicated on the left side of the punchcard. The 2 passes will make transfers to the left, the 4 make transfers to the right. See previous lace posts for further info on lace selection methods and accompanying charting.

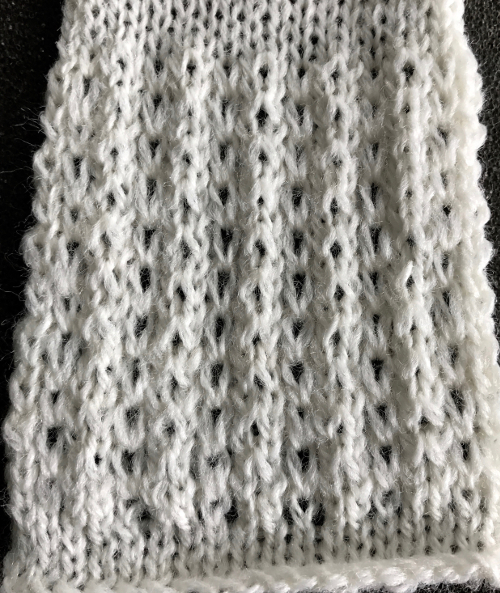

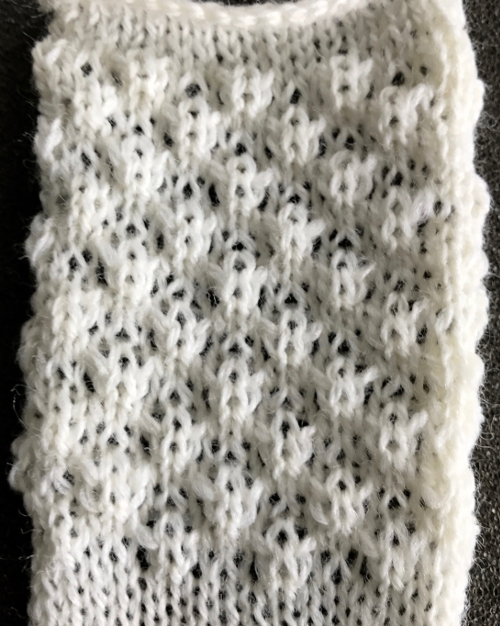

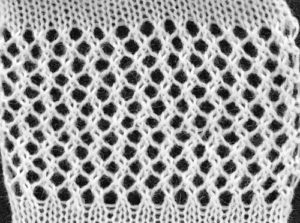

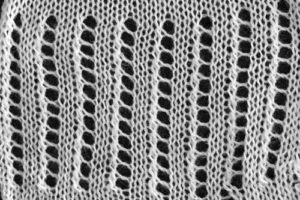

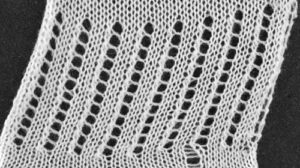

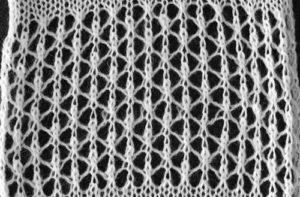

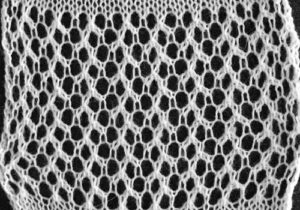

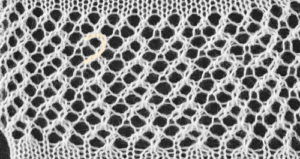

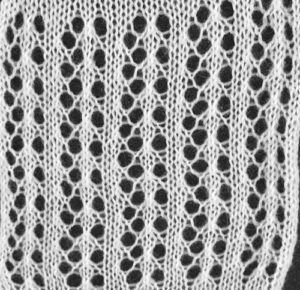

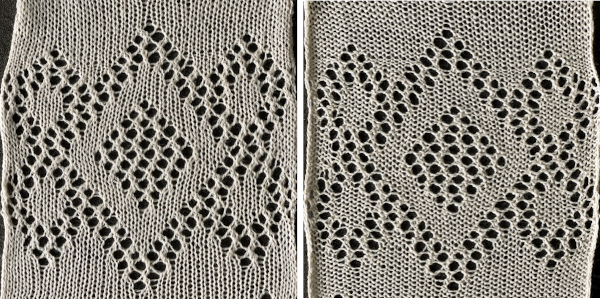

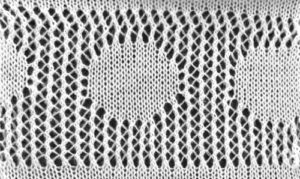

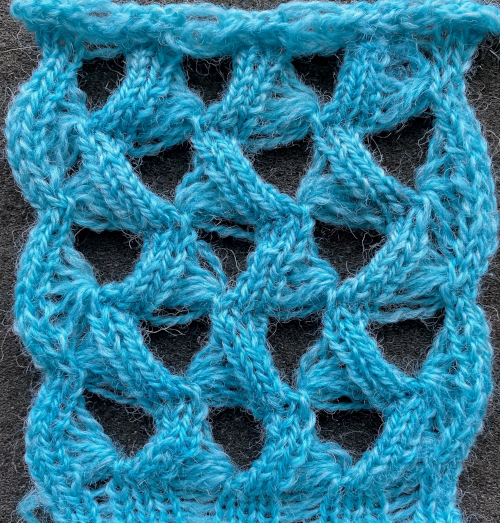

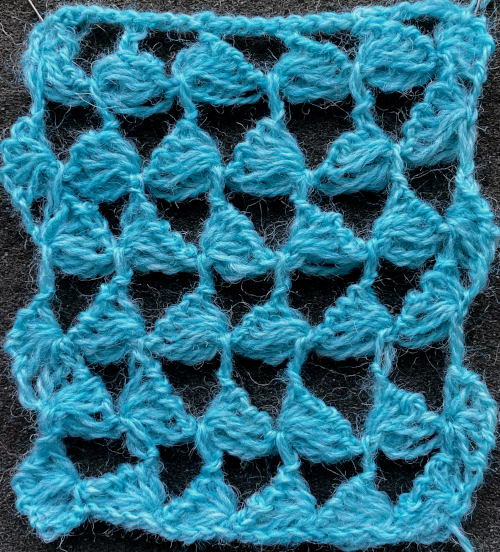

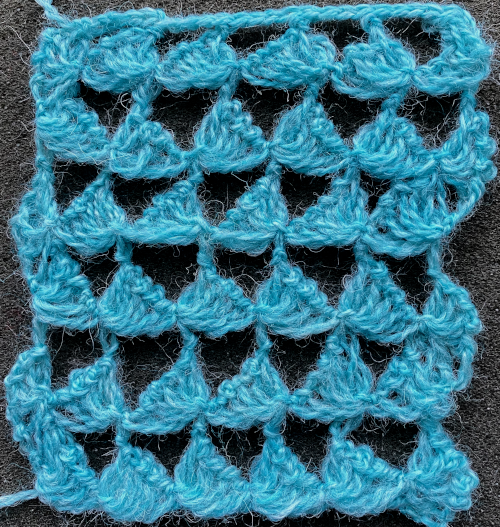

More variations and swatch photos: all patterns unless otherwise stated are knit with 4 passes of the lace carriage from left, followed by 2 rows of knitting.

More variations and swatch photos: all patterns unless otherwise stated are knit with 4 passes of the lace carriage from left, followed by 2 rows of knitting.

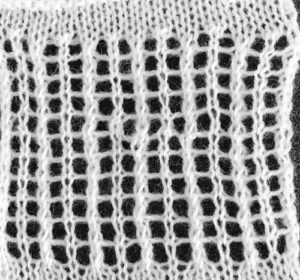

In this instance there are several vertical spaces between punched holes, creating the knit vertical stripe. The spacing can be adjusted to suit, but if “mock crochet” is the goal, superimposing an image onto every other needle mesh gives better results. It is possible to have 2 punched holes side by side on alternate rows, but not in the same row for stitches to knit properly without intervention on the next pair of all knit rows. In patterns such as the first and third below, stitches are transferred onto the adjacent needle in one direction, then both stitches are transferred back onto the previously emptied needle. The transferred stitch then sits on the front of the work (duplicating the look in hand knitting), instead of remaining on the adjacent stitch on the purl side of the fabric. With transfers in the same direction, the swatch biased after relaxing

a mylar marking error as drawn (3A)

a mylar marking error as drawn (3A)

the intended repeat (3B)

the intended repeat (3B)

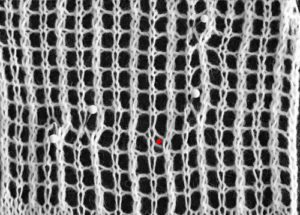

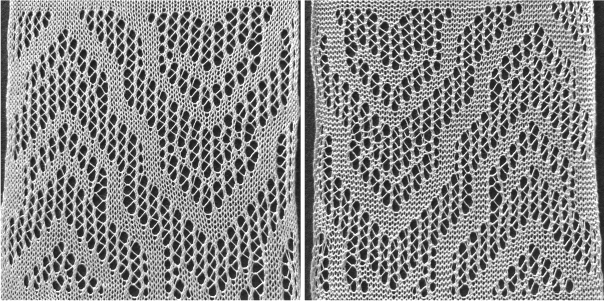

The above swatch and the one below (4) are similar, transfers occur in the opposite direction, so vertical columns of stacked stitches occur in the alternate columns of the finished fabric. I had some transfer issues in similar spots in both fabrics, have not analyzed the possible direct cause. As seen below, the dropped stitches did not result in the frequent large holes often seen in lace knitting. Pins and the red dot indicate problem spots, which could be repaired with careful stitching at the end of knitting. The best prevention of the problem is to visually check after sets of transfers to make certain all stitches have indeed been moved properly.

The above swatch and the one below (4) are similar, transfers occur in the opposite direction, so vertical columns of stacked stitches occur in the alternate columns of the finished fabric. I had some transfer issues in similar spots in both fabrics, have not analyzed the possible direct cause. As seen below, the dropped stitches did not result in the frequent large holes often seen in lace knitting. Pins and the red dot indicate problem spots, which could be repaired with careful stitching at the end of knitting. The best prevention of the problem is to visually check after sets of transfers to make certain all stitches have indeed been moved properly.

LC is used alternately for 2, and then 4 passes between knit rows (5).

LC is used alternately for 2, and then 4 passes between knit rows (5).

The transfers create a sort of “shape”, highlighted in the photo; the LC operates in sequences of 4 rows, followed by 2 rows, and repeat (6).

The transfers create a sort of “shape”, highlighted in the photo; the LC operates in sequences of 4 rows, followed by 2 rows, and repeat (6).

This one is a bit trickier, LC operates for 4 rows resulting in side by side transfers; in the first trial yarn caught up on gate pegs, dropped stitches, etc,

This one is a bit trickier, LC operates for 4 rows resulting in side by side transfers; in the first trial yarn caught up on gate pegs, dropped stitches, etc,

after reducing KC tension and adjusting the amount of weight

after reducing KC tension and adjusting the amount of weight  Mylar repeats can be very small, it is easy to be one stitch off in entering data; here one blank row was added to the left (a possibility for intentional vertical stripes of knitting) and the program was one row short on the right of the single full repeat

Mylar repeats can be very small, it is easy to be one stitch off in entering data; here one blank row was added to the left (a possibility for intentional vertical stripes of knitting) and the program was one row short on the right of the single full repeat

knit with the corrected program

knit with the corrected program  The “variations” and repeats in summary:

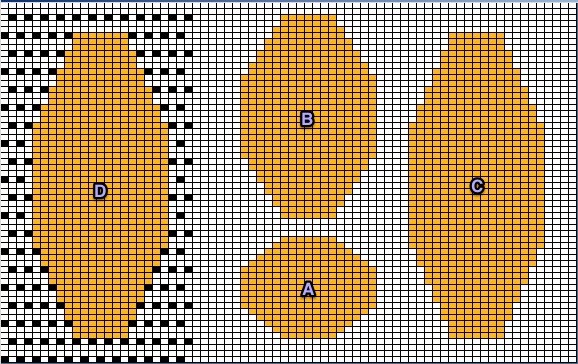

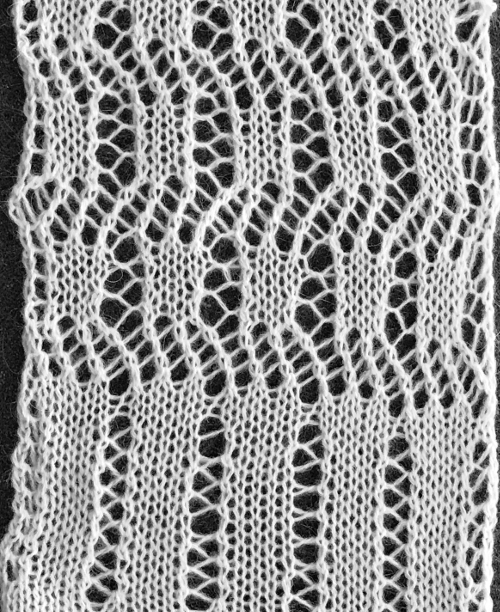

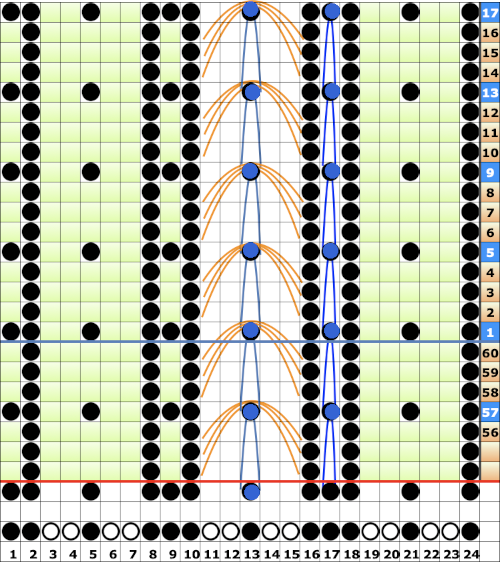

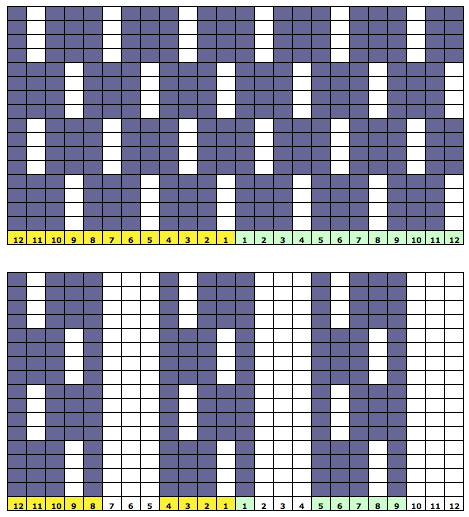

The “variations” and repeats in summary:  Adding geometric forms to mesh: a working MK chart for a cousin to the fabric link provided at the top of this post, the underlying mesh repeat is the same as that for card 17

Adding geometric forms to mesh: a working MK chart for a cousin to the fabric link provided at the top of this post, the underlying mesh repeat is the same as that for card 17

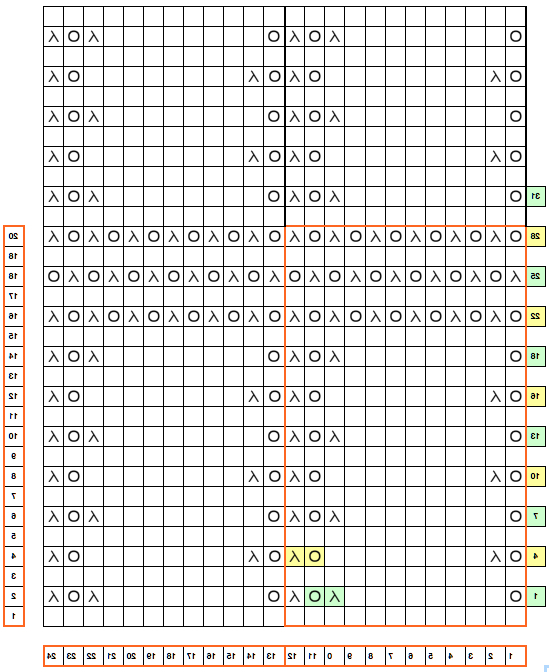

The corresponding punched holes: 2 LC passes for transfers to left (purl side), 4 LC passes for transfers to the right (purl side) throughout on Brother KM

The corresponding punched holes: 2 LC passes for transfers to left (purl side), 4 LC passes for transfers to the right (purl side) throughout on Brother KM chart flipped horizontally, suitable for hand knitting

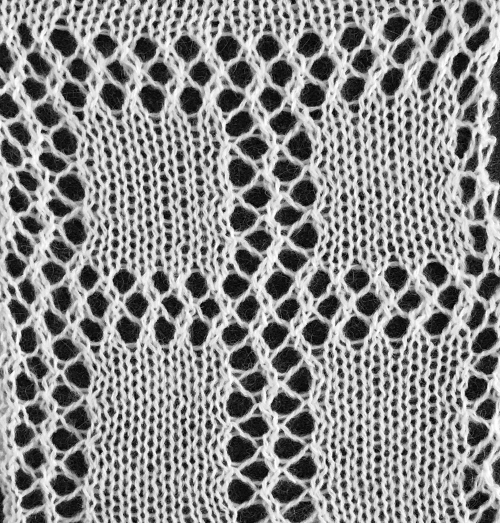

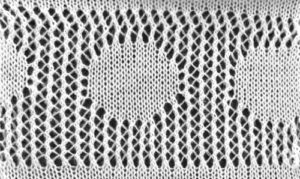

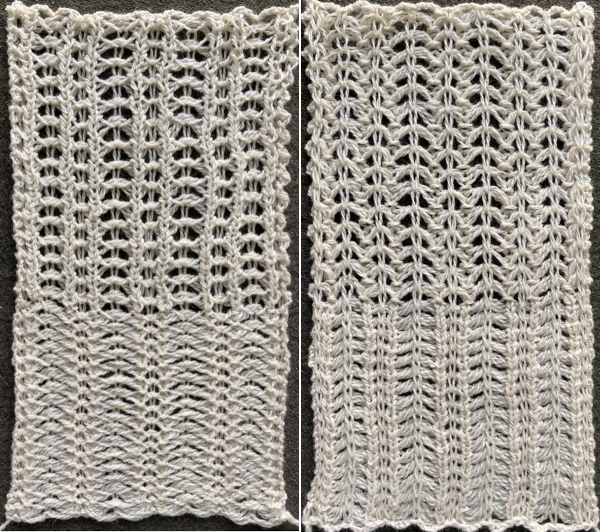

chart flipped horizontally, suitable for hand knitting  the swatch, MK, knit side

the swatch, MK, knit side  Note: the appearance of the “straight line” edges is altered by the formation of the eyelets along the sides as well as the top of the shape. As more shapes are played with, some adjustments may need to be made in punched holes after knitting a test swatch.

Note: the appearance of the “straight line” edges is altered by the formation of the eyelets along the sides as well as the top of the shape. As more shapes are played with, some adjustments may need to be made in punched holes after knitting a test swatch.

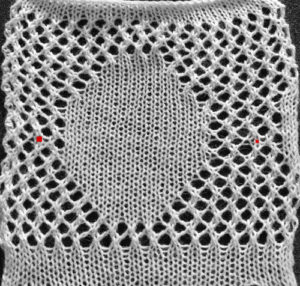

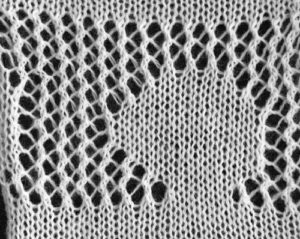

Custom shapes become a bit more complex. So I like the circle in the previous experiment, but I want to accomplish it with traditional lace transfers. I previously discussed a possible approach to filet mesh. This is the swatch where there is one row knit for each row of eyelets, discussed more recently.  Below is the result of working with a traditional mesh, where there are 2 rows of knitting to form each eyelet. The third row in the “design” on a punchcard is needed for the lace carriage to travel to its proper place for the alternating direction of transfers, which is not technically a knit row. The fabric is wider and longer than that above, and there is some elongation of the “circle”. Large patterns are mylar and punchcard real estate hogs. The swatch for slightly more than a single repeat with red dots indicating where one square in the mylar did not have a dark enough mark, resulting in a missing eyelet

Below is the result of working with a traditional mesh, where there are 2 rows of knitting to form each eyelet. The third row in the “design” on a punchcard is needed for the lace carriage to travel to its proper place for the alternating direction of transfers, which is not technically a knit row. The fabric is wider and longer than that above, and there is some elongation of the “circle”. Large patterns are mylar and punchcard real estate hogs. The swatch for slightly more than a single repeat with red dots indicating where one square in the mylar did not have a dark enough mark, resulting in a missing eyelet

A: is my desired shape 17 units by 17, B: that shape elongated X 2 (17 X 34), to try to approximate elongation with knitting 2 rows for each set of eyelets. It is drawn on a square, not a rectangular or gauge-specific grid, however, so if that is a consideration in the design, it would have to be a case of “back to the drawing board”. C: the shape is elongated X 3 (17 X 51), for placement on the mesh, and D shows it in my desired spot. Lace gauge is harder to gauge because of stretch in the final fabric, and the changes are subject to pressing and blocking depending on yarn fiber content. Because transfers in this method occur on rows 1 and 2 to the left, 3 and 4 to the right, no pure straight edges along design borders can be achieved. If simple superimposing a large shape on the mesh is possible, there may be even more distortion along those edges. Ultimately a lot of this boils down to personal preference and patience.

A: is my desired shape 17 units by 17, B: that shape elongated X 2 (17 X 34), to try to approximate elongation with knitting 2 rows for each set of eyelets. It is drawn on a square, not a rectangular or gauge-specific grid, however, so if that is a consideration in the design, it would have to be a case of “back to the drawing board”. C: the shape is elongated X 3 (17 X 51), for placement on the mesh, and D shows it in my desired spot. Lace gauge is harder to gauge because of stretch in the final fabric, and the changes are subject to pressing and blocking depending on yarn fiber content. Because transfers in this method occur on rows 1 and 2 to the left, 3 and 4 to the right, no pure straight edges along design borders can be achieved. If simple superimposing a large shape on the mesh is possible, there may be even more distortion along those edges. Ultimately a lot of this boils down to personal preference and patience.

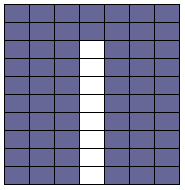

For single vertical line(s) in mesh whether single, at regular intervals, or for use in pattern transitions place repeats as shown where eyelets are desired. Markings for Brother row 1 selection on the right of the chart.  For directions on using lace mesh to create pleated skirts please see post-2017/08/16/pleats-created-with-lace-transfers/

For directions on using lace mesh to create pleated skirts please see post-2017/08/16/pleats-created-with-lace-transfers/

Unconventional uses for punchcards 2: thread lace cards for “filet” mesh

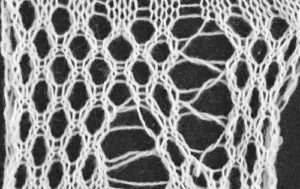

Mock filet crochet machine knit lace has surfaced in a Ravelry blog of late. The sample in question was made by Tanya Cunningham, using a hacked knitting machine and software to download the repeat. Sometimes punchcard machines or early electronic users feel left out of creating particular fabrics. If one can settle for working with simpler and far smaller repeats, however, one can achieve interesting results on that scale.

Several years ago I wrote a series of posts on lace meshes and lace patterns inspired by filet crochet. They are interspersed in the mesh category. There also has been a thread lace Ravelry “thread”, and today’s avoidance of housework led me to think about pre-drawn thread lace patterns to create a filet-like mesh.

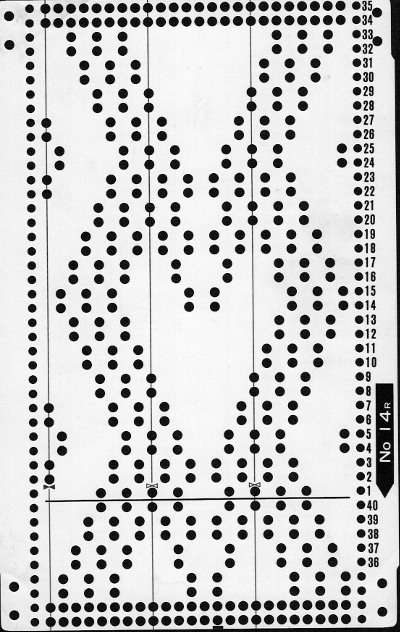

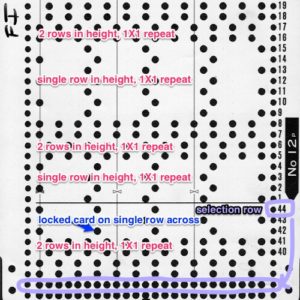

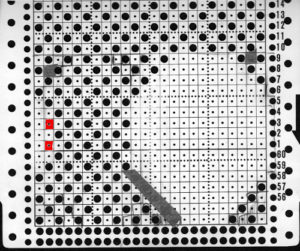

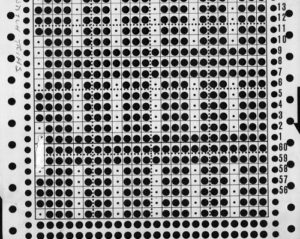

What to look for a first experiment (Brother punchcard machines only): large unpunched areas creating motifs, with no side-by-side punched holes, and no more than 2 consecutive punched rows. Some samples are provided in-stock cards that come with machine purchases. One such  The lace carriage (LC) selects on the first pass, transfers on the second. It advances the card with each pass of the carriage if it is operated consistently from the same side.

The lace carriage (LC) selects on the first pass, transfers on the second. It advances the card with each pass of the carriage if it is operated consistently from the same side.

If 2 knit carriages (KC) set to select needles for any technique are in use in punchcard machines, as one is put to rest and the other one begins to move from the opposite side, the card does not advance on the first pass, so selection for the previous row is repeated one more time.

If all lace transfers are made in the same direction the resulting fabric will bias. For balanced lace fabrics, the direction of the transfers needs to be reversed, whether in alternating series of rows or with every other set of transfers. In a situation such as this, the LC makes one set of transfers operating from the left, with the next set of transfers operating from the right.

For the correct setup, the first-row selection with the card is made on the row just below the one marked #1 (in this instance that would be row #40), then the card is set to advance as usual.

If the first selection row is made with the card set to below the #1 line, the card needs to be already joined with snaps into a drum or the card reader will be selecting the all-punched row which is normally part of the overlap that sits over the last 2 rows of the pattern repeat.

I began with my LC on the left for transfers to the left and alternately placed it on the right after knit row(s) for transfers to the right.

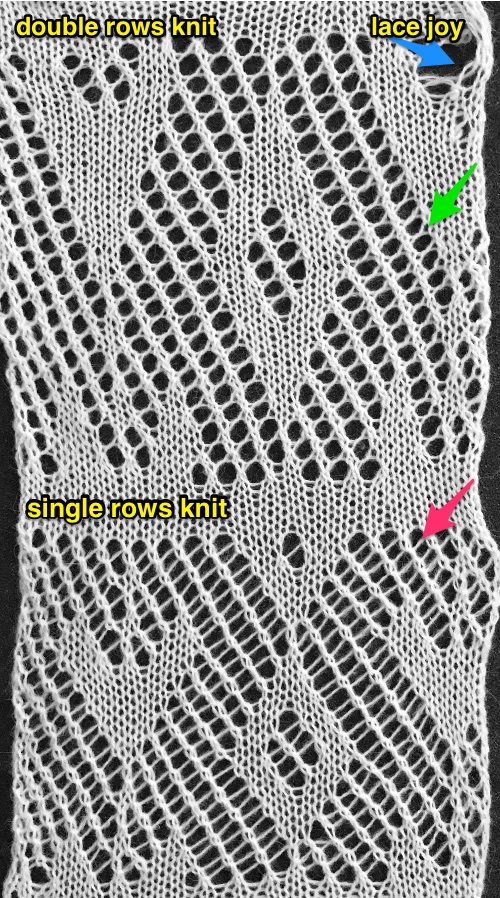

A “simple” lace is produced with only one-row knit between transfers, and a more complex lace if 2 rows are knit between them.

The LC moves left to right and transfers back to left. If the knit carriage is used for one pass only, it stays on left. The LC is now taken off the machine and moved to the right, used for 2 rows, and will be removed from the bed to ready it for its return to the left side.

The KC follows with one pass from left to right.

The LC is returned to left and operated for 2 rows, starting the sequence over again. The LC is always moving toward the KC to select, and away from it to transfer.

Brother knitters are used to knitting 2 rows after lace transfers.

It may be done with this card as well. The problem here is that when knitting for 2 rows, the knit carriage consistently returns to the same side so that when transfers need to be made from its starting side with the LC, the KC needs to come off the machine until after transfers are made.

There is a lot more juggling of carriages and keeping track of what needs to be where. The elongation that occurs with 2 rows knit after each set of transfers, and the differences in the appearance of the yarn forming the eyelets (single/magenta arrow vs crossed/glow green arrow strands) for the respective methods are shown below.  Three more candidates for experimenting with the technique.

Three more candidates for experimenting with the technique.  Working the fabric on an electronic, the repeat used:

Working the fabric on an electronic, the repeat used:  The single knit row between repeats is fairly easy and rhythmic to produce. The first preselection row is made with the lace carriage, beginning on the left, the design is used as given in the punchcard.

The single knit row between repeats is fairly easy and rhythmic to produce. The first preselection row is made with the lace carriage, beginning on the left, the design is used as given in the punchcard.

LCOL preselects for transfers to the left as it moves to the right

LCOR transfers preselected needles to the left and preselects the same needles, now empty, a good time to check for any dropped stitches or split yarn. Remove LC from the bed to place it on the right before transfers in the reverse direction

KCOR knit one row to the left, leave it there

LCOR preselects for transfer to the right as it moves to the left, transfers on its return to the right, and preselects the same needles, now empty of any yarn. Again, remove it from the bed in order to place it on the left before transfers in the reverse direction

KCOL knit one row to the right, leave it in that position

LCOL begin the sequence again

preselection with the LC is always toward the knit carriage, and transfers are always away from it  If working the same repeat as transfer lace, the knit carriage moves to and from the right with every 2 rows knit, so in order to make transfers with the LC to the right, the knit carriage needs to be moved off the needle bed for the LC to be able to operate from that side.

If working the same repeat as transfer lace, the knit carriage moves to and from the right with every 2 rows knit, so in order to make transfers with the LC to the right, the knit carriage needs to be moved off the needle bed for the LC to be able to operate from that side.

The process is a tad fiddly, if the technique is to be used for an all-over design, converting the design to the traditional transfer lace format would be worth the effort. Barring that, some sort of note-taking to serve as a reminder of which side the LC carriage should operate from is also helpful.

The BMP for the full repeat including blank rows at the top

The BMP for the full repeat including blank rows at the top ![]() Returning to another Brother punch card, more possibilities in ways to experiment

Returning to another Brother punch card, more possibilities in ways to experiment

The above shows long vertical lines of transfers are possible in design motifs (punched holes).

The above shows long vertical lines of transfers are possible in design motifs (punched holes).

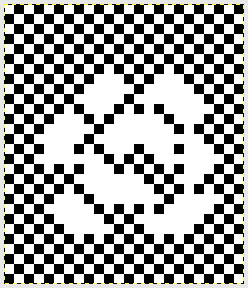

Adding shapes to all over mesh may require some editing along edges where the shapes meet the mesh. Varying size swatches are recommended before committing to any large piece.

As always punched errors may be taped over. Red squares in the image below reflect holes missing in the card if the goal is to achieve a smoother circular shape.

When this technique is used, selection, transfers, and knitting occur in each single, completed row of the design.  note the differences in circle sides

note the differences in circle sides  a wider, amended repeat

a wider, amended repeat  The slight bias zig zag at the top of the swatch results from a missing reverse direction transfer before continuing with plain knitting and binding off. Ultimately whether the final fabric is worth the effort in making it is a personal choice.

The slight bias zig zag at the top of the swatch results from a missing reverse direction transfer before continuing with plain knitting and binding off. Ultimately whether the final fabric is worth the effort in making it is a personal choice.

Sometimes small swatches work like a dream, and when large pieces are produced, problems multiply or the result is disappointing.

In the past, I have also tried to use thread lace-inspired patterns for drop stitch lace (ribber fabric), but have found the result far more subtle than expected.

As always yarn and color choice make a significant difference. The yarn used in these samples is a 2/15 wool blend, knit at tension 6.

BTW: Studio pattern books have multiple sections of published 24-stitch thread lace patterns. Not all Brother machines have the capacity for knitting this type of fabric, so not all of their publications include “suitable patterns”. If one understands what punched holes vs unpunched do, some of the Brother weaving and “pick rib” perhaps another post’s topic) can be used as-is or adapted.

punchcard http://machineknittingetc.com/pattern-library-for-punchca…

previous blog notes on thread lace 2016/11/03/thread-lace-on-brother-km/

2023 Brother electronic 930, the image is automatically mirrored

Using StitchWorld #545 ![]() Use a yarn that has previously worked well in lace transfer knitting.

Use a yarn that has previously worked well in lace transfer knitting.

On the 930, the Knit Carriage ends On the Left, after casting on. As in any standard transfer lace, it knits stocking stitch rows, does not advance the pattern.

The Lace Carriage begins On the Right, selects needles as it moves to the Left

LCOL the LC transfers to the right, slide it off the machine

KCOL the Knit Carriage makes a pass to the right, knitting a single row, stops and stays there

LCOL returned to the knit bed, the LC preselects as it moves to the right

LCOR transfers as it moves to the left, slide it off the machine

KCOR knits a single row as the carriage returns to the left and stays, knitting a single row

LCOR the LC is returned to the knit bed, preselects moving to the left and the process continues.

At times patterns are best executed with hand transfers as opposed to using the convenience of automating them. In instances such as them, begin the same way, with KCOL

LCOR make a pass toward the knit carriage, transfers stitches manually away from the lace carriage

LCOL make a pass away from the knit carriage, the same needles preselect, they should have no stitches on them now, this is a good time to check all transfers have been made properly and that there are no dropped stitches, slide LC off the machine

KCOL makes a pass to the right, knitting a single row, stops there

LCOL the LC is returned to the knit bed, preselects needles as it moves to the right, hand transfer selected needles away from the LC

LCOR the same needles will be selected on the way back to the left, and are now empty, slide the LC off the needle bed

KCOR knits a single row as it makes a pass returning the the right, and the process begins again

In both automated and hand technique, the LC always moves toward the KC, transfers are always made away from it.

The final mesh is quite different than the standard meshes produced with LC performing all selection and transfers, followed by the KC knitting 2 rows

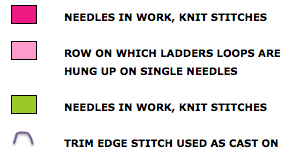

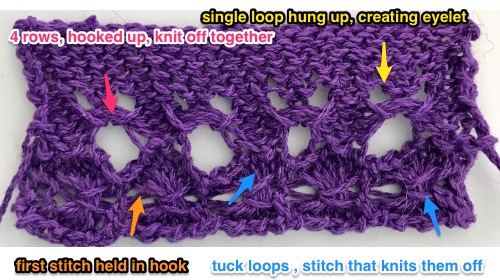

Tuck lace trims and fabrics 2

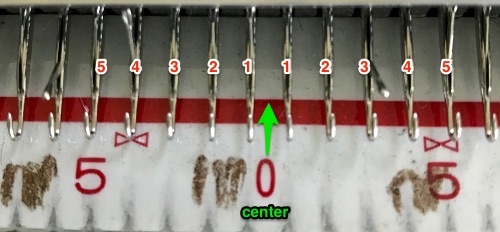

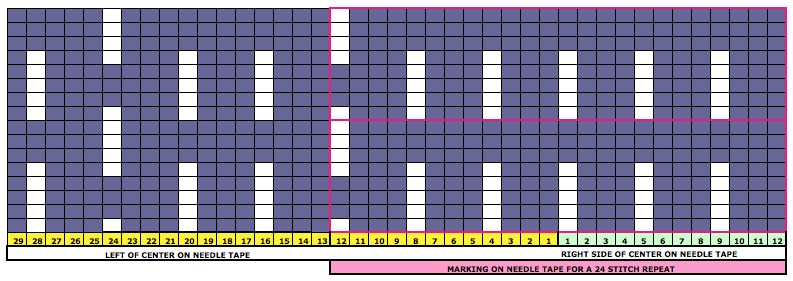

Working between electronic and punchcard machines needs to take into account that repeats on a punchcard KM must be a factor of 24 (2, 3, 4, 6, 8, 12). An electronic tuck stitch repeat may be any width.  Since the above is seven stitches wide, if punched accordingly it would occupy 21 out of 24 stitch units on a punchcard. As is unless those extra needles on the far right or left are left out of work for ladders or transferred down to the ribber, it would not be suitable for an all-over fabric. It can, however, be used for a trim. If the latter is the intent, only one series of vertical repeats as seen in the chart needs to be punched. The numbers below the image indicate Brother needle tape markings. The Brother needled tape has a center O position marking, with numbers beginning count with one and radiating out marked in groups of 5 in both directions.

Since the above is seven stitches wide, if punched accordingly it would occupy 21 out of 24 stitch units on a punchcard. As is unless those extra needles on the far right or left are left out of work for ladders or transferred down to the ribber, it would not be suitable for an all-over fabric. It can, however, be used for a trim. If the latter is the intent, only one series of vertical repeats as seen in the chart needs to be punched. The numbers below the image indicate Brother needle tape markings. The Brother needled tape has a center O position marking, with numbers beginning count with one and radiating out marked in groups of 5 in both directions.  This is a 6-row tuck fabric, thinner yarns should be used if the pattern is automated, as tuck loops build up in needle hooks. If you wish to experiment with slightly thicker yarns, decrease the unpunched areas to 4 rows, or execute the repeat using holding. Held stitches sit on top of the needle shank, tolerance is determined by how many rows it either takes for knit stitches on sides of the loops jump off needles or accumulated loops in hooks or any stitches become unable to knit off consistently on the next all knit pass.

This is a 6-row tuck fabric, thinner yarns should be used if the pattern is automated, as tuck loops build up in needle hooks. If you wish to experiment with slightly thicker yarns, decrease the unpunched areas to 4 rows, or execute the repeat using holding. Held stitches sit on top of the needle shank, tolerance is determined by how many rows it either takes for knit stitches on sides of the loops jump off needles or accumulated loops in hooks or any stitches become unable to knit off consistently on the next all knit pass.

To test the yarn and repeat out, try the technique by using holding, then punch your card. Automating makes the process less prone to error and faster if great lengths of trim are needed. It is also possible to punch or program only the part of the card that is planned for the repeat.

The single-width repeat may be programmed as pixels, on left, or punched holes on right. In electronics a single 8-row repeat is adequate, punchcard knitters repeat 5 times to 40 pattern rows punched.

The single-width repeat may be programmed as pixels, on left, or punched holes on right. In electronics a single 8-row repeat is adequate, punchcard knitters repeat 5 times to 40 pattern rows punched.  I prefer starting such designs on a knit row. To do that, the design repeat start may be shifted

I prefer starting such designs on a knit row. To do that, the design repeat start may be shifted  Using the trim as the cast on edge for a garment: determine the length required after a technique test. Knit a bit extra and remove on waste yarn, so more may be added or some be unraveled if needed or you wish to change the configuration using it as your cast on. Rehang and cast on later when it is completed. The flared-out portions of the trim will be used to “cast on” the edge of the piece, continuing with some needles out of work. An attempt at a line drawing of the “trim” sideways

Using the trim as the cast on edge for a garment: determine the length required after a technique test. Knit a bit extra and remove on waste yarn, so more may be added or some be unraveled if needed or you wish to change the configuration using it as your cast on. Rehang and cast on later when it is completed. The flared-out portions of the trim will be used to “cast on” the edge of the piece, continuing with some needles out of work. An attempt at a line drawing of the “trim” sideways  Using the curved out edge of the trim, hang half stitches if possible, or one full stitch away from its edge as illustrated below. Knit 4 rows. With a tool pick up all ladder loops created by NOOW (RC 1-4) and hang them on the center empty needle. Knit rows (RC 5, 6), hang ladder loops on still empty needles, knit across all needles, continue with garment

Using the curved out edge of the trim, hang half stitches if possible, or one full stitch away from its edge as illustrated below. Knit 4 rows. With a tool pick up all ladder loops created by NOOW (RC 1-4) and hang them on the center empty needle. Knit rows (RC 5, 6), hang ladder loops on still empty needles, knit across all needles, continue with garment

needle arrangement  picking up loops

picking up loops

The yarn used is cotton and appears to have a tendency toward biasing on knit rows as seen in the tendency to lean in one direction in the above photos. It has no stretch, so stitches that knit off several tuck loops remain elongated. A look at the structure on the purl side:

The yarn used is cotton and appears to have a tendency toward biasing on knit rows as seen in the tendency to lean in one direction in the above photos. It has no stretch, so stitches that knit off several tuck loops remain elongated. A look at the structure on the purl side:  For more trims in this family, please see later post Tuck trims 4 and other edgings

For more trims in this family, please see later post Tuck trims 4 and other edgings

In Brother knitting when needles are out of work, the automatic end needle selection may interfere with the pattern, and this is a consideration in many stitch types.

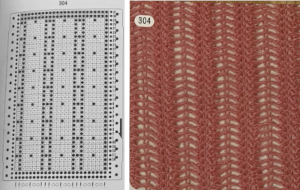

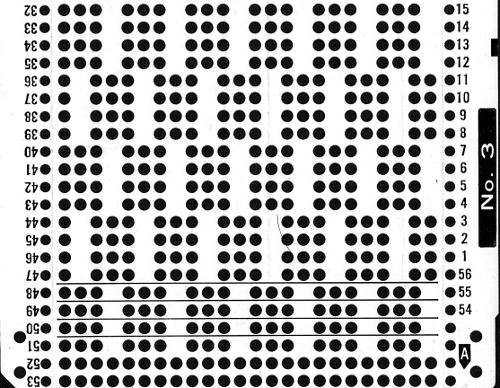

All over fabrics, analyzing a published Brother tuck lace punchcard repeat:

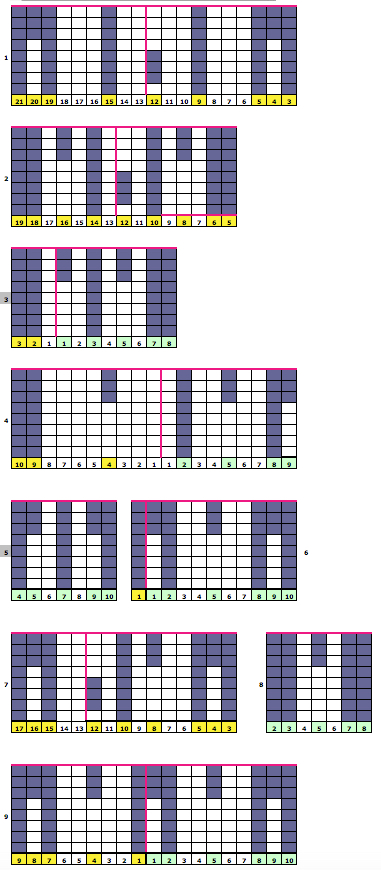

Single bed: to test the pattern, arrange the needles as shown below the full pattern repeat.

Cast on and knit a few rows, set the change knob to KCII, knit one row. Push in both tuck buttons, and knit the desired number of rows.  If using the pattern on electronic machines, the needle selection needs to match on the top bed. Depending on the model electronic, the pattern may have to be reversed for accurate needle selection.

If using the pattern on electronic machines, the needle selection needs to match on the top bed. Depending on the model electronic, the pattern may have to be reversed for accurate needle selection.

I prefer to start on a row where all needles in work are selected, providing an added visual check that indeed the proper needles are in use.

Begin with waste yarn and ravel cord, followed by a permanent cast on.

I like to use a crochet cast on and bind off, with extra chains where needles are out of work. The fabric will stretch sideways depending on the number of rows tucked as well as needle set up, so casting on and binding off needs to accommodate that stretch in finished pieces.

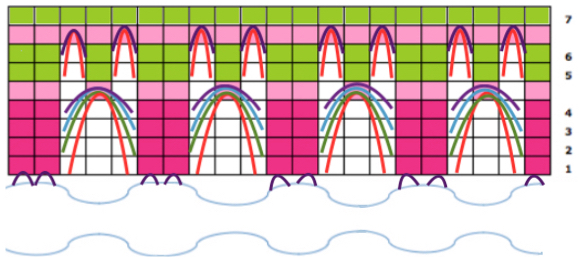

Punched holes or black pixels represent knit stitches, as always unpunched areas of the card, or white squares represent tucked rows. The knit stitch (blue) above which tuck loops (red) are formed becomes elongated for as many rows as unpunched cells or white pixels in the pattern until that same stitch is selected forward to be knit  When using card 304, tucking happens for 3 rows forming loops that span across needles out of work, then all stitches on needles on rows with numbered markings on blue cells knit for one row. Orange gradient-filled cells represent rows on which tuck loops are being formed on the held single stitches, which in turn grow in length.

When using card 304, tucking happens for 3 rows forming loops that span across needles out of work, then all stitches on needles on rows with numbered markings on blue cells knit for one row. Orange gradient-filled cells represent rows on which tuck loops are being formed on the held single stitches, which in turn grow in length.  The full 24 stitch repeat, shifted for my preference, with the smallest electronic 8 stitch repeats outlined with red border

The full 24 stitch repeat, shifted for my preference, with the smallest electronic 8 stitch repeats outlined with red border![]()

In electronic knitting, repeats may be planned across the number of needles in work based on personal preference. Here the repeat is adjusted to produce knit stitches on both sides of the swatch, 35 stitches X 16 rows.

In electronic knitting, repeats may be planned across the number of needles in work based on personal preference. Here the repeat is adjusted to produce knit stitches on both sides of the swatch, 35 stitches X 16 rows.  On the 930: the odd number of needles are automatically placed on the left, with the pattern used in the isolated design setting.

On the 930: the odd number of needles are automatically placed on the left, with the pattern used in the isolated design setting.

Air knitting the selection for the first row will bring proper needles to forward position, odd number on left, even number on right.

Unselected needles on the right and left must be taken out of work, knitting will continue on the remaining selections.  Double bed: there are a couple of options for varying the fabrics. In one, to retain the laciness of the knit transfer only stitches creating those long vertical columns on the top bed down to the ribber. In the other, any or all out-of-work needles on the main bed will be transferred down to the ribber. Hybrid combinations of both modes of transfer could explore the knit further in yet more ways.

Double bed: there are a couple of options for varying the fabrics. In one, to retain the laciness of the knit transfer only stitches creating those long vertical columns on the top bed down to the ribber. In the other, any or all out-of-work needles on the main bed will be transferred down to the ribber. Hybrid combinations of both modes of transfer could explore the knit further in yet more ways.

If casting on in rib, set half pitch lever on H, racking indicator on 5. Cast on the desired number of stitches and knit base rows.

Set half pitch lever on P, transfer stitches between beds arranging them as shown with NOOW on both beds. Set change knob to KCII, knit one row. Push in both tuck buttons on the main bed, knit in pattern for the desired number of rows.

Lately, I have been experimenting with chain or crochet cast ons and bind offs with extra chains between needles in work, and actually began my single bed swatch in pattern immediately after the cast-on row on the needles preselected in air knitting for row 1. Some weight, distributed evenly across all stitches is necessary. The main bed remains set to tuck in both directions throughout, the ribber when used is set to knit in both.

The bottom of the swatch shows the single bed fabric, the top a double bed version.

When knitting on the double bed, in this instance, the stitches where those all knit vertical columns occur on the main bed, marked with red dots, were transferred down to the ribber. Here the main bed needles, continuing in pattern, are selected forward for knitting on the next carriage pass,

Here the main bed needles, continuing in pattern, are selected forward for knitting on the next carriage pass,  here the elongated stitches and tuck loops are shown after they have been knit together on the main bed.

here the elongated stitches and tuck loops are shown after they have been knit together on the main bed.

Transferring all non-selected needles down to the ribber:

Transferring all non-selected needles down to the ribber:  the tuck loops still form on the main bed, the ribber is set to knit every needle in both directions.

the tuck loops still form on the main bed, the ribber is set to knit every needle in both directions.  The resulting knit, very different in appearance and in width than the previous sample, using the same tensions

The resulting knit, very different in appearance and in width than the previous sample, using the same tensions

For how-tos, illustrations, and swatches showing fabrics knit with all needles in work on both beds, please see post: Ribber fabrics with main bed tuck patterning 1/ pick rib

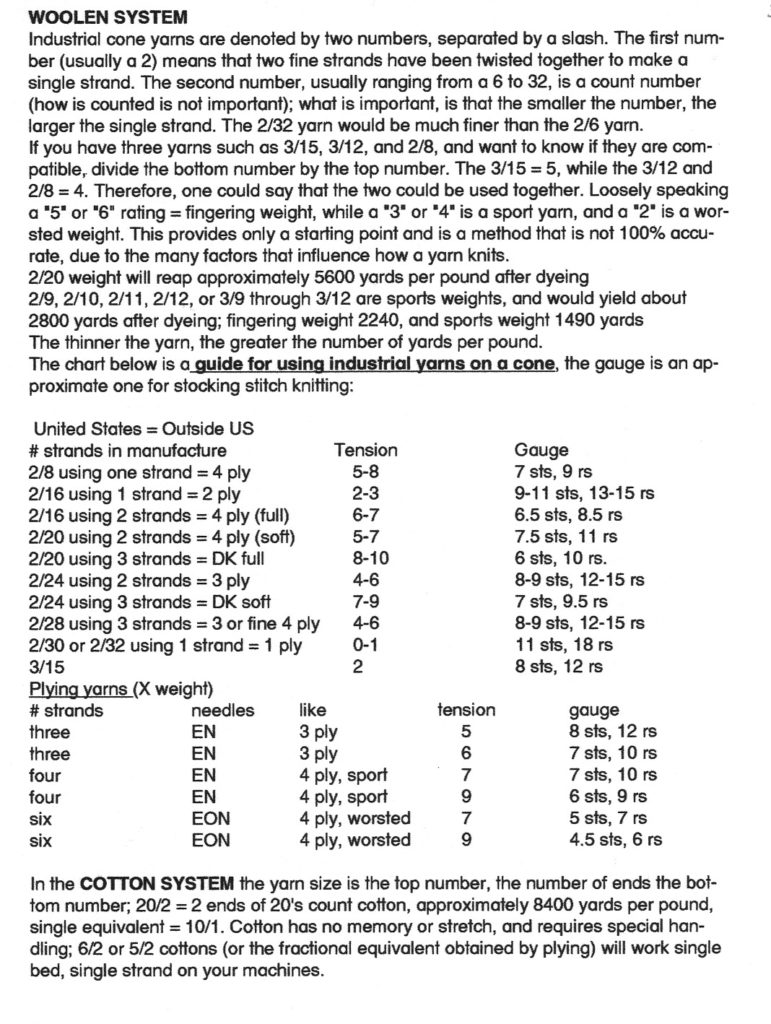

Machine knitting yarns info

More of my class notes, assembled from various sources.

Yarn thickness is determined by the number of times the standard length of yarn is spun.

The thickness number is calculated using the thickness of a single strand of spun yarn.

The number of spinnings and the number of plies (strands) produce the yarn ‘count’.

The thinner the yarn, the higher the number and the more yards to the pound.

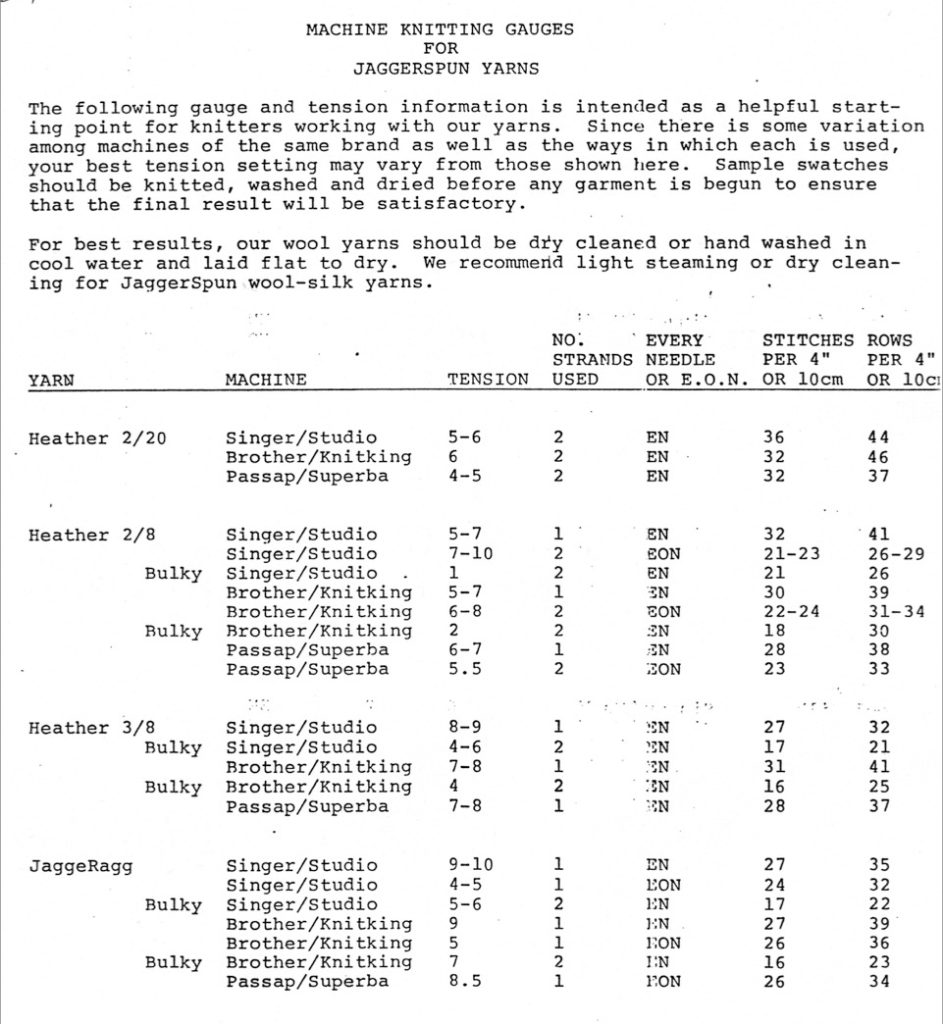

These guidelines were provided for knitting using Jaggerspun yarns. I have no affiliation with the company. I do still continue to use some of the lines and have a great appreciation for all their yarns. Their wool used to be the required fiber in my knit labs at RISD until students began to understand some of the basics in stitch construction. I have permission from the company to share content. Superfine merino and zephyr wool silk are both 2/18.

These guidelines were provided for knitting using Jaggerspun yarns. I have no affiliation with the company. I do still continue to use some of the lines and have a great appreciation for all their yarns. Their wool used to be the required fiber in my knit labs at RISD until students began to understand some of the basics in stitch construction. I have permission from the company to share content. Superfine merino and zephyr wool silk are both 2/18.

Some yardage references: 2/24 = approximately 5500 to 6700 yards per pound

Some yardage references: 2/24 = approximately 5500 to 6700 yards per pound

3/15 = approximately 2650 yards per pound

2/15 = approximately 3670 yards per pound

A few more bits:

fixed length of yarn spun from a specified weight of the material

1’s 1 spinning

1’s Yorkshire woolen 256 yards per pound

1’s linen 300 yards per pound

1’s worsted 500-560 yards per pound primary standard for wool and acrylic

1’s cotton 840 yards per pound

1’s spun silk840 yards per pound

2’s mean that twice the above length of yarn was spun from one pound of raw material

yardage reference: the first number refers to the number of plies twisted together to form the yarn, the larger the second number, the thinner the spun strand; conversely the smaller the second number, the thicker the diameter of the strand

yardage may vary with plies depending on mill and country where the yarn is spun

2/24 5500 to 6700 yards per pound

3/15 2650 yards per pound (530)

2/15 3670 yards per pound (489)

in cotton, the markings are reversed

3/2 Cotton 3 x 840 divided by 2 = 1,260 yards/pound

20/2 Cotton 20 x 840 divided by 2= 8,400 yards/pound

one standard for hand knitting yarn: gauge is per inch, not for a 10 X 10 cm or 4 X 4-inch swatch

fingering = 5 or 6, knits approximately at 8 sts/12 rows per inch

sport weight yarn = 3 or 4, knits approximately at 6 sts/8 rows per inch

worsted yarn = 2, knits approximately at 4 sts/ 6 rows per inch

3/15 machine knitting yarn: the second number by the first = 5, so this would knit at approximately the same gauge as fingering weight

stranding math

2 strands 2/24 = 4/24 = 6 = fingering weight

3 strands 2/24 = 6/24 = 4 = sport weight

4 strands 2/24 = 8/24 = 3 = heavy sport weight

5 strands 2/24 =10/24 = 2.4 = close to worsted

6 strands 2/24 =12/24 = 2 = worsted

A copyrighted Master Yarn Sett document with extensive information on a variety of fiber content from Handwoven Magazine

The American Craft Council standard yarn weight system is included in their PDF on standards and guidelines for crochet and knitting http://media.craftyarncouncil.com/files/CYC_YS_s_and_g_rev2015_6.pdf

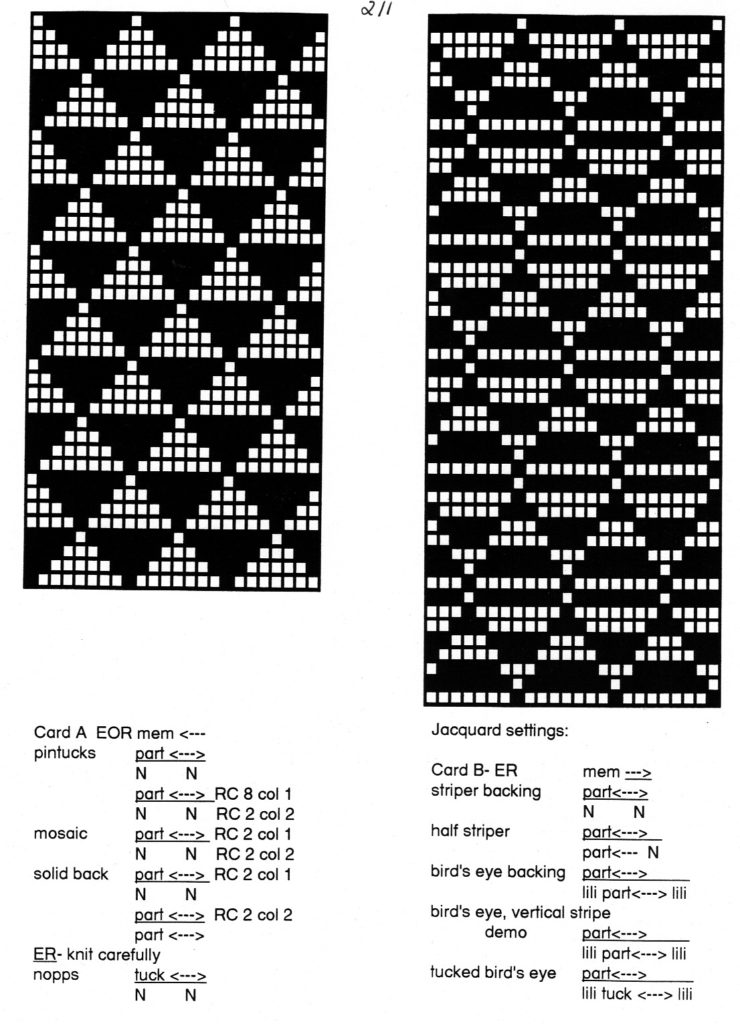

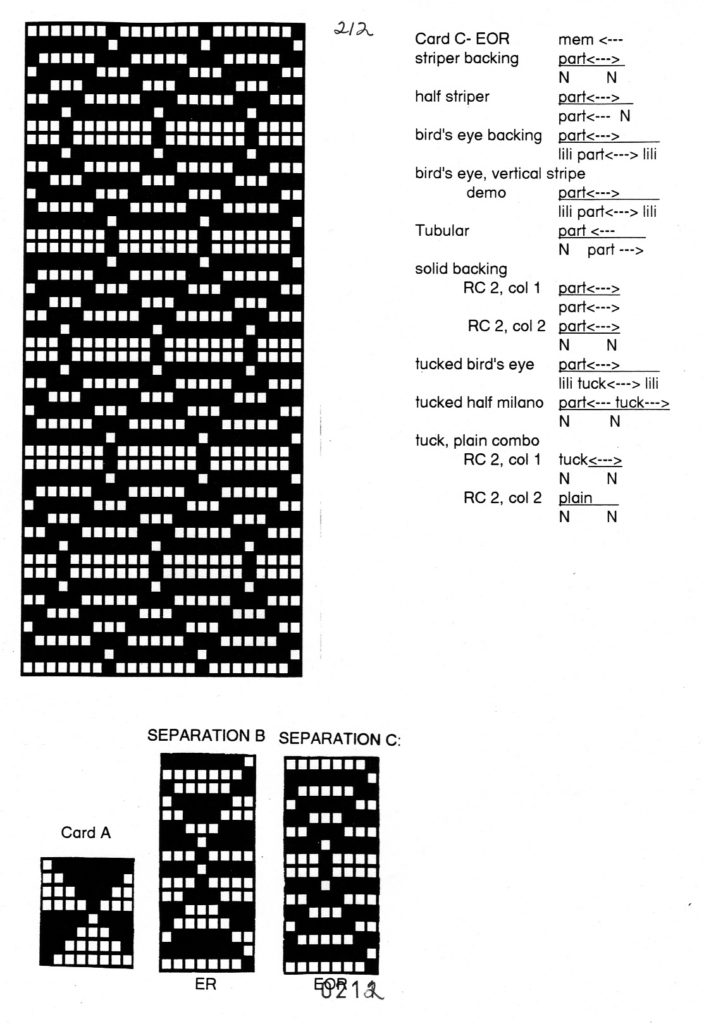

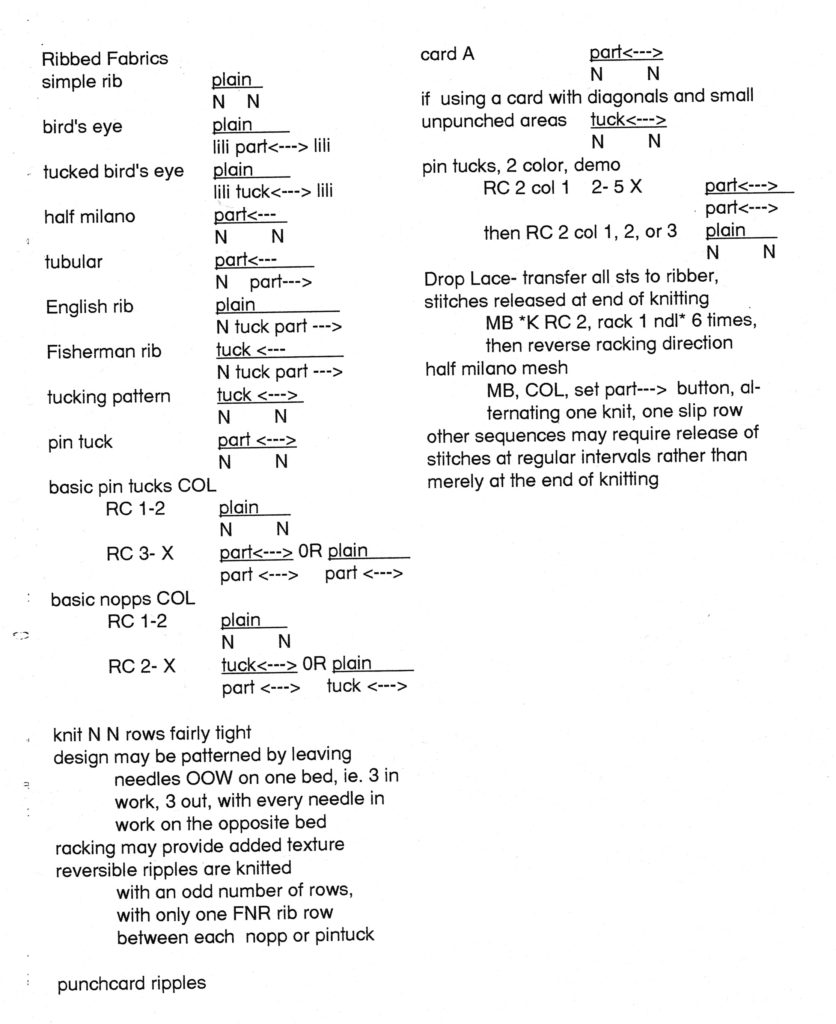

Ribber setting options Brother machine

I have been going through some of my teaching notes, assembled from a variety of sources. There are many previous posts on DBJ, including 2013/04/21/double-jacquard1/ and related swatches in 2013/04/22/double-jacquard-2/.

Here is more complete information on the pattern used and its variation details

“Crochet” meets machine knitting techniques: working with short rows 1

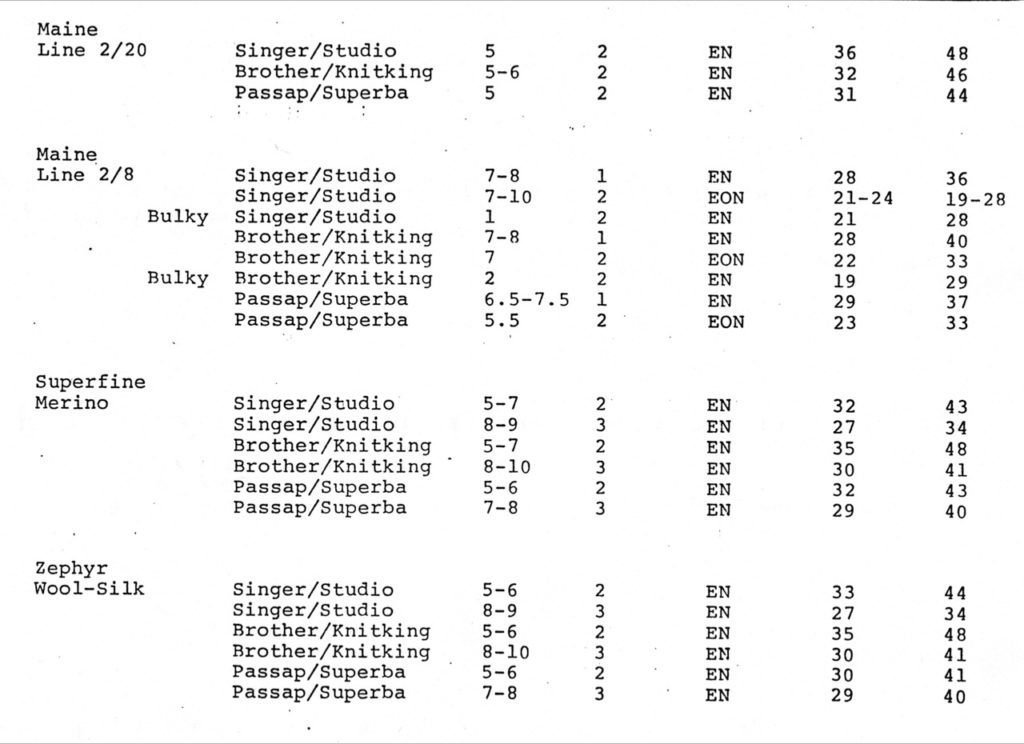

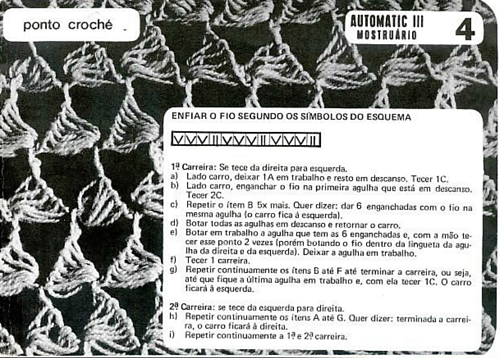

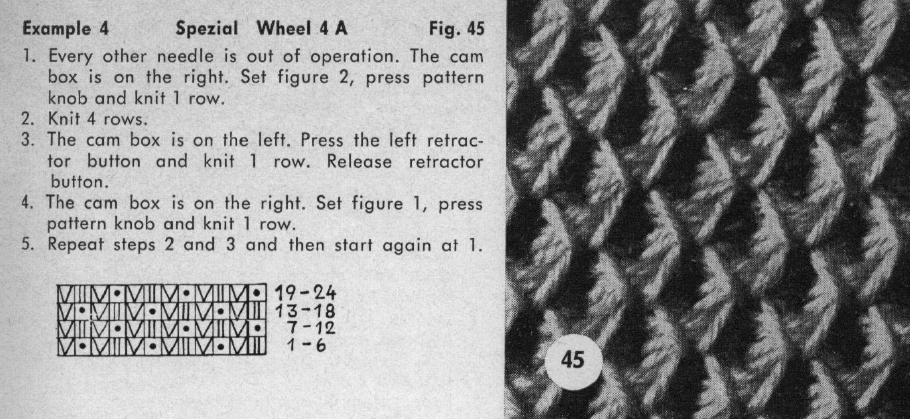

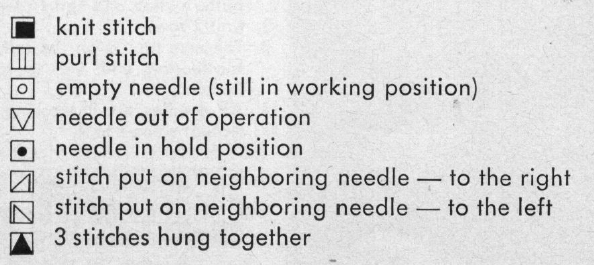

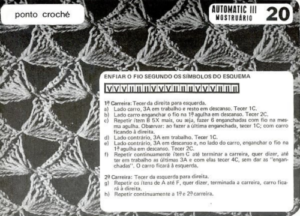

Another Ravelry thread recently looked at knitting this pattern, from an old Knittax pattern book

I found this in a different manual, with a similar structure, and “English” directions

I found this in a different manual, with a similar structure, and “English” directions  Translation of symbols used in Knittax patterns

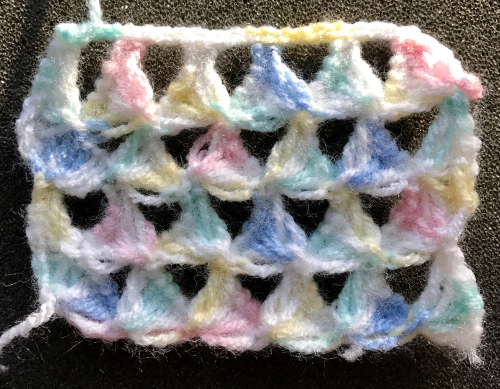

Translation of symbols used in Knittax patterns  On the purl side, this creates structures that emulate crocheted shells. My first attempts at trying to knit anything like this were in thin yarn, and I had enough issues to give up for the moment. Things worked out much better when I switched to a sport weight yarn that seemed to like knitting at T 10 for stocking stitch. With NOOW set up, my sample was knit at T 9. Waste yarn and ravel cord are often a good way to start, but not always necessary, the same is true of weight. I began with a crochet cast on, every needle, multiple of 4 st + 2, then dropped the alternate pairs of needles between the first and last 2 pairs of needles in work, pulling the needles back to A position, determining the width of my “shells”

On the purl side, this creates structures that emulate crocheted shells. My first attempts at trying to knit anything like this were in thin yarn, and I had enough issues to give up for the moment. Things worked out much better when I switched to a sport weight yarn that seemed to like knitting at T 10 for stocking stitch. With NOOW set up, my sample was knit at T 9. Waste yarn and ravel cord are often a good way to start, but not always necessary, the same is true of weight. I began with a crochet cast on, every needle, multiple of 4 st + 2, then dropped the alternate pairs of needles between the first and last 2 pairs of needles in work, pulling the needles back to A position, determining the width of my “shells”

My initial experiment was an adaptation of the concept, with more needles in work than in the inspiration photo.

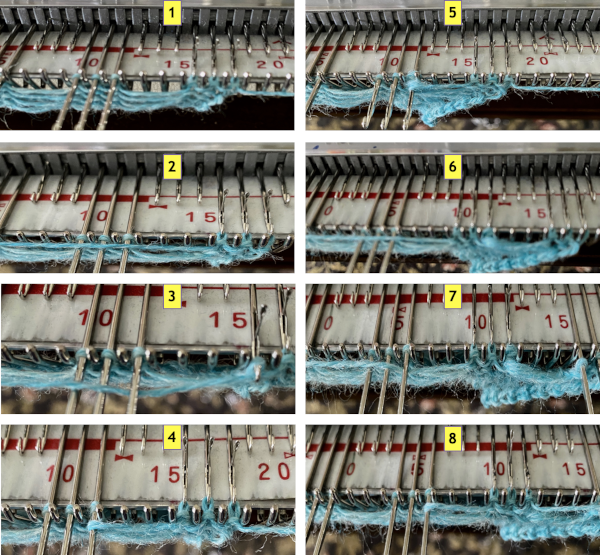

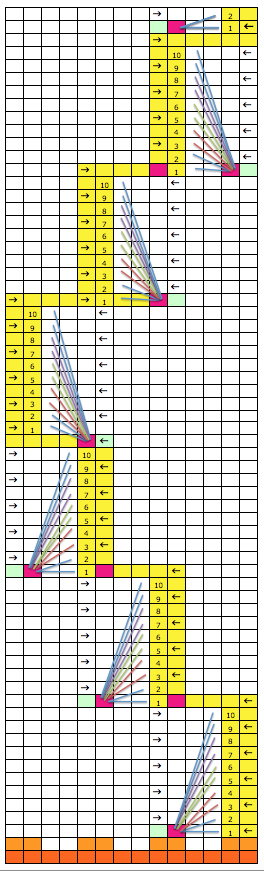

Working from right to left, starting with COR; the first pair of needles on carriage side in work, remaining needles away from carriage are in hold position  moving toward left, the adjacent needle in the first pair in hold gets wrapped; be sure to retain proper positions for knitting and holding

moving toward left, the adjacent needle in the first pair in hold gets wrapped; be sure to retain proper positions for knitting and holding  the first wrap completed, needles in position to continue

the first wrap completed, needles in position to continue  the process is repeated X number of times. I chose to wrap X 5, which requires 10 rows of knitting, making the row counter usable to track rows in easy increments. When wraps are completed, push wrapped needle and its partner into work, knit one row

the process is repeated X number of times. I chose to wrap X 5, which requires 10 rows of knitting, making the row counter usable to track rows in easy increments. When wraps are completed, push wrapped needle and its partner into work, knit one row  make certain all the loops have knit off, wrap the first needle to their left, bring pair on the right to hold

make certain all the loops have knit off, wrap the first needle to their left, bring pair on the right to hold  continue for your desired number of wraps

continue for your desired number of wraps  return wrapped needle and its partner to work position, knit one row, wrap next single needle on left

return wrapped needle and its partner to work position, knit one row, wrap next single needle on left  remember to bring needles to right of the pair just knit into hold

remember to bring needles to right of the pair just knit into hold  repeat to end of row. Reverse process moving from left to right (in progress photo). I found a single tooth from a claw weight on the pair of stitches doing all the knitting helpful.

repeat to end of row. Reverse process moving from left to right (in progress photo). I found a single tooth from a claw weight on the pair of stitches doing all the knitting helpful.

Variations can include the number of needles in and out of work, yarn choices, etc.

Variations can include the number of needles in and out of work, yarn choices, etc.  The needle arrangement to match the symbols with 3 in work, 3 out of work

The needle arrangement to match the symbols with 3 in work, 3 out of work ![]() The same steps sequence is followed as for the first swatch, using a 2/8 wool. Summarizing the beginning series of movements starting with COR

The same steps sequence is followed as for the first swatch, using a 2/8 wool. Summarizing the beginning series of movements starting with COR

The full series of patterns may be found in the Portuguese language booklet

The full series of patterns may be found in the Portuguese language booklet  The illustrated needle arrangement for #4

The illustrated needle arrangement for #4 I like to begin using a chain cast on, and then dropping chains off needles out of work

I like to begin using a chain cast on, and then dropping chains off needles out of work 1: COR, leave the first needle in work, pull the remainder out to hold, knit 1 row

1: COR, leave the first needle in work, pull the remainder out to hold, knit 1 row

2: COL, bring the thread under the first needle in hold position  3: COL, knit 2 rows, repeat 1-3 5 more times, creating a total of 5 wrapped loops, ending COL

3: COL, knit 2 rows, repeat 1-3 5 more times, creating a total of 5 wrapped loops, ending COL

4: COL, put the needle storing the wrapped threads into work, and knit this stitch by hand twice, leave it in work

5: push the adjacent needle to its left into work, the needle on its right out to hold, knit one row, ending COL

Repeat steps 2-5 The fabric shares knitting sequences with the first 2 samples

The fabric shares knitting sequences with the first 2 samples

Here a similar technique is used for a trim, both sides are shown

Here a similar technique is used for a trim, both sides are shown

trying to imagine the process in chart format

trying to imagine the process in chart format

Online inspiration:

a youtube shawl

techniques that use holding while moving across the needle bed in a similar manner, though not necessarily producing “crochet-like” fabrics: https://www.youtube.com/watch?v=XR_7Ys9KIaU&t=4s

http://postila.ru/post/29275341

A follow-up post with more fabrics inspired by the Knittax pattern book

“Crochet” meets machine knitting techniques: tuck lace trims and fabrics 1

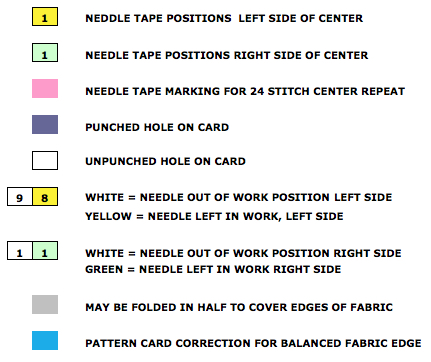

Any discussion of crochet like fabrics on home knitting machines, whether single or double bed, invariably lead to looking at gathered loops, whether created as a hand technique using holding or automated by using the tuck setting. The function of the card remains the same when cam buttons are engaged, regardless of whether knitting single or double bed. In Brother machines punched holes result in needles being selected to D position (brother has no C), those needles will knit (second color in FI, thin yarn in thread lace / B feeder). Unpunched areas remain in B position, and will tuck or slip, (color 1/A feeder FI, both yarns together in thread lace) based on cam settings. Another Brother feature is that the needle tape to help with markings for stitch counts, pattern repeats, etc. centers between 2 # 1 needle positions. This can cause some confusion when translating patterns from other makers that rely on needle position numbers only for their directions.

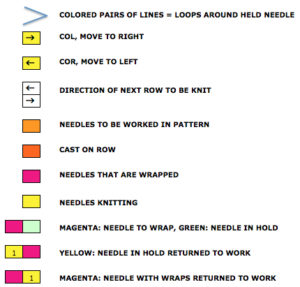

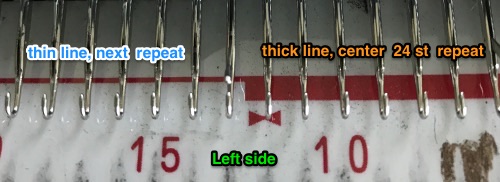

I often use punchcard designs on my electronic machines after isolating the repeat, most often for the sake of speed and convenience. Swapping out the needle tape for the electronic with one for a punchcard machine makes identifying and placing repeats easier. In Brother punchcard machines tapes the heavy solid line, followed by a thin line on alternate sides, reflects each 24 stitch repeat. Repeats on these KMs are fixed, there is no option for altering the starting position. When using electronics in some patterns, aside from the added convenience of color-reverse for minimal “drawing”, it is helpful to know that the punchcard design reflects what happens on the purl side, so letters, etc are reversed on the knit side. As a result, when translating for electronics, some patterns may also require being flipped horizontally. Using the markings on needle tape is pointless if the tape is not properly centered. Check needle “bow” mark at 100 on the left side, the last needle on that side should rest directly in its center. As the retainer bar begins to loosen a bit from wear, the tape may start shifting position, and cello tape may be needed to anchor it in place

Marking colors have varied over the years

“Trims” can be any width, from narrow to wider bands. Punching cards is enough work so that it is worthwhile to get as many functions or fabrics out of each card as possible. Various software makes it easy to check repeat tiling, or simply scan/copy the card with black paper behind it, cut it up, and cello segments together to sort out needle placement. I chart mostly in Excel, old fashioned colored pencils, and graph paperwork just fine

“Trims” can be any width, from narrow to wider bands. Punching cards is enough work so that it is worthwhile to get as many functions or fabrics out of each card as possible. Various software makes it easy to check repeat tiling, or simply scan/copy the card with black paper behind it, cut it up, and cello segments together to sort out needle placement. I chart mostly in Excel, old fashioned colored pencils, and graph paperwork just fine

self-drawn punchcard for Brother side by side repeats

side by side repeats

in this instance, left side needs some adjustment

in this instance, left side needs some adjustment

got a pre-punched card? tucks occurring for 3 rows  for an all-over pattern, or trim choosing a section of repeat

for an all-over pattern, or trim choosing a section of repeat  Studio card (use appropriate starting row for the machine)

Studio card (use appropriate starting row for the machine) same needle arrangement, tucks will now occur for 4 rows

same needle arrangement, tucks will now occur for 4 rows

Love your ribber? use any tuck lace appropriate card. Transfer any or all of the needles to be left in A position (OOW) on the main bed onto the ribber, and you will have a pattern combining knit and purl stitches. Use waste yarn, ravel cord, and ribber comb with weights through waste yarn. Cast ons and bind-offs may require planning and choice depending on yarn used and the number of rows tucking. These in turn result in a stretch in width and diminished length proportionately in the body of the finished fabric. After casting on and setting up both beds, set ribber on P (so needles on both beds are directly opposite each other) to center ribber created vertical columns between those on the opposite bed.

When more than one stitch tucks

A quick post to address another question:

Two cards that meet limitations on fabrics with side by side tuck stitches when using Japanese machines

Side by side tuck loops create floats similar to those created by slip stitch; the yarn is held in the needles however, so they are longer than those in slip stitch, which are simply not worked and travel in front of gate pegs. In Brother KM, the non selected needles tuck

In the card above left, after tucking for 2 rows, the needles are all selected forward in order to knit across the next whole row (every square punched). This is the result as needles come forward, illustrating some of the potential problems and limitations with wider or longer “tucks”