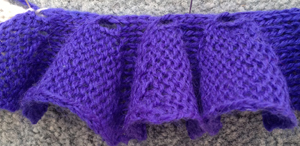

A recent MK forum request for a HK trim look alike led me to the following experiment :

the hand-knit trim

There are multiple ways to achieve knit and purl combinations on the KM. Brother garter carriage will do so “automatically” albeit slowly, ribbers may be used in combination with main beds, ladders may be latched up by hand, or one may use the garter bars to turn work over. When large widths are required the options are to use multiple panels, or to knit the fabric sideways letting the width become the length. Some HK fabrics are impractical if not impossible to duplicate on standard home knitting machines, and compromises are chosen. I tried to create a distant relative of the proposed trim, with a bit of family resemblance.

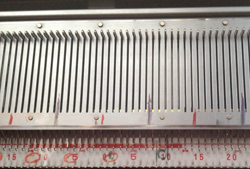

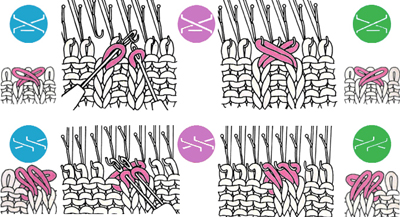

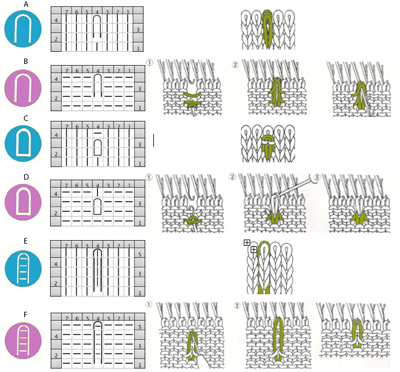

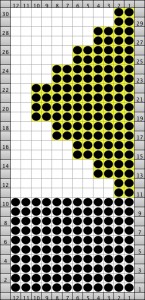

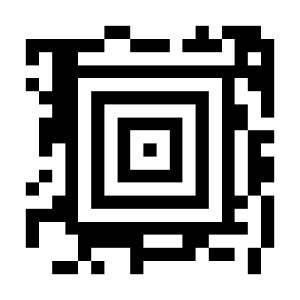

Below the short section to my garter bar is pictured. I mark every 10 eyelets with nail polish on my GBs to help with tracking stitch counts (do same with centers of ribber combs). The photo shows it in the position in which it needs to be held to take stitches off the machine prior to turning them over. The hollows under the eyelets (1) provide room for the needle hooks to slip under the yarn and catch the stitches when work is flipped over. Hollows under eyelets occur on the side with the convex ridge (2). There are many online sources for using the bars, now available in multiple gauges, including an article by Susan Guagliumi.

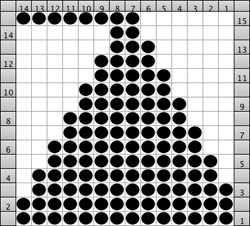

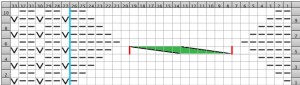

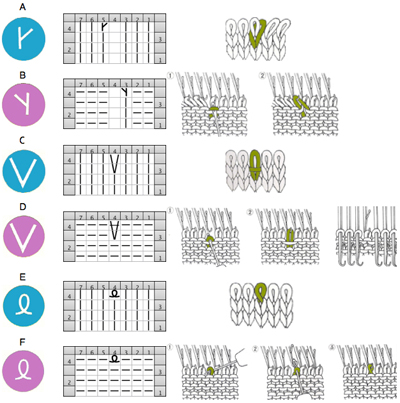

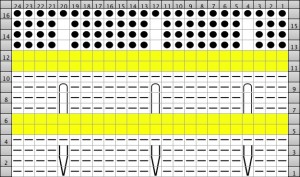

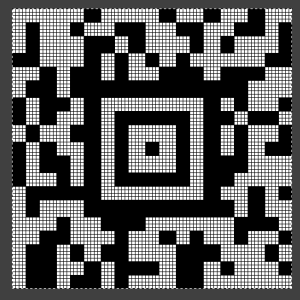

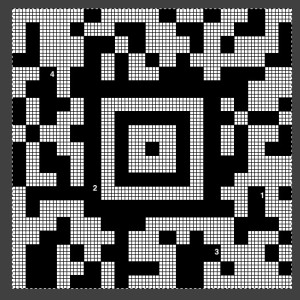

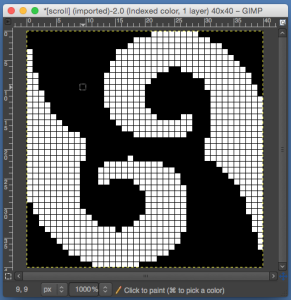

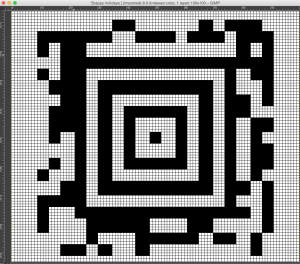

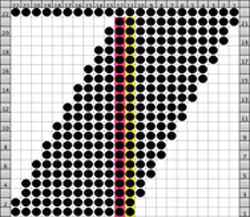

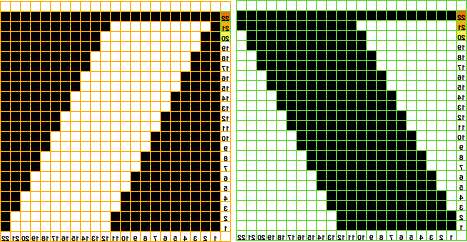

my working graph

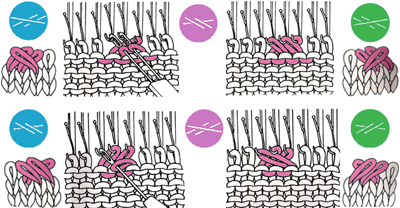

I worked my edging on multiple of 12 stitches. The purl/knit symbols represent how the knit will appear when viewed on the side where the held shape is convex. Work begins by knitting foundation rows and using waste yarn at the start with open stitches on the first row of knitting if the ruffle is to be seamed/joined at its ends upon completion. The magenta/green rows represent respective whole rows to be turned to the reverse side using the garter bar after each knitting sequence is completed. Testing first is required to establish the optimum stitch size for a gauge that will allow for easy stitch movement in transferring stitches on and off the garter bar:

arrows on the blue ground indicate the position of KC at beginning of sequences

end knitting of first “purl” section COR, turn work over (magenta)

COL: knit one row across all stitches, carriage moves to the right (pink). I find it easier after holding starts to move the carriage to the opposite side by taking it physically off the machine and leaving settings alone, results in fewer yarn tangles and problems for me.

COR: set the machine for hold except for the first 2 stitches on right. I tried one stitch at a time first, but the wedge was too deep, so I began working bringing stitches to hold 2 at a time, carriage side first. Stitches could be held opposite the carriage as well, but that created a set of additional holes when one returns to knitting those stitches in the opposite direction, and a pointy edge (segment marked with dot #2, more on a later post on miters and spirals). The number of stitches brought to hold can be varied as needed, the goal here is a symmetrical result.

COR: when only 2 needles at left are left in hold opposite carriage, knit an even number of rows (orange area, I chose to knit 4, then 6 rows in my test)

COR: when the last 2 stitches on right have been knit for 2 rows (green) transfer all the stitches to the garter bar

Get carriage to left, COL: return stitches to needles, knit for an odd number of rows (magenta, COR), turn work over

COL: knit one row across all stitches to right (pink)

COR: begin holding sequence again

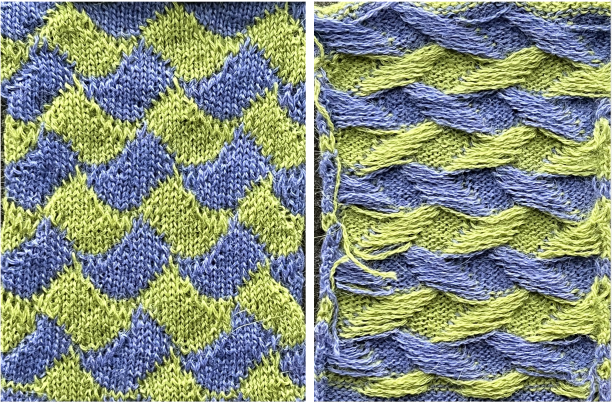

I began the sample with 5 rows in between the mitered shapes and then tried 11. This is labor-intensive if produced in significant lengths, so a choice can be made depending on personal taste and patience. Though it could be attached as one knits the item it is intended to trim, there is enough going on I would probably estimate the length, take it off on waste yarn, and hang it onto the larger item. If longer, the trim may be unraveled to suit. If an addition is required it may be added on but at least working with the much larger bulk of materials will not be for the duration. Holding lever may be set to knit for single passes prior to turning work over in sections using holding, or stitches may be pushed into work by hand.

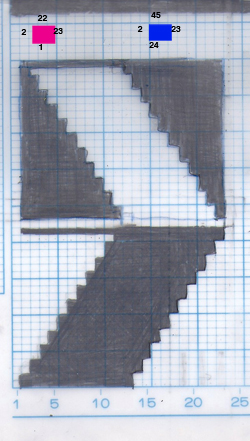

dot 1 rests on “killed acrylic” repeat test, the remaining sample is knit in wool: dot 2 marks the extra holes when the holding sequence is changed as described above

with five “purl” rows between turning and holding

11 “purl” rows between turning and holding

the reverse side

about half the wool portion of the ruffle was pressed, the knit became smoother, the edges less rolled. Those are properties that can become a design choice/decision

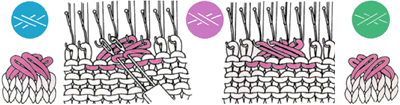

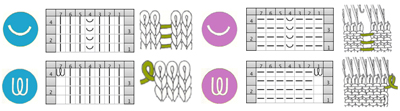

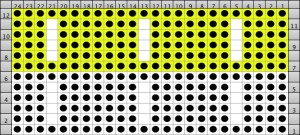

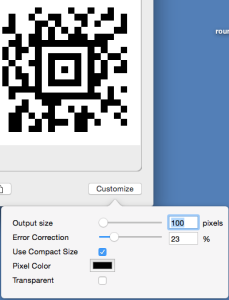

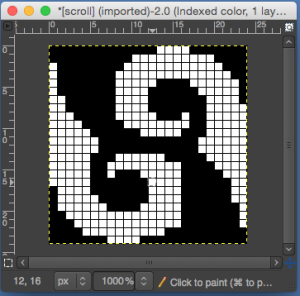

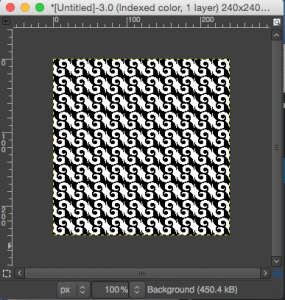

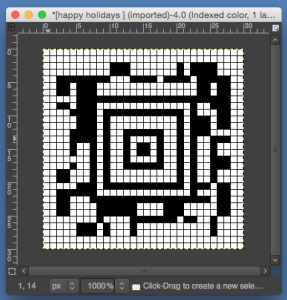

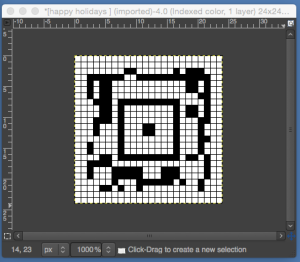

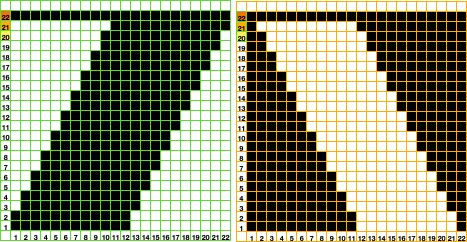

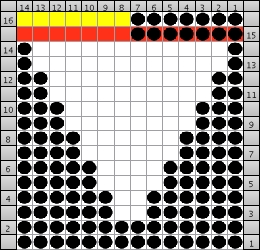

If an all stocking stitch ruffle serves the purpose this could be the start of the working repeat for using slip stitch to knit programmed needles selected to patterning position; here the black dots represent areas that knit, white squares stitches in holding. The repeat must be an even number of rows, using it as drawn, the starting side depends on whether one is using a punchcard machine or electronics

…

For some hints on how to use the garter bar see later post

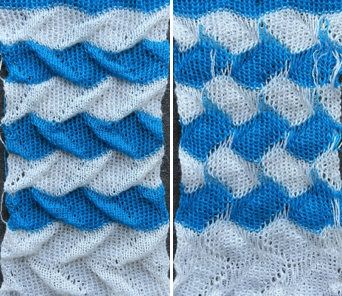

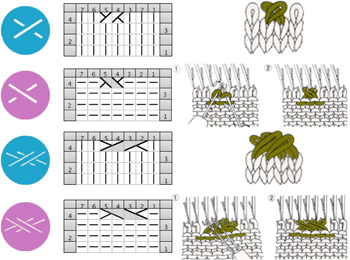

The execution was in a brick configuration

The execution was in a brick configuration