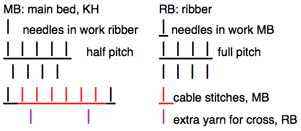

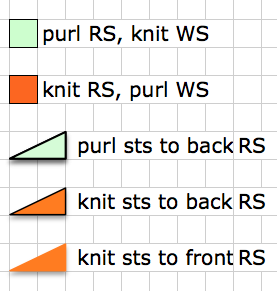

Using two beds is the obvious means of creating a purl ground in combination with your cables, it will be addressed in later posts. If you are trying to cable more than 4 stitches on the main bed, using the ribber to provide extra yarn for the cross over may solve problems in accomplishing the cross. The ribber needs to be set at half-pitch the row before the cables. Needles on the ribber are kept out of work until that row, pushed up to work position, and the row is knit. The loops formed on those needles are then dropped off, the ribber needles are put out of work, and the cables are crossed. The main bed knits until the next row before the cable crossings are once again due. I have recently begun to use water-soluble markers to mark needles positions on metal beds clearly for help in keeping track of locations for specific manipulations.

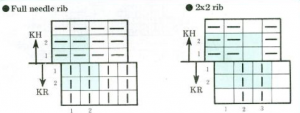

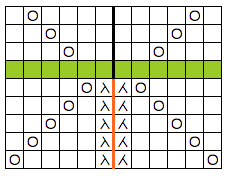

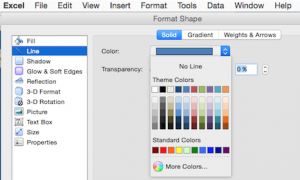

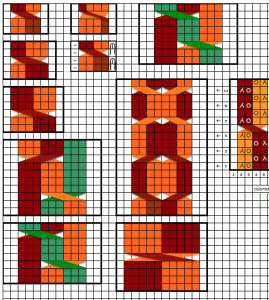

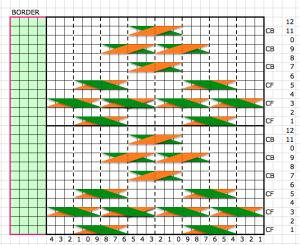

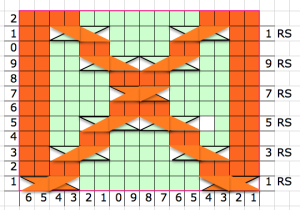

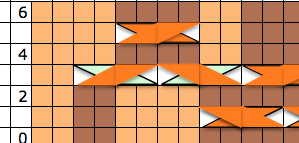

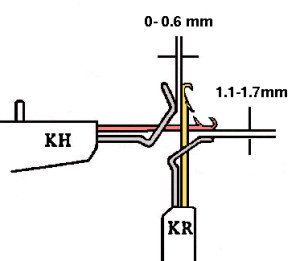

An illustration of 2 (or more) possible places to pick up extra yarn for a 6 stitch cable cross

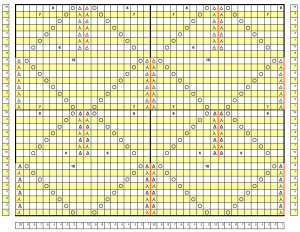

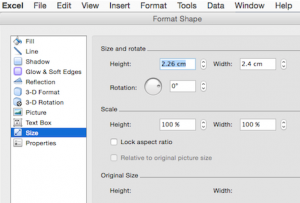

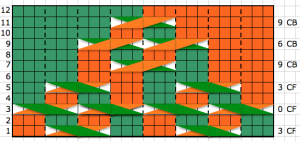

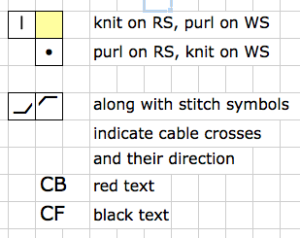

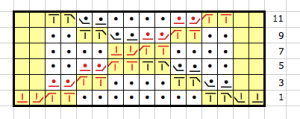

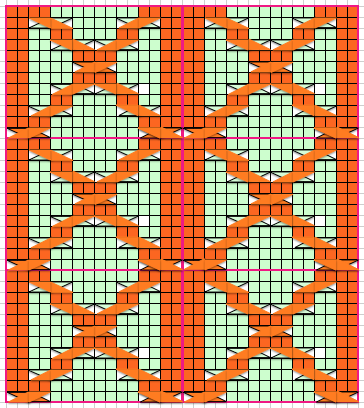

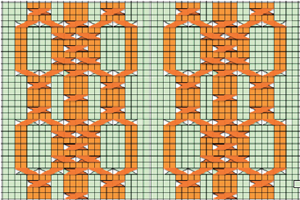

Below is a revision of a punchcard used in a previous post to track crossings for 3X3 cables, with punched holes added, taking into consideration locations for picking up extra yarn on the ribber. After 2 needles are selected on the main bed, one needle on the ribber on either side of them is brought into work. As the carriages knit across, the ribber needles pick up loops, while 6 needles are selected indicating the location of the cable cross on the next row. Ribber loops are dropped, and the needles creating them are returned to out of work position. The cable stitches are then crossed, and knitting resumes, continuing until needle selection once again indicates that an action is required.

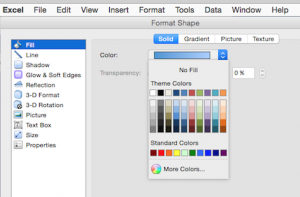

An alternative solution: reverse the beds, with the ribber doing the knitting. A card may then be drawn to select needles for picking up those extra loops, now on the main bed. The knit carriage is set to slip throughout. Punched holes (or programmed pixels in downloads, black squares in mylars) will preselect in Brother KMs, not only keeping the needle selection error-free but also tracking rows knit between cable crosses being made. Brother ribbers tend to knit more tightly than main beds, so tensions will require adjustment as well. With a bit of planning ahead and doing some “air” knitting, all needles not involved in picking up the extra yarn may be noted and placed out of work. Only the needles for selection will remain in work, thus making it easier to drop the loops formed on them during knitting.

This method allows for creating the cables while retaining a somewhat tighter tension. Since the ribber carriage has no wheels or brushes to help hold the knit in place, weight must be used. Too much of it will lead to more frequently dropped stitches. It is always good to bring cable group stitches out to holding (E) in order to visually check that transfers have occurred properly, and that there are no dropped stitches before continuing to knit.

…

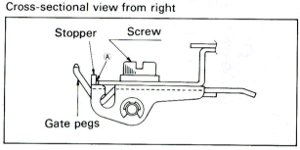

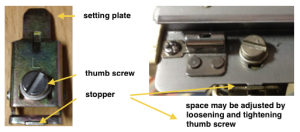

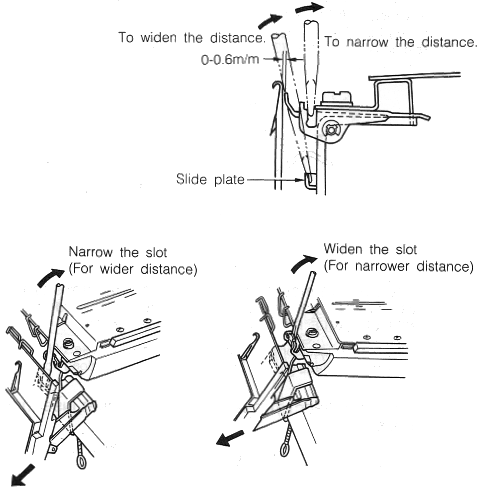

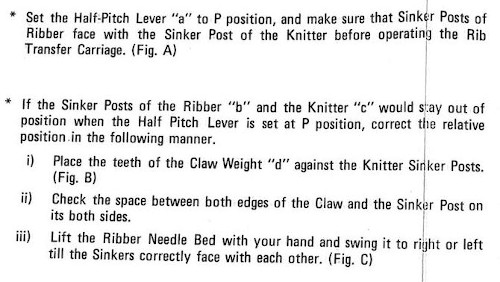

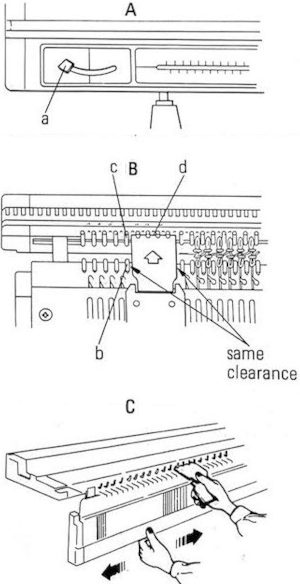

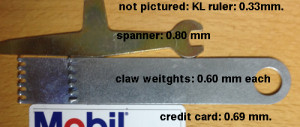

To check the height of the ribber: pitch lever on H, bring it to the full up position (Brother has 2 up positions), and bring forward at least 10 needles at each end of the main bed. Use spacers ie. a credit card, or claw weight hangers that came with ribber as measuring aides; they should slip easily between main bed needles and ribber gate pegs, the recommended distance between the back of the KR needles and the KH gate pegs is 0-0.6 mm.

To check the height of the ribber: pitch lever on H, bring it to the full up position (Brother has 2 up positions), and bring forward at least 10 needles at each end of the main bed. Use spacers ie. a credit card, or claw weight hangers that came with ribber as measuring aides; they should slip easily between main bed needles and ribber gate pegs, the recommended distance between the back of the KR needles and the KH gate pegs is 0-0.6 mm.

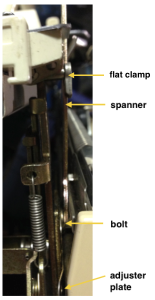

Brother bulky on top of the standard clamp, its shorter cousin

Brother bulky on top of the standard clamp, its shorter cousin