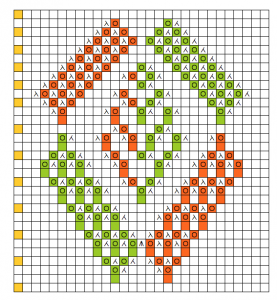

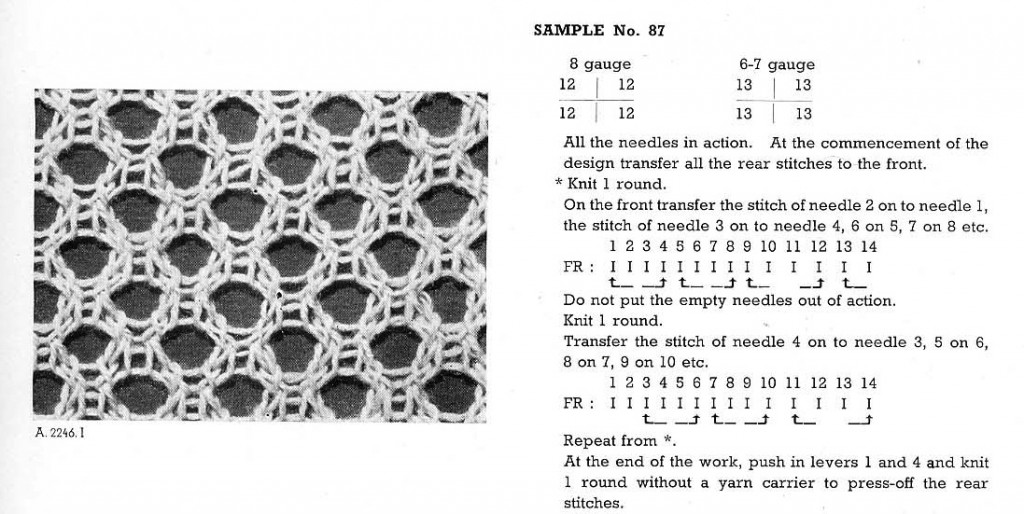

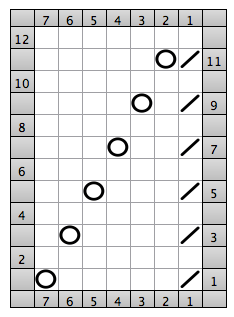

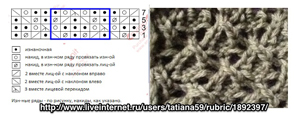

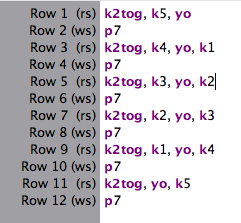

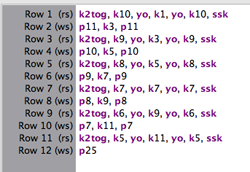

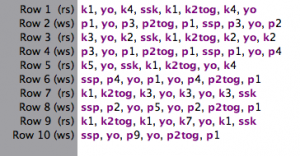

I recently saw a semi circular HK shawl pattern that used graduated lace shell motif bands, and went hunting for a possible such repeat with the intent of subsequently knitting it on the machine. Taking into consideration the chart lenght required if using the lace carriage, I began with a “small” hand knit possible repeat

the text (Intwined)

the text (Intwined)

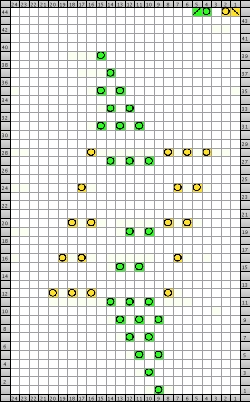

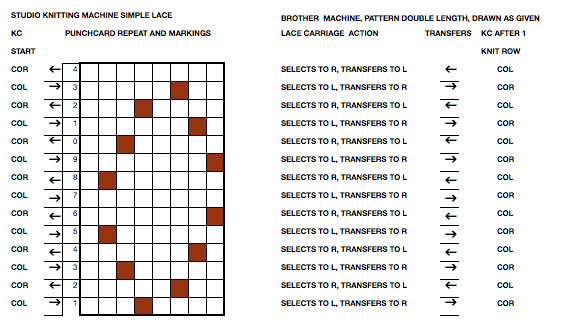

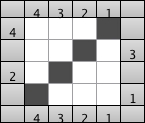

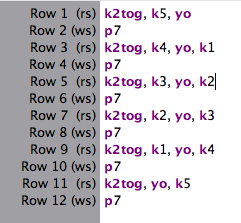

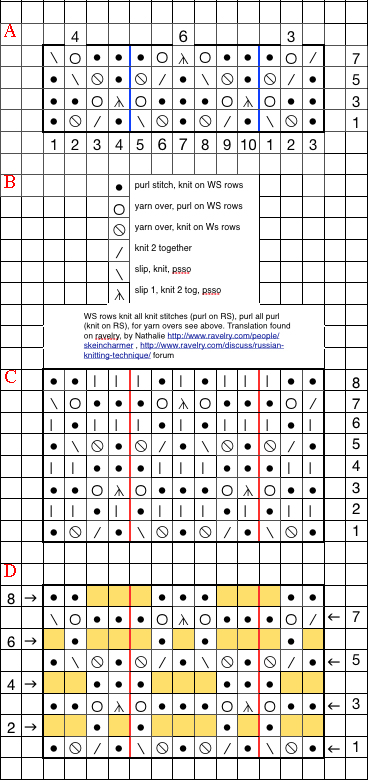

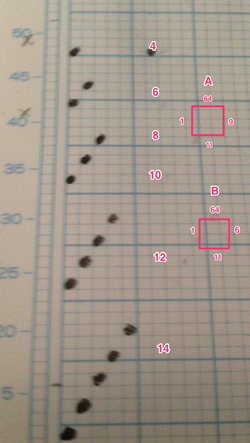

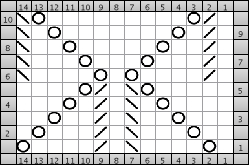

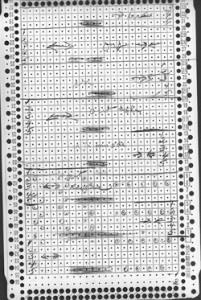

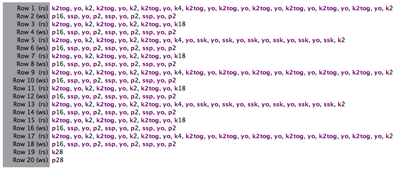

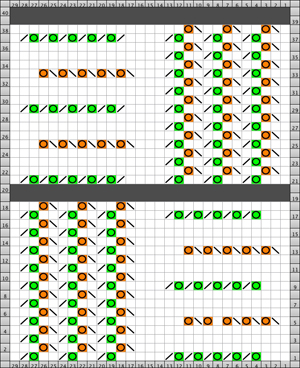

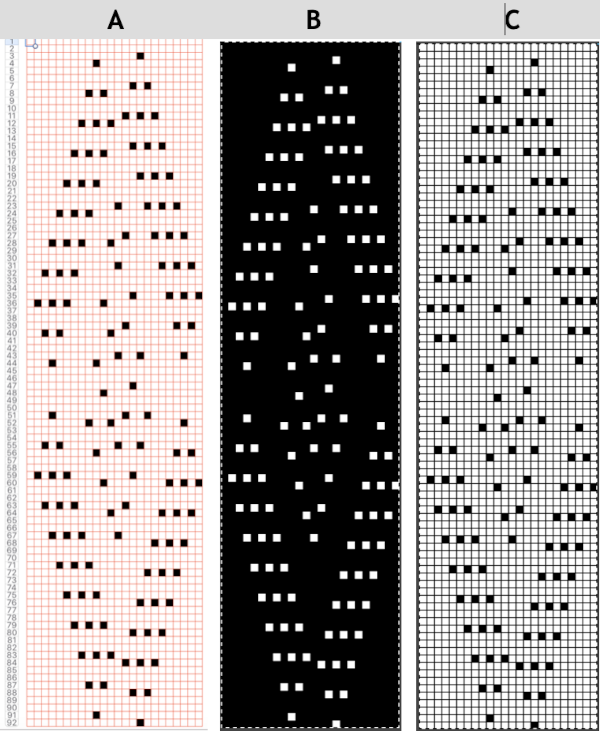

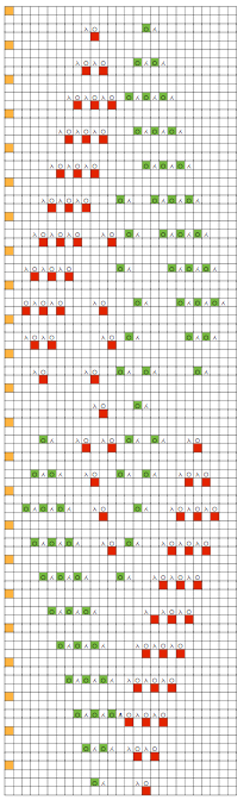

pictured below is a mylar repeat worked out for use with the lace carriage with 2 programming options: A, B. Notations in this instance were made using a free mac program (for my the first time), Skitch, which allows one to work with screenshots and basic image-editing tools all in one place. The middle column of numbers indicate the number of passes required for the lace carriage for each repeat prior to pairs of rows of plain knitting. The transfers are made all in one direction, so the spacing between each set of transfers and knit rows is different from the traditional 2 rows of blanks. I find it easier to have multiple blank rows before selections for transfers as a place to pause, check my stitches, and have clearer starts if knitting needs to be unravelled; this repeat takes that into consideration

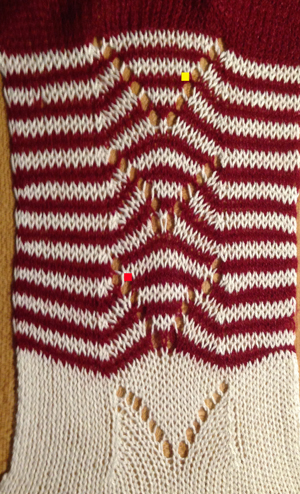

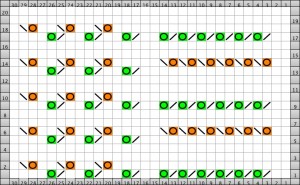

option A was knit with a ladder, NOOW set up:

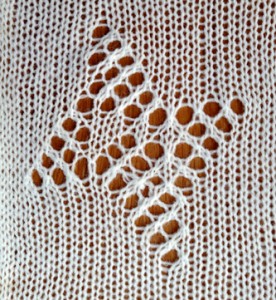

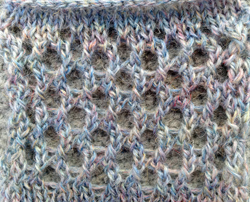

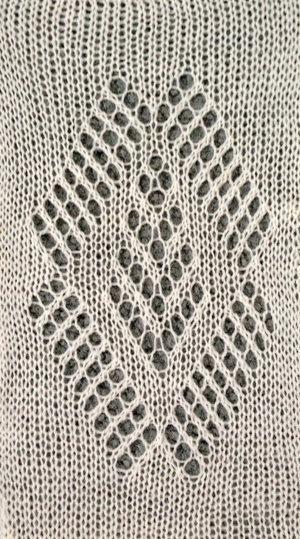

the resulting swatch in acrylic yarn, steamed, fairly straight edges

option B eliminates the ladders, a ridge is created by the transfers highlighting the “shell shape”. The sample clearly illustrates the issue with lace fabrics where transfers are all in one direction: note the resulting bias, which could be a problem or a design feature, depending on one’s perspective. It is particularly noticeable in the area of the color change. The top yarn is a rayon, the ridge created by the transfers flattened with pressing but is still in evidence, the occasional noticeable problems are operator errors (and laziness in changing bent needles), not pattern ones.

shortening the repeat: I found this one a bit more confusing to follow, black horizontal marks on right edge of mylar are a visual cue to rows on which knitting needs to occur; note there are no occurrences of 2 consecutive blank rows, only singles

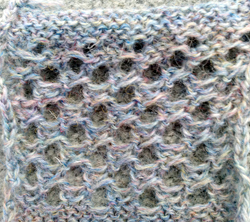

the fabric is identical, with the same problems in terms of biasing

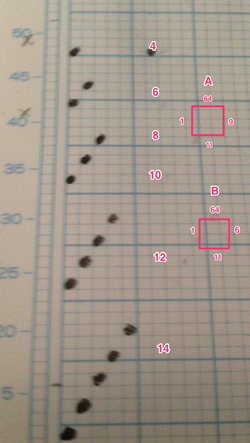

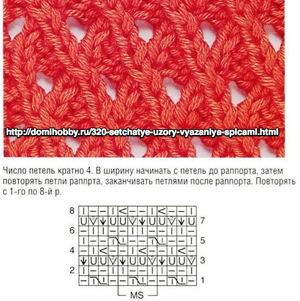

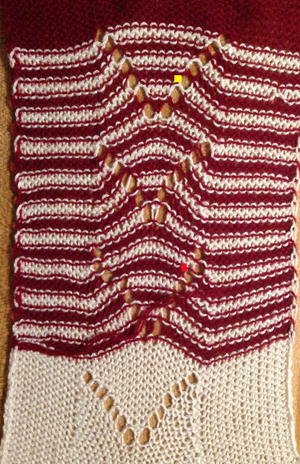

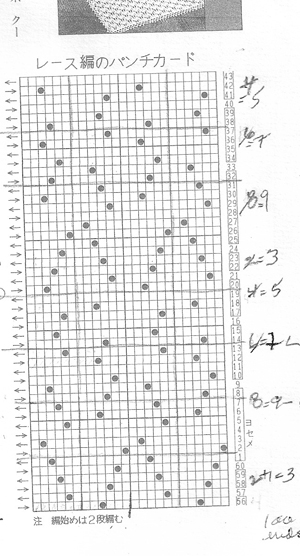

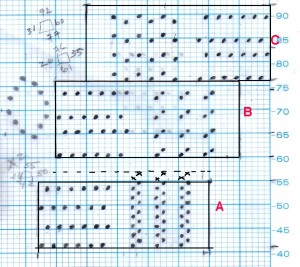

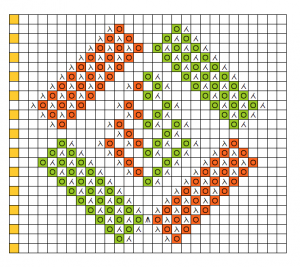

taking out the swing, moving in 2 directions, and back to a hand technique: the black squares indicate groups of stitches that will be moved to create lace holes. In the boottom segment selected needles are transferred to the right, lace holes will move in a curve, transfers double up on the same needle location on the bed. In the top segment, beginning with the doubled up stitch from the last transfer to right, direction of transfers is reversed, moving toward left, and always beginning with the same needle position. Markings on mylar on the far right indicate direction in which the stitches are transferred. This repeat is 7 stitches wide by 12 rows in height, could be adjusted to suit. Adjustable transfer tools make the work progress faster.

the corresponding swatch, without blocking, much more “straight”

4/11

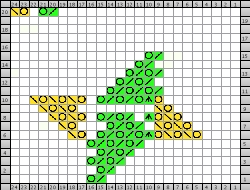

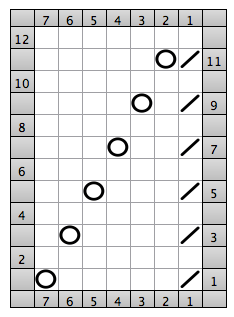

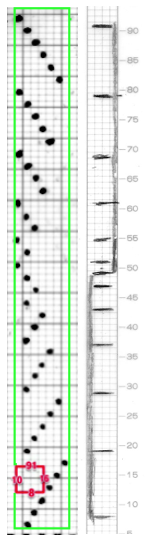

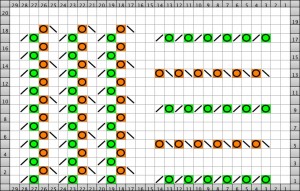

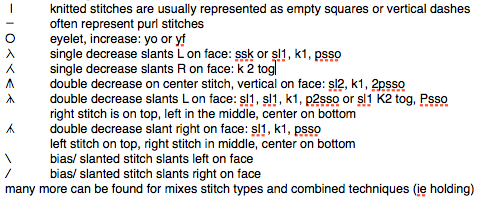

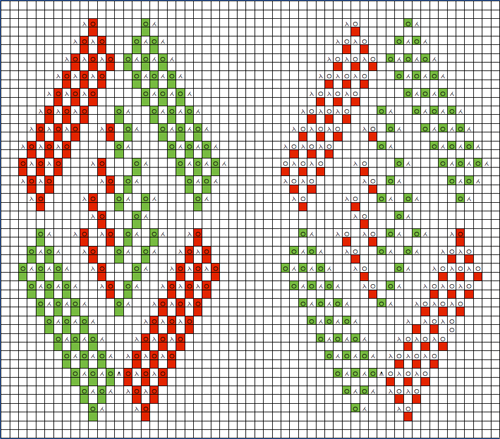

a mylar repeat for use with lace carriage, 910

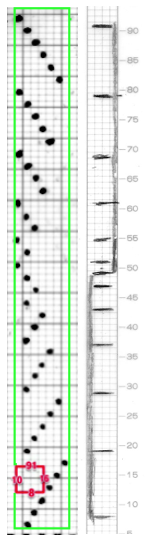

in the image on left the repeat is hi-lighted by the green border; in the one on the right there are visual cues for operations. The vertical lines indicate which side of the bed the lace carriage needs to be placed for the next group of transfers, the horizontal lines mark the end of the transfer sequence, when a single row of knit occurs. Respective carriages need to be taken off the bed after most passes to allow use of the opposing carriage and maintain proper direction of moves, a different sort of “hand technique”. Below is a swatch, the red spot is a poorly corrected dropped stitch.

the technique is manageable for experienced knitters, this was my second try at a hurried repeat (weight adjustments and dropped stitches on first) and photo as I get ready to travel to the opposite coast.

B

B A

A

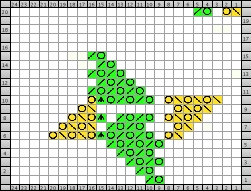

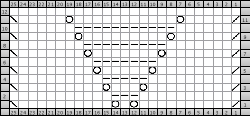

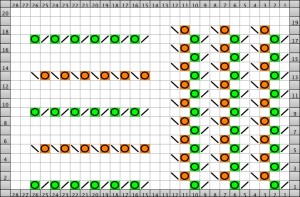

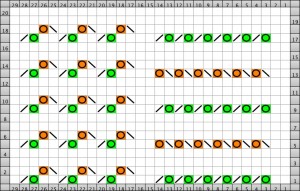

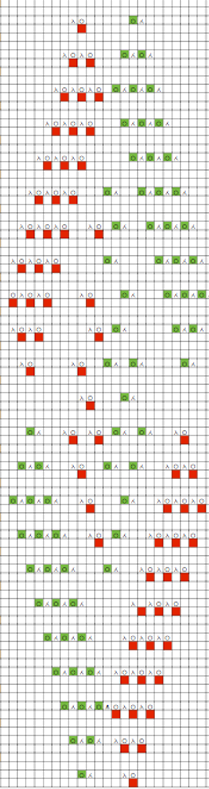

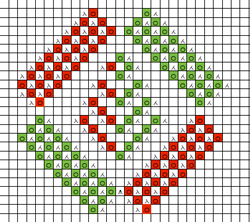

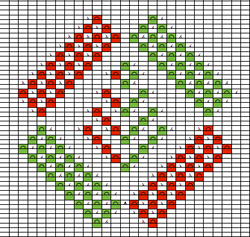

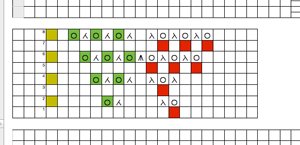

The hand-knit motif inspiration and symbols remain unchanged in this post, The colors were assigned for coding the direction of transfers to maintain the mesh transfer sequence

The hand-knit motif inspiration and symbols remain unchanged in this post, The colors were assigned for coding the direction of transfers to maintain the mesh transfer sequence  splitting rows, is an option eliminated by apple in later versions of numbers

splitting rows, is an option eliminated by apple in later versions of numbers  copy and paste the above in a “blank” part of spreadsheet creating a new table; resize cells by selecting all in the new table, and clicking/ dragging on the bottom line of any of the grey, numbered row cells on left to number/ measurements of cells in the original document. Release the mouse, and all cells will be uniform in size.

copy and paste the above in a “blank” part of spreadsheet creating a new table; resize cells by selecting all in the new table, and clicking/ dragging on the bottom line of any of the grey, numbered row cells on left to number/ measurements of cells in the original document. Release the mouse, and all cells will be uniform in size.

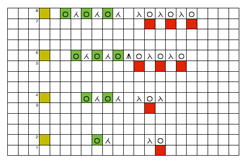

mark the outside of motif on the above right with a third color, beginning on the second row; cut and paste complete motif in a “clean area of your sheet so it is surrounded by blank space, this will save a lot of “erasing” (technically this creates a new table)

mark the outside of motif on the above right with a third color, beginning on the second row; cut and paste complete motif in a “clean area of your sheet so it is surrounded by blank space, this will save a lot of “erasing” (technically this creates a new table)

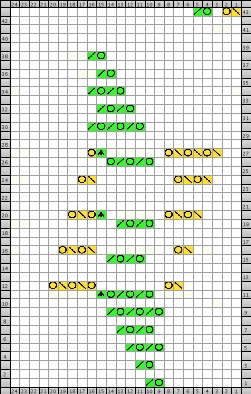

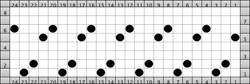

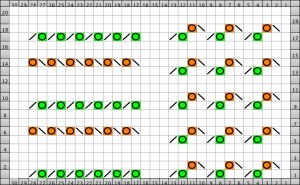

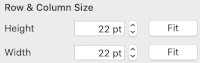

the resulting “separated” mesh repeat is now 92 rows long: spacing between repeats and number of knit rows at its top may be adjusted to suit preference/ taste. Red and green squares are what is punched, or black squares on mylar sheet, etc. Note: red containing rows have no symbols now, while green ones still do, another visual check

the resulting “separated” mesh repeat is now 92 rows long: spacing between repeats and number of knit rows at its top may be adjusted to suit preference/ taste. Red and green squares are what is punched, or black squares on mylar sheet, etc. Note: red containing rows have no symbols now, while green ones still do, another visual check  with repeats this long, it is worth marking up the final template like that encountered on the card or mylar as described in previous posts: a pdf

with repeats this long, it is worth marking up the final template like that encountered on the card or mylar as described in previous posts: a pdf

any change to repasted motif affects the whole document in that area, unlike as in creating a new table in numbers as I recently “discovered” (a very convenient difference)

any change to repasted motif affects the whole document in that area, unlike as in creating a new table in numbers as I recently “discovered” (a very convenient difference)