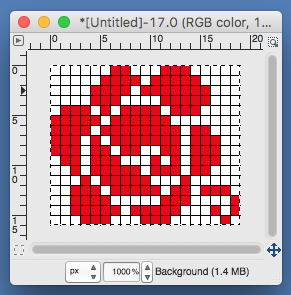

I like placing motifs, grounds, and borders myself whenever possible, in any knitting technique, rather than relying on adding or combining them via the built-in KM software. It is simply my strong personal preference in designing and gives me additional controls over patterning. However, the ability to superimpose is a convenient feature, available on multiple machines and worth mentioning. I have used it more frequently in operating my Passap, than my Brother 910. That said, it would appear to be an easy feature to use for programming shapes onto mesh grounds. For illustration purposes, I am using a 24 stitch repeat. Electronics width and height potential depend on the use of mylar or PC download. The “rose” is not a workable, resolved repeat. When electronics were first introduced, at one point Kathleen Kinder wrote a book on electronic knitting (? 1984), exploring the full potential of managing designs by combining settings and flipping buttons for both the Brother 910 and the Studio 560.

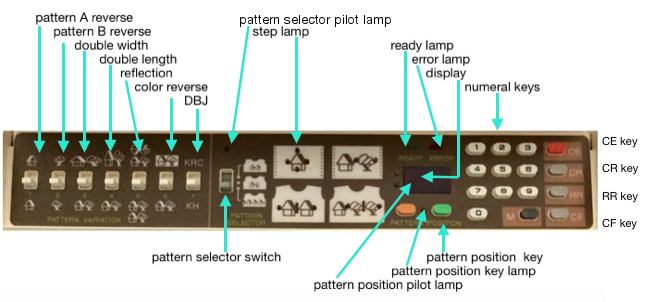

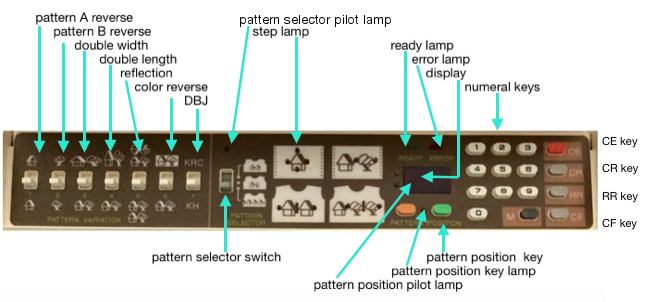

A bit of review on machine buttons and functions for the Brother pattern case for those unfamiliar with it.  M= Memory: each of the tiny red spots on the garment representations lights up, as specs on motif are entered or reviewed. CE= cancel entry: corrects programmed numbers or cancels the red error light when it flashes. CR= cancel row: press in a number, say 2 on the panel, and the card moves back 2 rows. If you press the button and no number is entered, the error light flashes and the card stops advancing. This is the same as locking the punchcard to repeat a pattern row. RR= row return brings the card back to the set line. This is routinely done before shutting off the machine when knitting is complete or to remove the mylar for editing. CF= card forward. The mylar returns to programmed design row 1. Numbers pressed in using CR or CF do not change those programmed using the M button.

M= Memory: each of the tiny red spots on the garment representations lights up, as specs on motif are entered or reviewed. CE= cancel entry: corrects programmed numbers or cancels the red error light when it flashes. CR= cancel row: press in a number, say 2 on the panel, and the card moves back 2 rows. If you press the button and no number is entered, the error light flashes and the card stops advancing. This is the same as locking the punchcard to repeat a pattern row. RR= row return brings the card back to the set line. This is routinely done before shutting off the machine when knitting is complete or to remove the mylar for editing. CF= card forward. The mylar returns to programmed design row 1. Numbers pressed in using CR or CF do not change those programmed using the M button.

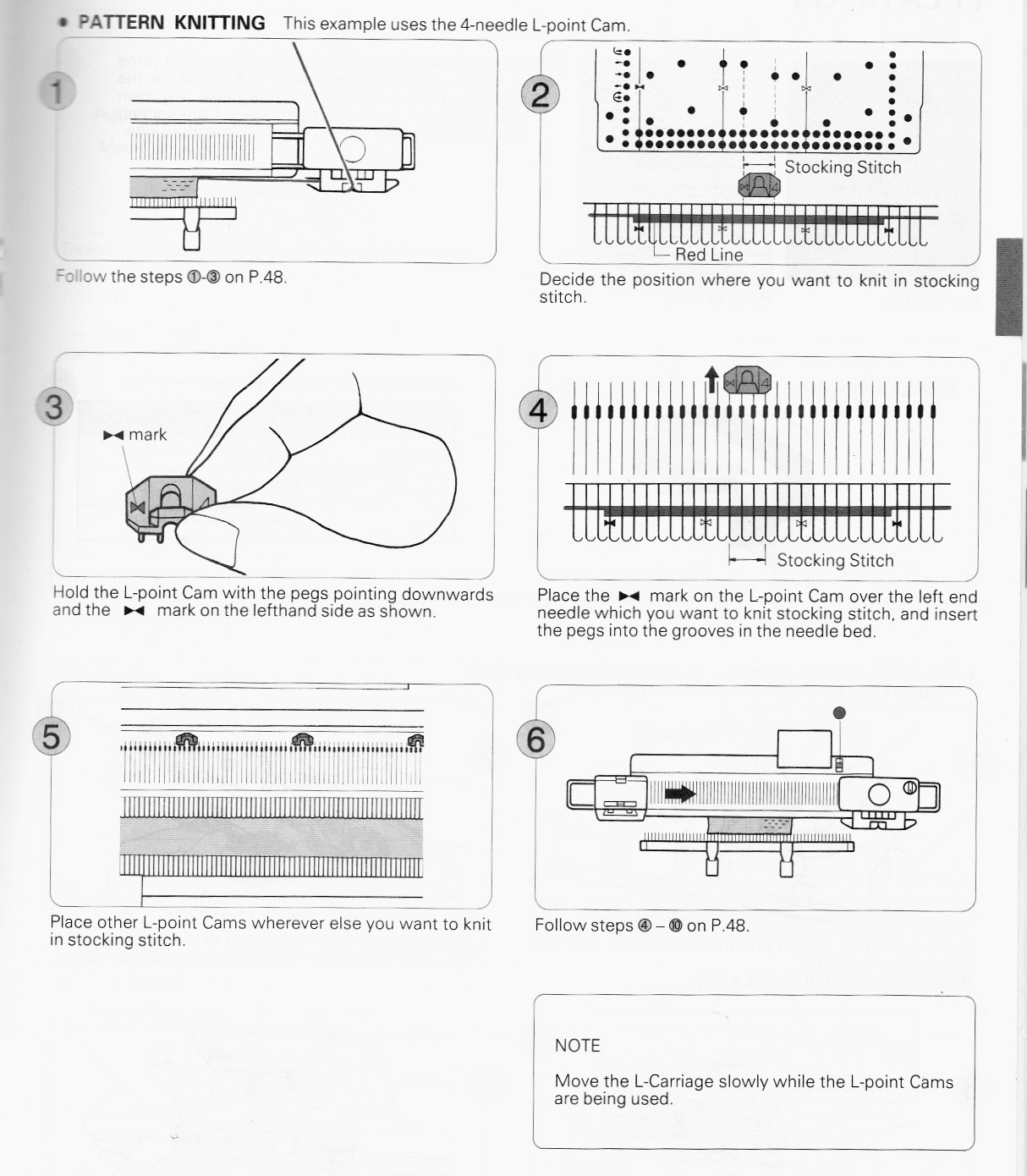

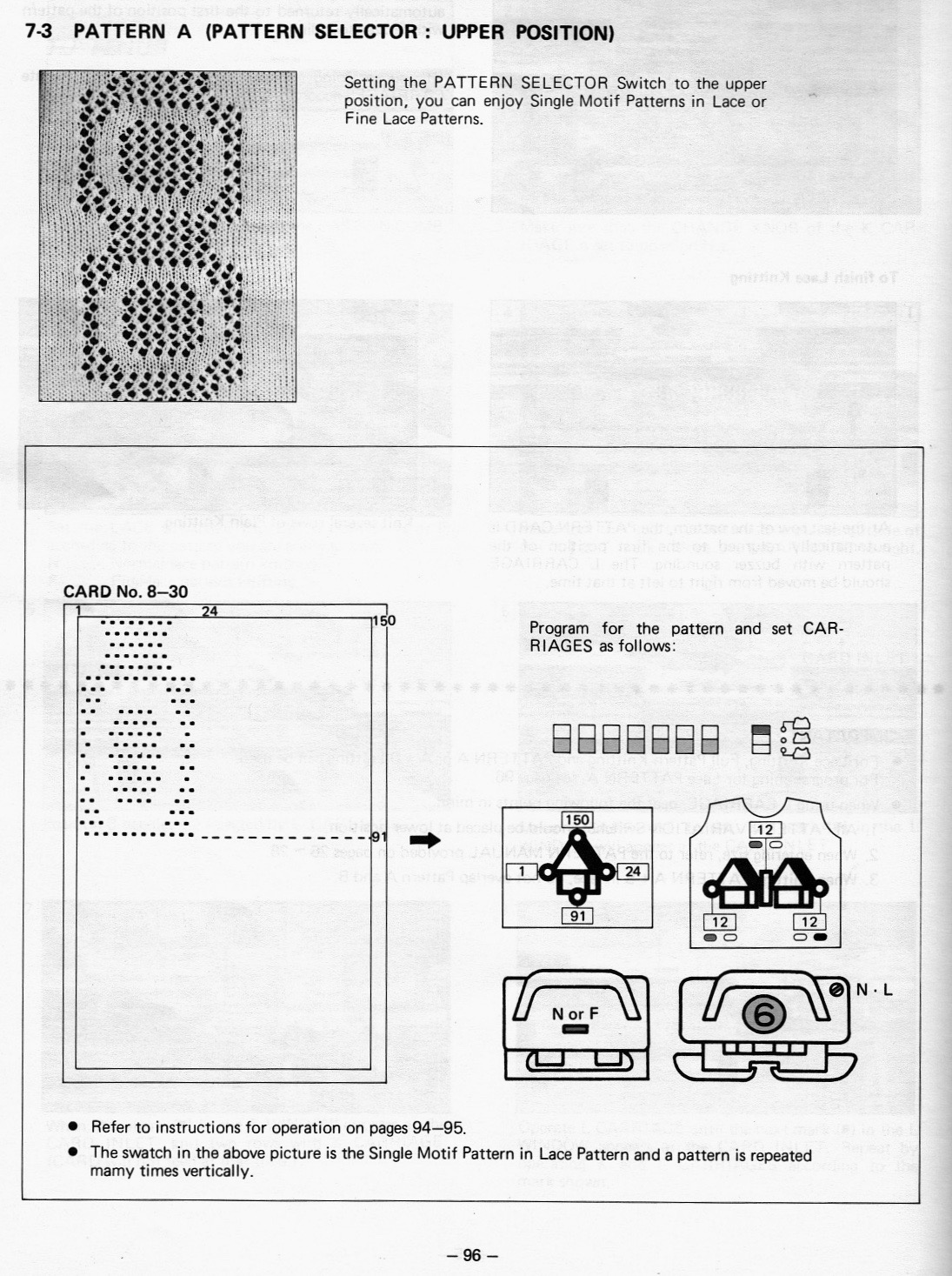

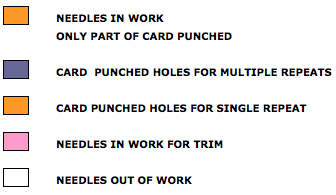

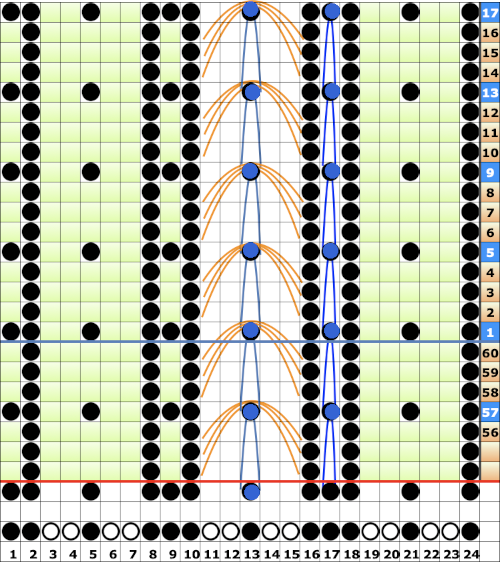

When the pattern selector button on the 910 is down, the pattern is centered on green #1. A reminder: Brother has 2 needle #1 positions, one on each side of 0. When the pattern has an even number of stitches, it will be centered with half that number of stitches divided evenly on each side of 0. For 24 stitches, the pattern’s limits are yellow 12 and green 12. If the repeat is an odd number of units wide, the center stitch then will be placed on green #1 (right of 0). If the repeat is 25 stitches wide, then the pattern limits are yellow 12 and green 13. If using a 24 stitch repeat, the machine automatically knows that the first needle position (FNP) for the pattern is yellow 12. When the pattern selector is in the upper position (motif A) and the middle position (motifs A & B) we can choose the FNP and with A & B the number of stitches separating them. One way to produce filet lace is to program A & B motifs. The lace mesh is the A motif, the “rose” the stocking stitch motif. The A motif can be on the left or right of the mylar, but it is always the taller of the 2. In most cases, it is the dominant pattern. The starting row for the combined motif is shared.

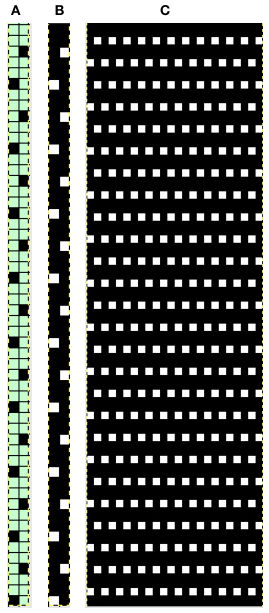

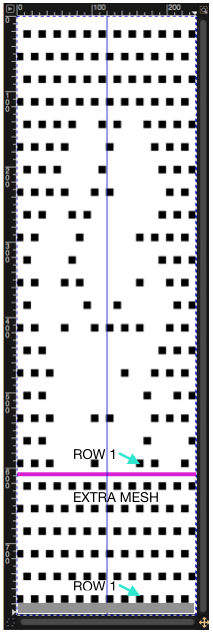

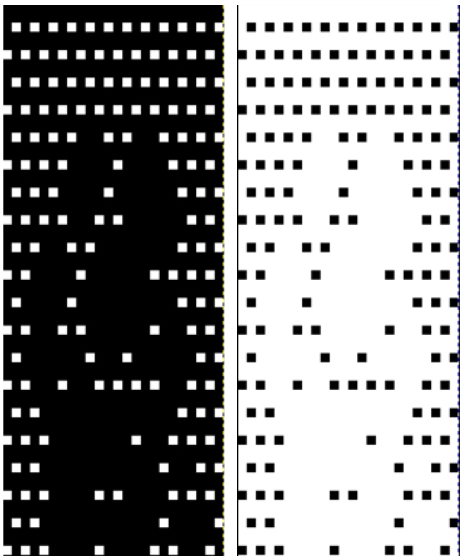

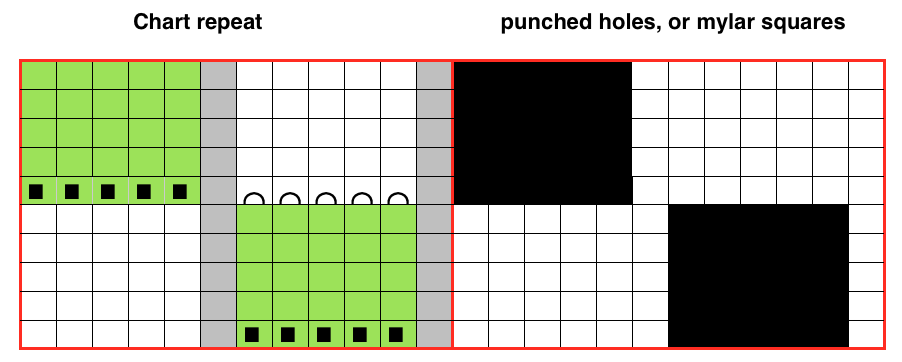

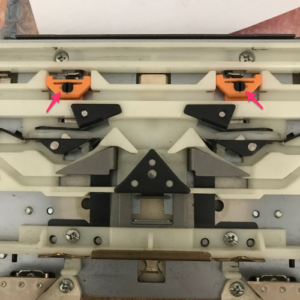

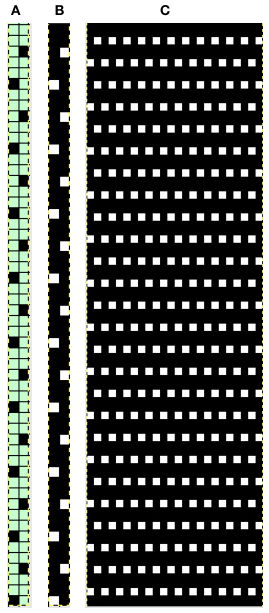

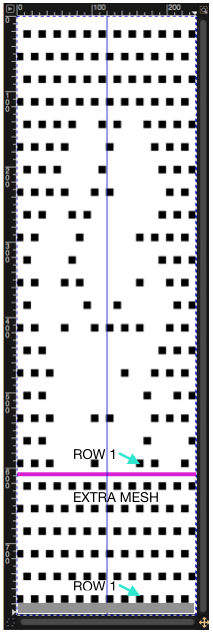

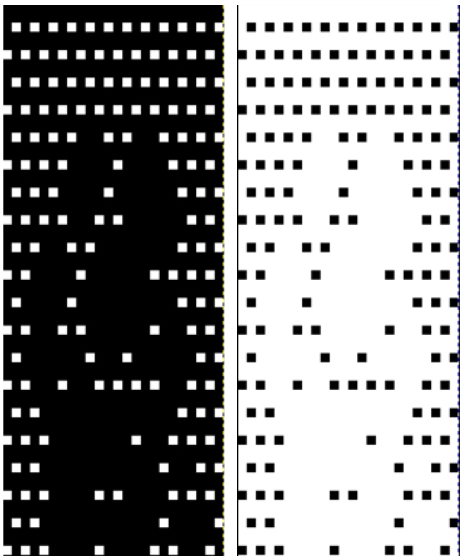

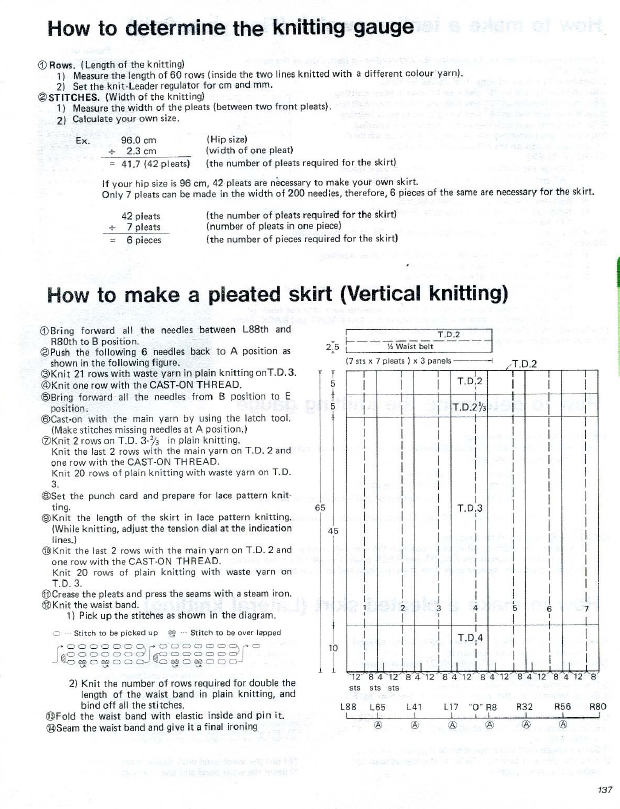

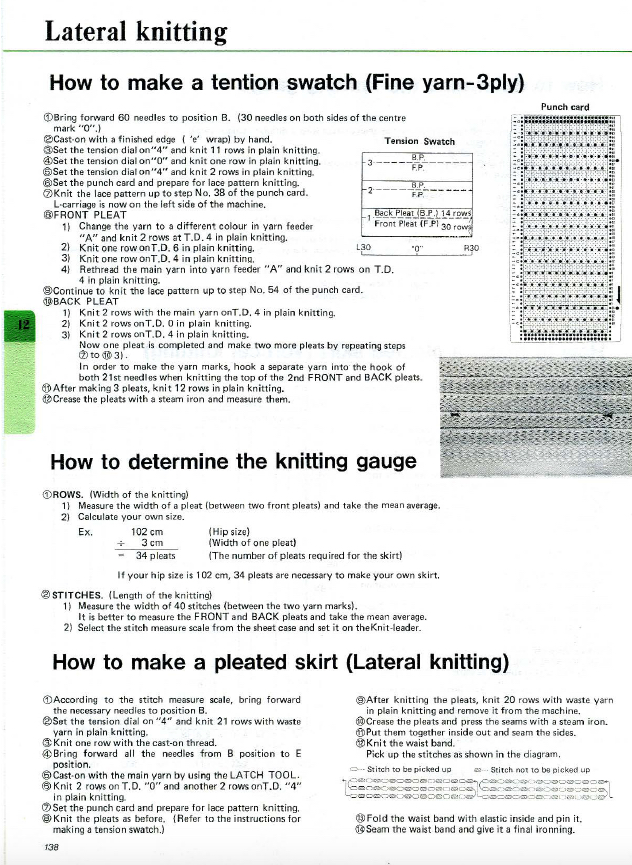

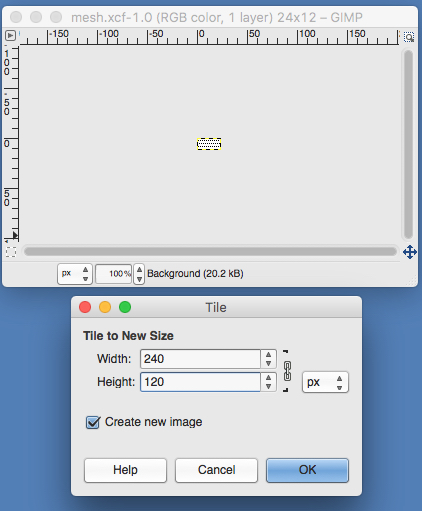

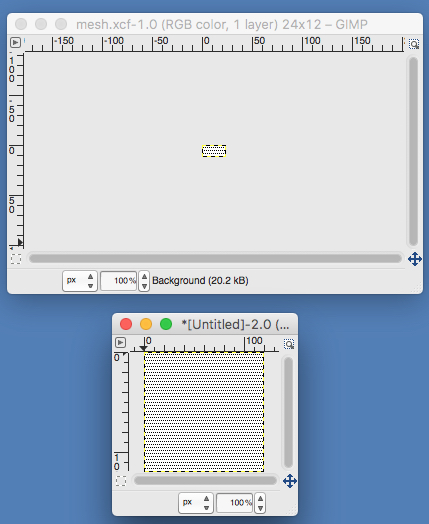

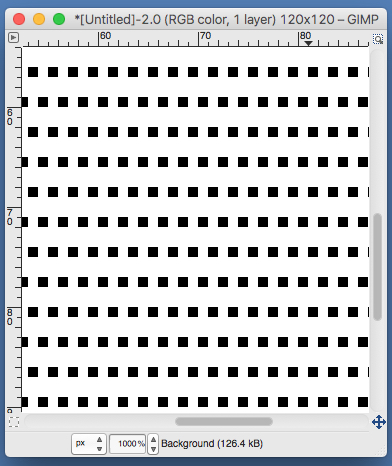

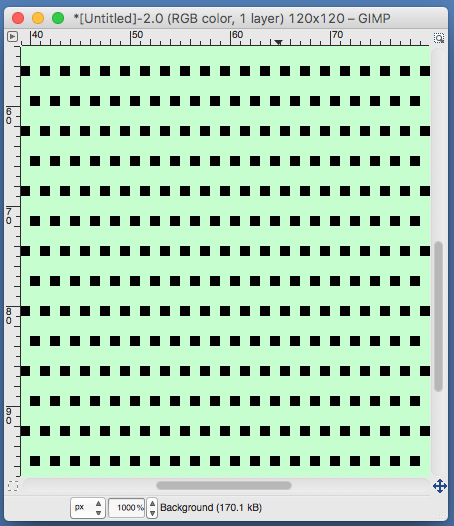

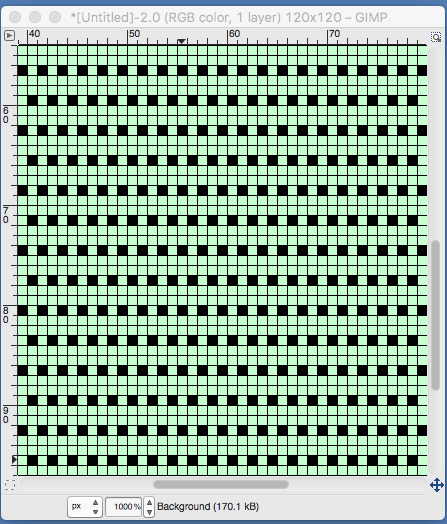

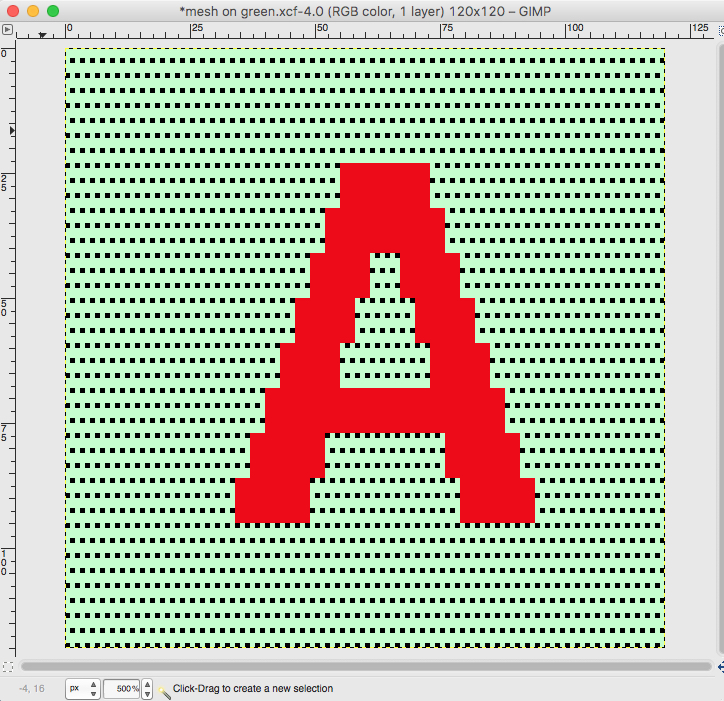

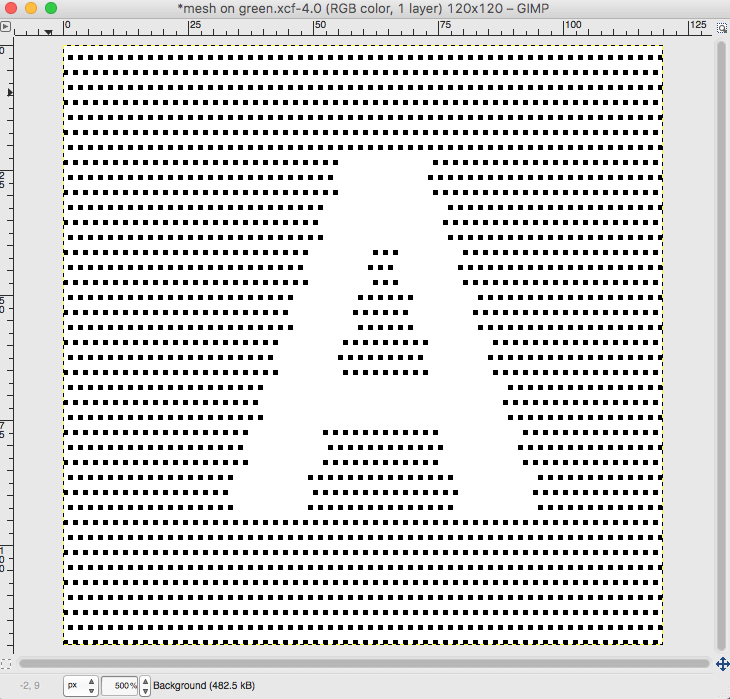

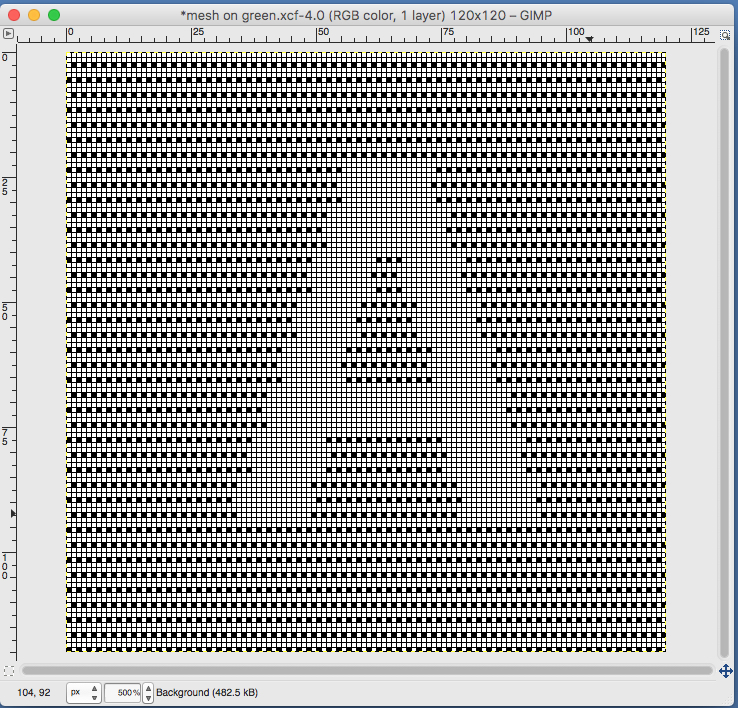

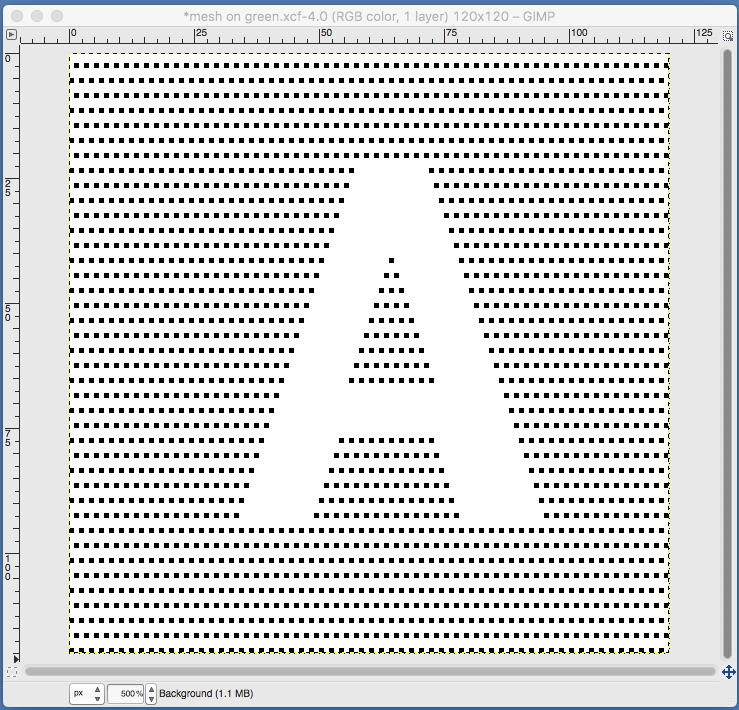

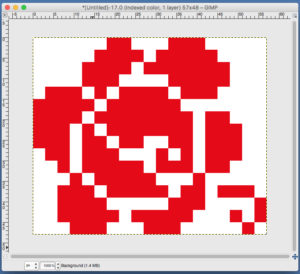

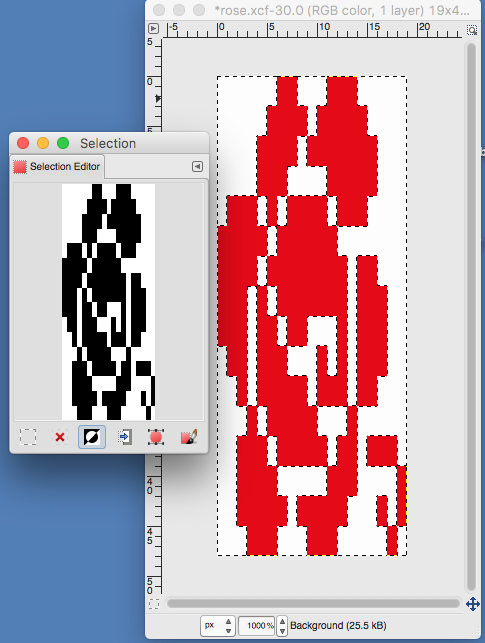

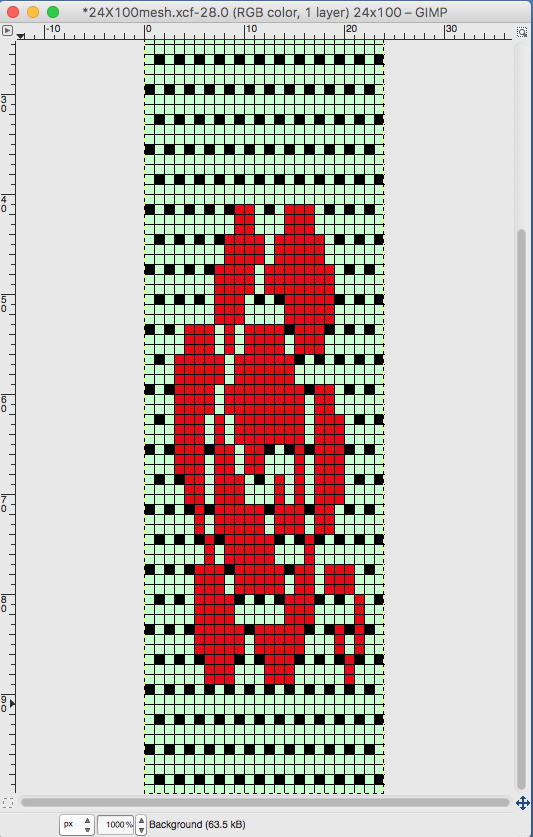

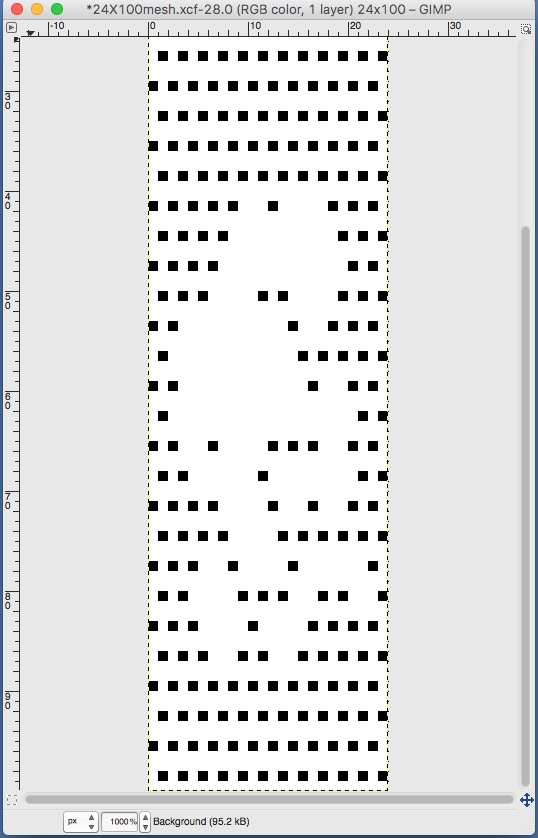

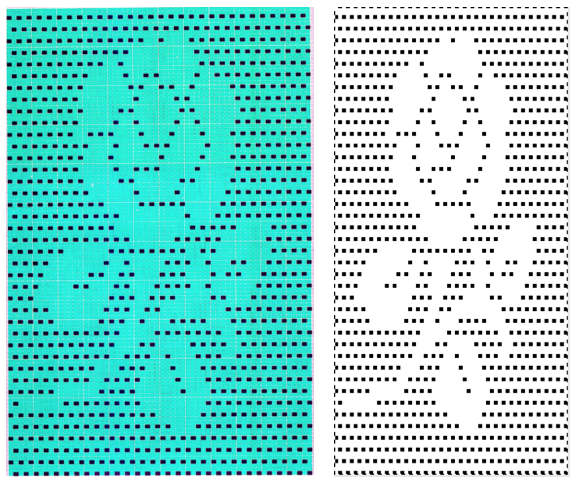

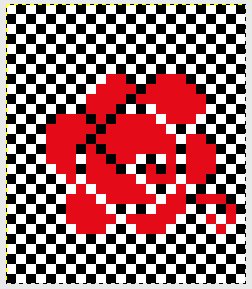

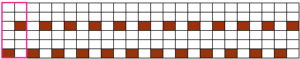

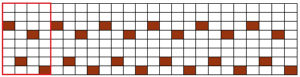

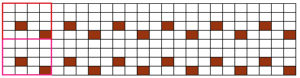

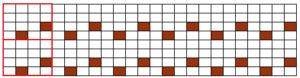

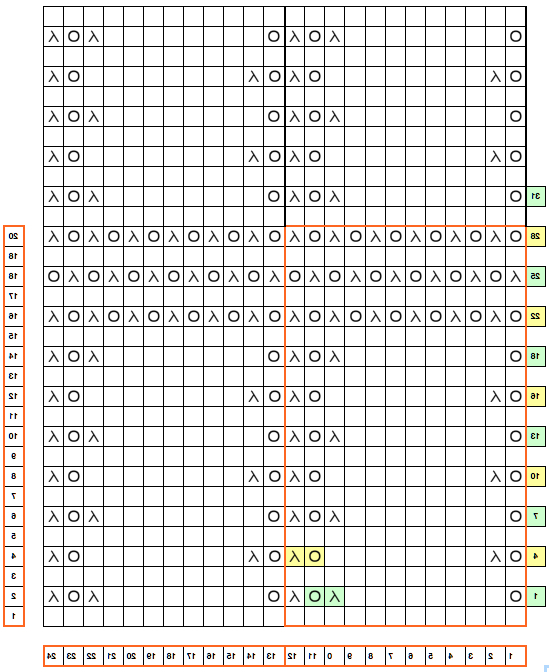

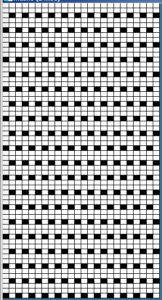

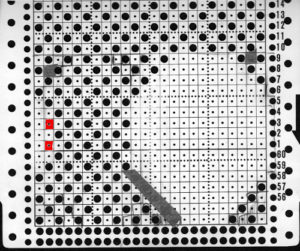

In lace knitting transfers and resulting eyelets are programmed as black squares. Superimposed solid patterns in stocking stitch occur in unmarked areas of the mylar or downloaded image, so they need to be “white squares”. In order to get the 2 to meet, the mesh repeat in the height required (column A in the illustration), and a single width is drawn or programmed in reverse (column B), with the result being read as (column C) when it is programmed as the base for a complete overlap. The basic mesh becomes the A motif in programming the 910, the stocking stitch “shape” is the B motif. If end needles are selected during knitting, they need to be pushed back to B manually or use the orange L cams. It is possible in addition to mark the “L window” on mylar, but the mesh repeat is so regular you may not find that necessary. The “rose’ would also need to be drawn in black, and positioned or programmed, with first placement resulting in the image seen below right. The color reverse is then used converting white squares to black, and lace knitting could proceed based on the black markings resulting in eyelets. As is already noted, there is no guarantee the image placement on the mesh the will yield a precise shape or the best possible results for motif edges, its definition, and its segments’ outline

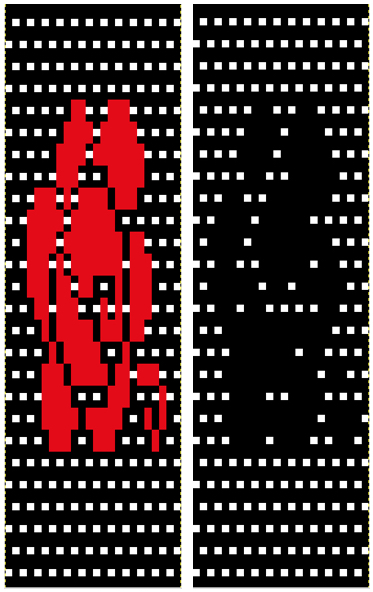

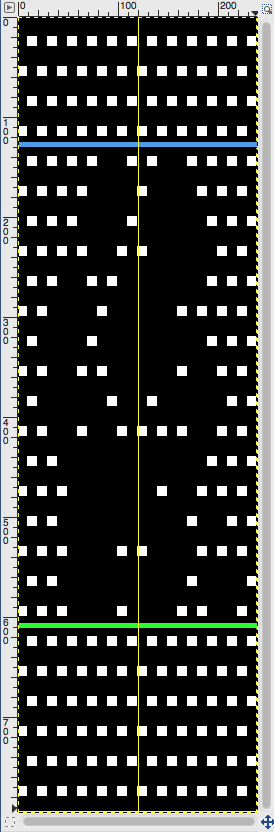

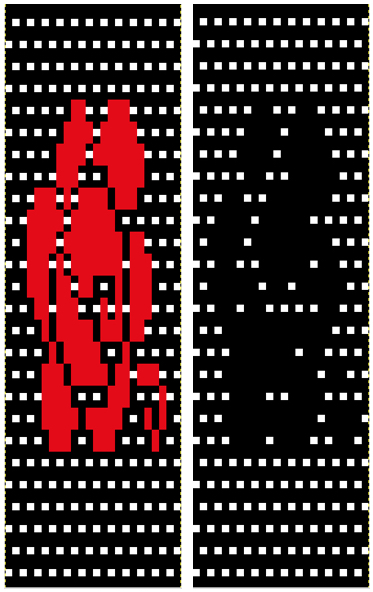

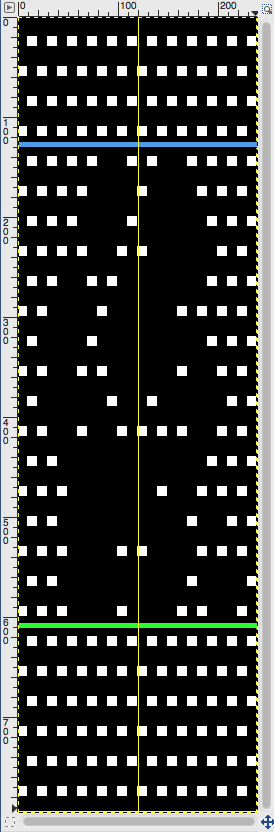

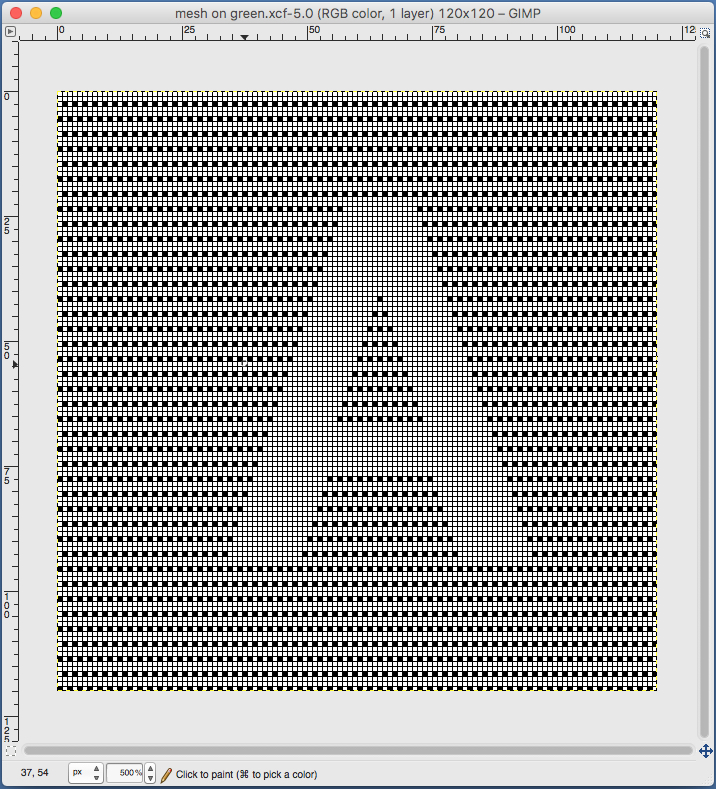

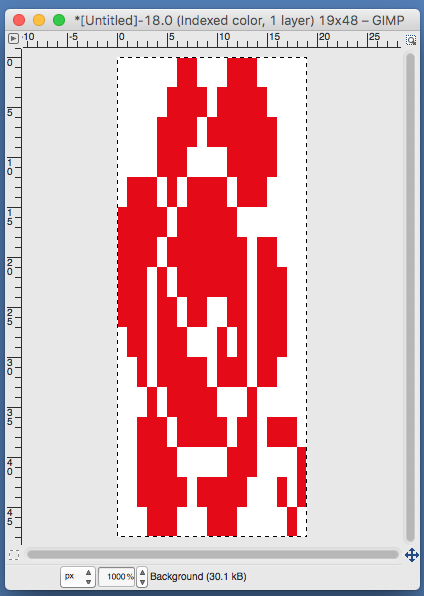

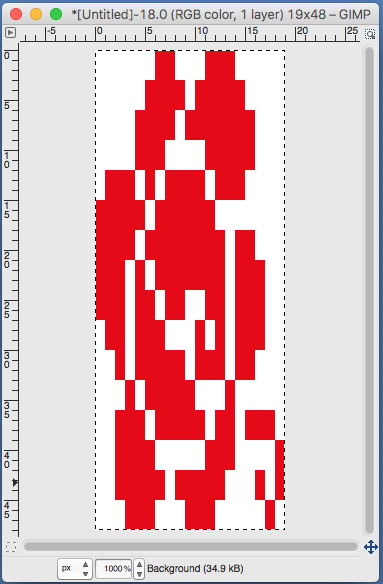

The “rose’ would also need to be drawn in black, and positioned or programmed, with first placement resulting in the image seen below right. The color reverse is then used converting white squares to black, and lace knitting could proceed based on the black markings resulting in eyelets. As is already noted, there is no guarantee the image placement on the mesh the will yield a precise shape or the best possible results for motif edges, its definition, and its segments’ outline  In terms of placement: if the all-over mesh is programmed centered on G1, and the motif is positioned with FNP other than G1, any simple, extra rows of mesh prior to starting the all-over pattern (below green line), will need to be programmed separately with adjustments also in FNP to match the superimposed segment. The programmed repeat for the mesh “rose” below would begin immediately above the blue line, and the extra mesh rows at the top would provide the transition to the start of the rose once again. The height of the pattern seen in the B column in the first illustration may be adjusted accordingly.

In terms of placement: if the all-over mesh is programmed centered on G1, and the motif is positioned with FNP other than G1, any simple, extra rows of mesh prior to starting the all-over pattern (below green line), will need to be programmed separately with adjustments also in FNP to match the superimposed segment. The programmed repeat for the mesh “rose” below would begin immediately above the blue line, and the extra mesh rows at the top would provide the transition to the start of the rose once again. The height of the pattern seen in the B column in the first illustration may be adjusted accordingly.

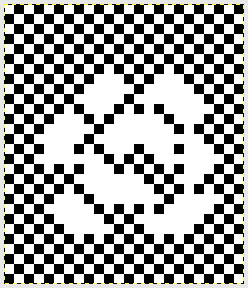

Color reverse (button #6) will provide “black squares” for the creation of transfers to create eyelets. The mesh and superimposed design need to share the same starting row. The image above reversed shows extra white at the bottom of the chart that needs to be eliminated. Brother lace starts on a selection row (black squares), ends with 2 blank rows at the top of the pattern (white squares). This is reversed in Studio knitting.

What happens when starting row placement is the same for both motifs, and the color reverse is used: the first-row lace carriage selection is good to go. The height of the mesh above the rose may be adjusted to suit. Trying to place multiple roses in different locations on the finished piece using this method is more than my brain wants to even consider.  Punchcard knitters are not completely out of the superimpose loop. If you are so inclined, areas on mesh punchcard ground may be taped over to test the repeat. Again, this works best for simple shapes. Tape may be shifted or trimmed as needed. If intended for extended use, trace holes over a blank card, punch the final version, and proceed. Images on punchcard machines are reversed on the stockinette side. If direction matters, flip the card over horizontally, mark and punch, or if the card is already punched, work with lace carriage on right, knit carriage on left. No worries about multiple programs or a mix of starting points, etc. Know the rules for where to begin and end for lace knitting.

Punchcard knitters are not completely out of the superimpose loop. If you are so inclined, areas on mesh punchcard ground may be taped over to test the repeat. Again, this works best for simple shapes. Tape may be shifted or trimmed as needed. If intended for extended use, trace holes over a blank card, punch the final version, and proceed. Images on punchcard machines are reversed on the stockinette side. If direction matters, flip the card over horizontally, mark and punch, or if the card is already punched, work with lace carriage on right, knit carriage on left. No worries about multiple programs or a mix of starting points, etc. Know the rules for where to begin and end for lace knitting.

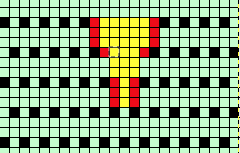

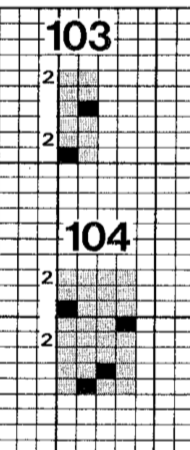

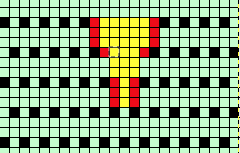

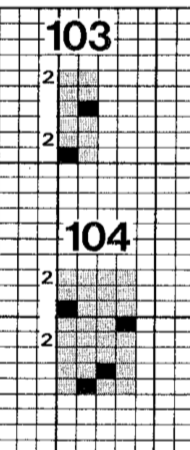

Sharp single stitch points are not attainable. In the illustration below, the yellow indicates the “desired point”, red squares indicate the additional stitches knit, adding to the intended shape as the alternating directions transfers are completed. The one stitch start is actually converted to 3 stitches, 3 to 5, etc. Later model electronics included “stitch world” pattern books. A usable mesh is # 103. Do not use 104, since it leaves 2 adjacent needles empty.

Later model electronics included “stitch world” pattern books. A usable mesh is # 103. Do not use 104, since it leaves 2 adjacent needles empty.  If aspect ratio matters in the superimposed image, knit test swatches to determine gauge. Cell/ grid size may be set to knit proportions rather than square to make visualization of finished shape easier. The mesh created using 103 uses 6 pattern rows for each 4 knitted, so you must add those rows “ to the height of the overlay design. Similar adjustments are needed if other mesh repeats are used. Simply scaling the image may require some clean up as well before the motif can be placed on the ground design.

If aspect ratio matters in the superimposed image, knit test swatches to determine gauge. Cell/ grid size may be set to knit proportions rather than square to make visualization of finished shape easier. The mesh created using 103 uses 6 pattern rows for each 4 knitted, so you must add those rows “ to the height of the overlay design. Similar adjustments are needed if other mesh repeats are used. Simply scaling the image may require some clean up as well before the motif can be placed on the ground design.

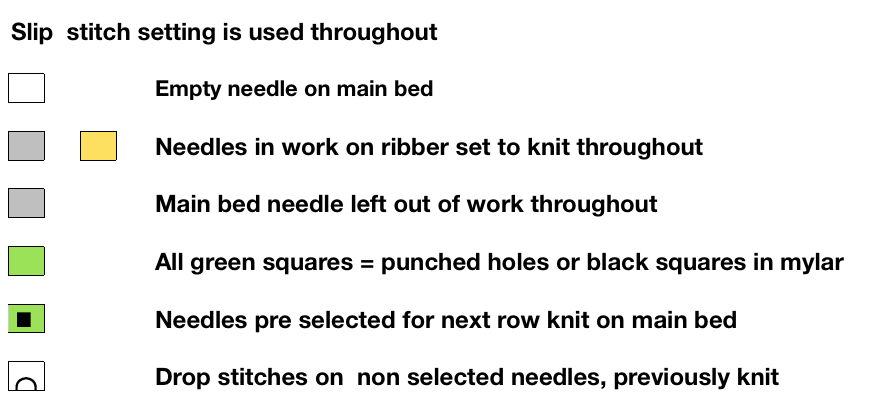

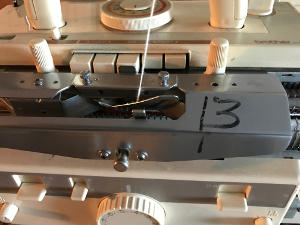

Working in multiple of repeat -1 on the top bed, plus one needle in work at each end on the ribber. Considerations need to be made to align the design properly. The markings on my metal bed are from a different project.

Working in multiple of repeat -1 on the top bed, plus one needle in work at each end on the ribber. Considerations need to be made to align the design properly. The markings on my metal bed are from a different project.  The goal is this needle arrangement

The goal is this needle arrangement  “air knitting” with carriage set to KC will help identify patterning repeats. Groups of 7 include a needle on each end which will be pushed back to A position in the body of the knit/ NOOW (needle out of work) indicated in the chart for the main bed needle setup

“air knitting” with carriage set to KC will help identify patterning repeats. Groups of 7 include a needle on each end which will be pushed back to A position in the body of the knit/ NOOW (needle out of work) indicated in the chart for the main bed needle setup  the first selection row

the first selection row  a needle on either side of the groups of 7 is pushed back to A position, remain there throughout the piece

a needle on either side of the groups of 7 is pushed back to A position, remain there throughout the piece an extra needle is brought into work on the ribber on either side of repeat ends. Machine settings: main bed set to slip <->, ribber set to normal knit

an extra needle is brought into work on the ribber on either side of repeat ends. Machine settings: main bed set to slip <->, ribber set to normal knit the ribber has now been set up for knitting every needle, every row, with the caston and desired edging completed. The first row is selected on the main bed for pattern knitting.

the ribber has now been set up for knitting every needle, every row, with the caston and desired edging completed. The first row is selected on the main bed for pattern knitting.  since there are needles out of work and pattern knitting is involved, if KCI is used or end needle selection is not canceled, the end needles on the areas being slipped will be selected to the knitting position, so patterning errors will occur. The first row knit on both beds is shown on the remaining needles

since there are needles out of work and pattern knitting is involved, if KCI is used or end needle selection is not canceled, the end needles on the areas being slipped will be selected to the knitting position, so patterning errors will occur. The first row knit on both beds is shown on the remaining needles Brother knits a row while preselecting for the next one. Here the needles in B would slip/ not knit on the next row, and needles out to D (Brother skipped the letter C in needle positions) will knit. Before knitting that next row, stitches on the now non-selected needles should be dropped across the bed

Brother knits a row while preselecting for the next one. Here the needles in B would slip/ not knit on the next row, and needles out to D (Brother skipped the letter C in needle positions) will knit. Before knitting that next row, stitches on the now non-selected needles should be dropped across the bed  this shows those stitches have been dropped, their needles are now empty, and returned to B position

this shows those stitches have been dropped, their needles are now empty, and returned to B position

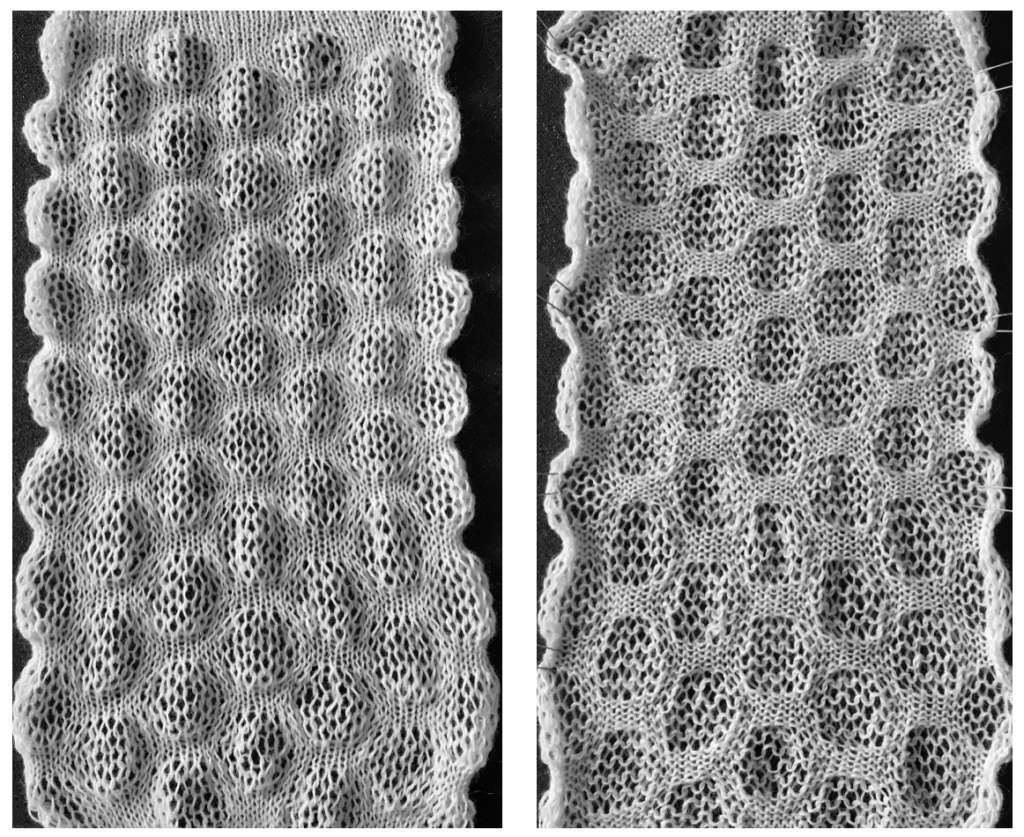

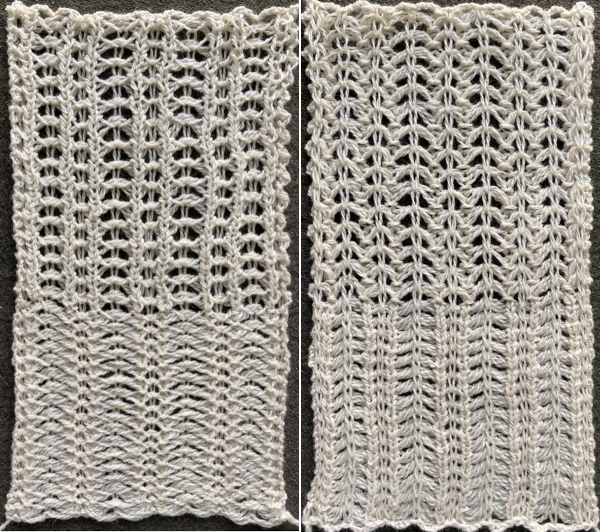

after steaming and pressing

after steaming and pressing the variation in width is due to adjustments in tension, the swatch folded over itself shows the difference in another way

the variation in width is due to adjustments in tension, the swatch folded over itself shows the difference in another way

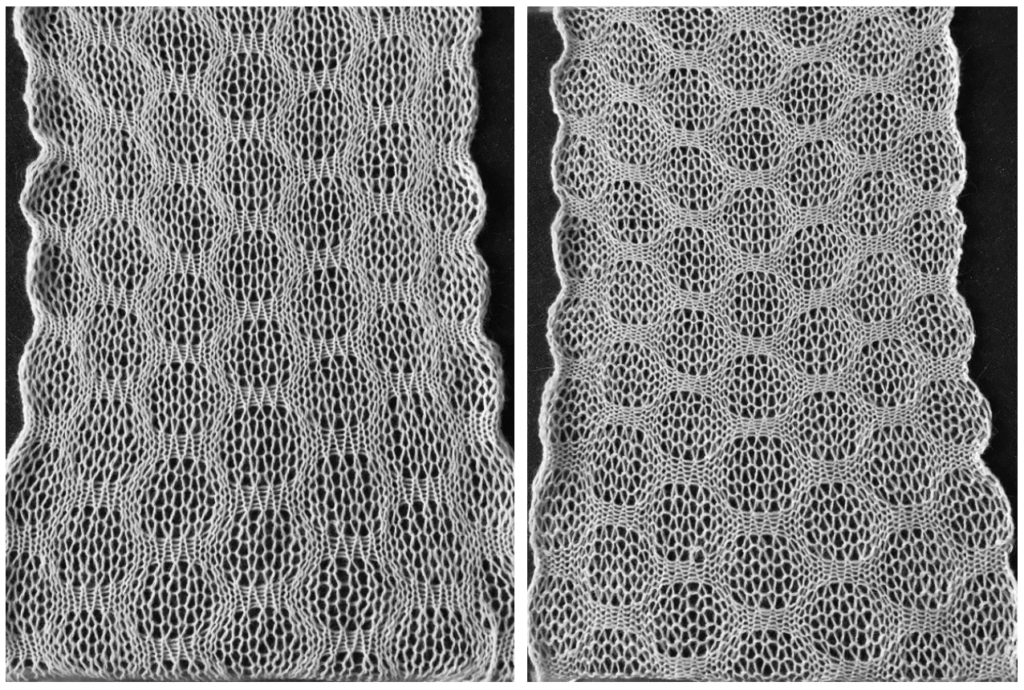

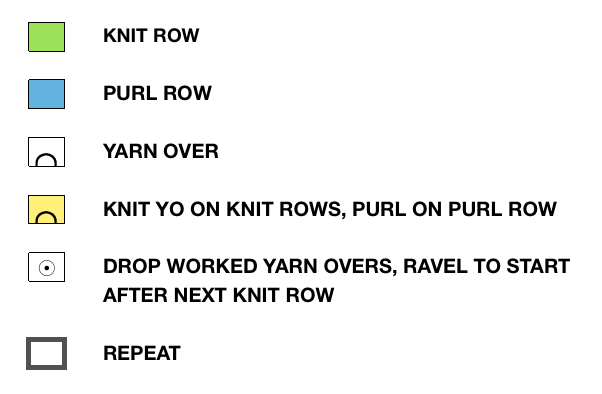

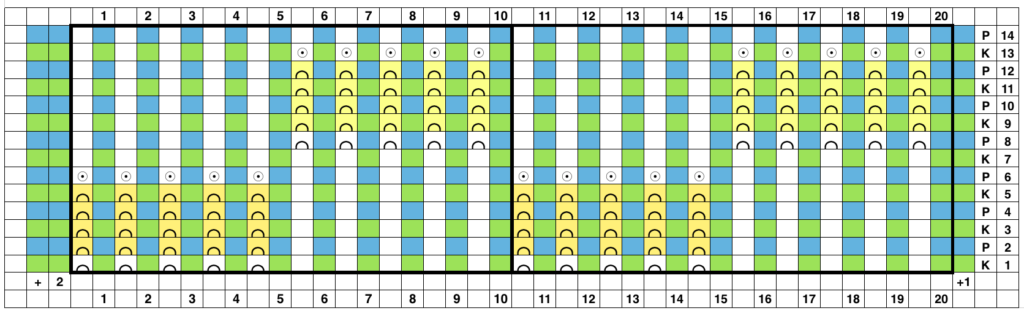

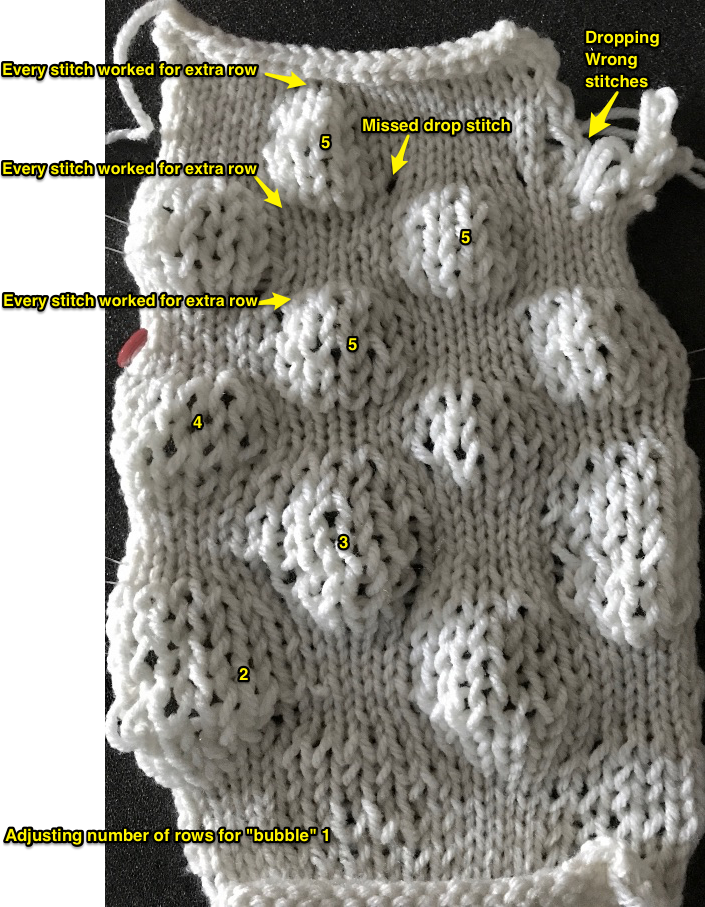

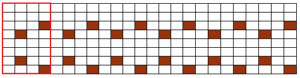

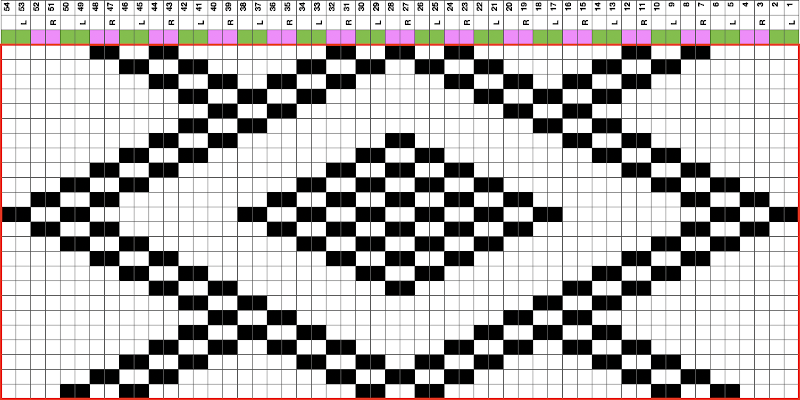

So I now own a new Mac, no longer have Microsoft Office available, and am now working my way through charting diagrams using Mac Numbers. Below is a possible working chart with a different stitch count than above. I would suggest larger blocks of all knit stitches and rows between “bubble” repeats

So I now own a new Mac, no longer have Microsoft Office available, and am now working my way through charting diagrams using Mac Numbers. Below is a possible working chart with a different stitch count than above. I would suggest larger blocks of all knit stitches and rows between “bubble” repeats

the reverse of the fabric, lightly killed with steaming and pressing

the reverse of the fabric, lightly killed with steaming and pressing

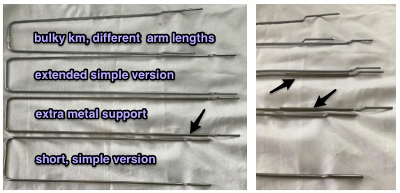

over the years color varied, but the function remains the same

over the years color varied, but the function remains the same  When using extension rails for lace or whenever using 2 carriages, beware not all rails are the same and that may make a difference with some KM model years

When using extension rails for lace or whenever using 2 carriages, beware not all rails are the same and that may make a difference with some KM model years

one with a color reverse border on only one end

one with a color reverse border on only one end

M= Memory: each of the tiny red spots on the garment representations lights up, as specs on motif are entered or reviewed. CE= cancel entry: corrects programmed numbers or cancels the red error light when it flashes. CR= cancel row: press in a number, say 2 on the panel, and the card moves back 2 rows. If you press the button and no number is entered, the error light flashes and the card stops advancing. This is the same as locking the punchcard to repeat a pattern row. RR= row return brings the card back to the set line. This is routinely done before shutting off the machine when knitting is complete or to remove the mylar for editing. CF= card forward. The mylar returns to programmed design row 1. Numbers pressed in using CR or CF do not change those programmed using the M button.

M= Memory: each of the tiny red spots on the garment representations lights up, as specs on motif are entered or reviewed. CE= cancel entry: corrects programmed numbers or cancels the red error light when it flashes. CR= cancel row: press in a number, say 2 on the panel, and the card moves back 2 rows. If you press the button and no number is entered, the error light flashes and the card stops advancing. This is the same as locking the punchcard to repeat a pattern row. RR= row return brings the card back to the set line. This is routinely done before shutting off the machine when knitting is complete or to remove the mylar for editing. CF= card forward. The mylar returns to programmed design row 1. Numbers pressed in using CR or CF do not change those programmed using the M button.

In terms of placement: if the all-over mesh is programmed centered on G1, and the motif is positioned with FNP other than G1, any simple, extra rows of mesh prior to starting the all-over pattern (below green line), will need to be programmed separately with adjustments also in FNP to match the superimposed segment. The programmed repeat for the mesh “rose” below would begin immediately above the blue line, and the extra mesh rows at the top would provide the transition to the start of the rose once again. The height of the pattern seen in the B column in the first illustration may be adjusted accordingly.

In terms of placement: if the all-over mesh is programmed centered on G1, and the motif is positioned with FNP other than G1, any simple, extra rows of mesh prior to starting the all-over pattern (below green line), will need to be programmed separately with adjustments also in FNP to match the superimposed segment. The programmed repeat for the mesh “rose” below would begin immediately above the blue line, and the extra mesh rows at the top would provide the transition to the start of the rose once again. The height of the pattern seen in the B column in the first illustration may be adjusted accordingly.

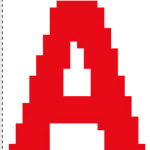

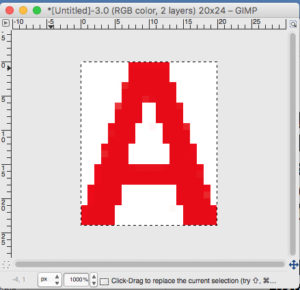

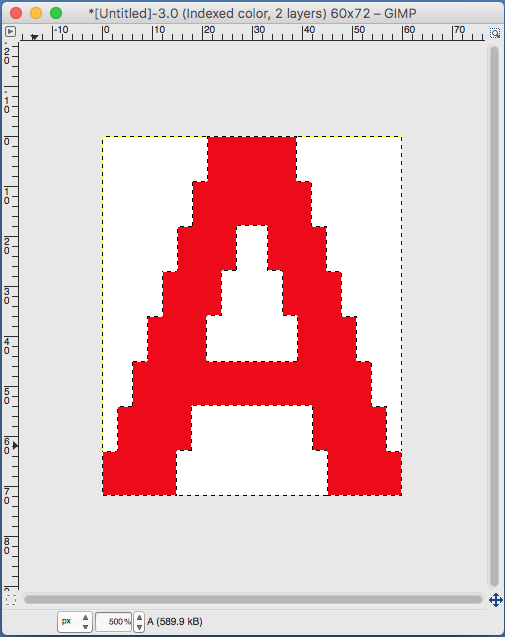

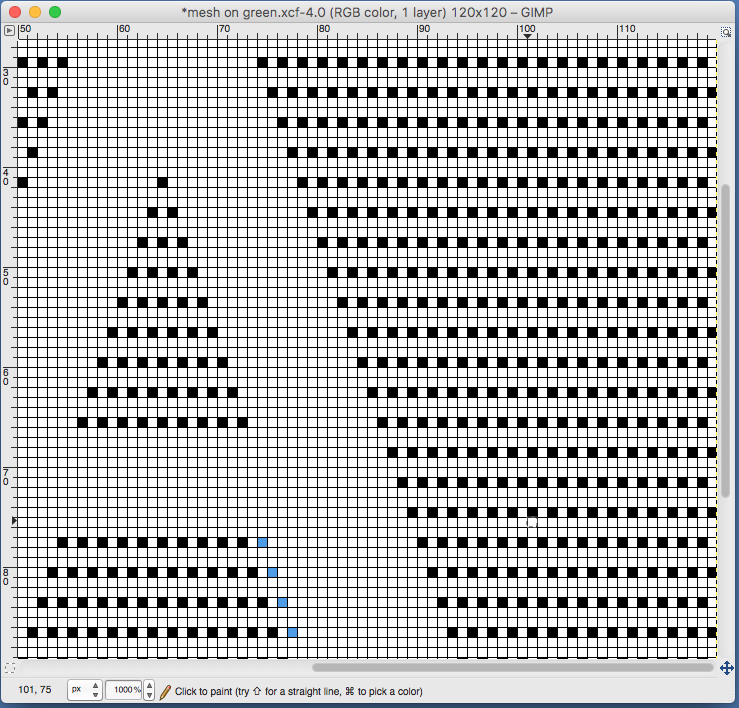

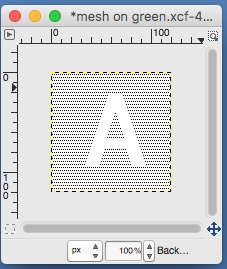

the A pasted in place

the A pasted in place

feeling better, with the exception of the left side bottom of right leg of A

feeling better, with the exception of the left side bottom of right leg of A one last bit of clean up, switching between magnification as needed

one last bit of clean up, switching between magnification as needed

use selection editor or fuzzy select

use selection editor or fuzzy select paste and move to “best” spot

paste and move to “best” spot  not quite a rose

not quite a rose

When satisfied, export in format for download.

When satisfied, export in format for download.

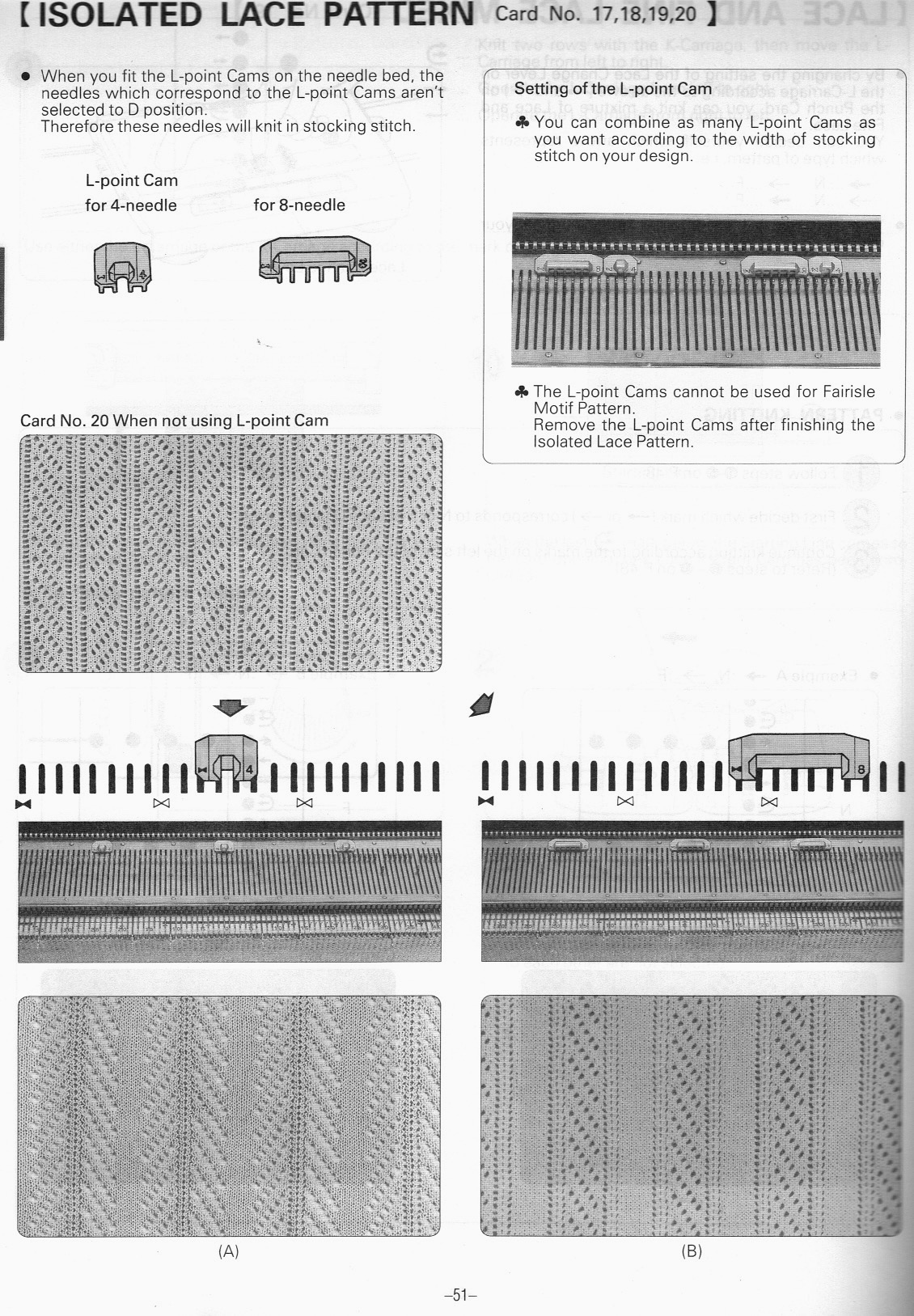

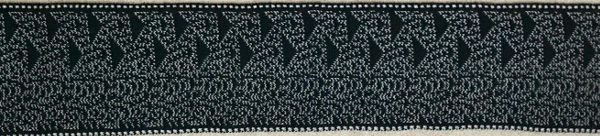

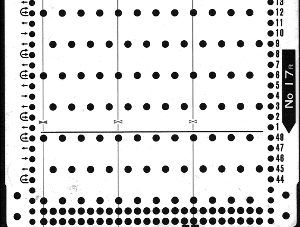

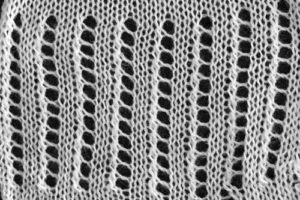

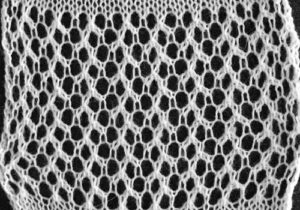

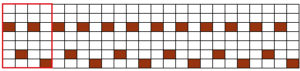

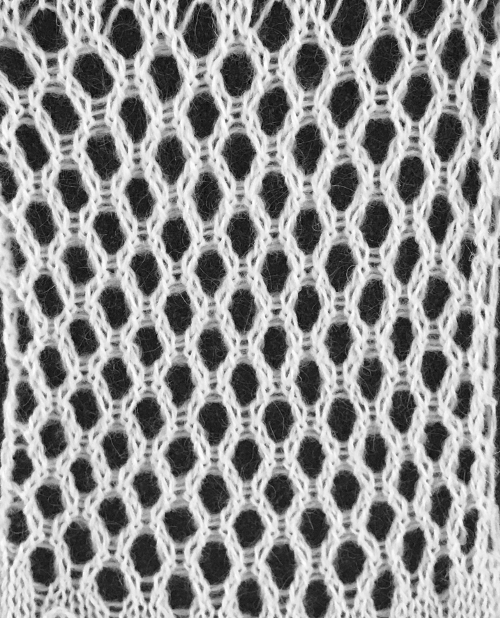

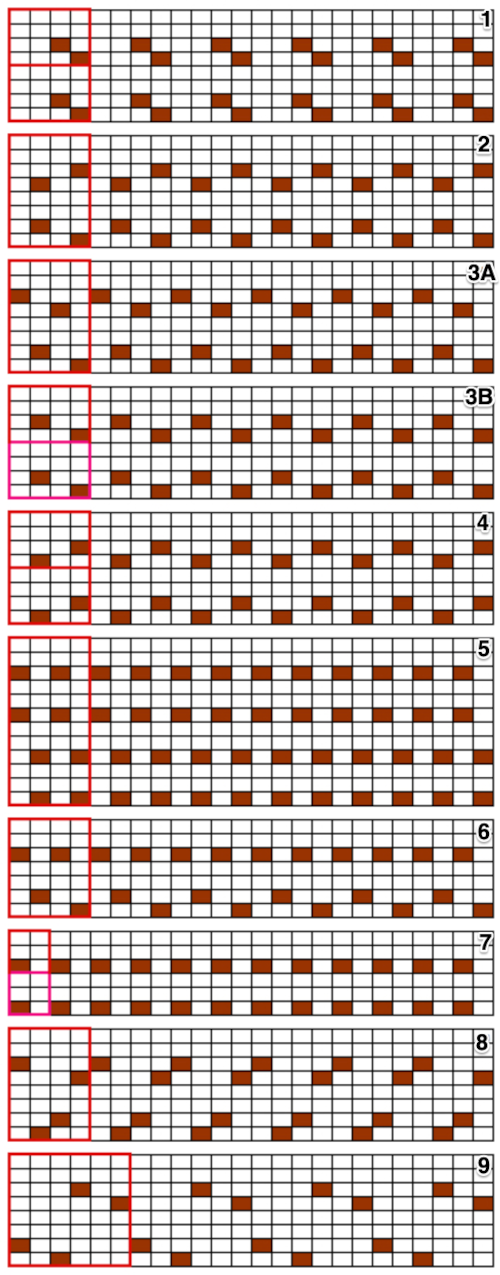

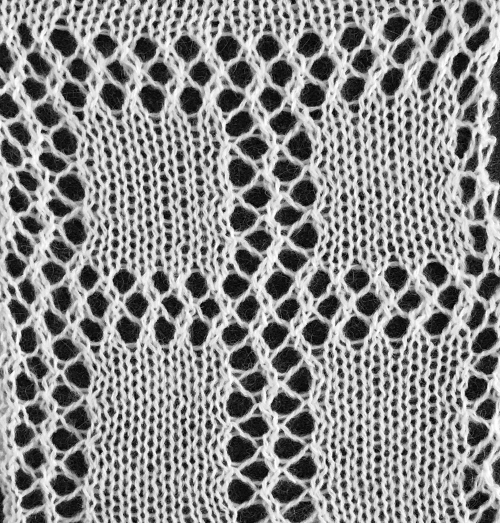

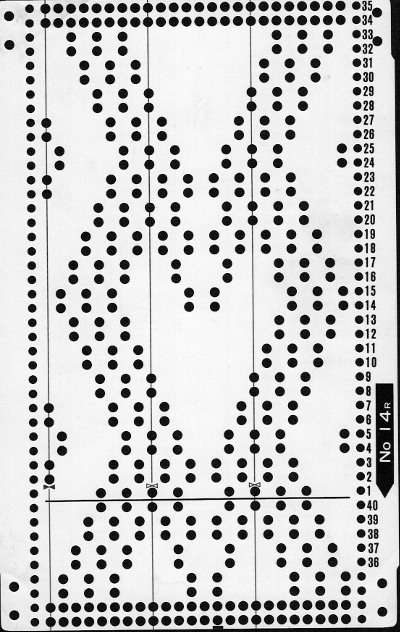

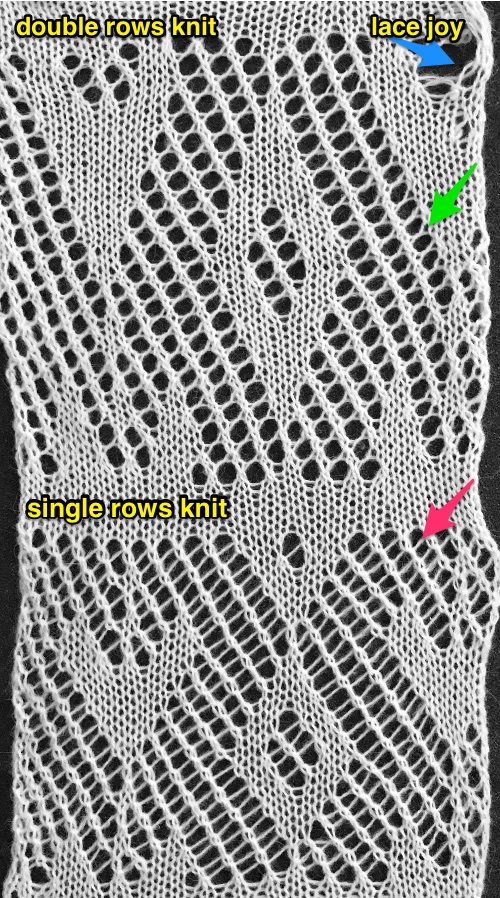

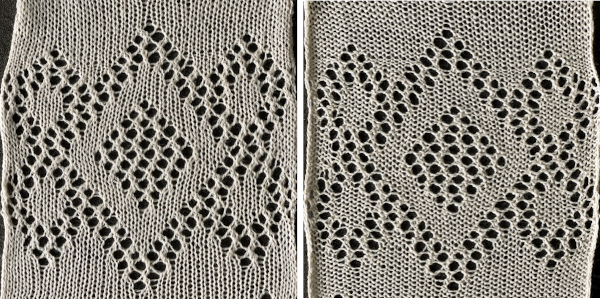

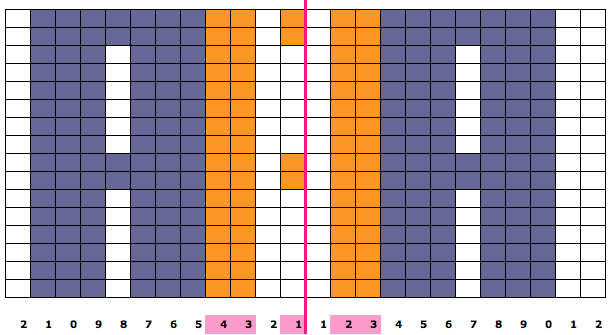

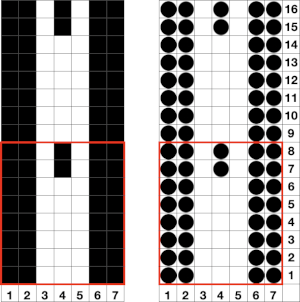

This repeat appears in my pre-punched factory basic packs as both #17 and #20. The lace carriage is used for 2 passes and then for 4 alternately, as indicated on the left side of the punchcard. The 2 passes will make transfers to the left, the 4 make transfers to the right. See previous lace posts for further info on lace selection methods and accompanying charting.

This repeat appears in my pre-punched factory basic packs as both #17 and #20. The lace carriage is used for 2 passes and then for 4 alternately, as indicated on the left side of the punchcard. The 2 passes will make transfers to the left, the 4 make transfers to the right. See previous lace posts for further info on lace selection methods and accompanying charting.

More variations and swatch photos: all patterns unless otherwise stated are knit with 4 passes of the lace carriage from left, followed by 2 rows of knitting.

More variations and swatch photos: all patterns unless otherwise stated are knit with 4 passes of the lace carriage from left, followed by 2 rows of knitting.

a mylar marking error as drawn (3A)

a mylar marking error as drawn (3A)

the intended repeat (3B)

the intended repeat (3B)

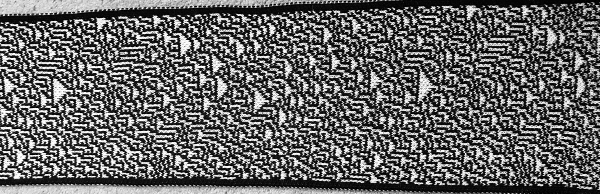

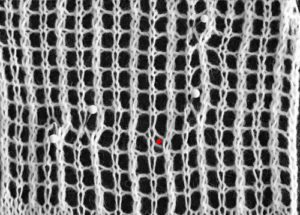

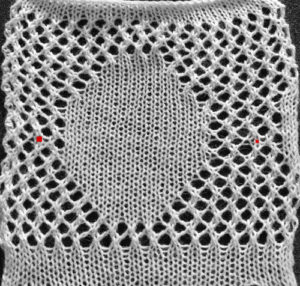

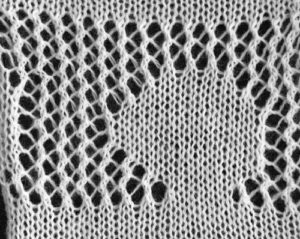

The above swatch and the one below (4) are similar, transfers occur in the opposite direction, so vertical columns of stacked stitches occur in the alternate columns of the finished fabric. I had some transfer issues in similar spots in both fabrics, have not analyzed the possible direct cause. As seen below, the dropped stitches did not result in the frequent large holes often seen in lace knitting. Pins and the red dot indicate problem spots, which could be repaired with careful stitching at the end of knitting. The best prevention of the problem is to visually check after sets of transfers to make certain all stitches have indeed been moved properly.

The above swatch and the one below (4) are similar, transfers occur in the opposite direction, so vertical columns of stacked stitches occur in the alternate columns of the finished fabric. I had some transfer issues in similar spots in both fabrics, have not analyzed the possible direct cause. As seen below, the dropped stitches did not result in the frequent large holes often seen in lace knitting. Pins and the red dot indicate problem spots, which could be repaired with careful stitching at the end of knitting. The best prevention of the problem is to visually check after sets of transfers to make certain all stitches have indeed been moved properly.

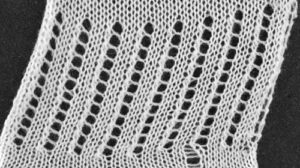

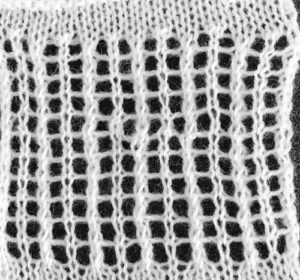

LC is used alternately for 2, and then 4 passes between knit rows (5).

LC is used alternately for 2, and then 4 passes between knit rows (5).

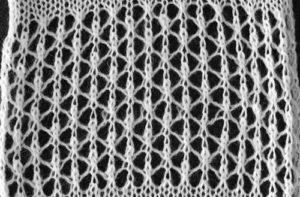

The transfers create a sort of “shape”, highlighted in the photo; the LC operates in sequences of 4 rows, followed by 2 rows, and repeat (6).

The transfers create a sort of “shape”, highlighted in the photo; the LC operates in sequences of 4 rows, followed by 2 rows, and repeat (6).

This one is a bit trickier, LC operates for 4 rows resulting in side by side transfers; in the first trial yarn caught up on gate pegs, dropped stitches, etc,

This one is a bit trickier, LC operates for 4 rows resulting in side by side transfers; in the first trial yarn caught up on gate pegs, dropped stitches, etc,

after reducing KC tension and adjusting the amount of weight

after reducing KC tension and adjusting the amount of weight  Mylar repeats can be very small, it is easy to be one stitch off in entering data; here one blank row was added to the left (a possibility for intentional vertical stripes of knitting) and the program was one row short on the right of the single full repeat

Mylar repeats can be very small, it is easy to be one stitch off in entering data; here one blank row was added to the left (a possibility for intentional vertical stripes of knitting) and the program was one row short on the right of the single full repeat

knit with the corrected program

knit with the corrected program  The “variations” and repeats in summary:

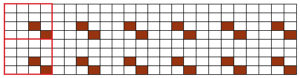

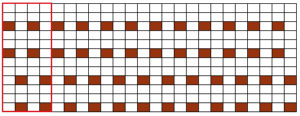

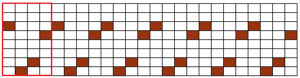

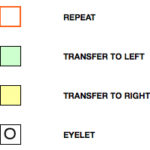

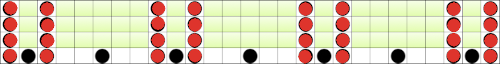

The “variations” and repeats in summary:  Adding geometric forms to mesh: a working MK chart for a cousin to the fabric link provided at the top of this post, the underlying mesh repeat is the same as that for card 17

Adding geometric forms to mesh: a working MK chart for a cousin to the fabric link provided at the top of this post, the underlying mesh repeat is the same as that for card 17

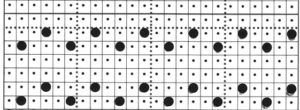

The corresponding punched holes: 2 LC passes for transfers to left (purl side), 4 LC passes for transfers to the right (purl side) throughout on Brother KM

The corresponding punched holes: 2 LC passes for transfers to left (purl side), 4 LC passes for transfers to the right (purl side) throughout on Brother KM chart flipped horizontally, suitable for hand knitting

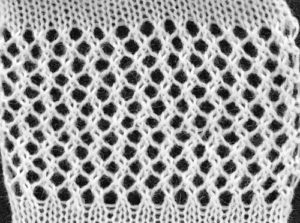

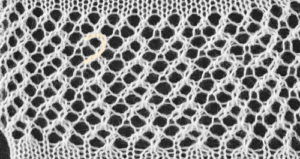

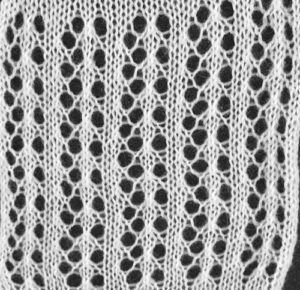

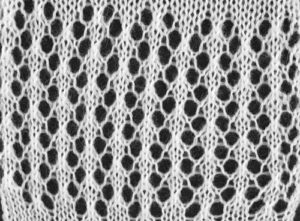

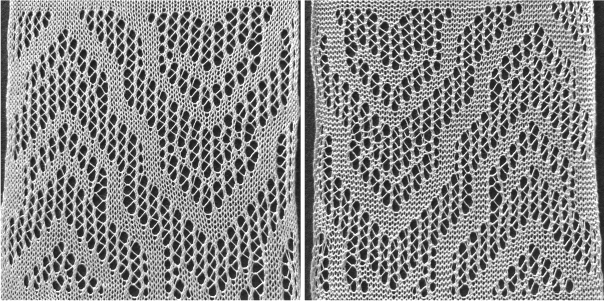

chart flipped horizontally, suitable for hand knitting  the swatch, MK, knit side

the swatch, MK, knit side  Note: the appearance of the “straight line” edges is altered by the formation of the eyelets along the sides as well as the top of the shape. As more shapes are played with, some adjustments may need to be made in punched holes after knitting a test swatch.

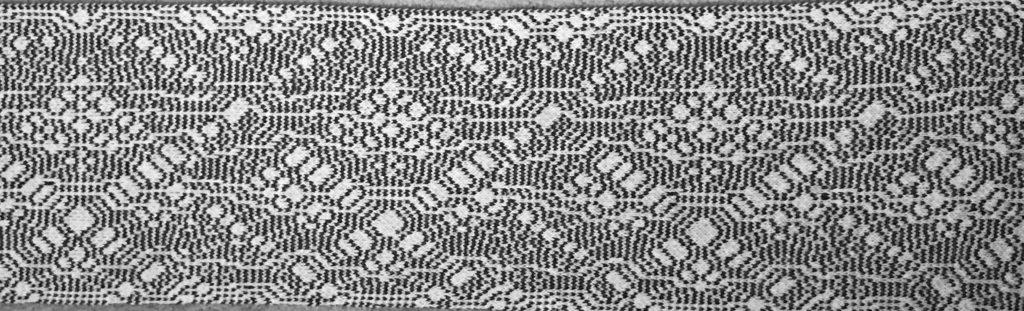

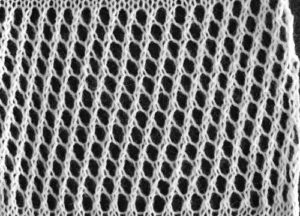

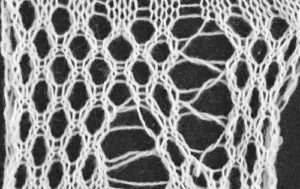

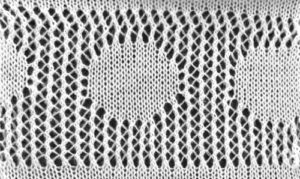

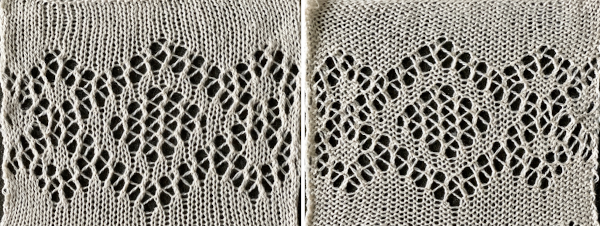

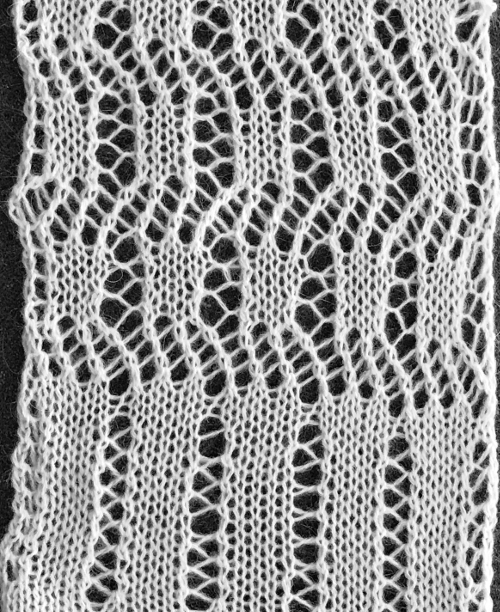

Note: the appearance of the “straight line” edges is altered by the formation of the eyelets along the sides as well as the top of the shape. As more shapes are played with, some adjustments may need to be made in punched holes after knitting a test swatch. Below is the result of working with a traditional mesh, where there are 2 rows of knitting to form each eyelet. The third row in the “design” on a punchcard is needed for the lace carriage to travel to its proper place for the alternating direction of transfers, which is not technically a knit row. The fabric is wider and longer than that above, and there is some elongation of the “circle”. Large patterns are mylar and punchcard real estate hogs. The swatch for slightly more than a single repeat with red dots indicating where one square in the mylar did not have a dark enough mark, resulting in a missing eyelet

Below is the result of working with a traditional mesh, where there are 2 rows of knitting to form each eyelet. The third row in the “design” on a punchcard is needed for the lace carriage to travel to its proper place for the alternating direction of transfers, which is not technically a knit row. The fabric is wider and longer than that above, and there is some elongation of the “circle”. Large patterns are mylar and punchcard real estate hogs. The swatch for slightly more than a single repeat with red dots indicating where one square in the mylar did not have a dark enough mark, resulting in a missing eyelet

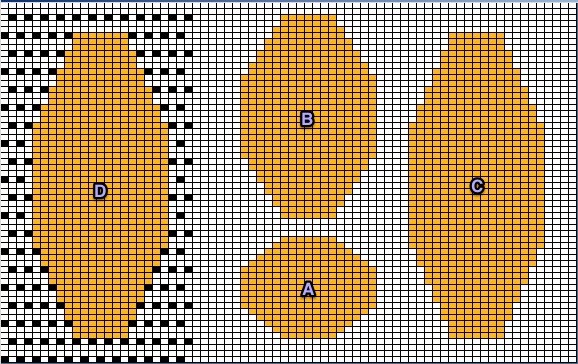

A: is my desired shape 17 units by 17, B: that shape elongated X 2 (17 X 34), to try to approximate elongation with knitting 2 rows for each set of eyelets. It is drawn on a square, not a rectangular or gauge-specific grid, however, so if that is a consideration in the design, it would have to be a case of “back to the drawing board”. C: the shape is elongated X 3 (17 X 51), for placement on the mesh, and D shows it in my desired spot. Lace gauge is harder to gauge because of stretch in the final fabric, and the changes are subject to pressing and blocking depending on yarn fiber content. Because transfers in this method occur on rows 1 and 2 to the left, 3 and 4 to the right, no pure straight edges along design borders can be achieved. If simple superimposing a large shape on the mesh is possible, there may be even more distortion along those edges. Ultimately a lot of this boils down to personal preference and patience.

A: is my desired shape 17 units by 17, B: that shape elongated X 2 (17 X 34), to try to approximate elongation with knitting 2 rows for each set of eyelets. It is drawn on a square, not a rectangular or gauge-specific grid, however, so if that is a consideration in the design, it would have to be a case of “back to the drawing board”. C: the shape is elongated X 3 (17 X 51), for placement on the mesh, and D shows it in my desired spot. Lace gauge is harder to gauge because of stretch in the final fabric, and the changes are subject to pressing and blocking depending on yarn fiber content. Because transfers in this method occur on rows 1 and 2 to the left, 3 and 4 to the right, no pure straight edges along design borders can be achieved. If simple superimposing a large shape on the mesh is possible, there may be even more distortion along those edges. Ultimately a lot of this boils down to personal preference and patience. For directions on using lace mesh to create pleated skirts please see post-

For directions on using lace mesh to create pleated skirts please see post-

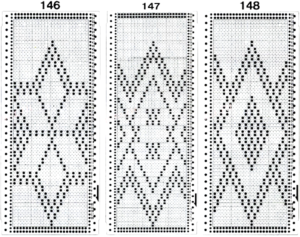

Three more candidates for experimenting with the technique.

Three more candidates for experimenting with the technique.

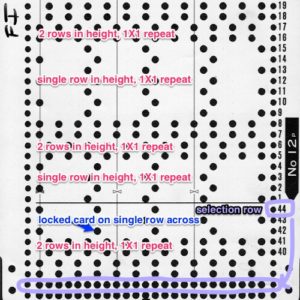

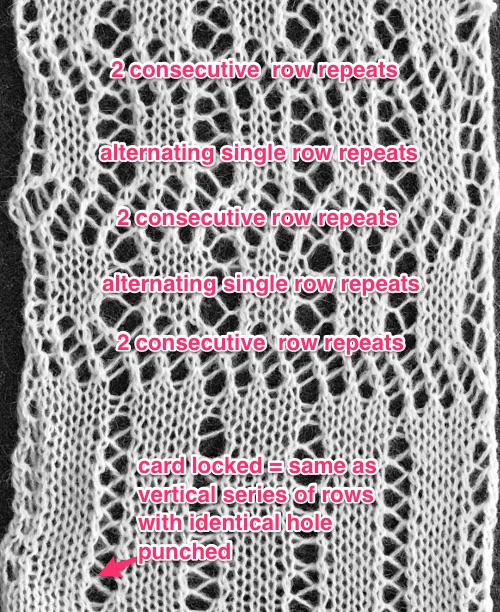

The single knit row between repeats is fairly easy and rhythmic to produce. The first preselection row is made with the lace carriage, beginning on the left, the design is used as given in the punchcard.

The single knit row between repeats is fairly easy and rhythmic to produce. The first preselection row is made with the lace carriage, beginning on the left, the design is used as given in the punchcard.

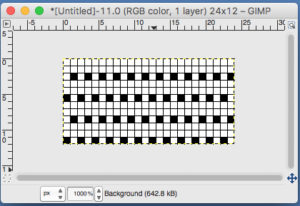

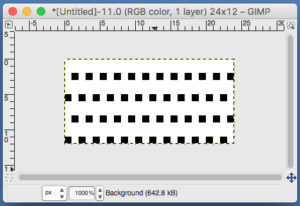

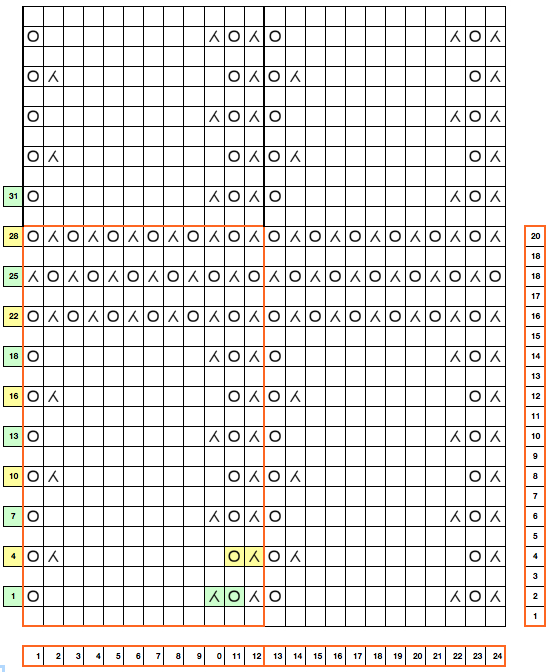

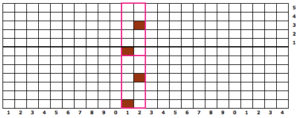

The BMP for the full repeat including blank rows at the top

The BMP for the full repeat including blank rows at the top

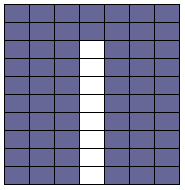

The above shows long vertical lines of transfers are possible in design motifs (punched holes).

The above shows long vertical lines of transfers are possible in design motifs (punched holes).

Since the above is seven stitches wide, if punched accordingly it would occupy 21 out of 24 stitch units on a punchcard. As is unless those extra needles on the far right or left are left out of work for ladders or transferred down to the ribber, it would not be suitable for an all-over fabric. It can, however, be used for a trim. If the latter is the intent, only one series of vertical repeats as seen in the chart needs to be punched. The numbers below the image indicate Brother needle tape markings. The Brother needled tape has a center O position marking, with numbers beginning count with one and radiating out marked in groups of 5 in both directions.

Since the above is seven stitches wide, if punched accordingly it would occupy 21 out of 24 stitch units on a punchcard. As is unless those extra needles on the far right or left are left out of work for ladders or transferred down to the ribber, it would not be suitable for an all-over fabric. It can, however, be used for a trim. If the latter is the intent, only one series of vertical repeats as seen in the chart needs to be punched. The numbers below the image indicate Brother needle tape markings. The Brother needled tape has a center O position marking, with numbers beginning count with one and radiating out marked in groups of 5 in both directions.

The single-width repeat may be programmed as pixels, on left, or punched holes on right. In electronics a single 8-row repeat is adequate, punchcard knitters repeat 5 times to 40 pattern rows punched.

The single-width repeat may be programmed as pixels, on left, or punched holes on right. In electronics a single 8-row repeat is adequate, punchcard knitters repeat 5 times to 40 pattern rows punched.  I prefer starting such designs on a knit row. To do that, the design repeat start may be shifted

I prefer starting such designs on a knit row. To do that, the design repeat start may be shifted  Using the trim as the cast on edge for a garment: determine the length required after a technique test. Knit a bit extra and remove on waste yarn, so more may be added or some be unraveled if needed or you wish to change the configuration using it as your cast on. Rehang and cast on later when it is completed. The flared-out portions of the trim will be used to “cast on” the edge of the piece, continuing with some needles out of work. An attempt at a line drawing of the “trim” sideways

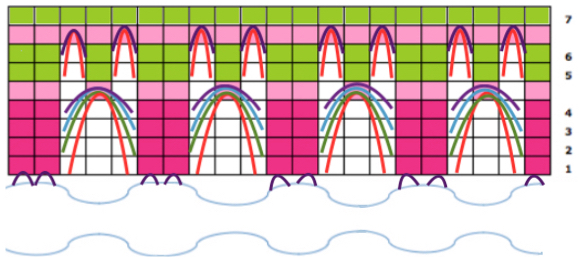

Using the trim as the cast on edge for a garment: determine the length required after a technique test. Knit a bit extra and remove on waste yarn, so more may be added or some be unraveled if needed or you wish to change the configuration using it as your cast on. Rehang and cast on later when it is completed. The flared-out portions of the trim will be used to “cast on” the edge of the piece, continuing with some needles out of work. An attempt at a line drawing of the “trim” sideways  Using the curved out edge of the trim, hang half stitches if possible, or one full stitch away from its edge as illustrated below. Knit 4 rows. With a tool pick up all ladder loops created by NOOW (RC 1-4) and hang them on the center empty needle. Knit rows (RC 5, 6), hang ladder loops on still empty needles, knit across all needles, continue with garment

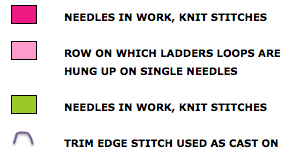

Using the curved out edge of the trim, hang half stitches if possible, or one full stitch away from its edge as illustrated below. Knit 4 rows. With a tool pick up all ladder loops created by NOOW (RC 1-4) and hang them on the center empty needle. Knit rows (RC 5, 6), hang ladder loops on still empty needles, knit across all needles, continue with garment

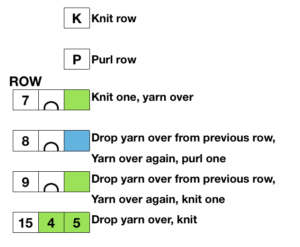

The yarn used is cotton and appears to have a tendency toward biasing on knit rows as seen in the tendency to lean in one direction in the above photos. It has no stretch, so stitches that knit off several tuck loops remain elongated. A look at the structure on the purl side:

The yarn used is cotton and appears to have a tendency toward biasing on knit rows as seen in the tendency to lean in one direction in the above photos. It has no stretch, so stitches that knit off several tuck loops remain elongated. A look at the structure on the purl side:  For more trims in this family, please see later post

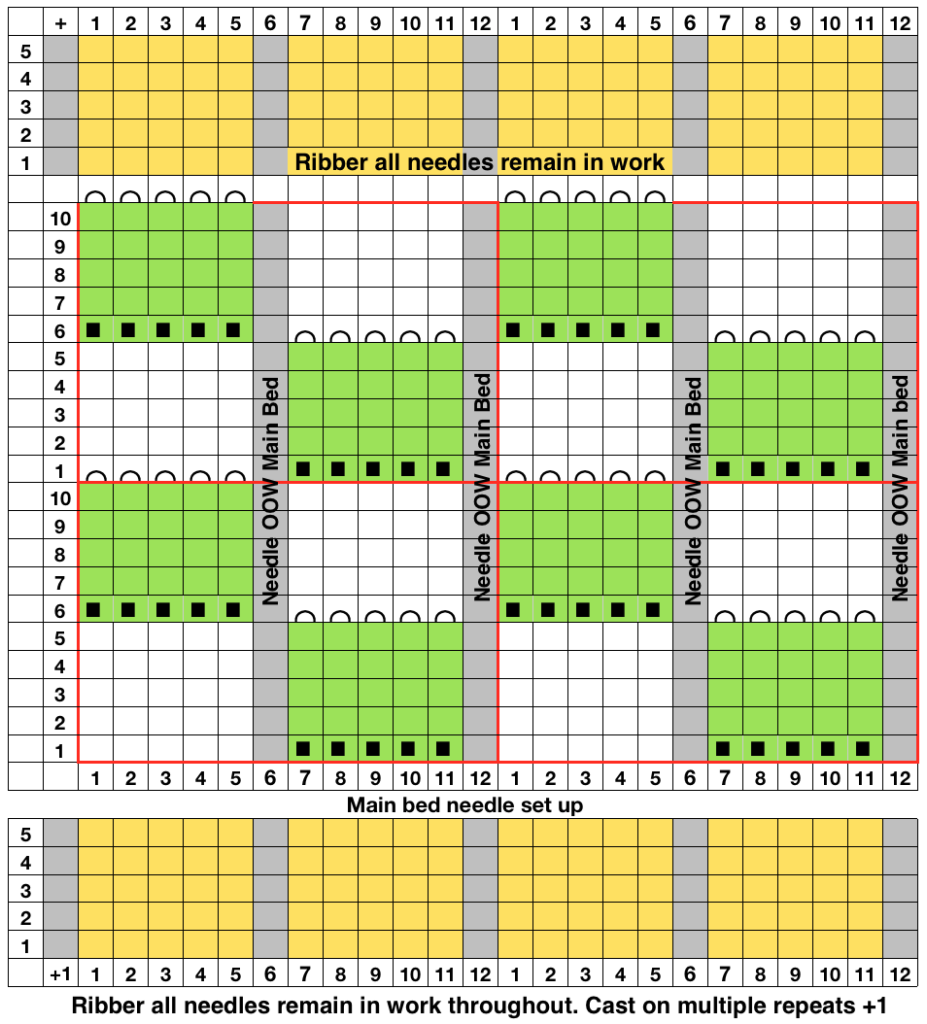

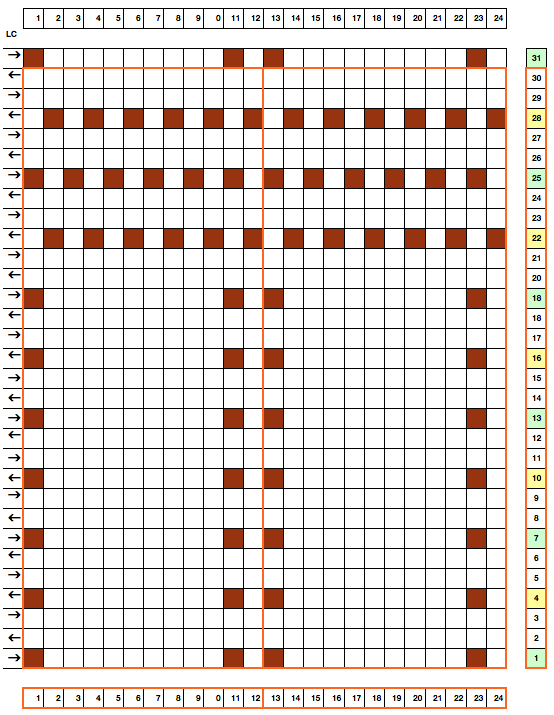

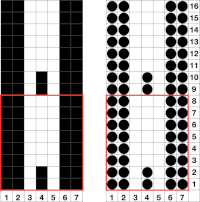

For more trims in this family, please see later post  If using the pattern on electronic machines, the needle selection needs to match on the top bed. Depending on the model electronic, the pattern may have to be reversed for accurate needle selection.

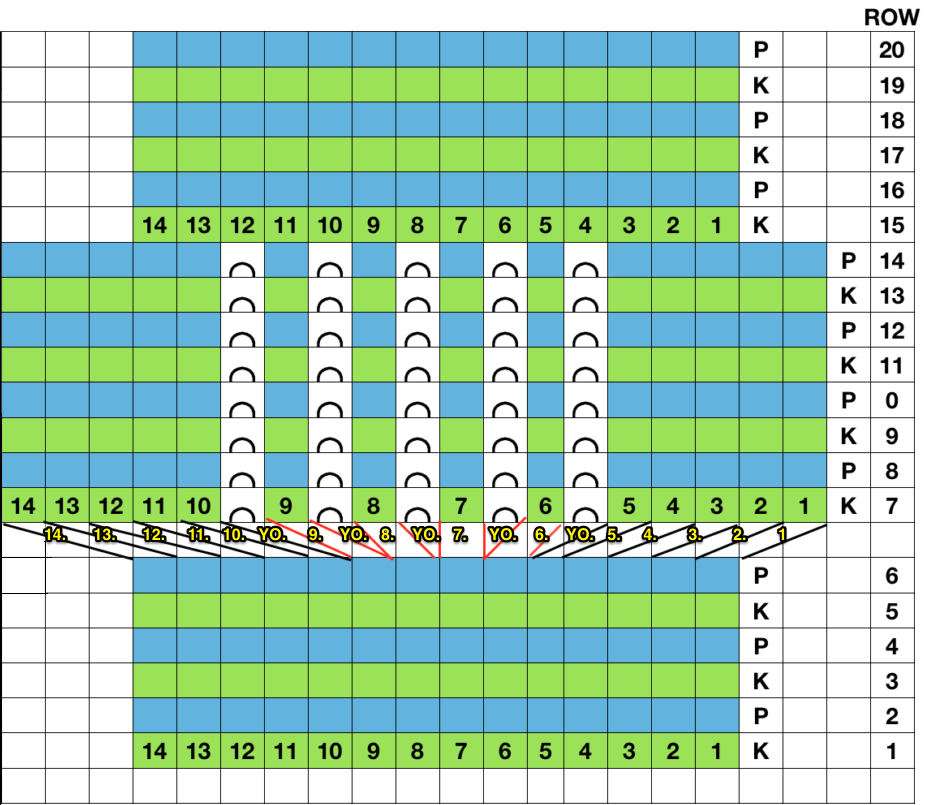

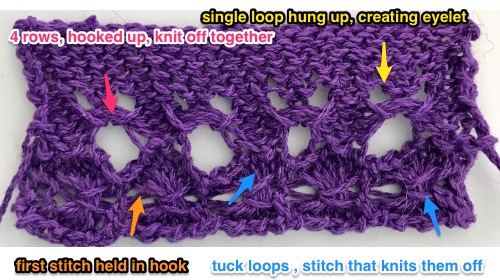

If using the pattern on electronic machines, the needle selection needs to match on the top bed. Depending on the model electronic, the pattern may have to be reversed for accurate needle selection. When using card 304, tucking happens for 3 rows forming loops that span across needles out of work, then all stitches on needles on rows with numbered markings on blue cells knit for one row. Orange gradient-filled cells represent rows on which tuck loops are being formed on the held single stitches, which in turn grow in length.

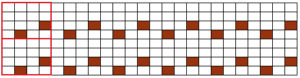

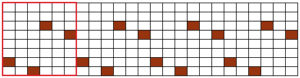

When using card 304, tucking happens for 3 rows forming loops that span across needles out of work, then all stitches on needles on rows with numbered markings on blue cells knit for one row. Orange gradient-filled cells represent rows on which tuck loops are being formed on the held single stitches, which in turn grow in length.  The full 24 stitch repeat, shifted for my preference, with the smallest electronic 8 stitch repeats outlined with red border

The full 24 stitch repeat, shifted for my preference, with the smallest electronic 8 stitch repeats outlined with red border

On the 930: the odd number of needles are automatically placed on the left, with the pattern used in the isolated design setting.

On the 930: the odd number of needles are automatically placed on the left, with the pattern used in the isolated design setting.

the tuck loops still form on the main bed, the ribber is set to knit every needle in both directions.

the tuck loops still form on the main bed, the ribber is set to knit every needle in both directions.  The resulting knit, very different in appearance and in width than the previous sample, using the same tensions

The resulting knit, very different in appearance and in width than the previous sample, using the same tensions