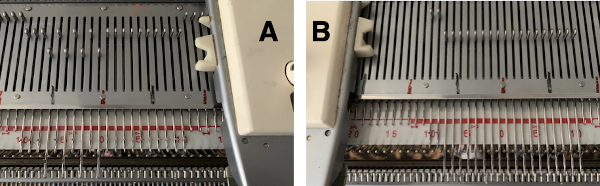

Early versions of the Brother Lace Carriage (LC) for machines such as the 830 and 860, even for the 890 did not offer options for choosing to using end needle selection, the default was none. From the 890 manual:  That said, they are present in the LC that accompanied my 892E punchcard model which match the 930 LC ones in appearance and operation and can override the selection made by the patterning device on the end needles. The two carriages, side by side, seen here with the slot in the horizontal position, indicating end needle selection is on.

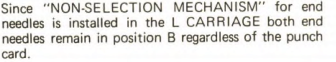

That said, they are present in the LC that accompanied my 892E punchcard model which match the 930 LC ones in appearance and operation and can override the selection made by the patterning device on the end needles. The two carriages, side by side, seen here with the slot in the horizontal position, indicating end needle selection is on.  The slot in the very center can be turned with a transfer tool, OW/out of work/ off, and W/work/on.

The slot in the very center can be turned with a transfer tool, OW/out of work/ off, and W/work/on.  In lace knitting, if any needles are selected for transfer to an end needle not in use in the piece, the LC still will attempt to transfer that stitch, and if no needle hook is there to accept it, the stitch will drop.

In lace knitting, if any needles are selected for transfer to an end needle not in use in the piece, the LC still will attempt to transfer that stitch, and if no needle hook is there to accept it, the stitch will drop.

With all over patterning across the needle bed, when an end needle has been selected on either or both edges, those needles must be pushed back to B position manually.

Since such selection is not likely to happen on every row, it may be an easy thing to forget as the length of the piece grows.

There are also point cams, that help to change the spacing between vertical lengths of design repeats. For images of the Lace carriage and use of point cams please see posts 2017/10/05/lace-point-cams-…brother-machines ..

Electronic carriages are equipped with a magnet, and must always travel past the center needle 0 position center mark on the needle tape.

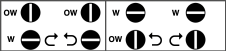

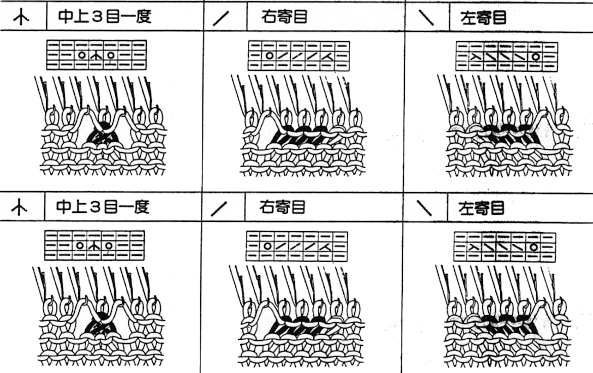

Markings on factory punchcards give clues as to which carriage to use and for how many passes.

They also may vary depending on the year the punchcards or mylars were issued. To review, here are some of the markings commonly found The graphic from the KH 860 punchcard model manual

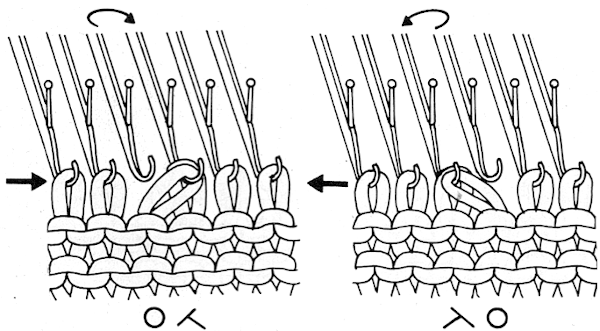

The graphic from the KH 860 punchcard model manual  Illustration modified and adapted from multiple decades-old Japanese magazines of fine lace

Illustration modified and adapted from multiple decades-old Japanese magazines of fine lace

single complete transfers

single complete transfers  Multiple transfers may be made either as a hand technique or expanded for use in electronics. Because single stitches are moved with each carriage pass, pattern repeats can become quite long, with few punched holes or black pixels

Multiple transfers may be made either as a hand technique or expanded for use in electronics. Because single stitches are moved with each carriage pass, pattern repeats can become quite long, with few punched holes or black pixels  Use a smooth yarn that has some stretch and does not break easily. Because the yarn will be transferred to and from or in addition also being shared between needles in fine lace, some extra yarn may be needed for proper stitch formation. In overall meshes begin testing using a tension at least one whole number higher than when using the same yarn for stocking stitch. Too loose a tension can result in dropped stitches or loops getting hung up on gate pegs, too tight and the stitches will not knit off properly or drop, or the yarn may even break. When eyelets are few, tension adjustments may not be needed.

Use a smooth yarn that has some stretch and does not break easily. Because the yarn will be transferred to and from or in addition also being shared between needles in fine lace, some extra yarn may be needed for proper stitch formation. In overall meshes begin testing using a tension at least one whole number higher than when using the same yarn for stocking stitch. Too loose a tension can result in dropped stitches or loops getting hung up on gate pegs, too tight and the stitches will not knit off properly or drop, or the yarn may even break. When eyelets are few, tension adjustments may not be needed.

Begin with waste yarn and ravel cord, then followed by casting on and knitting at least 2 rows before beginning to use the LC.

The cast-on will need to stretch to accommodate the growth in width which increases with increasing numbers of eyelets. The same applies to the bind-off. One option for matching both is seen in this “Answer Lady” video.

It is only when the knit carriage is operated that actual knitting takes place.

The movements of the lace carriage serve only to move or transfer stitches across the surface of the fabric. The card does not advance when the KC knits a row, so the movement of the card does not reflect the progress of actual knitting.

In most punchcard repeats, if when the row of transfers is completed there are two or more empty needles side by side, troubleshooting is required to solve the problem unless they are intentionally planned in the design, with deliberate adjustments to components of the overall pattern repeat.

The needles need to be in good condition, with latches that open and close smoothly and easily. Also, check for any bent gate pegs, and use a tool to even out the spacing between them if needed.

Error corrections need to be made to match the proper stitch formation.

As in any other knit, if tuck stitches occur in the same location and are not part of the planned fabric, it is likely the needle is damaged and needs to be replaced.

If a loop is sitting on top of a needle with a closed latch before knitting the following row, that stitch will drop. If it is noticed before knitting the row, the loop can be knit through the stitch manually while being mindful of what action that same stitch should take in the progression of the pattern.

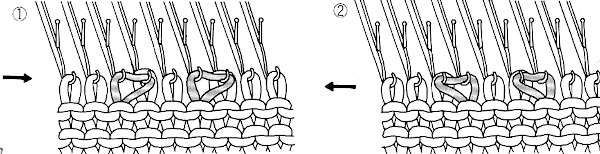

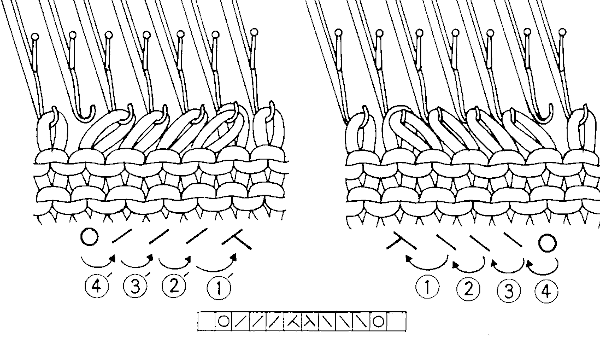

The appearance of tuck loops, red row To form eyelets a loop is created on the needles emptied by the transfers on the first pass with the knit carriage to the left (red), the stitch on that needle is completed as the knit carriage returns to the right (cyan)

To form eyelets a loop is created on the needles emptied by the transfers on the first pass with the knit carriage to the left (red), the stitch on that needle is completed as the knit carriage returns to the right (cyan) If when trying to correct the direction of a transfer or a dropped stitch the transfer is not formed properly and the stitch in that location is knit manually the eyelet will be absent

If when trying to correct the direction of a transfer or a dropped stitch the transfer is not formed properly and the stitch in that location is knit manually the eyelet will be absent

The traditional placement is for the LC (Lace Carriage) on the left, and the KC (knit carriage) on the right, but some patterns can work with their placement reversed or even swapped at regular intervals as knitting progresses.

Bringing needles out to E before the all-knit row may help avoid additional dropped stitches when there are multiple stitches on any needles.

Though knitting may proceed smoothly, checking the work frequently visually will make the rescue of problem areas possible as opposed to having to restart the project.

If test swatches are hard to knit, the problems will likely multiply when a larger group of needles is in use and the project should be put aside.

Because there are so few markings in lace, the lace card does not necessarily resemble the finished stitch appearance.

Needle pre-selection does not make as much sense as in other types of patterns. Where knit stitches occur in vertical stripes may also not be immediately evident. Needle selection on punchcard models is fixed, some shifting on the needle bed rather than centering may be required to have a specific repeat placement or a cleaner edge, which also matters in seaming.

There are definite top and bottom directions to lace, so in knitting scarves or sleeves that is a consideration. One solution is to knit 2 pieces in mirrored directions with many possibilities for methods to join them.

No top-down knitting on sleeves if you wish to match the body and it has been knit from the bottom up.

It is possible to use short rows combined with lace patterns, but any shapes created are likely to change visually, so planning is required unless those changes are deemed suitable.

Traditional holding by changing the knit carriage setting may not be used. Needles to be put on hold need to be knit back to A position and brought back into work as needed.

Ravel cord or any tightly twisted cotton may be used.

If needles have a tendency to slide forward when holding large sections or at the hold starting side as the piece progresses, some tape may need to be placed in front of the needle butts on the metal bed to hold those needles in place.

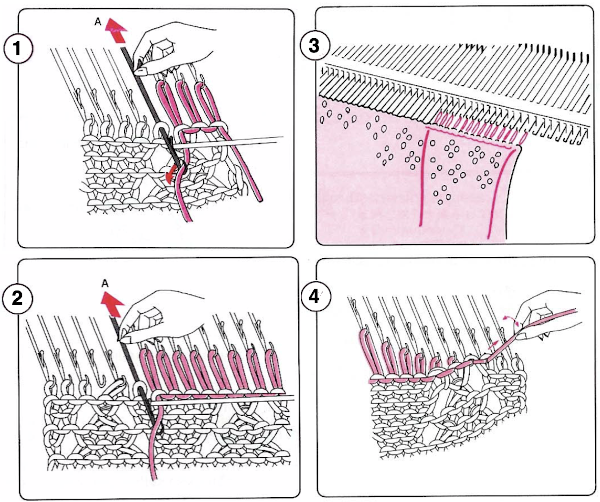

These illustrations of the process are from an early Brother machine manual  Lace and holding effects may be produced by combining LC use with the knit carriage set to slip stitch and also selecting needles in pieces such as automated edgings or doilies. The design repeats are not interchangeable between punchcard and electronic models.

Lace and holding effects may be produced by combining LC use with the knit carriage set to slip stitch and also selecting needles in pieces such as automated edgings or doilies. The design repeats are not interchangeable between punchcard and electronic models.

When two carriages in Brother punchcard machines first move in the same direction selecting needles, ie. the knit carriage moves from left to right, the LC follows it also moving from left to right, the card does not advance. The same needles are re-selected on the next pass, repeating the design row.

On electronic machines, the mylar or memory/downloaded patterns are triggered by the magnet at the rear of the knit carriage to advance on every row.

The designs need to be planned or adapted based on the type of machine.

As with any knitting, there are times when nothing seems to work for no good reason after intervals of smooth knitting and no other changes, and a break is best for both the operator and the machine.

The greater the number of eyelets in the pattern, the wider the finished knitting. Blocking in some form will usually be required to set the stitches, and may be required if the piece grows in length and narrows as it is worn or hung when stored.

Out of habit I usually leave weaving and tuck brushes in use for all my knitting, but particularly when creating textured stitches and lace.

Gauge swatches should be larger than usual, all in the pattern, and treated as the final piece will be in terms of pressing, blocking, washing, and allowed to rest before obtaining measurements for garment calculations.

When stitch symbols first appeared in Japanese publications they were represented as the stitch formation occurring on the knit side of the fabric, which could be confusing since in machine knitting we are looking at the purl side. Eventually, Nihon publications made the transition and other pubs followed.  A comparison of hand-to-machine stitch symbols with illustrations and more information: hand-to-machine-symbols-5-lace/

A comparison of hand-to-machine stitch symbols with illustrations and more information: hand-to-machine-symbols-5-lace/

For cross-brand use: 2019/02/23/revisiting-use-of-lace-patterns-studio-vs-brother-machines/

I have been blogging for years and sometimes return to topics after long absences. In terms of more information on lace design and some tips on translating hand-knitting instructions for machine knitting please see: 2013/07/23/from-hand-knit-lace-chart-to-punchcard-1/

2013/07/24/from-lace-chart-to-punchcard-2/

2013/07/26/from-lace-chart-…3-adding-stripes/

2013/07/27/from-lace-chart…-4-a-border-tale/

2013/07/29/from-lace-chart-to-punchcard-5-to-electronic/

2013/08/29/from-lace-chart-to-punchcard-6-to-electronic/

Transfer lace cards have very few black squares to avoid transcribing errors for punching holes or generating electronic repeats, work with a reproduction of the graph that makes it easy to view squares or pixel placements ie using Gimp, X800+.

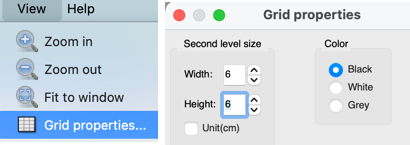

Blank Brother cards are dotted in lines dividing the cards into 6X6 blocks.

Mark graph paper or software grids) if possible, in 6X6 blocks.

In ArahPaint the latter can be done by adjusting grid properties

The Brother, Toyota, and Studio fashion lace punchcards may be used on all 3 brands as long as there are 2 blank rows after each transfer sequence.

The first row on Brother is preselected from left to right and transferred from right to left, while on Toyota it is transferred from left to right. Brother and Toyota cards are interchangeable provided the repeat is mirrored vertically or knitting starts with and operates with the carriages on the opposite sides recommended by the alternate brand.

Studio knitting begins with 2 blank rows, Brother starts with a punched row and ends with 2 blank rows, the first preselection row on the cards with locked selection needs to be adjusted accordingly.

The Brother LC does not advance the row counter, only the KC does.

Stitches are transferred in the direction that the lace carriage is moving. In most cases, the LC preselects toward the KC and transfers when moving away from it. Brother and Toyota cards are marked with U-shaped arrows to identify when to knit with the knit carriage.

Studio simple lace cards where stitch transfers and knitting occur in the same carriage pass may also be used on Brother machines, but require special handling discussed in other posts.

One of many methods to deal with dropped stitches: secure them by going through them using a needle threaded with a ravel cord.

Unravel back to an all-knit row undoing lace transfers carefully, to the point where stitches were dropped, rehang the dropped stitches, and remove the ravel cord.

Roll back the card, mylar, or electronic row count to match the number of rows unraveled.

Unless the knitting carriage is also set to select needles, only the LC advances the design rows. I prefer to roll back cards or electronic counts after each row is unraveled.

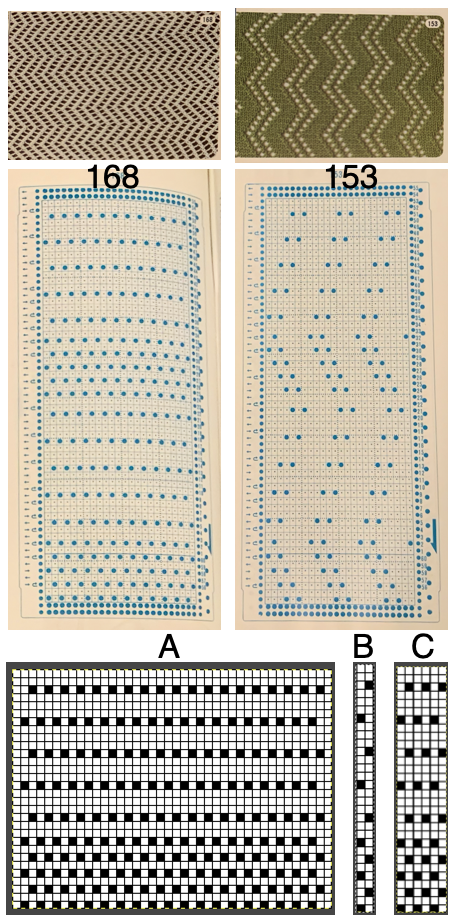

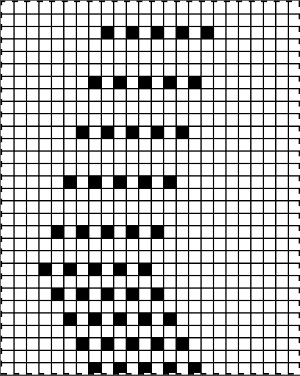

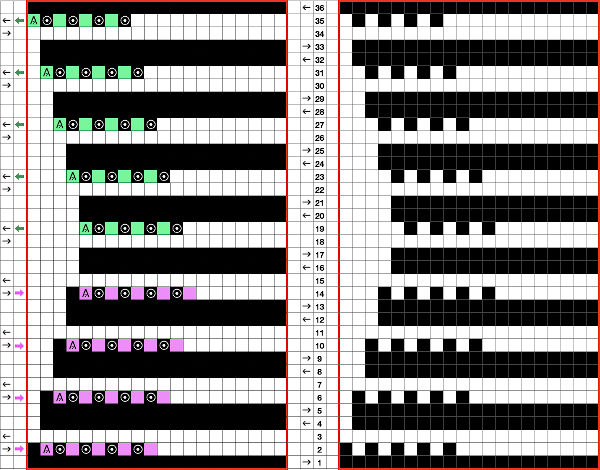

A punchcard tale: after the chevron post, single-color sideways chevrons appealed to me. Two variations from a Brother Punchcard Volume  A the full 24 stitches wide repeat, half the required height for the punchcard user.

A the full 24 stitches wide repeat, half the required height for the punchcard user.

B the single electronic repeat.

C the single electronic repeat tiled X3, checking to see that pixel actually line up properly.

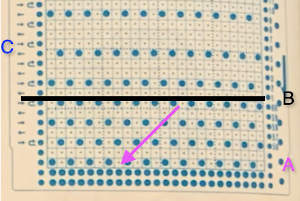

Punchcard markings of note:

A design row 1

B mark for the first row visible on the exterior of the machine, the card reader is reading 7 rows down

C typical markings for the direction of the LC movement on that row, and for knit rows The two rows at the bottom of the card reflect the overlap when punchcard snaps are in use to keep the pattern continuous.

The two rows at the bottom of the card reflect the overlap when punchcard snaps are in use to keep the pattern continuous.  Looking at it in more detail

Looking at it in more detail  Column identification at the bottom of the chart:

Column identification at the bottom of the chart:

A direction of the lace carriage, pixels, or punched holes preselected on that carriage pass

B direction of transfers; note there are extra blank rows where their direction is reversed indicated also by the change in the color of the arrows. Multiple rows in one direction only, happening here in a series of 5, will result in biased knitting. As bias is reversed, the zigzag shape begins to be created.

C markings for 2 rows worked with the knit carriage, the pattern does not advance on those rows on any machine

D markings on factory punchcard

E design rows

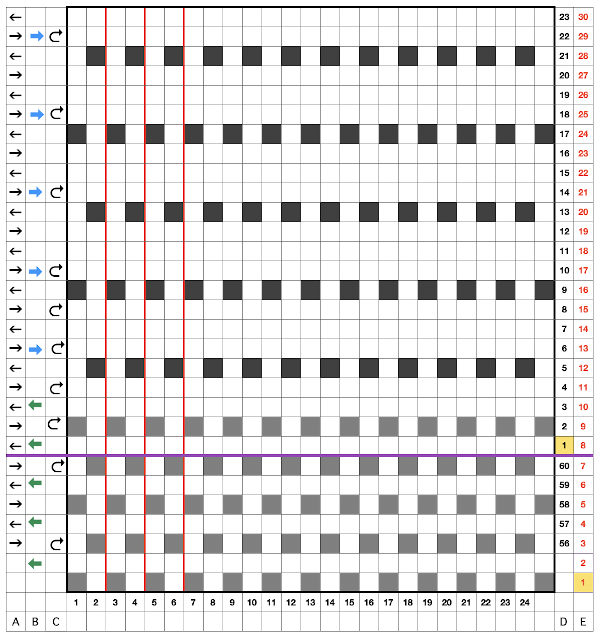

When working with electronics, the actions need to match those indicated on the factory design beginning with the row one punchcard marking on the right.

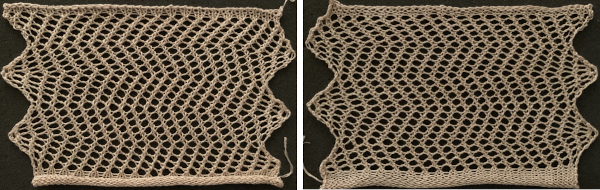

The width of the planned swatch or piece may be programmed for use with the single motif setting in img2track or the required default in Ayab. Adding a blank square at each end ensures the end needle will knit on every row, no pushing back needles by hand will be required. Changing fibers opens up a brand new world: this swatch (unblocked) is knit in a tightly twisted rayon, and edges also begin to create clearer shapes than that achieved by knitting the same design using wool.

Changing fibers opens up a brand new world: this swatch (unblocked) is knit in a tightly twisted rayon, and edges also begin to create clearer shapes than that achieved by knitting the same design using wool. Spacing out the zigzags, another 24X30 repeat. This is the minimum repeat for electronic KMs as well, knit stitch spacing (white squares) can be planned to suit

Spacing out the zigzags, another 24X30 repeat. This is the minimum repeat for electronic KMs as well, knit stitch spacing (white squares) can be planned to suit

Once again, one must be aware of whether the lace repeat needs to be mirrored on the specific model machine. I initially forgot to do this on my 930, which results in error with the lace carriage operated from the left.

Planning the placement on the needle bed controls the number of knit stitches on either side of the resulting mesh shape. Today the rayon was having no part of knitting properly, this swatch is once again in wool.

Ideas for automating mesh patterns in lace edgings using the LC and the KC (knit carriage) set for slip stitch

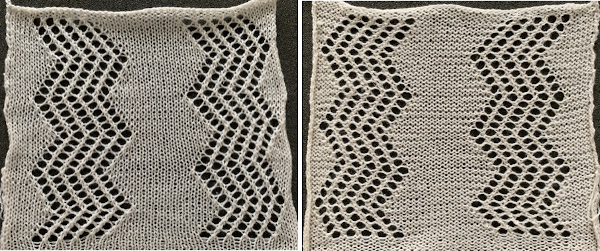

Changing the above repeat for a zigzag border: in my first experiment, I tried keeping the number of eyelets in the zigzags across rows constant, did not like the visual “extra” line away from the edge, and was happier with my second try. This fabric would do better with a yarn that can be blocked to shape, the wool used here is a tad too thin. There will be some tendency on the part of the eyelets on the very edge to appear smaller as the edge stitches are stretched into shape. It appears I also have a needle that needs to be changed The transfers of the stitches by the LC while using the knit carriage set to slip in both directions to create the knit rows, and will automatically create increases and decreases along the left edge. Due to this fact, there will be one less eyelet in each transferred row than the number of pixels/punched holes in its corresponding pattern row.

The transfers of the stitches by the LC while using the knit carriage set to slip in both directions to create the knit rows, and will automatically create increases and decreases along the left edge. Due to this fact, there will be one less eyelet in each transferred row than the number of pixels/punched holes in its corresponding pattern row.

The knit carriage in this instance preselects rows for the lace carriage, the lace carriage preselects all needles required on its way back to the left for the knit carriage to knit on its next pass.

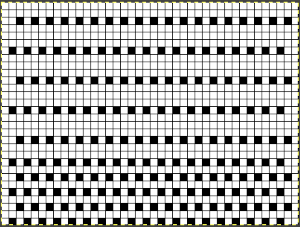

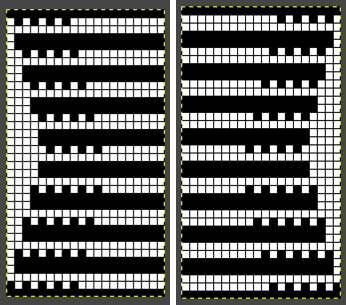

This chart attempts to show the movements of the carriages and the location of stitches after they have been moved along with eyelet symbols in their locations after the transfers  The pattern repeat on the left below is as I drew it and intended it, on the right, it is mirrored for use to knit it on my 930

The pattern repeat on the left below is as I drew it and intended it, on the right, it is mirrored for use to knit it on my 930 The first preselection row is from right to left, the knit is centered with 10 stitches on each side of 0.

The first preselection row is from right to left, the knit is centered with 10 stitches on each side of 0.

In edgings beginning with a single all black pixels row, end needle selection is canceled on the knit carriage (KCII), turned on in the lace carriage (LC).

The first row is knit, when the KC reaches the left side, set it to slip in both directions. As it returns to the right it will form a second knit row on all needles in work, and preselect for the first LC pass.

Extension rails must be used as both carriages will lock onto the belt for pattern selection.

At the start of the piece, as the LC moves from left to right it will transfer preselected needles to the right. On its return to the left, it preselects needles that will knit as the KC returns to action from the right.

Each carriage in this design makes alternating pairs of passes.

When the top half of the pattern repeat is reached, the LC makes its pass to the right on a blank design row. As it does it preselects for the next row of transfers, which are made to the left as the LC returns to its home there (A). Though the Brother LC does not knit and transfer on the same row as the Studio one can, it can transfer and preselect for the next row of knitting (B). The above fact allows for planning transfers in both directions while still keeping the routine of 2 passes for each carriage to and from their original home.

The above fact allows for planning transfers in both directions while still keeping the routine of 2 passes for each carriage to and from their original home.

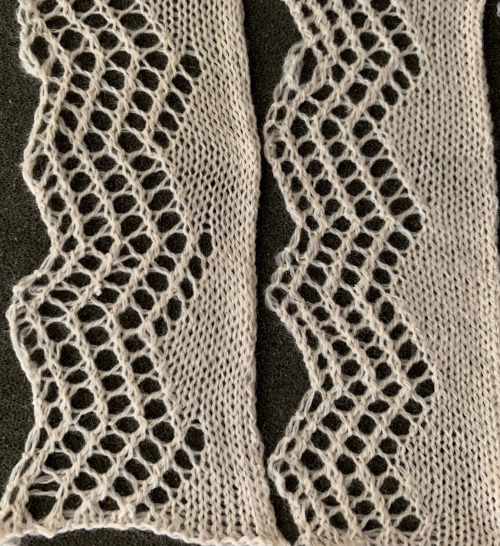

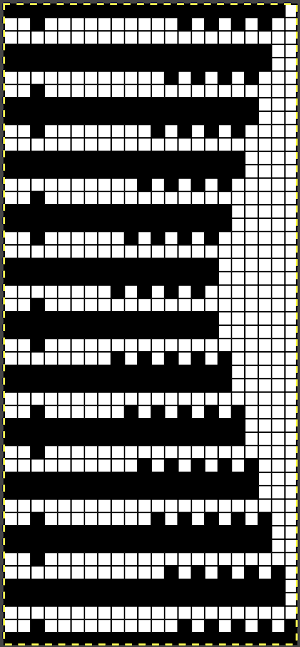

Based on that concept, here is another trim with eyelets in alternating directions along the side opposite the zigzag shape.

The repeat is now adjusted to 22 stitches X 48 rows to accommodate the reversing eyelets arrangement.

It is shown here mirrored for download to my 930.

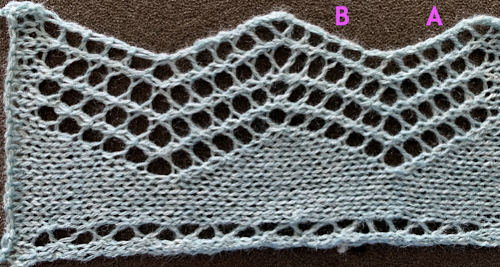

There is a blank square at the top right corner, the corresponding stitch will be cast on by the knit carriage on its move to the left and transferred automatically when there is a return to transfers at the bottom of the design repeat.  The yarn used or the swatch is a 2/18 wool silk. There will be 2 stitches on each needle (A) at the very edge where stitches are transferred for decreases and look different than where the edge stitch is simply moved one needle to its left (B), leaving behind an empty needle. A parallel, similar difference is also noted at the inner edge of the zigzag shape. The sample is pictured turned 90 degrees counter-clockwise, and its bottom edge appears on the right

The yarn used or the swatch is a 2/18 wool silk. There will be 2 stitches on each needle (A) at the very edge where stitches are transferred for decreases and look different than where the edge stitch is simply moved one needle to its left (B), leaving behind an empty needle. A parallel, similar difference is also noted at the inner edge of the zigzag shape. The sample is pictured turned 90 degrees counter-clockwise, and its bottom edge appears on the right  Transfer lace on the Passap: the console will be used to select needles for hand transferring stitches. The technique will determine the number of plain rows between transfers. Use tech 137 for two rows between transfers. The pushers will set the corresponding black cells for transfers, they will stay in that position until the next set of transfers. Many tuck patterns may be used to make the selections, they are not designed to knit on adjacent needles, choose ones that have white columns for nonselected pushers 2 rows in height. Stitches are worked on the front bed. The front lock is set to N and the back lock to GX. Move selected pushers up so that the corresponding needles are easily identified, and use a tool to move stitches right or left. Move all stitches in the same direction, first across a row to the right, then across a row to the left to avoid biasing if the pattern is an all-over one, for borders all transfers in the same direction may work as well. Leave the needles in the work position, return the pushers to rest, and continue in the pattern.

Transfer lace on the Passap: the console will be used to select needles for hand transferring stitches. The technique will determine the number of plain rows between transfers. Use tech 137 for two rows between transfers. The pushers will set the corresponding black cells for transfers, they will stay in that position until the next set of transfers. Many tuck patterns may be used to make the selections, they are not designed to knit on adjacent needles, choose ones that have white columns for nonselected pushers 2 rows in height. Stitches are worked on the front bed. The front lock is set to N and the back lock to GX. Move selected pushers up so that the corresponding needles are easily identified, and use a tool to move stitches right or left. Move all stitches in the same direction, first across a row to the right, then across a row to the left to avoid biasing if the pattern is an all-over one, for borders all transfers in the same direction may work as well. Leave the needles in the work position, return the pushers to rest, and continue in the pattern.