Some notes on how tubular software color separations such as the one automated in the ayab circular setting may be found in the previous post

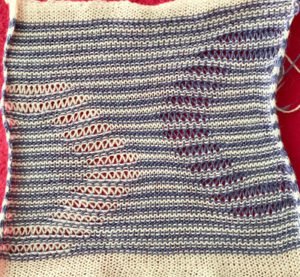

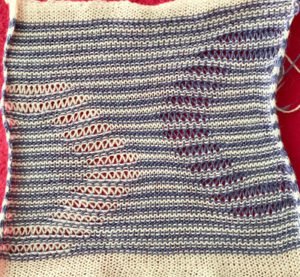

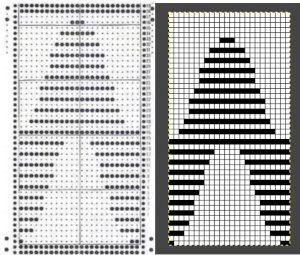

In an effort to respond to a request I have had via my blog, I am sharing information on this topic as I have time to explore it. My first attempt when up and running with the Ayab software, was to reproduce an earlier sample I had created as a color separation originally intended for a hand-knit shadow knit experiment.

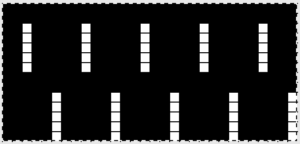

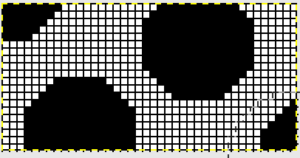

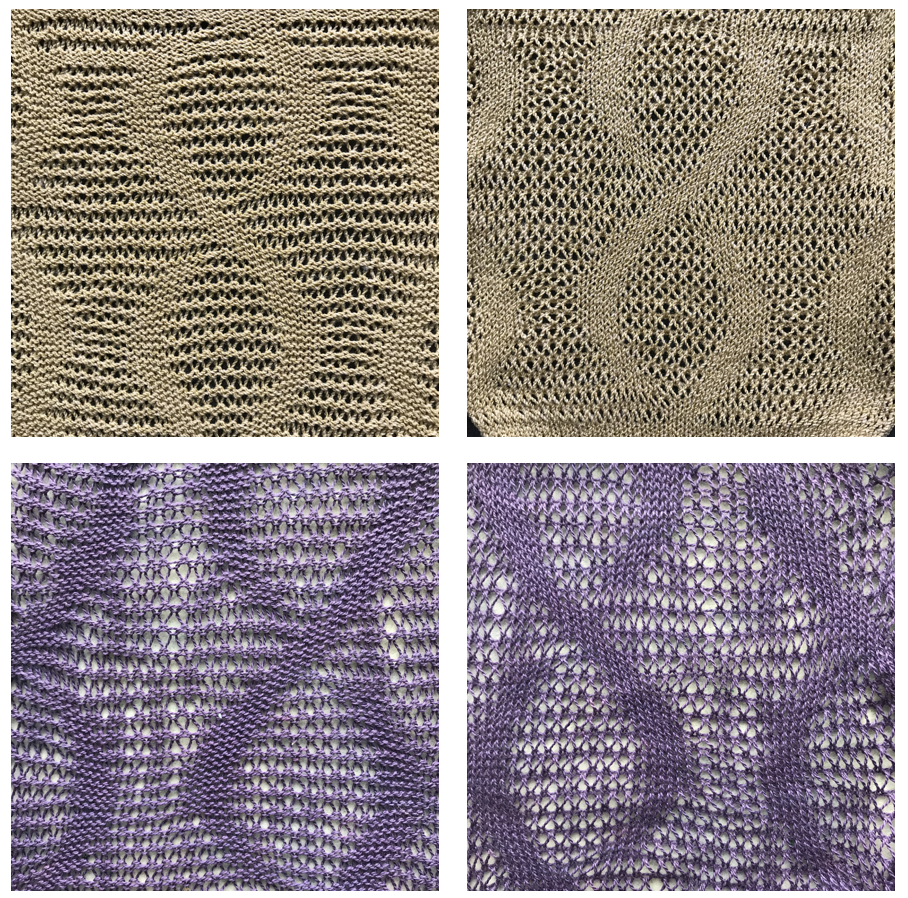

a chart from that blog post  the resulting hand knit, on the purl side

the resulting hand knit, on the purl side

the color-separated sample knit pre ayab

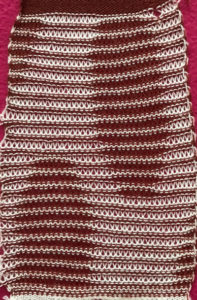

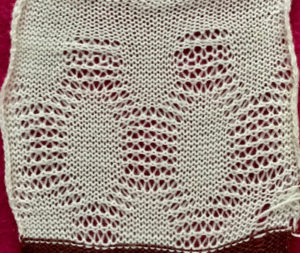

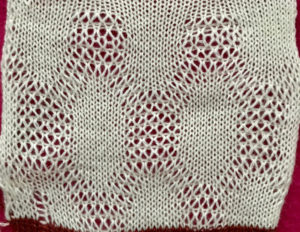

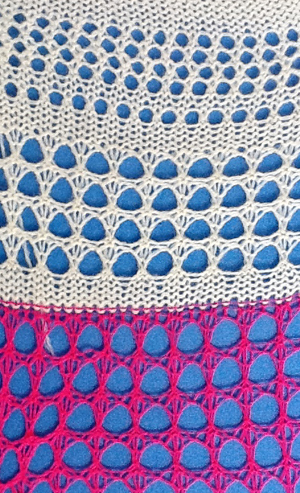

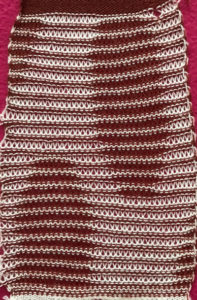

the color-separated sample knit pre ayab  the sample knit using the Ayab circular setting

the sample knit using the Ayab circular setting

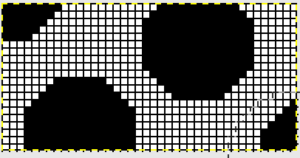

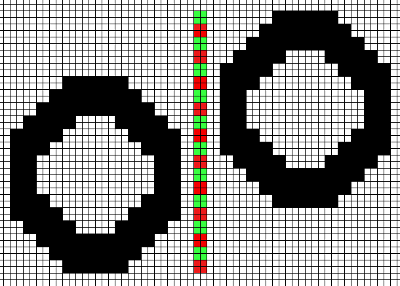

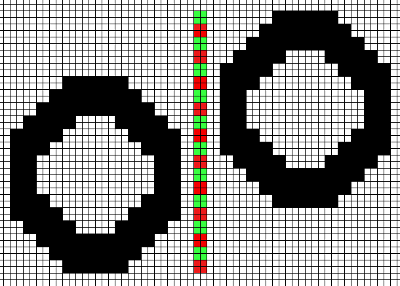

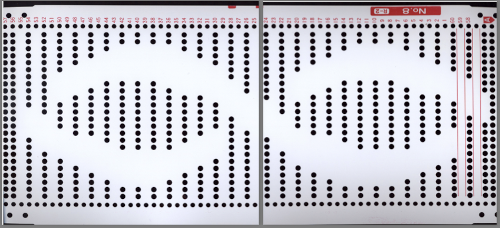

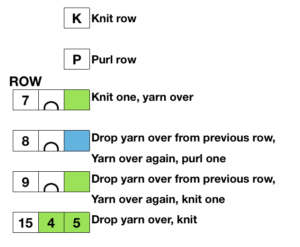

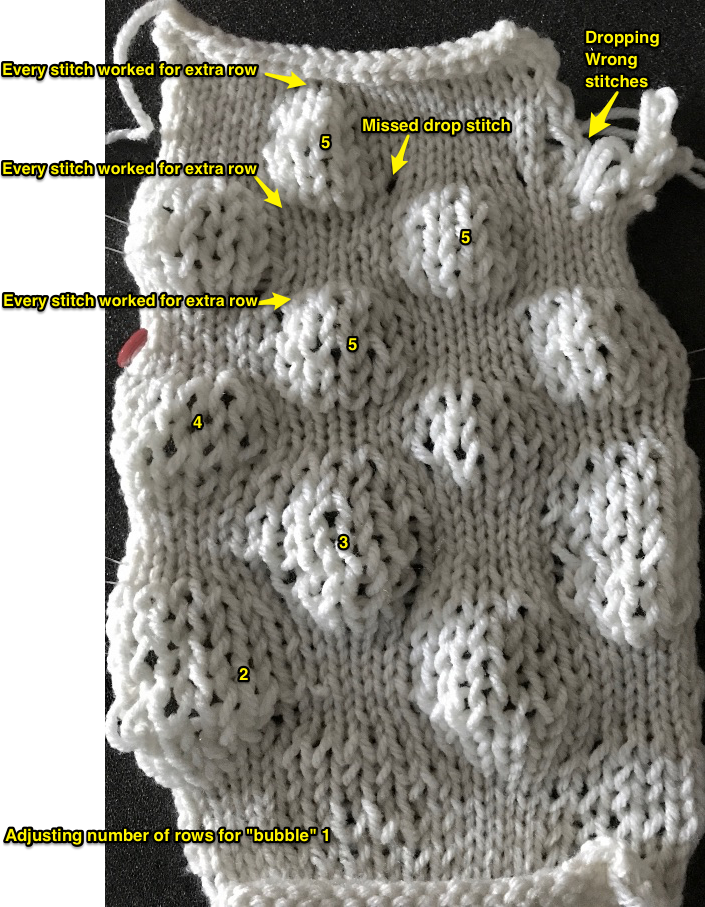

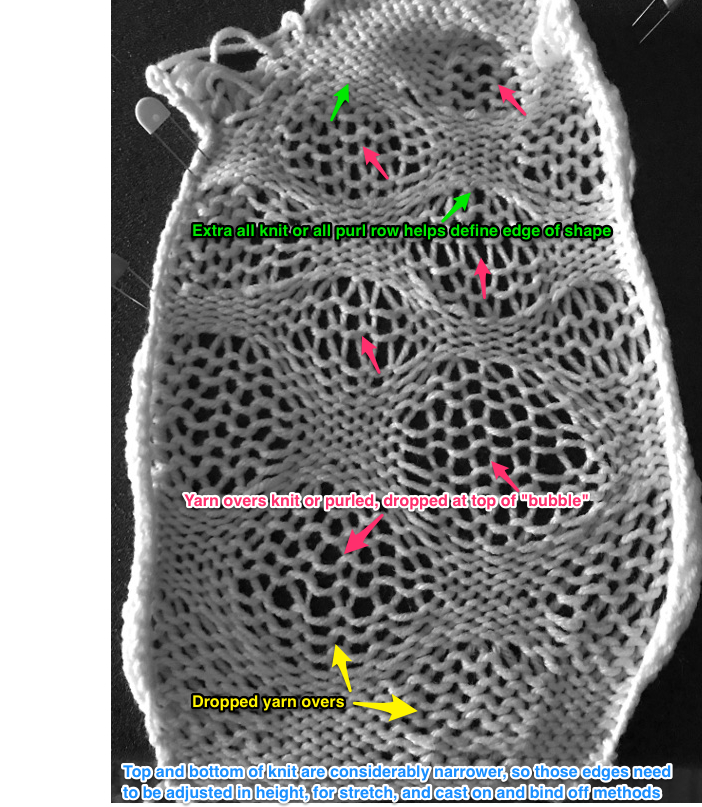

Patterns predawn for shadow knitting, appear to be one published source for interesting 2 color drop stitch variations. What about geometric shapes or developing your own designs? Designs created using this technique lengthen considerably when off the machine. Both color sets of stitches become elongated as they are dropped, and that should be a consideration in planning your design. If your goal is a circle, the actual shape programmed may have to be closer to an egg laid horizontally rather than that of a “true” circle. The fabric also widens considerably when blocked and off the machine, making the cast on and bind off methods considerations another necessity. Design repeats may be drawn in Paintbrush or GIMP (both freeware), or Photoshop. I have been a long time GIMP user, and prefer to use it in tiling repeats as opposed to the copy and paste features in Paintbrush to accommodate the Ayab requirement of programming the repeats horizontally in the width of your piece.

In my previous, how-to posts on designing your own 2 color drop stitch lace, part of the color separation required elongating the design X 2. The starting side in Ayab for needle selection always needs to be from left to right, and elongation of the motif is not required when using the Ayab circular option.

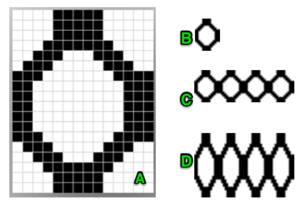

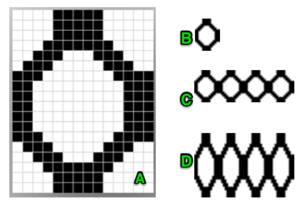

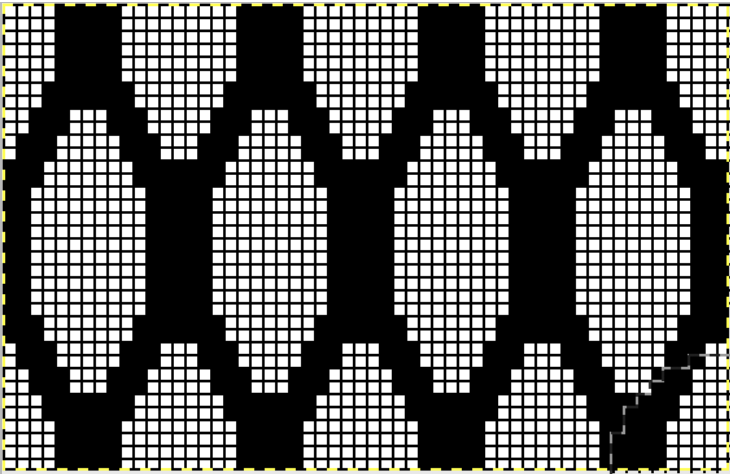

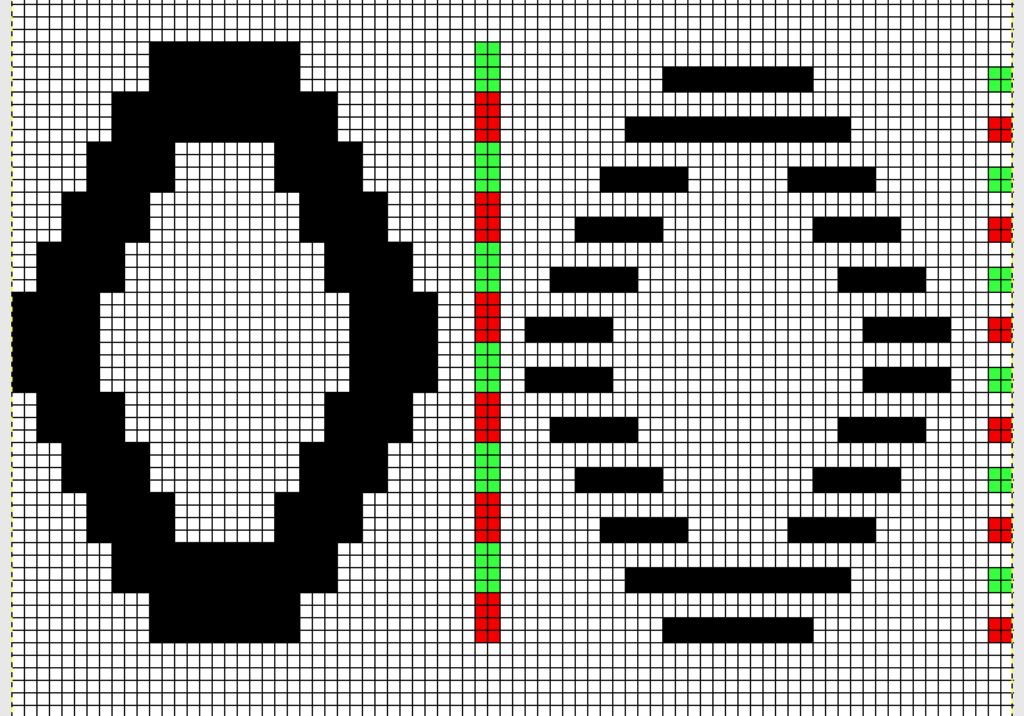

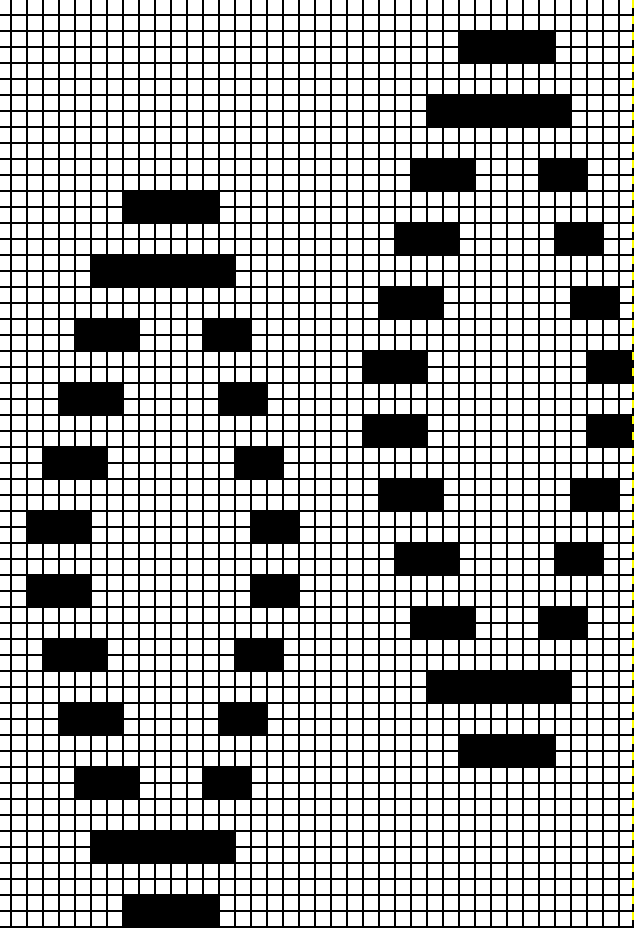

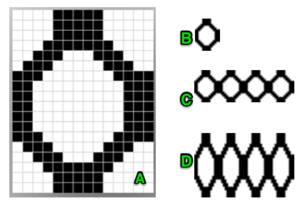

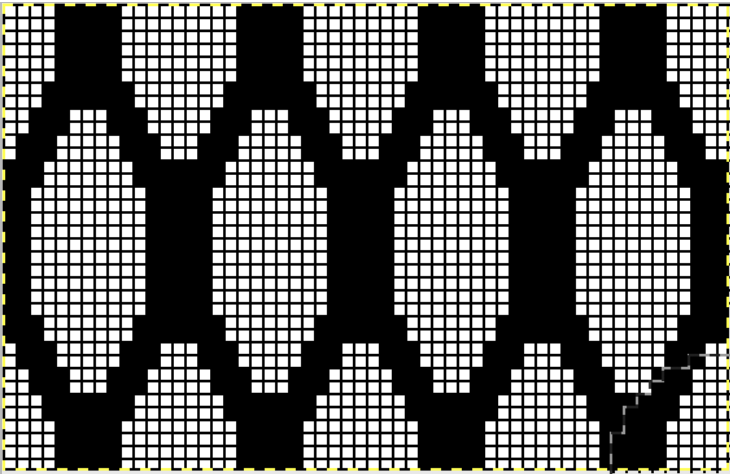

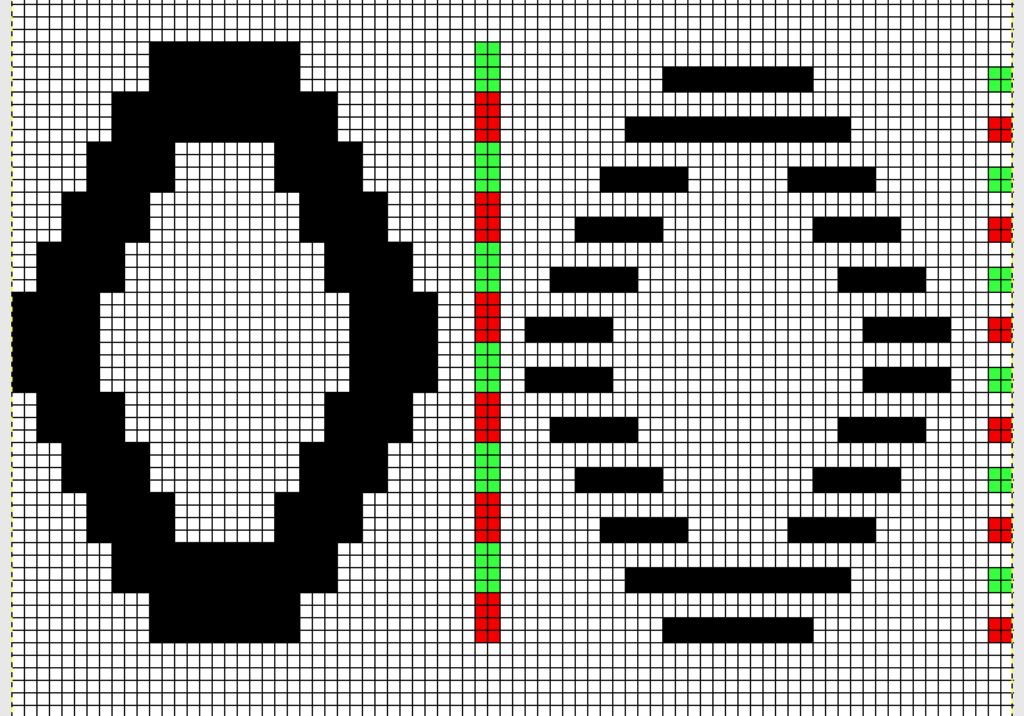

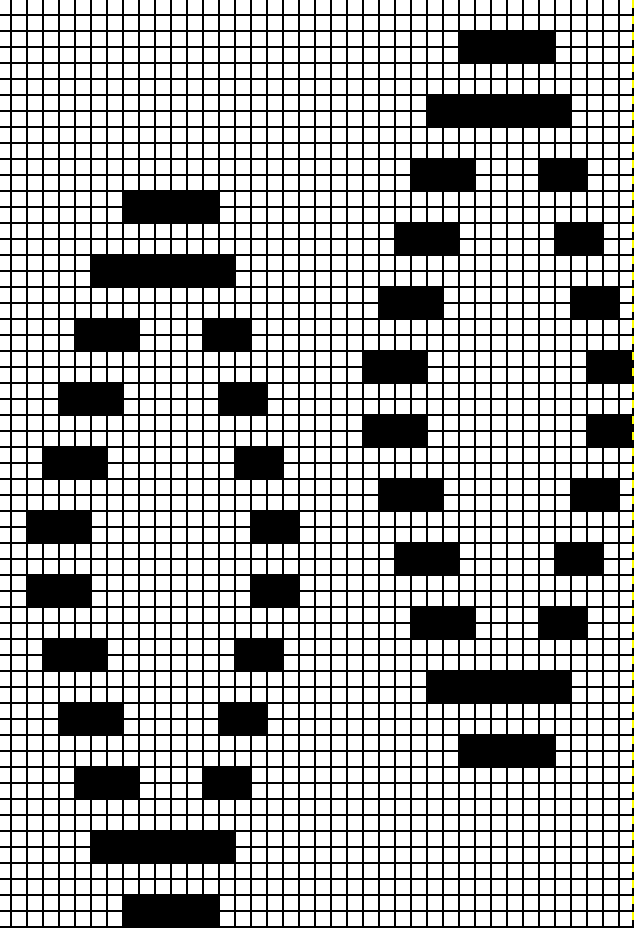

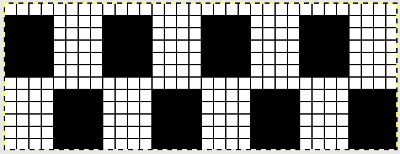

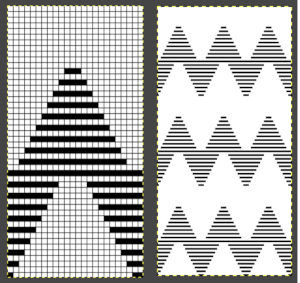

This was my first working repeat, A = repeat charted out. B = the working bitmap or png, etc. (which would be the only requirement for the mylar). C = the image tiled for the chosen number of stitches (again, Ayab requires the repeat to be programmed for the width of your knit piece). D = the image elongated, not usable for this fabric, it results in too much elongation. If you would like a knit border on either side, that can be achieved by having extra stitch(es) in work on the ribber.  a possible ayab repeat, 56 stitches wide by 36 rows high

a possible ayab repeat, 56 stitches wide by 36 rows high

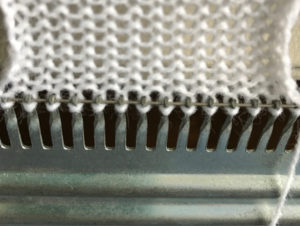

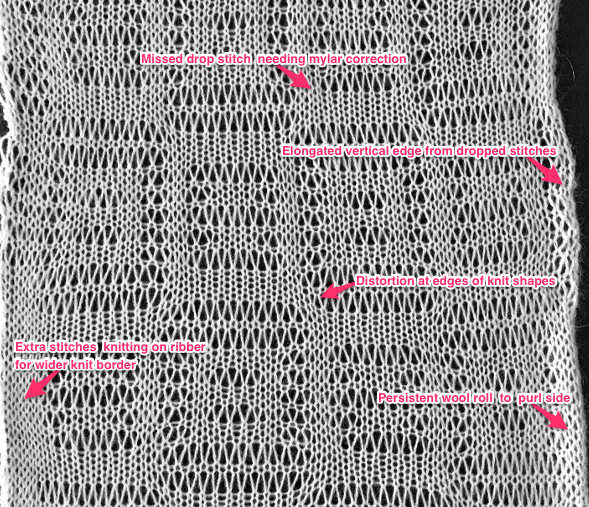

The results up to the point in which I had a yarn caught in brushes and stitches dropping on the left of the needle bed:

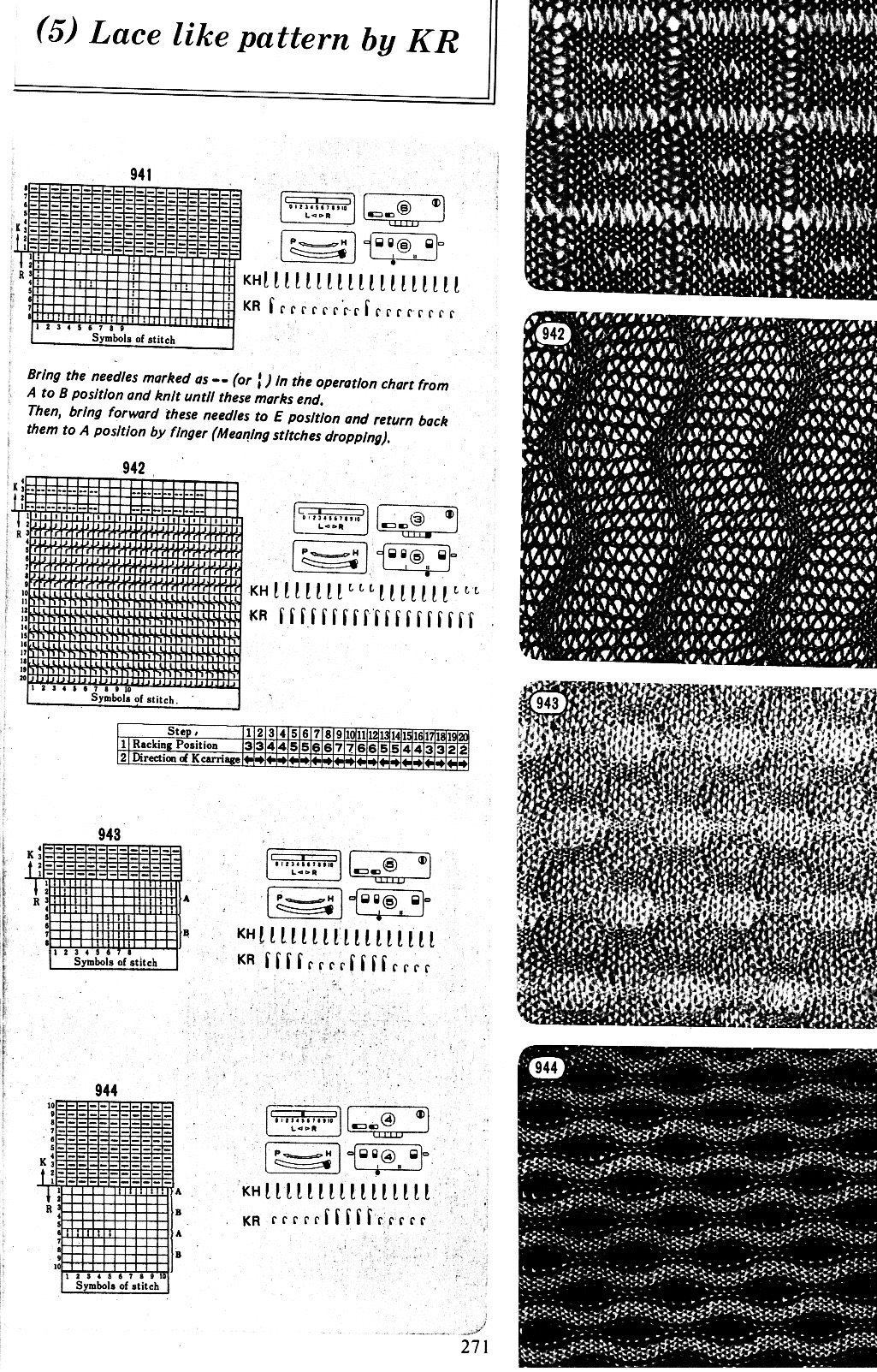

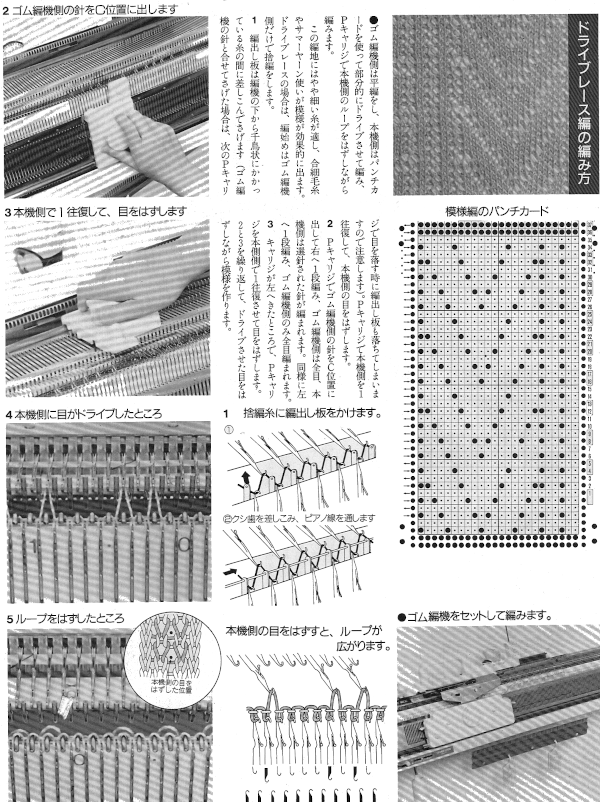

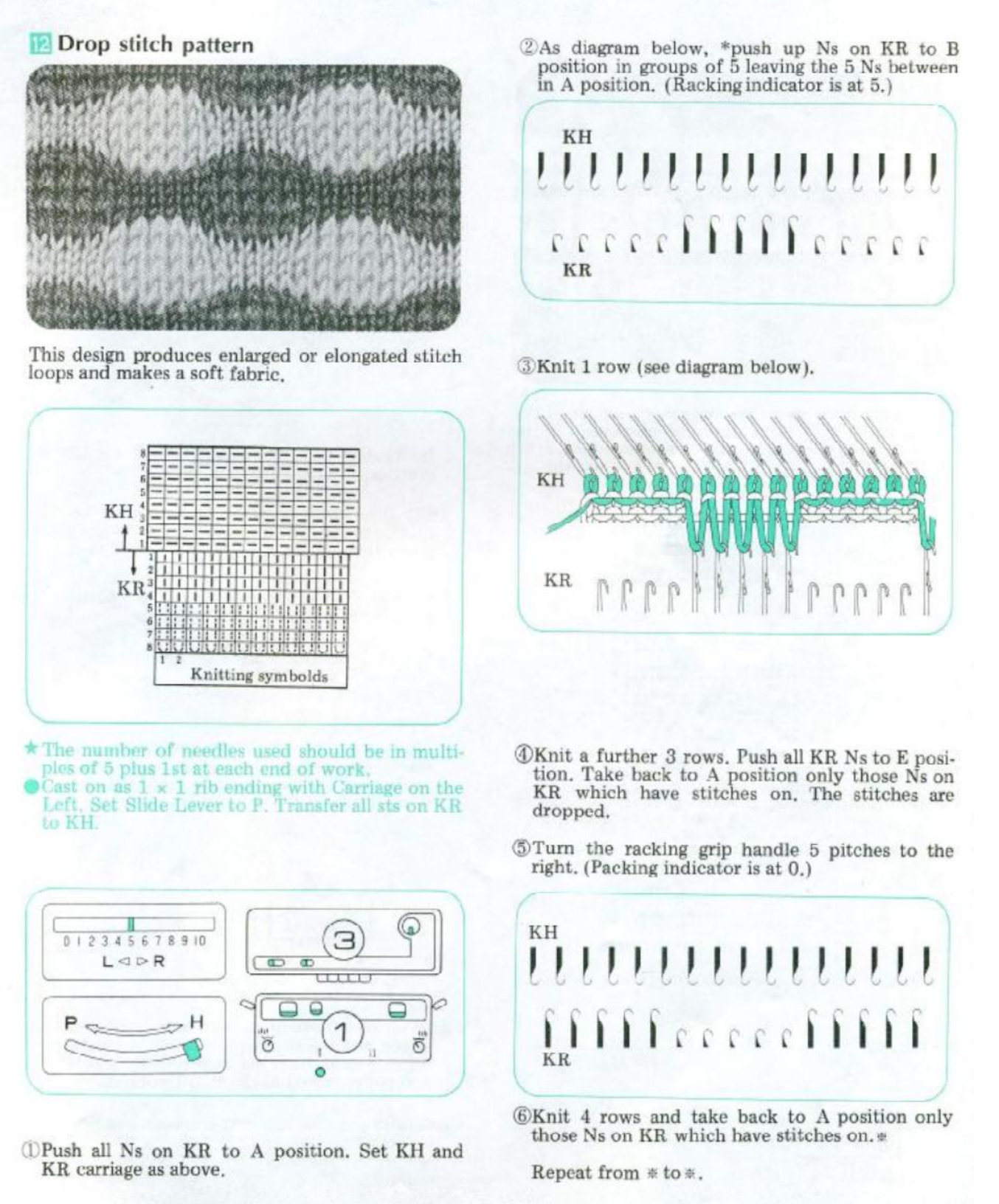

Drop stitch lace has been referred to over the years in other terms as well, such as release stitch, drive lace, and summer fair isle in Passapese. Passap knitters will recognize the results from this first method are akin to those produced using Technique 185.

Getting started: stitches intended to be dropped may be created on either bed. If the ribber is used to create loops, then the technique is a manual one. Using the main bed in Japanese machines to program dropped stitches increases accuracy and ease.

If you are swatching and testing, a permanent cast on is not necessary. The broken toe cast on is one of the two quickest on the Japanese machines, usable on either bed. It is fondly called that because if ribber cast on comb and weights are in the wrong place so that the wrong loops are dropped, everything falls to the floor, and likely on your toes. There is an online video by Diana Sullivan that shows its use for a tighter cast on row in 1X1 rib, but the use here is for a different purpose.

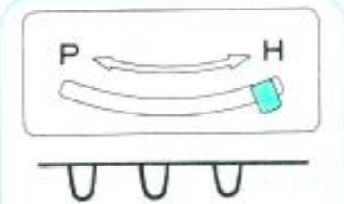

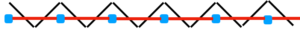

In producing this fabric you are technically knitting every needle rib.  Cast on a fairly tight zig-zag row. The ribber comb wire needs to be placed so that it holds down the stitches on the bed on which you need to keep them. The principle and results are akin to the first row knit when you use a single bed cast on comb, and the second pass, with the first knit row anchors open loops before you continue to knit. Any loops not secured by the comb will result in dropped stitches. Any fabric, any time, when 2 stitches are empty side by side, stitches are not formed and the yarn is dropped off them creating a float or ladder. The red line indicates the ribber wire on top of the ribber loops in the zigzag row, placed so released knitting will be left on the ribber. Black lines your zig-zag yarn loops, blue dots the teeth of your ribber cast on comb. You can check placement by dropping just a few loops on the main bed before hanging your weights on the comb.

Cast on a fairly tight zig-zag row. The ribber comb wire needs to be placed so that it holds down the stitches on the bed on which you need to keep them. The principle and results are akin to the first row knit when you use a single bed cast on comb, and the second pass, with the first knit row anchors open loops before you continue to knit. Any loops not secured by the comb will result in dropped stitches. Any fabric, any time, when 2 stitches are empty side by side, stitches are not formed and the yarn is dropped off them creating a float or ladder. The red line indicates the ribber wire on top of the ribber loops in the zigzag row, placed so released knitting will be left on the ribber. Black lines your zig-zag yarn loops, blue dots the teeth of your ribber cast on comb. You can check placement by dropping just a few loops on the main bed before hanging your weights on the comb.

zigzag row showing the placement of cast on comb teeth, on each side of main bed needles

with wire in place, anchoring ribber stitches

with wire in place, anchoring ribber stitches  testing out dropping a few stitches

testing out dropping a few stitches  all stitches now on the ribber in preparation for dropping stitches created on main bed

all stitches now on the ribber in preparation for dropping stitches created on main bed

It is possible to also use a wired cast-on comb for an open stitch cast on the top bed only. Remove the wire from the comb. Bring the comb up and between needles to be used, and re-insert wire. Needles and latches will need to travel easily under the wire when the first knit row takes place.

The knit carriage will not clear the comb properly because of the location of its brushes, etc. For the “cast on” row, exchange the sinker plate on your knit carriage for the one normally used with the ribber. The first photo below shows the approximate location for the comb during the first row knit. Needles are centered between the teeth, the teeth themselves line up with gate pegs. The comb needs to be manually held in place since there is no opposing bed in use to help balance it. Working with the ribber up would ease the process in wider pieces of knitting. The ribber sinker plate has no brushes or wheels to anchor knitting on the knitting bed. Any rows knit single bed using it, will need to have needles brought out to hold position prior to knitting each row for all stitches to be formed properly

the comb in position pass is made slowly with the ribber sinker plate in place

pass is made slowly with the ribber sinker plate in place  the comb is dropped

the comb is dropped  bring all needles out to hold position

bring all needles out to hold position  knit one more row, returning to starting position

knit one more row, returning to starting position  change sinker plate on knit carriage if needed, proceed with knitting

change sinker plate on knit carriage if needed, proceed with knitting

To use the same method with ribber in place: hold the appropriate ribber comb with the bump(s) up facing you, so that the teeth line up with gate pegs as shown above, and so the needles can come through the gaps. Leave the wire in, hold the bump(s) against the ribber, and tilt the comb against the knit bed. Hold the comb high enough to take the carriages across to the opposite side. Move carriages to the other side, drop the comb and weigh it. If continuing on the top bed only drop the ribber, switch sinker plates, and continue to knit.

“bumps”: Brother comb

For other purposes and an edge similar to a weaving cast-on executed on Japanese machines use EON for the cast-on row, then bring into work and add the rest of the needles prior to knitting the second row.

Use a cast-on comb appropriate for your knitting machine’s gauge ie 4.5mm, 5mm, etc., the brand is not relevant, only tooth spacing is. It is possible to cut ribber cast on combs into different widths for use when knitting is planned on fewer stitches than those accommodated by their available commercial widths.

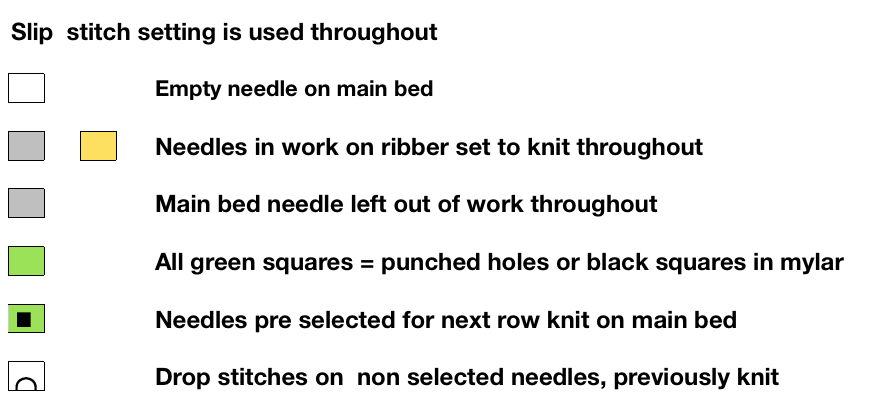

As for dropping those loops that will form the long stitches, one can do so manually with improvised tools. For more automatic dropping of stitches using knit carriage in Brother patterning, one may punch a card or draw a mylar with a method akin to color separation. A pass of the KH carriage across the knit is made with no yarn in the feeder, color 2 is actually no yarn/empty from left to right while establishing the proper needle selection on its return. The ribber would need to be reset to slip, or the ribber carriage separated from the knit one for the 2 passes to and from the color changer. This is the “scariest” option by far, more error-prone. It is not applicable when using the circular Ayab setting in creating the fabric. Without a specific tool, all stitches can be brought to E and back to B with a ruler, piece of garter bar, ribber cast on comb, or other handy ‘toy’. Dropping stitches is done while carriages are on the left, after the return to the color changer side. It is possible to modify the Studio accessory used to drop stitches

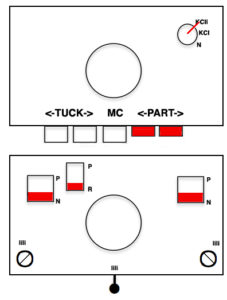

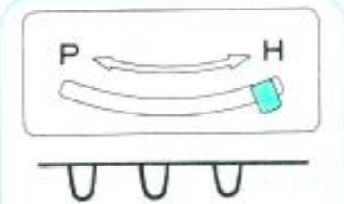

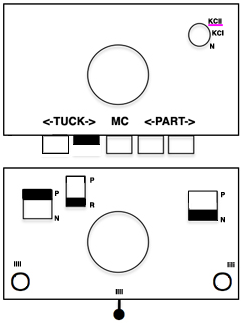

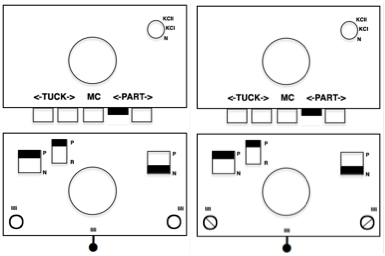

For 2 color drop stitch, the main bed is set to slip in both directions. Because not all needles on the main bed are used for patterning on every row, the KC II setting on the change knob is used, eliminating end needle selection on the 910. The ribber is set to knit every row

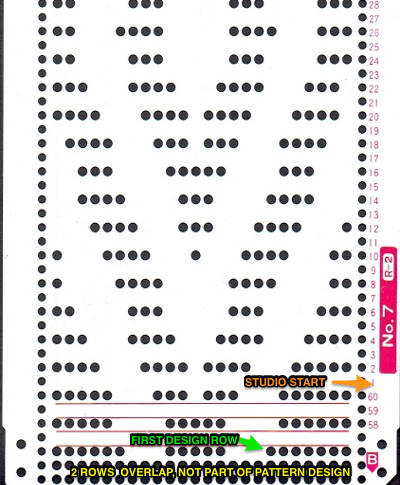

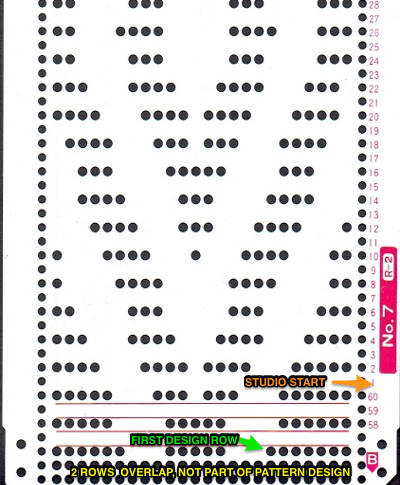

Ayab: begin your design repeat on your first row, choose its circular setting in machine type pull-down menu on the right

The first design row is preselected left to right

The main bed is set to slip <– –>, change knob on KC II (end needle selection is canceled)

Ribber is set to knit <– –> for the duration

COL: as you go from the left to right, needles are preselected on the top bed, they will knit, picking up loops that you will in turn drop on the subsequent passes of the knit carriage from right to left.

COR, the KC knits on preselected needles as it moves to the left.

Clear the color changer, set up your next color. Drop the stitches knit on that last pass

It may be necessary to push those loops down between the beds before you next pass, remember to pull down on your knitting periodically, visually check needle alignment on the main bed (all needles in B in the work area)

*With the new color move to the right, preselecting the next row of loops

Knit right to left, picking up loops on preselected needles, change colors, drop stitches,** and repeat * to ** steps in 2-row rotations

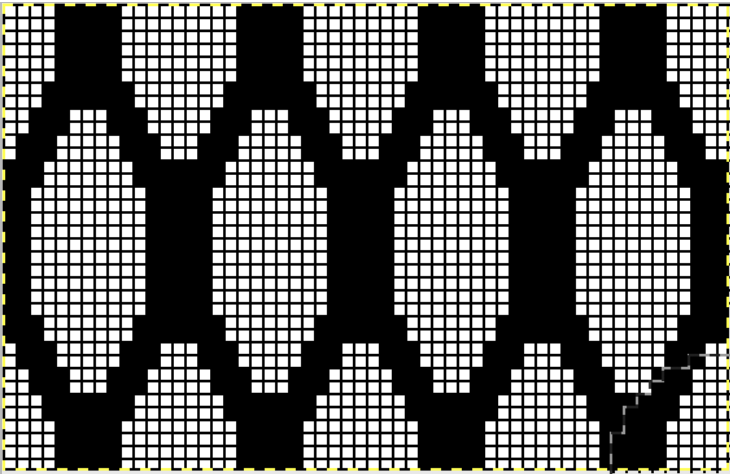

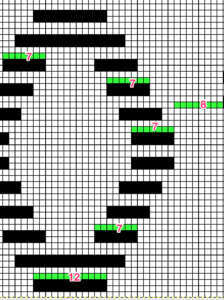

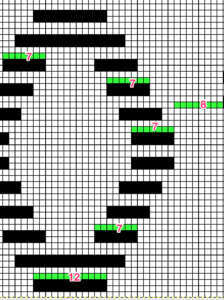

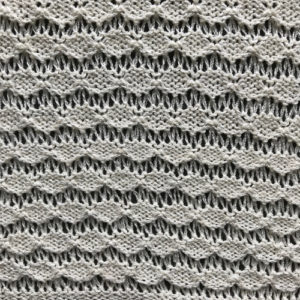

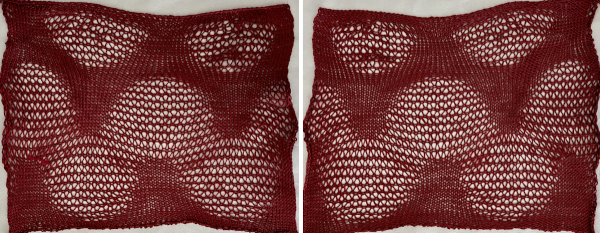

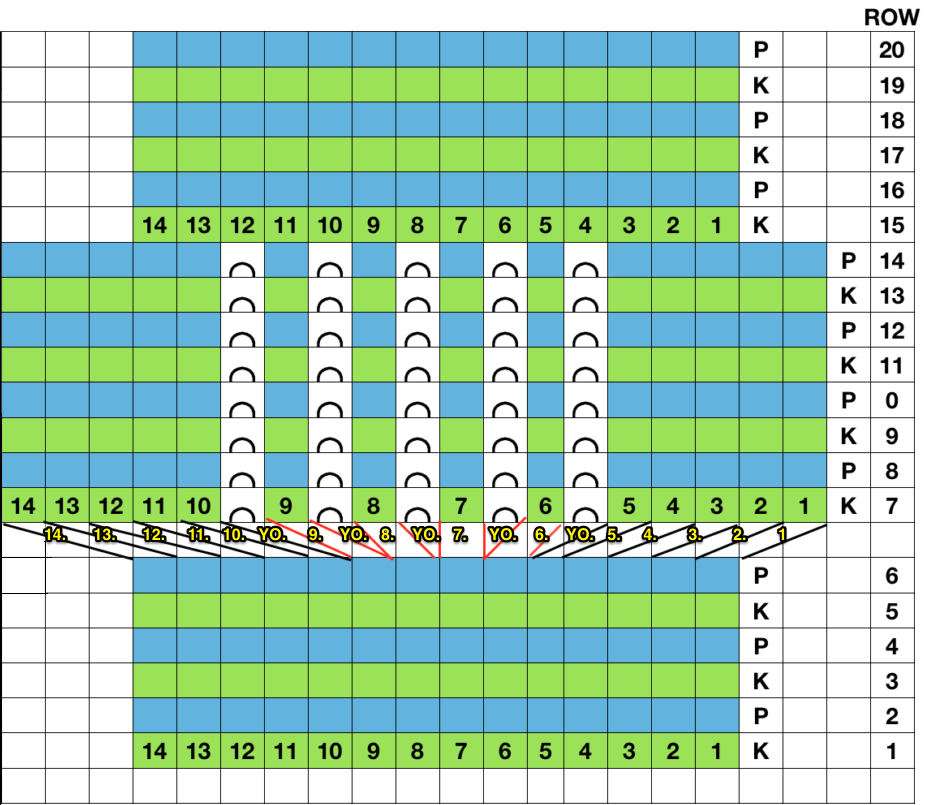

so I want circles, here is my test pattern  more like eggs, the black squares in shape appear as drawn on the purl side

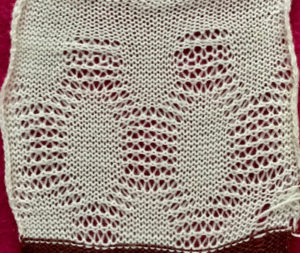

more like eggs, the black squares in shape appear as drawn on the purl side  shapes are reversed as drawn on the knit side

shapes are reversed as drawn on the knit side

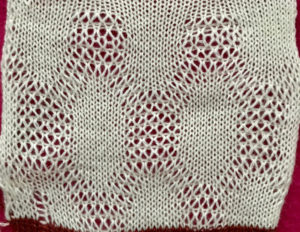

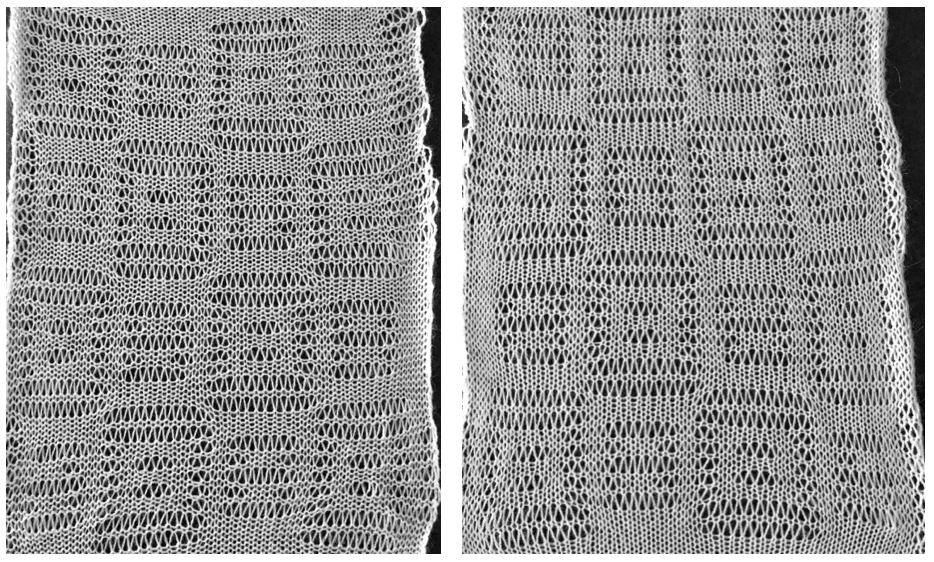

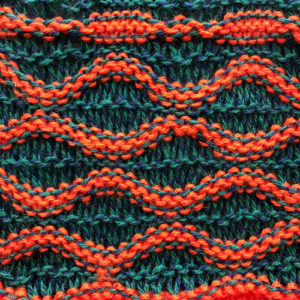

It is possible using the circular setting to drop only one of the 2 colors, whether background or shape. I began by dropping the white ground. I used to encourage students to develop a tune/ repeat in their heads when regular actions needed to be taken. For me, in terms of yarn color, it was “white, knit, drop”, “brown = erase (push back to B), go back”. 1: white travels to the right, needles are pre-selected; 2: white travels to left, picking up loops 3: on left, change color, drop stitches. For brown: 1. travel to the right, needles are preselected 2: on the right, before traveling back to left push all selected needles back to B. Only the ribber knits on the way back to left, so brown will have knit 2 rows with no dropped stitches. I ran out of brown yarn, started over with the blue and white, planning on having the shape drop the stitches. There is a difference in the fabric width with the change in the distribution of stitches. I stopped knitting, not due to any mispatterning, but because I encountered another Ayab behavior that may be well known to punchcard knitters. Due to a yarn mast issue, I moved the knit carriage back to disentangle the yarn, and lo and behold the pattern advanced a row. Punchcard machines will advance a row with any movement of the carriage outside the edges of the knit. This was never an issue in the unaltered 910. At that point, I stopped knitting.

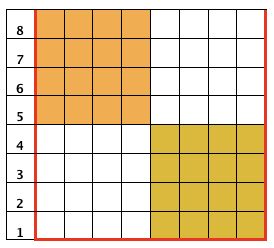

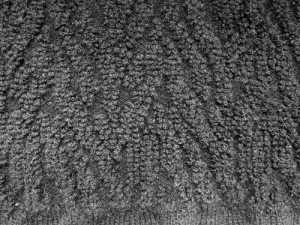

Not fond of stripes? prefer one color? the sample below was worked on 40 stitches in width, using the repeat charted for 56 stitches. Here decisions are made at the design phase of your repeat. For single color, drop stitch use an image double length, and single setting in the Ayab software. The process is the same: *preselect stitches left to right, knit on selected needles right to left, drop loops just picked up traveling to left**, repeat from * to **. Settings are the same as for the 2 color drop stitch, but the elongation depending on the number of stitches dropped is not as noticeable. The texture in my swatch is diminished after a quick press, the yarn is an acrylic blend. The charted repeat illustrated is wider, but I worked it on only the center 40 stitches. As always in slip stitch, the black squares knit and they represent the stitches that are dropped. If you wish to create the long stitches on the ground (white squares), reverse use Ayab Action Invert prior to knitting

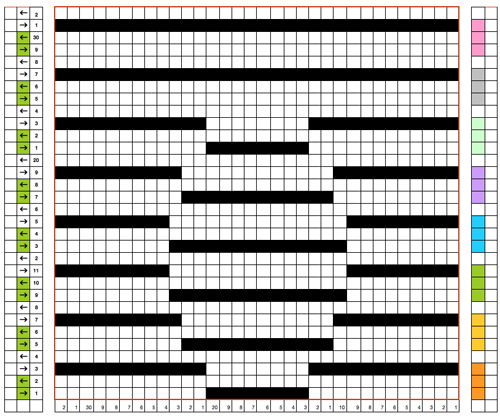

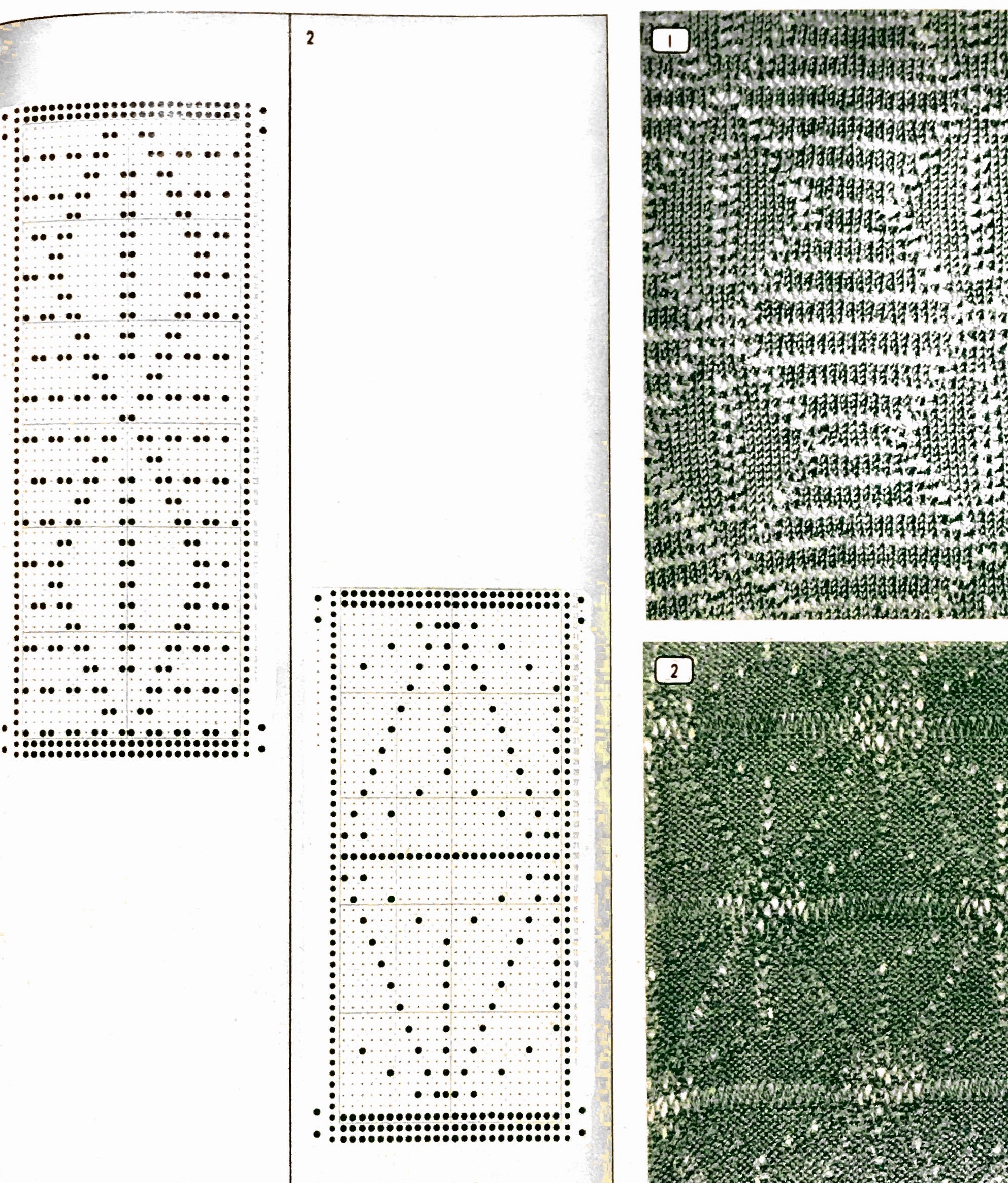

the chart as viewed and explained at the top of the post

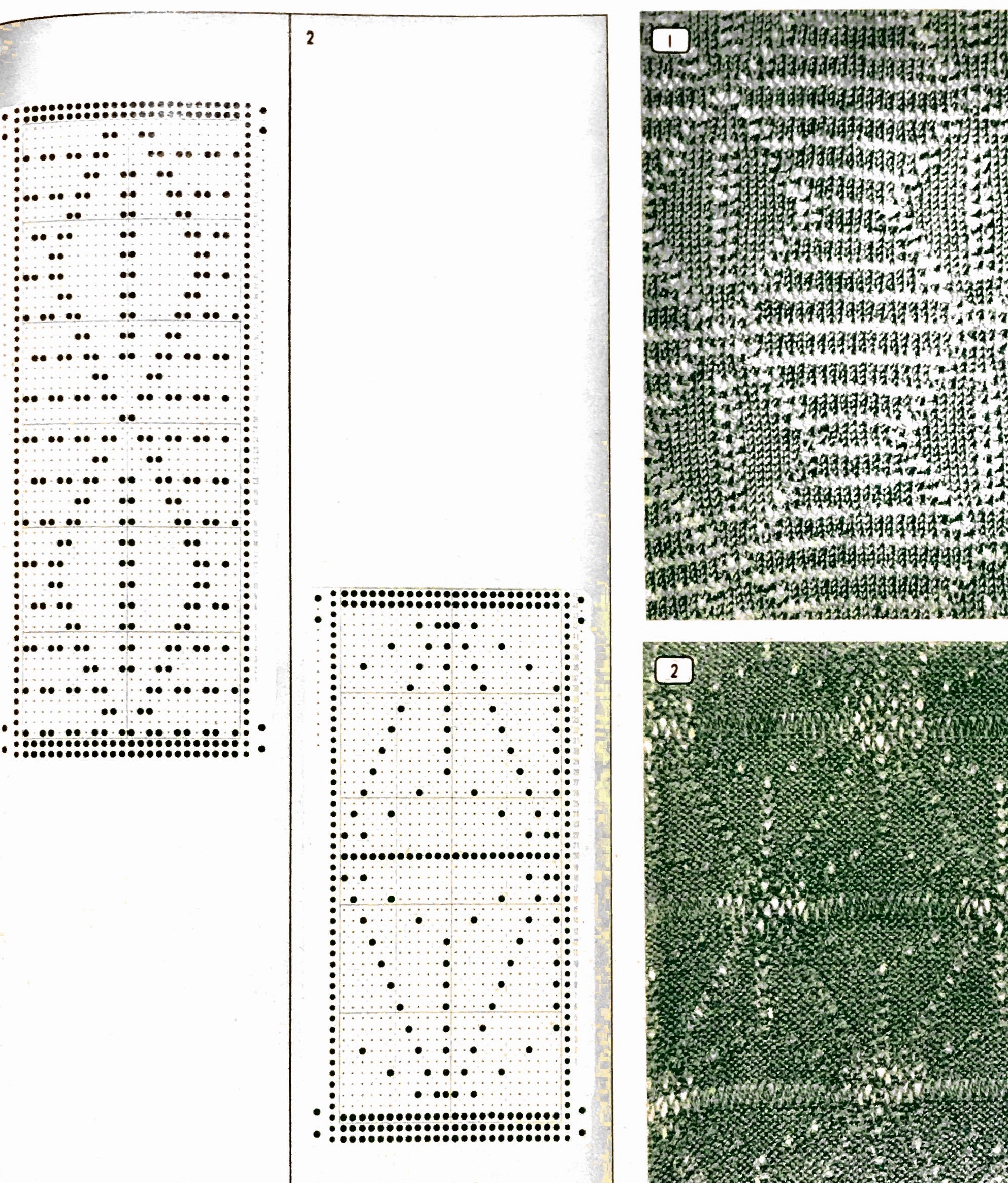

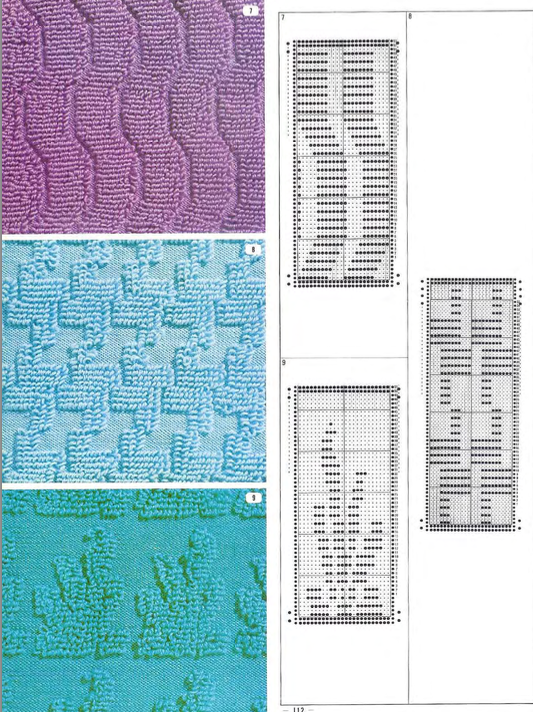

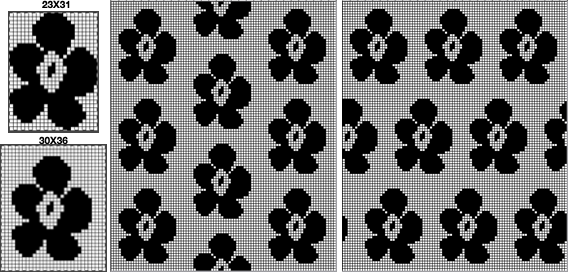

Sources of inspiration from studio publications vary, patterns designed for pile knitting make for suitable one color drop stitch. A partial punchcard repeat

from an electronic collection

and a punchcard pattern book, where markings emulate eyelets, usable only for single color knitting

Note that in #2 card directly above, there is a solid row at the very start that is a design row (third all punched). In Ayab again, first-row preselection is left to right, you will be picking up loops on preselected needles going from right to left and then dropping them. That first design row needs to have punched holes or black squares/pixels in it. The color separation is essentially done for you in the source image. Do not use circular in Ayab, but rather, use “single” setting and follow instructions for creating the fabric as described above, with no color changes. The blank punchcard rows match the no selection rows in self-drawn color separations,

If double bed work is daunting, for a different stitch, worked single bed, that may cause interesting distortions in all knit, single bed fabrics see block stitch post.

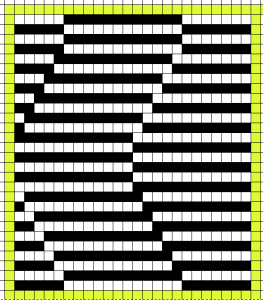

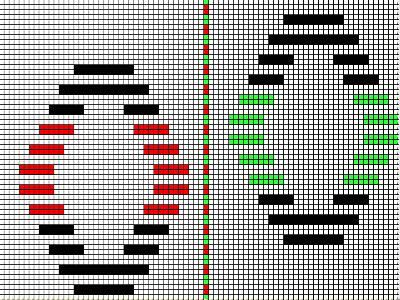

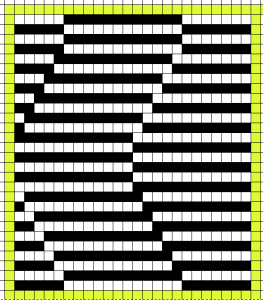

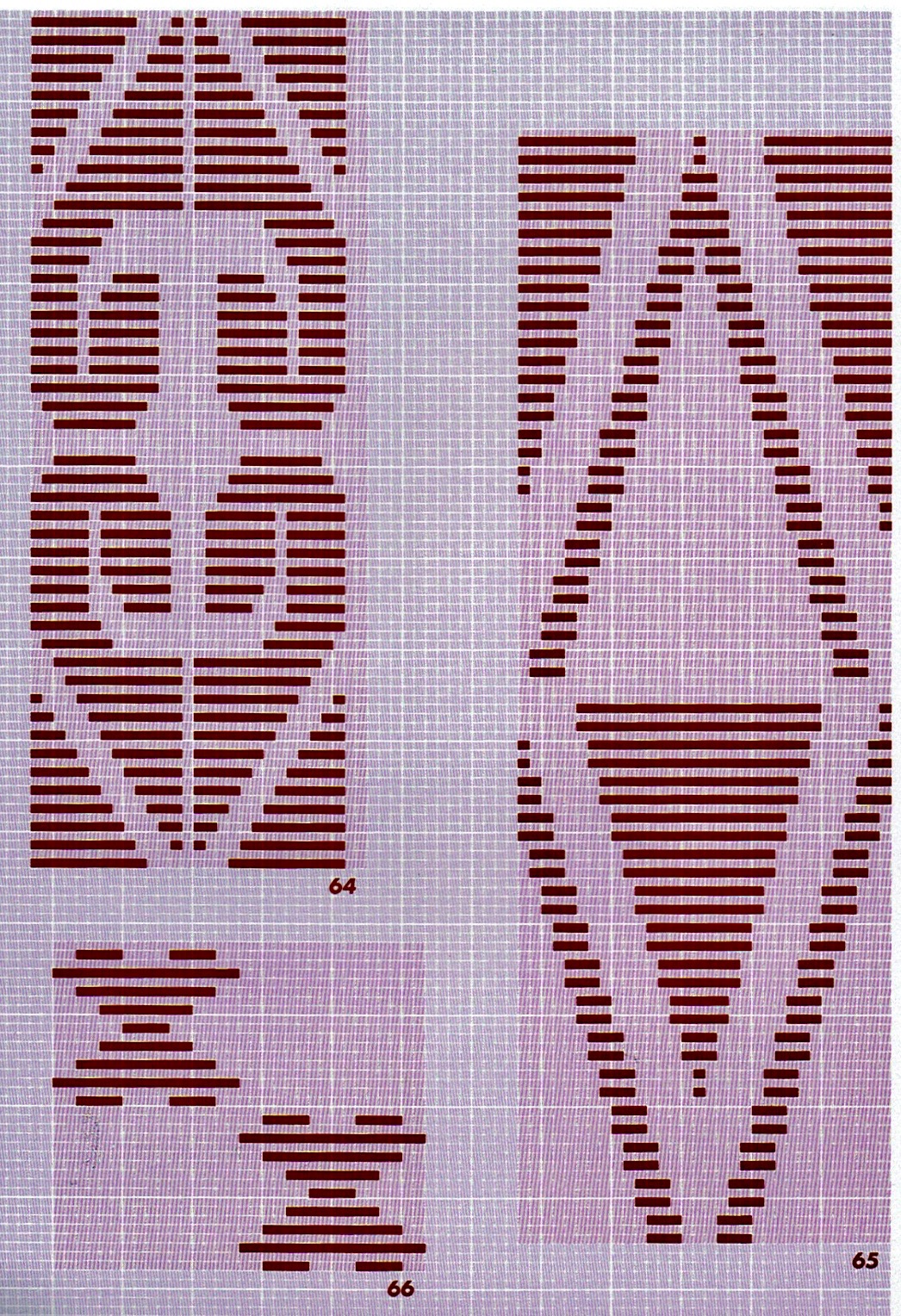

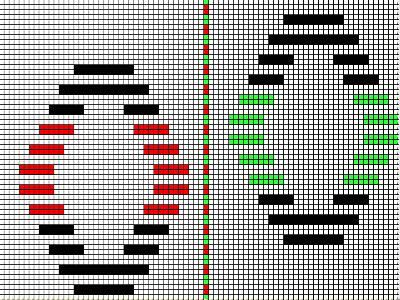

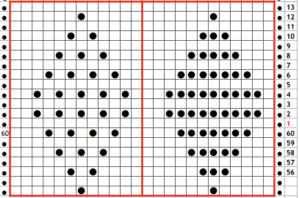

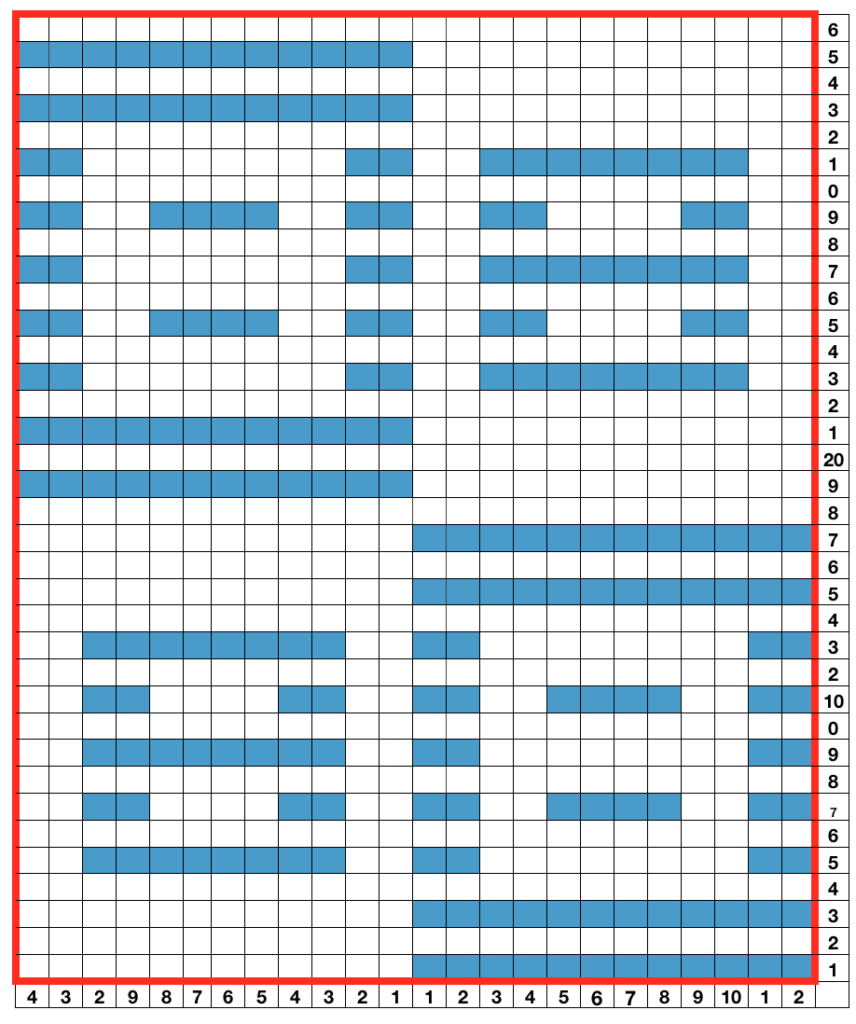

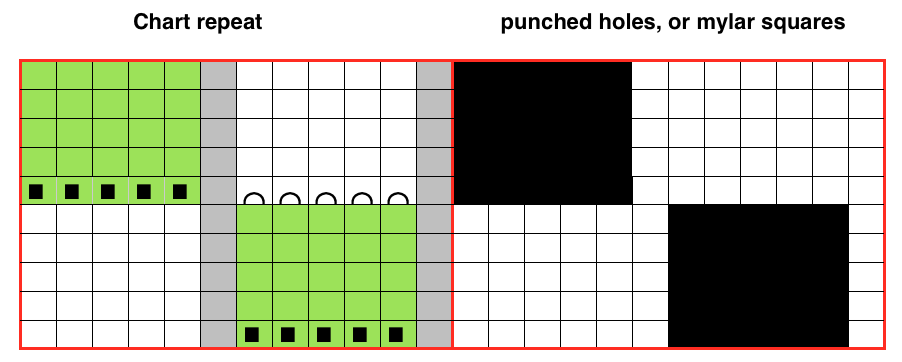

The self-drawn design repeats for 2 color drop stitch may be offset as well, resulting in colors being dropped alternately. The design shape needs to be created in 4-row blocks in order for the yarn to make it back and forth to the color changer with both colors to complete one design row. The second pairs of rows in each 4-row block is erased. In this instance as well, rows marked with black squares will pick up loops on the main bed, which are in turn dropped to create the long stitches. The second design repeat is offset to try to get sections of it to create loops to be dropped as well. The final motif must be a multiple of 8 rows in height if it is to be used as Ayab’s infinite repeat in length.

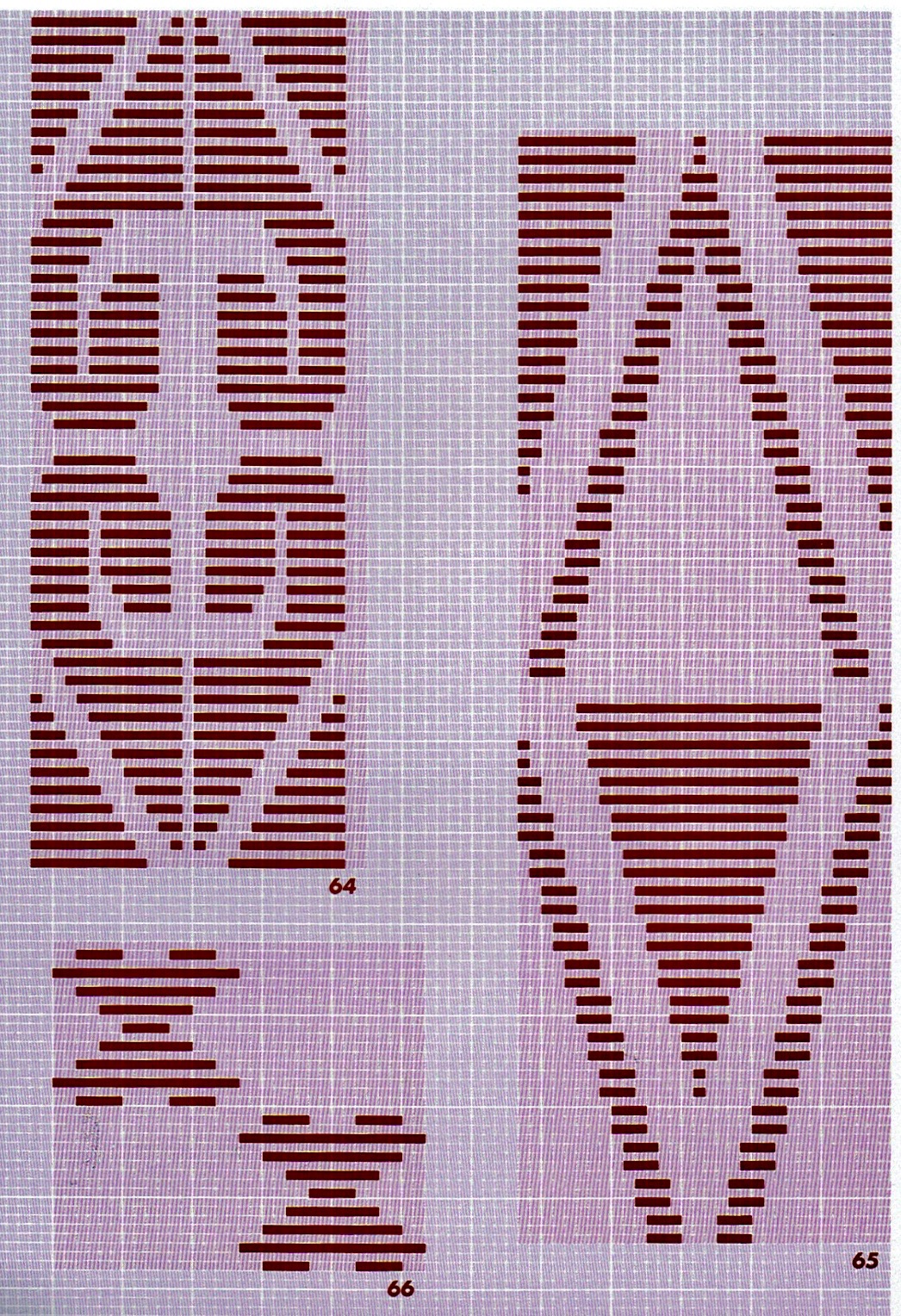

Color changes are indicated in the vertical strip in the center of the design. This was my starting idea

Elongation to 4 rows per block, erasing the second pair of rows for each color on right. The repeat on the right may be used if only one color is to be dropped; the 2 blank rows in the design field represent stitches that will knit only on the ribber for 2 rows. No stitches are dropped in color(s) used in sequential rows of blank squares in all “white” areas of the chart, including multiple rows above and below the design shape. Color changes every 2 rows continue, creating continuous stripes.  shapes staggered, visually checking for placement of alternately dropped stitches

shapes staggered, visually checking for placement of alternately dropped stitches

To accommodate the Ayab preselection for the first row to be knit from left to right, move the last blank row in the design to the first-row position. As the carriages travel from left to right and back to the color changer, the stitches will knit 2 rows only on the ribber. Continue knitting in steps as described earlier in the post, changing colors every 2 rows. On a larger knit ground such shapes may be arranged to suit. This was my working repeat, but I used a third fewer stitches in the swatch than in the chart.  Note that the images will be reversed on the knit side, so if preferred, use Action Mirror to flip the image horizontally prior to knitting it

Note that the images will be reversed on the knit side, so if preferred, use Action Mirror to flip the image horizontally prior to knitting it

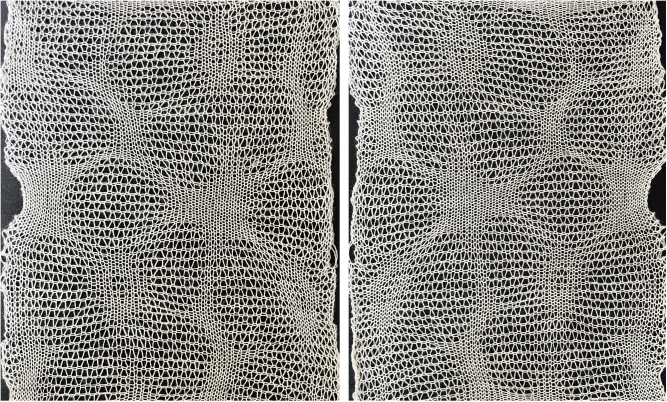

The swatch has been quickly pressed, so the texture is flattened out, but I am reminded of a few shadow knits when viewing its purl side.

In an unaltered 910 with the ability to double the width of the programmed repeat, mylar users are not excluded from exploring a similar fabric. The repeat above may be rescaled to half the width, drawn that way, and then use the twice as wide built-in feature. Gimp does an “interesting” thing when scaling this design to half-width, note the right side of each repeat is an odd number of squares, the left side an even. The repeat may be used as-is or redrawn, adding or eliminating black squares if symmetry in each shape matters. Paintbrush produces the same image, mirrored.

The explanation: further analysis of the original design reveals the fact that some of the pixel numbers in the design black square blocks are uneven in width. In this instance, 3.5 is half of 7, and half pixels cannot be rendered, so the software assigns the split to 4 and 3.

ayab repeat for 30 stitch swatch, requires color invert

ayab repeat for 30 stitch swatch, requires color invert  the same repeat, not requiring color invert after loading into software

the same repeat, not requiring color invert after loading into software  tuck fabrics are usually more interesting on their purl side

tuck fabrics are usually more interesting on their purl side  Tuck stitch combined with lace transfers

Tuck stitch combined with lace transfers large-diagonal-eyelets

large-diagonal-eyelets

the color-separated sample knit pre ayab

the color-separated sample knit pre ayab

revised with fewer single dots, and solid lines in the ground

revised with fewer single dots, and solid lines in the ground

using any method you prefer, set up knitting so all stitches are on the ribber. If you prefer to set up complete repeats prior to watching, “air knitting” prior to ribber set up or using the position option on the main bed if that is available, will help achieve that

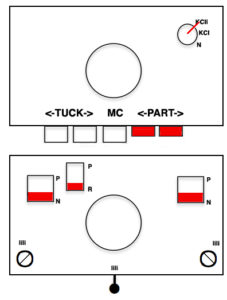

using any method you prefer, set up knitting so all stitches are on the ribber. If you prefer to set up complete repeats prior to watching, “air knitting” prior to ribber set up or using the position option on the main bed if that is available, will help achieve that  set knit carriage to KC II (used when patterning does not occur on every needle across the needle bed), both part buttons pushed in for free pass to the opposite side of km, no knitting occurs but the first row of pattern knitting is selected. Ribber is set to N<–> throughout

set knit carriage to KC II (used when patterning does not occur on every needle across the needle bed), both part buttons pushed in for free pass to the opposite side of km, no knitting occurs but the first row of pattern knitting is selected. Ribber is set to N<–> throughout the carriages now move to the opposite side, selected needles on the main bed pick up loops, and nonselected needles stay empty. Ribber knits every stitch

the carriages now move to the opposite side, selected needles on the main bed pick up loops, and nonselected needles stay empty. Ribber knits every stitch  using a ribber cast on comb, stitch “dumper”, or another tool, move needles holding stitches forward to drop loops, and return empty needles to work position (B)

using a ribber cast on comb, stitch “dumper”, or another tool, move needles holding stitches forward to drop loops, and return empty needles to work position (B) as carriages move to the opposite side, needles are selected for next row of knit stitches to be knit on main bed

as carriages move to the opposite side, needles are selected for next row of knit stitches to be knit on main bed  carriages now move to the opposite side, loops are picked up on selected needles

carriages now move to the opposite side, loops are picked up on selected needles

carriages move to the opposite side, picking up loops

carriages move to the opposite side, picking up loops  before carriages move again, drop stitches formed. Watch loops after they are dropped, if tugging knitting it is not enough to pull them out of the way of needles returning to patterning, take a tool, or something like a credit card. Slide it from one side to the other between the beds, thus keeping loops clear away from the main bed

before carriages move again, drop stitches formed. Watch loops after they are dropped, if tugging knitting it is not enough to pull them out of the way of needles returning to patterning, take a tool, or something like a credit card. Slide it from one side to the other between the beds, thus keeping loops clear away from the main bed

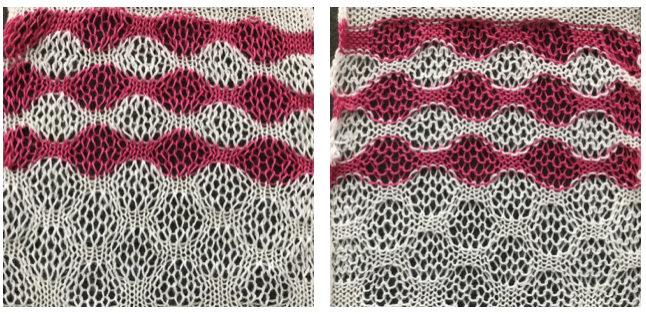

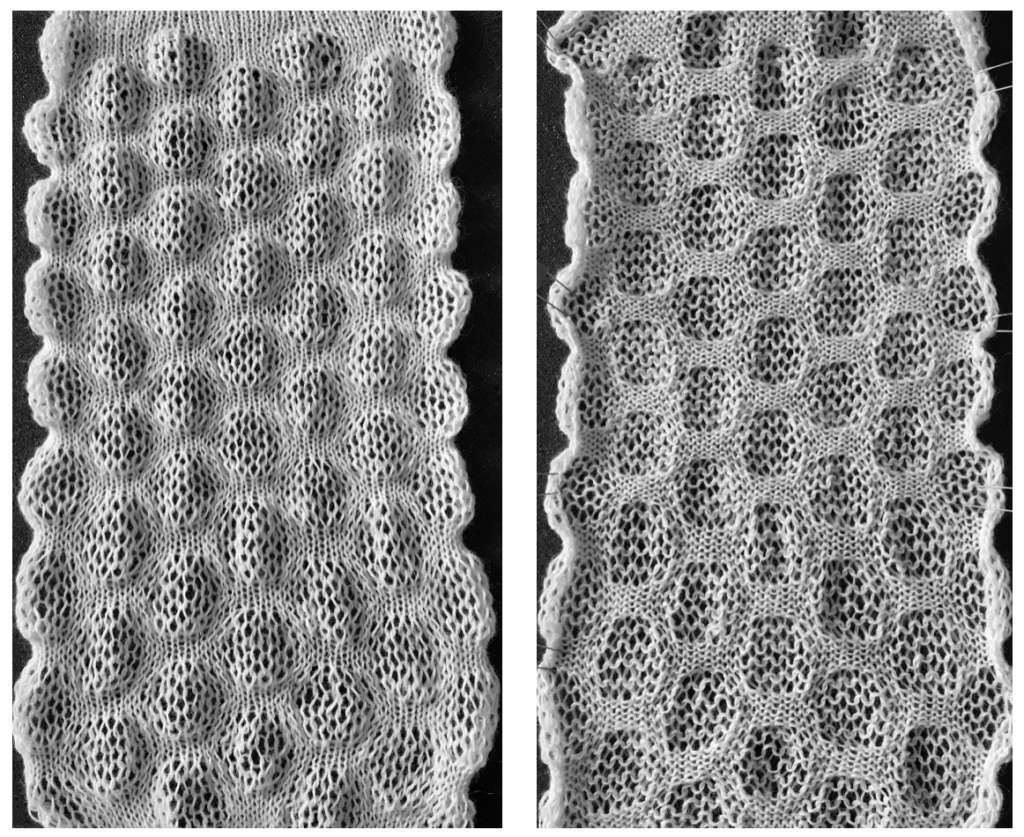

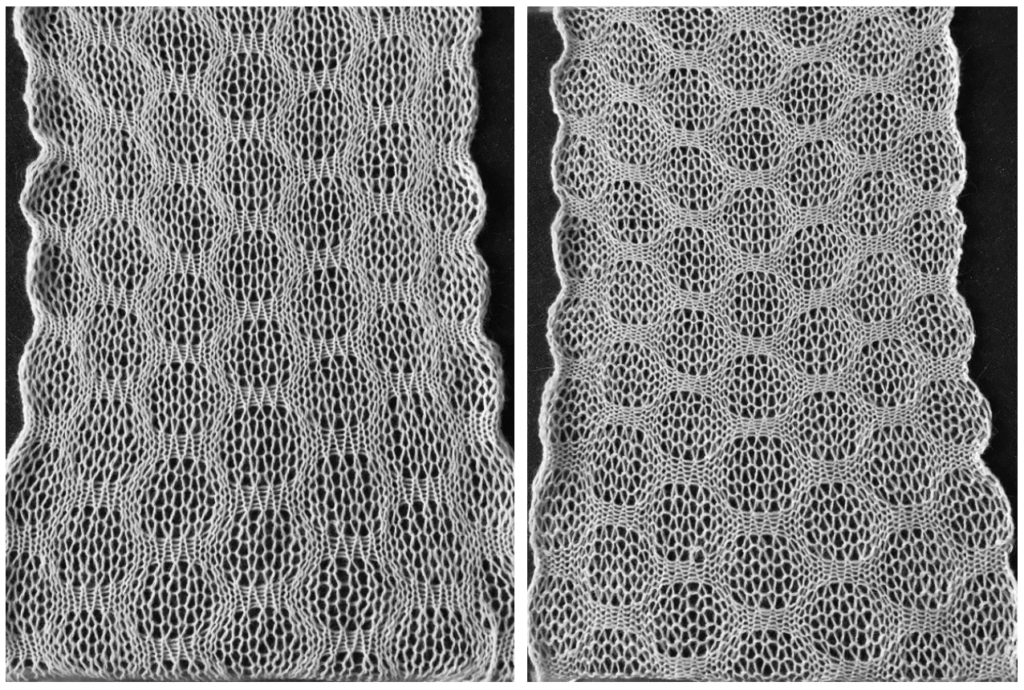

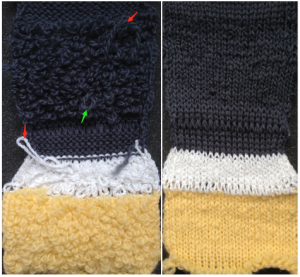

purl side is shown first for each segment, followed by its knit

purl side is shown first for each segment, followed by its knit

If using punchcard machines, factory issue punch cards provided with the KM may be used

If using punchcard machines, factory issue punch cards provided with the KM may be used

A slip stitch edge may be planned to keep edges of items such as scarves from rolling

A slip stitch edge may be planned to keep edges of items such as scarves from rolling  consider top and bottom edgings that include the technique (illustrated in the

consider top and bottom edgings that include the technique (illustrated in the

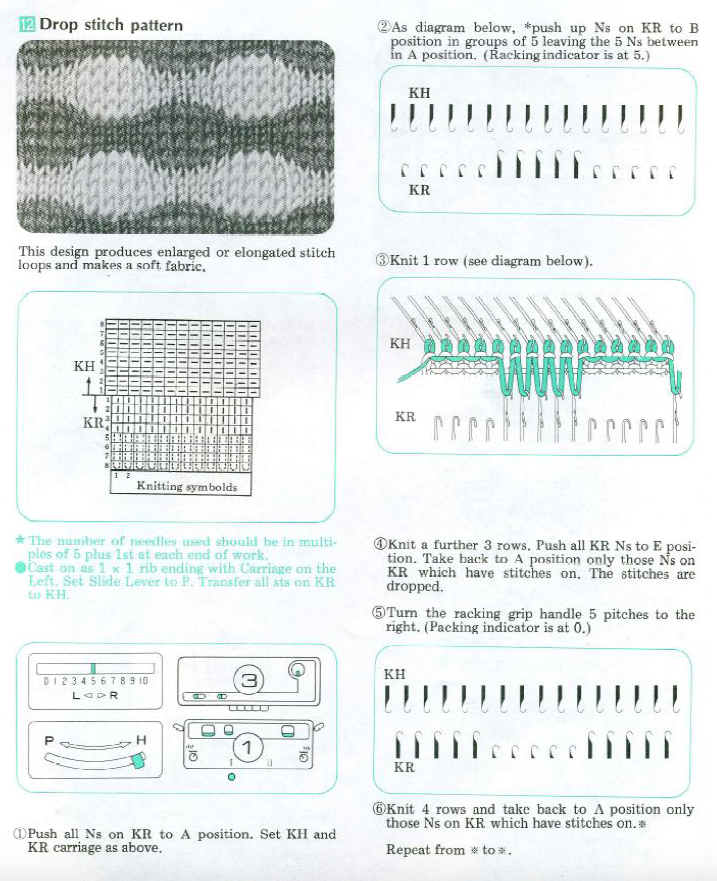

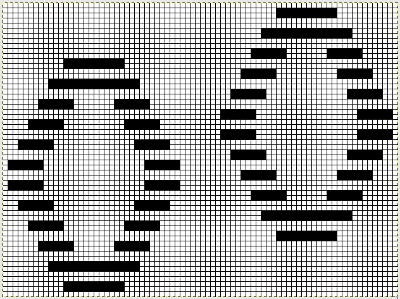

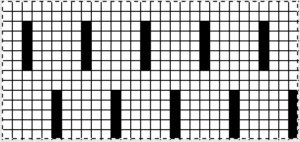

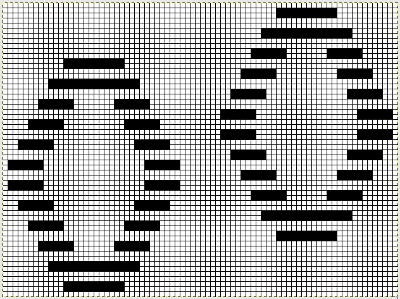

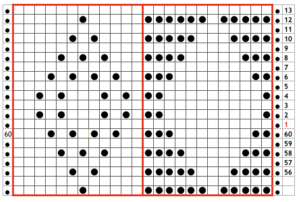

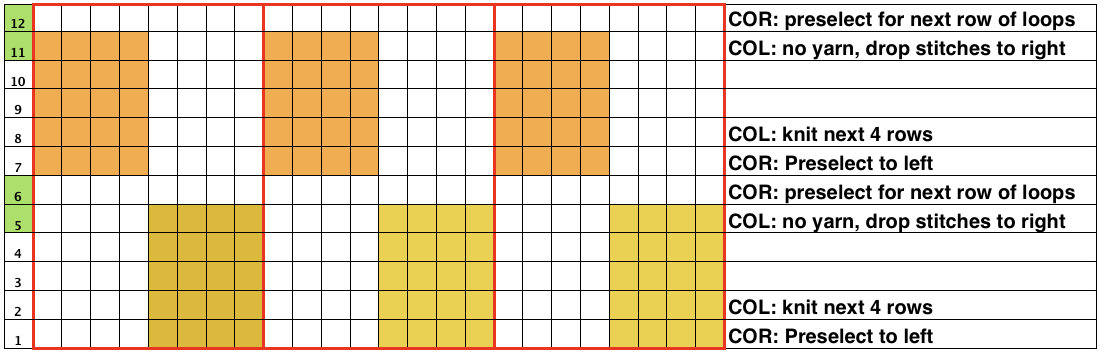

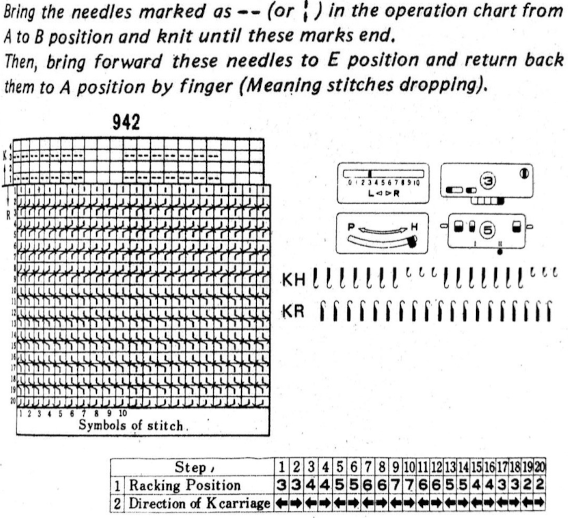

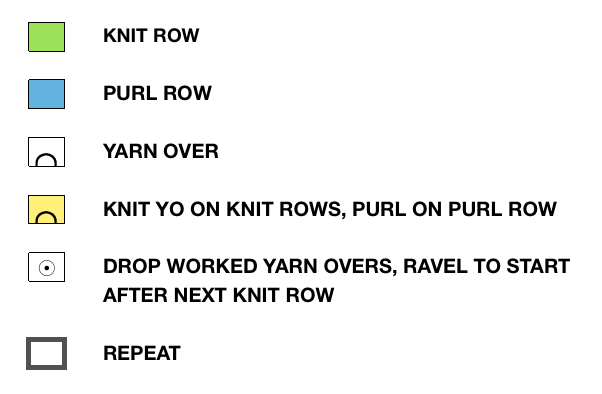

An alternative way to produce this fabric on Brother is to use the knit carriage with no yarn to do the “stitch ditching”. The basic design programmed into any brother machine, electronic or punchcard will need to be altered. The intended design in my sample is a 4 X 4 square, colors represent what would be punched holes, black squares, or pixels. Simple block patterns such as these may be released upon completion of each “square” series, in this case, after 4-row segments.

An alternative way to produce this fabric on Brother is to use the knit carriage with no yarn to do the “stitch ditching”. The basic design programmed into any brother machine, electronic or punchcard will need to be altered. The intended design in my sample is a 4 X 4 square, colors represent what would be punched holes, black squares, or pixels. Simple block patterns such as these may be released upon completion of each “square” series, in this case, after 4-row segments.

Rows 5 and 6, 11, and 12 are not part of the original repeat. The 5th design row provides needle selection, traveling from right to left. When the carriage passes in turn from left to right with no yarn, those preselected needles will drop while preselecting a blank design row (6) that allows the carriage to return to the left-hand side. As it moves back to the left, the carriage will preselect the first row of the design. With COL yarn is picked up in order to knit the next set of dropped stitches. A color change may be made while the carriage is on the left.

Rows 5 and 6, 11, and 12 are not part of the original repeat. The 5th design row provides needle selection, traveling from right to left. When the carriage passes in turn from left to right with no yarn, those preselected needles will drop while preselecting a blank design row (6) that allows the carriage to return to the left-hand side. As it moves back to the left, the carriage will preselect the first row of the design. With COL yarn is picked up in order to knit the next set of dropped stitches. A color change may be made while the carriage is on the left.

More to try: the typical appearance to look for in the source inspiration is that of single-row horizontal geometric designs with all blank rows separating them from each other.

More to try: the typical appearance to look for in the source inspiration is that of single-row horizontal geometric designs with all blank rows separating them from each other.

The yarn used here was a softly spun rayon that began eventually to split, and get partially caught up on gate pegs, leading to the ending of the swatch

The yarn used here was a softly spun rayon that began eventually to split, and get partially caught up on gate pegs, leading to the ending of the swatch

Fair Isle

Fair Isle

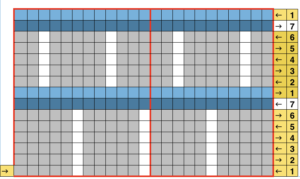

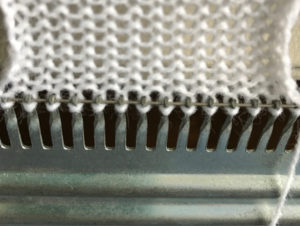

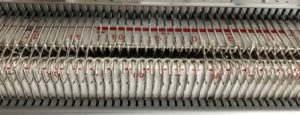

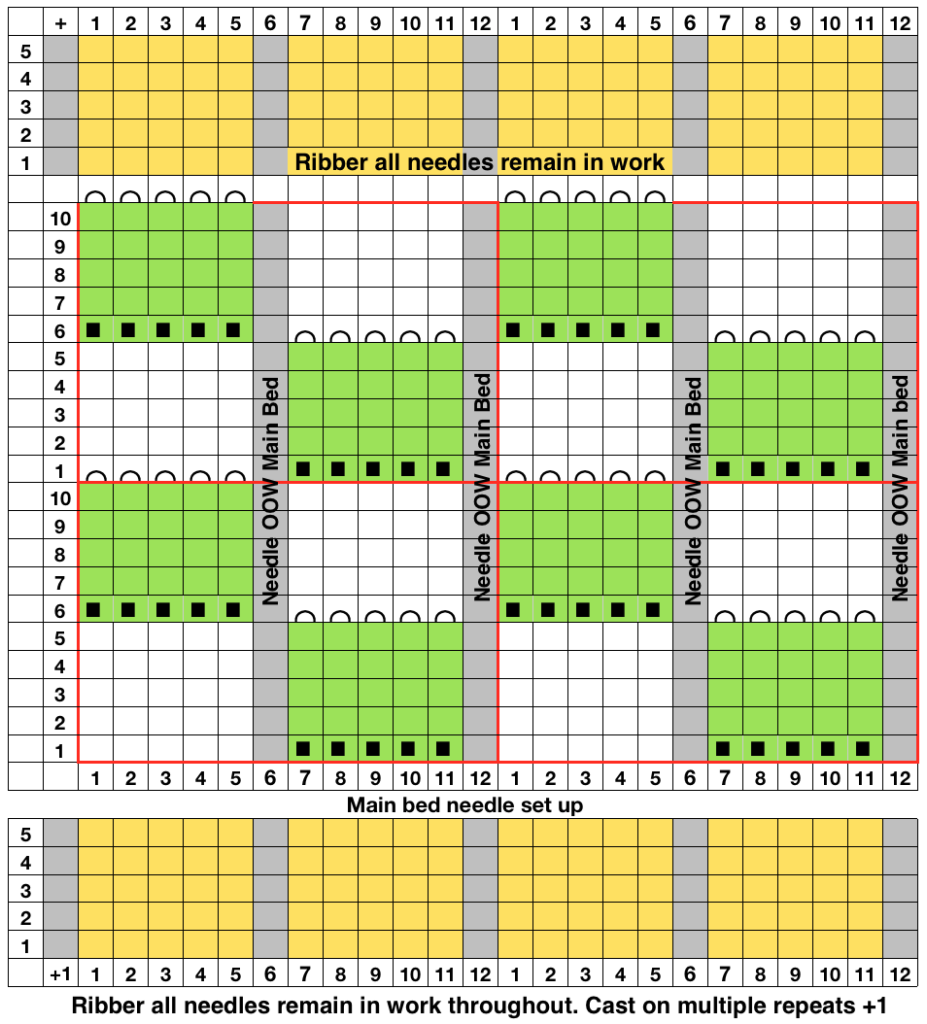

Working in multiple of repeat -1 on the top bed, plus one needle in work at each end on the ribber. Considerations need to be made to align the design properly. The markings on my metal bed are from a different project.

Working in multiple of repeat -1 on the top bed, plus one needle in work at each end on the ribber. Considerations need to be made to align the design properly. The markings on my metal bed are from a different project.  The goal is this needle arrangement

The goal is this needle arrangement

the first selection row

the first selection row  a needle on either side of the groups of 7 is pushed back to A position, remain there throughout the piece

a needle on either side of the groups of 7 is pushed back to A position, remain there throughout the piece

the ribber has now been set up for knitting every needle, every row, with the caston and desired edging completed. The first row is selected on the main bed for pattern knitting.

the ribber has now been set up for knitting every needle, every row, with the caston and desired edging completed. The first row is selected on the main bed for pattern knitting.

the variation in width is due to adjustments in tension, the swatch folded over itself shows the difference in another way

the variation in width is due to adjustments in tension, the swatch folded over itself shows the difference in another way

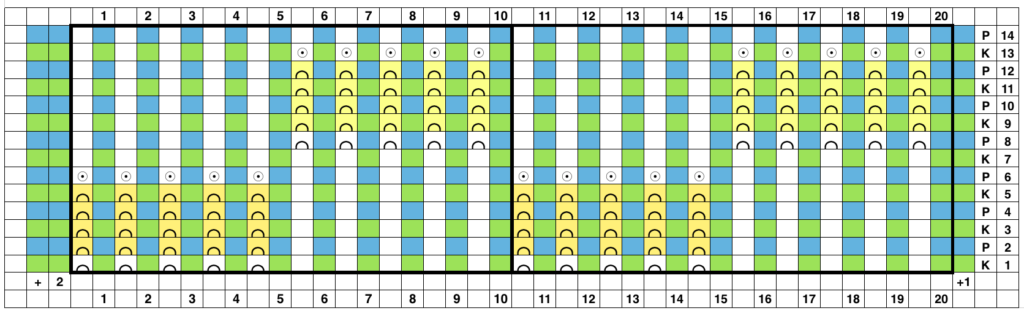

So I now own a new Mac, no longer have Microsoft Office available, and am now working my way through charting diagrams using Mac Numbers. Below is a possible working chart with a different stitch count than above. I would suggest larger blocks of all knit stitches and rows between “bubble” repeats

So I now own a new Mac, no longer have Microsoft Office available, and am now working my way through charting diagrams using Mac Numbers. Below is a possible working chart with a different stitch count than above. I would suggest larger blocks of all knit stitches and rows between “bubble” repeats

the reverse of the fabric, lightly killed with steaming and pressing

the reverse of the fabric, lightly killed with steaming and pressing

Analyzing what is required to move between km brands with the goal of achieving 2 color or isolated pile motifs: in Passap with the back bed set to FX, one arrow key, EON pusher/ needle selection changes every 2 rows. In Brother, this may be achieved on the main bed by pushing in one tuck button and programming a repeat. The alternate, adjacent cam button, left in its normal position, will knit every stitch when knitting direction is reversed regardless of whether any needle selection is happening. On the ribber, lili buttons may be used for alternate needle selection. Its levers determine whether tucking or slipping, in one direction or both, occur. The number of stitches on the ribber must be even. An easy visual check is to check markings on needle tape, which consists of what I refer to as dashes and blanks. For an even number begin with one, end with the other. Passap will automatically revert to the alternate pusher for patterning on the subsequent 2 rows. In using lilis this is not an automatic function, and some handwork is required to obtain the same effect by changing the first needle selection every third row as seen in this

Analyzing what is required to move between km brands with the goal of achieving 2 color or isolated pile motifs: in Passap with the back bed set to FX, one arrow key, EON pusher/ needle selection changes every 2 rows. In Brother, this may be achieved on the main bed by pushing in one tuck button and programming a repeat. The alternate, adjacent cam button, left in its normal position, will knit every stitch when knitting direction is reversed regardless of whether any needle selection is happening. On the ribber, lili buttons may be used for alternate needle selection. Its levers determine whether tucking or slipping, in one direction or both, occur. The number of stitches on the ribber must be even. An easy visual check is to check markings on needle tape, which consists of what I refer to as dashes and blanks. For an even number begin with one, end with the other. Passap will automatically revert to the alternate pusher for patterning on the subsequent 2 rows. In using lilis this is not an automatic function, and some handwork is required to obtain the same effect by changing the first needle selection every third row as seen in this

charting things out

charting things out