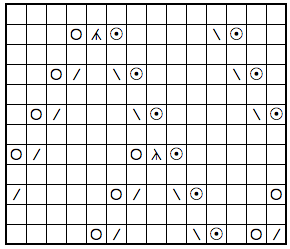

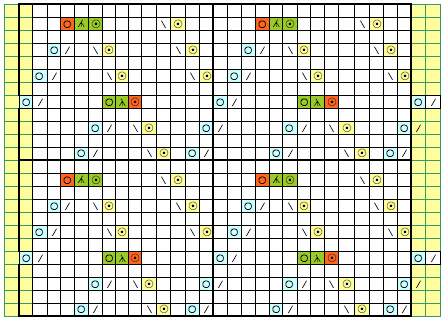

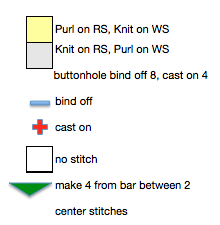

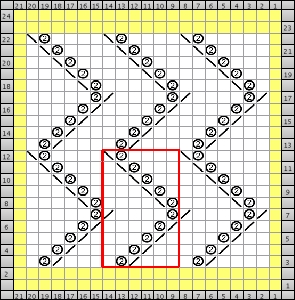

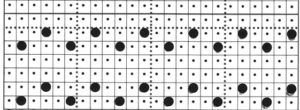

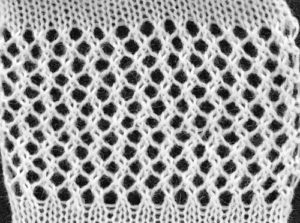

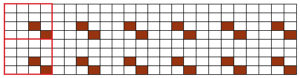

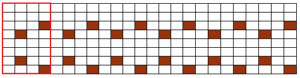

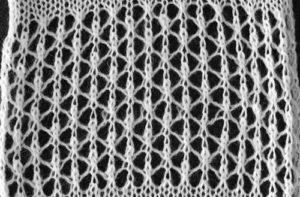

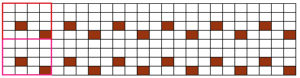

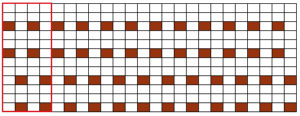

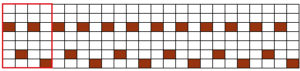

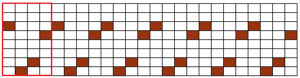

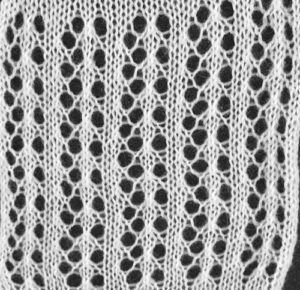

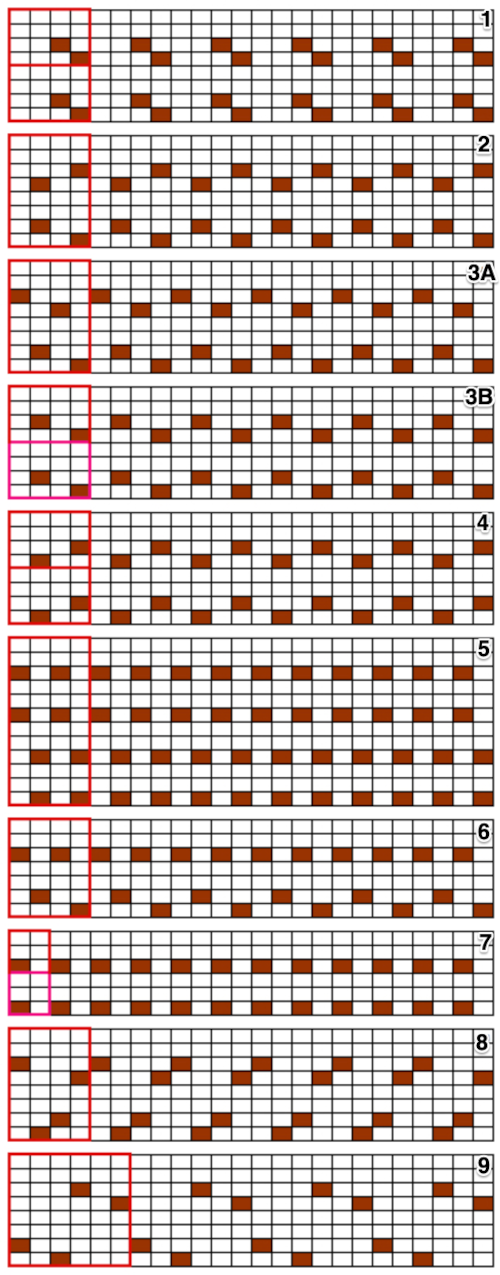

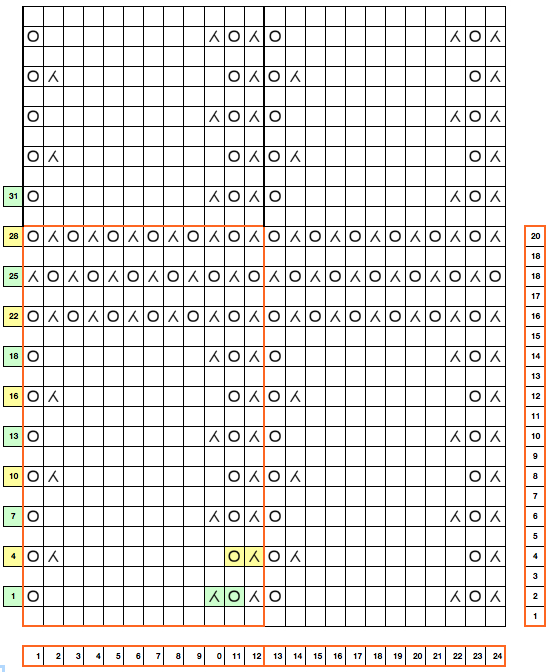

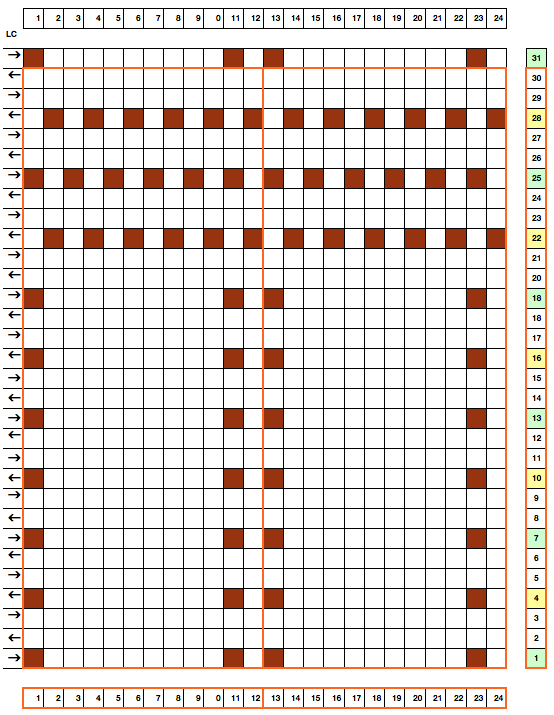

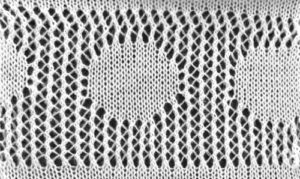

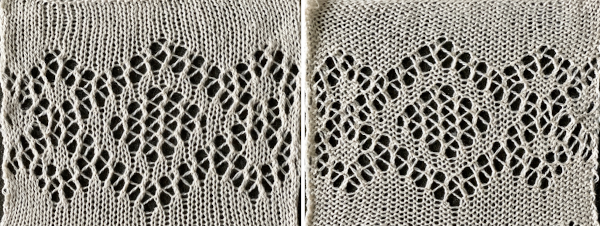

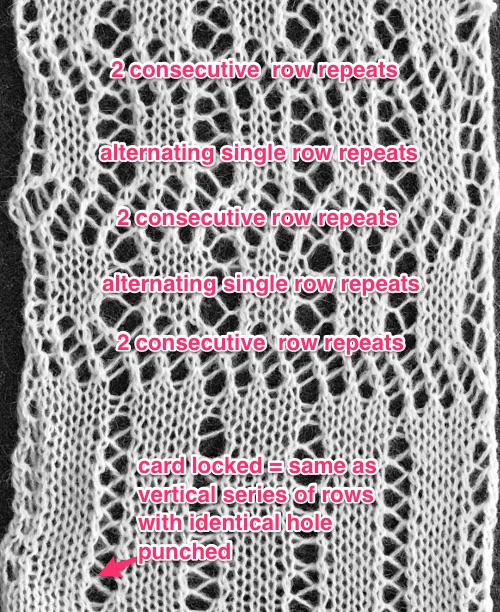

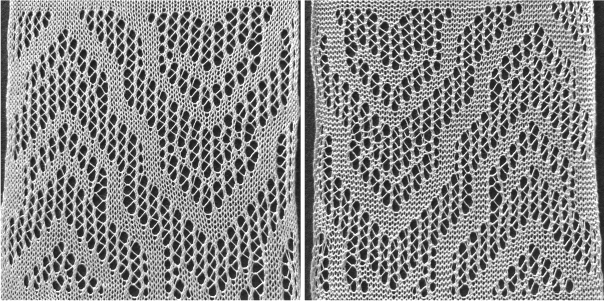

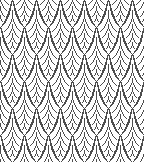

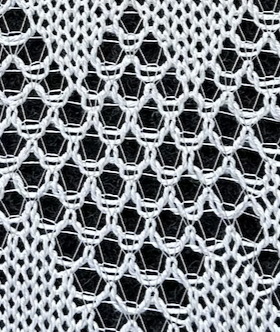

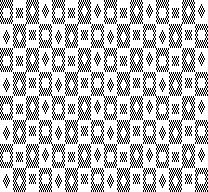

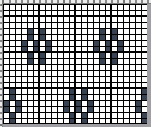

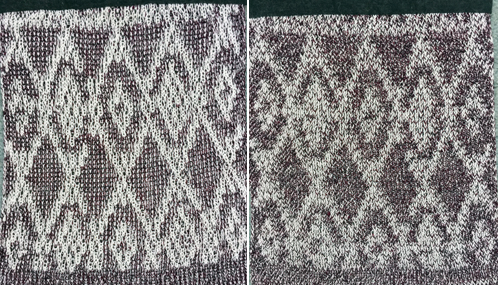

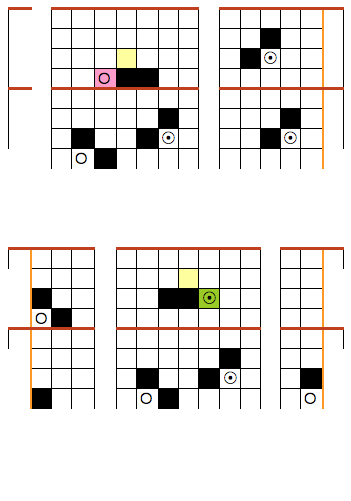

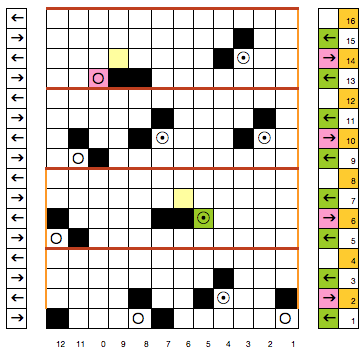

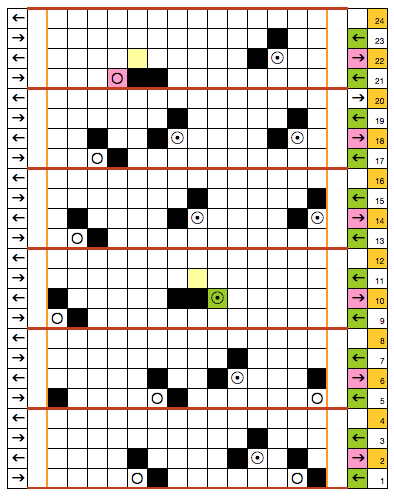

These patterns are suitable for punchcard machines. Individual repeats in excel illustrations are outlined in red. They in turn are the minimal repeat information for electronic machines. The lace carriage always begins on left, transfers are made during either 2 or 4 LC pass rows. In the first repeat below the LC operates for 4 rows, KC follows for 2 rows knit. For a fabric using it see post

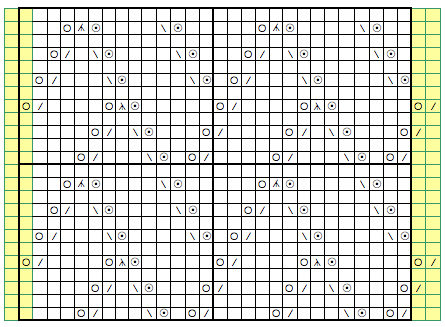

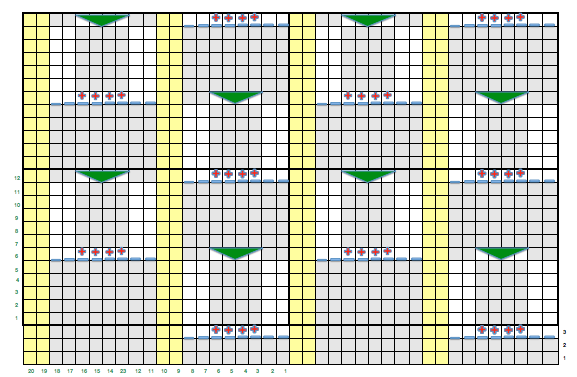

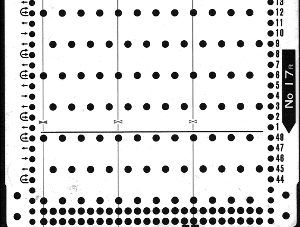

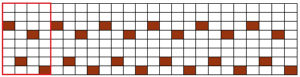

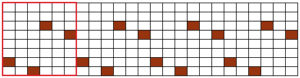

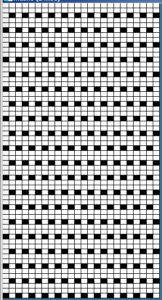

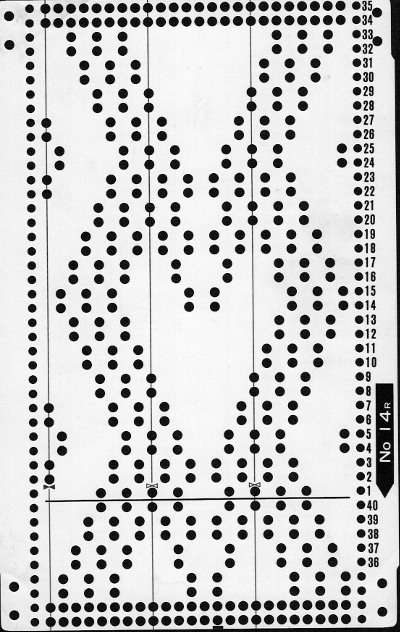

This repeat appears in my pre-punched factory basic packs as both #17 and #20. The lace carriage is used for 2 passes and then for 4 alternately, as indicated on the left side of the punchcard. The 2 passes will make transfers to the left, the 4 make transfers to the right. See previous lace posts for further info on lace selection methods and accompanying charting.

This repeat appears in my pre-punched factory basic packs as both #17 and #20. The lace carriage is used for 2 passes and then for 4 alternately, as indicated on the left side of the punchcard. The 2 passes will make transfers to the left, the 4 make transfers to the right. See previous lace posts for further info on lace selection methods and accompanying charting.

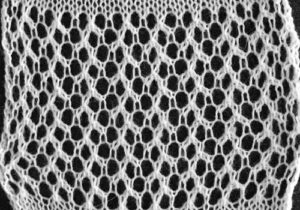

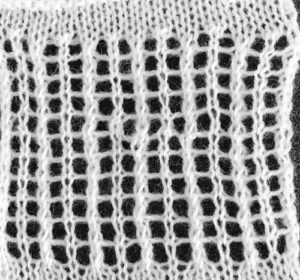

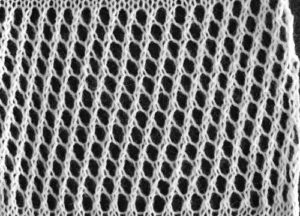

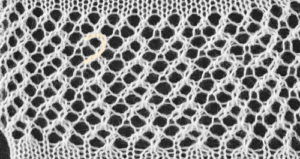

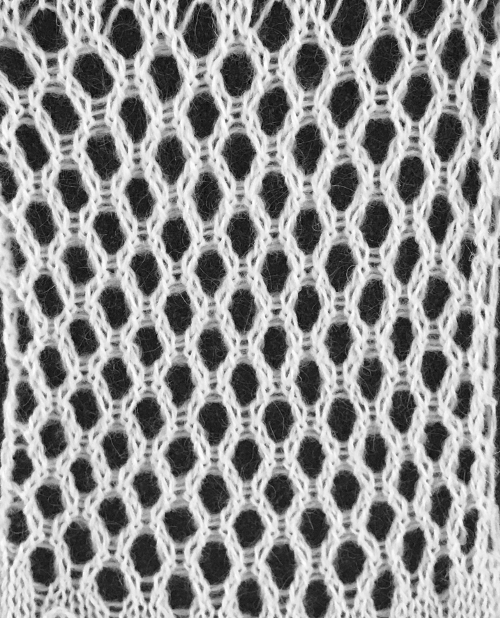

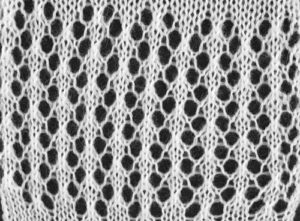

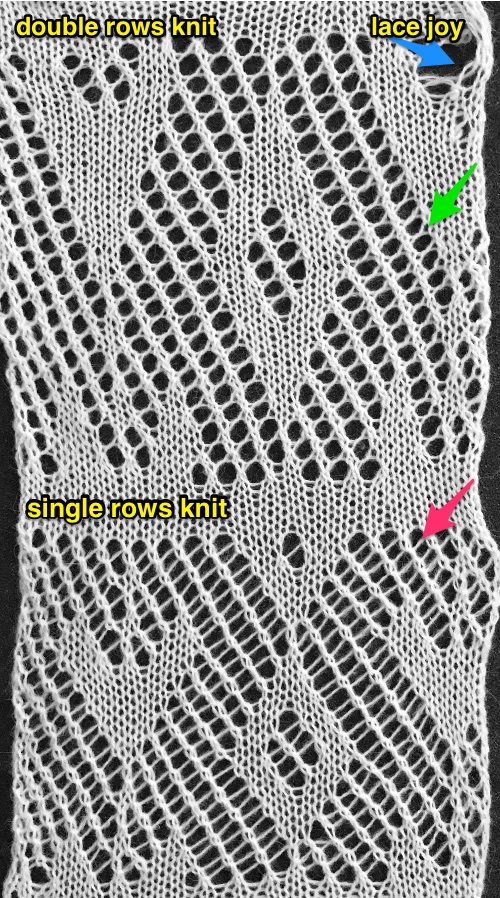

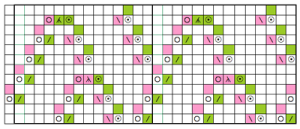

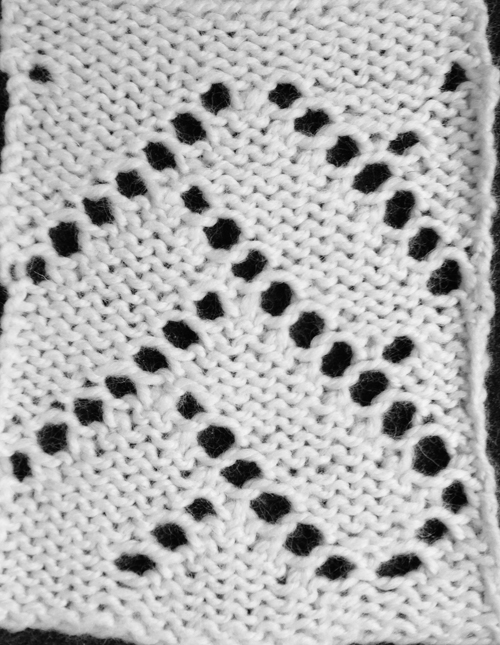

More variations and swatch photos: all patterns unless otherwise stated are knit with 4 passes of the lace carriage from left, followed by 2 rows of knitting.

More variations and swatch photos: all patterns unless otherwise stated are knit with 4 passes of the lace carriage from left, followed by 2 rows of knitting.

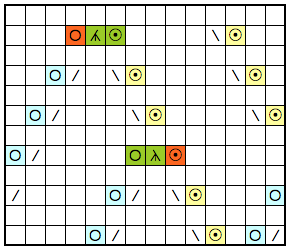

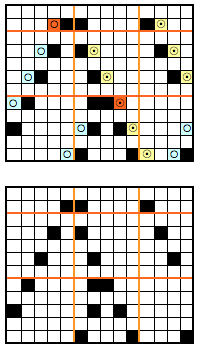

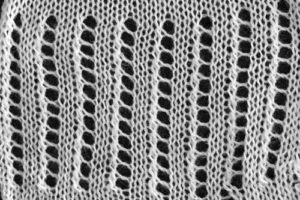

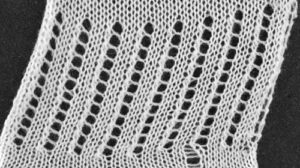

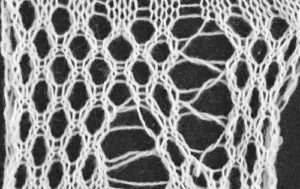

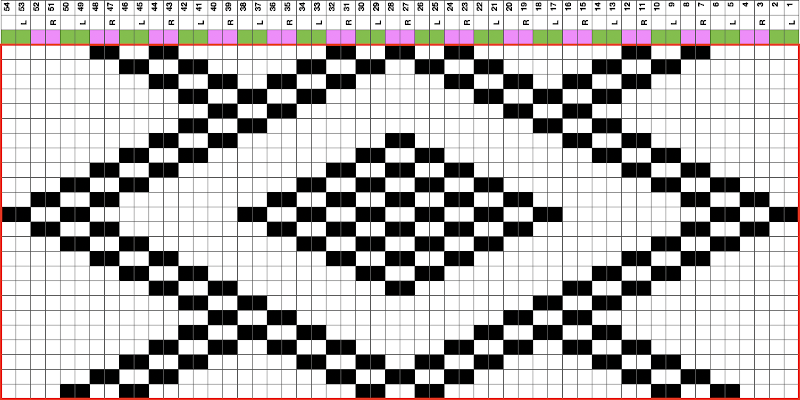

In this instance there are several vertical spaces between punched holes, creating the knit vertical stripe. The spacing can be adjusted to suit, but if “mock crochet” is the goal, superimposing an image onto every other needle mesh gives better results. It is possible to have 2 punched holes side by side on alternate rows, but not in the same row for stitches to knit properly without intervention on the next pair of all knit rows. In patterns such as the first and third below, stitches are transferred onto the adjacent needle in one direction, then both stitches are transferred back onto the previously emptied needle. The transferred stitch then sits on the front of the work (duplicating the look in hand knitting), instead of remaining on the adjacent stitch on the purl side of the fabric. With transfers in the same direction, the swatch biased after relaxing

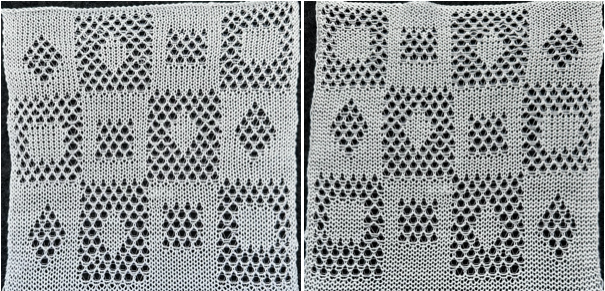

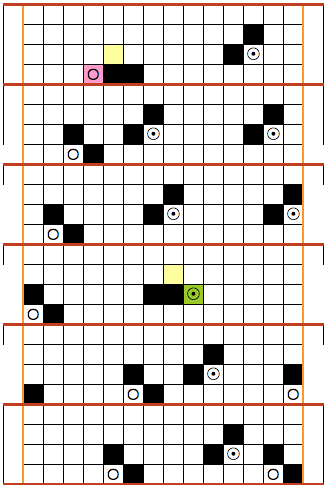

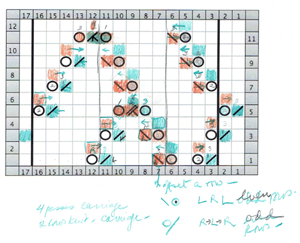

a mylar marking error as drawn (3A)

a mylar marking error as drawn (3A)

the intended repeat (3B)

the intended repeat (3B)

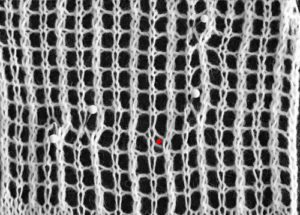

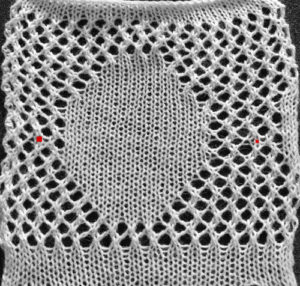

The above swatch and the one below (4) are similar, transfers occur in the opposite direction, so vertical columns of stacked stitches occur in the alternate columns of the finished fabric. I had some transfer issues in similar spots in both fabrics, have not analyzed the possible direct cause. As seen below, the dropped stitches did not result in the frequent large holes often seen in lace knitting. Pins and the red dot indicate problem spots, which could be repaired with careful stitching at the end of knitting. The best prevention of the problem is to visually check after sets of transfers to make certain all stitches have indeed been moved properly.

The above swatch and the one below (4) are similar, transfers occur in the opposite direction, so vertical columns of stacked stitches occur in the alternate columns of the finished fabric. I had some transfer issues in similar spots in both fabrics, have not analyzed the possible direct cause. As seen below, the dropped stitches did not result in the frequent large holes often seen in lace knitting. Pins and the red dot indicate problem spots, which could be repaired with careful stitching at the end of knitting. The best prevention of the problem is to visually check after sets of transfers to make certain all stitches have indeed been moved properly.

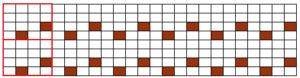

LC is used alternately for 2, and then 4 passes between knit rows (5).

LC is used alternately for 2, and then 4 passes between knit rows (5).

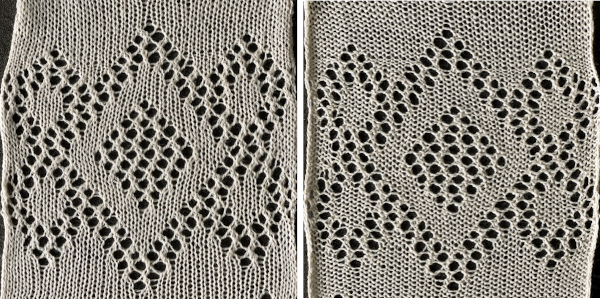

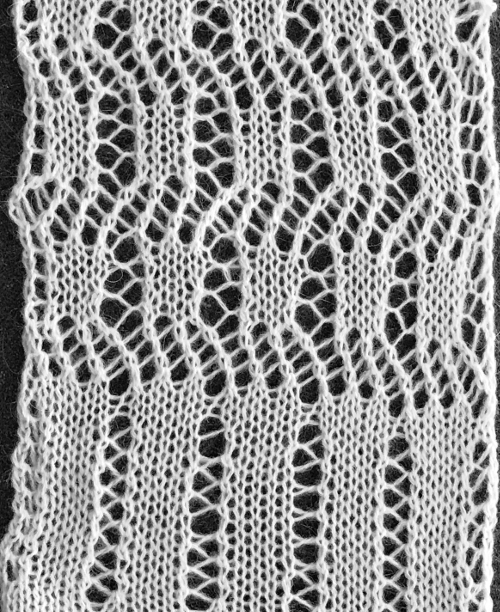

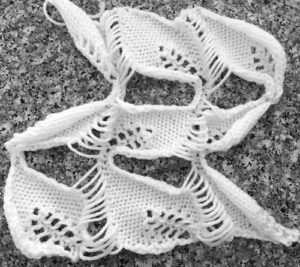

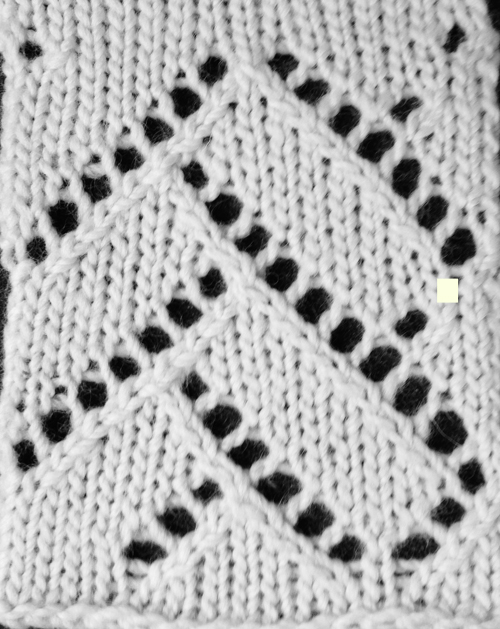

The transfers create a sort of “shape”, highlighted in the photo; the LC operates in sequences of 4 rows, followed by 2 rows, and repeat (6).

The transfers create a sort of “shape”, highlighted in the photo; the LC operates in sequences of 4 rows, followed by 2 rows, and repeat (6).

This one is a bit trickier, LC operates for 4 rows resulting in side by side transfers; in the first trial yarn caught up on gate pegs, dropped stitches, etc,

This one is a bit trickier, LC operates for 4 rows resulting in side by side transfers; in the first trial yarn caught up on gate pegs, dropped stitches, etc,

after reducing KC tension and adjusting the amount of weight

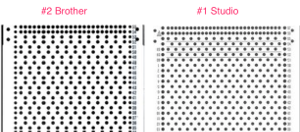

after reducing KC tension and adjusting the amount of weight  Mylar repeats can be very small, it is easy to be one stitch off in entering data; here one blank row was added to the left (a possibility for intentional vertical stripes of knitting) and the program was one row short on the right of the single full repeat

Mylar repeats can be very small, it is easy to be one stitch off in entering data; here one blank row was added to the left (a possibility for intentional vertical stripes of knitting) and the program was one row short on the right of the single full repeat

knit with the corrected program

knit with the corrected program  The “variations” and repeats in summary:

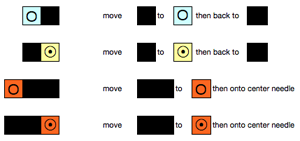

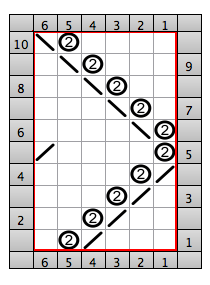

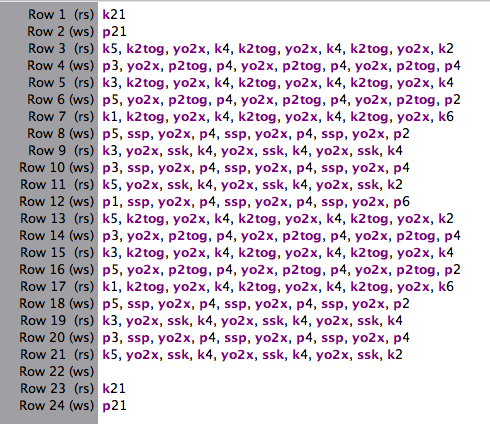

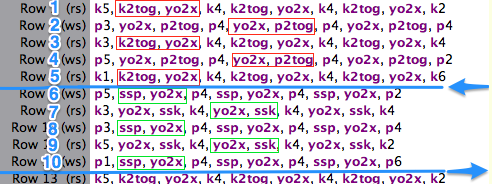

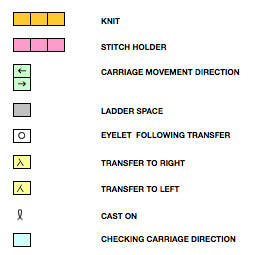

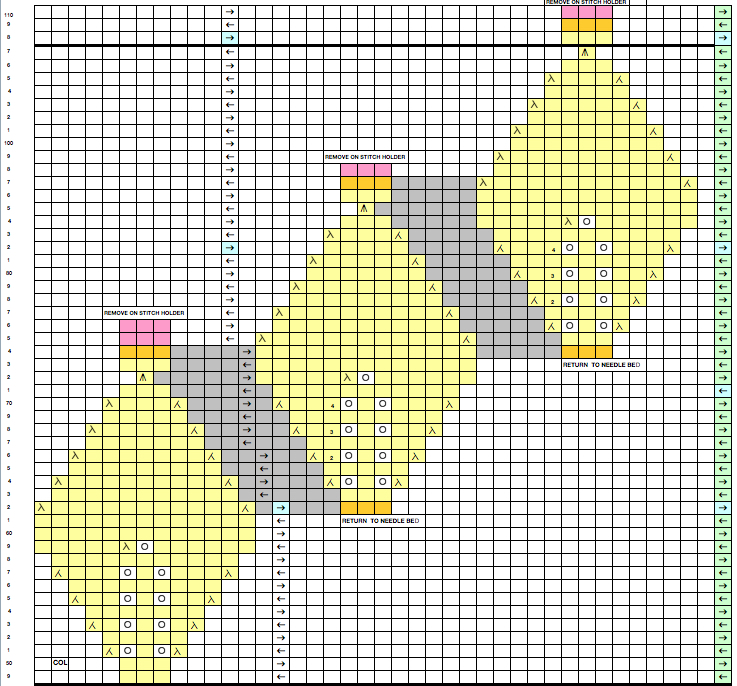

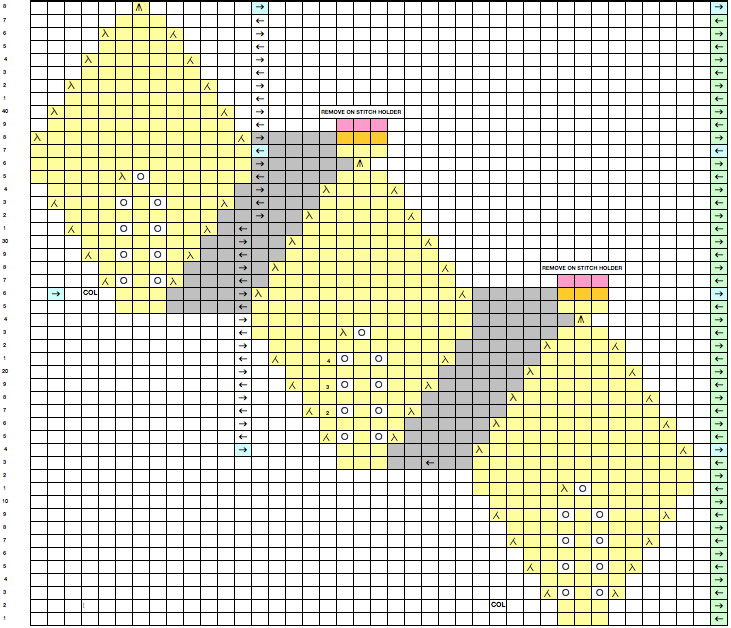

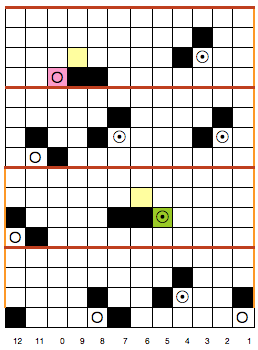

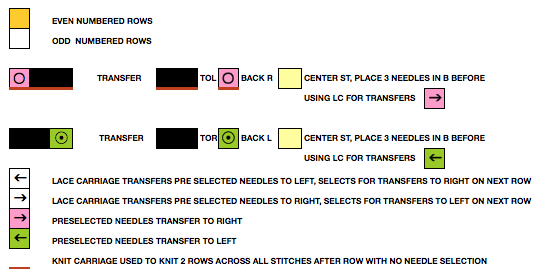

The “variations” and repeats in summary:  Adding geometric forms to mesh: a working MK chart for a cousin to the fabric link provided at the top of this post, the underlying mesh repeat is the same as that for card 17

Adding geometric forms to mesh: a working MK chart for a cousin to the fabric link provided at the top of this post, the underlying mesh repeat is the same as that for card 17

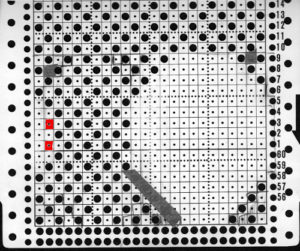

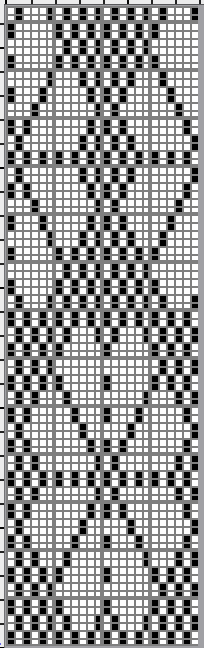

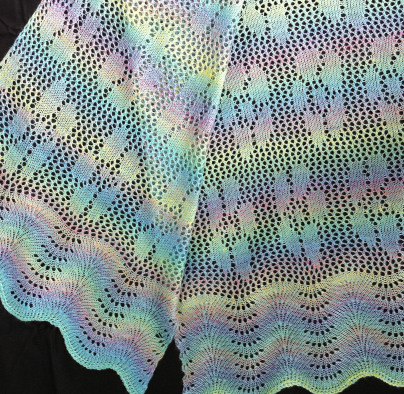

The corresponding punched holes: 2 LC passes for transfers to left (purl side), 4 LC passes for transfers to the right (purl side) throughout on Brother KM

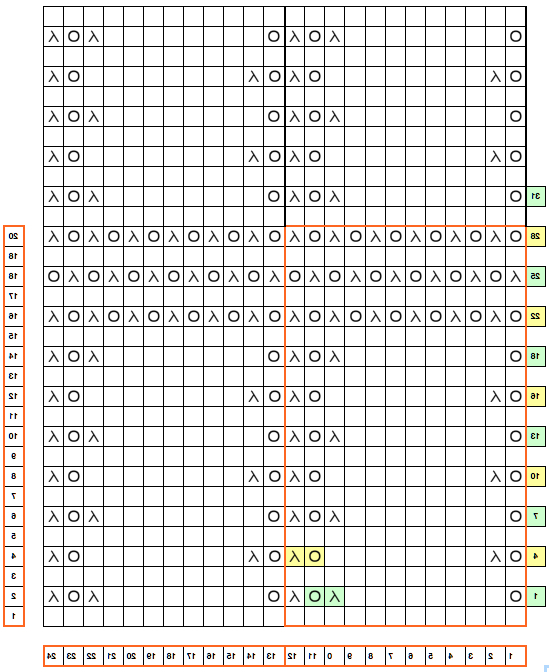

The corresponding punched holes: 2 LC passes for transfers to left (purl side), 4 LC passes for transfers to the right (purl side) throughout on Brother KM chart flipped horizontally, suitable for hand knitting

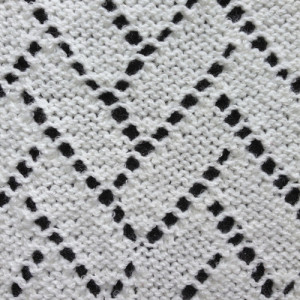

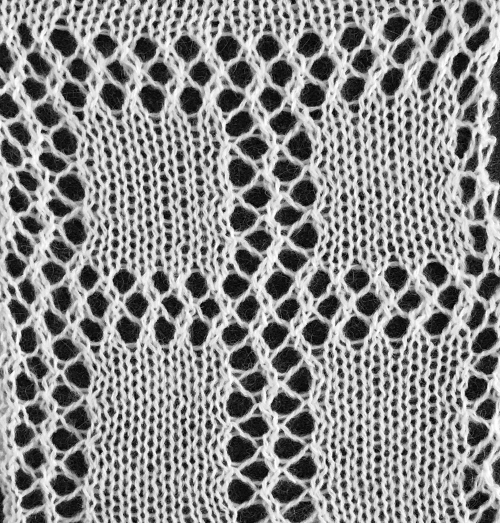

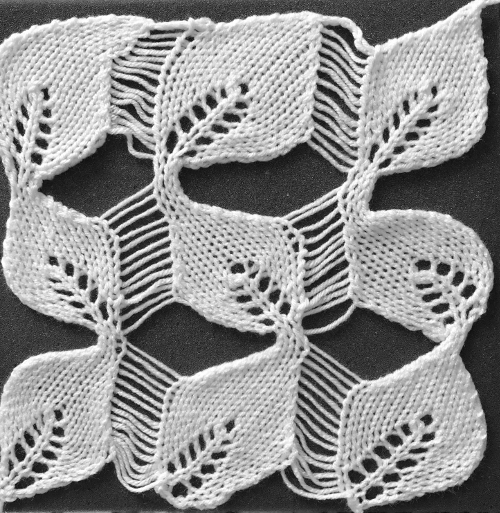

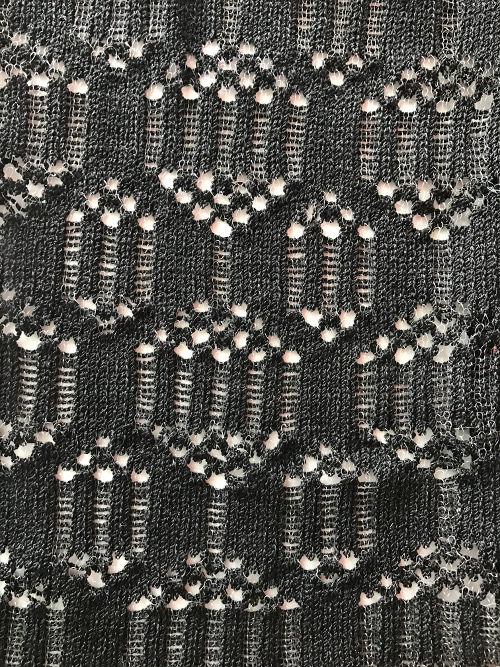

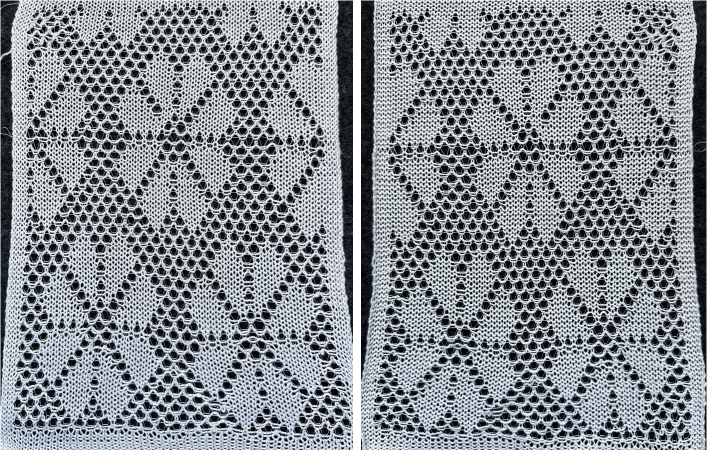

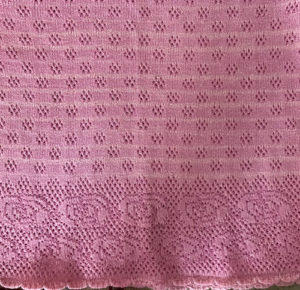

chart flipped horizontally, suitable for hand knitting  the swatch, MK, knit side

the swatch, MK, knit side  Note: the appearance of the “straight line” edges is altered by the formation of the eyelets along the sides as well as the top of the shape. As more shapes are played with, some adjustments may need to be made in punched holes after knitting a test swatch.

Note: the appearance of the “straight line” edges is altered by the formation of the eyelets along the sides as well as the top of the shape. As more shapes are played with, some adjustments may need to be made in punched holes after knitting a test swatch.

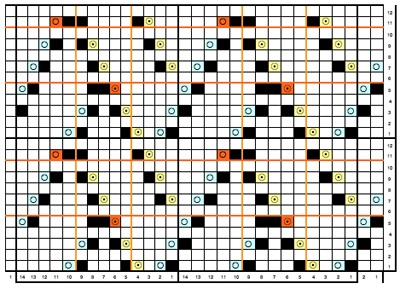

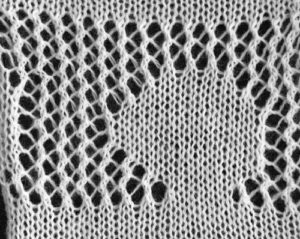

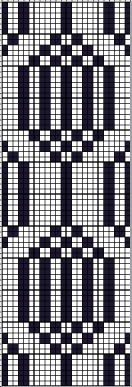

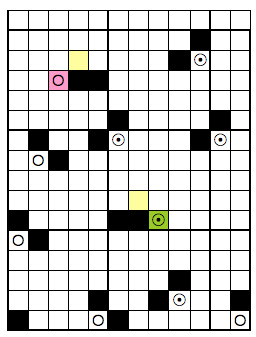

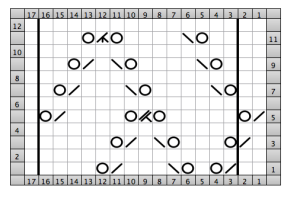

Custom shapes become a bit more complex. So I like the circle in the previous experiment, but I want to accomplish it with traditional lace transfers. I previously discussed a possible approach to filet mesh. This is the swatch where there is one row knit for each row of eyelets, discussed more recently.  Below is the result of working with a traditional mesh, where there are 2 rows of knitting to form each eyelet. The third row in the “design” on a punchcard is needed for the lace carriage to travel to its proper place for the alternating direction of transfers, which is not technically a knit row. The fabric is wider and longer than that above, and there is some elongation of the “circle”. Large patterns are mylar and punchcard real estate hogs. The swatch for slightly more than a single repeat with red dots indicating where one square in the mylar did not have a dark enough mark, resulting in a missing eyelet

Below is the result of working with a traditional mesh, where there are 2 rows of knitting to form each eyelet. The third row in the “design” on a punchcard is needed for the lace carriage to travel to its proper place for the alternating direction of transfers, which is not technically a knit row. The fabric is wider and longer than that above, and there is some elongation of the “circle”. Large patterns are mylar and punchcard real estate hogs. The swatch for slightly more than a single repeat with red dots indicating where one square in the mylar did not have a dark enough mark, resulting in a missing eyelet

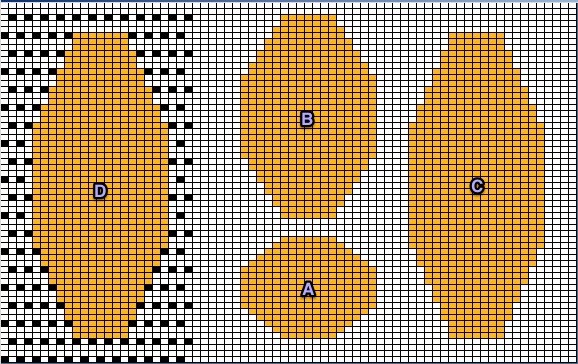

A: is my desired shape 17 units by 17, B: that shape elongated X 2 (17 X 34), to try to approximate elongation with knitting 2 rows for each set of eyelets. It is drawn on a square, not a rectangular or gauge-specific grid, however, so if that is a consideration in the design, it would have to be a case of “back to the drawing board”. C: the shape is elongated X 3 (17 X 51), for placement on the mesh, and D shows it in my desired spot. Lace gauge is harder to gauge because of stretch in the final fabric, and the changes are subject to pressing and blocking depending on yarn fiber content. Because transfers in this method occur on rows 1 and 2 to the left, 3 and 4 to the right, no pure straight edges along design borders can be achieved. If simple superimposing a large shape on the mesh is possible, there may be even more distortion along those edges. Ultimately a lot of this boils down to personal preference and patience.

A: is my desired shape 17 units by 17, B: that shape elongated X 2 (17 X 34), to try to approximate elongation with knitting 2 rows for each set of eyelets. It is drawn on a square, not a rectangular or gauge-specific grid, however, so if that is a consideration in the design, it would have to be a case of “back to the drawing board”. C: the shape is elongated X 3 (17 X 51), for placement on the mesh, and D shows it in my desired spot. Lace gauge is harder to gauge because of stretch in the final fabric, and the changes are subject to pressing and blocking depending on yarn fiber content. Because transfers in this method occur on rows 1 and 2 to the left, 3 and 4 to the right, no pure straight edges along design borders can be achieved. If simple superimposing a large shape on the mesh is possible, there may be even more distortion along those edges. Ultimately a lot of this boils down to personal preference and patience.

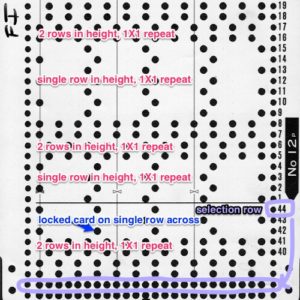

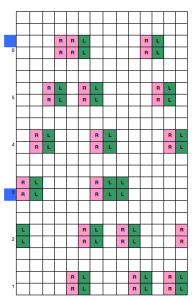

For single vertical line(s) in mesh whether single, at regular intervals, or for use in pattern transitions place repeats as shown where eyelets are desired. Markings for Brother row 1 selection on the right of the chart.  For directions on using lace mesh to create pleated skirts please see post-2017/08/16/pleats-created-with-lace-transfers/

For directions on using lace mesh to create pleated skirts please see post-2017/08/16/pleats-created-with-lace-transfers/

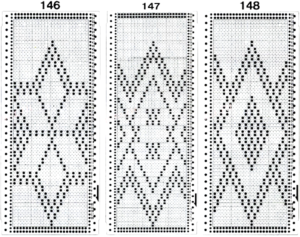

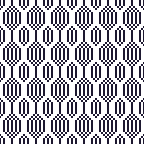

Three more candidates for experimenting with the technique.

Three more candidates for experimenting with the technique.

The single knit row between repeats is fairly easy and rhythmic to produce. The first preselection row is made with the lace carriage, beginning on the left, the design is used as given in the punchcard.

The single knit row between repeats is fairly easy and rhythmic to produce. The first preselection row is made with the lace carriage, beginning on the left, the design is used as given in the punchcard.

The BMP for the full repeat including blank rows at the top

The BMP for the full repeat including blank rows at the top

The above shows long vertical lines of transfers are possible in design motifs (punched holes).

The above shows long vertical lines of transfers are possible in design motifs (punched holes).

A later blog post on the topic with additional information on yarn placement, settings, and more:

A later blog post on the topic with additional information on yarn placement, settings, and more:

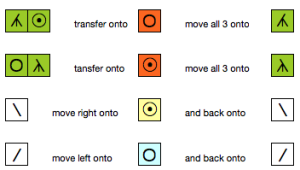

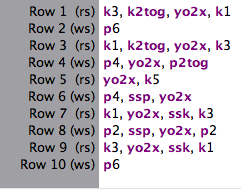

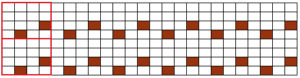

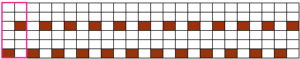

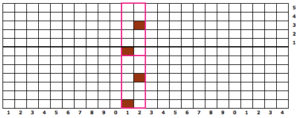

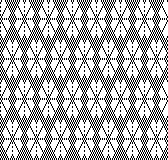

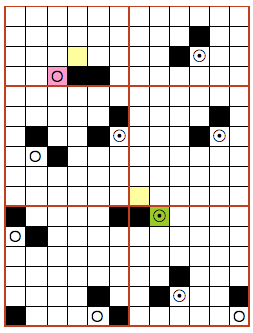

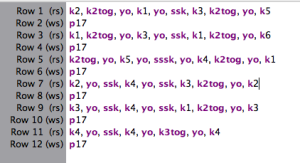

looking at charting differently, back to Excel: single repeat

looking at charting differently, back to Excel: single repeat