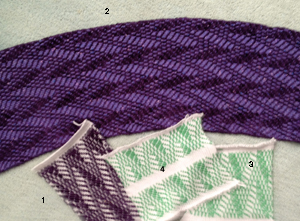

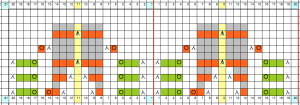

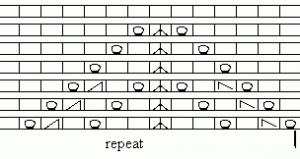

Fair isle accessories, scarves in particular, can be problematic. I tend to make most of my scarves in the 64-72 inch length after blocking, lining them would result in a very heavy scarf. Knit has a tendency to curl to the purl side in length, and toward the knit top and bottom. Rayon chenille is a customer favorite, knitting it double bed in any DBJ variant is nearly impossible on my E 6000 because of shedding and electronic eye reading errors (I would consider ladder DBJ), and I was left with finding a short float pattern that might look acceptable on its reverse, and lie flat. Weaving draft charts can be a great source for repeats for geometric FI knitting. The pattern used below is an adaptation of one. The first swatch (1) looked fine. The long one followed it. When I ironed it, however, I noticed not only a missing black square or 2 in my mylar repeat (hidden by the fuzz of the chenille in the first swatch) but how lovely for it to have a totally curved, far longer edge (if only that was what I wanted)! On analyzing the possible cause I noticed the repeat had many more stitches knit in the chenille than the wool along that edge. Back to the drawing board: the repeat was sorted out using high contrast, smooth yarns (3 and 4), and the pattern was adjusted to a different location on the needle bed.

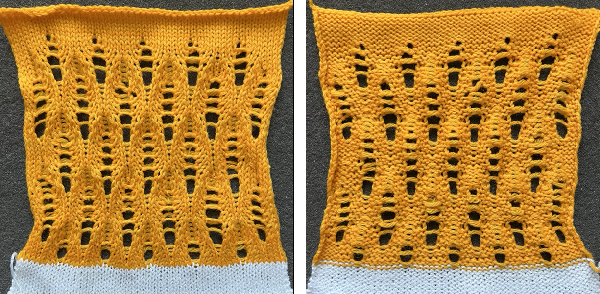

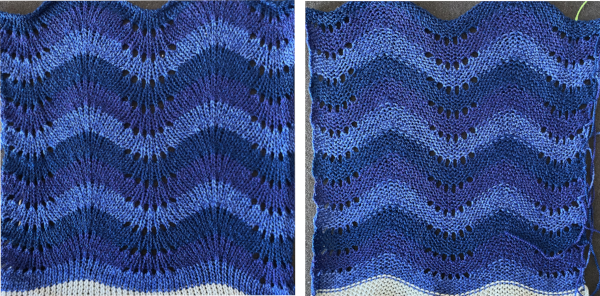

Then, I thought I might introduce a border. The chenille is thicker than the wool, so any hem or stocking stitch edge was too wide. I would have preferred to chain behind the knit to help flatten the bottom and top edges and ran into yarn breakage galore. The final piece was made using 1X1 FI in the chenille “solid” color stripe to keep a balanced width and fabric thickness, and cast on and bound off edges were rehung and “bound off” again, to help cut down on their rolling toward the knit. The finished scarf measures 8″X69″, both knit and purl sides are shown below, side edge lengths now match. Assuming one uses a crochet cast on and binds off around gate pegs at the top, a chain is created at both ends, akin to that created in crochet, and one can identify a front loop, a back loop, and the whole chain. Any of the 3 may be “rehung” onto the KM, and the options are to knit a row and bind off again, or simply bind off again, for different looks that start to emulate single crochet a bit and can help stabilize edges or decorate them. It is helpful to keep notes as to the sequence used and which side is facing with each re-hanging. Audrey Palmer at one point authored the Empisal book of linked edgings ISBN 0969485905. Intended for use with the Empisal (later = Studio) linker, there are lots of interesting uses for combinations of essentially find off techniques, and some resurfaced when she published her books on knit weaving.

Assuming one uses a crochet cast on and binds off around gate pegs at the top, a chain is created at both ends, akin to that created in crochet, and one can identify a front loop, a back loop, and the whole chain. Any of the 3 may be “rehung” onto the KM, and the options are to knit a row and bind off again, or simply bind off again, for different looks that start to emulate single crochet a bit and can help stabilize edges or decorate them. It is helpful to keep notes as to the sequence used and which side is facing with each re-hanging. Audrey Palmer at one point authored the Empisal book of linked edgings ISBN 0969485905. Intended for use with the Empisal (later = Studio) linker, there are lots of interesting uses for combinations of essentially find off techniques, and some resurfaced when she published her books on knit weaving.

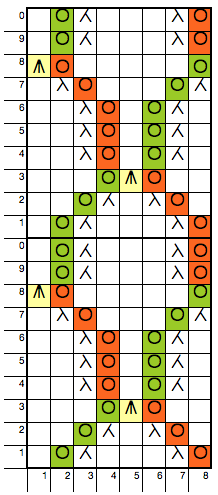

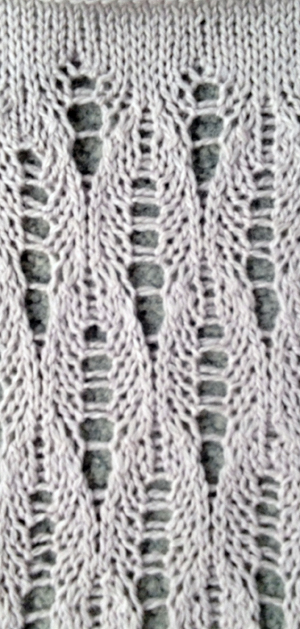

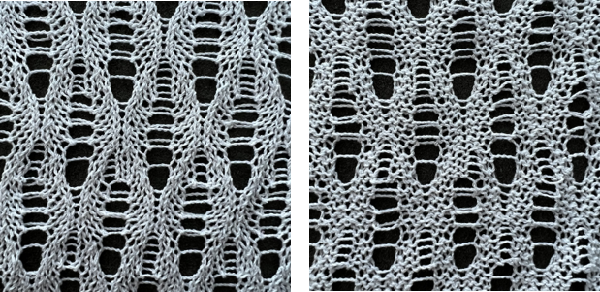

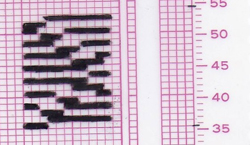

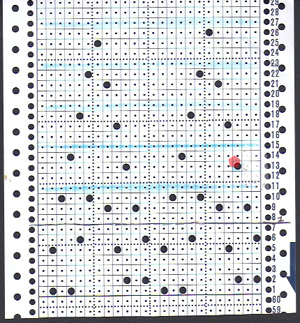

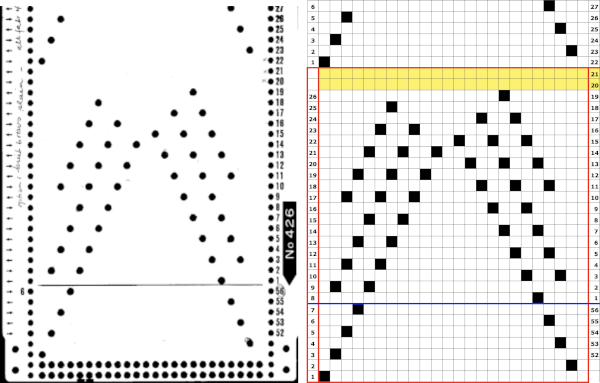

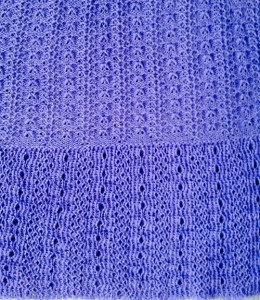

The same pattern knit on Passap, using tech 129 and 138; there is a noticeable difference in width and openness of fabric with yarn weight change, and at the top with tucking for twice as many rows.

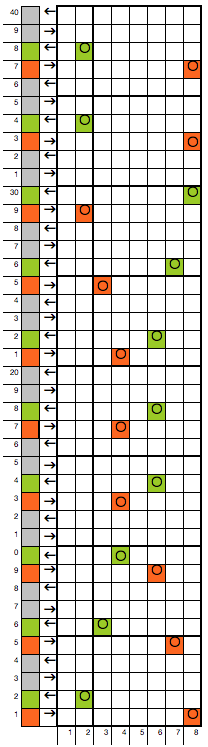

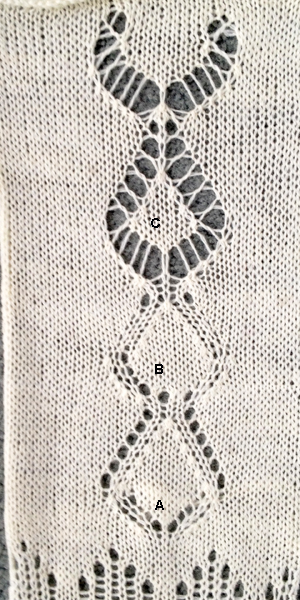

A scarf knit in pattern, using tech 138, double bed on Passap KM; lightweight and drape allow it to be wrapped and worn in multiple ways; knit in 16/2 cotton, measures 11 X 76 inches partially blocked

A scarf knit in pattern, using tech 138, double bed on Passap KM; lightweight and drape allow it to be wrapped and worn in multiple ways; knit in 16/2 cotton, measures 11 X 76 inches partially blocked

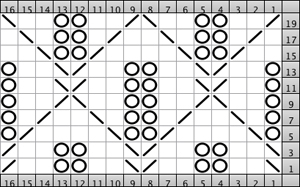

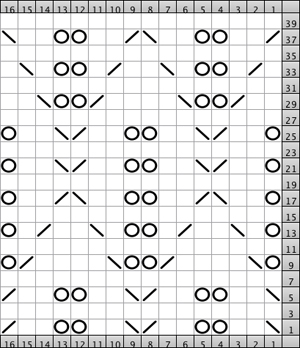

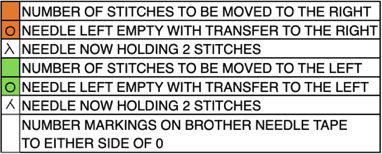

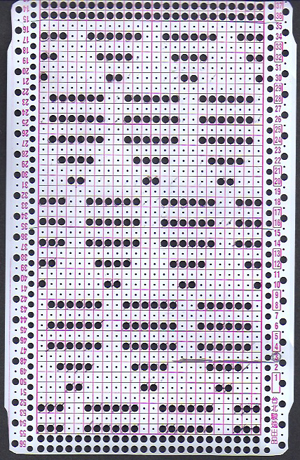

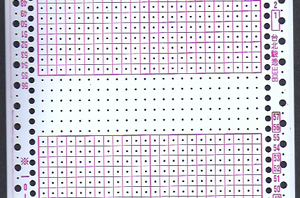

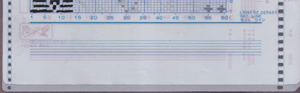

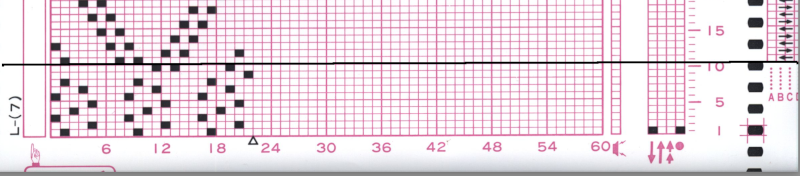

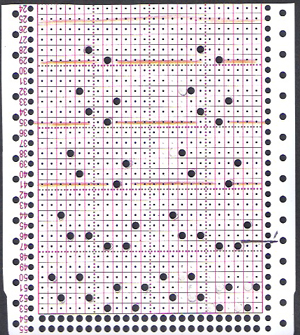

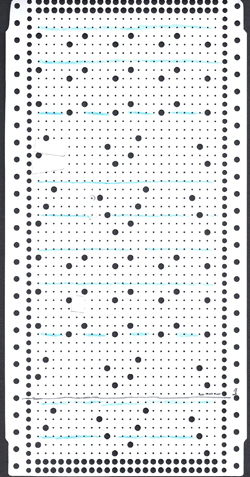

I had tested template markers on Brother mylars when ink pens were discontinued and I had no luck with permanent markers, found they shed a bit and pencils tips broke easily, while I could not be as neat in rendering small markings as simply by going the route of using a number 2 pencil on the mylar’s back ( I prefer the Mirado Warrior HB 2). Drawing with enough density “within the lines” on mylars is rendered far easier with one of these templates, at one point made available from Brother. Similar ones may sometimes be found in stationary or art/ drafting supply stores.

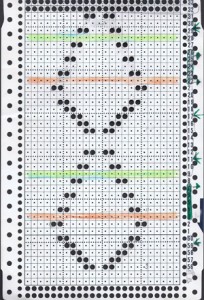

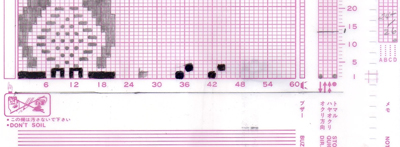

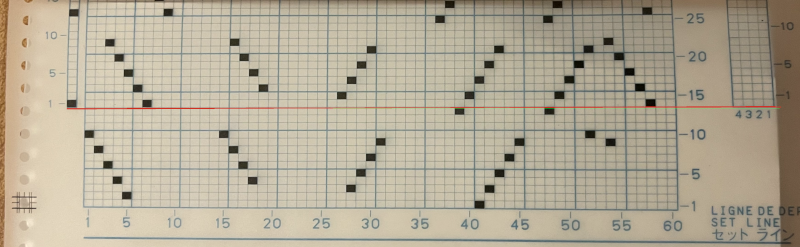

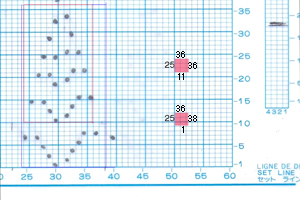

I had tested template markers on Brother mylars when ink pens were discontinued and I had no luck with permanent markers, found they shed a bit and pencils tips broke easily, while I could not be as neat in rendering small markings as simply by going the route of using a number 2 pencil on the mylar’s back ( I prefer the Mirado Warrior HB 2). Drawing with enough density “within the lines” on mylars is rendered far easier with one of these templates, at one point made available from Brother. Similar ones may sometimes be found in stationary or art/ drafting supply stores.  The images below show my first “new” tests: on the left, I drew with the template marker over previous pencil markings, the squares repeat over # 36 was made with multiple layers of a sharpie (which smeared even after what would seem like adequate drying time), the ones over #42 are made with the template marker. The sharpie did not get scanned properly by the reader, all other marks did. There is a guiding pencil line placed where the set line familiar to Brother users would be. In the first narrow column to the right, the pencil marking corresponds to the first visible row (design row 1 in reader). The column on the far right (absent from Brother) could be used for additional cues in knitting ie. color changes, knit rows between lace transfers, etc.

The images below show my first “new” tests: on the left, I drew with the template marker over previous pencil markings, the squares repeat over # 36 was made with multiple layers of a sharpie (which smeared even after what would seem like adequate drying time), the ones over #42 are made with the template marker. The sharpie did not get scanned properly by the reader, all other marks did. There is a guiding pencil line placed where the set line familiar to Brother users would be. In the first narrow column to the right, the pencil marking corresponds to the first visible row (design row 1 in reader). The column on the far right (absent from Brother) could be used for additional cues in knitting ie. color changes, knit rows between lace transfers, etc.

while Studio scans 10 rows below

while Studio scans 10 rows below  This explains why the columns intended for memos extend up and beyond the last row which can have cells marked for pattern in each brand.

This explains why the columns intended for memos extend up and beyond the last row which can have cells marked for pattern in each brand.

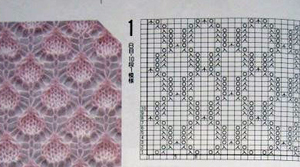

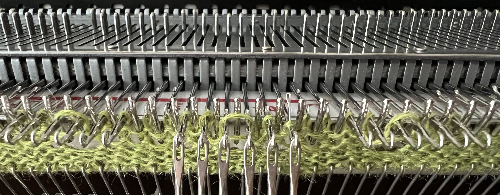

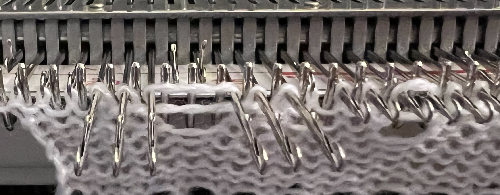

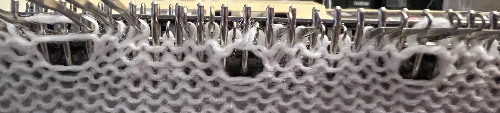

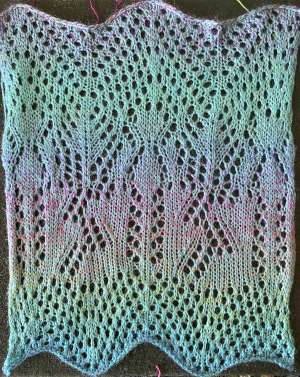

Space-dyed yarns may produce interesting effects, in lace sometimes the pattern is lost, however. In the swatch below I attempted to introduce a random striped sock yarn, thicker than the white previously used. When I loosened the tension for the knit rows, I began to have stitches consistently hung up on gate pegs, adding the second reason to switch my “color 2”. Color changing is every 4 rows, beginning with row 1

Space-dyed yarns may produce interesting effects, in lace sometimes the pattern is lost, however. In the swatch below I attempted to introduce a random striped sock yarn, thicker than the white previously used. When I loosened the tension for the knit rows, I began to have stitches consistently hung up on gate pegs, adding the second reason to switch my “color 2”. Color changing is every 4 rows, beginning with row 1 a larger swatch with tension adjustments and switching the 2nd color to equal weight, “friendlier” yarn

a larger swatch with tension adjustments and switching the 2nd color to equal weight, “friendlier” yarn

The narrower stripe is spaced 6 rows apart, the wider a full repeat.

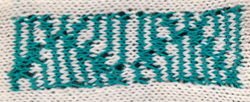

The narrower stripe is spaced 6 rows apart, the wider a full repeat. Knitting the pattern using a fuzzy yarn like rayon chenille results in little difference between knit and purl sides

Knitting the pattern using a fuzzy yarn like rayon chenille results in little difference between knit and purl sides

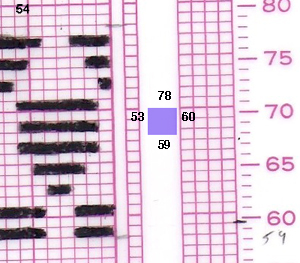

May 24, 2019 a greyscale mode scaled image processed in

May 24, 2019 a greyscale mode scaled image processed in