A Ravelry post discussing cable connections to knitting machines for downloading patterns and associated software has led me to accumulate the information below. I am primarily a Brother and a sometimes Passap knitter and can speak to only part of the content below from direct experience.

The information on electronic downloads cannot be separated from a history of hacking, which began with Brother machines when mylar sheets became less available and folks began to have an interest in bypassing them. A review of such efforts was also shared in a previous post:

a hacking history https://www.beautifulseams.com/2014/10/29/tricodeur-writeup/

only the intro is in German: a nearly hour-long presentation by Fabienne<https://www.youtube.com/watch?v=n1CRNjzOuto>

Brother 930: http://learn.adafruit.com/electroknit

Brother 970: http://glitchknit.tumblr.com

930 knitting: http://andrewsalomone.com

910: Claire Williams Wordpress site is no longer available

Fabienne http://fabienne.us/tag/knittingmachine/

keypad: http://travisgoodspeed.blogspot.com/2010/12/hacking-knitt…

FB100 Emulator software, disc utility program, cable

another approach for Brother models KH”‘930, 940, 950i, and 970: http://daviworks.com/knitting/ and the associated group on Ravelry

970 how to hack instructable

for additional cumulative information, software compatibility, and hardware specs see Claire Williams’ website

Superba hacking and open source software https://www.hackerspace-bamberg.de/Singer_Superba

E6000 https://www.hackerspace-bamberg.de/Passap_pfaff_e6000

hack and 3D printed accessories, Passap: Knitterstream

Present interfaces available for downloading patterns to Brother knitting machines: so far, both programs do not appear to run natively in the new iMac with M1 chip and Monterey OS.

That said, https://ayab-knitting.com , supported devices: https://ayab-knitting.com/supported-devices/. My experience using it has been with the 910. Pre-assembled kits used to be sold, over time they were offered by 2 different providers and were taken off the market by each of them. In many cases, there appear to be some issues with the program in DIY units as well resulting in mispatterning especially in long pieces of knitting.

Ayab operates as a true knit-from-screen, so the computer needs to be awake throughout the knitting process. In the case of the 910, the hack replaces the reader completely, the left side of the machine is left exposed, and the interface replaces the traditional patterning and power source, with its own cord connecting it to the power supply.

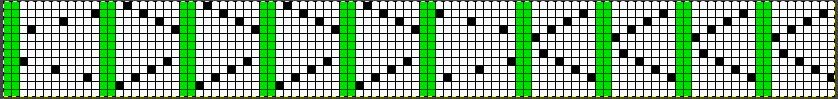

The last update to the program was in 2019. It performs color separations for dbj in multiple colors per row, including the only one of its kind, the Heart of Pluto, which eliminates jacquard color separation patterning errors and knits single passes for each color in each design row on the main bed.

Since the built-in patterning control buttons are rendered inoperable, Actions such as color invert, setting the number of repeats, vertical flip, mirror, rotate left, and rotate right are available within the program. Patterns may load both in color and shades of gray, palette color choices make a difference in achieving successful color separations.

Ribber settings include classic, middle color twice, HOP, and circular for tubular fair isle or other fabrics.

https://xxxclairewilliamsxxx.wordpress.com/hack-ta-machin… is an early post on the hack, showing steps involved. Kits with parts for DIY may be found online including at https://ko-fi.com/redpinkgreen/shop.

The program is free, any incurred expenses depend on how and from where the interface components are purchased.

The related Ravelry group has been quiet for a very long time, for more information on what is being developed and what users are knitting, the FB group has frequent shares. I would urge anyone interested in the program to join the group before making final decisions, to observe issues reported, and the finished projects if any using it https://www.facebook.com/groups/1384431355220966.

A recently added video KH 900+ KH 965 Brother knitting machine – How to install the AYAB Shield/alternative pattern control|

On my blog when I actively used the program, I shared my experiences using it and explored a variety of fabrics using its settings.

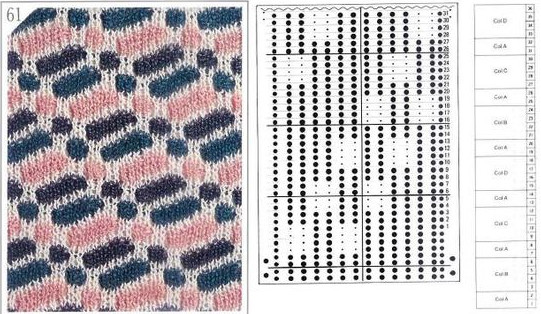

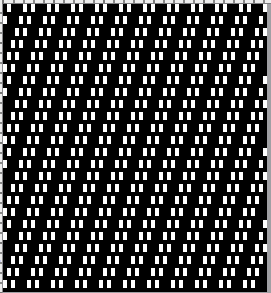

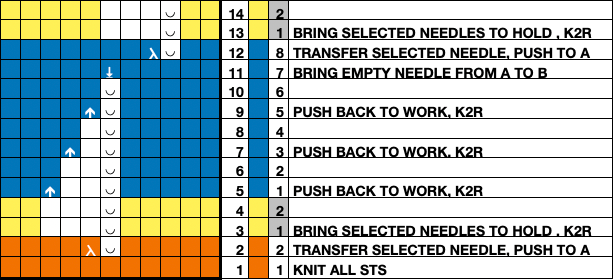

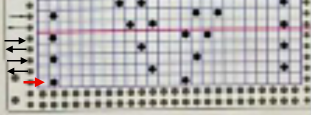

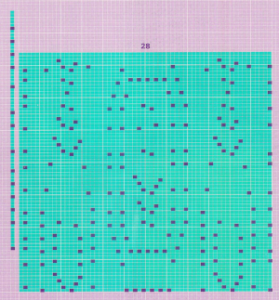

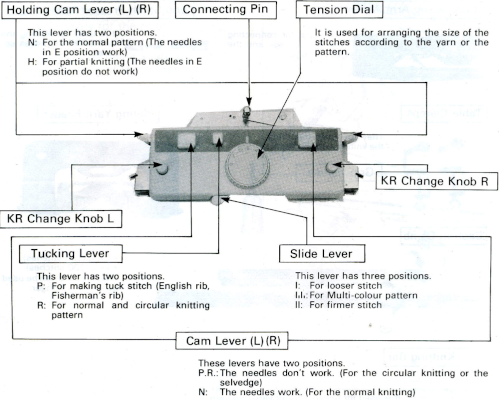

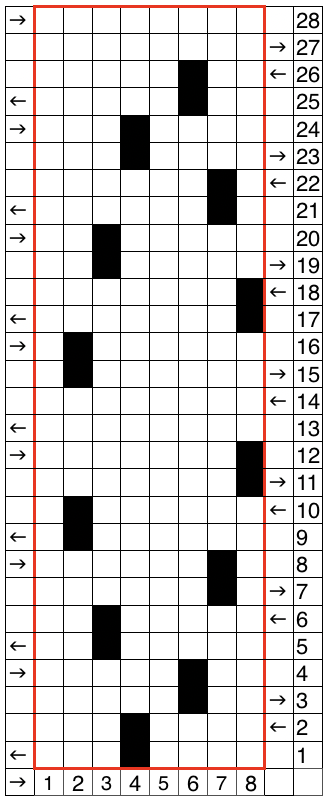

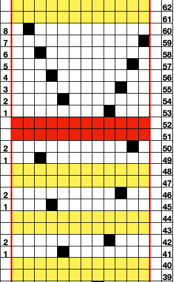

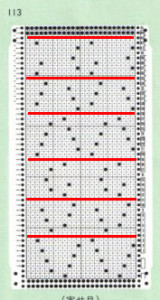

img2 track: works with Brother models KH 930, 940, 950i, 965i, and 970. https://daviworks.com/knitting/index.html. The program is also free to use on swatches limited to 60 stitches in width, to use the full width of the needle bed the purchase of a registration key is required, and the cost is around $100. The download cable can be ordered directly from Davi and directions are available for those with the ability to build their own. The program downloads the pattern into machine memory, so the computer does not need to be awake other than during download. The size of the download is limited by the machine model brain, with the 930 being the smallest.

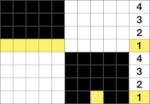

When large files are planned, the program will reduce the pattern into tracks, and each has to be entered as a new program after the previous track is completed. The KH-930 takes just a few seconds to load the track because the memory holds only 2 KB of data (about 13000 stitches). Later models have a much larger memory (32 KB). The KH-940 and KH-950i require 42 seconds to load a track. The KH-965i and KH-970 load only the requested pattern, so the loading time depends on the size of the pattern. With Brother models KH-965i and 970, you can load a pattern from img2track without erasing the previous ones in the KM, as long as they fit in the memory. So you can have 901, 902, etc. loaded and choose between them.

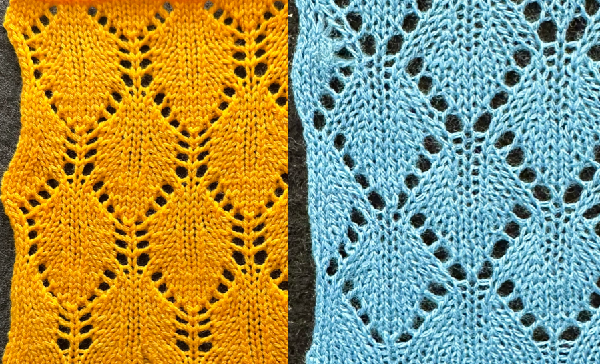

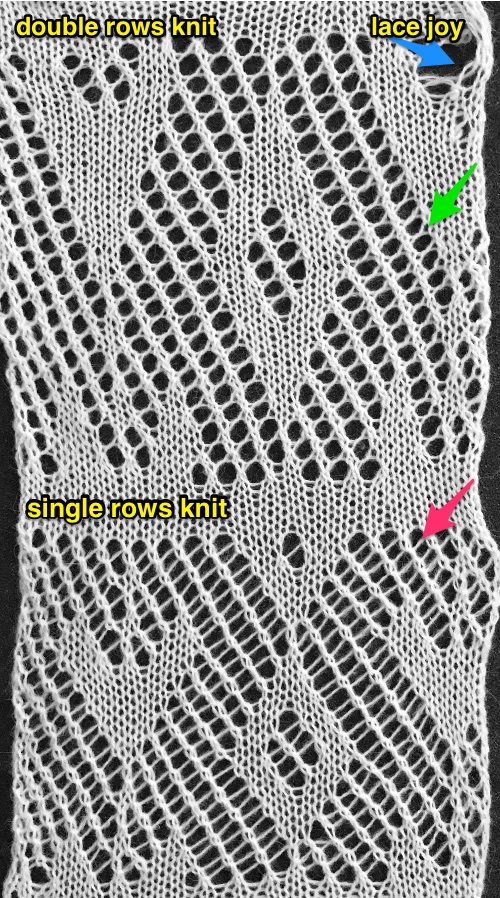

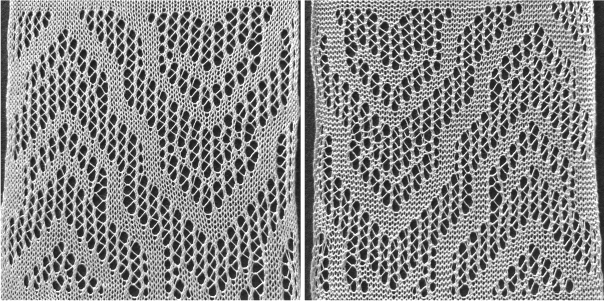

Color separations are available for multiple color dbj, but not as a single pass for each color in each row as in Ayab Heart of Pluto. Images open in shades of grey. Each color in each design row is knit twice. It is possible to knit each design row color only once by adding a hand technique.

Adjustments may be made for vertical stretch, maximum width, and the number of colors used. Any remaining changes can be made by using the knitting machine button selections.

Out of habit, I have used both programs to open bmps and pngs saved in indexed mode though both are said to open common file formats ie. jpg, gif, png, bmp, tiff, …Neither program exports files in other formats or allow for editing specific pixels in the designs in any way after they have been opened.

I have found img2track to be completely reliable, errors encountered during knitting or programming have usually been operator ones. I develop my patterns outside either program in paint programs, I prefer to use Gimp or ArahPaint6.

The AYAB GitHub offers a huge library of ready for download images from various sources, most in png format.

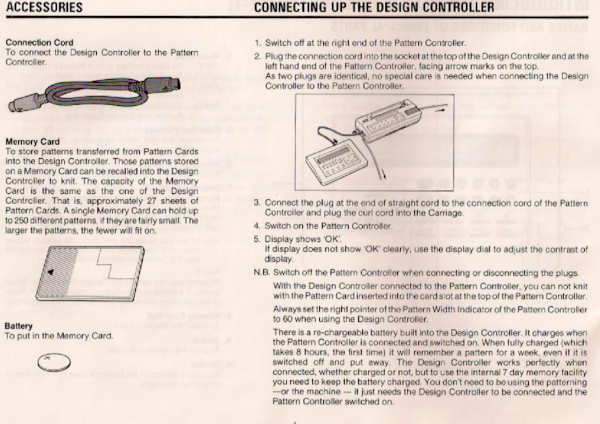

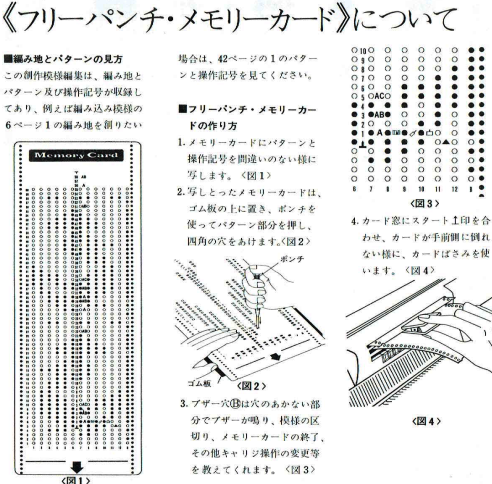

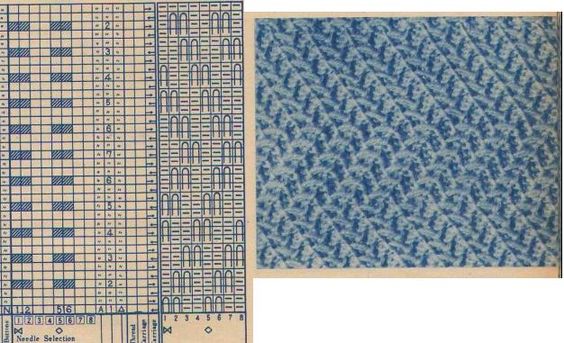

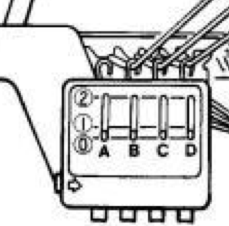

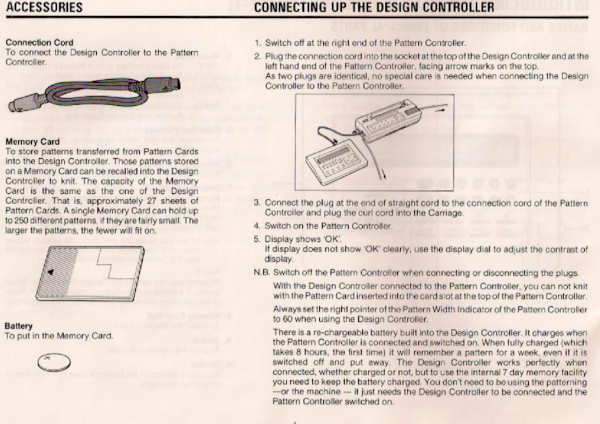

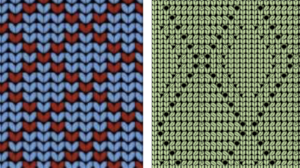

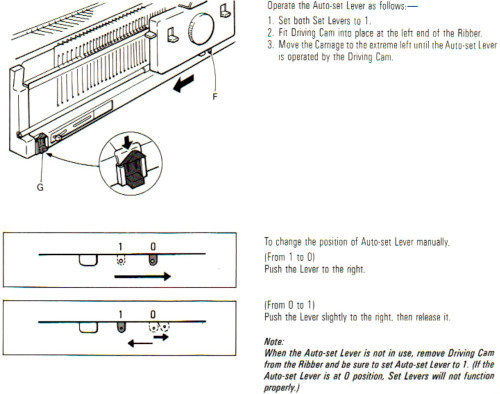

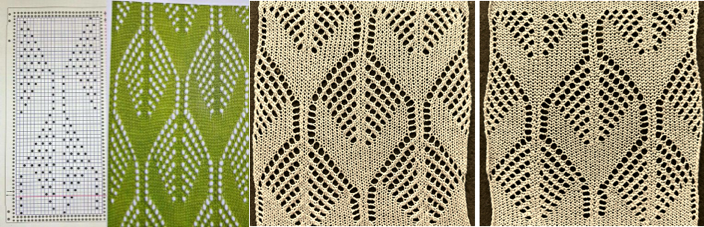

I do not have any direct experience with Studio Electronic machines post-EC1 Studio’s approach to machine brains was to develop an exterior box that could be purchased separately from the knitting beds, EC1 on the left, their PC1 on the right  From the manual on its use

From the manual on its use  The following information is gleaned from online searches: Studio or Silver Reed’s efforts to move away from mylar sheets as seen in the EC1, headed in a different direction than seen in Brother knitting. There are two options still available, the SilverKnit and SilverLink systems:

The following information is gleaned from online searches: Studio or Silver Reed’s efforts to move away from mylar sheets as seen in the EC1, headed in a different direction than seen in Brother knitting. There are two options still available, the SilverKnit and SilverLink systems:

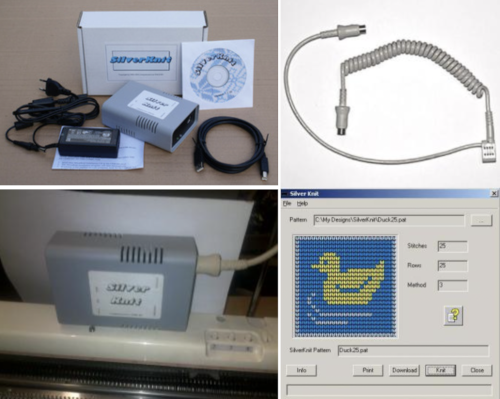

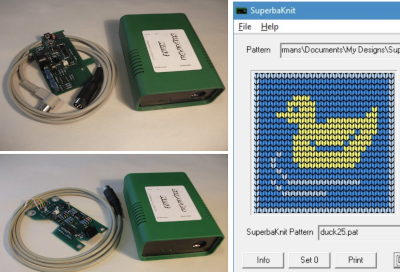

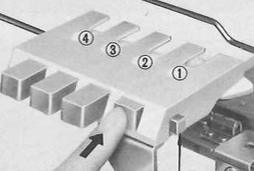

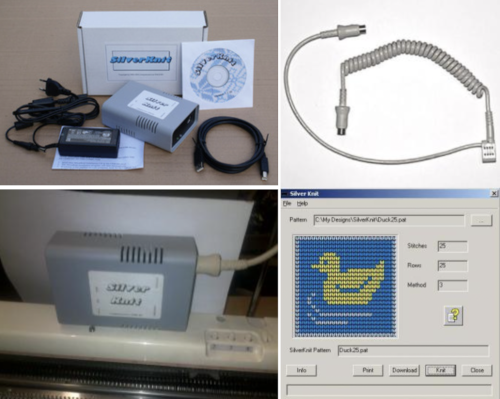

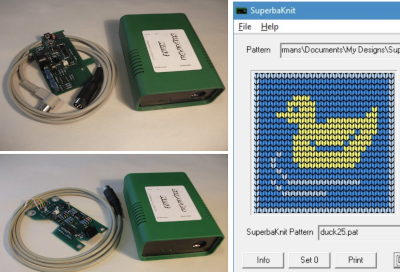

SilverKnit, with more info at https://silverknit.nl/dk/silverknit-en.htm “provides the knitting functionality of the EC1/PE1 for electronic Silver Reed machines. The site lists all pertinent information on system requirements and compatible models. One can knit patterns without the need for additional software, which may be created with a graphics package of your choice.” The pieces involved include a controller unit, a coil cable connector curly cord, and the box, which may be secured on its side to the knitting machine case using velcro strips, usually true for other switch boxes and control units as well. There is a SilverKnit software user interface.  For Superba machines, there are the Superbaknit packages available: type A for pressure pad, 624, 9000 models, and type B for light scanner/pegboard models. They allow patterning across the entire bed, accept multiple file formats, and seem to use the same platform as the Silverlink program.

For Superba machines, there are the Superbaknit packages available: type A for pressure pad, 624, 9000 models, and type B for light scanner/pegboard models. They allow patterning across the entire bed, accept multiple file formats, and seem to use the same platform as the Silverlink program.

The Silverlink, now in Series 5 is for use with DAK. Manuals for softbyte cables include information on series 3, 4, and 5.  There are distributors in each country listed on the Softbyte site. There are also individual sellers in other states and locations. Prices are not necessarily fixed, and relationships with local dealers may foster easier-to-reach individual support.

There are distributors in each country listed on the Softbyte site. There are also individual sellers in other states and locations. Prices are not necessarily fixed, and relationships with local dealers may foster easier-to-reach individual support.

A 2020 review of the Five Pattern Control Methods for a Silver Reed Knitting Machine.

Passap knitters were first introduced to Creation 6 as the proprietary Madag E6000 software, usable with a short dongle on computers available at the time, making it necessary to remove the card reader from the machine to get it close enough to the computer for download. The dongle was plugged into where the curly cord connects on top of the console. Cochenille developed a download, knit from screen cable, and my early Passap pieces were made using Suzan Lazear’s BitKnitter on a reader with 8K memory. With true knit-from-screen, console memory is bypassed. The system was also available for Studio machines, but both became abandoned.

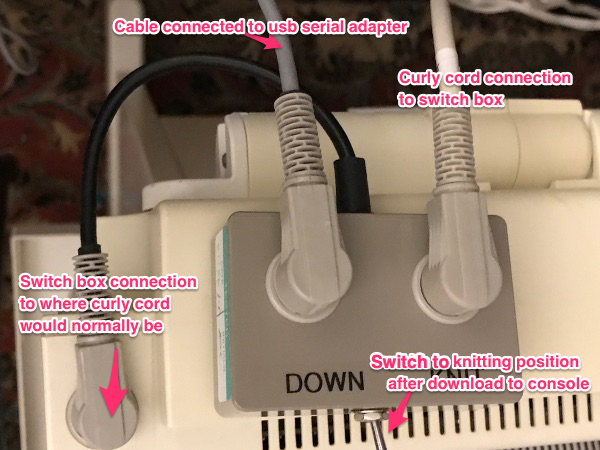

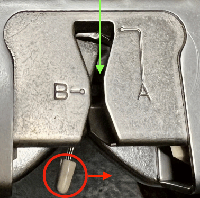

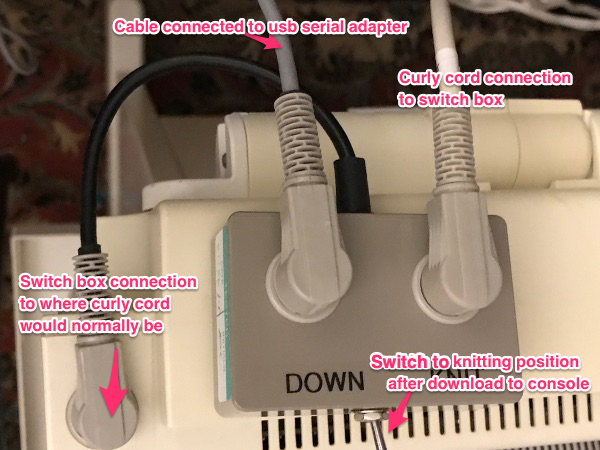

As is true for the present DAK system, there was also a proprietary Passap file format used, CUT, aka Dr. Halo. Eventually, I purchased a switch box and download cable from Richard Croucher in England, and up to the present day that has been my go-to for downloading patterns using an ancient laptop. Personally, where I go now that I have a new PC available, is TBD. I failed to get the system to work using VMware on my old iMac.

One of the caveats with downloading to the Passap is that the cable connection for both the curly cord and the download cable share a single entry point to the console. This connector was temporarily available and spared some of the wear and tear on the console  The addition of a switch box, secured with velcro on the console, allows for the possibility of downloading and knitting patterns without having to make any multiple other connections.

The addition of a switch box, secured with velcro on the console, allows for the possibility of downloading and knitting patterns without having to make any multiple other connections.

Aside from connections to the machine, there was the issue of available software for drawing repeats and downloading in the proper format.

Aside from connections to the machine, there was the issue of available software for drawing repeats and downloading in the proper format.

In the heyday of machine knitting aside from textbooks and articles beginning to appear from authors such as Lewis in the US, Kinder in the UK, and Carmen Router in Australia, lots of practical accessories and other info grew out of a very active knitting community in Australia as well. Accessories included a plaiting feeder and a stitch ditcher, and homegrown freeware was shared for printing reader cards. To this day Wincrea is still available for downloading to the E6000 machines. Others have followed ie Journal 6, which is now available as freeware, the repository may be found here. Wincrea remains the easiest to use. Supported formats are CUT/ Dr. Halo, BMP, and WMF (Windows metafile). At present, downloads of patterns are only possible in machines that allow PC downloads with later manufacturer chips and larger, 32K memory.

CUT files have a separate palette, the program reads the palette if it is found in the same folder as the CUT file. If the program palette is not the same as when the pattern was saved previously, the colors may not be as expected.

Some scaling may be done within the program. Files may be saved in both CUT and BMP formats.

If one chooses to, saving palettes is done by using specified names in the 256-color PAL (Dr. Halo) format.

When a design is uploaded to Wincrea step one is to have it read the correct number of needles and the number of colors used. If it does not recognize a com port, it will give an error message, and com-ports can be reassigned using the E6000 settings option menu. Once it recognizes the port, then it will come up with the download to E6000 option, and will also give an estimated time for the download to take place. It walks the user through how to prepare the machine for download. Two things are required: the console’s correct buttons need to be pushed to get to a “PC start” programming position, which verifies the machine itself is capable of accepting the download, and the switch must be in the download position. If things work, a beep follows once the download option is selected and the LED screen on the passap shows a progress bar for downloads that take longer than a few seconds. If the pattern has indeed downloaded successfully, the console beeps again and then follows up with questions on whether you want to alter the design in any way from its built-in additional options, what knitting “technique” you want to use, how many needles you want in work on either side of 0, and if you want to place the design in any particular place on the bed. It is possible to continue programming, either segments or different patterns altogether. At that point, cables are swapped out or if using a switch box, providing the operator remembers to flip the switch to the knitting position, things should go smoothly. If one has forgotten to change to the knit position, the machine will beep and give you a different error message and beep. The Passap console has a whole series of lovely beeps, for all sorts of prompts and reasons that may be at times downright infuriating to people using the machine.

Passap color changers were available as add-ons for automatic sequential color changing for up to 4 colors, and are placed on the right rather than on the left as in Japanese machines, so programming downloads and first preselection rows must consider that.

As CUT files proliferated, shared by Madag and individual designers, or as knitters wished to create their own, interest grew in creating, reading, and converting formats. Programs like Dr. Cutter for doing have long since become unavailable. Stitchpainter’s early versions were able to save CUT files, but I have not been able to verify online whether the present version still does.

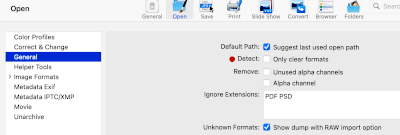

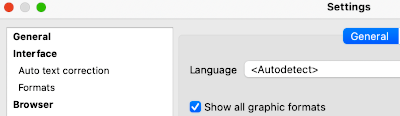

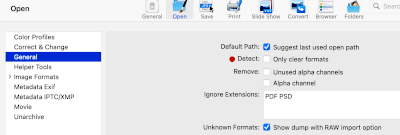

Present-day options for opening and converting CUT files include the for purchase Graphic converter. On my new M1 iMac, I had issues with CUT files not opening. The software developer was responsive to questions and troubleshooting, a nod of thanks to Thorsten Lemke. The advice: please download the latest version http://www.lemkesoft.org/beta.html, and make certain that in preferences, the box aside Detect Only clear formats is unchecked.  and for solving the same issue in XnviewMP, a nod of thanks to Pierre-e Goulet for the solution: in Settings, General, make certain that Show all graphic formats is checked.

and for solving the same issue in XnviewMP, a nod of thanks to Pierre-e Goulet for the solution: in Settings, General, make certain that Show all graphic formats is checked.  Xn Convert allows for easy batch conversions. I did not encounter any issues on Mac.

Xn Convert allows for easy batch conversions. I did not encounter any issues on Mac.

As these programs have grown in complexity, some of the CUT files open in strange colorways, and need adjustments and editing, possible within the above programs, for increased or any visibility while some are viewed clearly. Batch conversions to other formats are possible and performed easily and quickly. A Windows-only image conversion program for exploration: Konvertor

DAK proprietary formats ie STP and PAT to my knowledge are not readable by any program outside the DAK universe.

Softbyte now offers a similar setup with a switch box allowing for download to a console capable of accepting PC downloads, the E6000 Link 2. “This link has a switch that enables the selection of either downloading or Interactive Knitting. It means that the cable can be kept permanently attached to both the E6000 console and bed. This avoids the need for repeated connection and disconnection of the link, and therefore also avoids wear and tear on the E6000’s sockets. The other links do not have the switch and need to be disconnected after downloading, so even if Interactive Knitting is not required, we recommend using the Serial E6000Link 2.” The Softbyte links for Brother machines include versions for downloading and uploading with a Brother PPD or to machines that take a pattern cartridge. The magnet arm for interactive knitting is not included with all, may be purchased separately. “The USB Brother Link 5 enables patterns to be downloaded from DesignaKnit, and any 900 series patterns to be uploaded to DesignaKnit. The 900 series pattern numbers are those loaded from another source into your knitting machine or PPD (e.g. from the PPD, Brother FB100 Disk Drive, or DesignaKnit). This link supports downloading and uploading with the KH930, KH940, KH950i, KH965i, KH970, and with the PPD using Cartridge III in KH900 mode, or with the PPD using the CK35 cartridge. This link is identical to the USB BrotherLink 1 except that it includes a magnet arm that attaches to the carriage and enables Interactive Knitting with any knitting machine, including non-electronic ones.”

The Softbyte links for Brother machines include versions for downloading and uploading with a Brother PPD or to machines that take a pattern cartridge. The magnet arm for interactive knitting is not included with all, may be purchased separately. “The USB Brother Link 5 enables patterns to be downloaded from DesignaKnit, and any 900 series patterns to be uploaded to DesignaKnit. The 900 series pattern numbers are those loaded from another source into your knitting machine or PPD (e.g. from the PPD, Brother FB100 Disk Drive, or DesignaKnit). This link supports downloading and uploading with the KH930, KH940, KH950i, KH965i, KH970, and with the PPD using Cartridge III in KH900 mode, or with the PPD using the CK35 cartridge. This link is identical to the USB BrotherLink 1 except that it includes a magnet arm that attaches to the carriage and enables Interactive Knitting with any knitting machine, including non-electronic ones.”

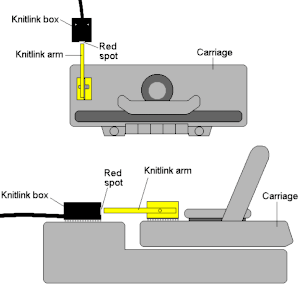

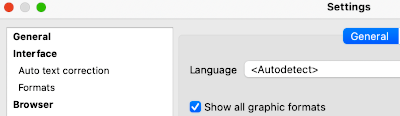

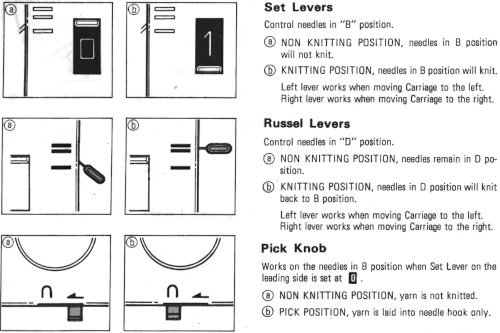

The ScreenLinks provide row by row instructions and audible memo alerts for non-electronic machines or anyone using mylars, built-in patterns, or other software for the pattern downloads. They are not able to download patterns. The Universal Link for DesignaKnit allows one to connect any knitting machine, including plastic beds, to the DesignaKnit interactive knitting as opposed to knit from screen function. The USB cable is attached to your personal computer. The other end of the cable is attached to the mainframe of your knitting machine, the magnet to the carriage or lock of your knitting machine. The cable senses the magnet as it moves past it, and as it does DesignaKnit will advance the pattern one row. From the manual:  And shown applied to a plastic bed machine @ https://www.allbrands.com/

And shown applied to a plastic bed machine @ https://www.allbrands.com/

Garment shapes filled with patterns may be developed in DAK, the cable allows one to use DesignaKnit as a knitleader or knit radar device increasing the capabilities of the knitting machine when shapes are created illustrating pixel-based increases and decreases, akin to what could be drawn on graph paper with each cell representing both a single row and a single stitch, and connecting dots placed on the basis of gauge calculations.

Garment shapes filled with patterns may be developed in DAK, the cable allows one to use DesignaKnit as a knitleader or knit radar device increasing the capabilities of the knitting machine when shapes are created illustrating pixel-based increases and decreases, akin to what could be drawn on graph paper with each cell representing both a single row and a single stitch, and connecting dots placed on the basis of gauge calculations.

Having a small supply of self-stick velcro tape to put on each of your machines, allows for the cable and magnet to be moved as required.

A second knitlink arm appears to be required for the use of the lace carriage. I would guess it might be attached to a second knit carriage as well if one is choosing to knit with 2 knit carriages selecting needles. DAK cable manuals published by Softbyte. Full Dak software manuals are not available until the program is purchased. There are 5 program modules. Some of the user experiences, answers to questions, and related knits may be found in the FB-associated group.

DAK cable manuals published by Softbyte. Full Dak software manuals are not available until the program is purchased. There are 5 program modules. Some of the user experiences, answers to questions, and related knits may be found in the FB-associated group.

eKnitter https://eknitter.com/, https://www.facebook.com/groups/eknitter, is an available wi-fi option that uses Ayab software and is still in varying degrees of development. On any model for which it is available, beware that it does not bypass the machine’s built-in memory; it completely replaces it, eliminating the original memory and stored patterns.

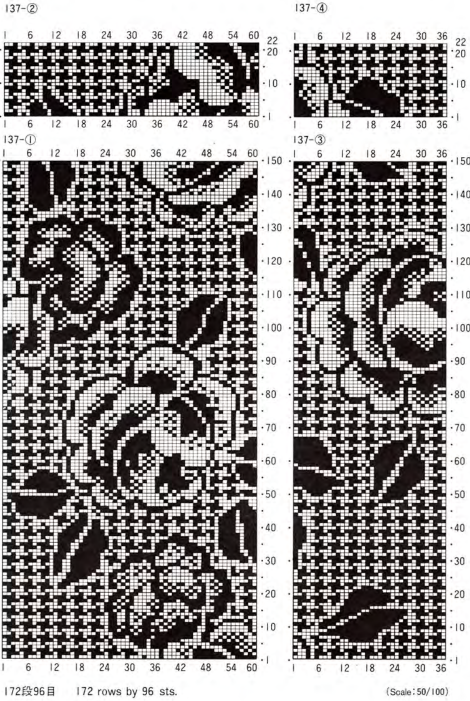

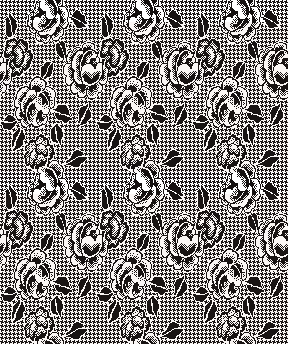

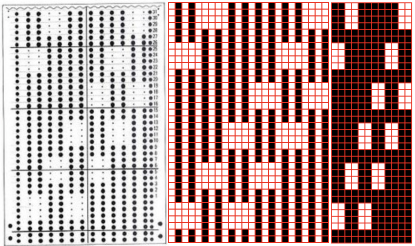

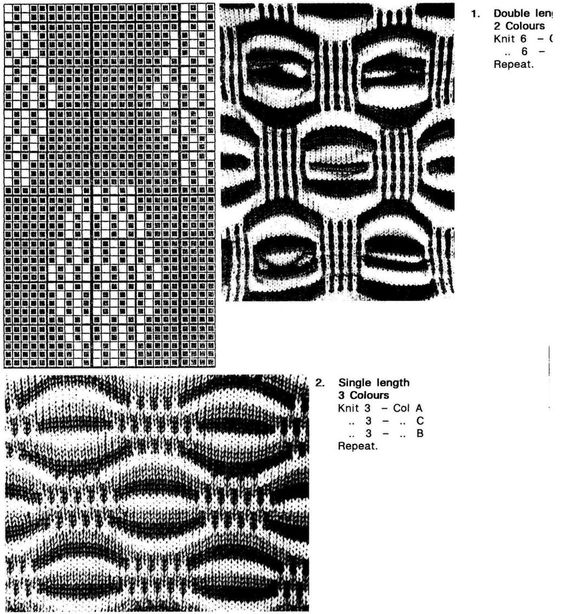

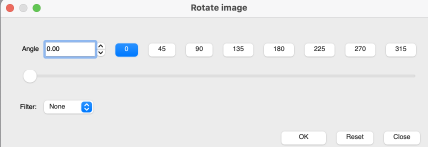

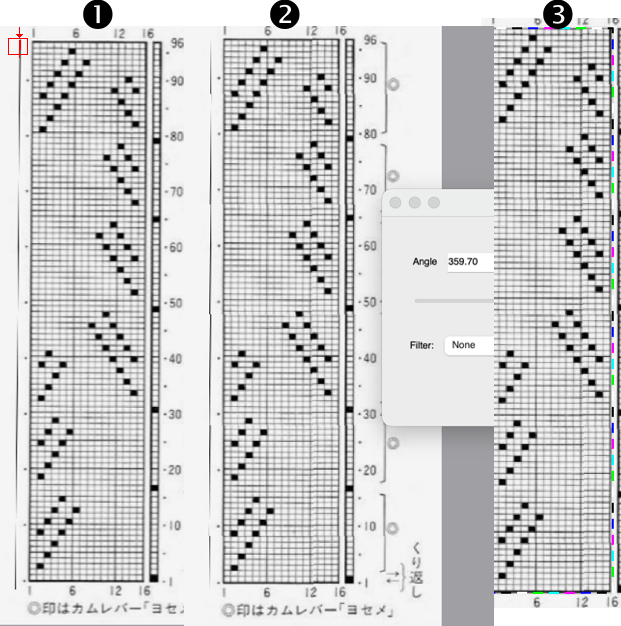

Conversion to the full 96X172 file.

Conversion to the full 96X172 file. Visualizing the potential large piece knit, it was not an instant favorite.

Visualizing the potential large piece knit, it was not an instant favorite.  Working towards a DIY design and examining varied methods and steps:

Working towards a DIY design and examining varied methods and steps: a small “rose” from a punchcard repeat, 24X24

a small “rose” from a punchcard repeat, 24X24![]() the first approach uses color to alpha to place the design on a pattern-filled ground, the file is adjusted to 30X30 to allow for outlining the rose in a third color

the first approach uses color to alpha to place the design on a pattern-filled ground, the file is adjusted to 30X30 to allow for outlining the rose in a third color ![]() the result, in turn, is centered on a 44X44 new image.

the result, in turn, is centered on a 44X44 new image.![]() in a new window, fill a new picture, 44X44, with pattern

in a new window, fill a new picture, 44X44, with pattern ![]() copy and paste the flower, anchoring it in place after rendering the cyan transparent

copy and paste the flower, anchoring it in place after rendering the cyan transparent ![]() and change the magenta outline to white,

and change the magenta outline to white, ![]() tile to 132X132

tile to 132X132 playing with the movement of the shapes to change the overall placement, the brick repeat immediately shows patterning problems, and the shapes appear small

playing with the movement of the shapes to change the overall placement, the brick repeat immediately shows patterning problems, and the shapes appear small  the 30-pixel file is doubled in size to 60X60,

the 30-pixel file is doubled in size to 60X60,  check that the number of colors is set to 3, fill the white background with pattern

check that the number of colors is set to 3, fill the white background with pattern  magenta pixels to white

magenta pixels to white

the intersection problem in a standard brick repeat reoccurs

the intersection problem in a standard brick repeat reoccurs  if the white outline is considered too thick, reduce it to one pixel from 2.

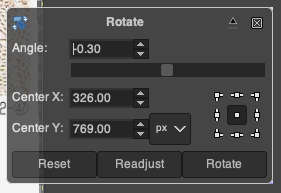

if the white outline is considered too thick, reduce it to one pixel from 2. Changing the approach: the above is drawn in repeat on a white ground. Rotating any individual elements becomes possible with no disruption in the yet-to-be brush-filled design.

Changing the approach: the above is drawn in repeat on a white ground. Rotating any individual elements becomes possible with no disruption in the yet-to-be brush-filled design.

Filling in the white ground with the pattern results in no tiling errors

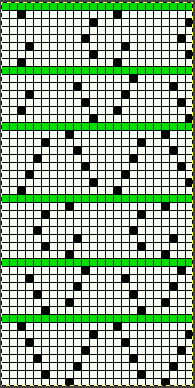

Filling in the white ground with the pattern results in no tiling errors  eliminating the third color, BW brick, it is not possible to isolate a smaller repeat

eliminating the third color, BW brick, it is not possible to isolate a smaller repeat  keeping directions constant in alternate rows of the pattern

keeping directions constant in alternate rows of the pattern  makes isolating the smallest repeat possible, 60X120.

makes isolating the smallest repeat possible, 60X120.

Back to the inspiration florals, isolating one of the roses, 61X59, note that the shape is not symmetrical

Back to the inspiration florals, isolating one of the roses, 61X59, note that the shape is not symmetrical  with a single-pixel third color outline, on a white ground, 64X64

with a single-pixel third color outline, on a white ground, 64X64 tiled in a simple brick repeat to 128X192 on a white ground

tiled in a simple brick repeat to 128X192 on a white ground  with the background pattern-filled

with the background pattern-filled 64X128 isolated smallest repeat

64X128 isolated smallest repeat

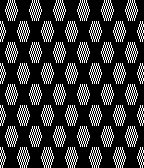

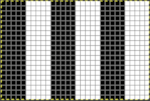

tiled in BW with colored outline removed

tiled in BW with colored outline removed  testing random placements

testing random placements

produce a design with the smallest programmable repeat

produce a design with the smallest programmable repeat  note that the horizontal distance between the flower shapes is not fixed

note that the horizontal distance between the flower shapes is not fixed

scaled to 58X58

scaled to 58X58 planning added borders 64X64

planning added borders 64X64  outlined

outlined  a full single repeat 192X256 using the same random arrangement

a full single repeat 192X256 using the same random arrangement

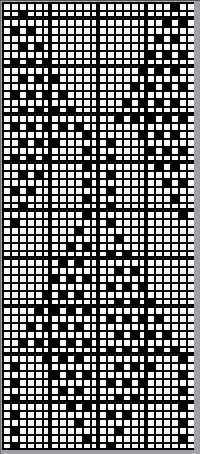

building the smallest straightforward single brick repeat if there are limitations on the size of the programmed image ie to avoid multiple tracks in machines such as the 930 using img2track

building the smallest straightforward single brick repeat if there are limitations on the size of the programmed image ie to avoid multiple tracks in machines such as the 930 using img2track

the slightly scaled design reduced to an 80X80 repeat to play with in any configuration of your choice.

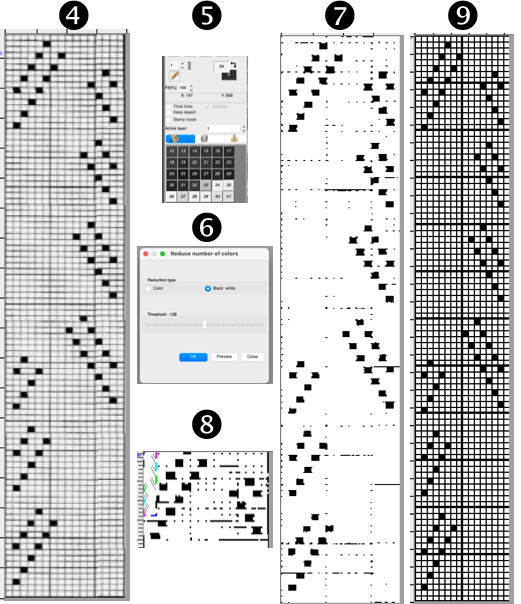

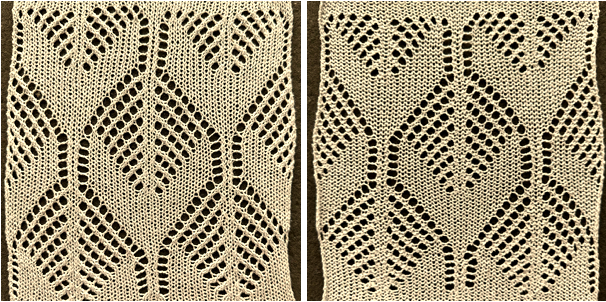

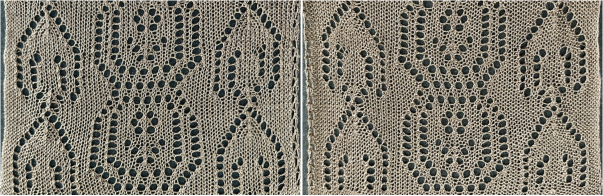

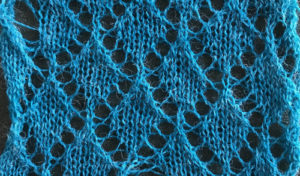

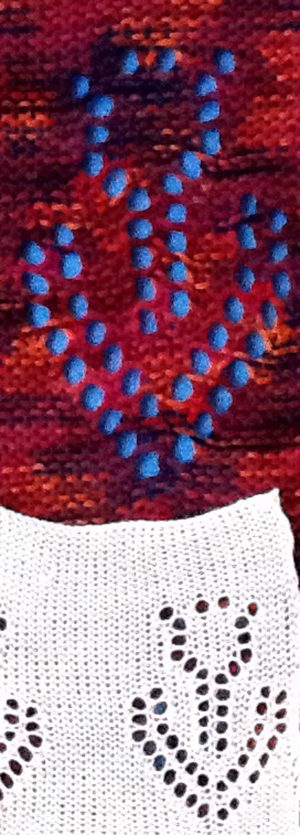

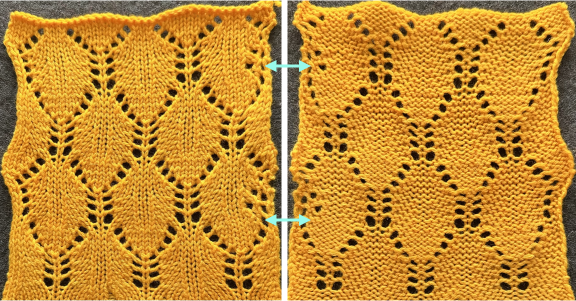

the slightly scaled design reduced to an 80X80 repeat to play with in any configuration of your choice.  The test swatch for the full single repeat

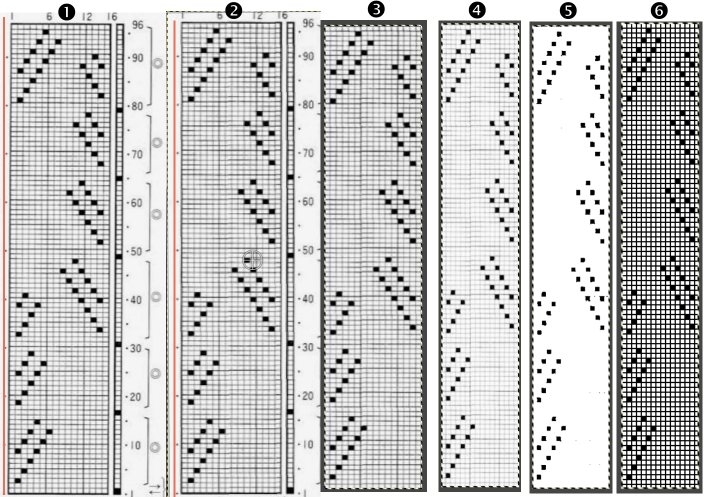

The test swatch for the full single repeat Continuing on a floral theme, inspired by a filet crochet design, 30X90

Continuing on a floral theme, inspired by a filet crochet design, 30X90 ![]() its half drop version, 60X90

its half drop version, 60X90 drawing both in repeat to 180X180 helps to determine whether further editing is needed, and if the shift in vertical/horizontal vs diagonal striping is preferred

drawing both in repeat to 180X180 helps to determine whether further editing is needed, and if the shift in vertical/horizontal vs diagonal striping is preferred

the 60X74 png

the 60X74 png

From the

From the

For Superba machines, there are the

For Superba machines, there are the

Aside from connections to the machine, there was the issue of available software for drawing repeats and downloading in the proper format.

Aside from connections to the machine, there was the issue of available software for drawing repeats and downloading in the proper format. and for solving the same issue in

and for solving the same issue in

The Softbyte

The Softbyte

DAK cable manuals published by Softbyte

DAK cable manuals published by Softbyte

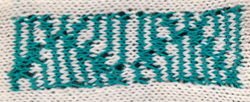

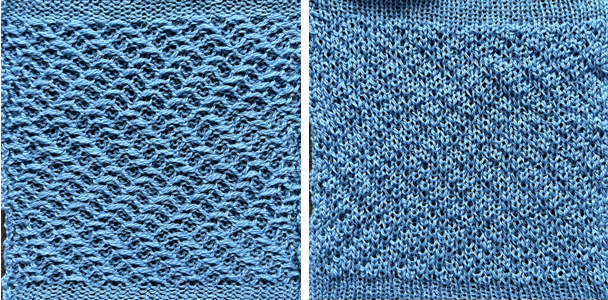

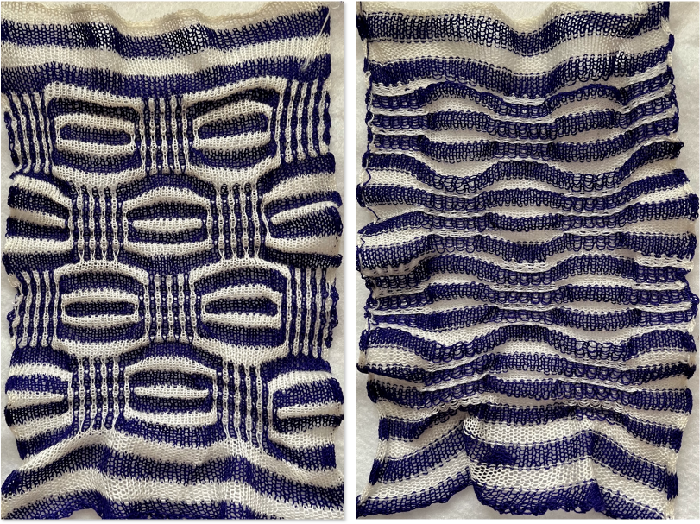

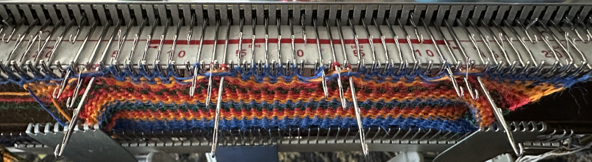

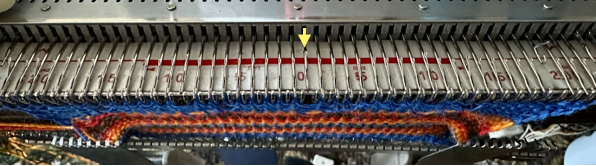

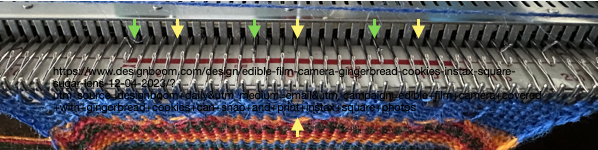

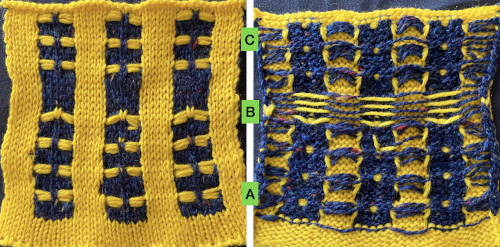

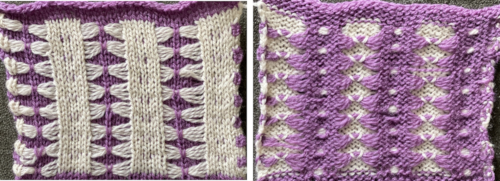

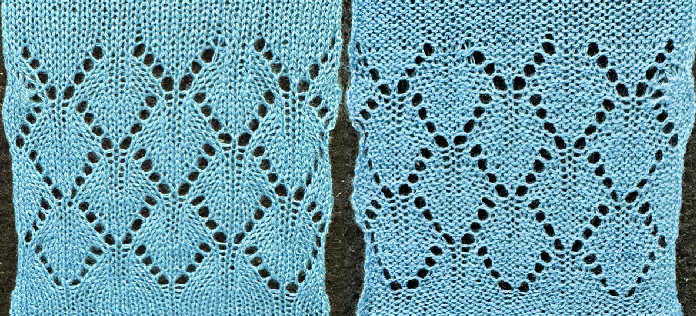

As stated, the process is easier and quicker working on non-selected groups. Above, the yellow yarn was thicker than the blue. To maintain proper color selection in the non-selected column, the center needle needs to remain in the B position, with the slipped stitch forming floats below it before the next row knits. If the needle is brought out to E, it will knit in the contrast color, forming floats in that color on the purl side, and a knit stitch in what was planned as an all-solid column on the knit. The results are seen at the top of the first sequence in the swatch. I chose to limit my number of floats to 4 to keep the process manageable, moved stitches on the left of the center needle to the front of the knit, and then followed with those to its right. One of the many things to explore in hand technique fabrics is finding a way to handle tools that may be more comfortable than others, practicing on single blocks of color first can help establish that. Below both yarns are equal in weight and thinner. The floats formed by the color in the B feeder are also hooked up on the center needle in each vertical group in that color, forming a pattern on the purl side as well.

As stated, the process is easier and quicker working on non-selected groups. Above, the yellow yarn was thicker than the blue. To maintain proper color selection in the non-selected column, the center needle needs to remain in the B position, with the slipped stitch forming floats below it before the next row knits. If the needle is brought out to E, it will knit in the contrast color, forming floats in that color on the purl side, and a knit stitch in what was planned as an all-solid column on the knit. The results are seen at the top of the first sequence in the swatch. I chose to limit my number of floats to 4 to keep the process manageable, moved stitches on the left of the center needle to the front of the knit, and then followed with those to its right. One of the many things to explore in hand technique fabrics is finding a way to handle tools that may be more comfortable than others, practicing on single blocks of color first can help establish that. Below both yarns are equal in weight and thinner. The floats formed by the color in the B feeder are also hooked up on the center needle in each vertical group in that color, forming a pattern on the purl side as well.  The needle position for selection for B feeder yarn also needs to be maintained. Bringing the needle out to E ensures it will knit on the next pass. In both of my tests, the slip stitch floats on the knit side lie more horizontally than the lifted-up floats on the purl.

The needle position for selection for B feeder yarn also needs to be maintained. Bringing the needle out to E ensures it will knit on the next pass. In both of my tests, the slip stitch floats on the knit side lie more horizontally than the lifted-up floats on the purl.

The transfers in the piece begin on row 5. Before the next row is knit in the alternate color, the slip stitch floats are reconfigured, bringing stitches 1 and 2, 4 and 5 in each group to the knit side of the fabric, leaving the center floats undisturbed.

The transfers in the piece begin on row 5. Before the next row is knit in the alternate color, the slip stitch floats are reconfigured, bringing stitches 1 and 2, 4 and 5 in each group to the knit side of the fabric, leaving the center floats undisturbed.  Bring the whole group out to the E position so they will form knit stitches with the first row of contrast as the carriage moves to the right.

Bring the whole group out to the E position so they will form knit stitches with the first row of contrast as the carriage moves to the right.

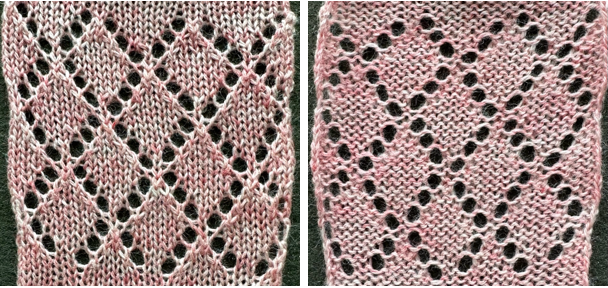

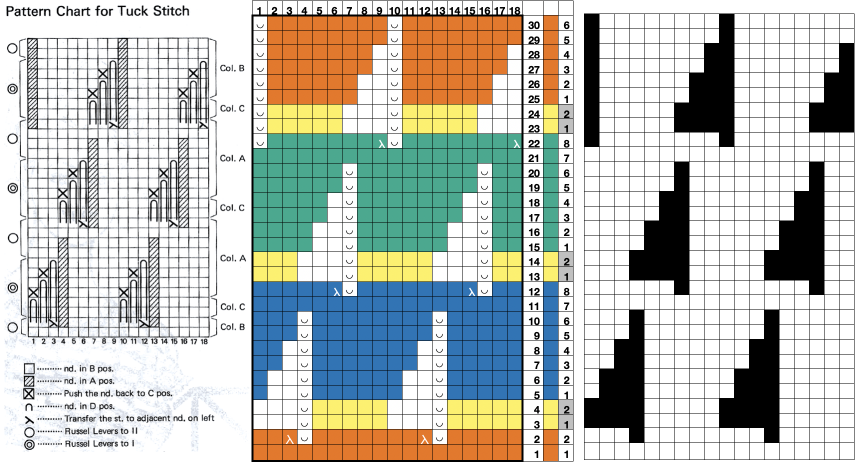

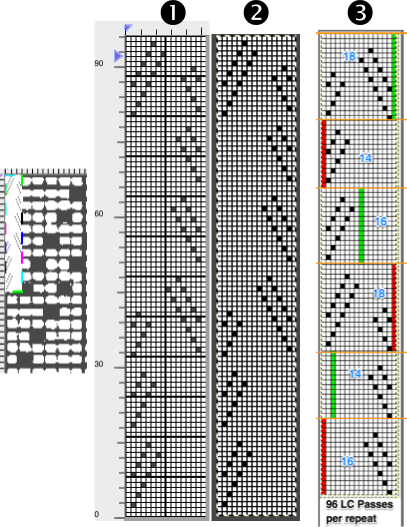

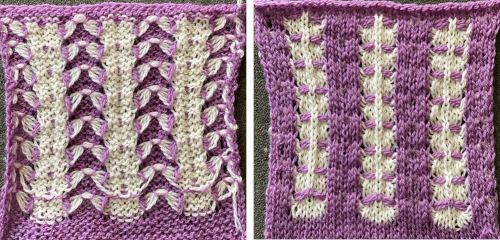

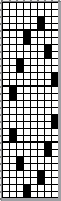

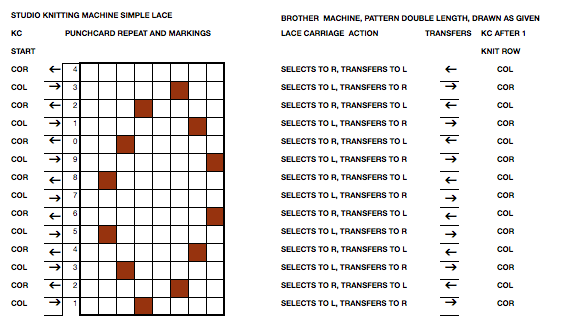

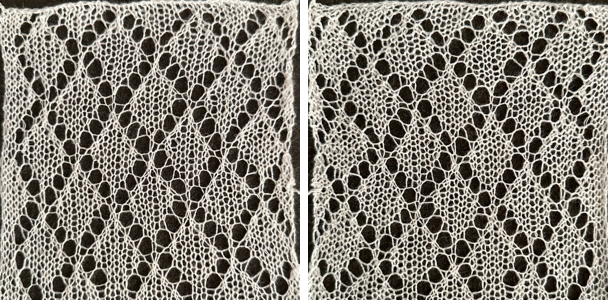

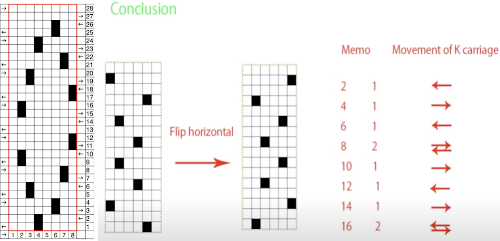

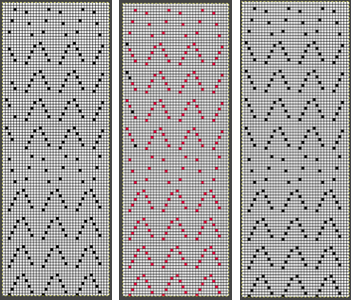

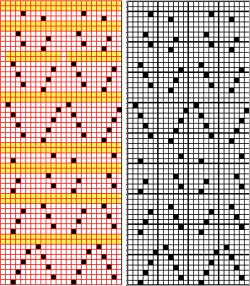

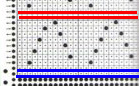

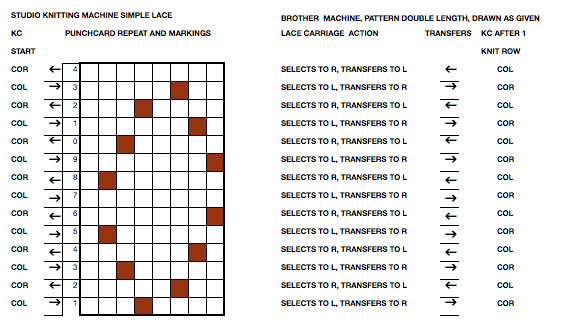

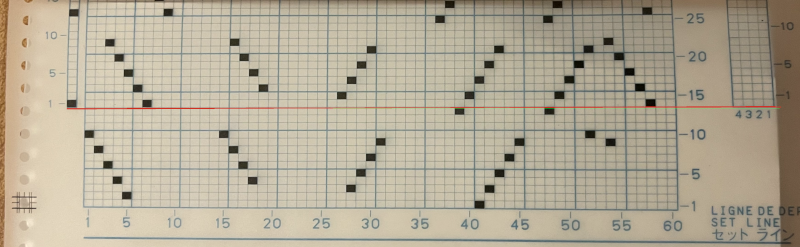

A comparison of my repeat using a single LC and the Knitlabo pattern expansion including memo options for use with 2 lace carriages

A comparison of my repeat using a single LC and the Knitlabo pattern expansion including memo options for use with 2 lace carriages

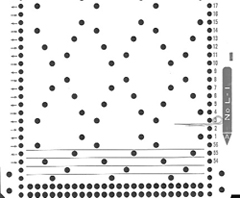

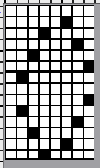

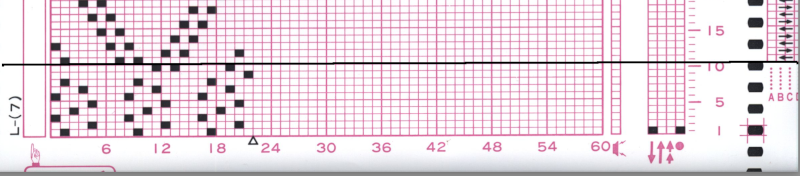

I had tested template markers on Brother mylars when ink pens were discontinued and I had no luck with permanent markers, found they shed a bit and pencils tips broke easily, while I could not be as neat in rendering small markings as simply by going the route of using a number 2 pencil on the mylar’s back ( I prefer the Mirado Warrior HB 2). Drawing with enough density “within the lines” on mylars is rendered far easier with one of these templates, at one point made available from Brother. Similar ones may sometimes be found in stationary or art/ drafting supply stores.

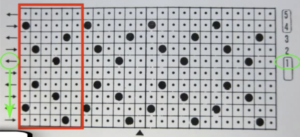

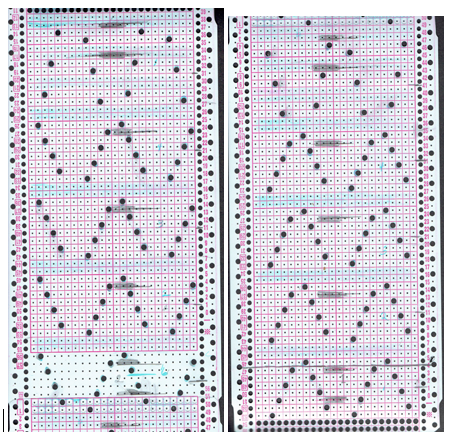

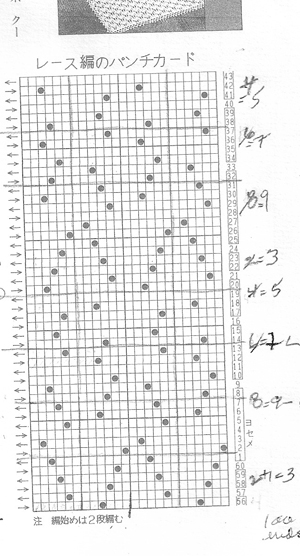

I had tested template markers on Brother mylars when ink pens were discontinued and I had no luck with permanent markers, found they shed a bit and pencils tips broke easily, while I could not be as neat in rendering small markings as simply by going the route of using a number 2 pencil on the mylar’s back ( I prefer the Mirado Warrior HB 2). Drawing with enough density “within the lines” on mylars is rendered far easier with one of these templates, at one point made available from Brother. Similar ones may sometimes be found in stationary or art/ drafting supply stores.  The images below show my first “new” tests: on the left, I drew with the template marker over previous pencil markings, the squares repeat over # 36 was made with multiple layers of a sharpie (which smeared even after what would seem like adequate drying time), the ones over #42 are made with the template marker. The sharpie did not get scanned properly by the reader, all other marks did. There is a guiding pencil line placed where the set line familiar to Brother users would be. In the first narrow column to the right, the pencil marking corresponds to the first visible row (design row 1 in reader). The column on the far right (absent from Brother) could be used for additional cues in knitting ie. color changes, knit rows between lace transfers, etc.

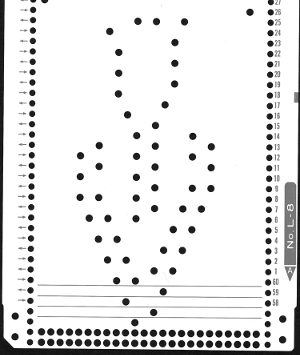

The images below show my first “new” tests: on the left, I drew with the template marker over previous pencil markings, the squares repeat over # 36 was made with multiple layers of a sharpie (which smeared even after what would seem like adequate drying time), the ones over #42 are made with the template marker. The sharpie did not get scanned properly by the reader, all other marks did. There is a guiding pencil line placed where the set line familiar to Brother users would be. In the first narrow column to the right, the pencil marking corresponds to the first visible row (design row 1 in reader). The column on the far right (absent from Brother) could be used for additional cues in knitting ie. color changes, knit rows between lace transfers, etc.

while Studio scans 10 rows below

while Studio scans 10 rows below  This explains why the columns intended for memos extend up and beyond the last row which can have cells marked for pattern in each brand.

This explains why the columns intended for memos extend up and beyond the last row which can have cells marked for pattern in each brand.