This is a work in progress post. I have now edited and included its previous version so the most recent observations appear first, the oldest last.

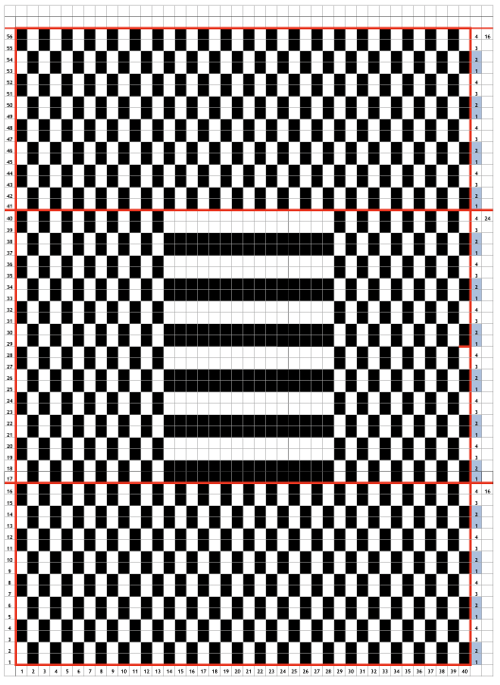

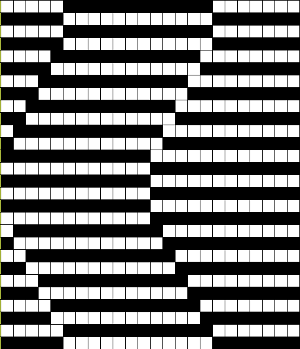

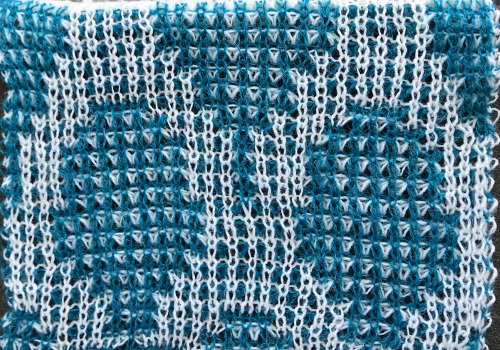

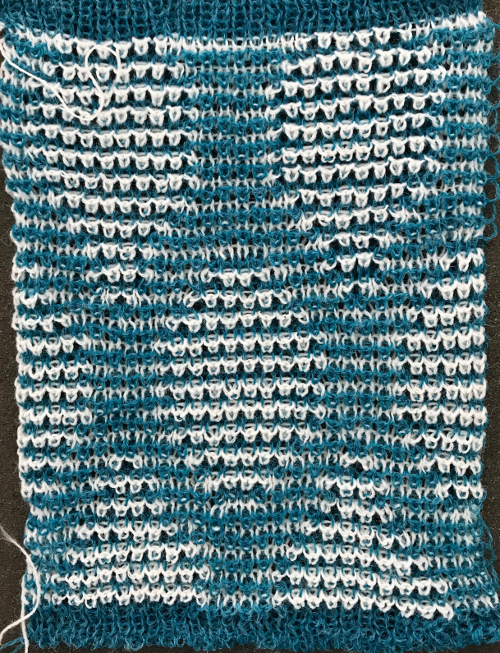

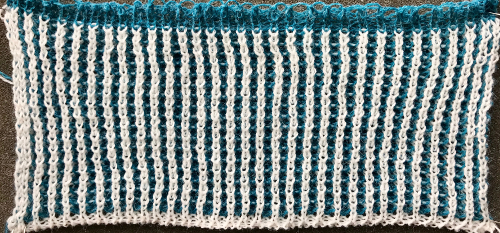

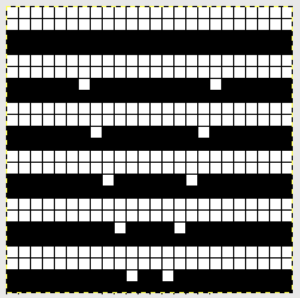

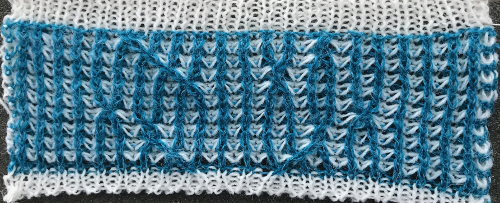

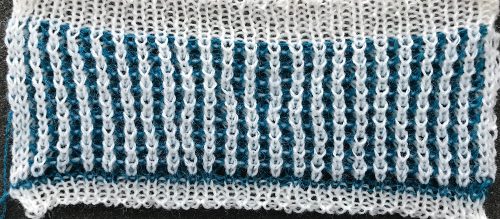

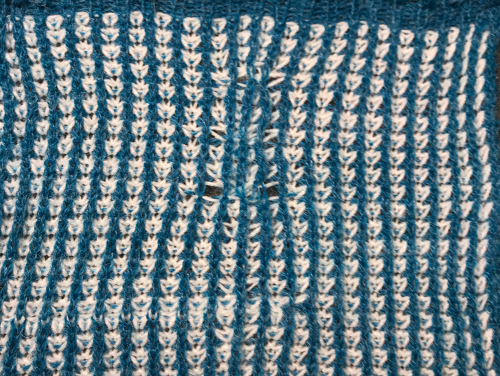

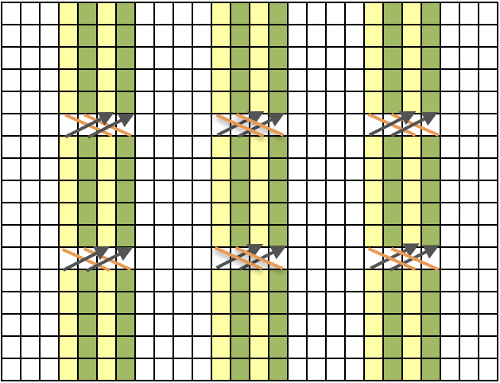

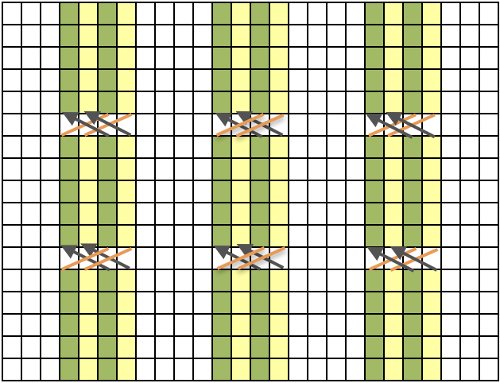

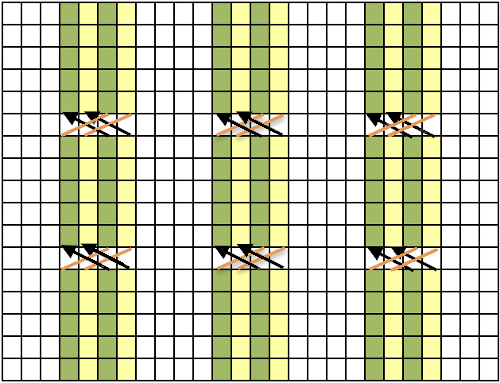

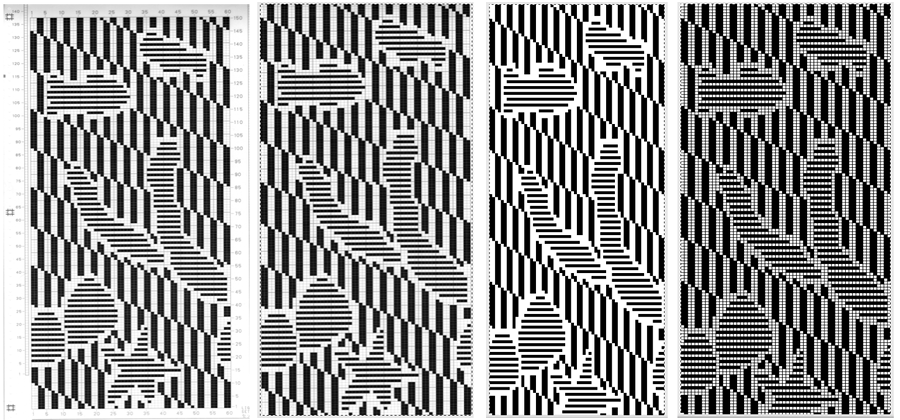

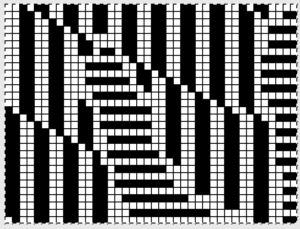

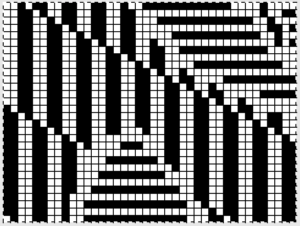

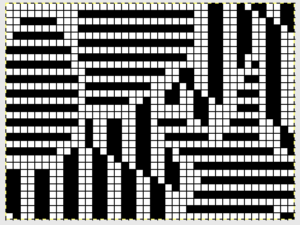

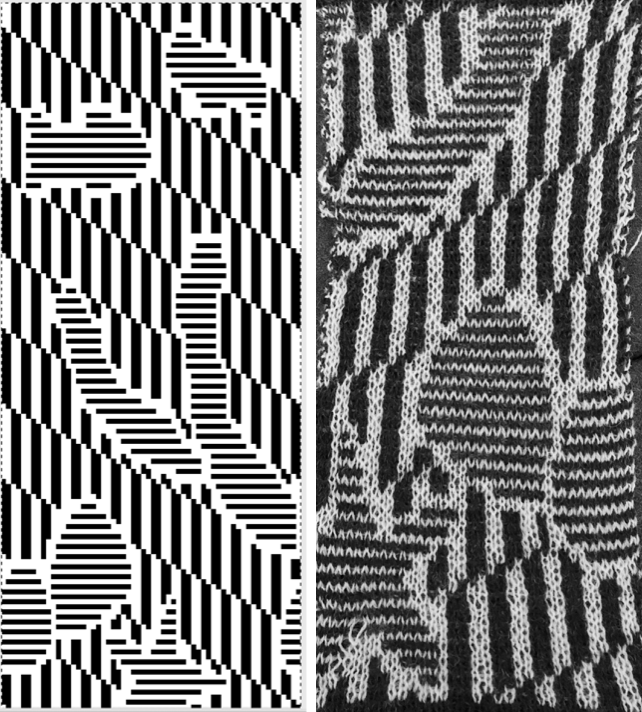

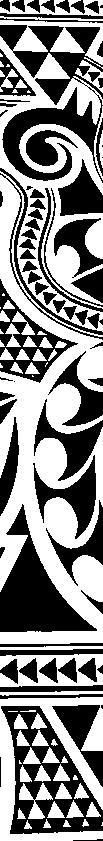

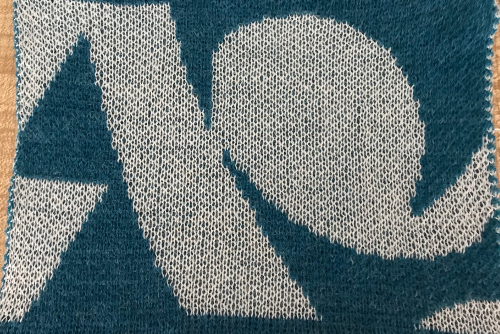

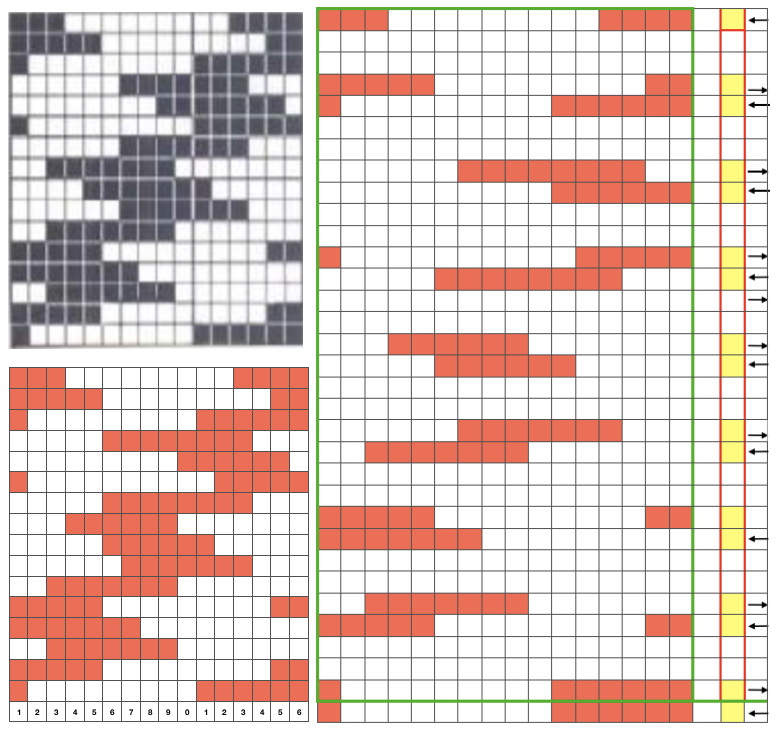

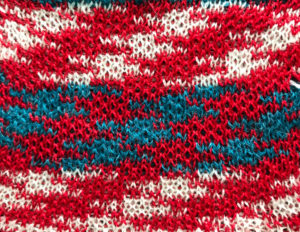

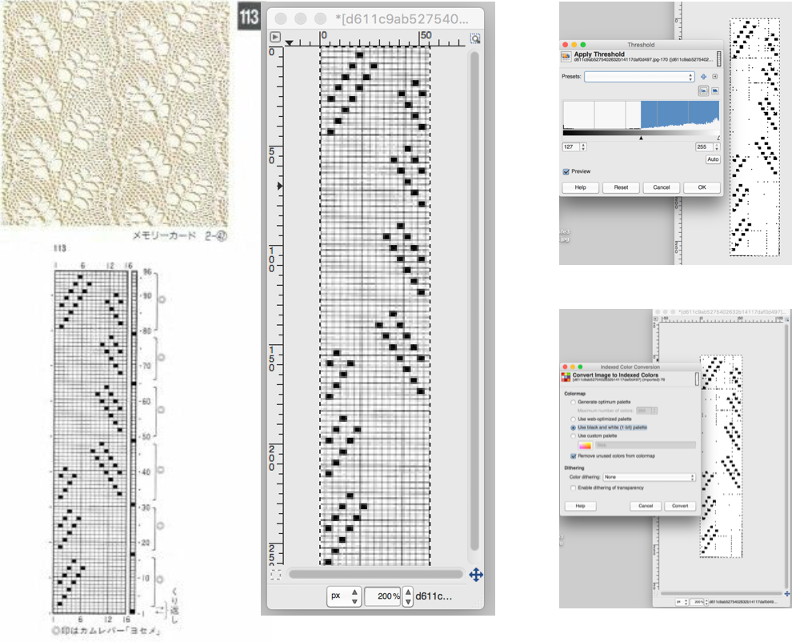

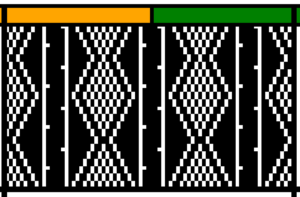

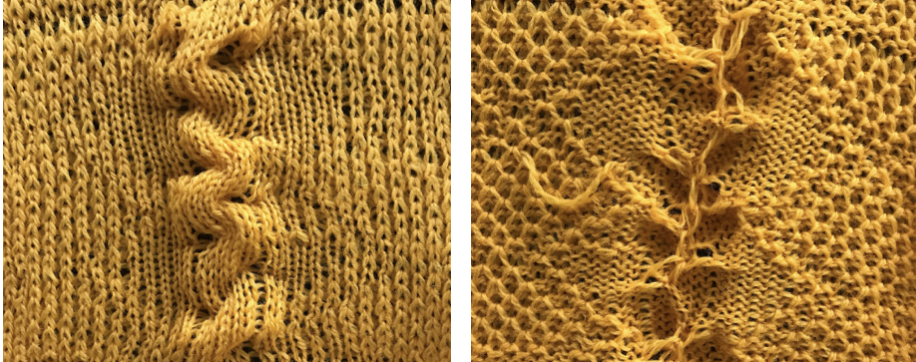

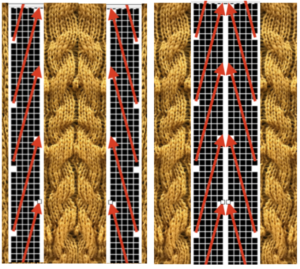

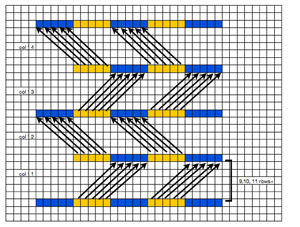

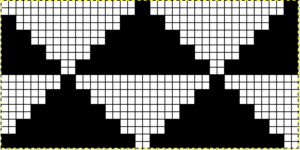

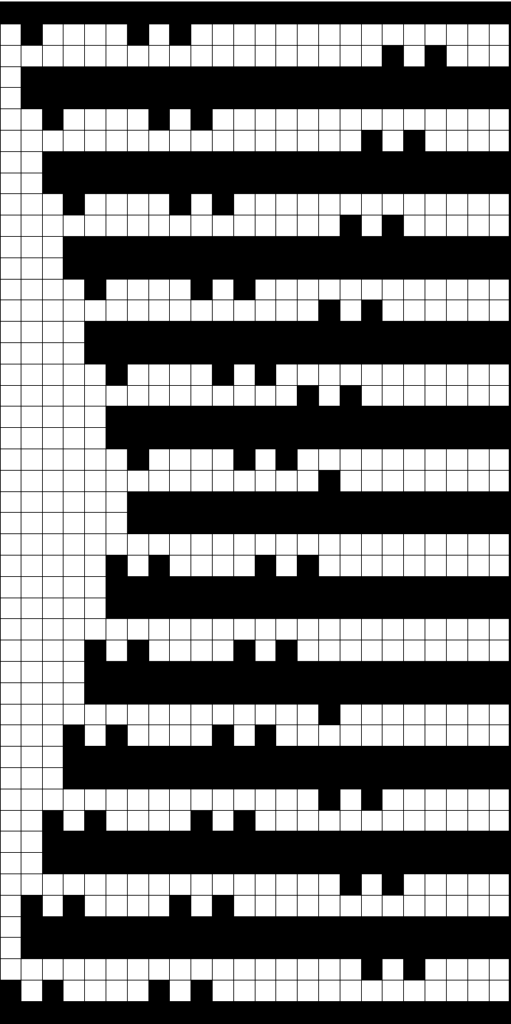

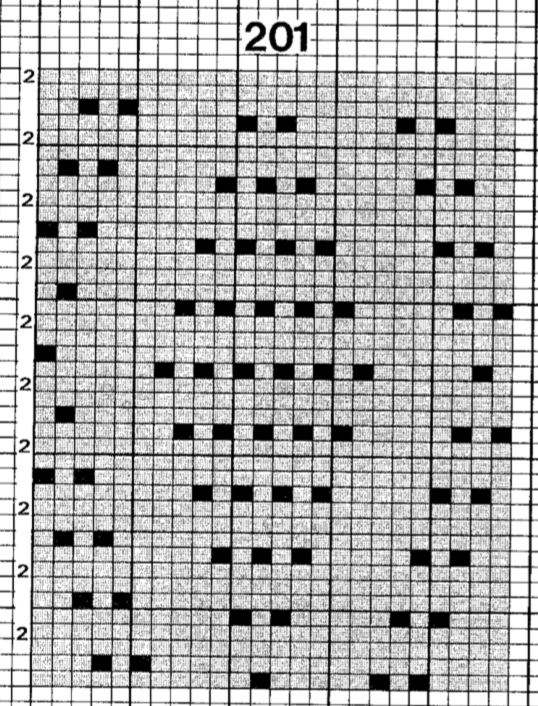

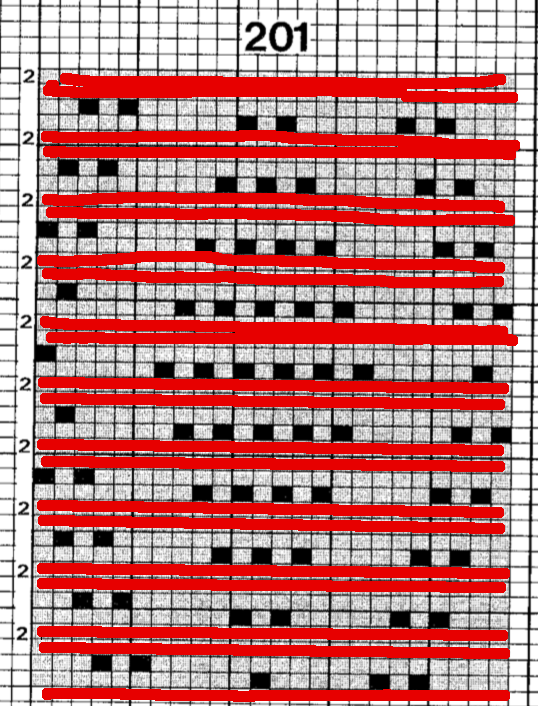

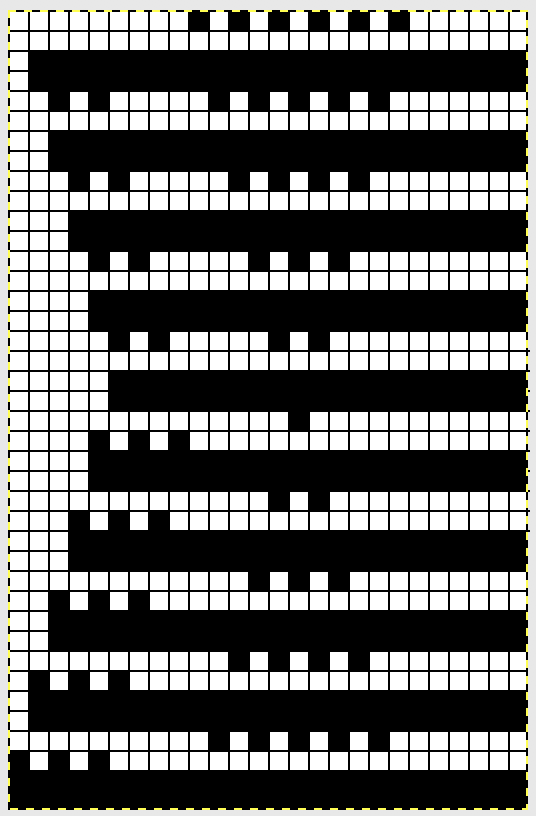

9/8/18 I have received a replacement unit from EMS. I got this far testing a large scale pattern, no fault of the program at my stopping point. I did not notice until I got across the last pattern row that I had actually knit with both strands of yarn. Rather than try to fix the issue, I decided to scrap off. This gave me a chance to test new yarns. I had never used chenille in DBJ on Passap, it sheds too much, resulting in error messages. I like to have my scarves at least 60 inches in length, and this combo looks as though it would reach that length when completed. I also did a bit more editing of the repeat as shown here. We shall see if the equipment and I both last to a whole 1200 rows or so in one sitting anytime soon 😉

6/25/18 the kit apparently has now gone from out of stock to officially no longer in production

5/28/18 replacement kit never received, it’s back to mylars for me to actually try to get any significant knitting done

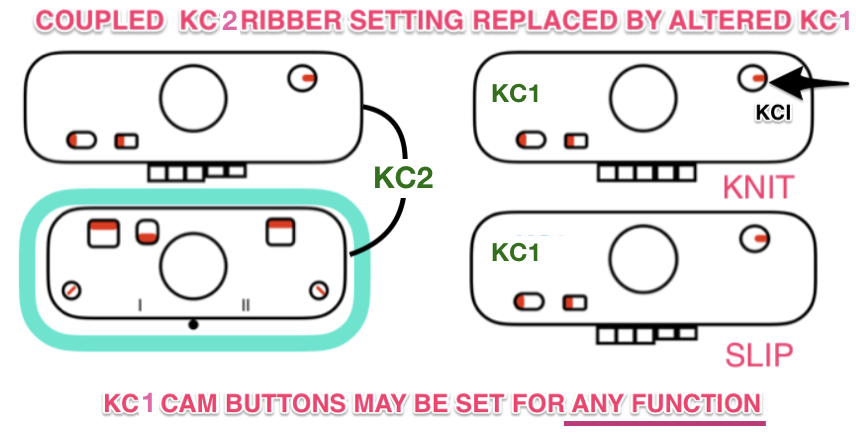

4/27/18 I have been able to develop some fabrics using two knit carriages selecting needles from opposite sides, though the lace carriage will not select from the right if the knit carriage is also selecting from the left. The posts include altering a knit carriage to use as the second one to select needles as an alternative to changing ribber settings between normal and pattern knitting, and addition to posting on combining KC patterning with racking

I had been told my kit would be replaced due to persistent patterning error issues. Sales are presently on hold while the hardware is reviewed, and work is being done on a new version of the software, so any changes in status are to be determined.

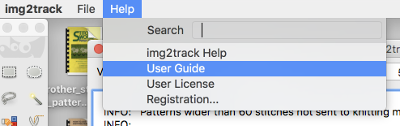

3/ 31/ 18 At present there is no English text manual for using the software or a quick start guide. I am sharing some of the differences and similarities in actions I have noted between the unaltered 910 and those of the hack, beginning with settings, and including a few tidbits gleaned from support as I encountered patterning problems. They may be of interest to those making the transition after previous knitting experience and familiarity with the machine, or to anyone curious about the program and some of its features and differences.

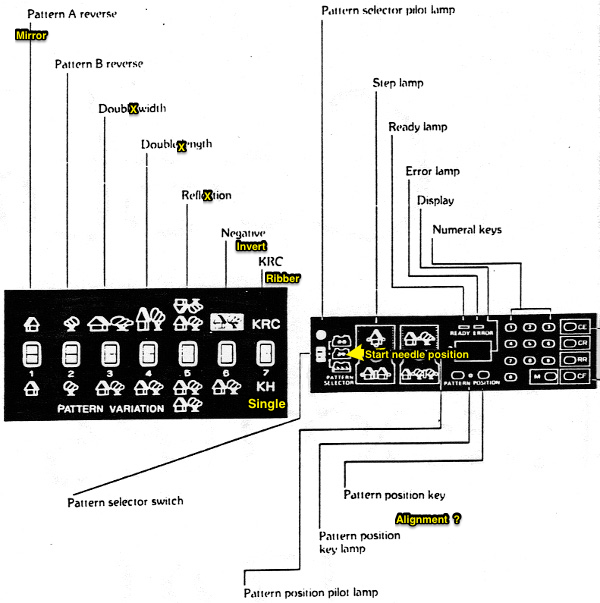

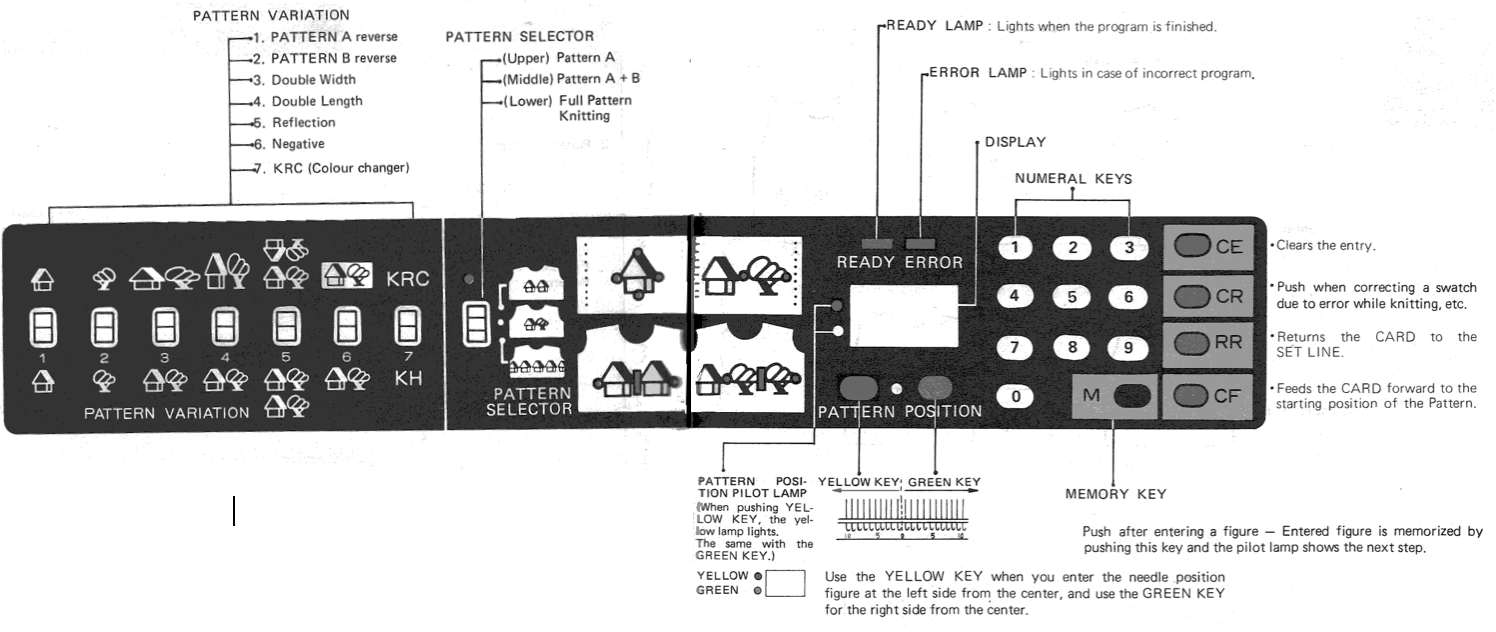

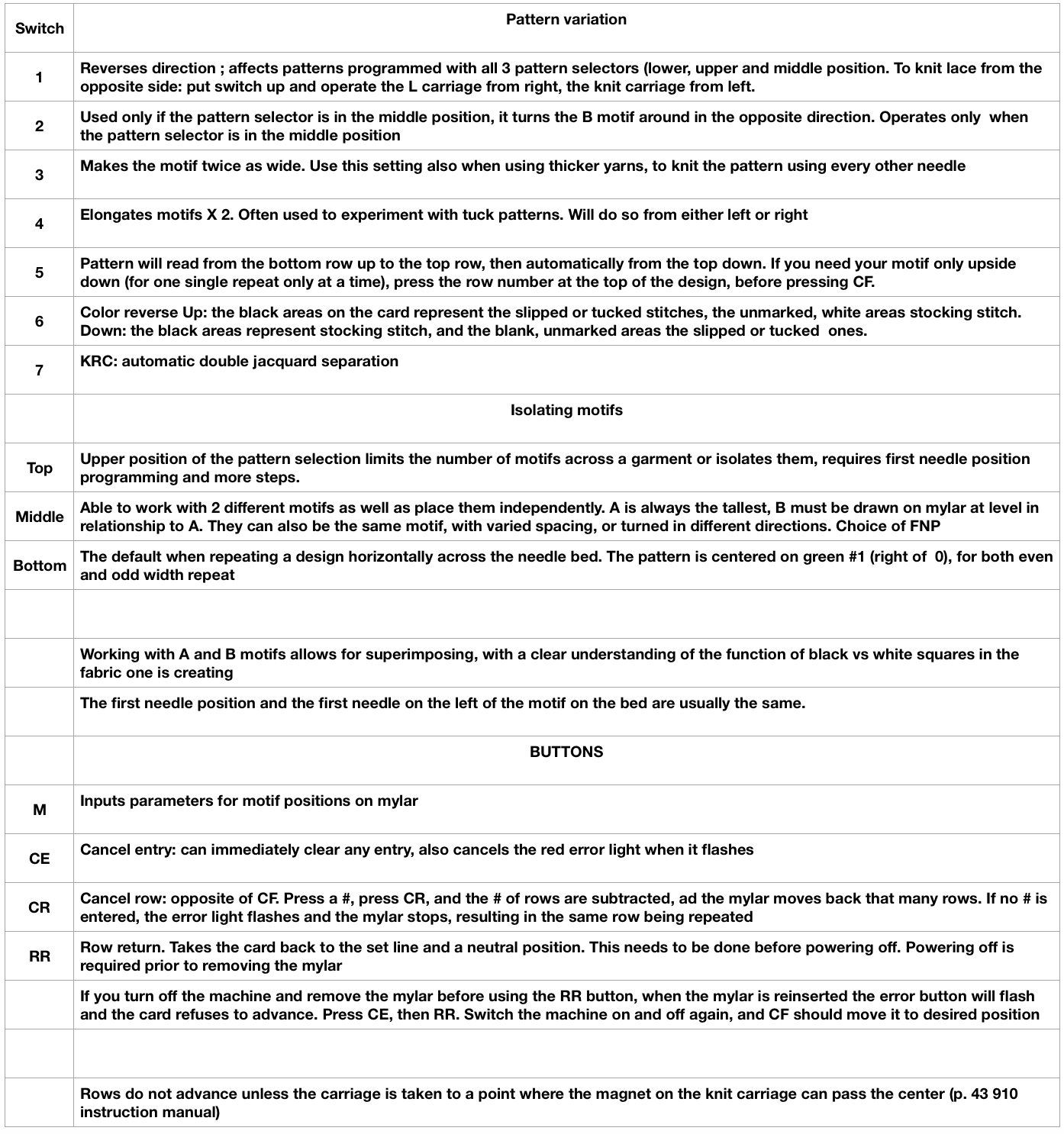

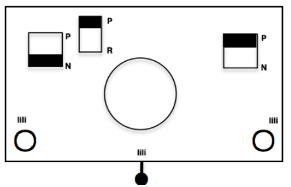

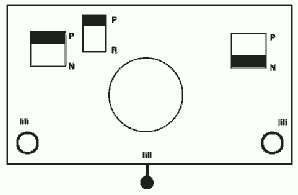

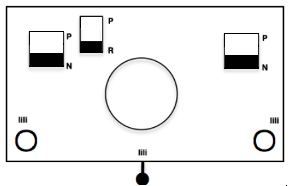

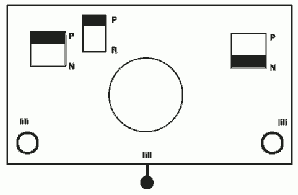

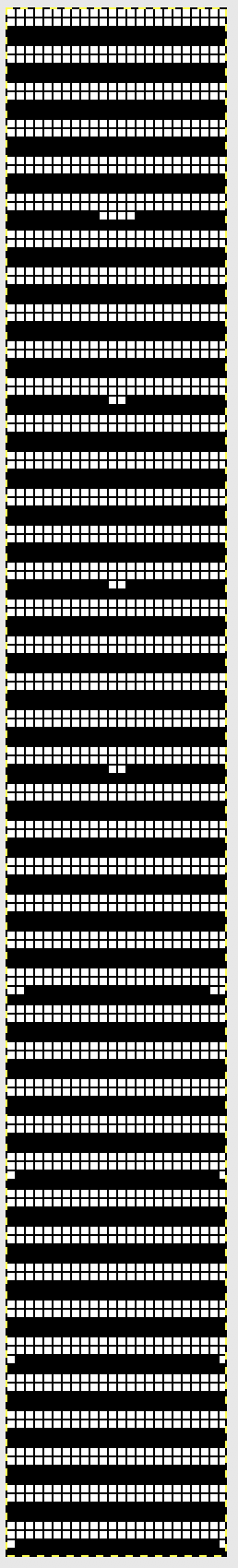

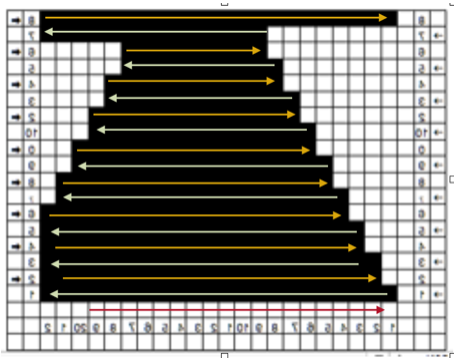

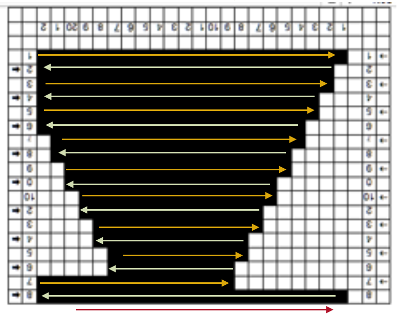

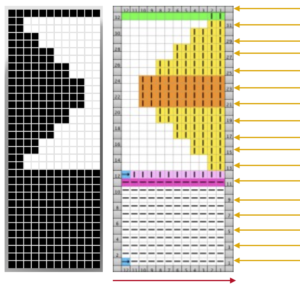

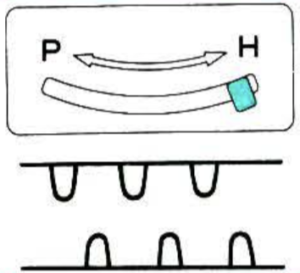

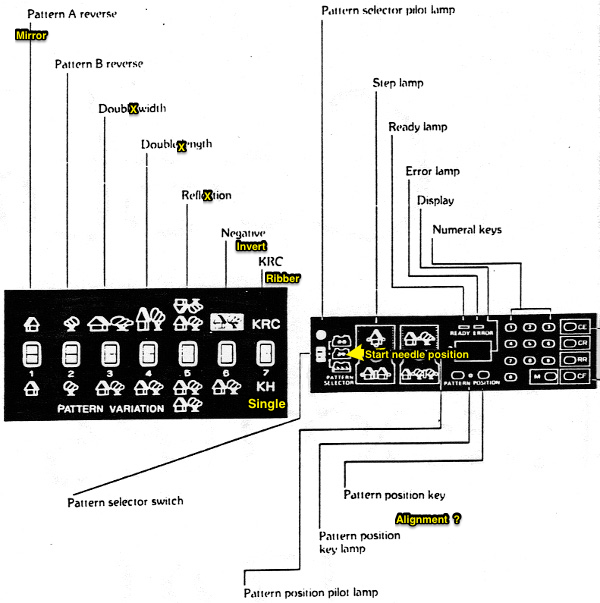

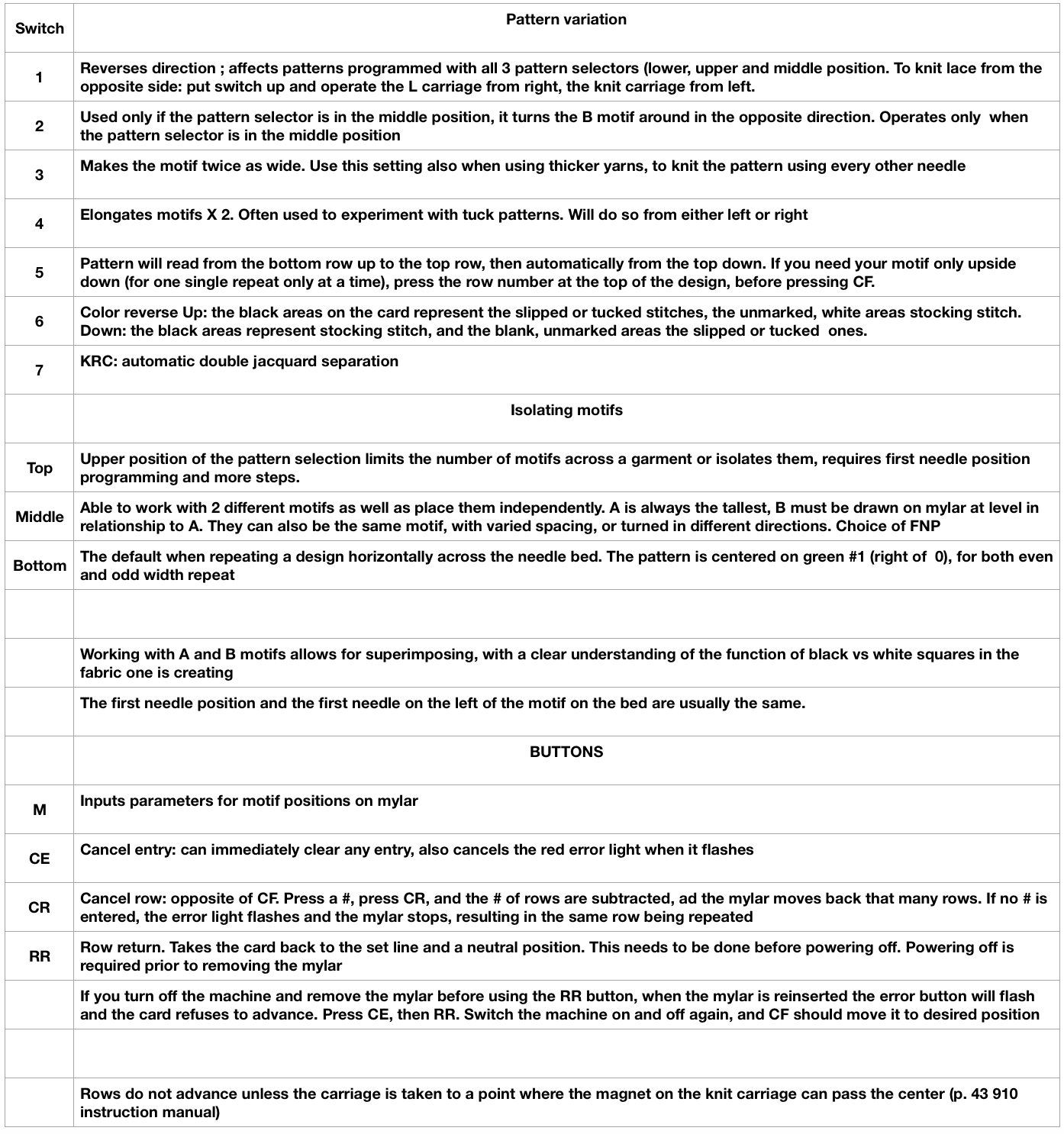

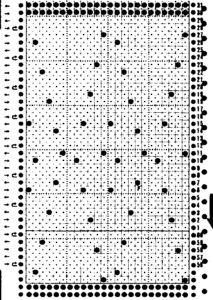

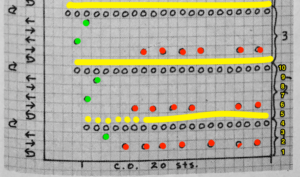

Yellow text in this first image from a publication on the 910 indicates matching functions I have identified so far in ayab software.

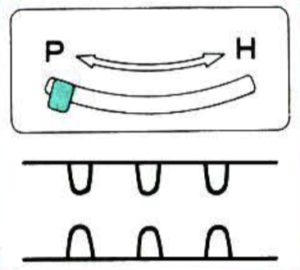

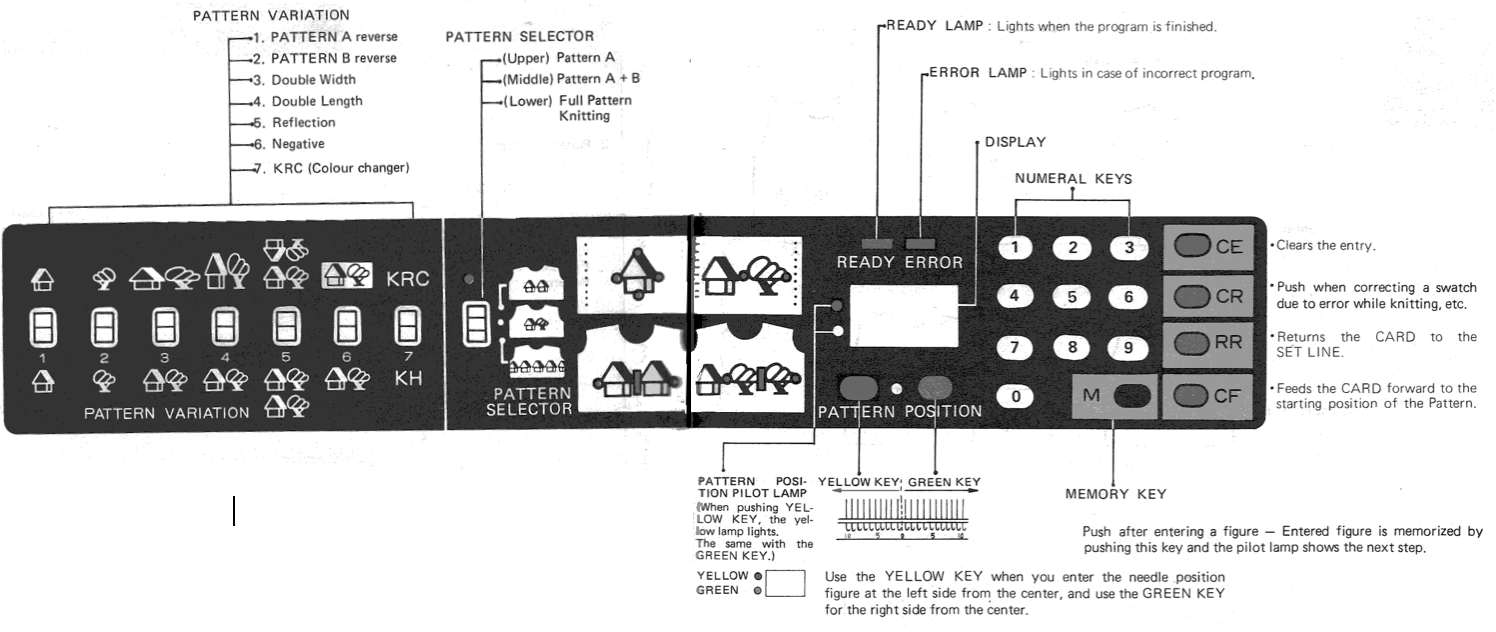

the full illustration from the 910 manual actions on the unaltered 910

actions on the unaltered 910

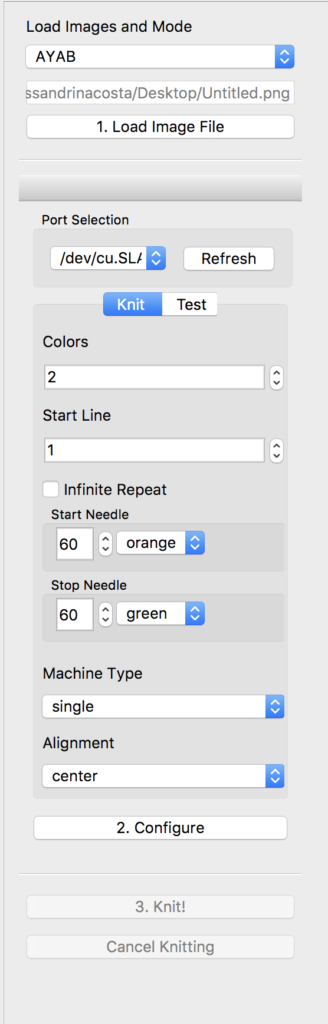

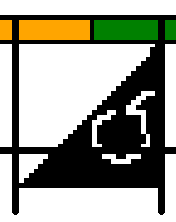

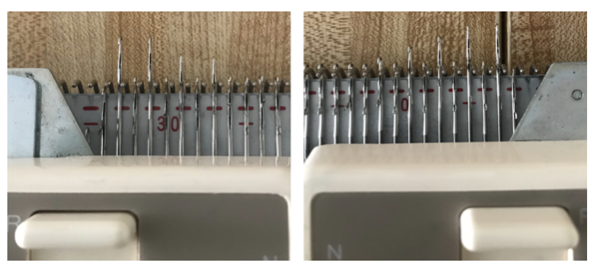

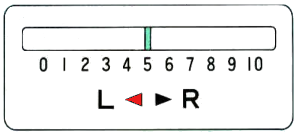

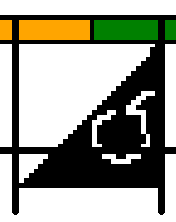

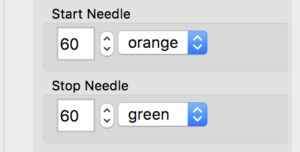

When the pattern selector is down, the pattern is centered on green #1 (right of 0). This means if the pattern is an even number, say 24 stitches, then the pattern limits are green 12 and yellow 12. If the pattern is an odd number of stitches the pattern limits are yellow 12 and green 13, the center being green #1. With an odd number of needles, Ayab places the larger number of needles on the left, its orange (yellow) side.

When the pattern selector is down, the pattern is centered on green #1 (right of 0). This means if the pattern is an even number, say 24 stitches, then the pattern limits are green 12 and yellow 12. If the pattern is an odd number of stitches the pattern limits are yellow 12 and green 13, the center being green #1. With an odd number of needles, Ayab places the larger number of needles on the left, its orange (yellow) side.

AYAB

I purchased my hardware kit (now off the market) from the developer : to purchase , wiki , interface , install. Online discussion groups: Ravelry , Facebook, and GitHub.

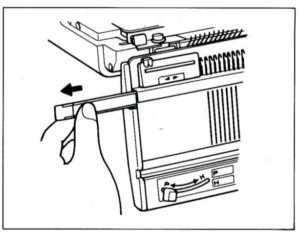

At present, there is no cover readily available for the machine once the unit is installed, so the left side of the main bed remains exposed.

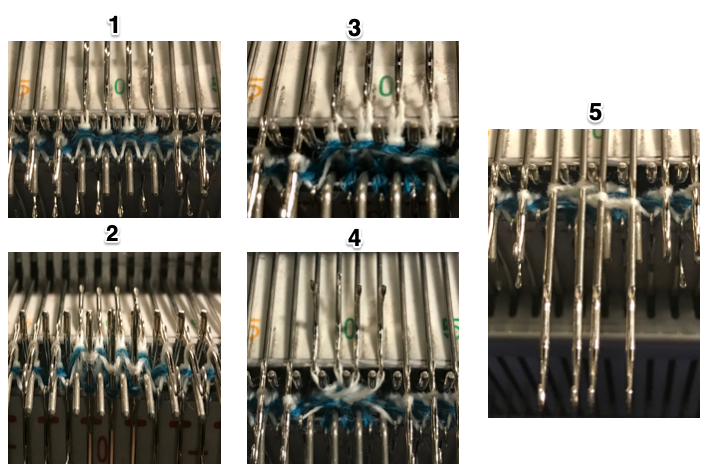

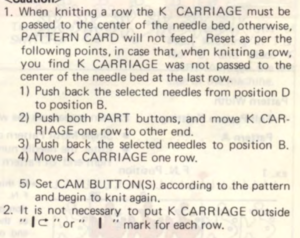

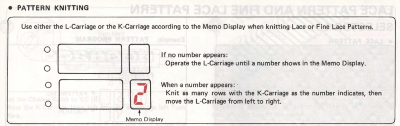

Though beeps heard upon preparing to preselect the first row from left to right are described as a triple beep, I hear them as a triple set of multiple beeps with pauses between. Not taking the time to “hear” them all will result in patterning errors from the get-go. Be sure to hear the beep and see the flashing of the unit before reversing carriage direction. Clear the left turn mark at least periodically while knitting. If you have experience with any production knitting on the unaltered machine you may feel the knitting speed is slowed when using the software and cable for downloading each row as opposed to that with which the mylar scanner accomplished the same task.

Ayab can be set for an infinite repeat in length, the function was automatic on the mylar unless one made the choice to stop at any point. A single repeat on the mylar was enough to program across the width of the needle bed, with ayab the full width of the pattern must be programmed, so designs need to be tiled accordingly.

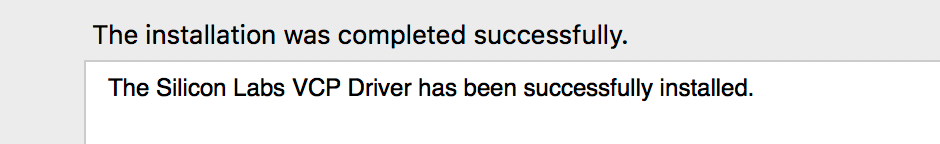

Installation of software can be achingly slow on Mac desktop (I am using High Sierra OS). SiLabsUSBDriver is also required. Security settings need to be checked/changed even if no warning is given by the computer leading one to assume there have been no issues with the download or the install. The driver will reside in the library/ extensions.

The hardware install is fairly straightforward.

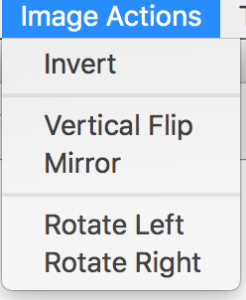

The USB connection needs to be made prior to launching the software for the port to be recognized. If port questions come up, click the “Refresh” button on the AYAB screen. When things are working correctly, you should be able to see a port name from the pop-up menu. The plug-in power supply supplies power only to the needle selection.

The popping noise or clunk is heard usually but not always when you cancel AYAB and restart and is produced by the solenoids. I have been reassured it “does no harm” by support.

The launcher box remains open throughout knitting.

To start knitting:

1. Load your pattern in the width of the planned repeat

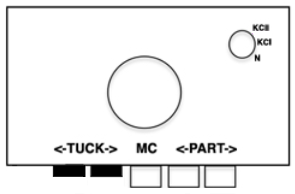

2. Set all the AYAB settings at default (2-color, start at row 1, single, center). Check infinite repeat if you want to knit more than one vertical repeat

3. Knit carriage is on the left, outside the turn mark

4. In the AYAB software, Configure/Knit

5. Wait until the software says Please Init carriage at bottom of the screen

6. Bring the carriage across the left turn mark and stop before crossing any needles, wait for the triple set of beeps.

8. Continue across the first row and stop, wait for flash and beep, then proceed with movements to and from each side, again waiting for flash and beep that indicate each row download is complete.

If knitting a repeat in single height, when you are one row ahead of the last selection the row numbers disappear as “Image Transmission is finished. Please knit until you hear the double-beep sound”. The marker on the image jumps down to the beginning. You knit across and it does the selection for the last row and gives the long beep sound. Knit one more row to actually knit that selection. When all needles are selected to B, you cancel your settings and you’re done.

In some instances clearing both turns marks seems to help avoid errors and ensure consistent patterning. Beware of moving the carriage back and forth for any reason, ie to fix a yarn loop, dropped stitch, etc. The movements in my experience have been counted as rows, resulting in patterning errors as would happen when using a punchcard machine. If working on a desktop as opposed to a nearby laptop you may be missing any visual cues for row advancement provided by the ayab screen.

The image displayed on the screen may be magnified and reduced to fixed amounts, but at present, there are no programmable cues as might have been used on mylar ie. for color changes, lace vs knit carriage actions, etc.

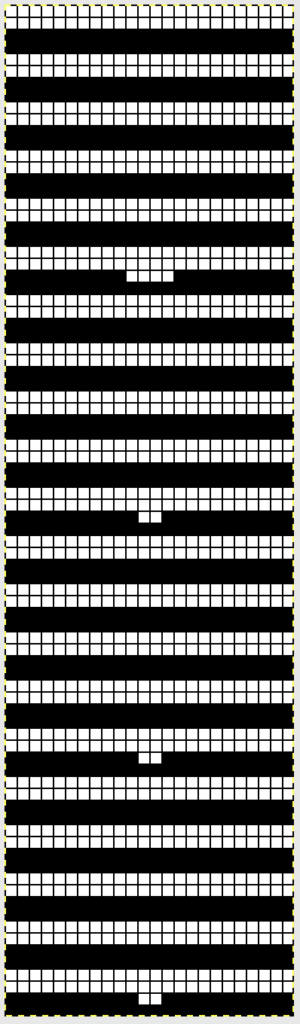

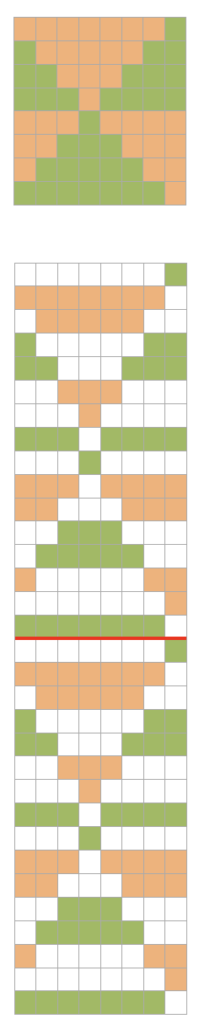

When exploring the menus, creating an easy to view repeat helps to sort out available actions

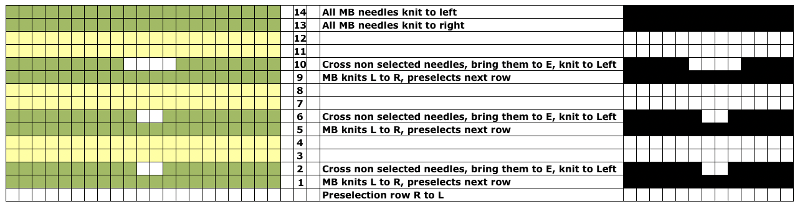

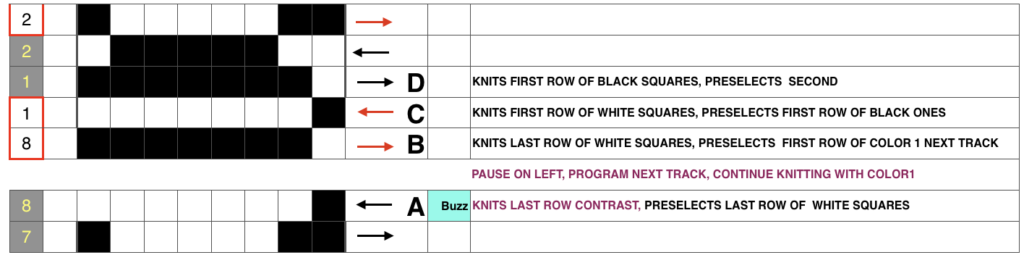

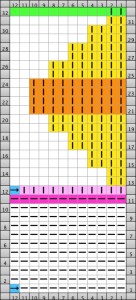

The single setting is used for all single bed fabrics. The row numbering starts from 1, not 0, and focuses consistently on the row whose pattern is being selected, not the row being knitted; design row start line placement

start needle design stitch position on needle bed

start needle design stitch position on needle bed

single design alignment test: left, center, right of the same repeat on an alternate start stop needle configuration

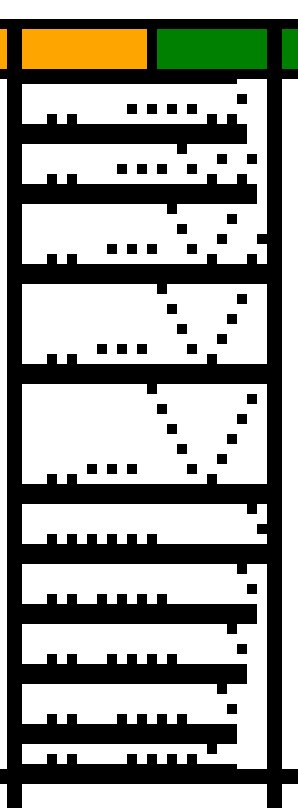

As mentioned, with an odd number of needles, Ayab places the larger number of needles on the left, its orange (yellow) side. It also automatically mirrors all patterns, so lettering and images appear on the knit side as drawn. The mirroring, however, is a problem with lace. If working from an established pattern, the lace repeat must be mirrored again either before loading the pattern or prior to knitting it or lace transfers will be made in the wrong direction. It is possible to operate the LC from the right side using Ayab, but if knit carriage is also set to selecting needles ie. if set to slip stitch, and is used in combination with the lace carriage, the LC will not select when operated from the right, and the pattern will not advance properly (documented by others as well).

I used to constantly use 2 knit carriages in a lot of my accessories. At this point, that function is not possible due to patterning errors or loss of patterning when the second carriage operates from the right.

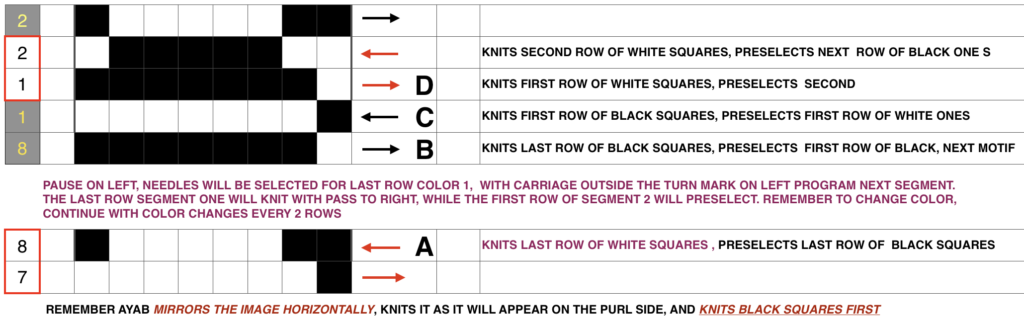

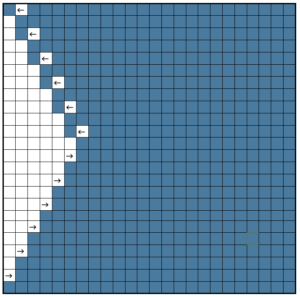

The first preselection row in Ayab is made from left to right. For any pattern that requires a start from right to left, ie one with color changes every 2 rows, there are 2 options. One is to place the design row start line at the very top row of the repeat. That row will be selected left to right, the first design row will then be preselected right to left, and the 2 color rotations using the color changer on the left can proceed accurately. The other option is to shift the last row in the programmed repeat down to row 1 position prior to downloading the pattern and saving that as the working repeat. I prefer the latter since it eliminates having to recall the change in the start line. An example of the shift is seen as applied to the automatically shaped lace trim

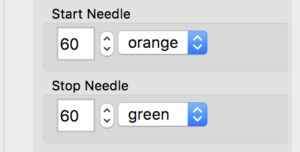

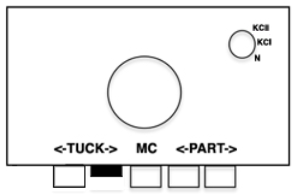

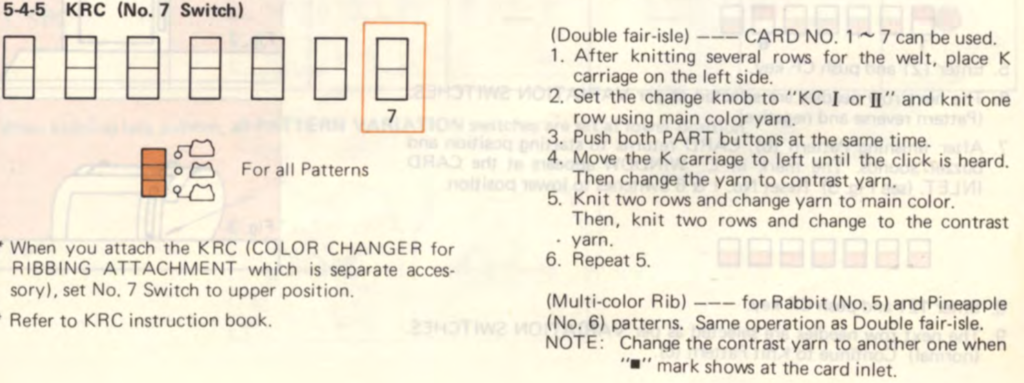

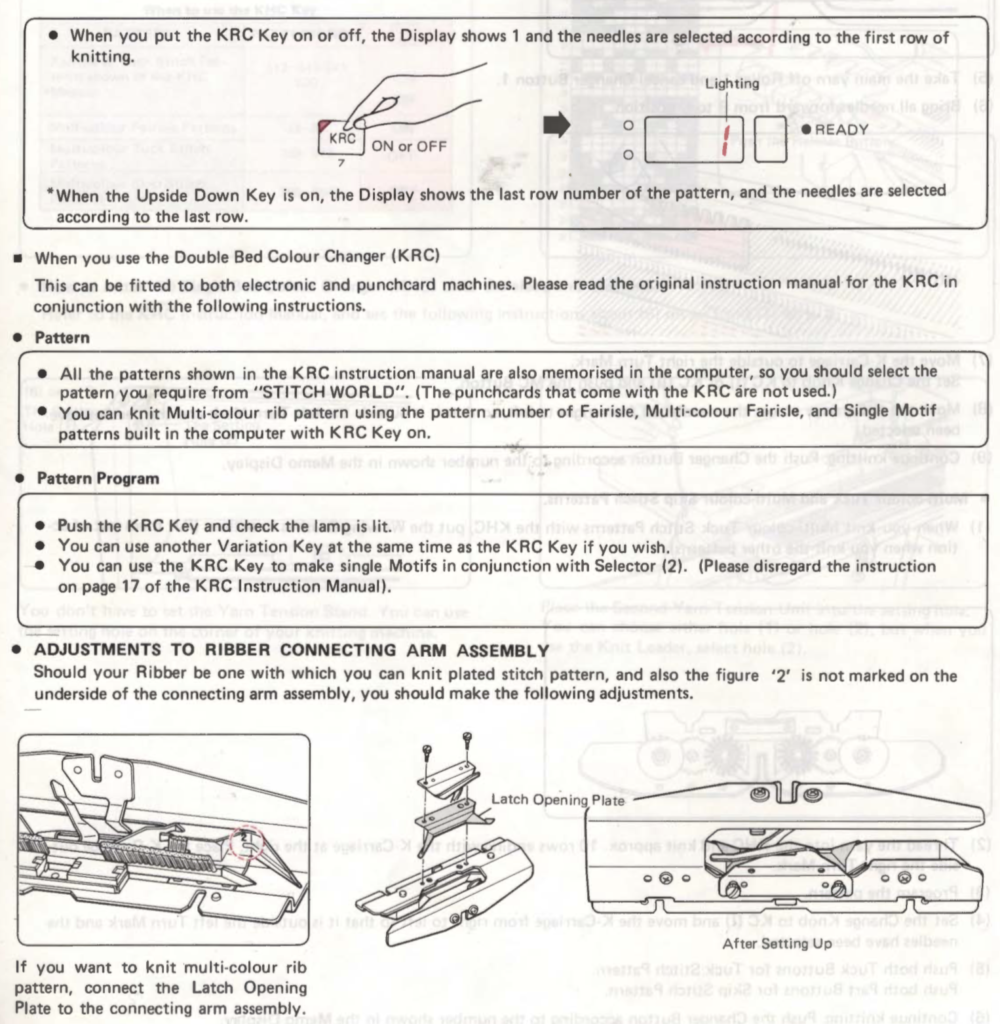

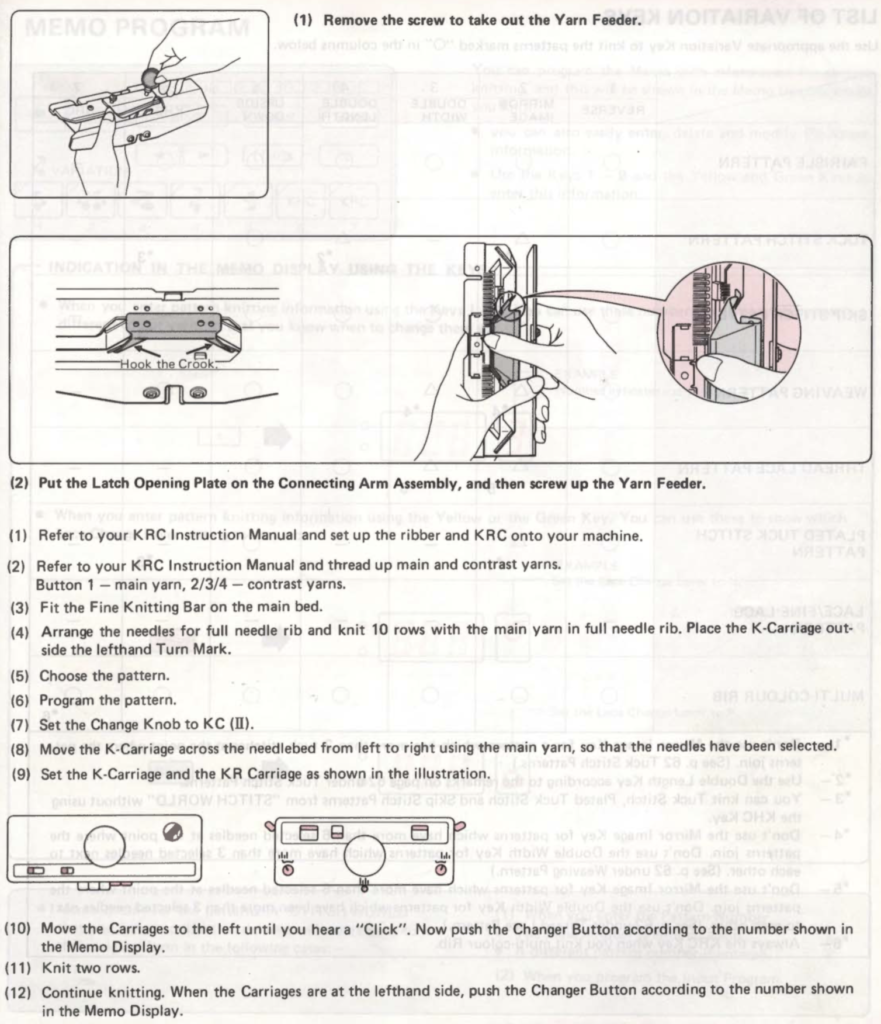

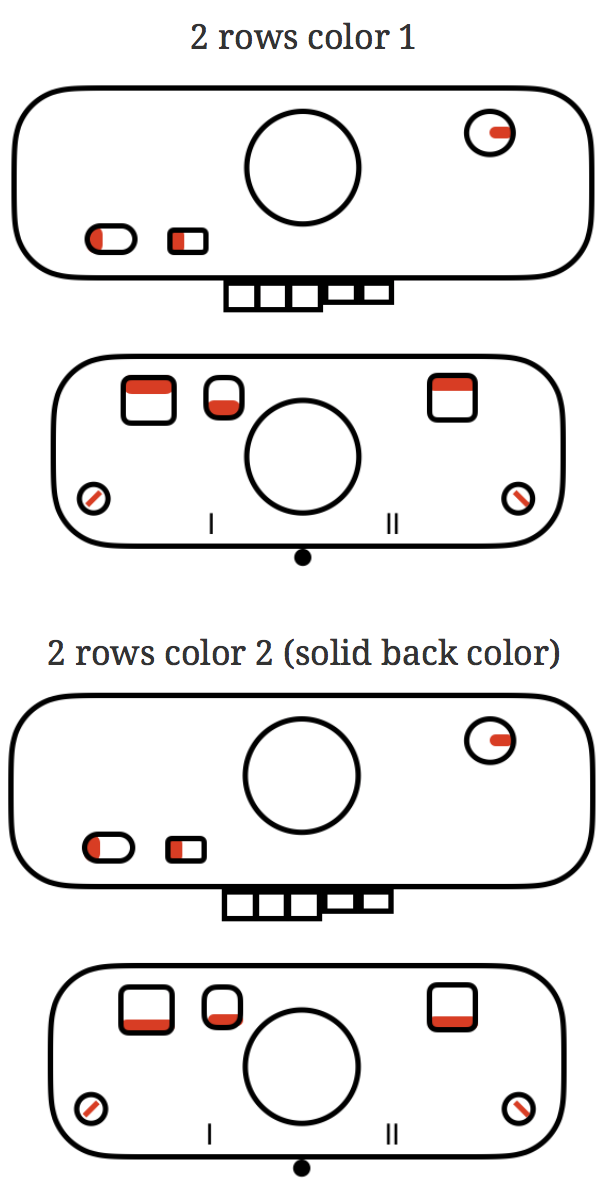

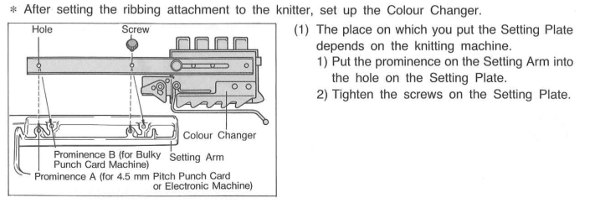

The ribber setting: a reminder, later color changers were also capable of being used on the bulky machine

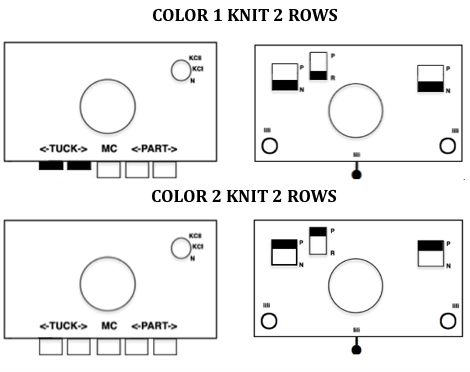

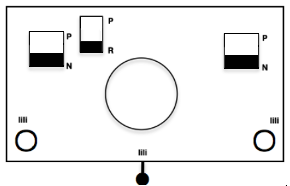

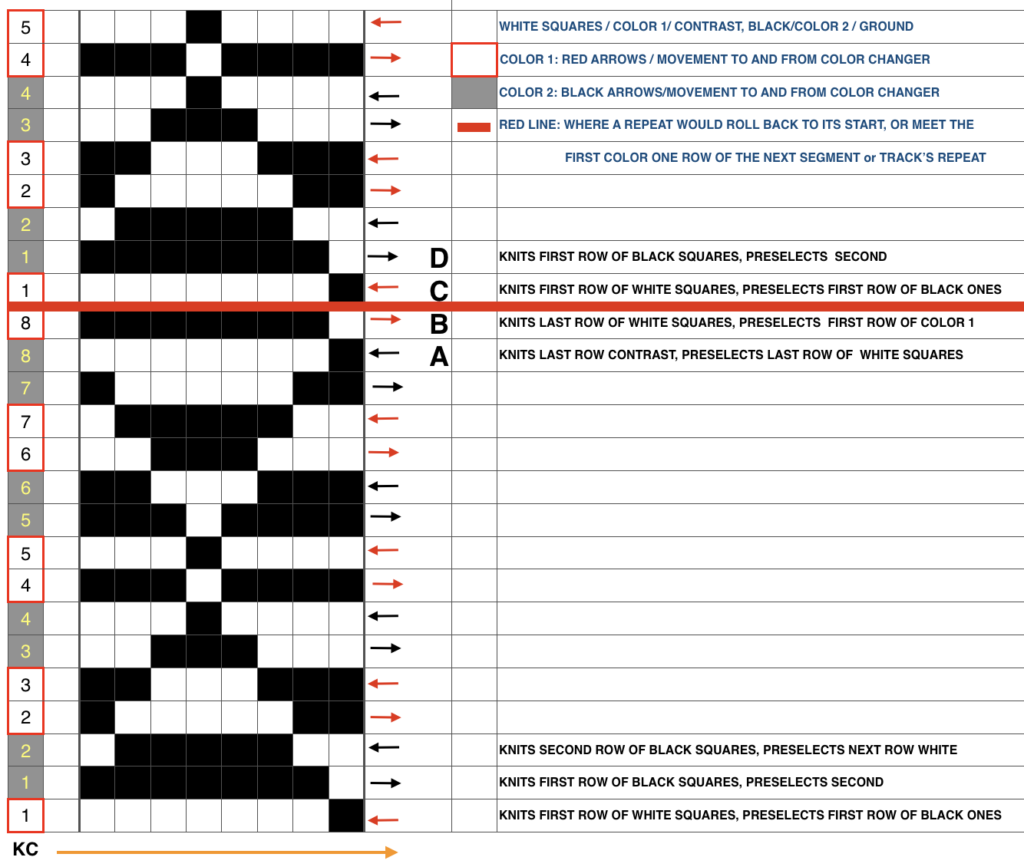

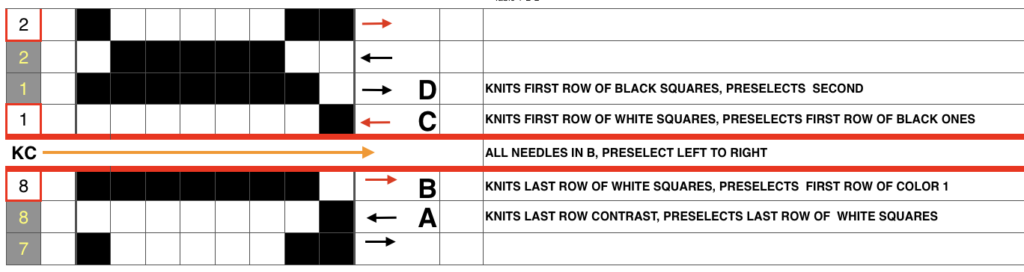

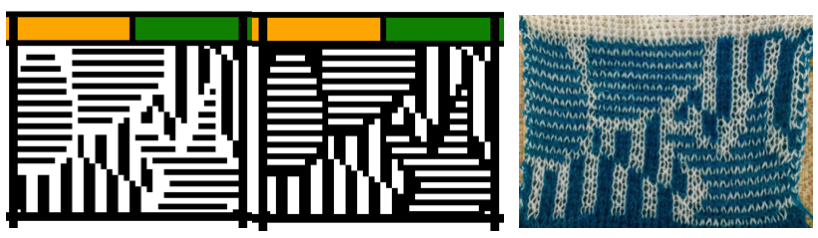

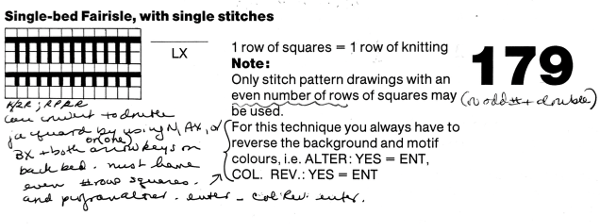

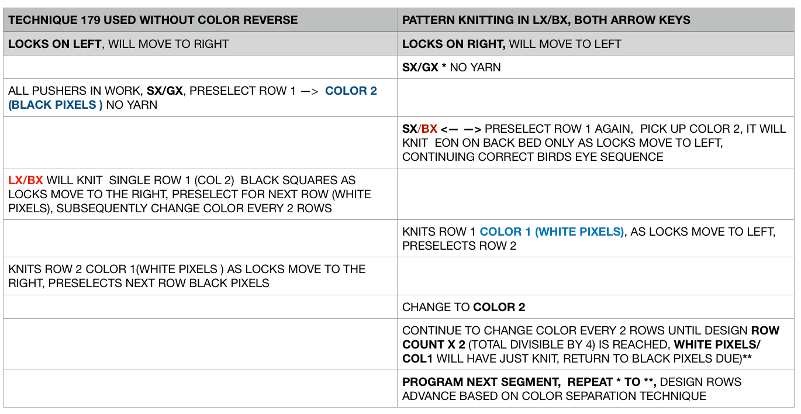

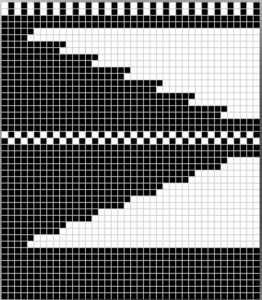

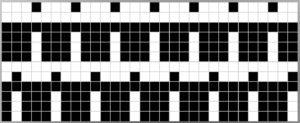

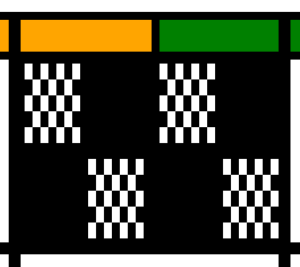

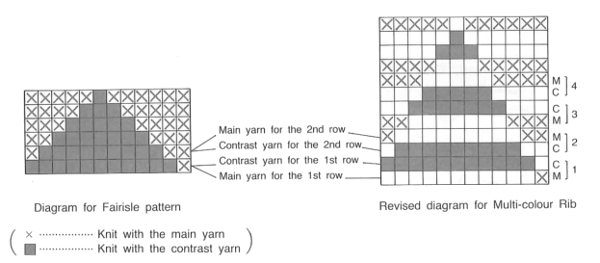

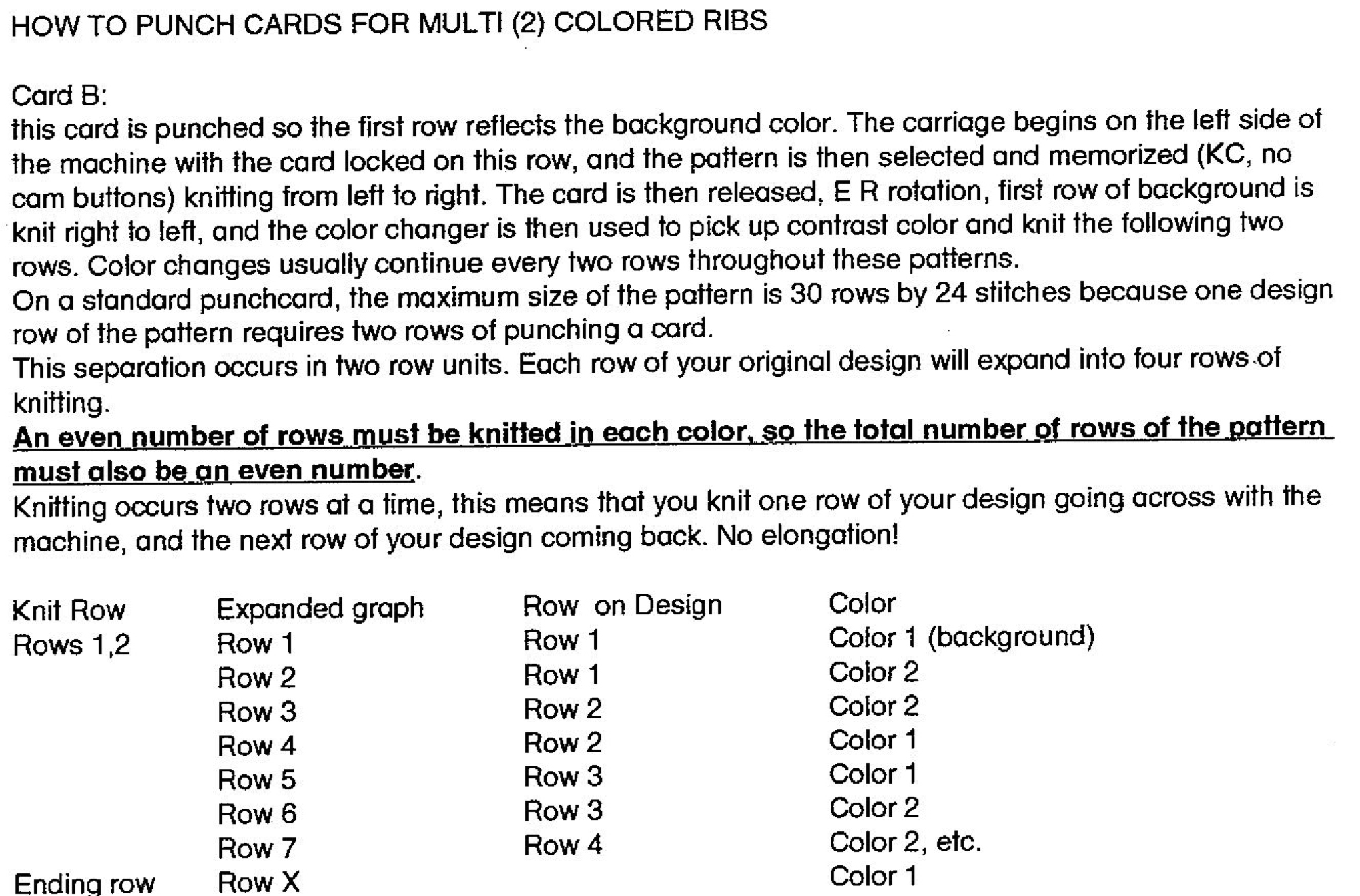

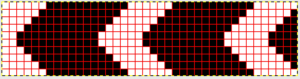

Brother DBJ KRC setting including on the 910: white is the background (color 1), punched holes, black squares or pixels are considered contrast (color 2)

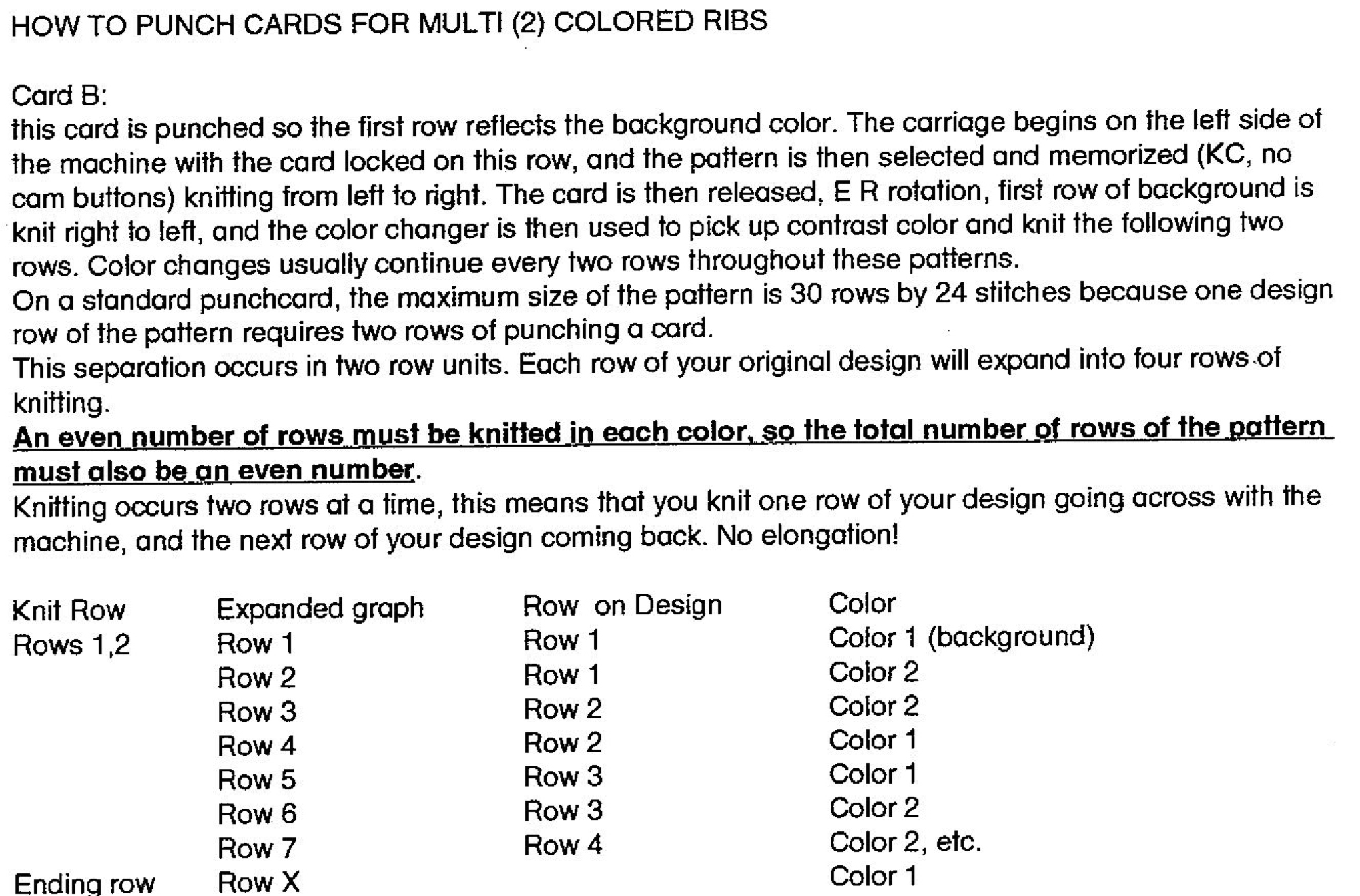

This is the KRC color separation described for DIY use on a punchcard machine:

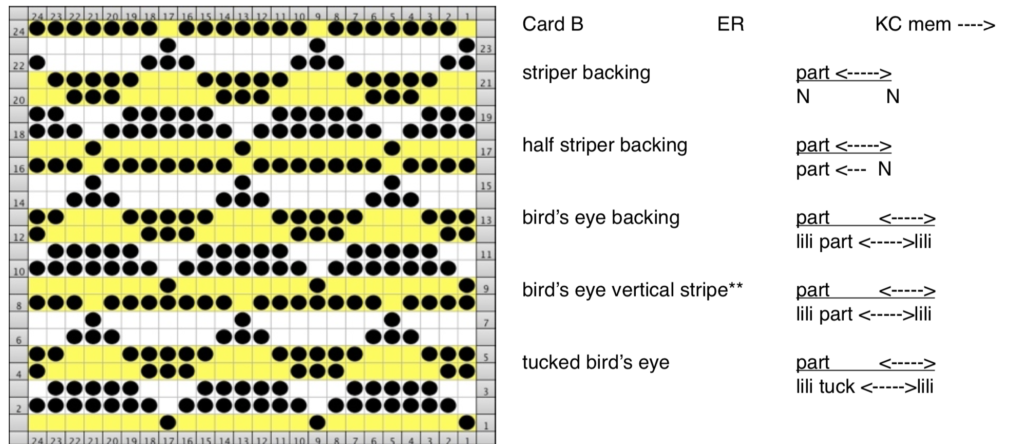

some of the possible backings (vertical striper requires extra steps)

Previous related posts: https://alessandrina.com/2015/04/18/a-simple-shape-an-exercise-in-dbj-brother-km/ and https://alessandrina.com/2017/10/26/dbj-and-color-separations-some-previous-posts-links/

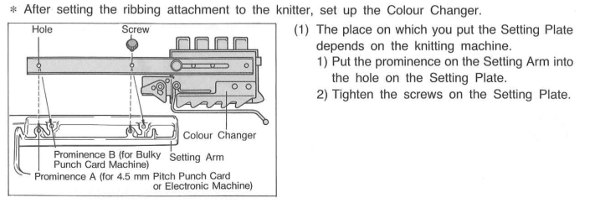

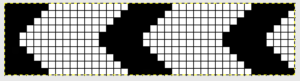

AYAB color sequence is reversed from the Brother convention of white pixels being color #1, and black pixels being color #2. It chooses black as color #1, white as color #2. The first pass to the right is set up with the “black” yarn. The actual position in the color changer can vary depending on how the yarn is threaded in the mast. The first pass to the right preselects for the first row of black squares, which will be knit on the first pass from right to left. In one option, the ribber needs to knit the yarn in order to get the carriages threaded with yarn to the other side, the KC makes a free pass, with nothing knit. This is achieved by having the main bed set to slip <– –>, and the ribber to selection to be used in the remaining DBJ fabric. After knitting across and waiting for beep, knit back to color changer, the beep happens again as you reach the opposite side. Press the button to change yarn to “white” and continue in pattern, changing colors every 2 rows. Depending on your choice of start to the piece, another option may be to have the ribber set to slip as well on the first preselection row from left to right, thread the “black” with the carriages on the right, using it to knit that first design row, moving toward its empty slot in the yarn changer, where you will then pick up the “white”. Check cam settings on both carriages before moving back toward the right. Thinking of the pattern in terms of black and white and matching the sequence as described frees one from the factory KRC convention.

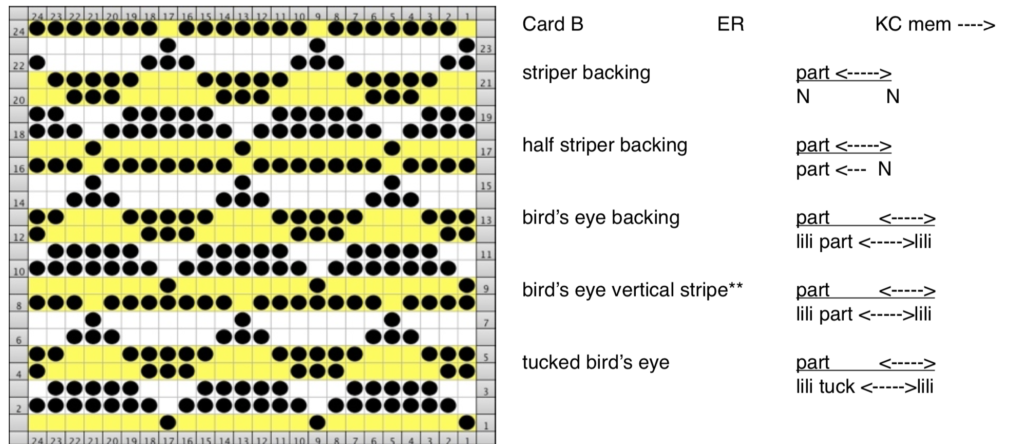

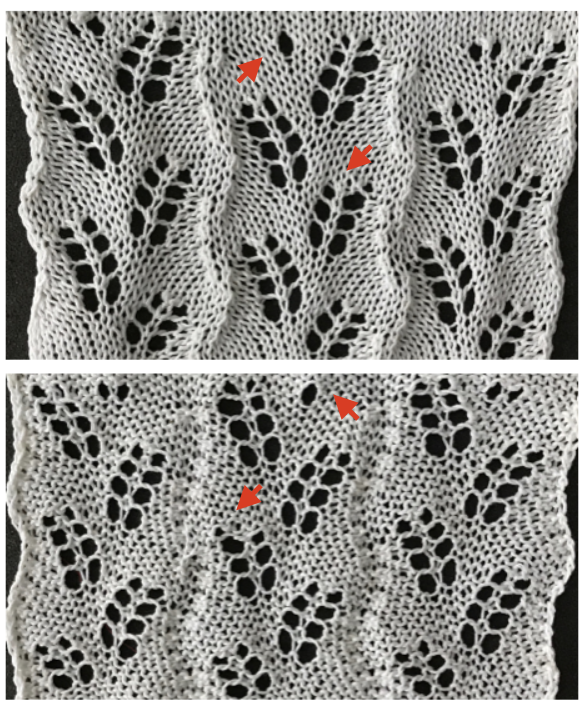

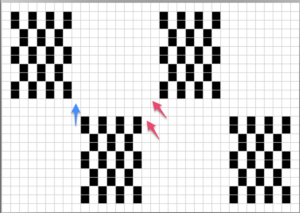

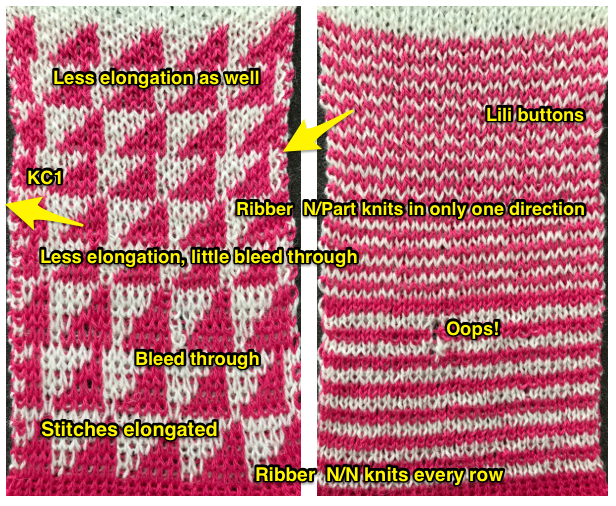

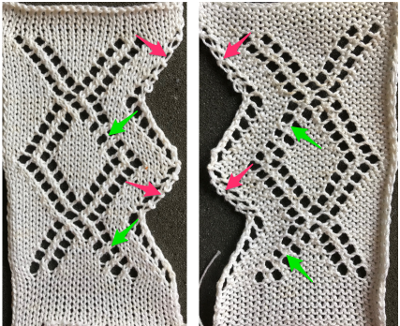

KC I or II may be used, needle arrangements can vary depending on the look one prefers on the edges. It is helpful to have some previous experience with ribber use and understanding of how stitches are formed. Patterning resulting from choices on end needle selection on either bed may be considered a boon or a distraction, at times even create a smaller, secondary pattern (arrows)

The circular setting: was intended for tubular fair isle, some of my experiments to produce other fabrics may be found in earlier posts. The ravelry group discussion on the topic including using the setting in knitting socks, with an extensive tutorial by Adrienne Hunter: https://www.ravelry.com/discuss/ayab/3346844/26-50#38

3/15/18 After more testing I have come to the conclusion that end needle selection cancellation on my 910 LC is working properly, but is not operative when I am working with my Ayab interface.

3/5/18 While working on a post on shaped lace edgings on Brother machines I encountered 2 new issues. One appeared to be I was unable to restore end needle selection on my LC while sorting out the repeats. The other was that if 2 carriages are in use, the lace carriage will not select needles if operated from the right, while if is the only carriage selecting needles, it will work from either side. This is a property that is not isolated only to my set up.

2/28/18 I have continued to intermittently knit swatches on my hacked 910. The software continues to be a boon in terms of avoiding the mylar and producing test fabrics quickly. At one point it was suggested I flash the Arduino “go to the Tools menu, Load AYAB firmware. Choose 910, Uno, 0.9. It takes a few seconds to reload the firmware (the part of the program that’s in the actual Arduino. The changes from 0.8 to 0.9 were minimal, but it’s best to make sure you are using the latest. EMSL preflashes them in testing so it’s not normally necessary for the user to do it.” Mine had not been. Doing so has not changed any of the behaviors that make me reluctant to even attempt to knit anything other than short fabric tests. The trick now has become to keep enough patience and distance to be able to not assume that any patterning issues or fabric inconsistency are due to the software and not my own inattention or faulty notes. A recent observation: if an odd number of needles are being used the rule is that the larger number will be on the left.

1/21/17 I have been reworking some of my previous posts to accommodate for the fact that Ayab preselects the first knit row only moving from left to right. After being contacted by a design school student in Europe with respect to creating specific designs in 2 color drop stitch using ayab, there is now a dedicated post on the topic. Nothing has changed in terms of my having reliable and consistent patterning for any significant knit lengths using Ayab. In addition, the knit carriage movements in the 910 when using the software now behave like the Brother punchcard knit carriages. Any change in movement in the opposite direction or jiggling of the KC for any reason can make the design advance pattern rows. This was never true for the unaltered 910 machines, which were wonderfully reliable if the knitting was interrupted, if carriage were moved outside the knit edges for any reason, did not need to clear end marks for any reason other than on the first row of knit, were able to preselect first row from either side, making patterns that required use of the color changer usable without design first row adjustments, and the list goes on. The Facebook group is an active one, and worth joining for anyone seeking more observations, advice, and inspiration.

1/7/18 Over the weekend it appears my software has now begun pre selecting first with errors, and now correctly on that first pass from left to right, so I will now be reviewing any instructions I have posted this past month in case settings need to be changed for anyone trying to execute the same fabrics, beginning with lace.

1/4/18 My Ayab software set up rows work this way: the first pass from left to right only gets the carriage to the right, selecting only first and last needle if change knob is set to KC I. The second pass from right to left preselects the first row of pattern. The third pass (from left to right), knits the first row of pattern, selects the second, and so on; the subsequent selection is correct, no rows of the design are skipped. It has been pointed out to me that this may be a unique feature to mine or one unreported by others. “First preselection row should occur on that first pass from left to right”. My posts on using the software are based on the first pattern row knitting from left to right, not right to left as would happen if the very first pass from left to right preselected for the first row of knitting. At this point in time, it is also not possible for the first preselection row to occur moving from right to left. This, in turn, needs adjustments if patterning needs to occur in 2-row sequences from the left ie. in knitting mosaics and mazes unless preselection happens from right to left, a result of my version’s “quirk”. Since I also knit on an E6000 the first 2 rows feature to complete preselection for the first row of pattern is a familiar one, and from the beginning, I assumed it was an intentional feature in the Ayab software as well. It actually solves the problem if the first selection row needs to happen toward the color changer. Fixed starting sides can be problematic depending on the type of fabric being knit. Lots of options to explore.

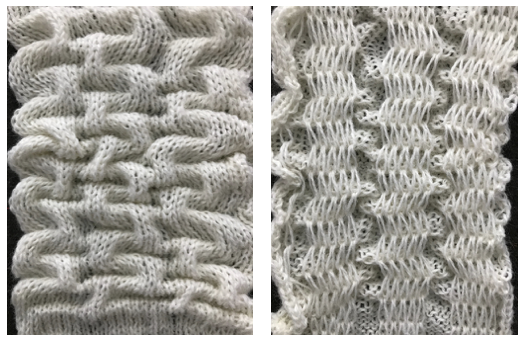

12/28/17: tuck lace meets hand technique

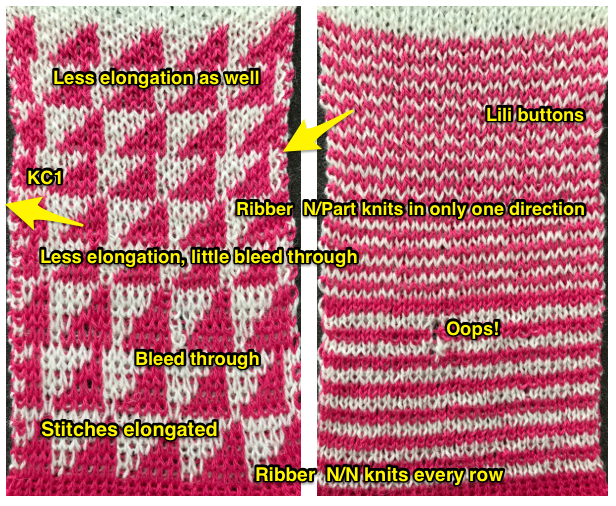

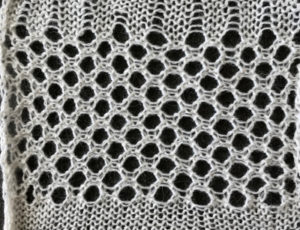

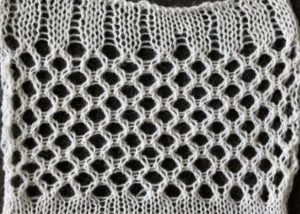

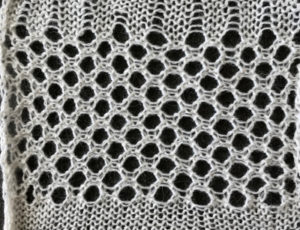

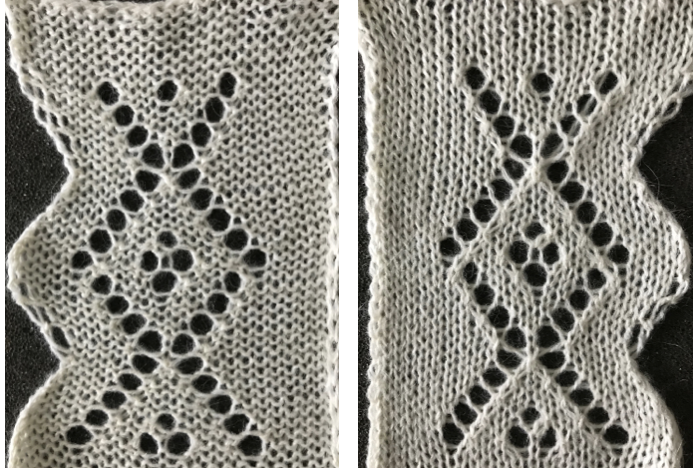

12/25/17 my first try at lace: the LC is the one to select for transfers, the KC knits to complete the formation of stitches. Brother punchcards for lace usually begin with selection rows, end with 2 blank rows at their top. Using Ayab the repeats need to repeat across the width of the piece. One nice added feature is that when doing so, blank rows may be planned and left at both sides, creating a knit stitch border and eliminating the problem of paying attention as to whether end needles are selected or not, or what other measures to take. This fabric creates large eyelets, there will be 2 empty needles side by side for the duration. Some of the old pattern books referred to it as one of the “mock crochet” ones.

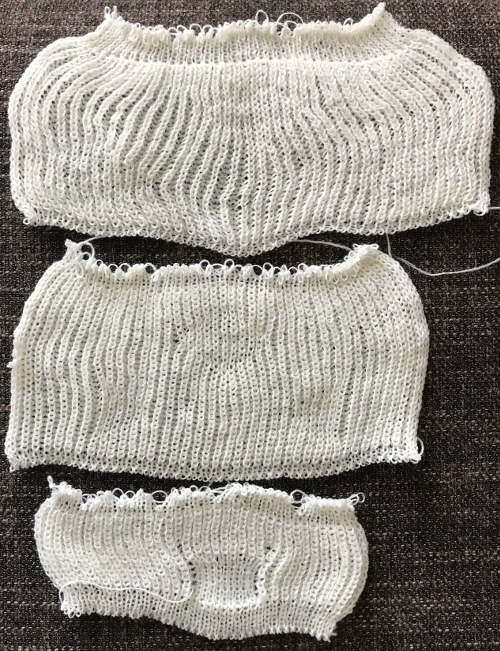

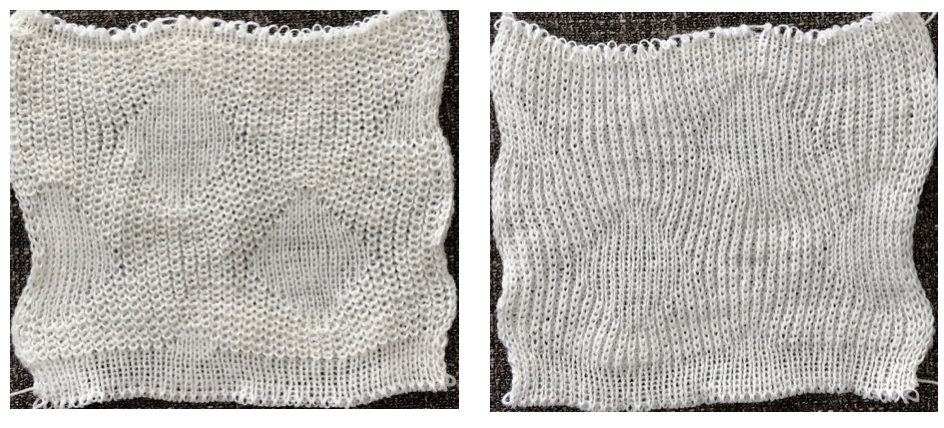

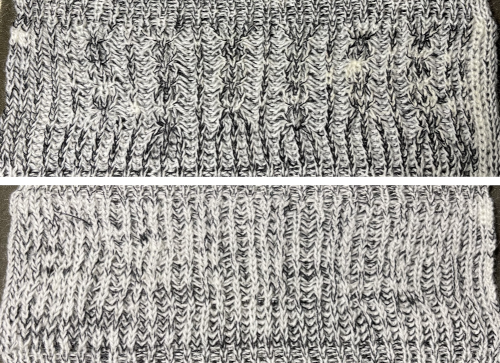

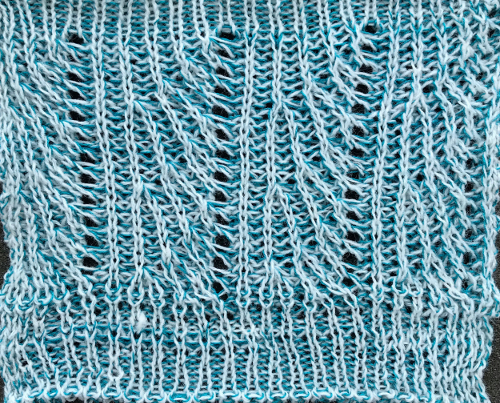

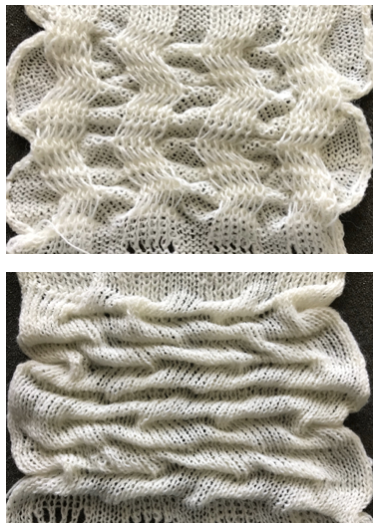

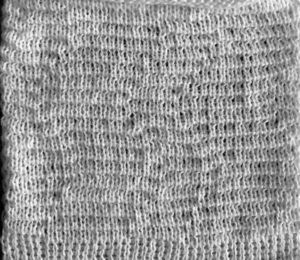

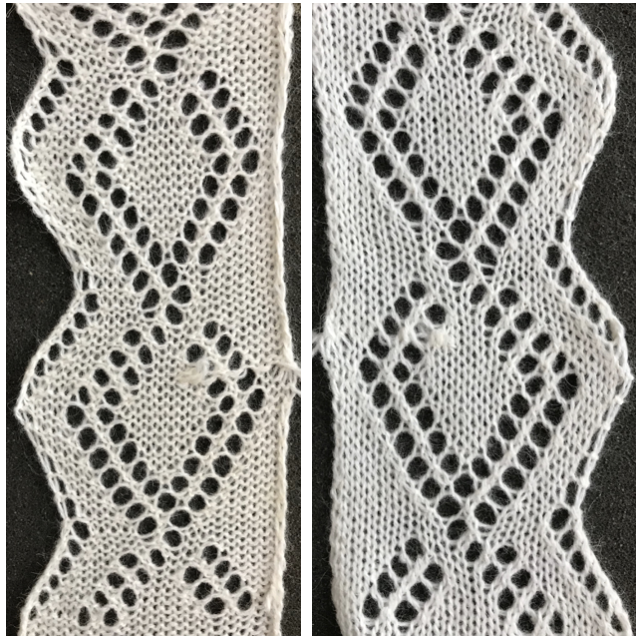

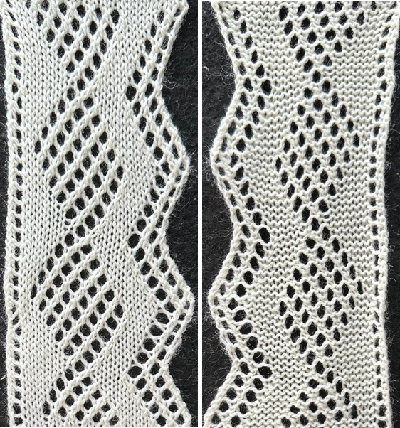

the resulting fabric, knit and purl sides

one more to try: a large diagonal eyelet lace combining lace and tuck

1/22/18 swatches with preselection from left, similar results for shapes that are shaped with single row increments in height. Double height, the fabric creates tiny pintucks, not blisters as can begin to be seen at top of swatch; KC slip <—, ribber slip —>;

shapes as seen in test swatch

verifying presence of pockets

verifying presence of pockets

For a full post on quilting in one or 2 colors please see later post

12/23/17 The “quilted” fabric produced below is different than the one achieved by specifically designed color separations, the fabric has an interesting blister like effect, the knit areas have more horizontal texture. Because of limitations due to the eventual needle selection errors, I am experiencing with the software, my swatches are limited in length or have interrupted patterns. My new repeat  two of the “pockets” have beads dropped into them to highlight their location

two of the “pockets” have beads dropped into them to highlight their location

12/22/17: settings given below are for first preselection row from right to left, not for left to right, testing out the waters with the circular settings, using the repeat. Please check later posts for reviewed content

I tried to go for “quilting, but think that may require switching levers on the ribber, so to start with, this was knit in an every needle rib, with the ribber set to knit <—->, main bed set to slip —>, producing a fabric with very subtle pintucks, which may be more interesting in 2 colors

Quilting: KC slip <—, ribber slip —>

Quilting: KC slip <—, ribber slip —>

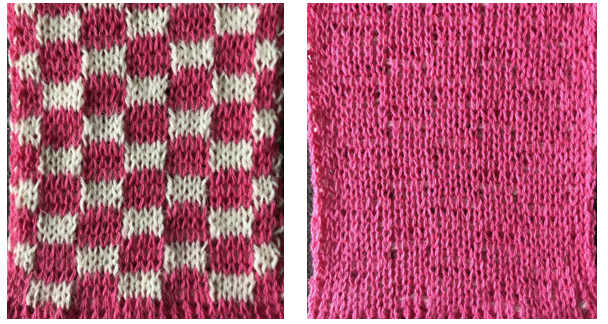

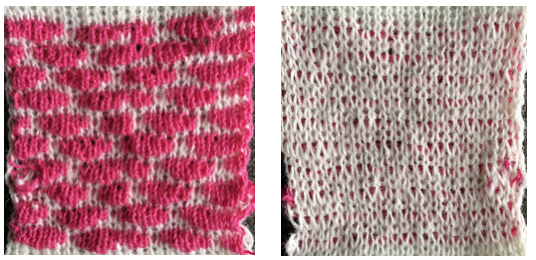

The pink and white swatch is in “drop stitch lace”, was also knit using the circular setting. Instructions for color separations for fabric, how-tos, tools, tips, and samples may be found in my posts on the topic, with the same repeat used in https://alessandrina.com/2015/06/16/geometric-shapes-in-drop-stitch-lace-2-brother-km/

the image resulting from my own past color separation

the image resulting from my own past color separation  its purl side, turned sideways

its purl side, turned sideways

Previous posts have covered manual color separations for fair isle, quilting 1, quilting2, and a summary of series on drop stitch lace. A later post on drop stitch lace using ayab .

One of the differences in using Ayab, is that knitting set up begins on the left, with first preselection row happening on the second carriage pass from right to left. This makes sense if the goal is to set up patterning for moving toward the color changer. Passap E6000 uses the SX/GX (2 Rows) for set up, with its color changer on the right. The knitter may set the carriages or locks for any chosen setting (knit for knit rows, slip if the extra 2 rows knit are not desired as part of the pattern or those suggested by console or other instructions). In the original state 910, the starting side is of no consequence as long as one is outside the set line, and preselection happens on a first, single pass. The same is true of preselection in the punchcard, one may start on either side. In some fabrics such as slip stitch worked holding techniques, or if the color changer is in use and making moves in even numbers of rows toward and away from it are required, starting side matters. The Ayab circular setting does the color separation for the fabrics above, but other cam and lever settings may need adjustment, based on sorting out what selected needles are doing when knitting starts. For the “quilted” swatch above the left part button on the KC, and the right one on the ribber were used. Sometimes the guide to color selection or cam settings is whether the first square in the imported image for download is black or white. With the loss of the built-in color reverse on a hacked machine, it is easy to work when swatching and testing to color reverse the repeat by using invert, available in the color menu, providing the alternative repeat. In Gimp the grid color may be adjusted as well if you choose to work in black and white as your starting palette. For the individual image, Image/ configure grid changes the preference for single use.

12/19/17 I am continuing to really appreciate the speed and ease for sampling pattern ideas. That said, I have also again experienced selection issues varying from lost selection to repetition of the same pattern row indefinitely, frequently after more than 50 rows are knit, and in spite of increasing attention being paid to beeps and flashes. Short pauses also seem to put the software into time out mode. I have not done enough knitting to evaluate whether moving the carriage past both turn marks with any frequency prevents those selection issues. Support is responsive, with new tools come new learning curves for everyone involved.

There is a popping noise /clunk that I have now learned is routine and “likely from the solenoids being engaged or disengaged, when they’re first powered up, or released at the end.” It is a noise I have never heard in standard 910 use. I usually power down equipment when not in use, and have been told: “For the sake of longevity on the knitting machine, it’s probably better to err on the side of disconnecting the USB cable when you power down the machines.”

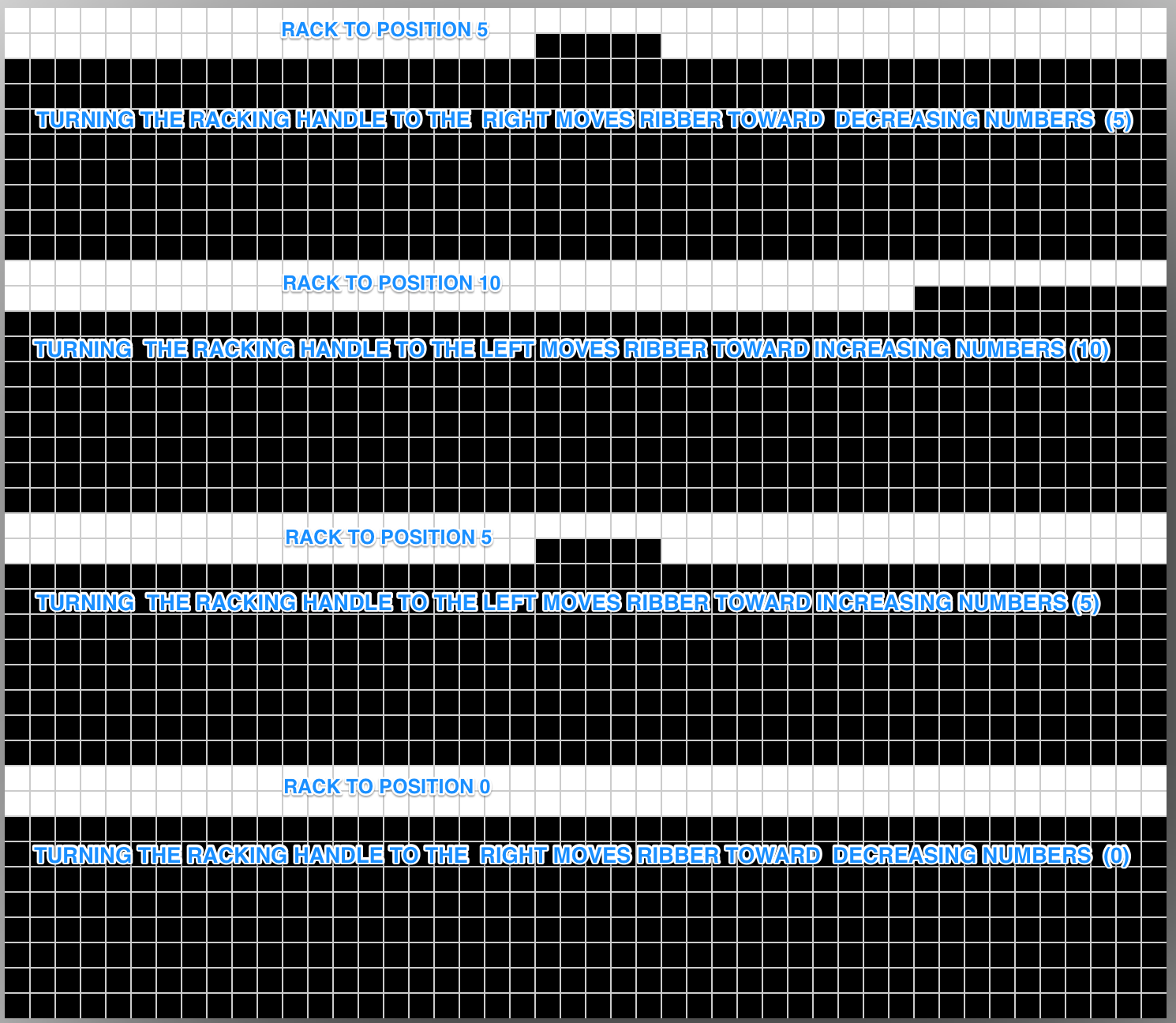

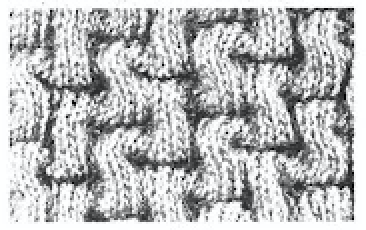

My present knitting efforts are to come up with some sort of variation of this fabric, published in an early Empisal Ribber Pattern Book, shared in a Facebook forum post. I have used racking in a variety of experiments but never traveling over a MB pattern as in this instance. There is now a dedicated post on the topic

12/17/17 I am brand new at using the system, my comments here are logging my personal experience and observation as I am learning a new tool, not intended as a guide. Please follow forums for advice from folks with more experience and knowledge.

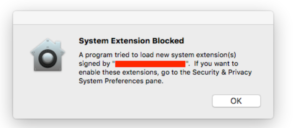

The ayab interface from EMS is now up and running on my 910. The process was easy and straightforward in terms of hardware. Software install on the Mac is very slow initially, but the launcher operates quickly after that. I am using the system connected to an iMac presently running OS 10.13.2. There initially were issues with port failure when attempting to use the program to download. No security warning was received when the driver download was completed, but rather, the image below, which I took at face value, so I did not immediately access the preferences security panel to make any changes there It took some sorting out with EMS support and finally accessing preferences security settings and “allowing” the install to solve the problem. Apparently, there may be some change in the message received within a half hour of the install. So, easy fix, check system preferences security settings regardless of pop up window even if lacking familiar and obvious warnings such as

It took some sorting out with EMS support and finally accessing preferences security settings and “allowing” the install to solve the problem. Apparently, there may be some change in the message received within a half hour of the install. So, easy fix, check system preferences security settings regardless of pop up window even if lacking familiar and obvious warnings such as

At present, there is no cover available to fit over the kit and its wires, so the left-hand side of the machine remains exposed. There is a row counter built into the software, but I tend to rely on the built-in on the 910. Any DIY cover should take clearing the row counter and the knit leader trippers into consideration. There is some conversation about 3D printed ones or even metal. Tiny detail: the kit comes with electrical zip ties to help secure the plastic shields on both sides of the board. Clip the ends, and twist them so join sits either on top or under the interface, thus keeping them clear of KM parts, and, particularly, the belt drive on the left.

There are a series of beeps and flashes that indicate that the pattern row has indeed been downloaded and is ready to be knit. 910 mylar users are familiar with the sound coming from the reader as each row is scanned. Prior to using the Ayab system, I was initially concerned about beeps for each row adding to machine operating noise, since I am familiar with the Passap screech and at one point was also with the Studio electronic version. The Ayab beeps are actually on the soft side, and background noise or inattention may actually lead one to miss the cues. LED flashes occur in pairs indicating the row is ready to knit as well. Again, any cover may hide the light or soften the beeps, even more, making the cues available via the screen more essential.

The kit comes with a 3 ft. cable. I have rearranged placement of my machines to make using both the Croucher cable, switch box, and wincrea on the Passap, and the Ayab system on my 910. My initial wish was for a longer cable, which is possible to use. That said, there are several knit from screen clues that if you are operating the machine any distance from the computer get lost and become hard to see, including indicators for row numbers and the pattern advancement lines on your motif.

So far I have small FI samples and DBJ samples. Ran into a problem after 60+ rows of each with mis patterning occurring, but that may well have been operator error. I have used my 910 for production accessories and was very familiar with a personal optimum speed. I believe I almost unconsciously with the initial samples, may have picked up speed and interfered with the accurate download of pattern rows. When I slowed down and was much more deliberate, waited for each flash and sound, a test got me to RC 110 with no issues before I quit for the day.

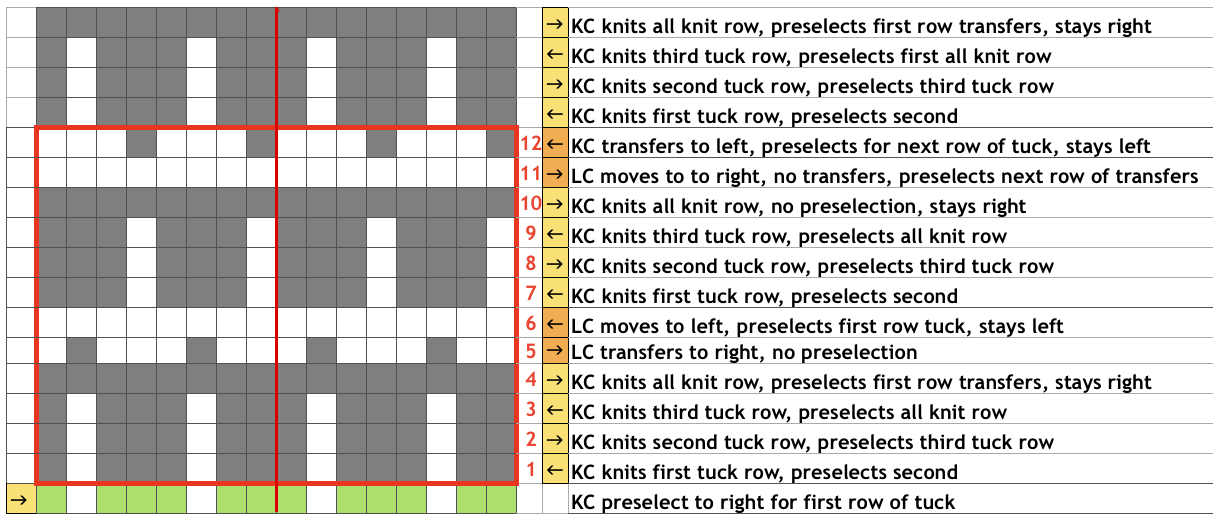

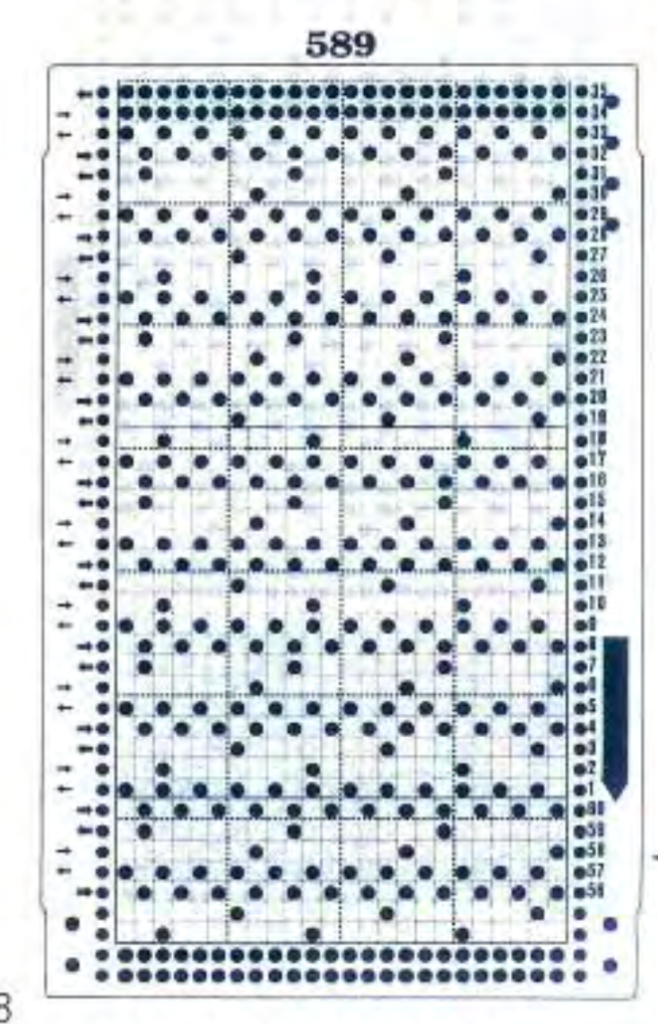

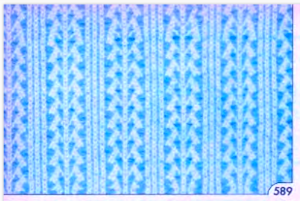

11/27/17 This punchcard was shared by someone trying to reproduce the implied fabric on their 910. It is intended to be used as a combination lace and weaving card, so on the punchcard machine, 2 carriages would be locked on the belt. If even number of passes are made with each carriage, there is the issue of the card not advancing each time when the opposite carriage makes its first pass. So far I have not been able to get this repeat to work for me as drawn, to produce results anything even resembling the “finished swatch” published photo. It did work for me using the LC carriage for 3 passes, releasing it, and following it by 2 rows knit with the KC set to tuck in both directions, a very different fabric. If the LC is released after an odd number of rows, then technically when the KC is first in use, the right to left and back to right selection is not interrupted, it is moving in the direction the LC carriage would have moved, and the punchcard row is not repeated. The first row with LC selects, second row transfers, selects next row. Third row transfers, selects every other needle for the first tuck row on the next pass of KC, and LC is released. The fabric then tucks for 2 rows as punched, on every other needle. The second tucked row is completed with KC on right. The first LC row has now been preselected, as the *LC heads back to the right (1) it transfers the selected needles, selects them again, but since they are now already empty, nothing happens to any yarn, and the next row of transfers is selected (2). The second set of transfers is made to the right (3) as the first tuck row is preselected. LC is removed. KC tucks for 2 rows (4, 5), selecting first LC transfer row with the second pass.* Repeat. The marks on the left should indicate carriage movements for each carriage, but they are off as well in my version of the fabric. My final repeats were for use on the 910 with a mylar.

the pattern book swatch image

the pattern book swatch image tuck swatch

tuck swatch

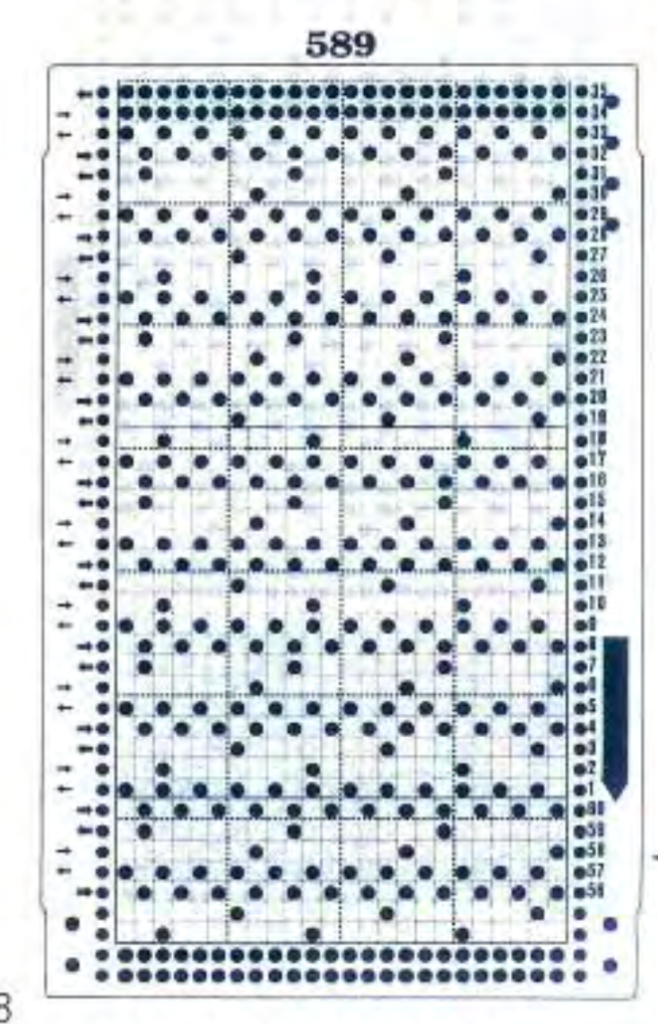

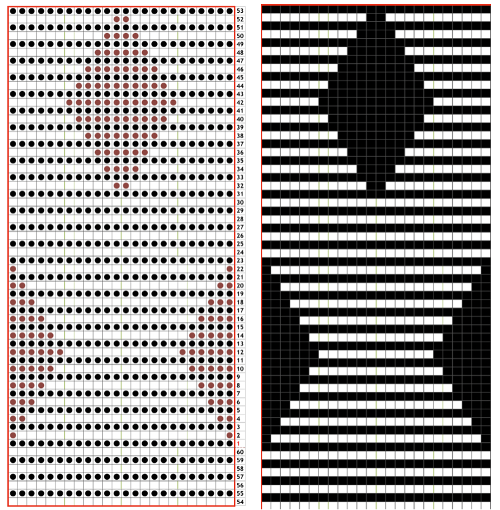

Lace is a challenging enough fabric without adding weaving yarn floats, and definitely combining them requires a clear understanding of what the yarn is doing on the needle hooks as one progresses through the repeat. I will be starting a separate post reviewing card markings in punchcard pattern books, and translating them for electronic use. For further information please see post on 589

I have always been interested in machine knitting hacks and began sharing information from the internet on the topic as early as 2013. I own the 910 Brother model, and when the ayab hack first became available, assembling electronic components was beyond my skill and interest. I have a good supply of mylars, but have always knit more complex fabrics on my E6000, which has the Croucher cable and switch box for download to and from a Windows laptop, using Wincrea . I had known a preassembled kit for the 910 hack was in development from a trip to CA, which included a visit to the Bay Area Machine Knitting Guild back in April 2016. A recent post on Ravelry alerted me to the fact that Ayab was “alive and well”, and that an assembled kit is now available and on the market. The hardware kit developer , to purchase , wiki , interface , install . My understanding is that the software is still being developed in Germany.

Online discussion groups: Ravelry , Facebook. My compiled list of online pattern generators, hacks, free KM manuals, and more: 5435

I have purchased a kit and will share my experiences with it as time passes. In addition to bypassing the mylar use, the idea of having software that will render color separations that would normally have to be hand drawn for larger repeats than would be practical, or for complex fabrics, is an exciting one.

An artist whose work I admire, using the interface early on is Claire Williams , her tutorial updated 2016 with DIY assembly of the original “kit”.

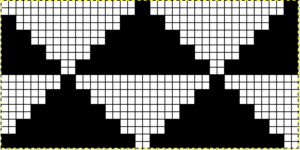

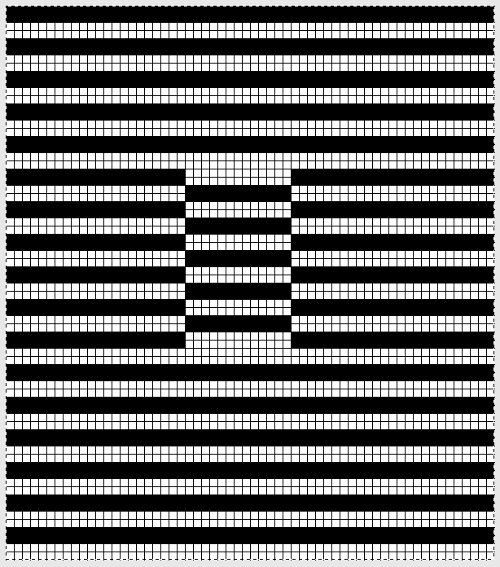

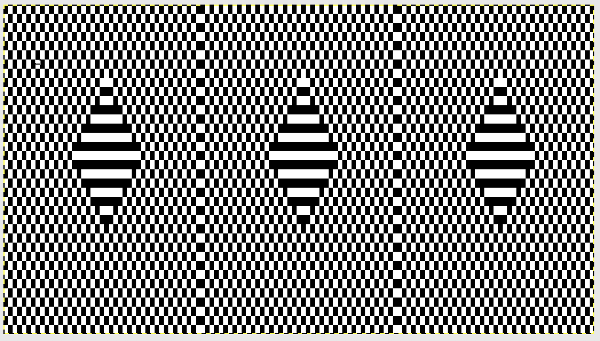

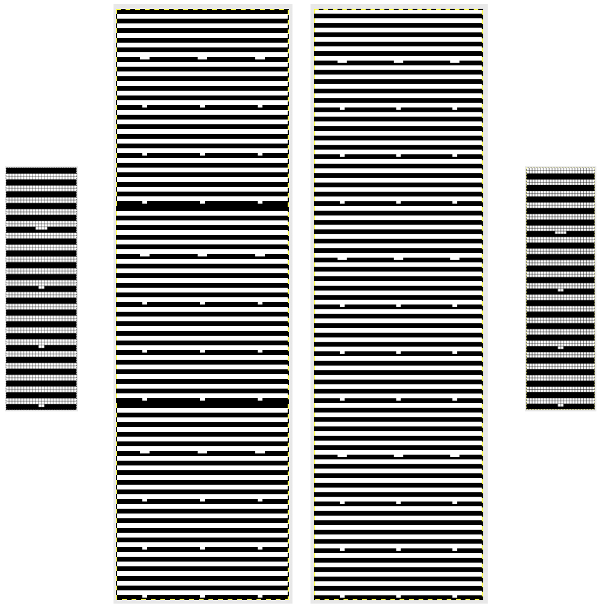

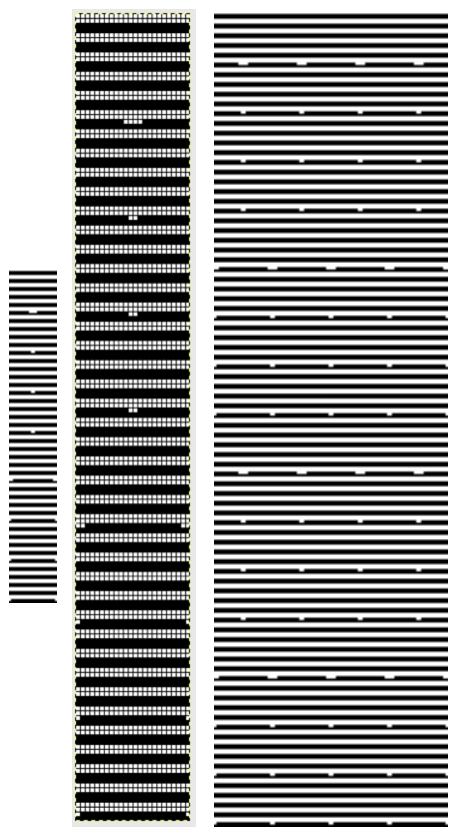

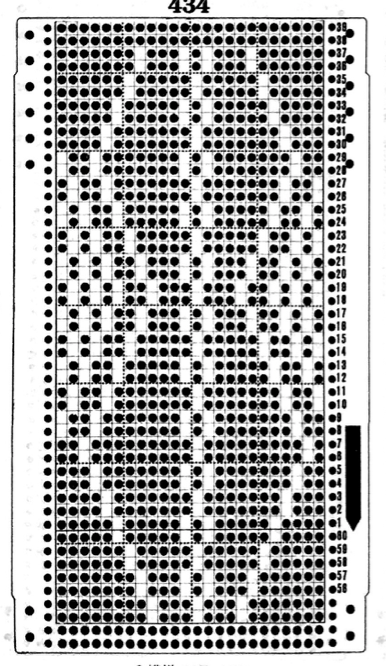

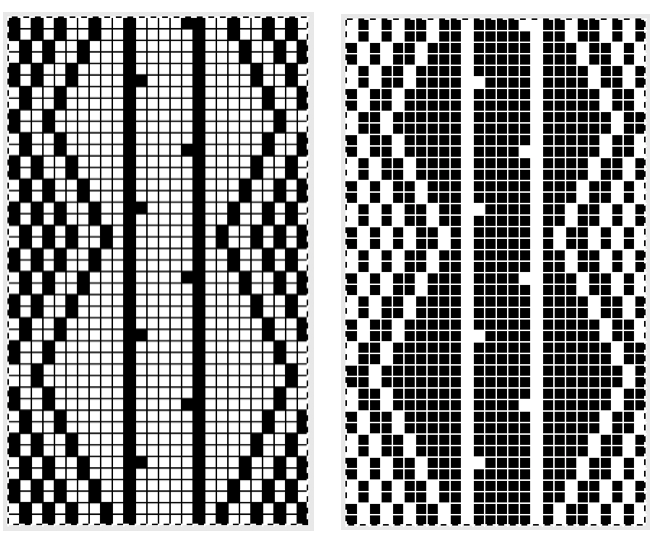

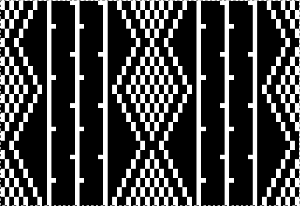

When attempting to knit isolated geometric areas on a field of frequently tucking stitches, automating the task when possible makes the process easier and faster. This was my first “diamond” pattern repeat, suitable for a punchcard machine as well. The design is illustrated on the left, converted to punched holes/black squares/pixels on the right

When attempting to knit isolated geometric areas on a field of frequently tucking stitches, automating the task when possible makes the process easier and faster. This was my first “diamond” pattern repeat, suitable for a punchcard machine as well. The design is illustrated on the left, converted to punched holes/black squares/pixels on the right  The knit carriage is set to tuck throughout. The programmed repeat will alternate the knit/ tuck functions across the bed based on black squares, punched holes, or pixels.

The knit carriage is set to tuck throughout. The programmed repeat will alternate the knit/ tuck functions across the bed based on black squares, punched holes, or pixels.  For full fisherman rib (top swatch) the ribber needs to tuck in one direction only, opposite to the action taking place on the main bed. A choice needs to be made on either of these 2 setting directions based on needle selection on the main bed and stays fixed throughout knitting. The ribber is set to knit on even-numbered design rows on the card, to tuck on odd. Row count numbers may be different than design row ones depending on row counter settings by the operator or built KM ones. Below are tuck settings for to the right on top, to the left on the bottom.

For full fisherman rib (top swatch) the ribber needs to tuck in one direction only, opposite to the action taking place on the main bed. A choice needs to be made on either of these 2 setting directions based on needle selection on the main bed and stays fixed throughout knitting. The ribber is set to knit on even-numbered design rows on the card, to tuck on odd. Row count numbers may be different than design row ones depending on row counter settings by the operator or built KM ones. Below are tuck settings for to the right on top, to the left on the bottom.

For half fisherman rib (middle swatch), the ribber is set to knit with every pass.

For half fisherman rib (middle swatch), the ribber is set to knit with every pass. Note the half fisherman fabric is narrower than the full. Also, I am not used to my 930, overlooked that the machine was set for isolation, so its bottom diamond-shaped repeats are incomplete.

Note the half fisherman fabric is narrower than the full. Also, I am not used to my 930, overlooked that the machine was set for isolation, so its bottom diamond-shaped repeats are incomplete.

Getting back to automating at least part of the process for such shapes: the repeat needs to be altered

Getting back to automating at least part of the process for such shapes: the repeat needs to be altered main bed will be knitting the black squares in the chart on the right on every row, tucking the white ones. When the ribber carriage is on the side appropriate for it to tuck the following row and no needles are selected in design segments on the top bed (odd-numbered design rows, ones with the majority of black squares, tuck may not be used in those locations because then the resulting stitches would be tucking on both beds with nothing holding the tuck loops down.

main bed will be knitting the black squares in the chart on the right on every row, tucking the white ones. When the ribber carriage is on the side appropriate for it to tuck the following row and no needles are selected in design segments on the top bed (odd-numbered design rows, ones with the majority of black squares, tuck may not be used in those locations because then the resulting stitches would be tucking on both beds with nothing holding the tuck loops down.

bring all needles between selected main bed needles up to hold on the ribber so that they will knit while the remaining needles tuck on the next pass of the carriages.

bring all needles between selected main bed needles up to hold on the ribber so that they will knit while the remaining needles tuck on the next pass of the carriages.

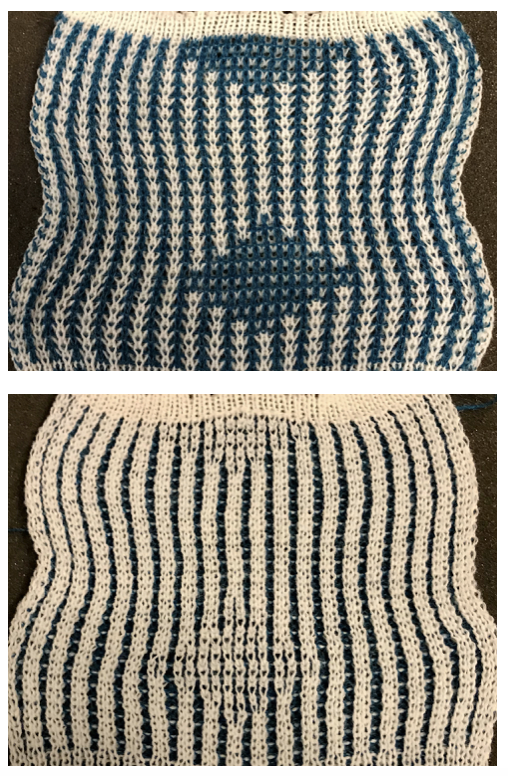

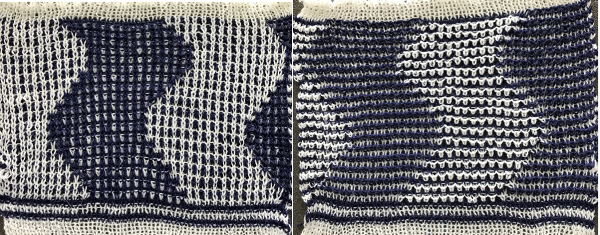

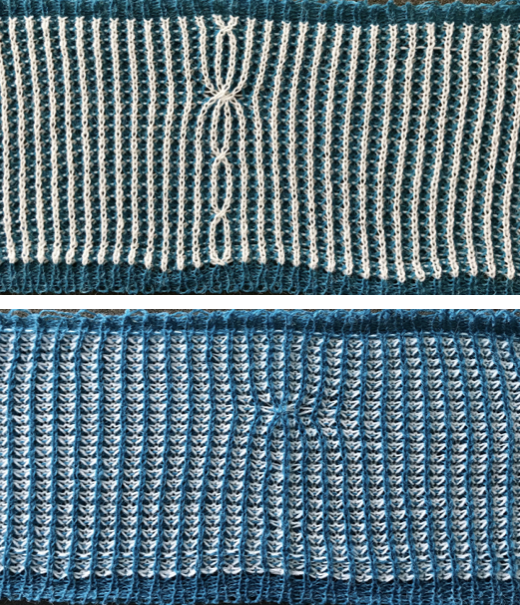

In my sampling, the ribber was set to tuck when moving from right to left. Below is the resulting swatch, shown on both sides. Part of one diamond shape is missing due to the fact I was concentrating on moving needles around and missed the change in selection on one side of the machine.

In my sampling, the ribber was set to tuck when moving from right to left. Below is the resulting swatch, shown on both sides. Part of one diamond shape is missing due to the fact I was concentrating on moving needles around and missed the change in selection on one side of the machine.  Back to the original method used in the previous post where ribber settings are changed from knit to tuck <– –> every 2 rows along with color changes. I chose a design that would make it easy to identify the location of non-selected needles on the main bed in rows where the ribber will be set to tuck in both directions. The result is interesting, but the solid areas, narrower than the remaining knit, are in the opposite color to the dominant one on each side, the reverse of the inspiration fabric.

Back to the original method used in the previous post where ribber settings are changed from knit to tuck <– –> every 2 rows along with color changes. I chose a design that would make it easy to identify the location of non-selected needles on the main bed in rows where the ribber will be set to tuck in both directions. The result is interesting, but the solid areas, narrower than the remaining knit, are in the opposite color to the dominant one on each side, the reverse of the inspiration fabric. When needles are not selected on the main bed, interrupting the every needle selection.

When needles are not selected on the main bed, interrupting the every needle selection.  Bring all needles on the ribber between selected needles up to hold on each of the 2 passes from left to right, and right to left. Stitches on those needles will knit rather than tuck

Bring all needles on the ribber between selected needles up to hold on each of the 2 passes from left to right, and right to left. Stitches on those needles will knit rather than tuck  resulting in this fabric

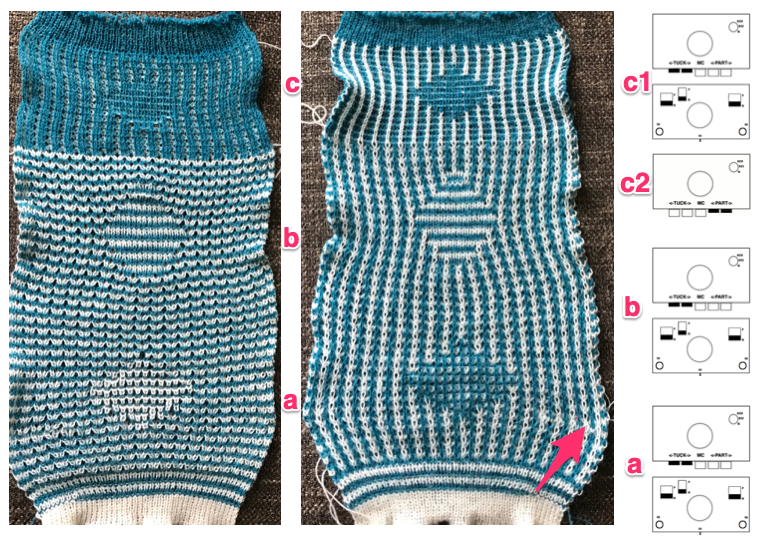

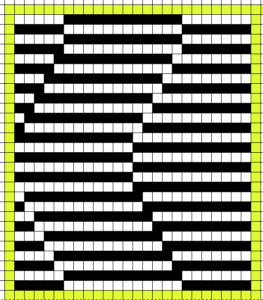

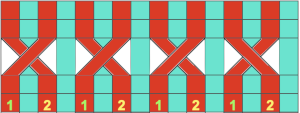

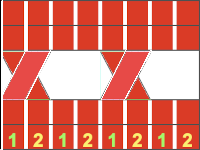

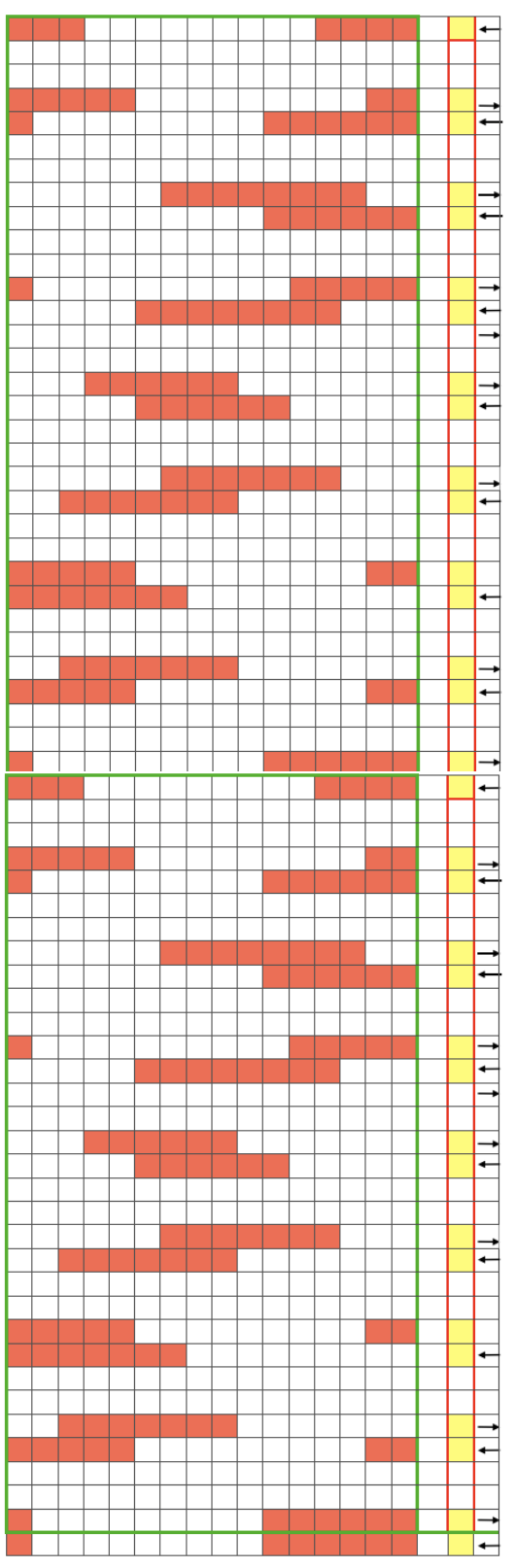

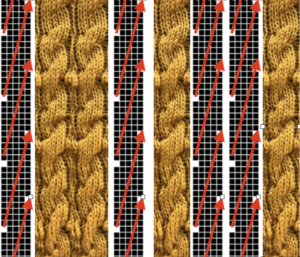

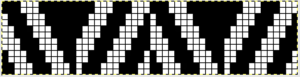

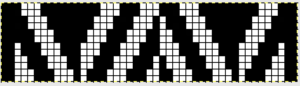

resulting in this fabric  The first swatch at the top of this post was achieved going a very different route. Two knit carriages were used to select and knit from opposite sides of the machine. Each carried one of the two colors. When working with the first color and coupled carriages the main bed is set to tuck <– –>, the ribber to knit <– –>. The second color is knit using the main bed knit carriage only, set to slip <– –>. A knit sinker plate may be altered and used so as to knit on the main bed only rows, adjustments to it are shown in the post: 2018/04/15/ribber-fabrics-produced-with-2-knit-carriages-selecting-needles/. The chart for my working repeat with a multiple of 4 rows in each pattern segment, color changes every 2 rows indicated on right

The first swatch at the top of this post was achieved going a very different route. Two knit carriages were used to select and knit from opposite sides of the machine. Each carried one of the two colors. When working with the first color and coupled carriages the main bed is set to tuck <– –>, the ribber to knit <– –>. The second color is knit using the main bed knit carriage only, set to slip <– –>. A knit sinker plate may be altered and used so as to knit on the main bed only rows, adjustments to it are shown in the post: 2018/04/15/ribber-fabrics-produced-with-2-knit-carriages-selecting-needles/. The chart for my working repeat with a multiple of 4 rows in each pattern segment, color changes every 2 rows indicated on right trying to produce a diamond shape using this technique, my first repeat had arbitrarily placed pixels:

trying to produce a diamond shape using this technique, my first repeat had arbitrarily placed pixels:  the cam settings on the right of the swatch images correspond to those used in each swatch segment. Colors were changed every 2 rows throughout. The first 2 rows in the pattern were knit in a tuck setting, followed by 2 rows knit in slip. In segment B when no needles were selected on the top bed, all those needles were brought out to hold before knitting to the opposite side. Because every row is now knitting in the corresponding color changes the result is a striped pattern. Segment C is knit with both carriages set for 2 rows as in C1 alternating with knit carriage only set as in C2. At that point the color being carried knits only on the ribber, skipping non selected needles on the top bed, avoiding the striped result. A float is created between the beds in areas where no needles are selected that will be “hidden” as one returns to knitting in rib with 2 carriages.

the cam settings on the right of the swatch images correspond to those used in each swatch segment. Colors were changed every 2 rows throughout. The first 2 rows in the pattern were knit in a tuck setting, followed by 2 rows knit in slip. In segment B when no needles were selected on the top bed, all those needles were brought out to hold before knitting to the opposite side. Because every row is now knitting in the corresponding color changes the result is a striped pattern. Segment C is knit with both carriages set for 2 rows as in C1 alternating with knit carriage only set as in C2. At that point the color being carried knits only on the ribber, skipping non selected needles on the top bed, avoiding the striped result. A float is created between the beds in areas where no needles are selected that will be “hidden” as one returns to knitting in rib with 2 carriages. The arrow in the chart points to an area where two colors were picked up with the color swap rather than one. The resulting swatch samples

The arrow in the chart points to an area where two colors were picked up with the color swap rather than one. The resulting swatch samples

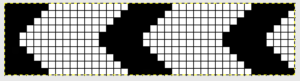

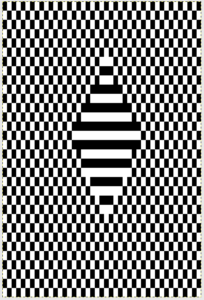

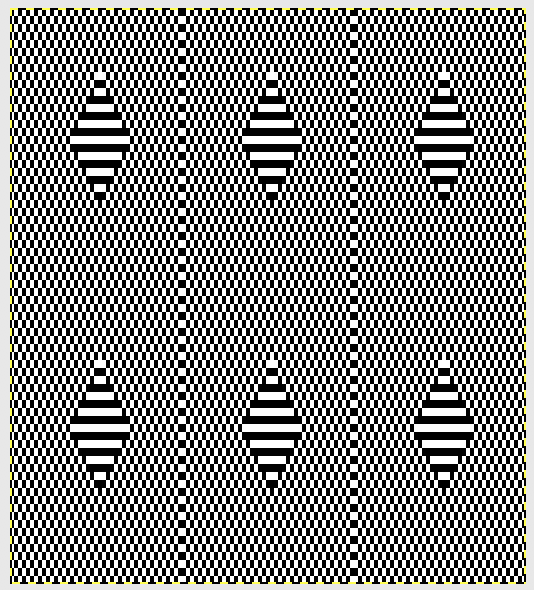

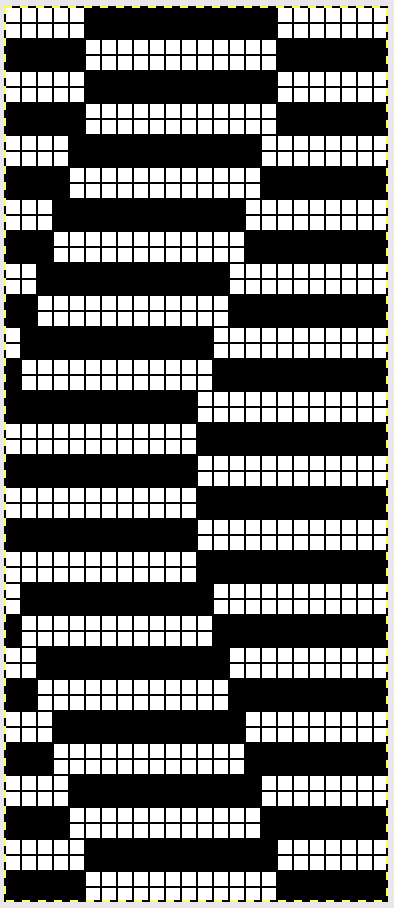

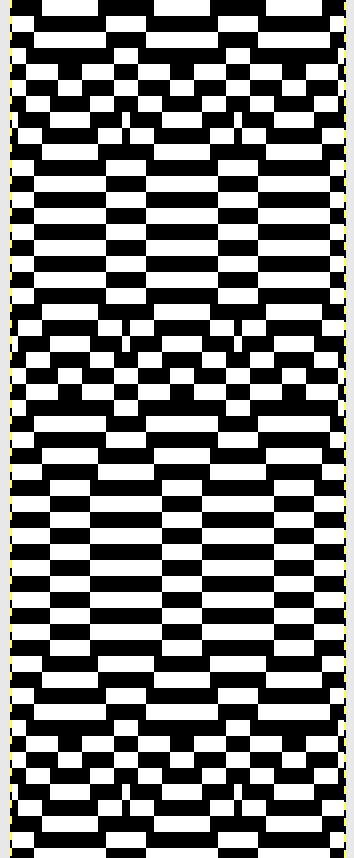

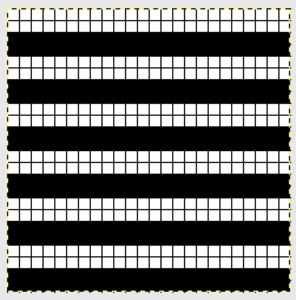

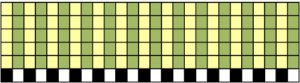

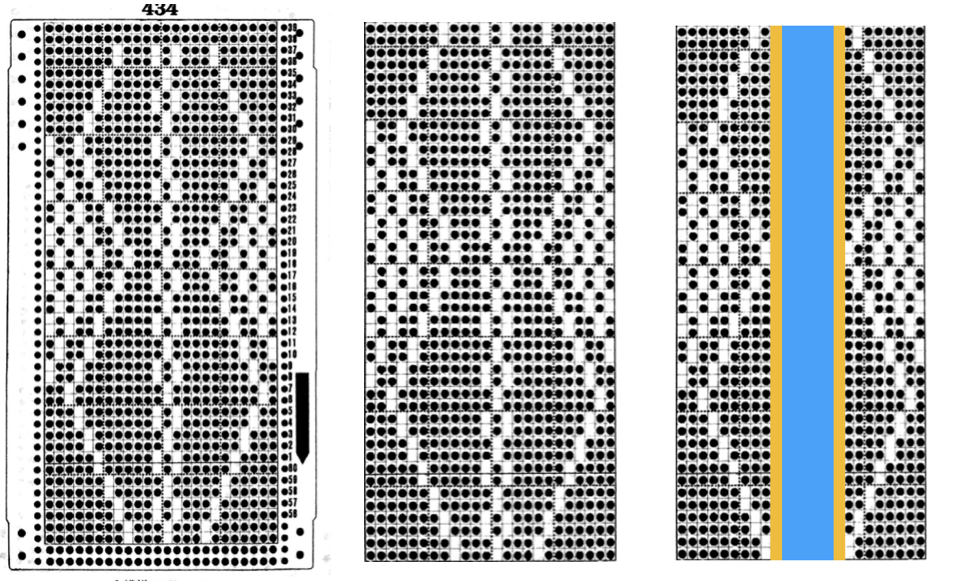

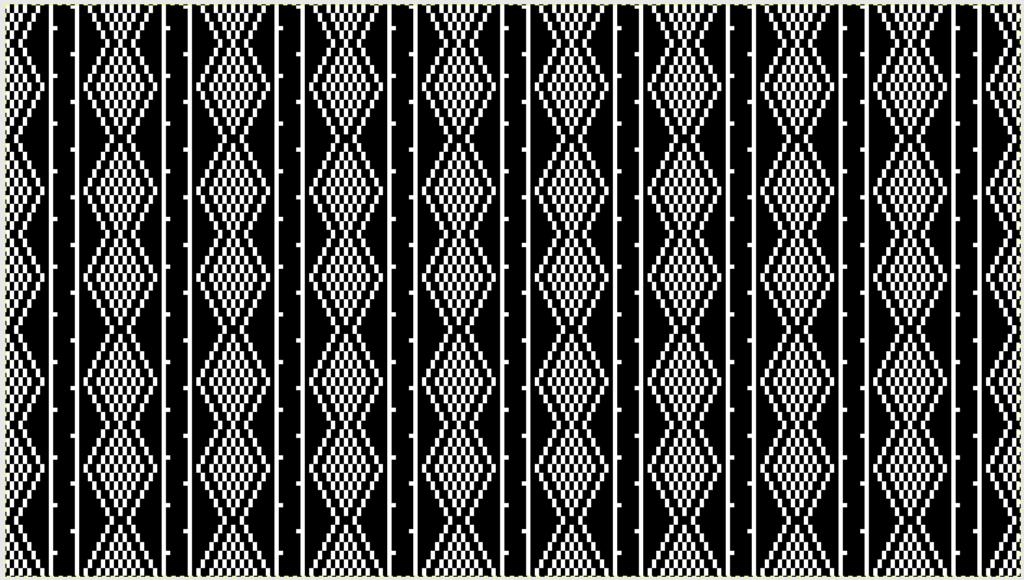

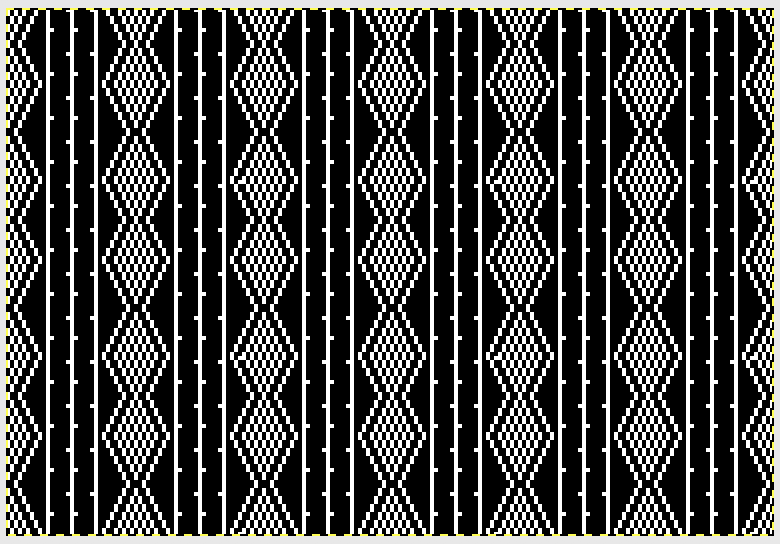

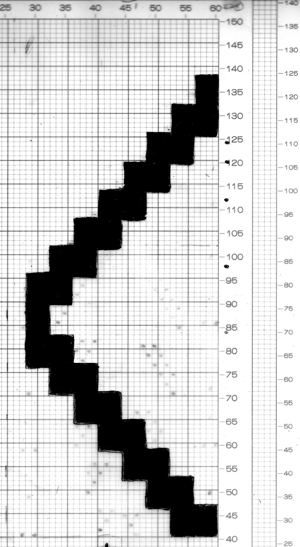

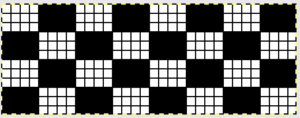

Other considerations in DIY designs. The background repeat for this pattern is actually composed of units 2 wide by 4 rows high. If the pattern is intended to be repeated across a larger number of stitches on the machine bed than that in the chart, it is always worth tiling the image to pick up any errors (sometimes happy design features). Tiling in width readily shows an error

Other considerations in DIY designs. The background repeat for this pattern is actually composed of units 2 wide by 4 rows high. If the pattern is intended to be repeated across a larger number of stitches on the machine bed than that in the chart, it is always worth tiling the image to pick up any errors (sometimes happy design features). Tiling in width readily shows an error  tiling in height as well proofs row intersections as well

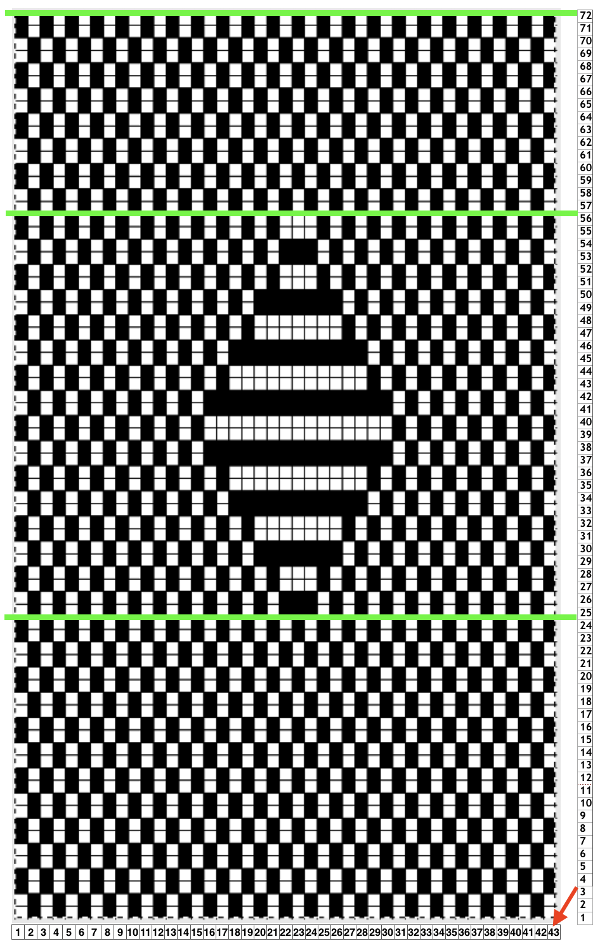

tiling in height as well proofs row intersections as well  tiling the corrected width repeat, now 42 stitches wide by 72 rows high

tiling the corrected width repeat, now 42 stitches wide by 72 rows high sometimes tend not to keep immediate notes when I test ideas, which often comes with a price. I knit my first swatch using this repeat beginning the pattern with 2 rows of tuck, resulting in this fabric (and some randomly dropped stitches once more) with the same color diamond on both sides:

sometimes tend not to keep immediate notes when I test ideas, which often comes with a price. I knit my first swatch using this repeat beginning the pattern with 2 rows of tuck, resulting in this fabric (and some randomly dropped stitches once more) with the same color diamond on both sides:  Beginning the pattern with 2 rows of slip stitch on the main bed only mirrors the swatch at the start of this post. Where no needles are selected on the main bed, with passes of the combined carriages, two rows of tuck will now be produced, resulting in the wider geometric shapes and the increased bleed through

Beginning the pattern with 2 rows of slip stitch on the main bed only mirrors the swatch at the start of this post. Where no needles are selected on the main bed, with passes of the combined carriages, two rows of tuck will now be produced, resulting in the wider geometric shapes and the increased bleed through

The tuck loops created by the white in this instance have the elongated slip stitches in the alternate color (blue) partially covering them, creating the darker geometric shape in the top detail photo. The blue is thinner than the white, the effect will vary depending on yarn weight and tension used for the main bed yarn. One can begin to observe the change in width in areas with more stitches tucking.

The tuck loops created by the white in this instance have the elongated slip stitches in the alternate color (blue) partially covering them, creating the darker geometric shape in the top detail photo. The blue is thinner than the white, the effect will vary depending on yarn weight and tension used for the main bed yarn. One can begin to observe the change in width in areas with more stitches tucking. 22 stitch shift results in a “correct” all over repeat

22 stitch shift results in a “correct” all over repeat

![]()

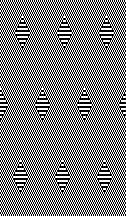

scaled to double length, 24 stitches wide by 56 rows high

scaled to double length, 24 stitches wide by 56 rows high ![]()

a tile test of the new pattern

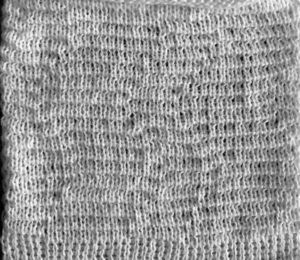

a tile test of the new pattern  The ribber remains set for knitting in both directions throughout, with the main bed set to tuck in both directions.

The ribber remains set for knitting in both directions throughout, with the main bed set to tuck in both directions. Better stitch formation results with the different yarn used for the second color

Better stitch formation results with the different yarn used for the second color

an “improved” version, the choice remaining as to whether to make all the blue shapes pointed at top and bottom or “flat”

an “improved” version, the choice remaining as to whether to make all the blue shapes pointed at top and bottom or “flat”

this is my repeat, tiled. It is 14 stitches by 84 rows

this is my repeat, tiled. It is 14 stitches by 84 rows  The single 14X84 png

The single 14X84 png ![]()

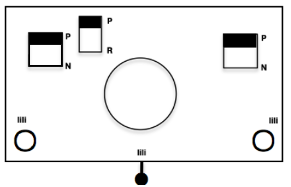

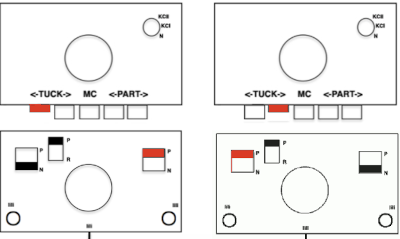

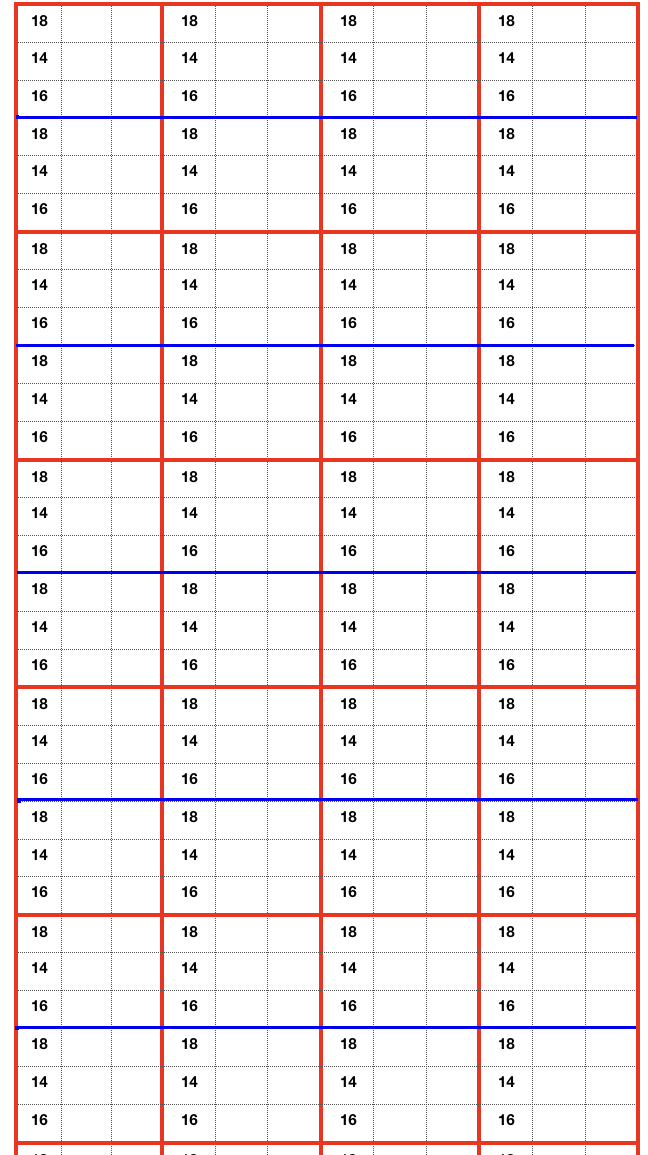

Each of the 2 colors tucks for 2 rows and in turn, knits for 2 rows alternately. Settings are changed manually as shown below after every 2 rows knit, following each color change on the left.

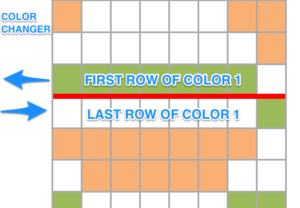

Each of the 2 colors tucks for 2 rows and in turn, knits for 2 rows alternately. Settings are changed manually as shown below after every 2 rows knit, following each color change on the left.  Making things a little easier: the top bed may be programmed on any machine, including punchcard models to avoid cam button changes in the knit carriage every 2 rows. With the main bed set to tuck <– —> throughout, black squares will knit for 2 rows, white squares will tuck, also for 2 rows. The first preselection row is toward the color changer. When no needles are selected on the top bed (white squares) the top bed will tuck every needle, the ribber is set to knit.

Making things a little easier: the top bed may be programmed on any machine, including punchcard models to avoid cam button changes in the knit carriage every 2 rows. With the main bed set to tuck <– —> throughout, black squares will knit for 2 rows, white squares will tuck, also for 2 rows. The first preselection row is toward the color changer. When no needles are selected on the top bed (white squares) the top bed will tuck every needle, the ribber is set to knit.

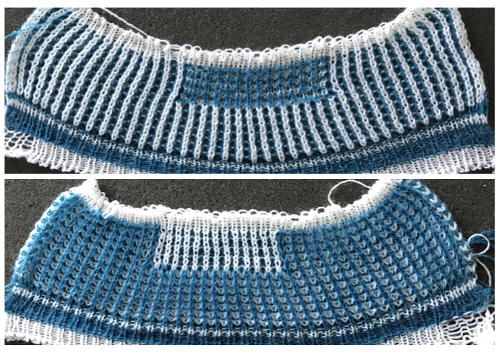

Another attempt at cabling, 1X1 and 2X2. That white line in the bottom image on the right was caused by the color changer picking up and knitting both colors for part of the row before I noticed it. I got rid of the “wrong” color from the feeder and continued on. The wider 2X2 cables require “special handling” and eyelets are formed on columns aside from them after transfers are made.

Another attempt at cabling, 1X1 and 2X2. That white line in the bottom image on the right was caused by the color changer picking up and knitting both colors for part of the row before I noticed it. I got rid of the “wrong” color from the feeder and continued on. The wider 2X2 cables require “special handling” and eyelets are formed on columns aside from them after transfers are made.

The situation is different when working on single bed vertically striped fair isle designs. One of my ancient machine-knit demo FI swatches:

The situation is different when working on single bed vertically striped fair isle designs. One of my ancient machine-knit demo FI swatches:

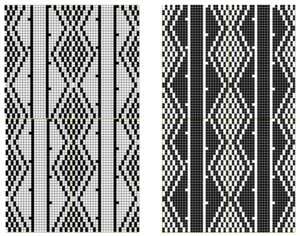

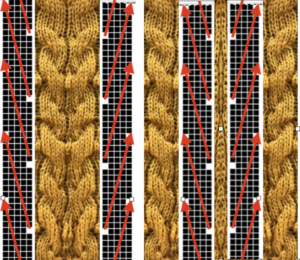

The charted repeat on the left below when tiled shows the area of a patterning error, on the right with the missing blank rows added the problem is shown to be resolved, the repeat is now 24 X 84.

The charted repeat on the left below when tiled shows the area of a patterning error, on the right with the missing blank rows added the problem is shown to be resolved, the repeat is now 24 X 84.

Adding complexity, there is the possibility of

Adding complexity, there is the possibility of

Other related fabrics may be found in posts:

Other related fabrics may be found in posts:

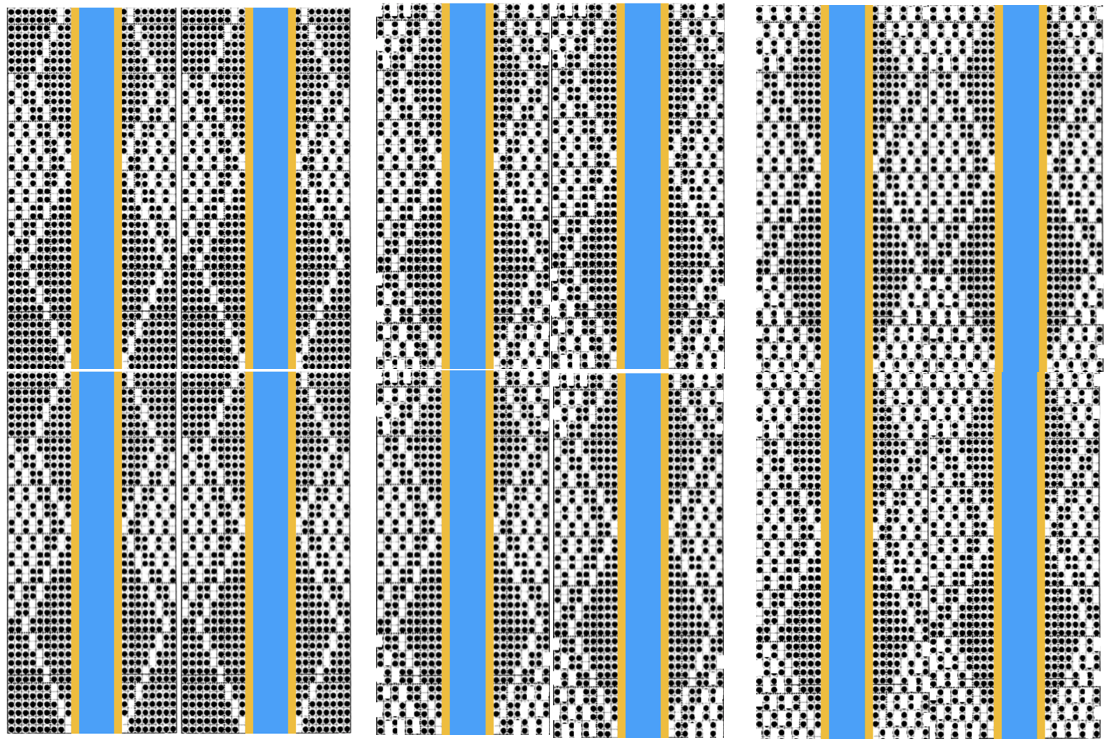

The card is cropped to the 24 X 44 stitch in width and height for the repeat to be worked in electronics. The area colored blue on the far right indicates possible all knit rows for hooking up “cables” during knitting, mustard color indicates ladders created by an out of work needle on each side of the central, all knit column. The ladders make it easier to identify each all knit column. The tape over holes idea does not work for masking a punchcard since that blue area would need to be all punched holes. The tape over would result in “unpunched” ones.

The card is cropped to the 24 X 44 stitch in width and height for the repeat to be worked in electronics. The area colored blue on the far right indicates possible all knit rows for hooking up “cables” during knitting, mustard color indicates ladders created by an out of work needle on each side of the central, all knit column. The ladders make it easier to identify each all knit column. The tape over holes idea does not work for masking a punchcard since that blue area would need to be all punched holes. The tape over would result in “unpunched” ones. This takes the revised card single repeat and indicates some quick possibilities for altering it

This takes the revised card single repeat and indicates some quick possibilities for altering it

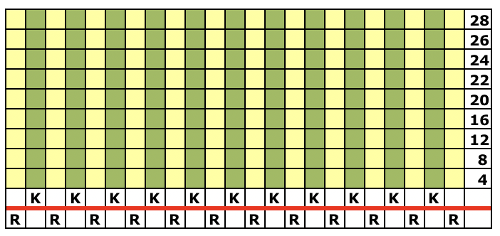

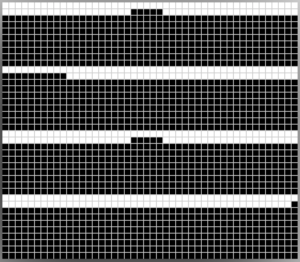

The plan is to automate the texture, knit it in one color, and find a way to track correct racking positions: cast on may be in any preferred method. With the pitch set to P, it is easier to transfer stitches between beds to the desired configuration. Every needle is in work on the top bed, for a multiple of 10+6

The plan is to automate the texture, knit it in one color, and find a way to track correct racking positions: cast on may be in any preferred method. With the pitch set to P, it is easier to transfer stitches between beds to the desired configuration. Every needle is in work on the top bed, for a multiple of 10+6

start needle design

start needle design

the image resulting from my own past color separation

the image resulting from my own past color separation

the pattern book swatch image

the pattern book swatch image tuck swatch

tuck swatch

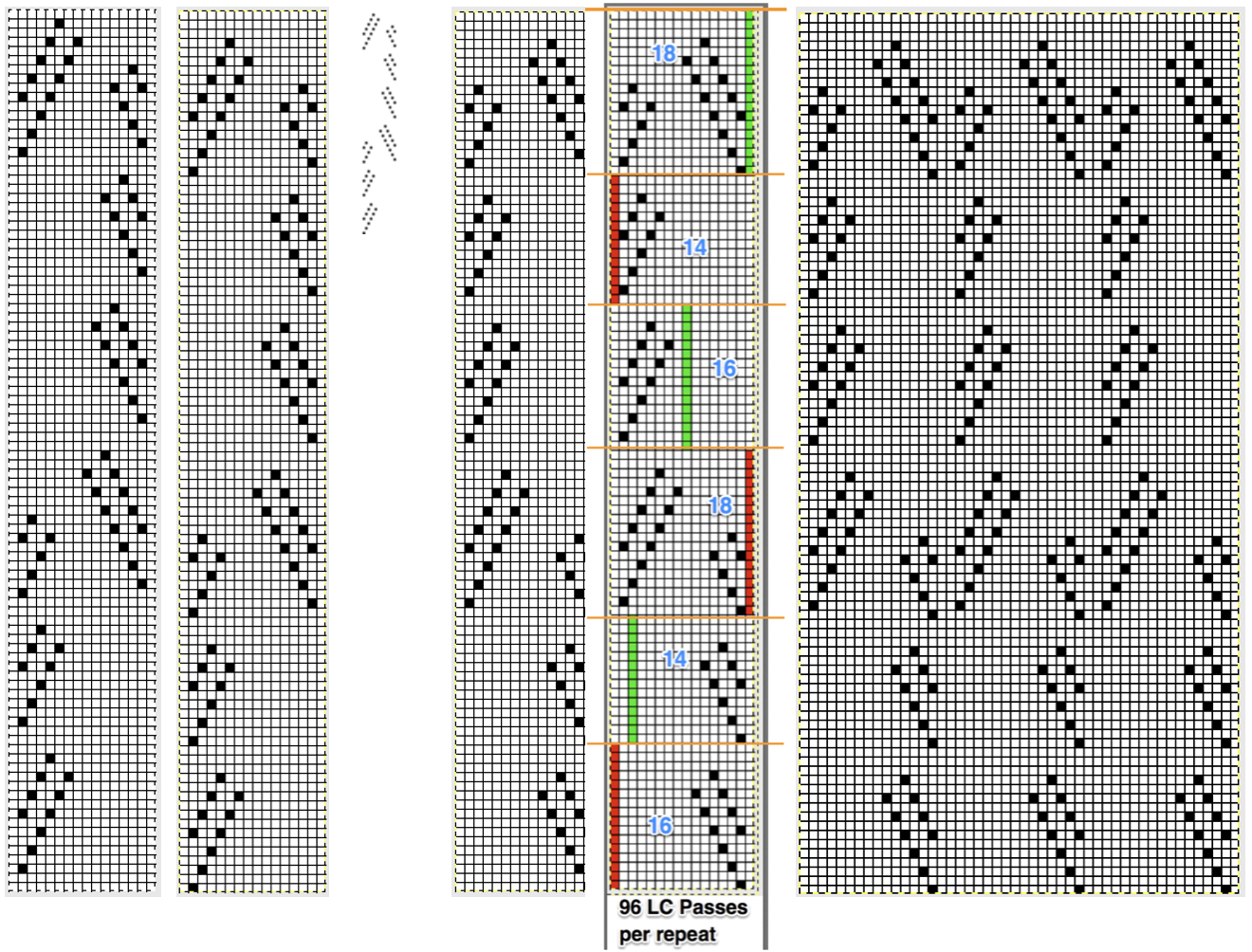

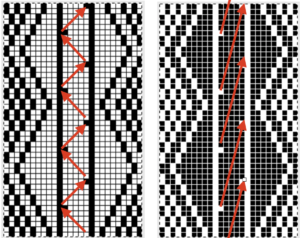

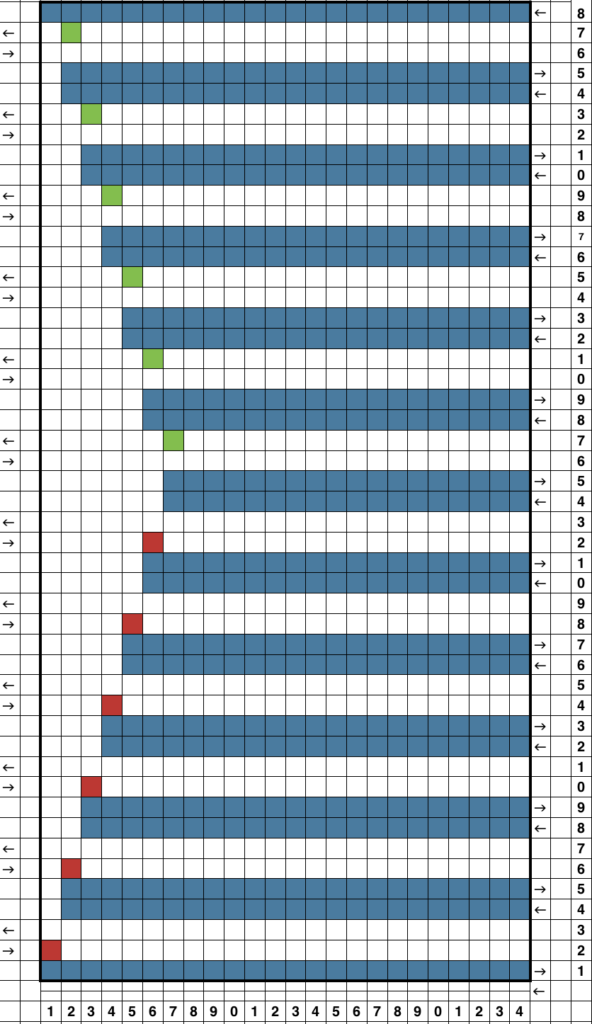

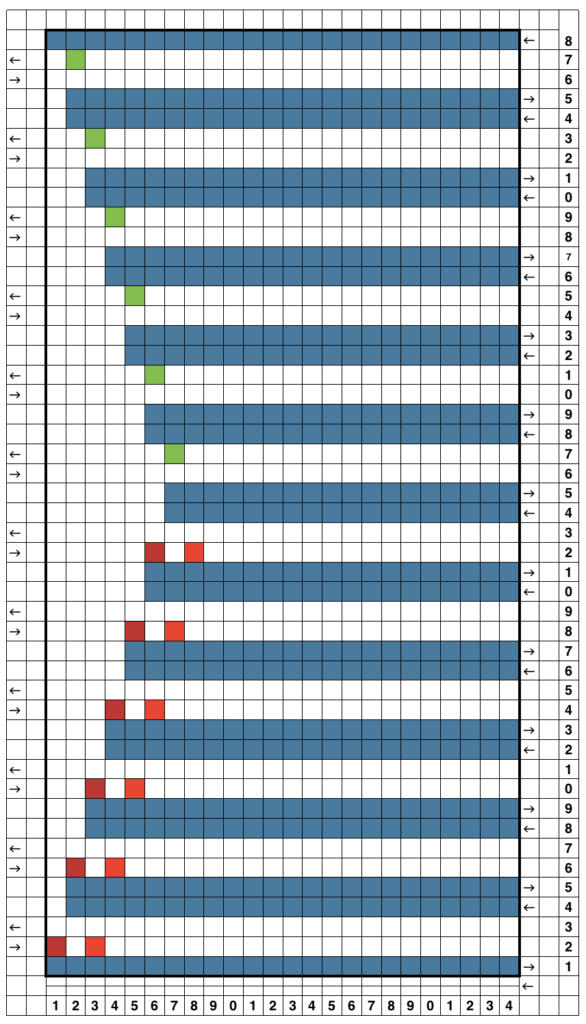

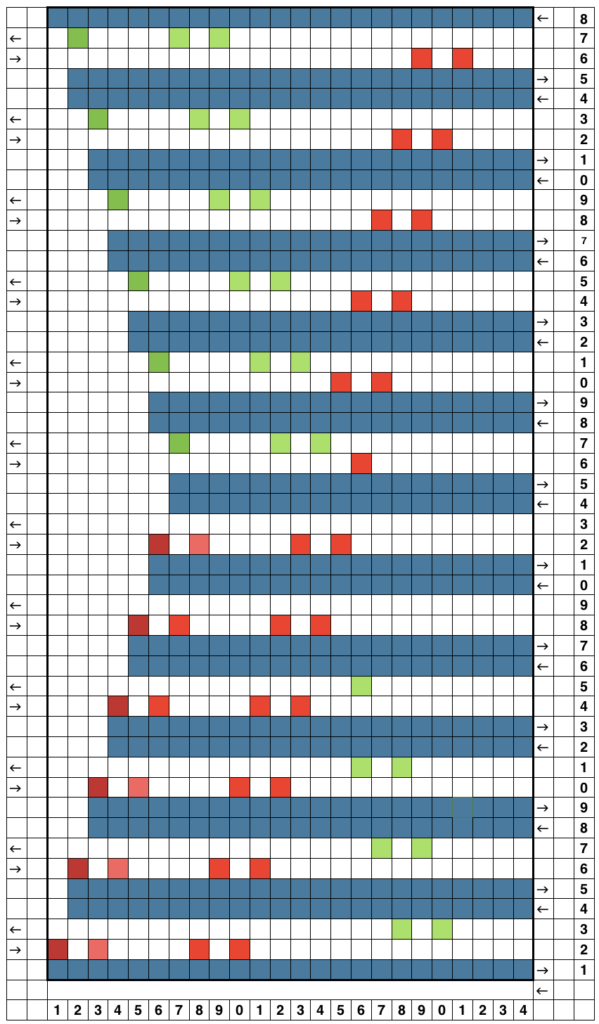

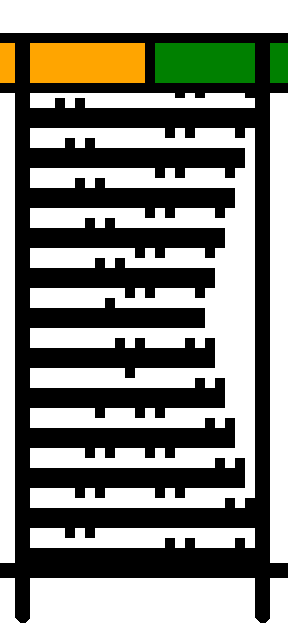

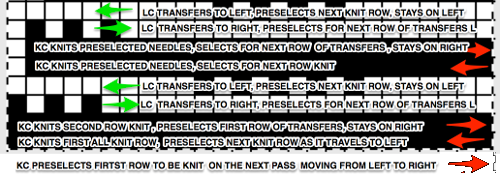

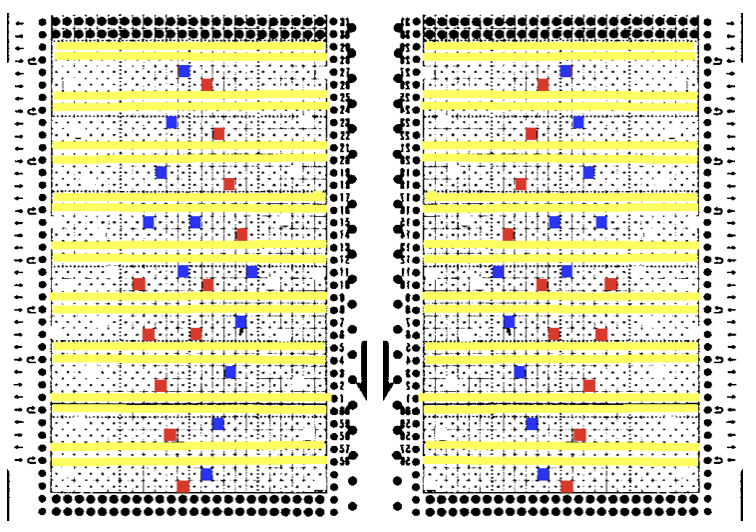

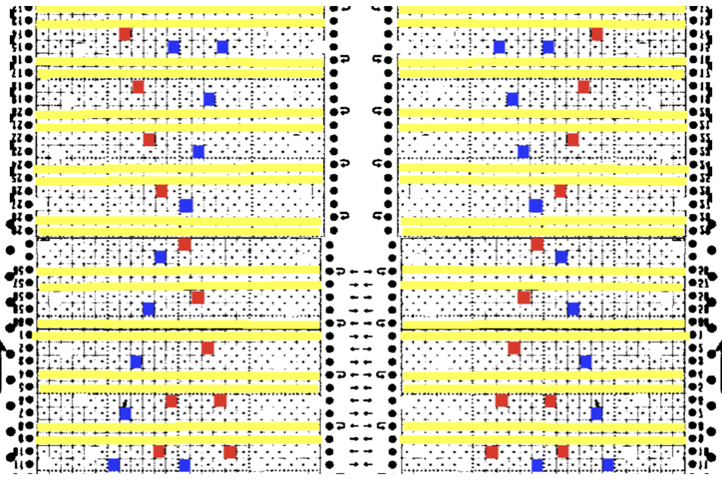

Arrows indicate the movement of the lace carriage on left, knit carriage on right. Red squares now represent transfers to right, green ones transfer to left

Arrows indicate the movement of the lace carriage on left, knit carriage on right. Red squares now represent transfers to right, green ones transfer to left

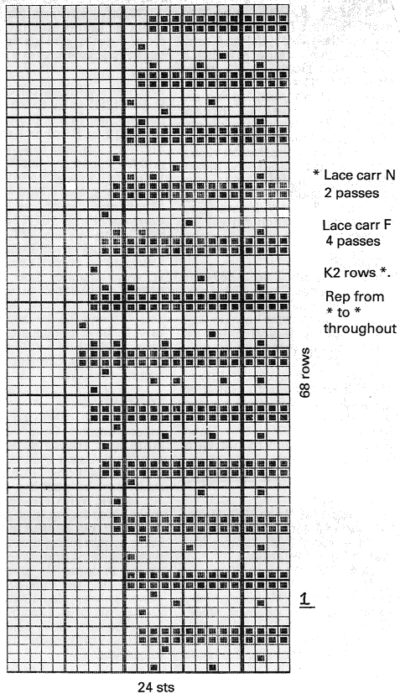

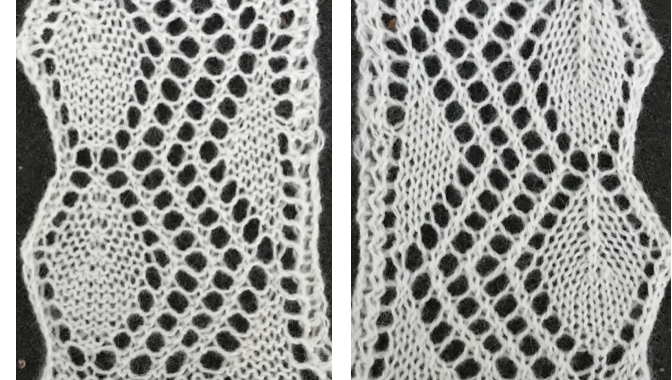

Going back to the wheel that has already been invented, how can pre-drawn published MK lace repeats be used instead of “winging it” endlessly or not having the confidence to perform the necessary assigning symbols and proceeding with the required separation? Still trying to work with a pattern that knits for 2 rows, transfers for 2, a chart from Stitch World:

Going back to the wheel that has already been invented, how can pre-drawn published MK lace repeats be used instead of “winging it” endlessly or not having the confidence to perform the necessary assigning symbols and proceeding with the required separation? Still trying to work with a pattern that knits for 2 rows, transfers for 2, a chart from Stitch World:

For pngs for this reworked, more resolved repeat see

For pngs for this reworked, more resolved repeat see

Adding extra stitches knit on the right side of the original repeat made it possible for me to use my cotton again, giving me a controllable edge on that side without having to pull stitches out to make them knit.

Adding extra stitches knit on the right side of the original repeat made it possible for me to use my cotton again, giving me a controllable edge on that side without having to pull stitches out to make them knit.

I prefer to start my repeats on the full width of the repeat, this 24X70 png shifts the first segment to allow for that, still with a single all knit row start, making it suitable for non-Ayab knitting, its png is mirrored as it might be, depending on end use prior to download

I prefer to start my repeats on the full width of the repeat, this 24X70 png shifts the first segment to allow for that, still with a single all knit row start, making it suitable for non-Ayab knitting, its png is mirrored as it might be, depending on end use prior to download