Additional information may be found in previous posts on ribber adjustments and color changers

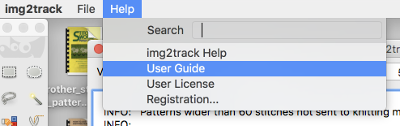

Recently I began to be curious as to how long, non-repetitive images might be handled when knitting on both Brother and Passap. The subject is not out of reach for punchcard knitters. In the early art-to-wear days when the options were for 24 or 40-stitch repeats, many artists joined punchcards in length to the desired height, and knit them in width + seam allowances, joining long panels together to form the large images, or hanging them as panels in tapestry format. One such artist was Nicky Hitz Edson. I have avoided working with such images since my bit knitter knit from screen days eons ago. Also, I always preferred DBJ variations on the Passap. I used the KRC function only in my very early Studio Electronic days, prior to acquiring the Passap or any of my Brother machines. Tools and machines available to me at present: 910 with EMS kit and Ayab software, old fashioned mylars also for the 910, an unknown capacity for accurate knitting “rehabilitated” 930 accompanied by img2track consultations for the moment with Tanya Cunningham, and Passap E6000 using technique 179.

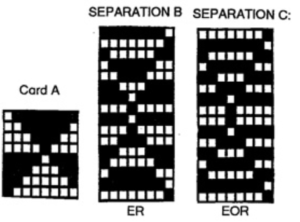

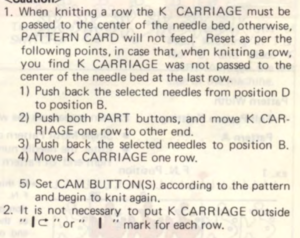

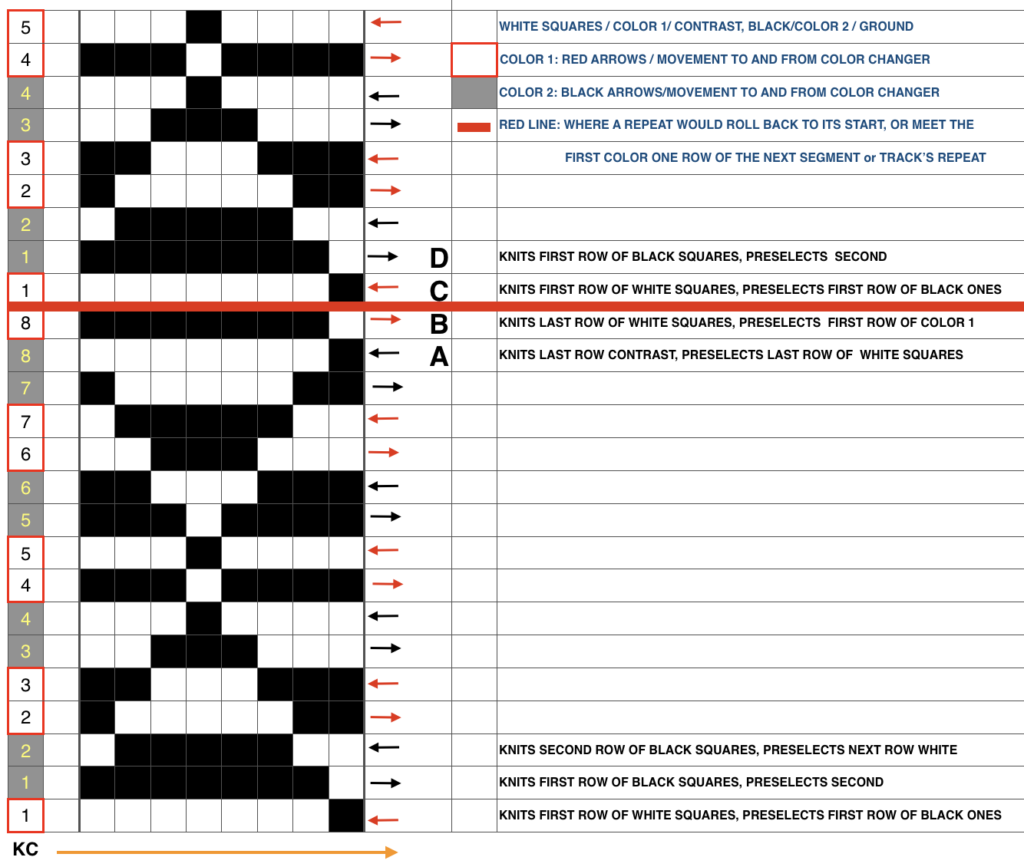

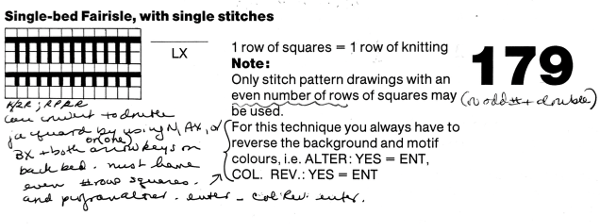

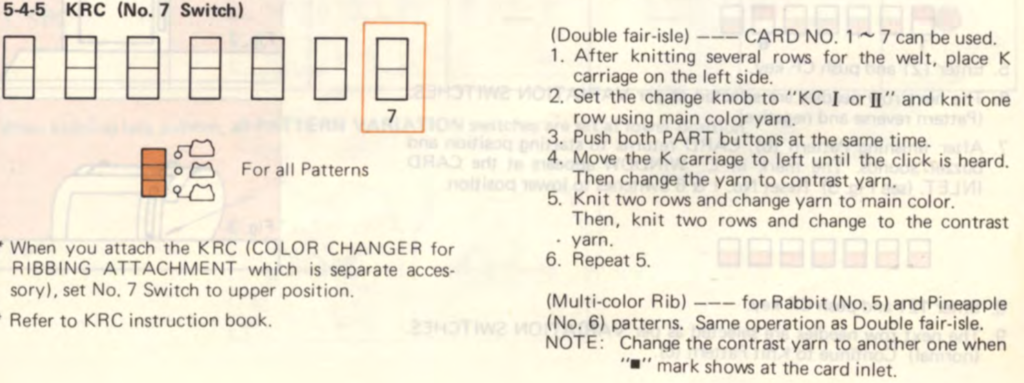

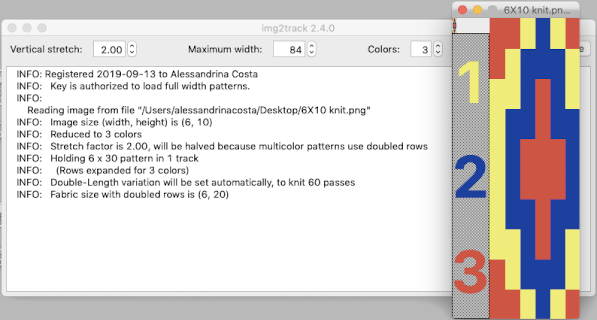

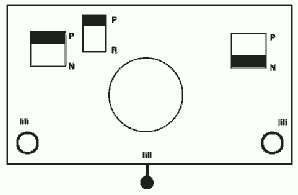

Reviewing some basics: the KRC function built into the 910 performs this separation automatically. It is the default dbj separation in Ayab and uses the built-in KRC button with img2track on the 930. Repeats must be an even number of rows in height.

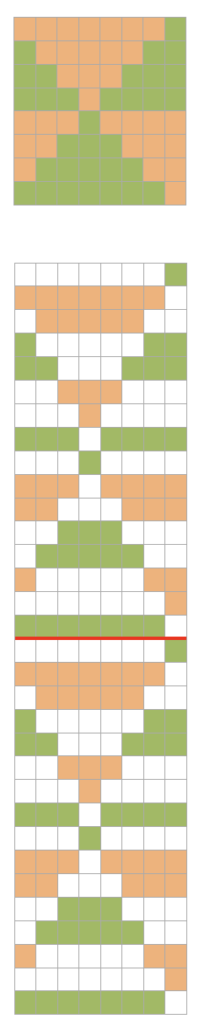

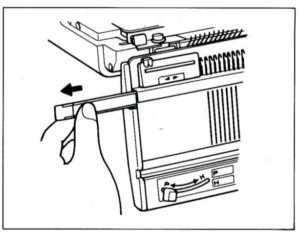

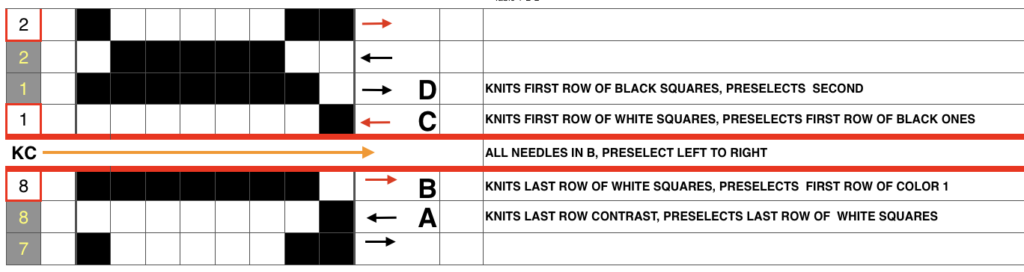

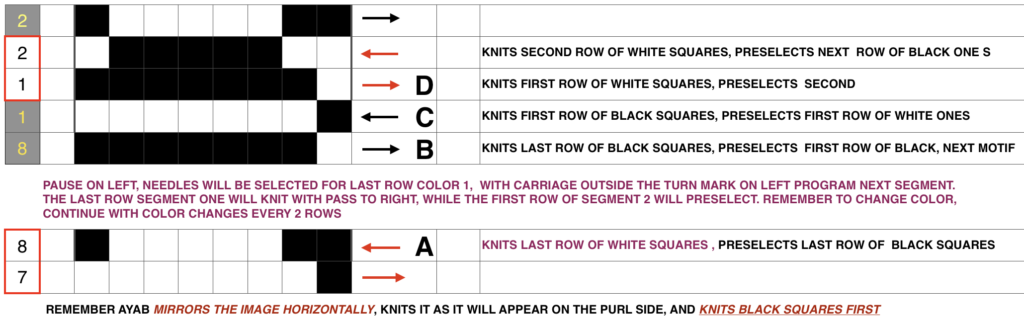

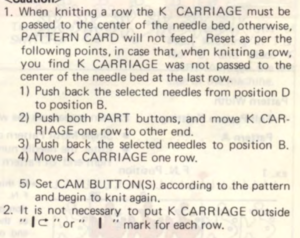

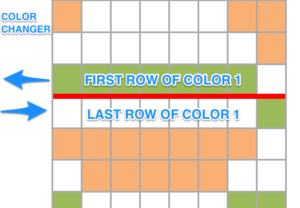

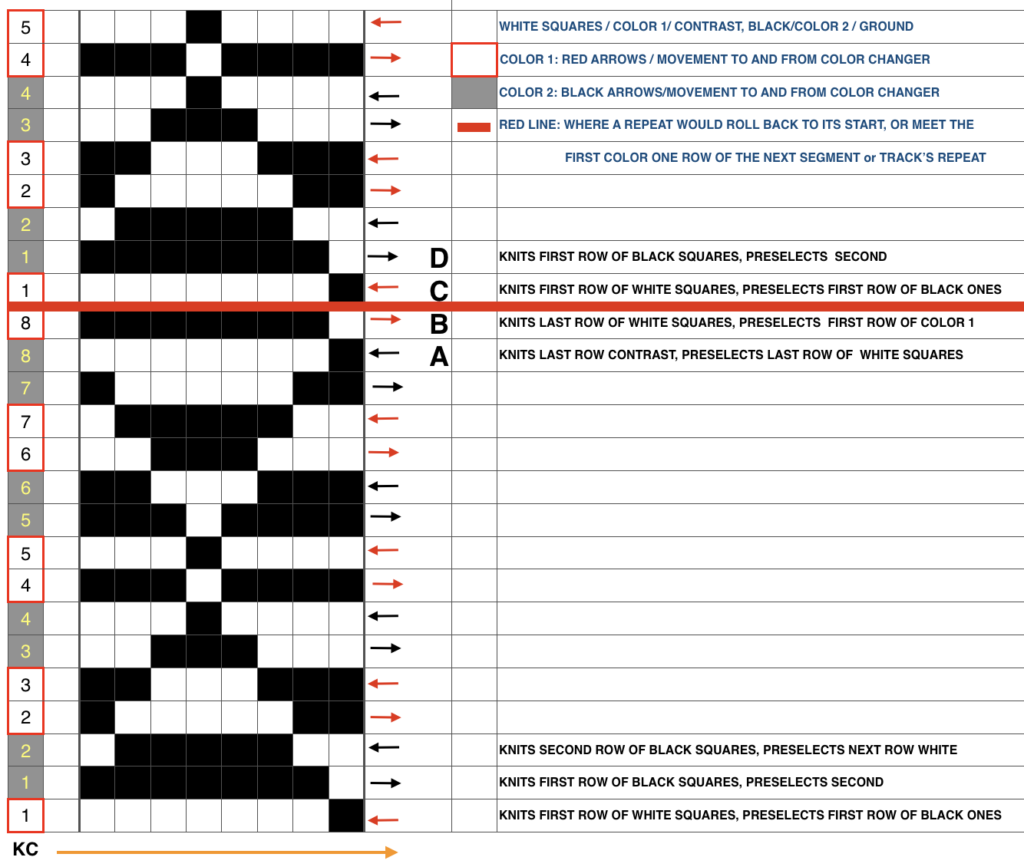

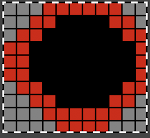

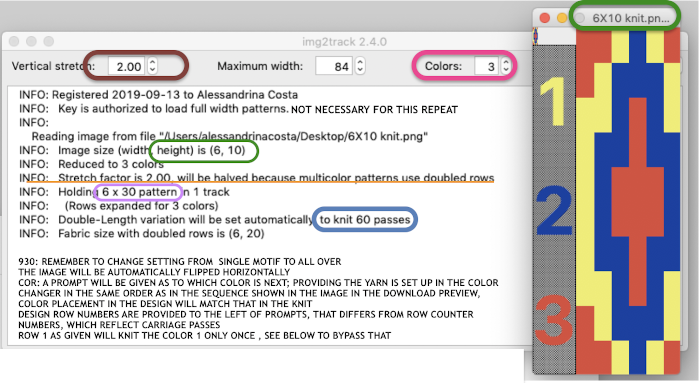

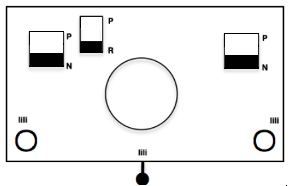

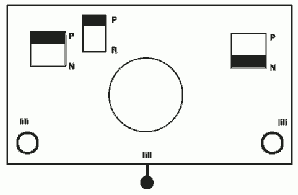

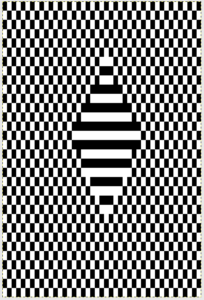

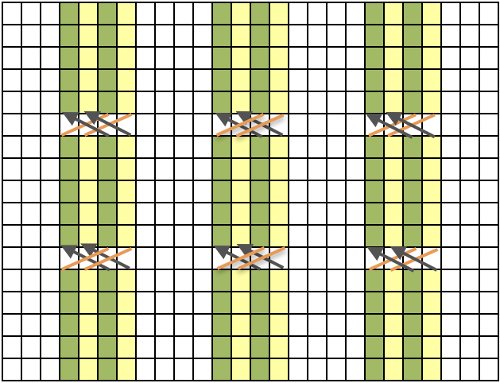

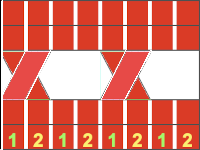

Here the simple shape illustrated in some of my previous is shown in color and repeating twice vertically. Note: the first color used knits only once, toward the color changer  This means the first preselection row needs to happen from left to right, with color knitting beginning from right to left, and subsequently every 2 rows. Pertinent reminders from the 910 manual: in any pattern knitting

This means the first preselection row needs to happen from left to right, with color knitting beginning from right to left, and subsequently every 2 rows. Pertinent reminders from the 910 manual: in any pattern knitting

and when knitting DBJ with factory mylar (or self-drawn patterns) White pixels knit first when images are drawn in black and white squares

White pixels knit first when images are drawn in black and white squares

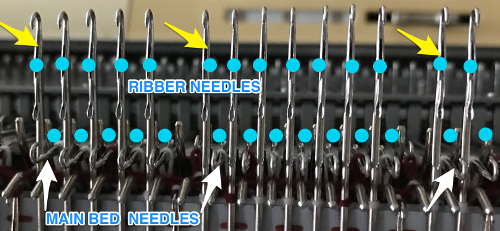

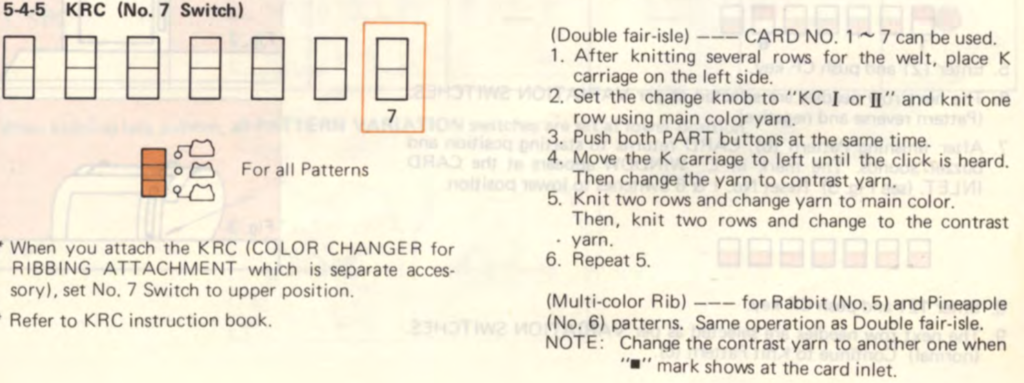

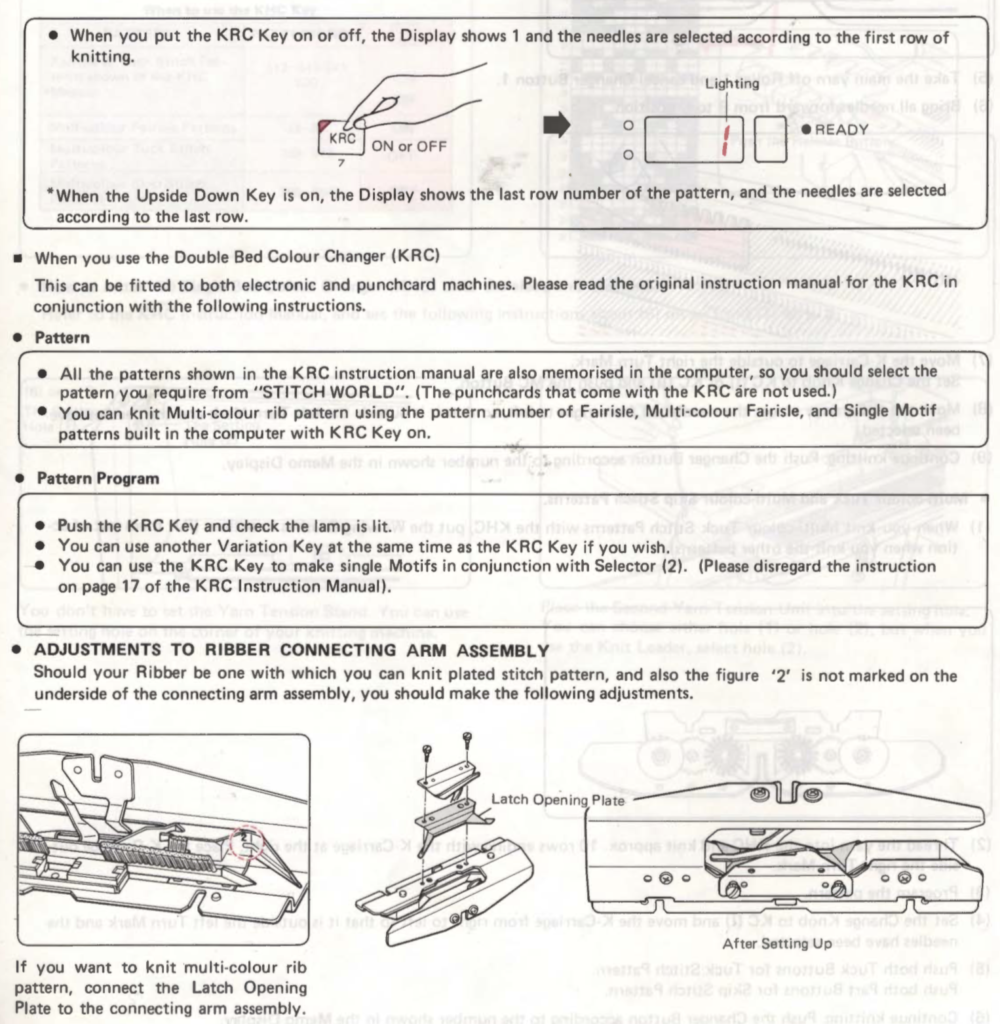

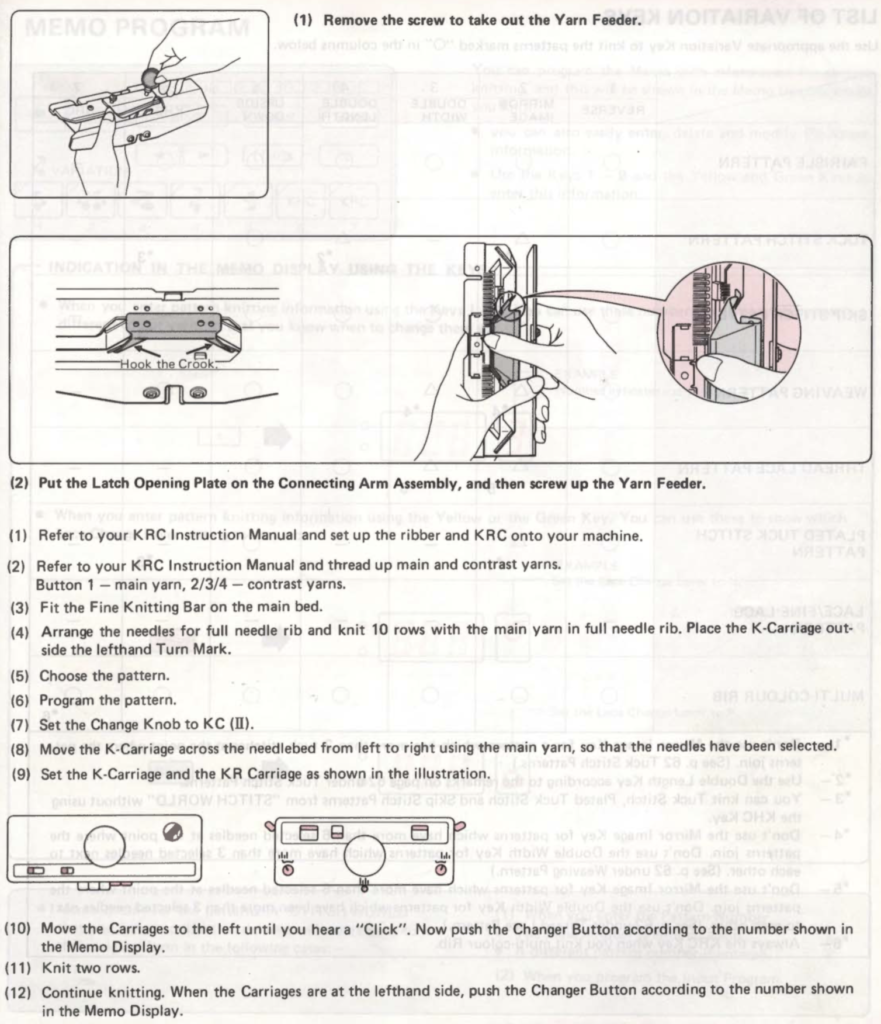

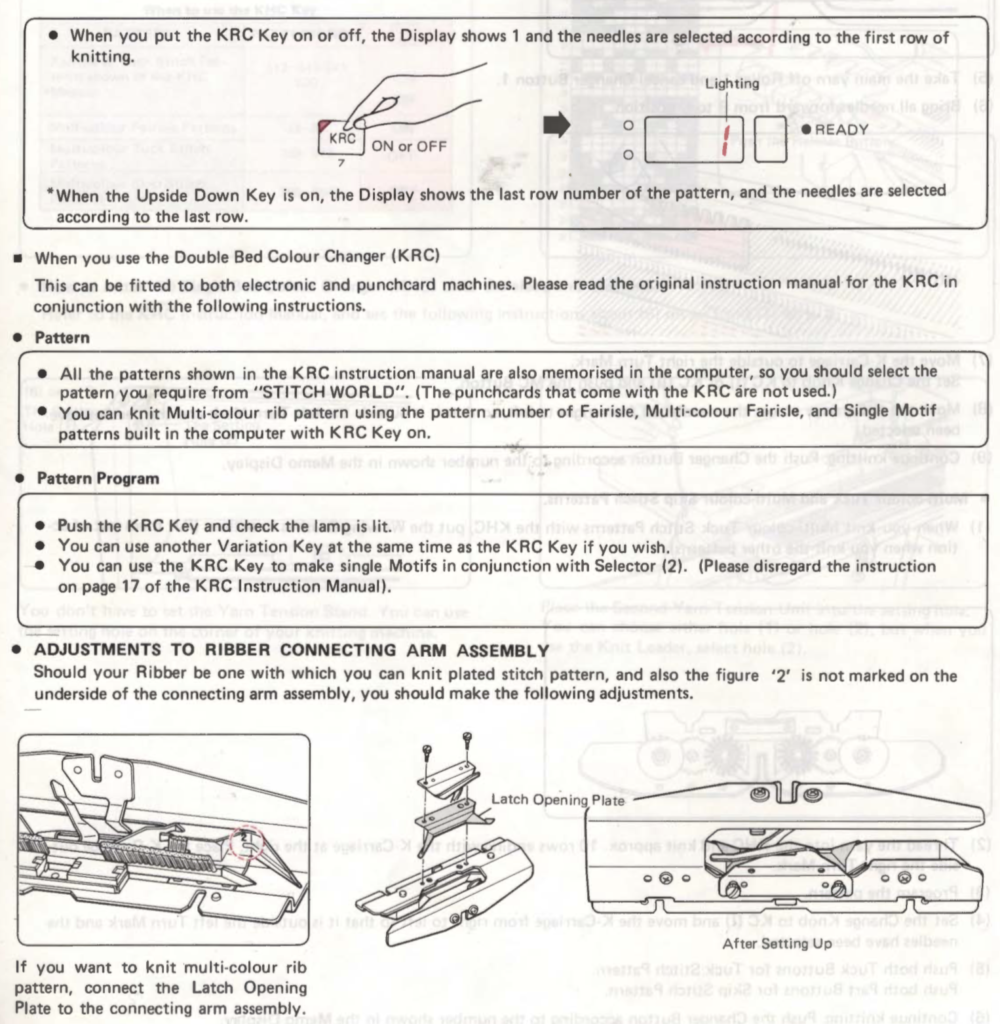

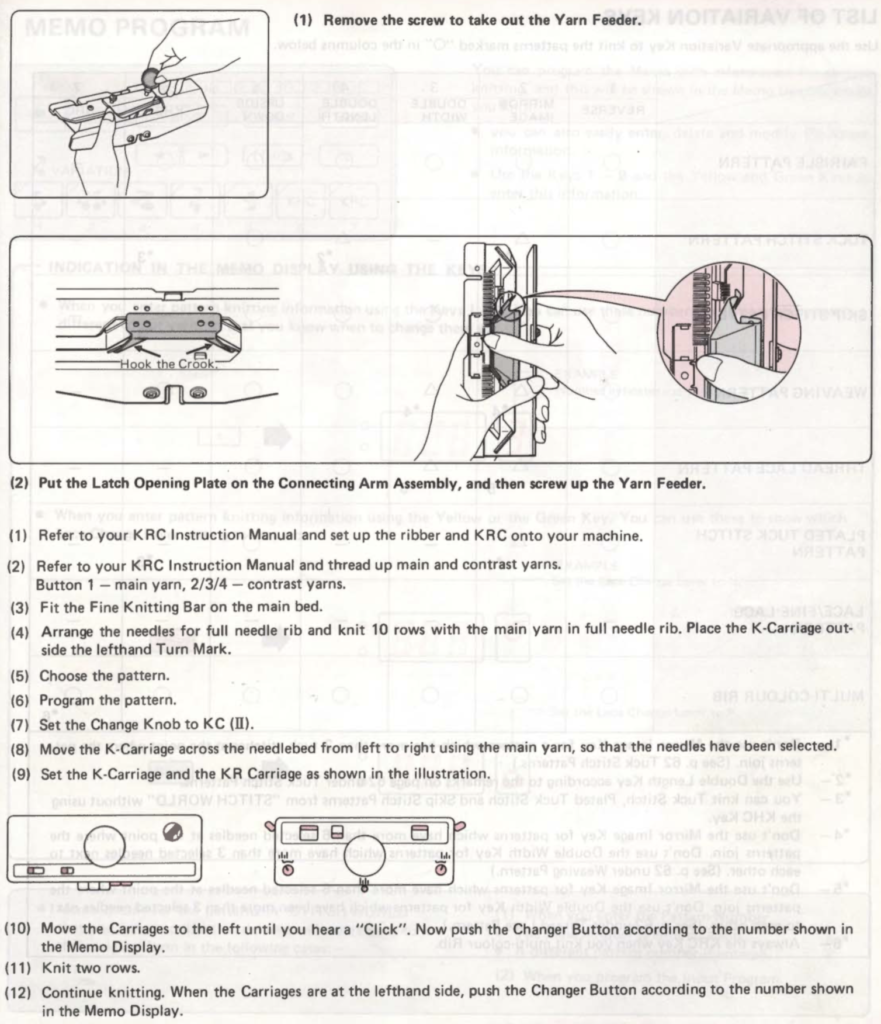

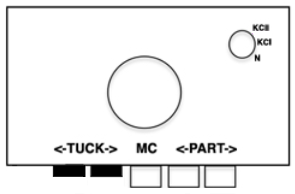

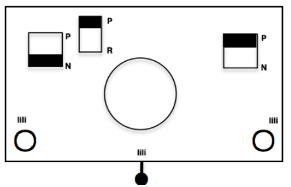

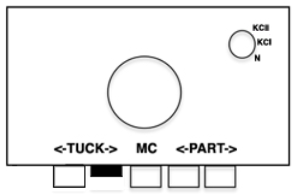

KC I or II may be used, needle arrangements can vary depending on the look one prefers on the edges. The 930_940 directions get a bit more elaborate, and show usage of an accessory “latch opening tool” (I have never used it on my 910, may have to give it a test in the future); img2track downloads to the machine’s built-in brain, the equivalent of downloading to the Passap console, which will hold the pattern program in memory until altered or erased. In re-reading manuals, I noted I have had a chronic habit since I began knitting of referring to the ribber “connecting arm” as its “sinker plate”.

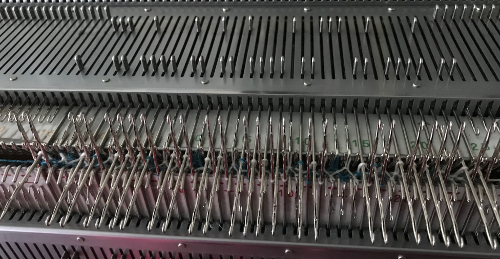

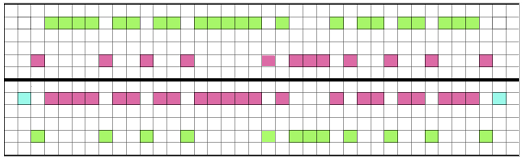

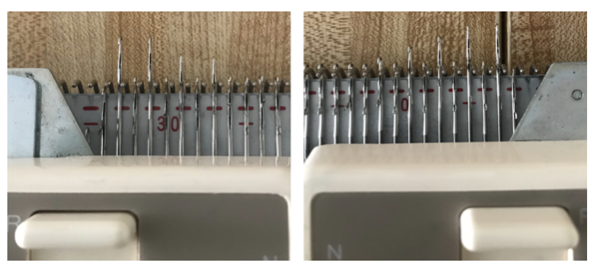

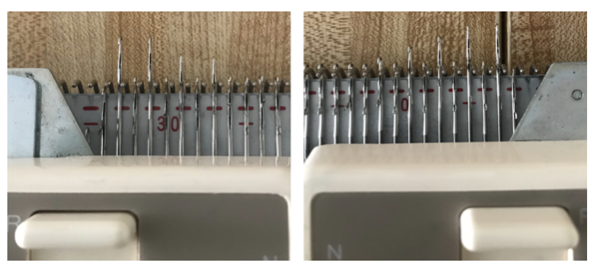

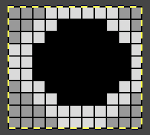

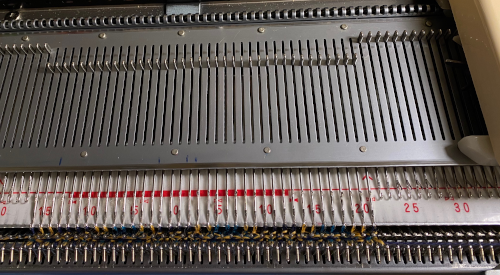

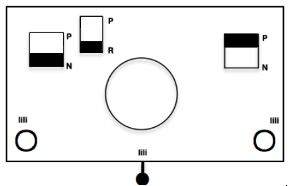

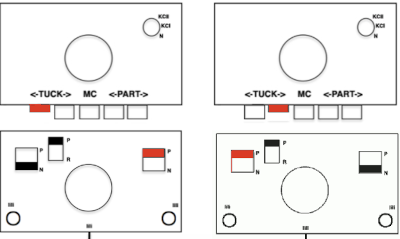

I have several sinker plates. In reference to the above, this photo illustrates the location of #2 when present vs. not

here the latch opening plate has been secured into place in the connecting arm without the #2 marking, where it makes a noticeable change, bringing the unit closer to needles when on the machine during knitting

A reminder: if the needle presser bar on the ribber (all plastic) is to be removed, it is reinserted back in with ridges facing, and flat side down

When the pattern selector is down, the pattern is centered on green #1 (right of 0). If a pattern is an odd number of stitches and the pattern limits are yellow 12 and green 13, the center is green #1. AYAB color sequence is reversed from the Brother convention of white pixels being color #1, and black pixels being color #2. It chooses black as color #1, and white as color #2. The first pass to the right is set up with the “black” yarn. The first pass to the right preselects for the first row of black squares, which will be knit on the first pass from right to left. With an odd number of needles, Ayab places the larger number of needles on the left, its orange (yellow) side.

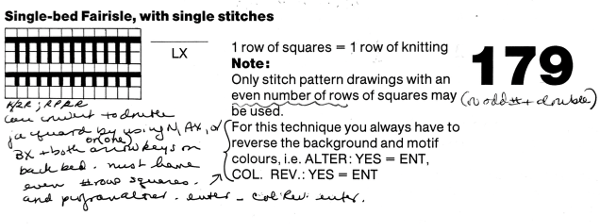

The closest relative to the KRC button in the PassapE6000 is Technique 179, intended for emulating single bed 2 color FI on Japanese machines, but it may be used with every needle rib and varied back lock settings to produce far less elongated DBJ than its standard built-in DBJ color separations. In single bed knitting GX/LX is used, for DBJ use every needle rib, and set back bed settings and pushers for desired backing (GX is the Passap equivalent of a free pass, with the bed in that setting not knitting any stitches, whether or not any needles are in use or holding yarn). The repeat must be an even number of rows in height. The instructions in the company publications are that color reverse must be used, swapping the background and motif colors. The color-changing sequence is the usual one. Both KRC and 179/ col rev knit white pixels first. When knitting a row in Brother machines the K carriage must pass the center of the needle bed, or the pattern will not advance properly. In Passap, programmed end needles for the pattern on each side must be cleared or error messages will be received, and a pattern “correction” will be required before continuing.

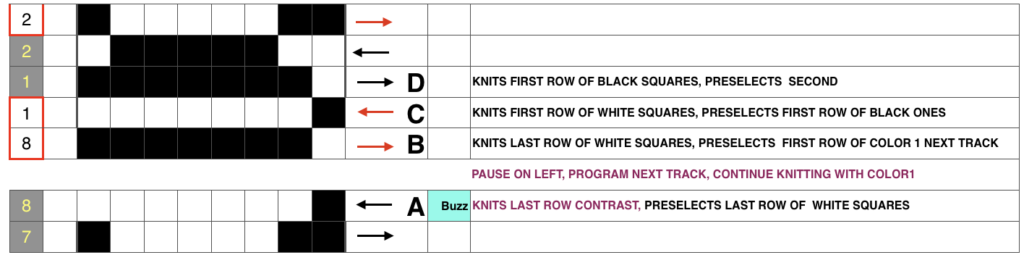

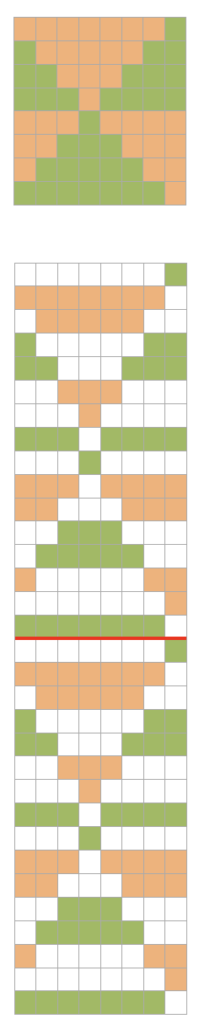

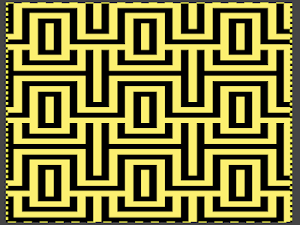

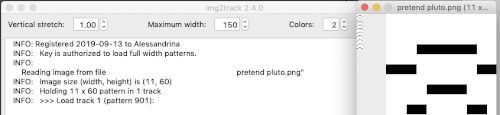

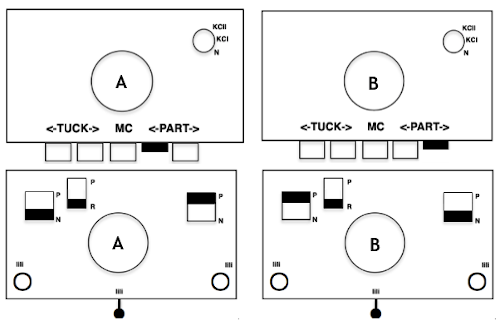

I am planning to begin by using a 2 color, large repeat factory mylar scanned and reduced to a downloadable image, details on how to in a previous post. The goal is to knit segments that are part of a continuous, “longer” image. My ultimate goal: is to knit scarves that are 70-84 stitches wide, with nonrepeating patterns for 12-1400 rows. My understanding is that such an image in img2track would be broken into tracks by the software, with each track programmed in turn as separate segments, and the software warning one when the last row for each track is reached. In Passap the segments will be entered as patterns A, B, and C, with no warnings at repeat ends, they are calculated based on math. Segments will be 30 pixels in height as “pretend” longer file components, for the sake of knitting speed.

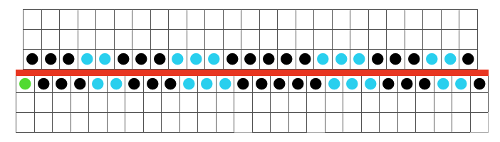

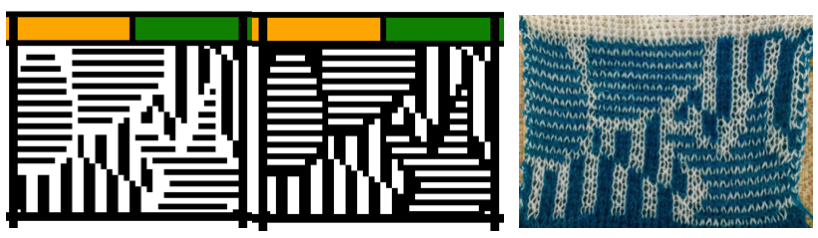

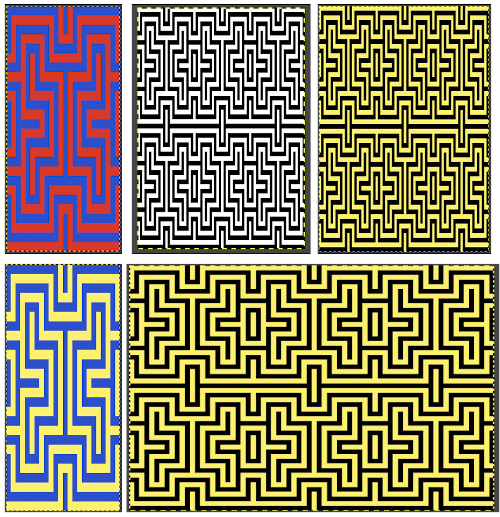

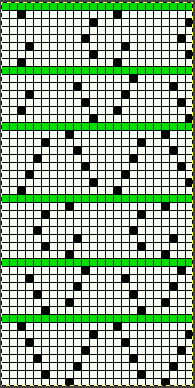

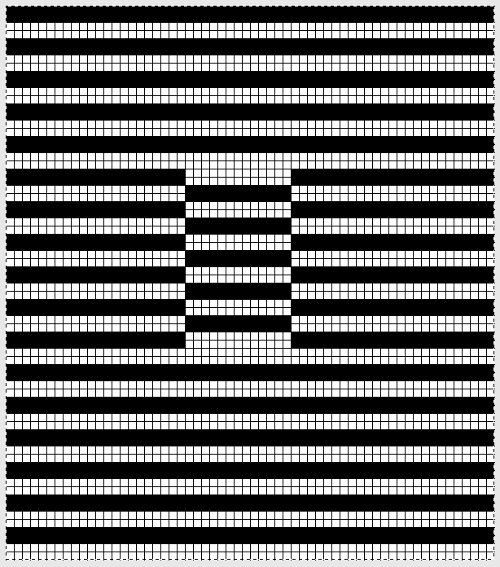

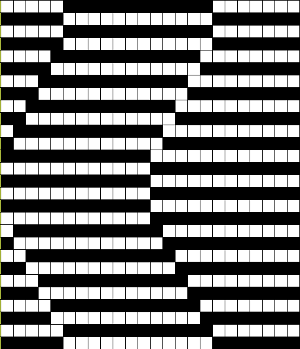

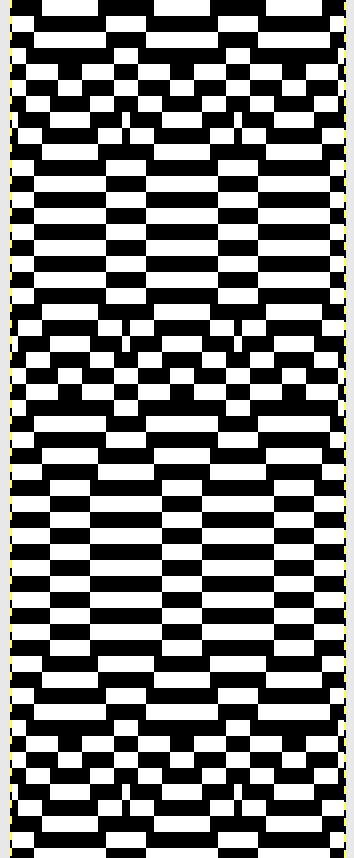

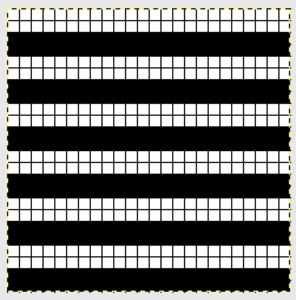

That row back to the color changer knitting row one again would show up as an error/ extra row below row 1 color 1 of the subsequent pattern.  Looking at it in terms of black and white squares, what happens the same repeats when stacked continuously above each other

Looking at it in terms of black and white squares, what happens the same repeats when stacked continuously above each other

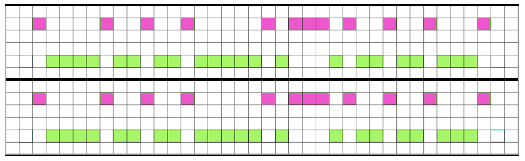

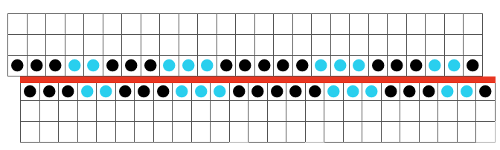

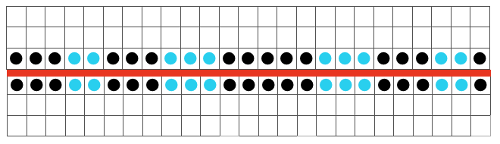

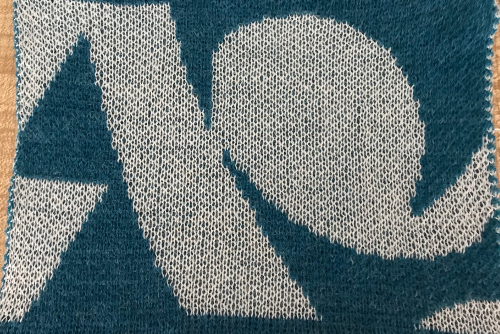

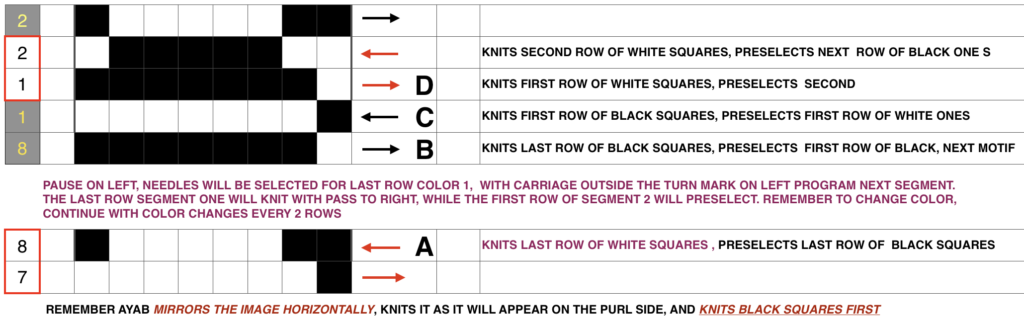

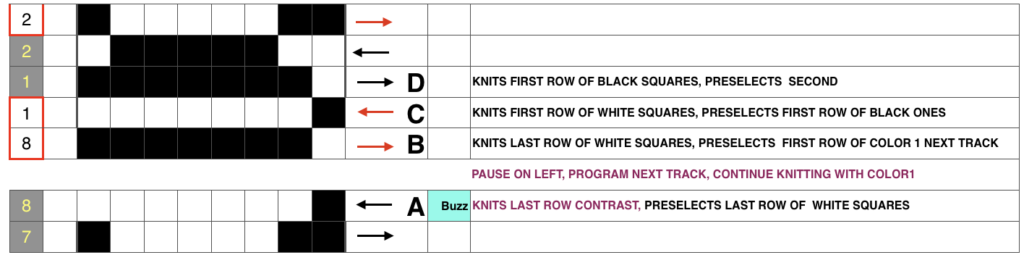

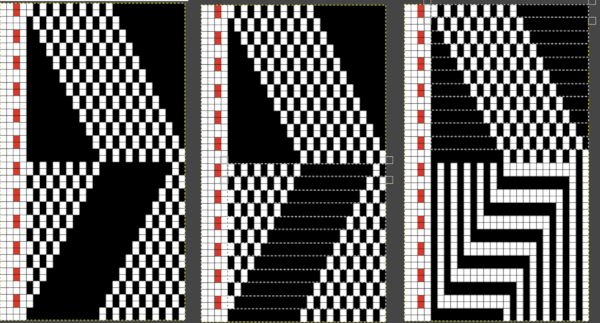

The problem comes at the intersection of the 2 different patterns; the assumption with the KRC separation is that you start with one row of color 1 opposite the color changer and if you are knitting a continuous, “looping/repeating” pattern, knit the last row of color 1 away from the color changer (B), and will start with row 1 color one again toward the color changer on the left in Brother (C). One approach is to stop knitting in pattern opposite the color changer, (red line), program the second piece of the “longer” design, and start to knit the first row of color 1 again for that pattern segment, going from right to left/ toward the color changer(C). Color changing then follows every 2 rows until the top of the second pattern piece is reached, repeating as needed.

The problem comes at the intersection of the 2 different patterns; the assumption with the KRC separation is that you start with one row of color 1 opposite the color changer and if you are knitting a continuous, “looping/repeating” pattern, knit the last row of color 1 away from the color changer (B), and will start with row 1 color one again toward the color changer on the left in Brother (C). One approach is to stop knitting in pattern opposite the color changer, (red line), program the second piece of the “longer” design, and start to knit the first row of color 1 again for that pattern segment, going from right to left/ toward the color changer(C). Color changing then follows every 2 rows until the top of the second pattern piece is reached, repeating as needed.

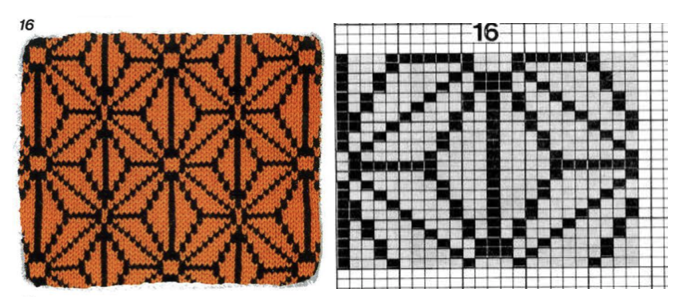

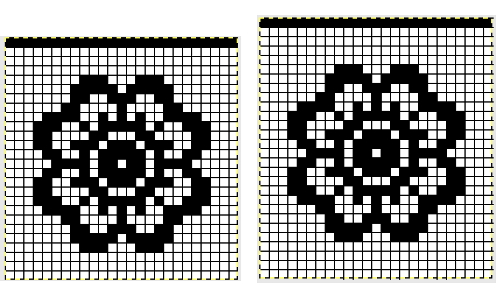

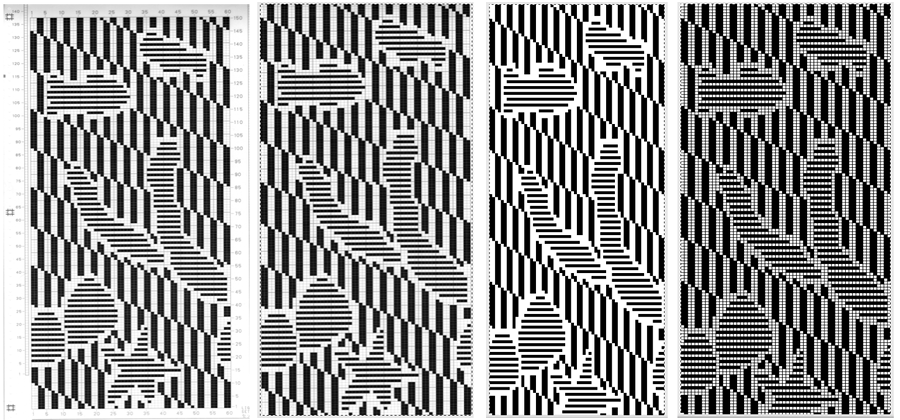

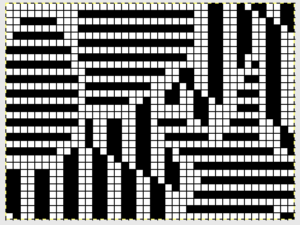

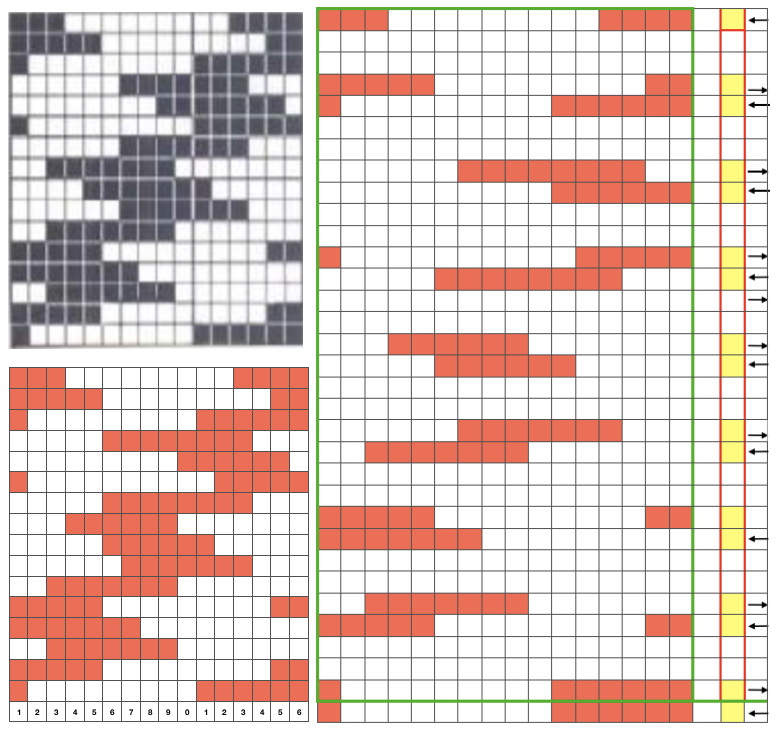

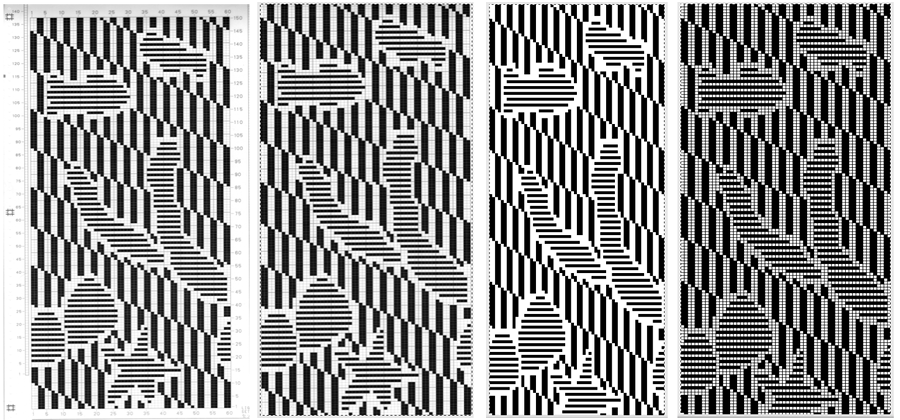

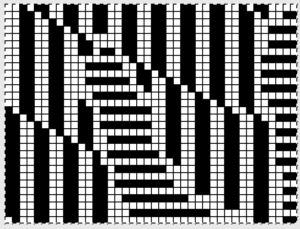

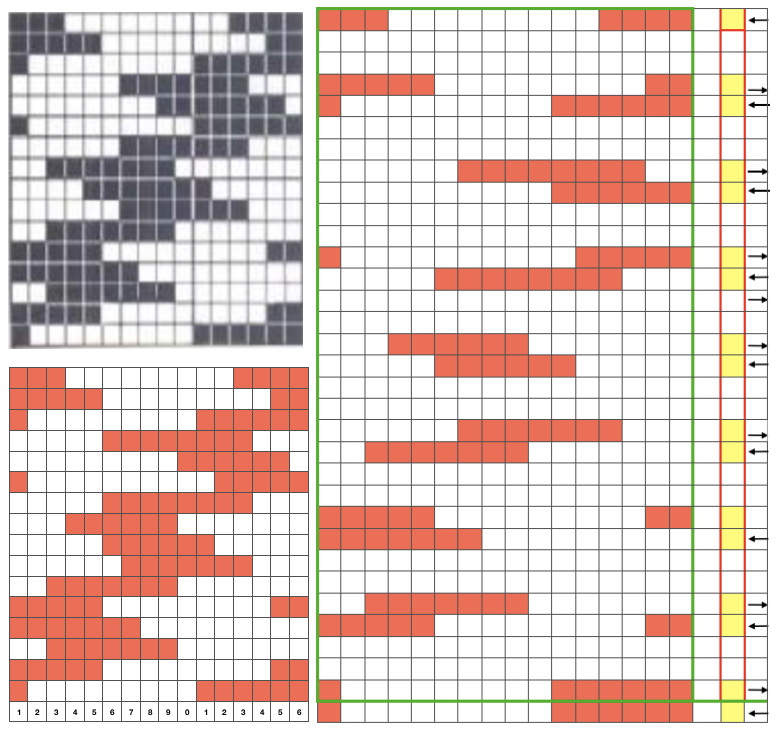

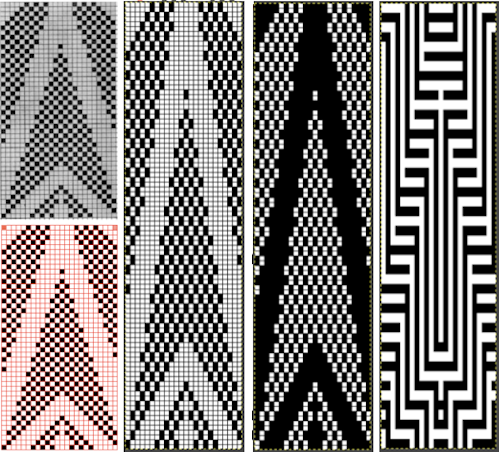

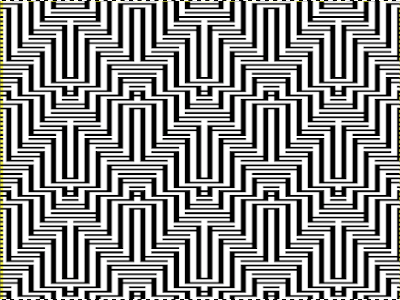

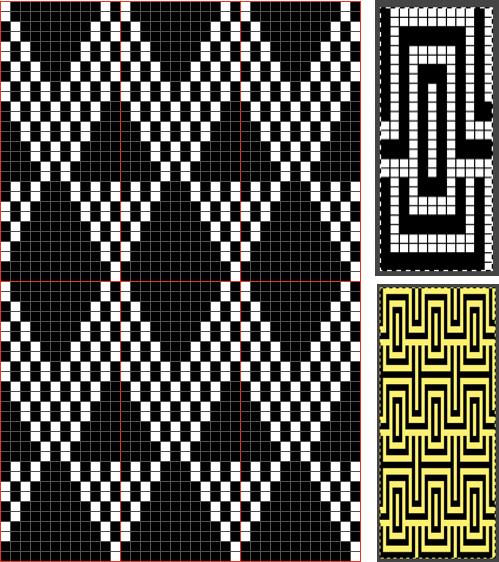

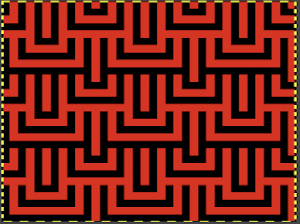

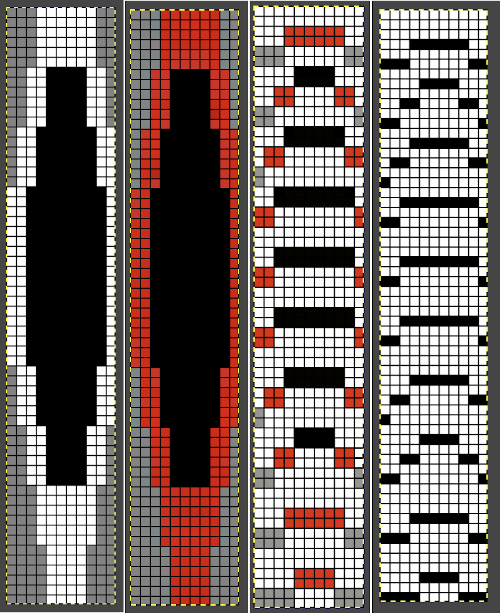

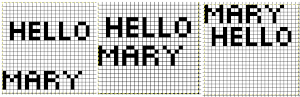

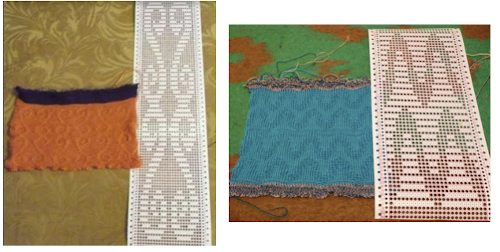

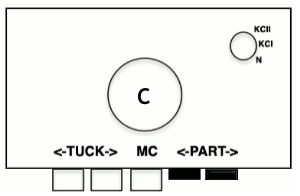

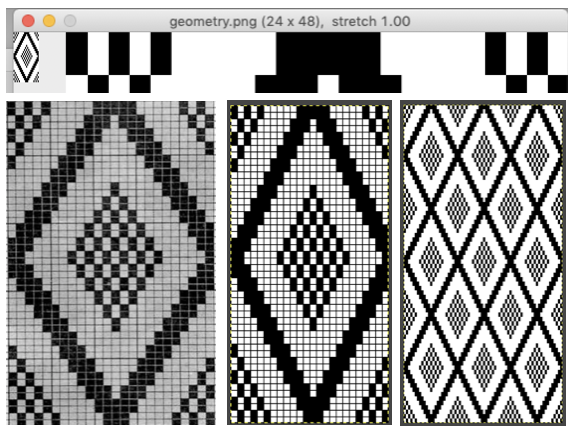

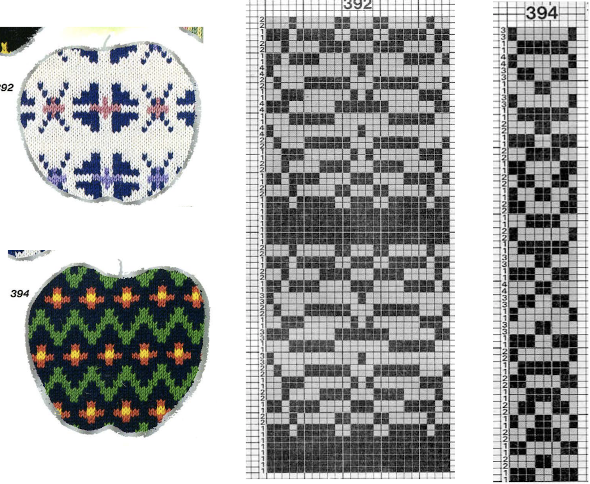

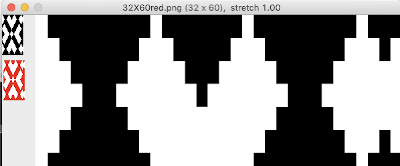

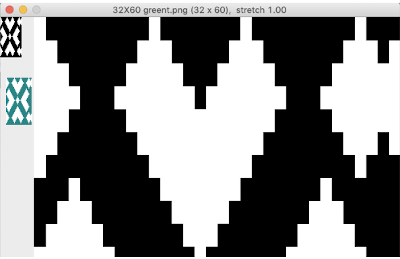

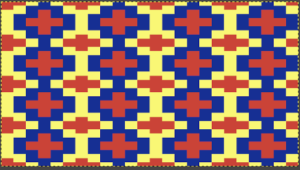

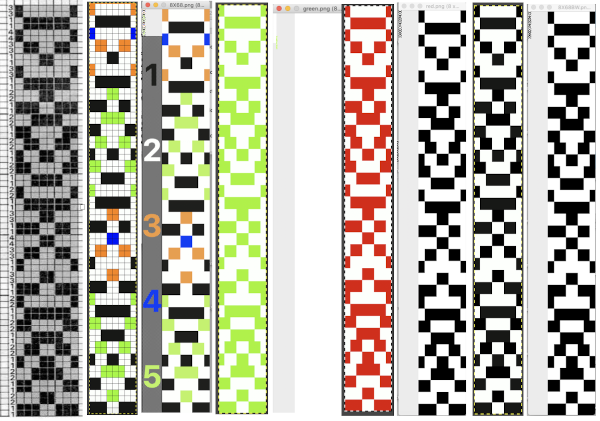

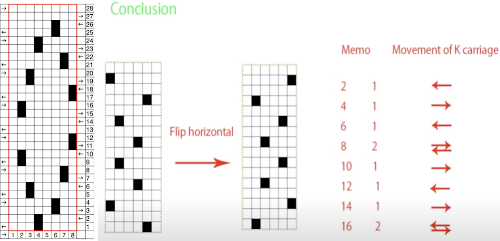

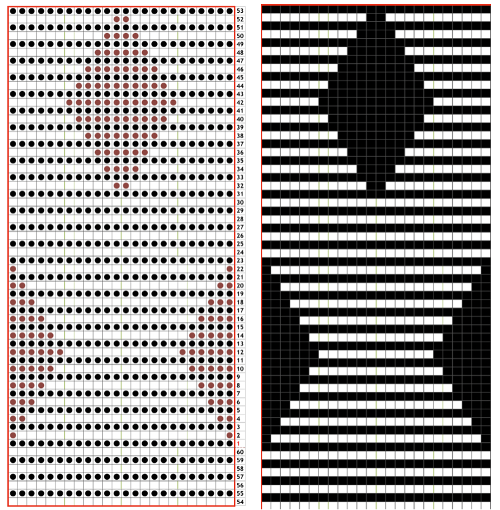

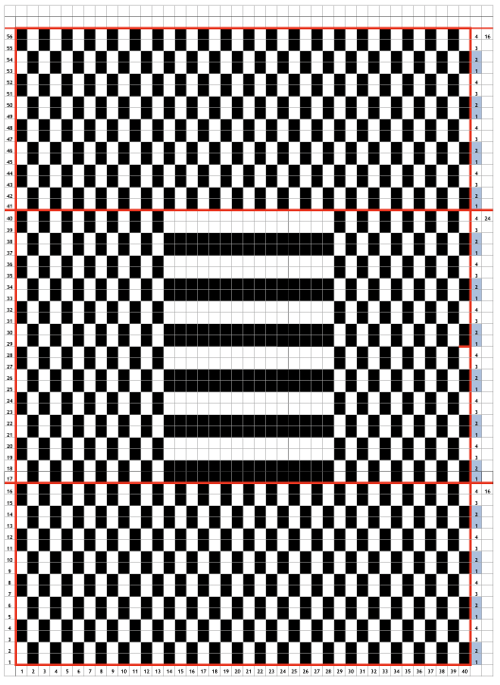

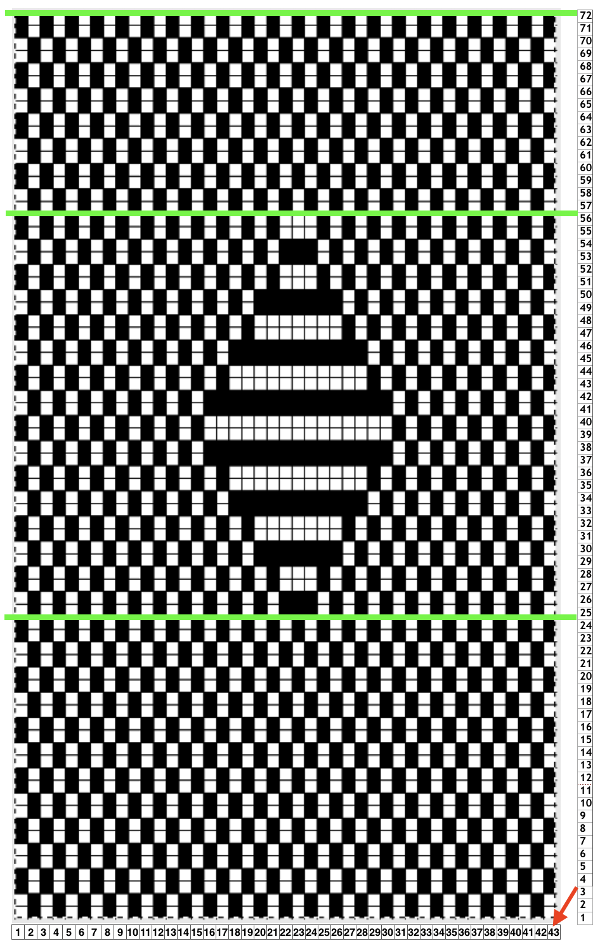

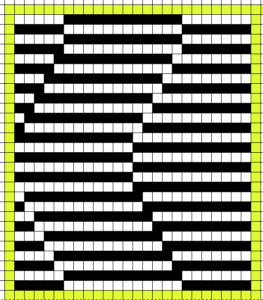

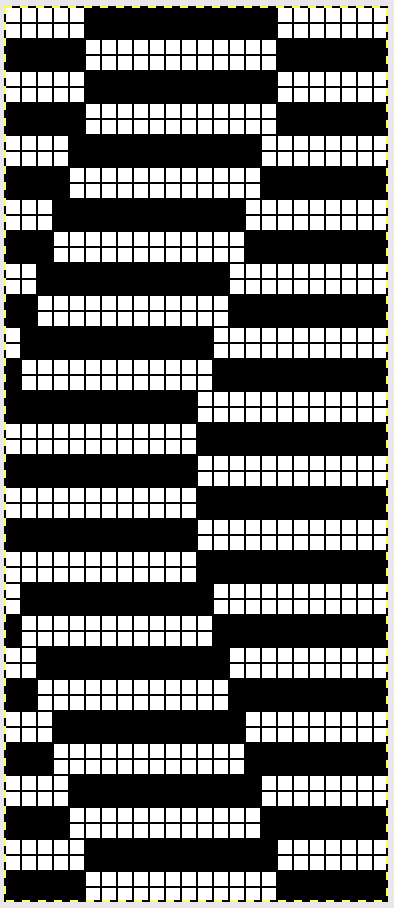

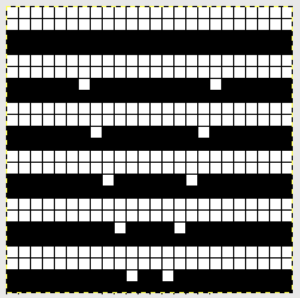

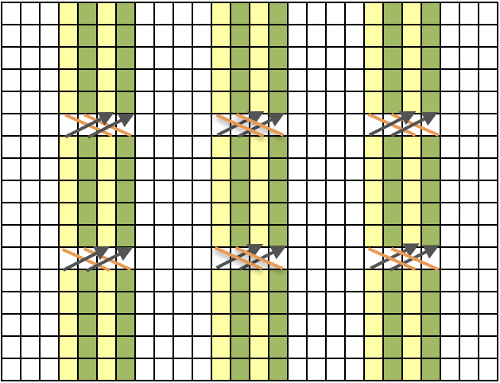

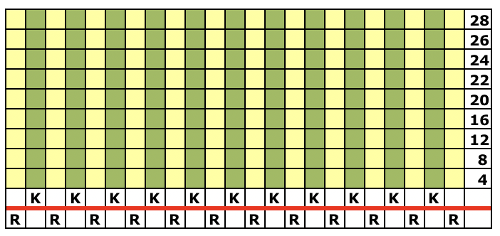

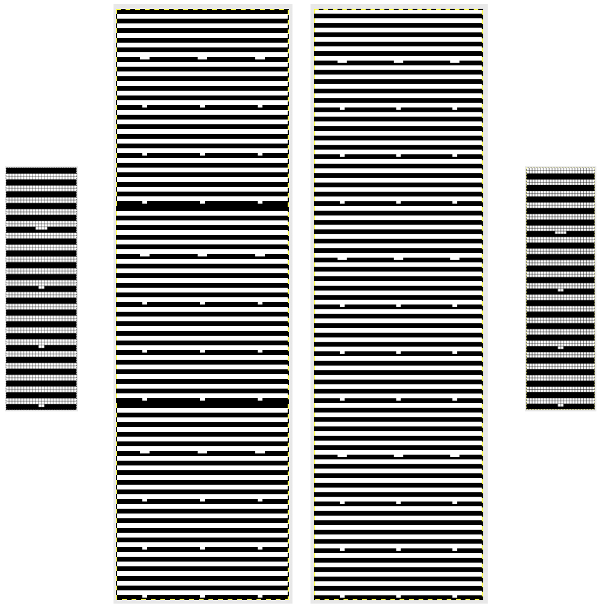

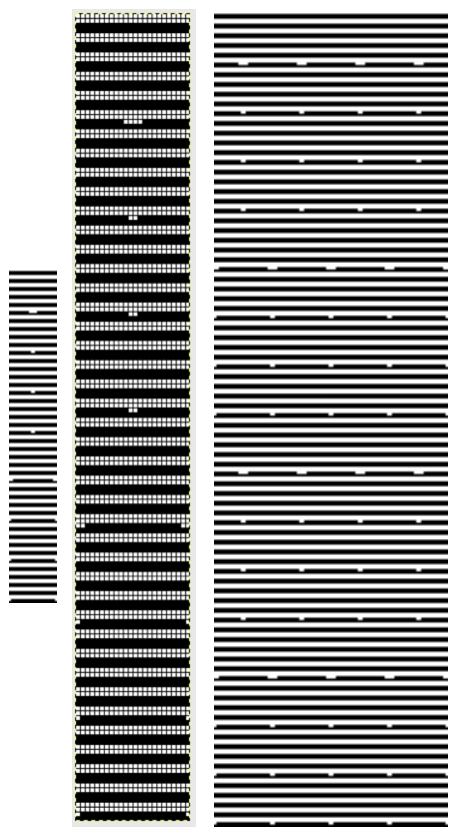

The full mylar repeat scanned and processed for use as images to be eventually downloaded via cable is shown in the top image. Below it segments 1-40 stitches, rows 1-30, 41-60, and 61-90 are shown as selected, cropped in turn, with corresponding .bmps saved for cable download. AYAB users can work with image software like Paint, Gimp, etc. to process and save them as b/w bitmap, png, etc. Img2track accepts common image formats (jpg, gif, png, .bmp, tiff). Both software programs may be used on PCs and Macs. Wincrea Win_Crea can open files in .cut (Passap), .bmp, or .wmf formats, and can be saved in .cut and .bmp. Passap and the 930s hold the segments in their own memory, while ayab knits from the screen. Stitch Painter (2.0) prior to the latest release used to have limited import and export formats, including .cut. There now is a new website for the program, and a new release, and I could not find info on exports beyond “There are now numerous export file formats including PDF, JPG, TIF, PNG, and other popular formats.”

The full mylar  three segments, selected from its bottom left

three segments, selected from its bottom left

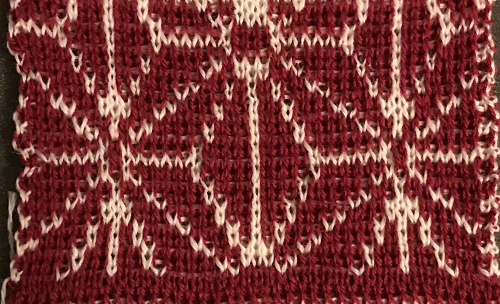

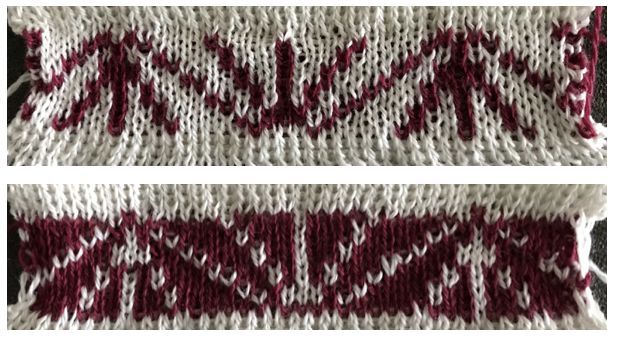

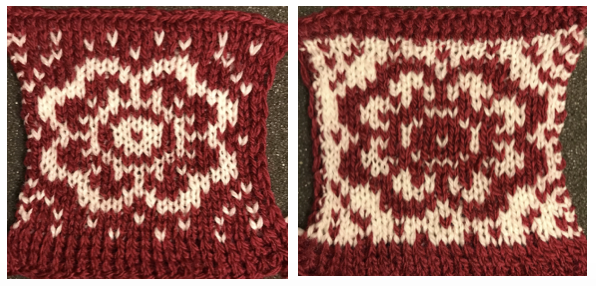

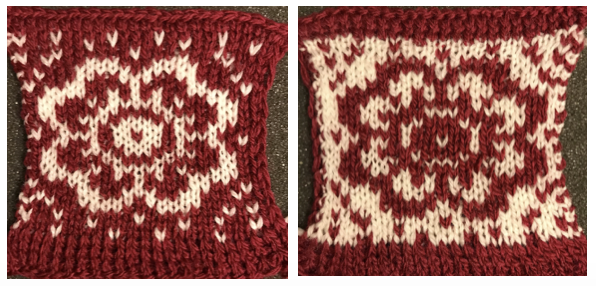

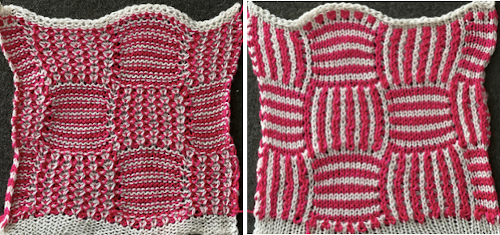

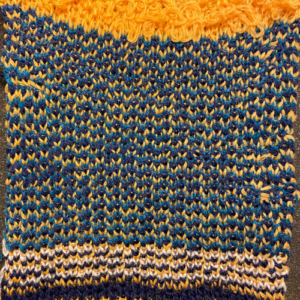

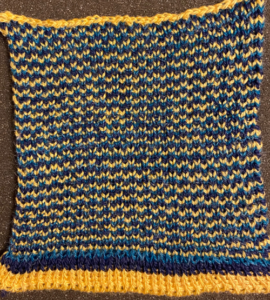

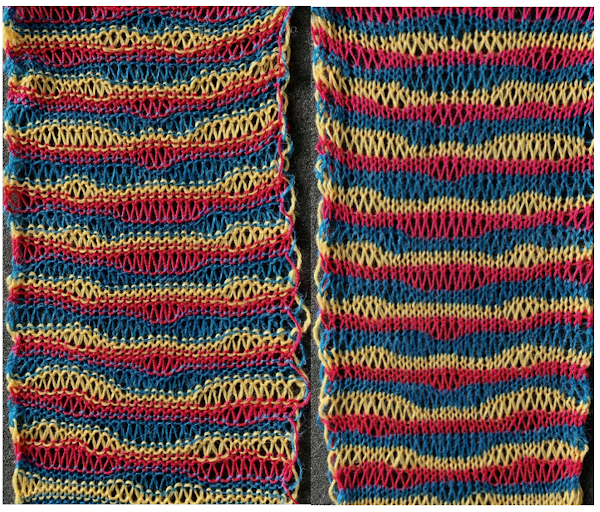

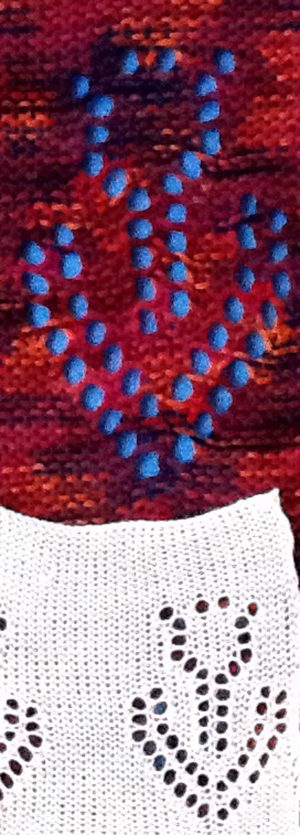

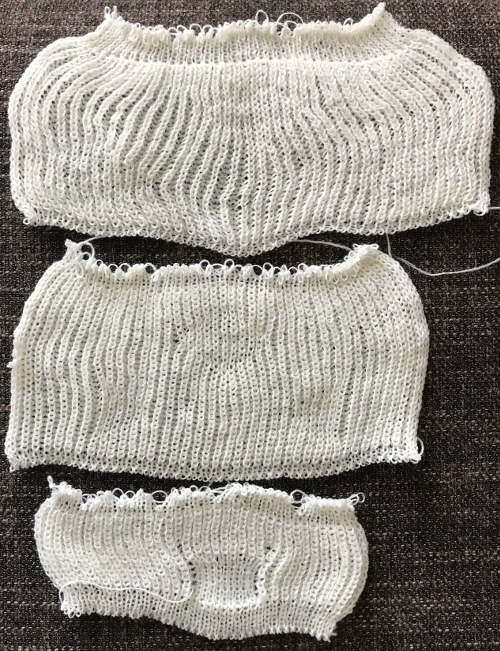

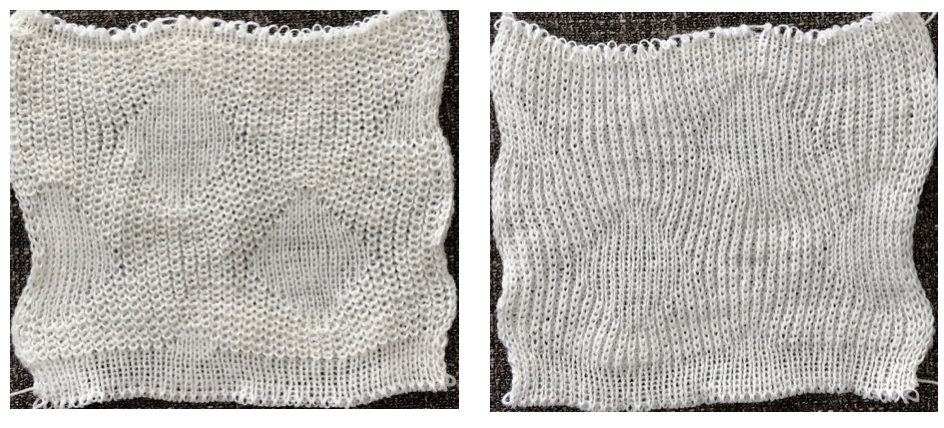

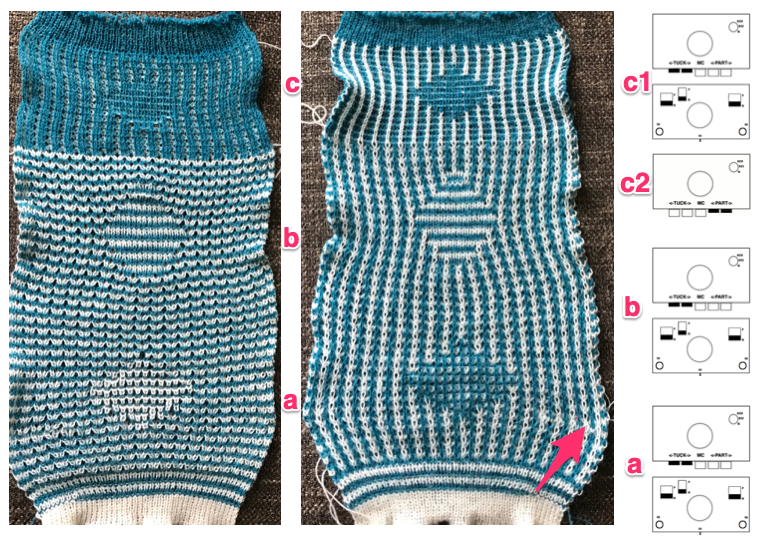

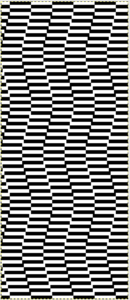

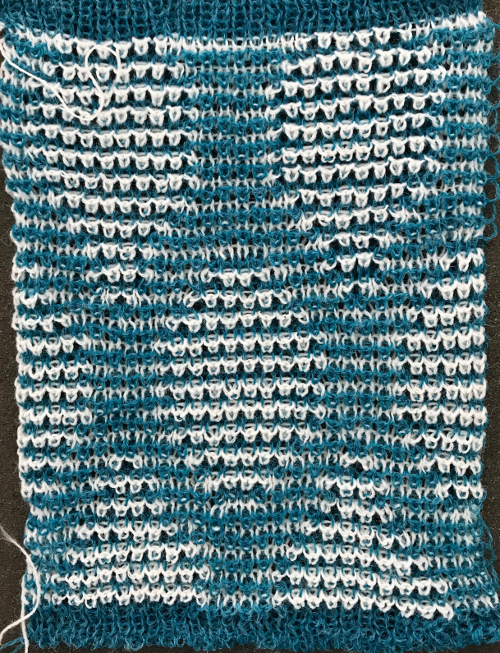

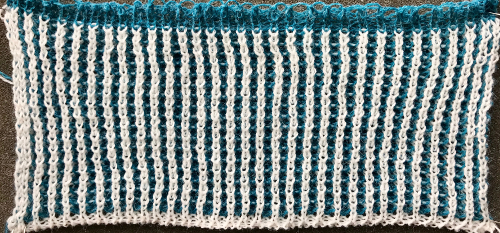

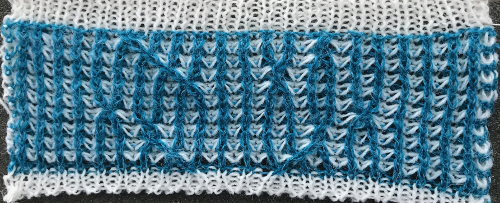

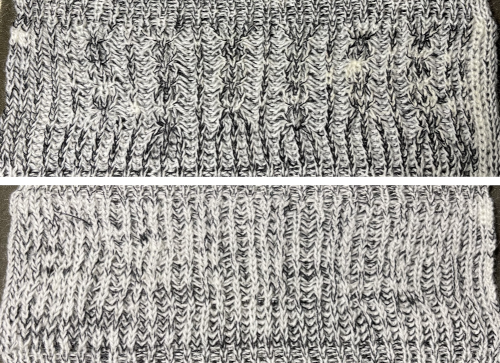

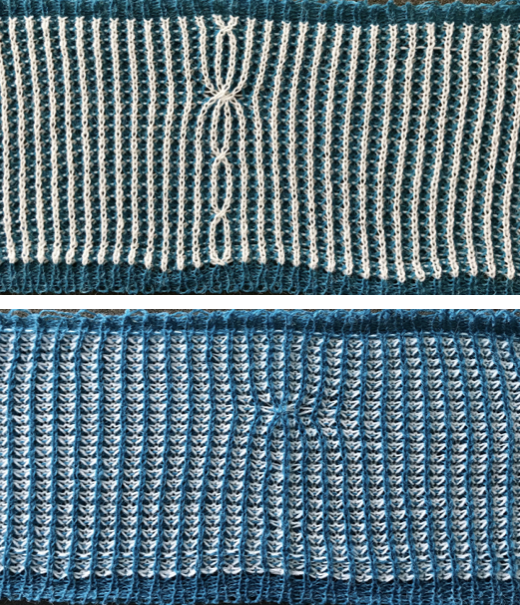

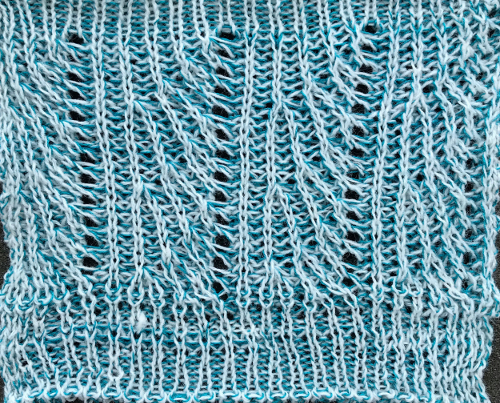

Proof of concept swatch on 910 using the mylar, programmed consistently in width on needles 1-40, with height for each segment 1-30, 31-60, 61-90. I was knit in a throw-away yarn, in unfamiliar DBJ tension settings, so I had some dropped stitches seen in the left, the bottom of the swatch image that were resolved with adjustments in settings. Note the image is reversed vertically by the program automatically with all variation levers down with the exception of the KRC one

One develops preferred ways of handling images as their knitting experience increases and varies. I have always done my own scaling prior to any actual knitting. Software programs at times offer to adjust the height based on knitting technique and either real or estimated gauge. Passap has a smooth edge feature to decrease stepped effects if the image is enlarged in multiples by the console. In double bed work, sample swatches are often much larger than when working on a single bed, at least 100 stitches by 100 rows. Because DBJ lengthens the image by default (every single row of design now requires 2 passes of the carriage), a separation for a 30-row design would require 60 rows of knitting on the machine to complete the repeat. Ribber settings can help reduce elongation in addition to any scaling of the motif. One alternative would have the ribber knitting in one direction, slipping in the other. This means that every other row the main bed will create floats for the non-knitting color, get caught between beds on the next pass.

In my test design, such floats are quite long in sections of the motif, resulting in problems, so that left me with choosing the lili setting.

Lili buttons on Brother machines behave like a 1X1 punchcard does on the main bed. There is no free pass with ribber set to slip in both directions if lili buttons are engaged. It is the equivalent of making such a pass on the main bed with every other needle selected, where any stitches on selected needles would be dropped if there is no yarn in use. Also, one may not slip on the same needles continually, so needles in use on the ribber must total an even number, in pairs of what I refer to as dash and blank or blank and dash markings on the needle tape. The pusher selection on the Passap selections operates differently, so an even vs. odd total # rule doesn’t apply.

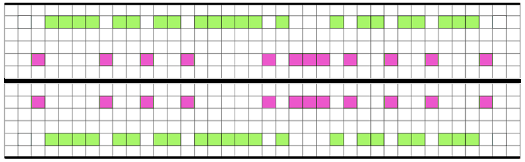

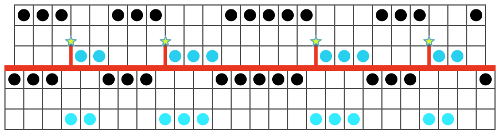

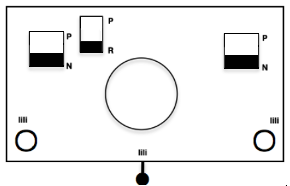

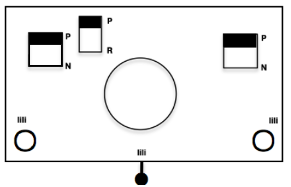

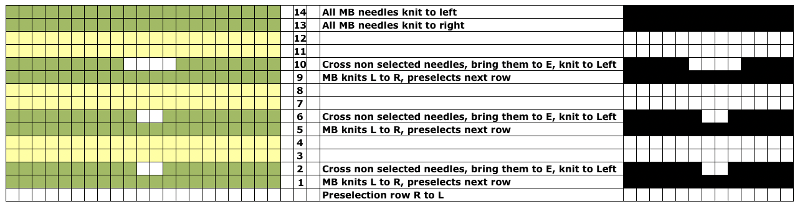

These photos illustrate needle selection on ribber, first beginning with a dash on the left, ending with a blank on the right, the second beginning with a blank on the left, and ending with a dash on the right. It is the second needle on the carriage side that gets selected in each direction, regardless of the starting mark for needle pairs. Here the blank knits to the right, the dash knits to the left,  and its reverse, with dash knitting to the right, and blank knitting to the left. There is no way without operator intervention to get that first needle to be the one knitting (such adjustments are made to achieve striper backing as opposed to birdseye, a different topic altogether

and its reverse, with dash knitting to the right, and blank knitting to the left. There is no way without operator intervention to get that first needle to be the one knitting (such adjustments are made to achieve striper backing as opposed to birdseye, a different topic altogether

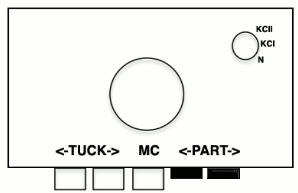

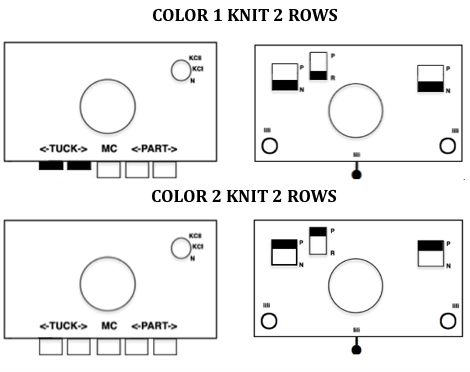

I programmed my first repeat segment after casting on, ending with dark color, both carriages on the left side. The white squares (in this case knit in white yarn) need to be knit on the first row from right to left. Either remove the ribber carriage and move it to the opposite side or tilt it forward and move it to the right, being careful not to engage any needles. After it is in place, set it for birds-eye backing

The knit carriage is now brought to the left, set to slip in both directions, KCI or II, in proper placement outside the turn mark for the first preselection row to the right. Make a free pass to the right, needles will be selected in pattern for the first single row of white squares (needles on the main bed after cast on are already only in B position). Place the yarn properly in the feeder, couple the carriages, knit right to left, and change color every 2 rows.

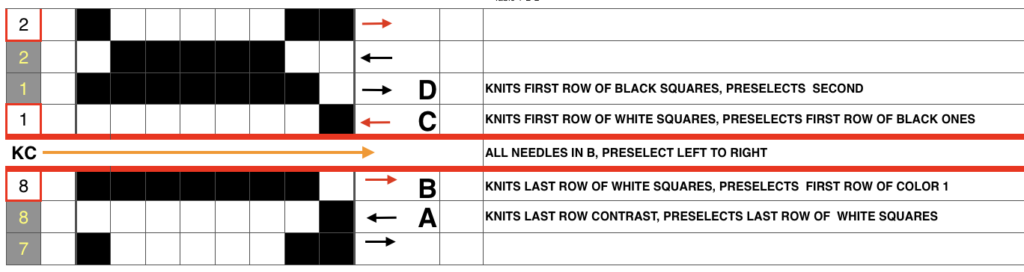

At the row before the last row of the pattern (top row, color 1), the card is automatically returned to the starting position of the pattern. When the machine buzzer alerts with its sound that the end of the repeat is being reached, the contrast color 2 (black squares) will be on the right side. In my initial attempts, I used the approach: knit to left, change to white (color 1), knit a single color 1 row left to right, and stop. Do not cut the yarn. The next pass to the left needs to knit the first white squares row in the next segment. The ribber carriage remains on the right, the bird’s eye pattern on the back will not be interrupted. I took the knit carriage off on the right, moved it back to the left side, it will not be holding any yarn. Prepare for knitting the second segment. There will still be needles selected (they would have knit the first white row when moving from right to left if the repeat were a continuing one). They need to be manually pushed back to B or those stitches will be dropped on the free pass to the right. Program the new repeat segment, and as usual, pre-select to right, place white yarn back in the proper position in the feeder, engage both carriages, and knit repeating the process until once again, a first, single row of the white is knit at the top of the second segment. The machine sounds serve as reminders when you have reached the point where things require attention. The process is repeated until all necessary pieces have been knit, composing the much longer image. As I worked further, I believe the same method may be used as seen below with the mylar in place. Knit the last row with the ground color to the left, preselection for the white squares is made on the way. Do not disturb needle selection on the bed or settings on either carriage. COL. Program the next segment, begin on the far left outside the turn mark, and change color to color 1 (white squares). As the carriages move to the right, the last row of segment one knits, and the first row of segment 2 is preselected. As the carriages return to the left to begin color-changing sequence every 2 rows, row 1 color 1 segment next will knit, while the first row of the ground (black squares) will preselect.

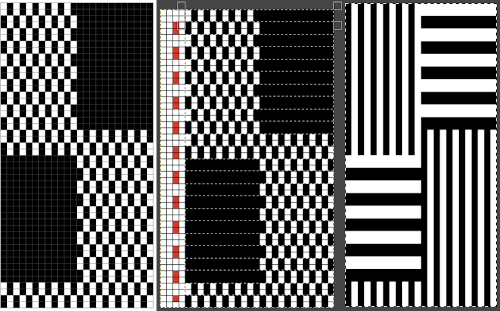

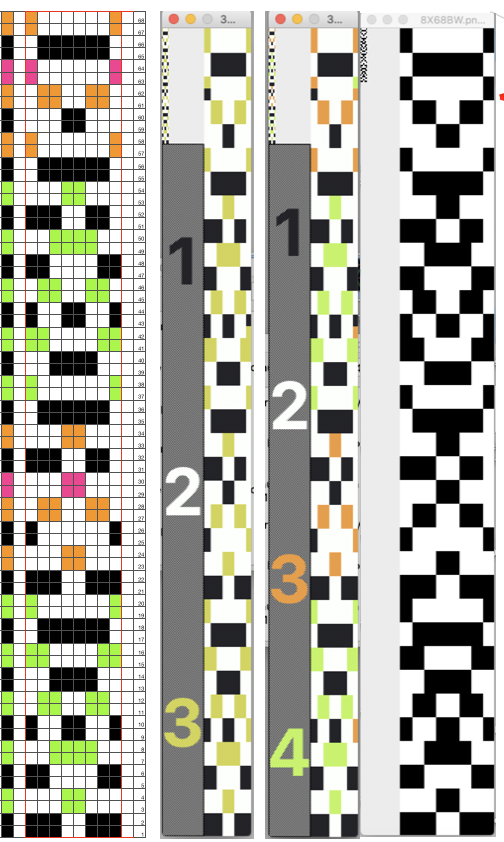

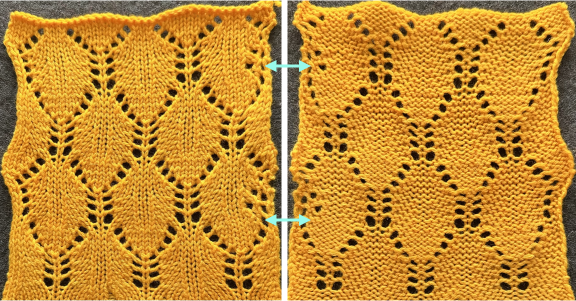

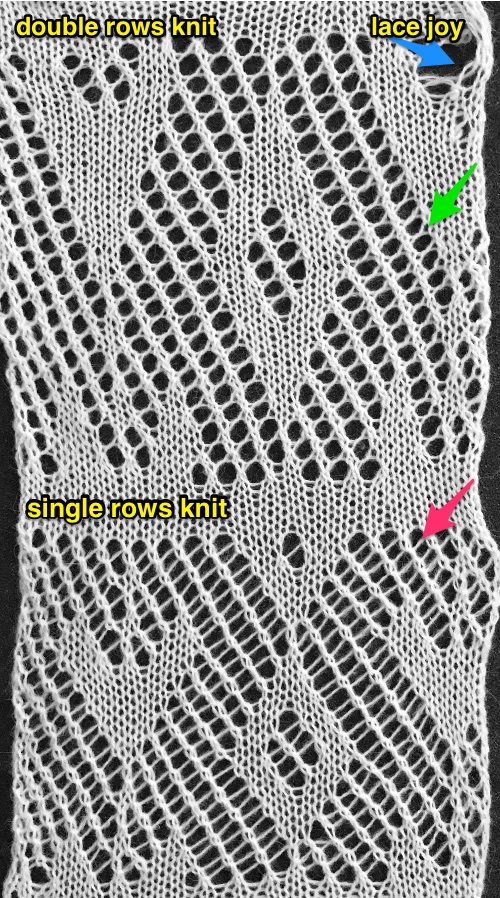

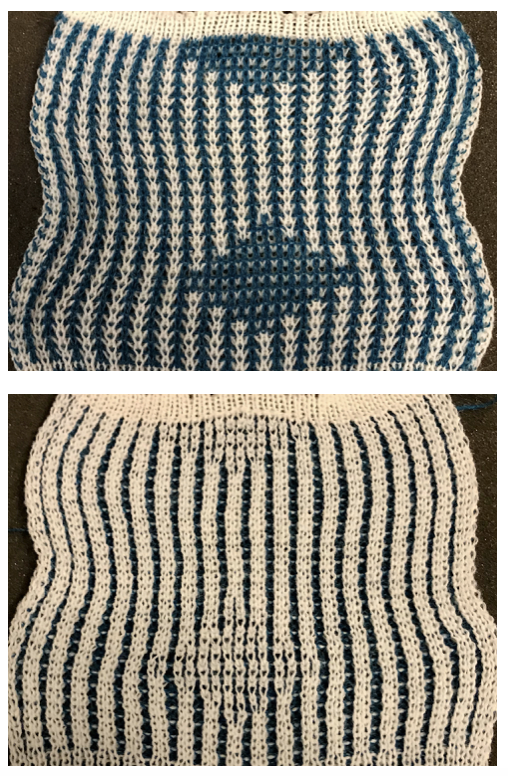

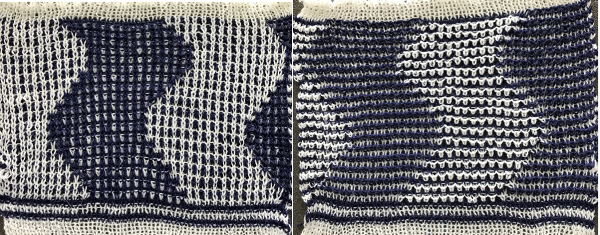

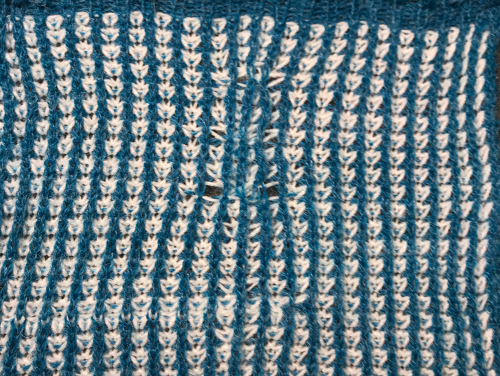

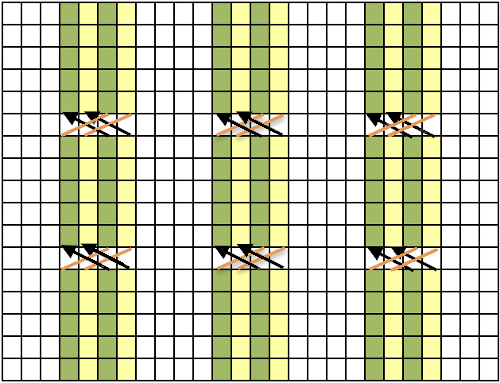

I recently received a second EMS Ayab kit I am just now beginning to use. Here the same image, bottom segment only, is tested. Knowing Ayab selects black squares first in its ribber setting I used the action invert available in the program itself to color reverse (middle image) so white would knit first. The process remains essentially the same in terms of ribber and other settings prior to knitting color 1 design row 1. The difference here as compared to the sample knit with the built-in KRC, all other buttons down, is that the native 910 KRC image is reversed on the knit side, it is knit as it would appear on the purl side. The Ayab version automatically mirrors the motif to have the original appear on the knit side as drawn.  I did attempt to load the 3 segments into the program, and knit them using the single setting (left), and the infinite one (right). The single setting gives one alert when the top of the repeat is reached akin to the native buzzer, the infinite relies on the operator to know to stop. I had problems with the yarn I was using and dropping stitches after out of curiosity I decided to add the latch opening plate to my ribber carriage. They went away when I removed it in subsequent swatches. I was not successful again using the single setting. The arrows mark what appears to be needle selection errors in both series.

I did attempt to load the 3 segments into the program, and knit them using the single setting (left), and the infinite one (right). The single setting gives one alert when the top of the repeat is reached akin to the native buzzer, the infinite relies on the operator to know to stop. I had problems with the yarn I was using and dropping stitches after out of curiosity I decided to add the latch opening plate to my ribber carriage. They went away when I removed it in subsequent swatches. I was not successful again using the single setting. The arrows mark what appears to be needle selection errors in both series.  9/18/18 Because of space restrictions at the moment my ayab and 910 are in “storage”. As I kept working, it occurred to me this method might be the way to go when using Ayab as well, at present it is untested

9/18/18 Because of space restrictions at the moment my ayab and 910 are in “storage”. As I kept working, it occurred to me this method might be the way to go when using Ayab as well, at present it is untested

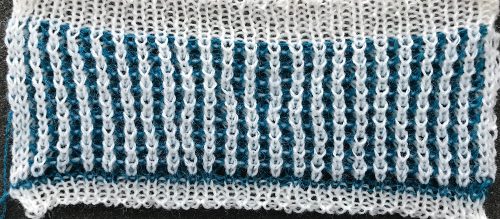

Here I attempted proof of concept with img2track on my 930 which is nice enough to track rows knit. As the top of the first segment was reached and the carriage began to reverse direction from the right, the machine made a warning sound, alerting me to the fact that the second row for row 30 of color 2 was about to be knit  as the carriage moved back toward the color changer selection was made for the last row of color 1

as the carriage moved back toward the color changer selection was made for the last row of color 1 making certain I did not disturb the needle selection in that row, I took the carriages to the far left, programmed the second segment in the repeat, with no other changes to carriage settings, changed to color 1. The above row is knit on the first pass to the right with color 1, while the preselecting row 1 for color 1 in the new segment and knitting it on the return to the color changer. The idea appeared sound, but then I ran into this: random dropped stitches. At first, I thought it might be a yarn issue (different fiber content and weight). After a break, I took the time to check all ribber adjustments, since this deconstruction was not part of the plan.

making certain I did not disturb the needle selection in that row, I took the carriages to the far left, programmed the second segment in the repeat, with no other changes to carriage settings, changed to color 1. The above row is knit on the first pass to the right with color 1, while the preselecting row 1 for color 1 in the new segment and knitting it on the return to the color changer. The idea appeared sound, but then I ran into this: random dropped stitches. At first, I thought it might be a yarn issue (different fiber content and weight). After a break, I took the time to check all ribber adjustments, since this deconstruction was not part of the plan.  Adjustments in ribber height (dropped a bit on each side) appeared to solve the problem. I began the swatch intentionally with plain knit stripes as an initial check, and switched color 2 to the other yarn to test any different behavior there as well. I had actually moved my ribber from my 910 to the 930 without checking alignment and spacing after doing so, lesson learned.

Adjustments in ribber height (dropped a bit on each side) appeared to solve the problem. I began the swatch intentionally with plain knit stripes as an initial check, and switched color 2 to the other yarn to test any different behavior there as well. I had actually moved my ribber from my 910 to the 930 without checking alignment and spacing after doing so, lesson learned.

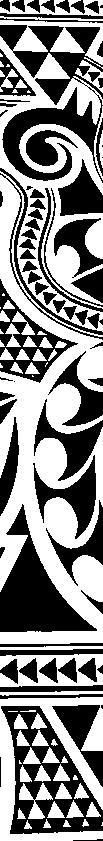

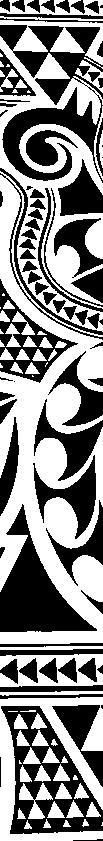

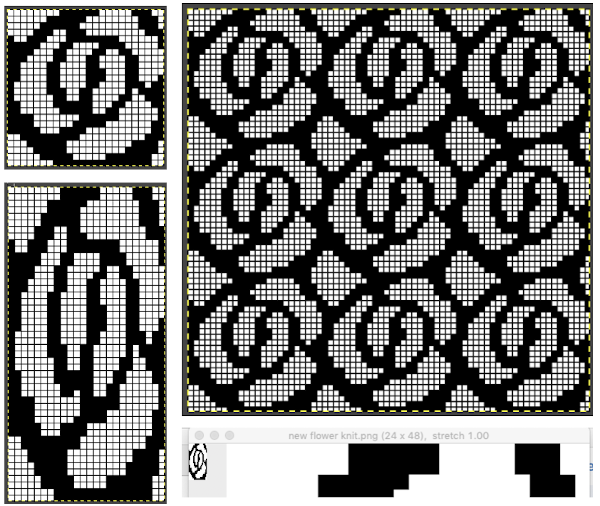

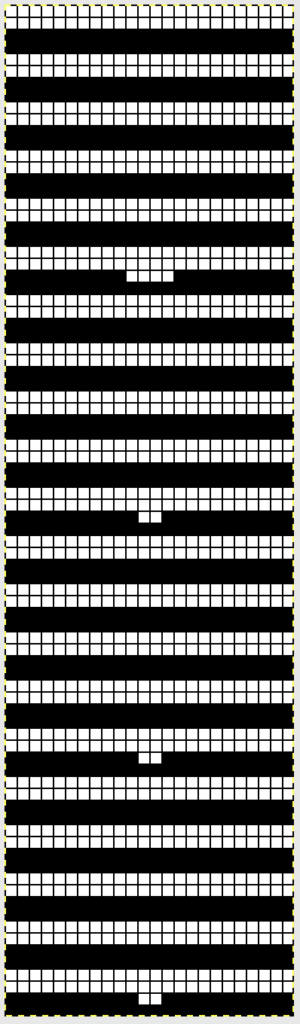

A theoretical design as a starting point for more discussion in Facebook

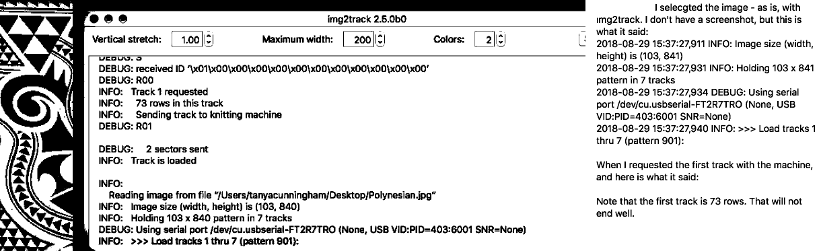

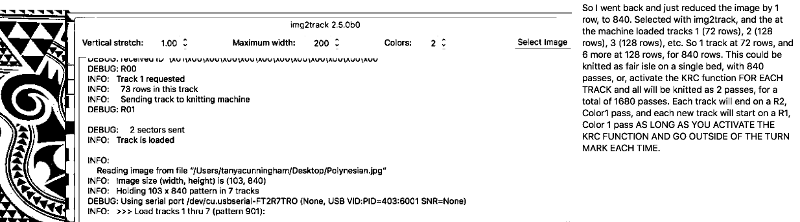

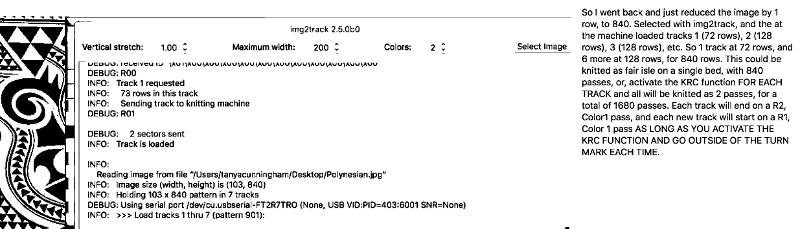

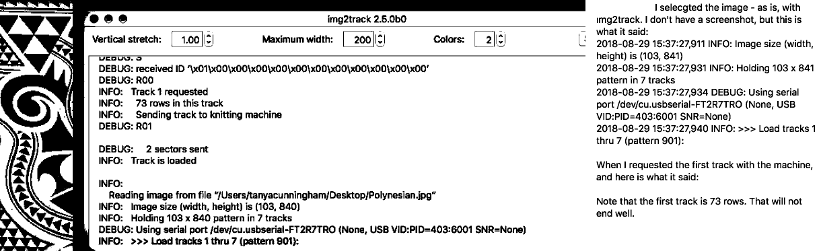

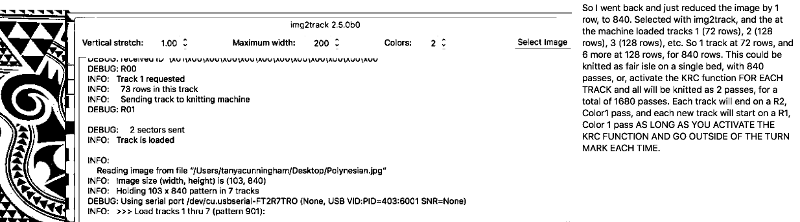

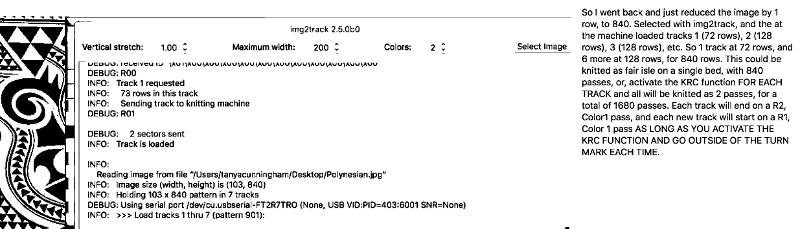

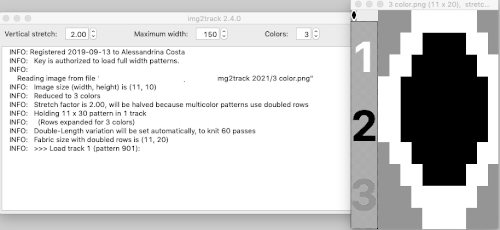

I cannot speak for img2track from personal experience. When I posed the question to the FB group as to how the program might handle a long, non-repetitive image, I supplied the image above. It is not knittable as is, 103X841(odd#) rows, from a random illustration, found online that would need a lot of “clean up”. Assuming it was knit ready, an even number of rows and other DBJ setup requirements are met does the 2 color separation work for the whole image length or must the image be divided into segments that are in turn knit and color separated separately? Tanya Cunningham, the creator of the group, was kind enough to respond in the forum, and I have her permission to share her response here. “Img2track creates a B&W pattern of the full length of the image. THAT file is useable in other applications. Many people create an image file with img2track, then load that image file into DAK to knit. Img2track does NOT create separate image files for the various tracks into which it breaks larger images. That happens when you request the pattern from the machine console. When img2track receives the request from the KM, it offers all tracks, and you select which one you wish to load. This image is already in a format such that it will not be altered by img2track (.bmp) (unless you restrict the width.) I selected it with img2track, and the resulting “pattern” was basically the identical image, just converted to a png.

The image was at first loaded in an uneven number of rows, and the software gave the warning “It will not end well!”

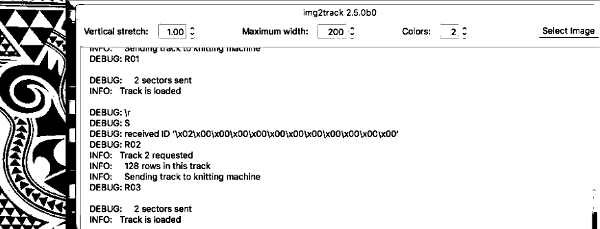

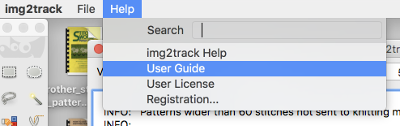

“As you knit the last row of each track (left to right) you will be selecting the needles for the first row of the next track. Thus, when you arrive at COR with color 1, you will be all set up for knitting the first row of the new track. Insofar as dividing up the pattern goes, that is done completely automatically by the software. You still have to load the successive tracks (and go outside the turn mark and select KRC). You just have to keep track of which tracks you’ve knitted. I write it down on a piece of paper each time I load a track, and how many rows it is. You can scroll back in the img2track window to see what was the last track knitted, unless img2track gets closed, and restarted, then it won’t show your previous activity unless you go to the img2track log..”

I put the same query to participants in the Facebook Ayab group. Ayab knits from the screen, so providing there is no interruption in power it appears some users are able to knit long, non-repetitive images without any subdivisions of the original pattern. Adrienne Hunter, an expert user, and great resource offered the following information: “there is effectively no length limitation in AYAB; the Arduino requests the next row as soon as it has finished selecting the current row, and the computer keeps sending the next row (color-separated as needed) until it reaches the top of the file. The pattern is in your computer’s memory which can be considered to be infinite; unlike a download to a 1980s self-contained knitting machine with very limited on-board memory. As you say, the computer must be set to stay awake, and as always you need to consciously wait for the beep on the right; the time it takes to do the color change is generally enough to cover the delay on the left.

I see occasional patterning errors in long narrow fair isle pieces too, but not in DBJ. That is because the errors can be prevented by crossing a turn mark every now and again, and with DBJ you cross a turn mark every two rows when you enter the color changer.

You will see the annoying UI bug where the display jumps back to the beginning of a long item so it isn’t showing you the section where it’s actually working. The knitting is doing the right thing, just not scrolling the display correctly to show it to you.” If accurate for the full image, this appears to be the ideal method to me.

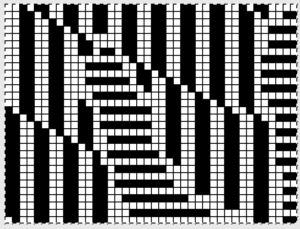

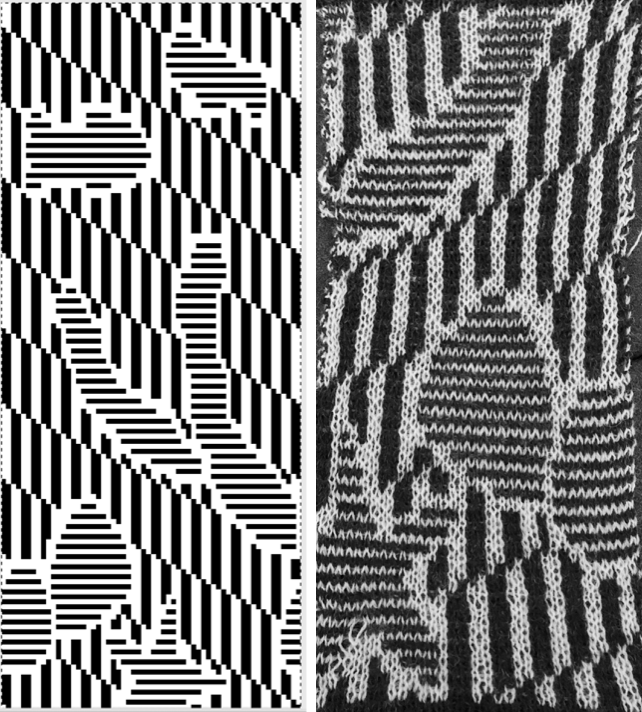

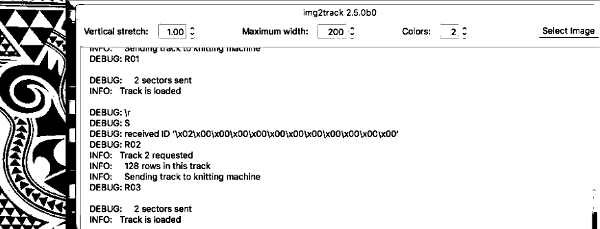

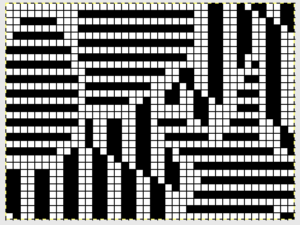

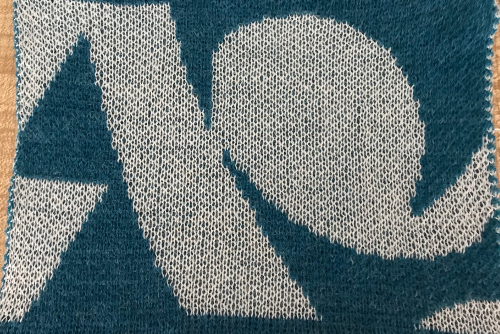

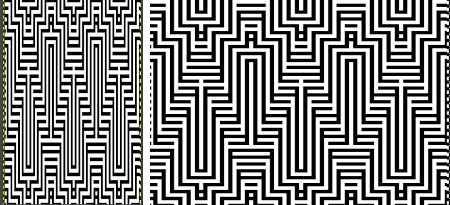

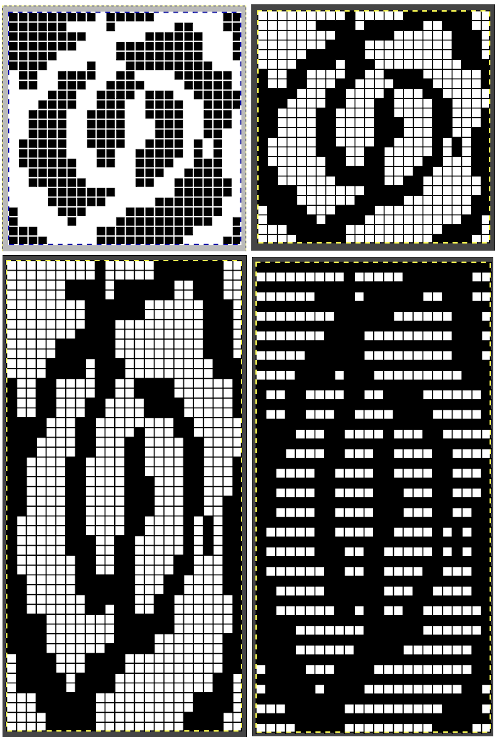

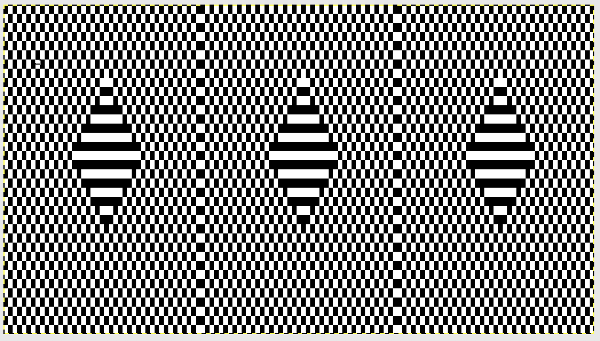

Paint programs allow for easy manipulation of images that make it a bit easier to imagine the finished product. With the assumption I wish to knit a scarf no longer than 1200 rows using the above design, the first task is to reduce the repeat to a workable, even number of rows in height, no more than 600 rows. So I cropped the image to 94X536. It is well worth studying how the image might appear if the color reverse is used, as well as what effect mirroring it may have (especially if direction matters in your design). Pairs of mirrored images may produce interesting, far wider pattern variations. Know whether the program works first with black or white squares, and you can simply choose that color when color 1-row one begins to knit from the right. The color reverse option is built into most software and electronics. I prefer to save images as I want to knit them.  Notes to self-using ayab with images such as above: black squares knit first, so if I want the white to knit first, matching any Japanese pattern knit using KRC style separation use color reverse. If direction matters, remember that the image will be flipped vertically by the program so that it will appear on the knit side as drawn. Though technically I have no plan to knit the whole piece, I decided to test a portion of it with my new ayab board. I programmed the image on the left, wishing to get the effect noted on the right. Began on the right with color 1 = white for design row 1. I am not used to working in this scale. That said, the pattern was accurate up to the point I decided to stop because of time factors. Though the design is 94 wide, I knit only on its center 80 stitches

Notes to self-using ayab with images such as above: black squares knit first, so if I want the white to knit first, matching any Japanese pattern knit using KRC style separation use color reverse. If direction matters, remember that the image will be flipped vertically by the program so that it will appear on the knit side as drawn. Though technically I have no plan to knit the whole piece, I decided to test a portion of it with my new ayab board. I programmed the image on the left, wishing to get the effect noted on the right. Began on the right with color 1 = white for design row 1. I am not used to working in this scale. That said, the pattern was accurate up to the point I decided to stop because of time factors. Though the design is 94 wide, I knit only on its center 80 stitches

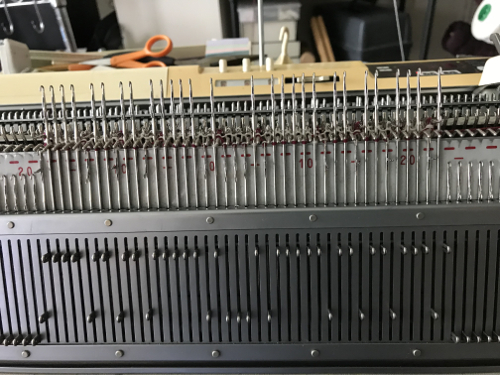

9/16/18 I received an orphan 930 which when first arrived had no movable parts related to patterning. The belt was frozen in place, and when that got liberated after cleaning and lubricating as much as I dared take apart at the time, after some initial errors the built-in patterns from several groups including lace knit perfectly, with only a slight squeak. After being stored again for a while, I tried built-in FI patterns again, and they displayed errors. I heard a new noise coming from the needle selector, exposed that, cleaned, and lubricated it, and it lost the added noise during operation. Tried built-in FI with resulting patterning errors once more. That said, test patterns in the service manual 881, 882, 884 knit perfectly. After another break for both of us, I got some built-in patterns to work again on both single and double beds and put working with them to rest. I began to work with img2track. I have not yet purchased a key. These were my first self-drawn single bed and dbj tests, none intended for any final piece.

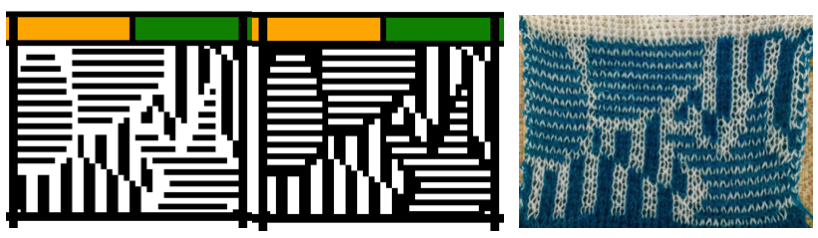

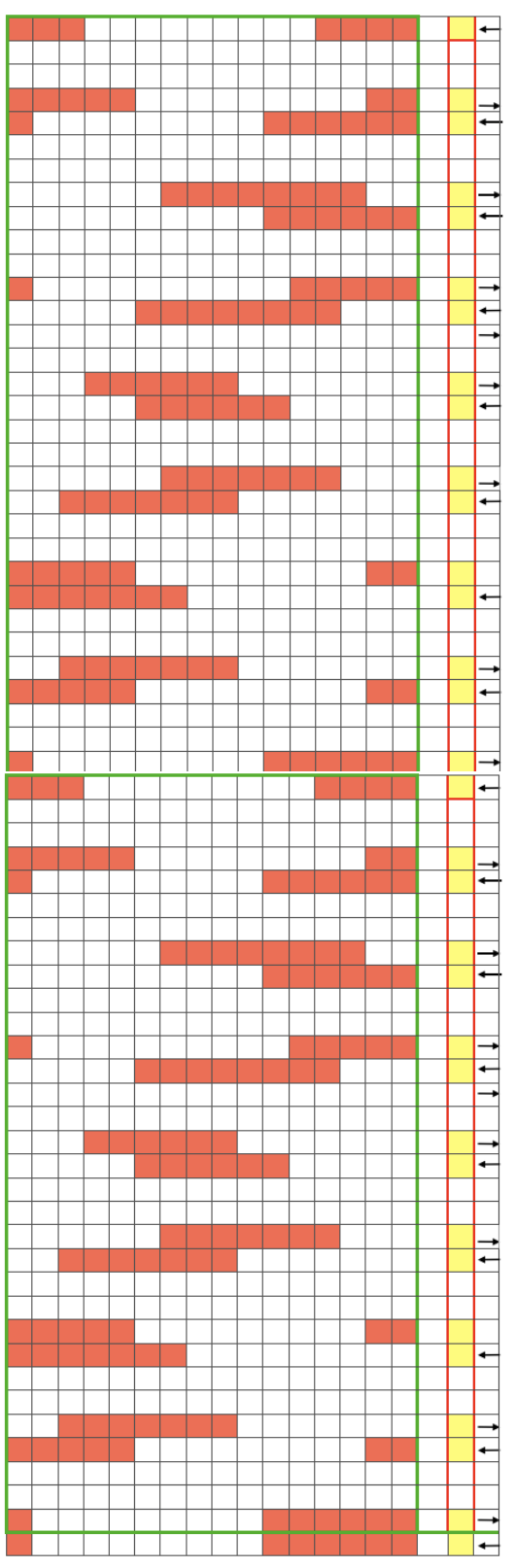

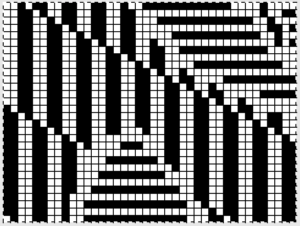

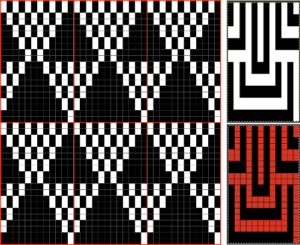

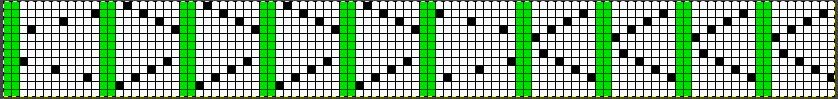

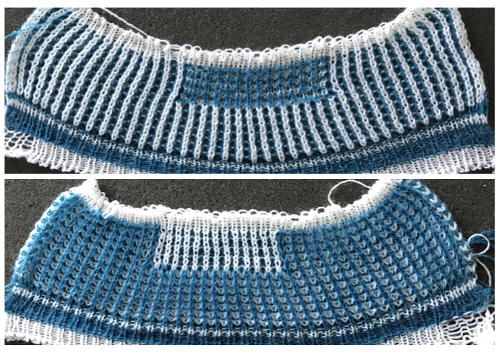

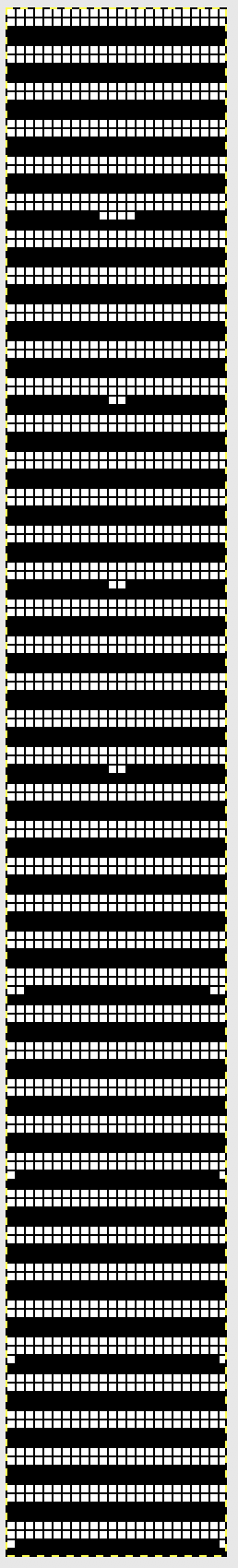

Here a quickly drafted long, narrow test design is shown with the first track self-repeating on the bottom, then with the second track programmed, and continuing on after the first (thanks to help and feedback in the FB group; long stitch striper backing and dropped stitches = extra “design features”. The program makes a sound when the last row of ground (black squares) is reached. The carriage is then moved to the left, knitting that last row of ground while selecting the last row of color 1 for that specific track. When on left, begin outside the turn mark, program the next track, change to color one, remember to set for KRC, knit to right (Cam button will already be set for KCI orII). As you do so, the last row of color 1 is knit, the first row of the next track for color 1 will be selected. The latter will knit on the way back to the color changer. Continue in pattern, changing colors every 2 rows. Knitting is uninterrupted by having to change carriage settings on either bed, the backing pattern is also uninterrupted.

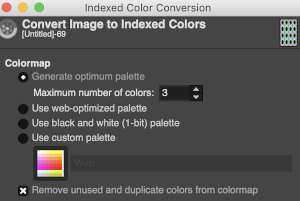

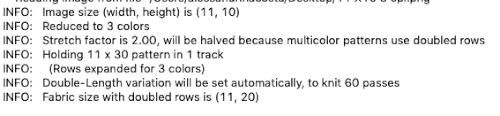

as described in the user guide: to download, launch program and select

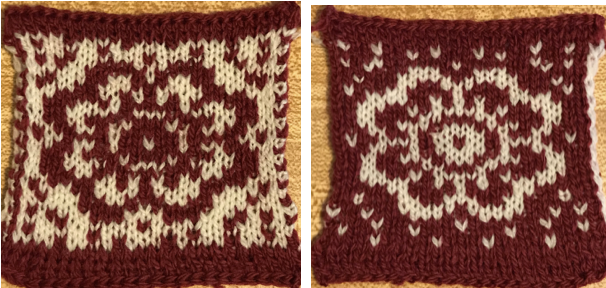

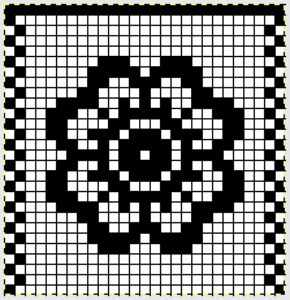

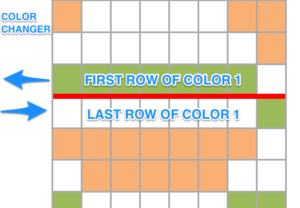

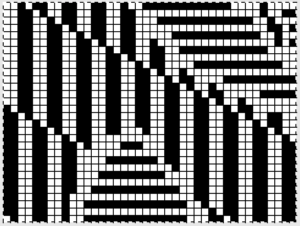

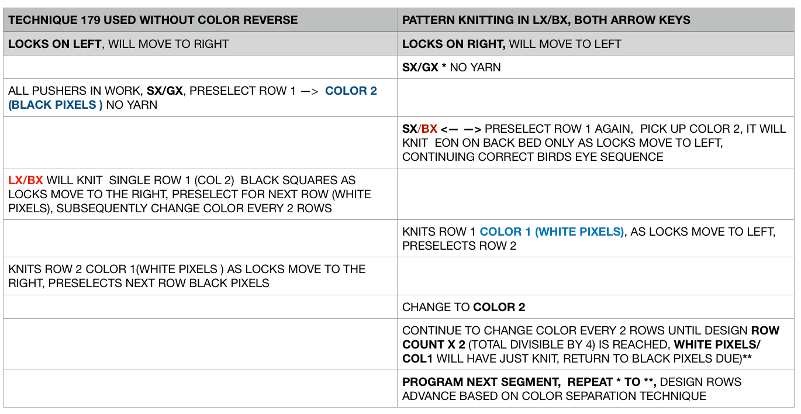

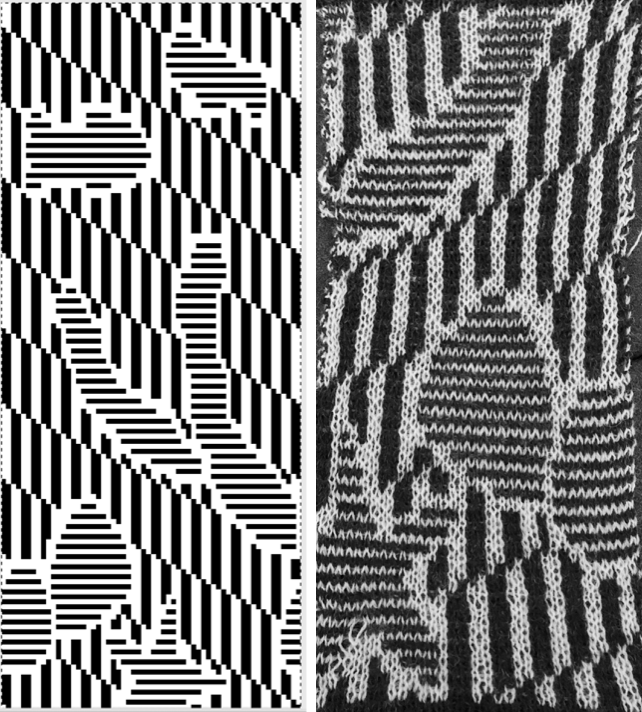

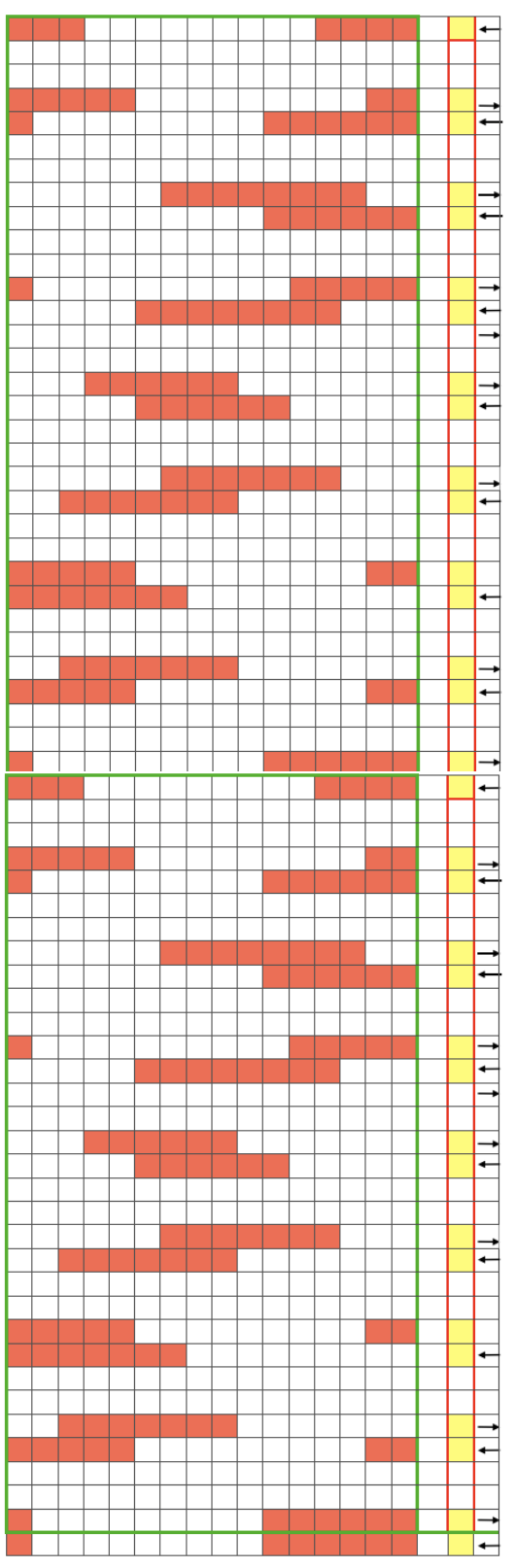

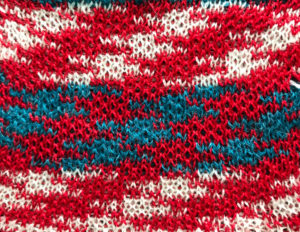

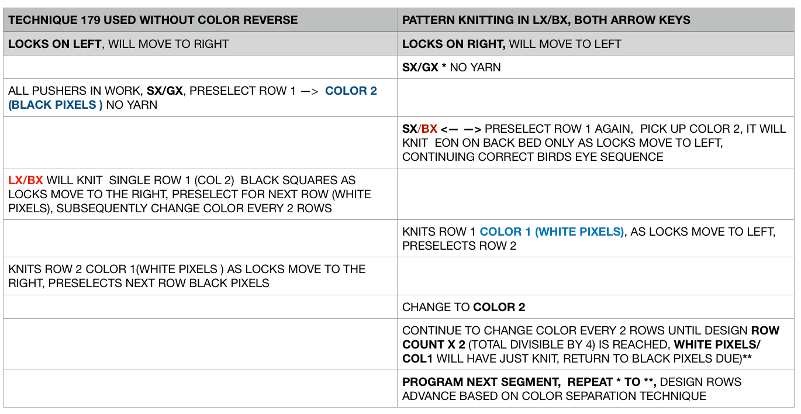

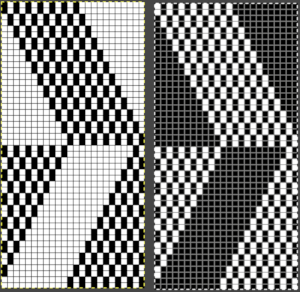

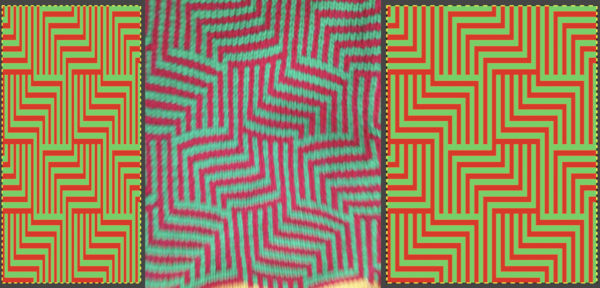

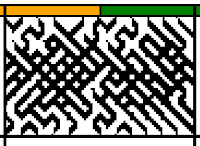

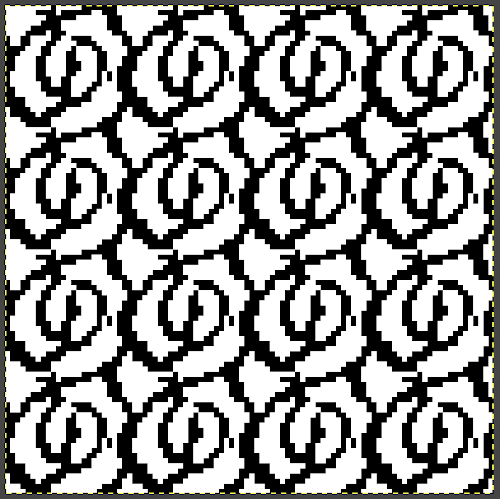

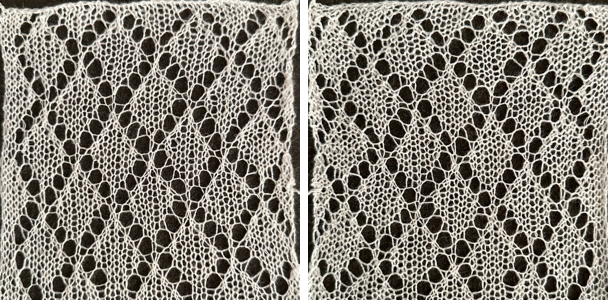

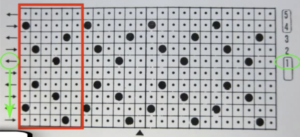

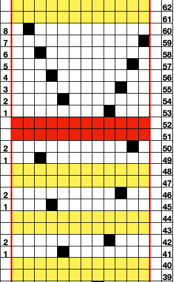

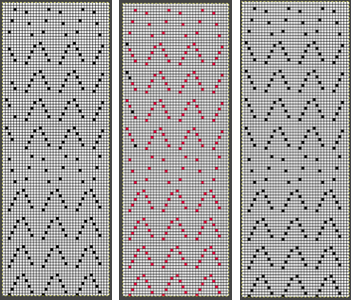

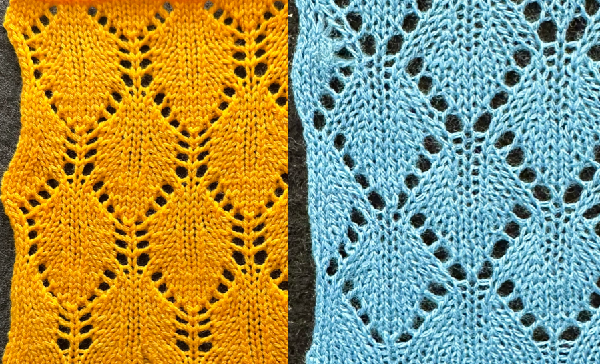

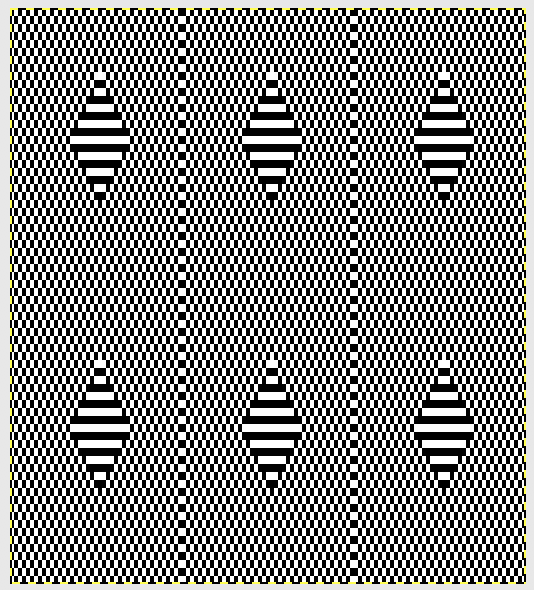

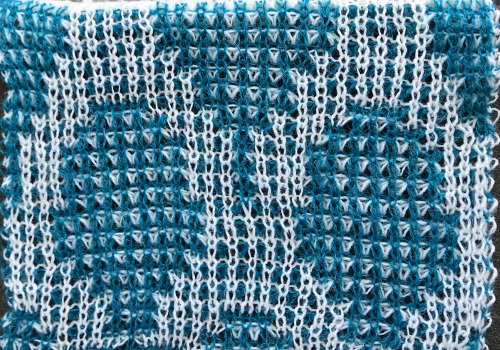

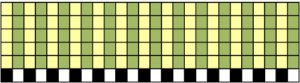

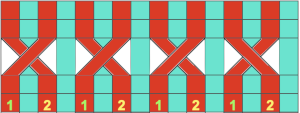

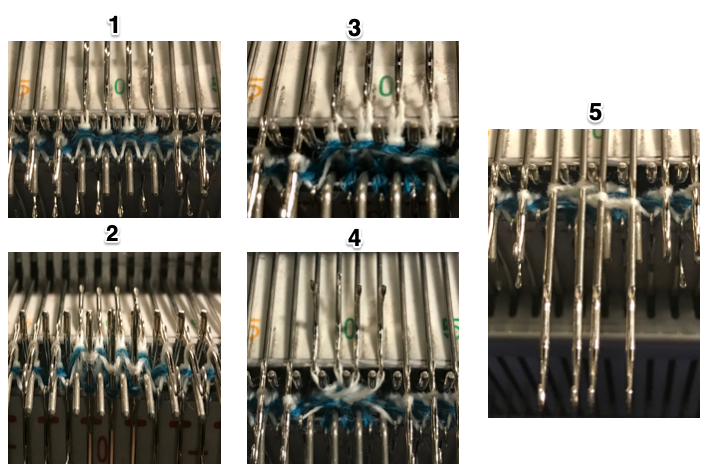

“The KH-930 takes just a few seconds to load the track because the memory holds only 2 KB of data (about 13000 stitches). Later models have a much larger memory (32 KB). The KH- 940 and KH-950i require 42 seconds to load a track.” “If your pattern was divided into more than one track, you will have to load successive tracks when completing the previous track. Listen for the beep from the knitting machine, indicating that the carriage is about to knit the next to the last row of the track, selecting needles for the last row of the track. Knit this second to the last row, and then STOP. (If you simply continue knitting at this point, the knitting machine will knit the last row of the track and select needles for the first row of the same track). To load the second track of the pattern, enter CE 551 STEP, and then 2 STEP prior to knitting the last row of the current track. (If your computer goes to sleep while you are knitting, you will be unable to load additional tracks. Be sure to check that your computer is not asleep before attempting to load successive tracks.) Before you begin to knit the last row and select needles for the first row of the next track, be sure that the carriage passes outside of the turn mark. The knitting machine will retain the loaded track in its memory until you alter it. You can turn it off, and later turn it on and resume where you left off.” So what about Passap and using it for emulating the KRC 2 color DBJ? The Passap color changer to start with is on the right side rather than the left. All preselection of pushers (they will, in turn, drive the needles to move into work or not) always starts from the left. The first pass to the left after casting on and the pattern is programmed brings them all in to work in a flat line, the first preselection row is left to right, with color changes following every 2 rows. Settings for those 2 rows can vary, the console guides you through supposed 2 free passes with settings at SX/GX, the equivalent of Brother slip in both directions/ slip in both directions. Technique 179 is intended for simulating single-bed FI in Japanese machines, the manual recommends color reverse. In DBJ that would line up with KRC selecting white squares first. I like thinking of my black squares as my pattern ones, so I tend not to use the color reverse, and choose my contrast color accordingly. I decided to program the same built-in pattern twice, as A and B, each using tech 179, a repeat in which I thought it might see easily what happens when the “2 separate segments” intersect. Below is the pattern is seen charted in B/W, tiled, and knit. Notice in the knit swatch that the first row in each sequence repeats twice.

So what about Passap and using it for emulating the KRC 2 color DBJ? The Passap color changer to start with is on the right side rather than the left. All preselection of pushers (they will, in turn, drive the needles to move into work or not) always starts from the left. The first pass to the left after casting on and the pattern is programmed brings them all in to work in a flat line, the first preselection row is left to right, with color changes following every 2 rows. Settings for those 2 rows can vary, the console guides you through supposed 2 free passes with settings at SX/GX, the equivalent of Brother slip in both directions/ slip in both directions. Technique 179 is intended for simulating single-bed FI in Japanese machines, the manual recommends color reverse. In DBJ that would line up with KRC selecting white squares first. I like thinking of my black squares as my pattern ones, so I tend not to use the color reverse, and choose my contrast color accordingly. I decided to program the same built-in pattern twice, as A and B, each using tech 179, a repeat in which I thought it might see easily what happens when the “2 separate segments” intersect. Below is the pattern is seen charted in B/W, tiled, and knit. Notice in the knit swatch that the first row in each sequence repeats twice.  What appears to be happening, is that only that very first row is repeated twice for one time in the color separation at the very beginning of the knit. The arrows on the right indicate movements of the locks to and from the color changer, knitting my black squares. If row one is knit in that color twice only once, and the pattern subsequently is kept continuous, rolling back to row one for only a single pass, the 2-row color rotation can be maintained. The bold, green border outlines the single, full repeat. The separation is only for illustration of placement for the one color.

What appears to be happening, is that only that very first row is repeated twice for one time in the color separation at the very beginning of the knit. The arrows on the right indicate movements of the locks to and from the color changer, knitting my black squares. If row one is knit in that color twice only once, and the pattern subsequently is kept continuous, rolling back to row one for only a single pass, the 2-row color rotation can be maintained. The bold, green border outlines the single, full repeat. The separation is only for illustration of placement for the one color.

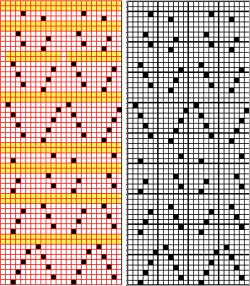

Swatching again with an attempt to produce it as 2 separate but continuous segments: I do not use color reverse, choose my color to match black squares, and that would be color 2 on the console prompt. In my first attempt, I followed other usual console prompts but used SX/GX settings for three rows rather than 2. The first pass will lift all pushers into work. The second pass preselects pushers for the first row of the pattern to the right. The third pass would normally knit the first row of the pattern, preselect for the second row to be knit from left to right, and so on. After the third SX/GX pass the locks are on the left side(LOL), I changed the settings for pattern knitting (LX/BX). On the right, make certain the empty yarn holder is up for the next color. On the left place the yarn into an eyelet, making certain it was positioned so it would not be crossing other color yarn on travel back to the color changer. Knit single row to the right, changed color, continued knitting in pattern unit the top of the segment was reached (row countX2, in this instance = 32). The design color knit its last pass, locks are on the right (LOR) Programmed second segment, repeated 3 rows of SX/GX. On the left, yarn in the feeder, proceed as above. This gave me correct continuous segments on the knit side of the fabric, but the bird’s eye backing was disrupted. On the bottom because of operator error in the lock setting, and the top because birds-eye normally knits EON for 2 rows, creating a bit jaggy, a single line of color after knitting on all needles when the second pass is knit, while here it EON for one row only, missing that second pass. Note yarn ends, the yarn would need to be cut to position it for those single-row passes from left.

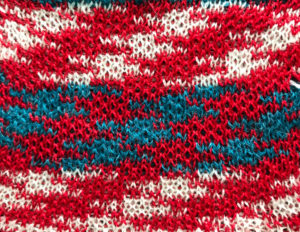

It is really helpful to use colors that are in high contrast when testing patterns. Here color positions are reversed, the red is now my ground (white squares with no color reverse), and the blue at the segment change muddies things considerably to my eye. Maintaining the Birdseye selection is now sorted out and actually makes for easier knitting

The color separation to approximate the result with color changes begins with the same process as that used for designing mosaics. Once the image is rendered as a correct B/W png with no apparent errors, it is copied and pasted on a larger canvas, the mode converted back to RGB. The red cells make it easier to keep track of rows that need to be color inverted. Using the shift key and rectangle tool, multiple pairs of rows can be selected sequentially and color inverted. Beginning the selection with the very edge of the black squares on the left does not interfere with changing the color of the extra columns on the left side of the design. If pixels are added accidentally drawn in any of the 4 extra columns on the left, they can easily be removed when the completed conversion is cropped to selection for the final repeat.

The color separation to approximate the result with color changes begins with the same process as that used for designing mosaics. Once the image is rendered as a correct B/W png with no apparent errors, it is copied and pasted on a larger canvas, the mode converted back to RGB. The red cells make it easier to keep track of rows that need to be color inverted. Using the shift key and rectangle tool, multiple pairs of rows can be selected sequentially and color inverted. Beginning the selection with the very edge of the black squares on the left does not interfere with changing the color of the extra columns on the left side of the design. If pixels are added accidentally drawn in any of the 4 extra columns on the left, they can easily be removed when the completed conversion is cropped to selection for the final repeat.  The completed color separation can then be bucket filled to match imagined colors

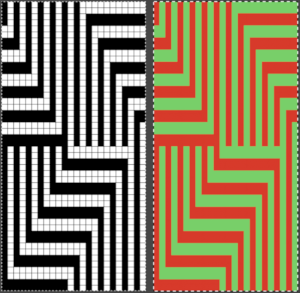

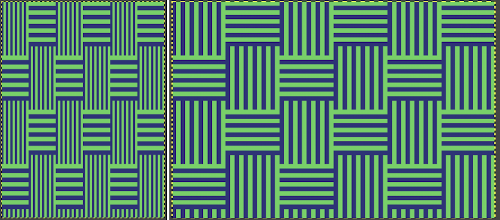

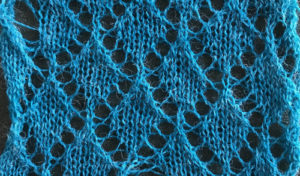

The completed color separation can then be bucket filled to match imagined colors Tiling the repeats to imagine the final knit presents the problem that results from working on a square grid and comparing the results to a knit, which usually produces a rectangular one. The representation for the linear patterns produced on the knit side of the piece cannot factor in some of the added distortions created by the stitch type used. I process my images in Pages or Numbers, depending on which document contains my most recent work and happens to be open. It is also possible to perform the final rescale in Gimp. Most knits approach a 4:3 ratio, with gauge variants in highly textured fabrics. To preserve a clean design, tile and save the original, screengrab the resulting image, load it in Gimp, and rescale. Repeat the motif for the same number in both height and width when tiling it.

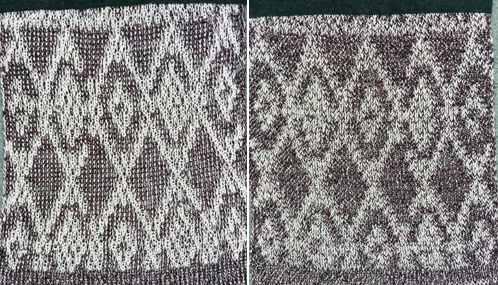

Tiling the repeats to imagine the final knit presents the problem that results from working on a square grid and comparing the results to a knit, which usually produces a rectangular one. The representation for the linear patterns produced on the knit side of the piece cannot factor in some of the added distortions created by the stitch type used. I process my images in Pages or Numbers, depending on which document contains my most recent work and happens to be open. It is also possible to perform the final rescale in Gimp. Most knits approach a 4:3 ratio, with gauge variants in highly textured fabrics. To preserve a clean design, tile and save the original, screengrab the resulting image, load it in Gimp, and rescale. Repeat the motif for the same number in both height and width when tiling it.  The colored versions before and after scaling, compared with the slip stitch swatch.

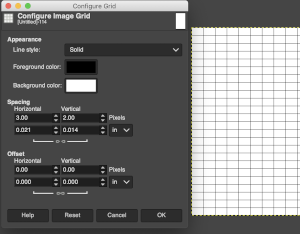

The colored versions before and after scaling, compared with the slip stitch swatch.  It is possible to produce a rectangular grid to start with on which to draw in Gimp, but the larger canvas size occupies a significantly larger space on the screen, complicating the process. For small designs, however, that may be an option to give one the sense of aspect ratio for the design in the final knit ie in representational FI. To resize the grid in uneven proportions, the chain-link below the spacing values needs to be broken

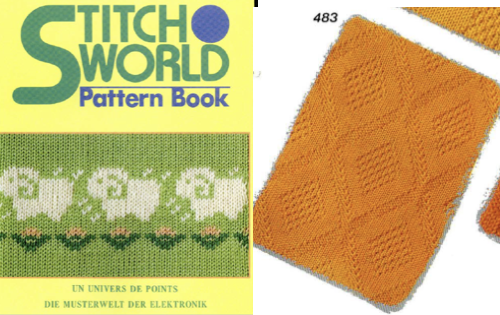

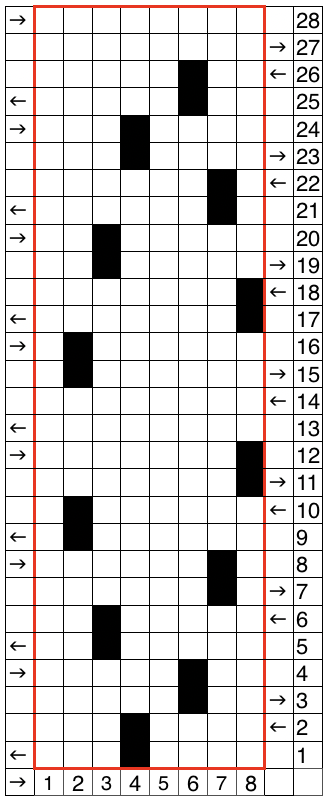

It is possible to produce a rectangular grid to start with on which to draw in Gimp, but the larger canvas size occupies a significantly larger space on the screen, complicating the process. For small designs, however, that may be an option to give one the sense of aspect ratio for the design in the final knit ie in representational FI. To resize the grid in uneven proportions, the chain-link below the spacing values needs to be broken  This repeat is designed for an electronic, requires color-reverse. Since it is 24 stitches wide and it may also be modified and used on a card. In this instance, the original marks for rows and stitches are single height. The image is processed, matching the original, rendered double-height, color reversed, and then alternate pairs of rows were color inverted to render the repeat used in the test swatch

This repeat is designed for an electronic, requires color-reverse. Since it is 24 stitches wide and it may also be modified and used on a card. In this instance, the original marks for rows and stitches are single height. The image is processed, matching the original, rendered double-height, color reversed, and then alternate pairs of rows were color inverted to render the repeat used in the test swatch  Once again, the possible change in scale is estimated. The repeat though only 24 stitches wide, is 92 rows high. On the left the repeat is shown as it appears on a square grid, to its right is the scaled 4:3 version, in a pixel count approximating the size of the swatch. It takes a bit of squinting to see the pattern more recognizable in the longer repeat in the larger tile

Once again, the possible change in scale is estimated. The repeat though only 24 stitches wide, is 92 rows high. On the left the repeat is shown as it appears on a square grid, to its right is the scaled 4:3 version, in a pixel count approximating the size of the swatch. It takes a bit of squinting to see the pattern more recognizable in the longer repeat in the larger tile

![]() The swatch was pressed, becoming wider than when first off the machine. It was knit using the slip stitch setting, could also be executed in tuck stitch, which would both widen and shorten the fabric and make the purl side more interesting. The software can provide a preview of the result far more quickly than knitting samples, but again, the previews are only approximations of the scale, and cannot show distortions to lines as one adds more texture.

The swatch was pressed, becoming wider than when first off the machine. It was knit using the slip stitch setting, could also be executed in tuck stitch, which would both widen and shorten the fabric and make the purl side more interesting. The software can provide a preview of the result far more quickly than knitting samples, but again, the previews are only approximations of the scale, and cannot show distortions to lines as one adds more texture.

![]() and with a check tuck pattern that may change in aspect ratio considerably when knitted

and with a check tuck pattern that may change in aspect ratio considerably when knitted

The proof of concept swatch, knit in tuck stitch, begins to show the distortion by the stitch formations, textures vs plain knit, easily seen at the top edge. The bind-off is around 2 gate pegs in order to allow enough stretch.

The proof of concept swatch, knit in tuck stitch, begins to show the distortion by the stitch formations, textures vs plain knit, easily seen at the top edge. The bind-off is around 2 gate pegs in order to allow enough stretch.  Anyone familiar with either or both programs may find this a very quick way to visualize the scaling and moving of motifs within DIY designs and their possible outcomes prior to test knitting

Anyone familiar with either or both programs may find this a very quick way to visualize the scaling and moving of motifs within DIY designs and their possible outcomes prior to test knitting

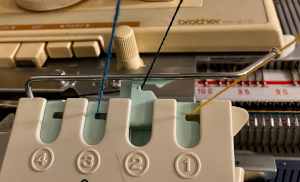

with my color changer in this threading sequence throughout

with my color changer in this threading sequence throughout

where normally each color in each design row knits twice. Because selection occurs for pairs of rows, the first preselection row is from right to left. To decrease the backing rows, the ribber is set for birdseye. I prefer to have an end needle on each end on the ribber, keeping in mind that the total number of needles in use there needs to be even. The machine provides reminders as to which color should be knitting. My samples are knit using KCI on the top bed. Because the preselection happens twice, it is easy enough to knit in pattern from left to right,

where normally each color in each design row knits twice. Because selection occurs for pairs of rows, the first preselection row is from right to left. To decrease the backing rows, the ribber is set for birdseye. I prefer to have an end needle on each end on the ribber, keeping in mind that the total number of needles in use there needs to be even. The machine provides reminders as to which color should be knitting. My samples are knit using KCI on the top bed. Because the preselection happens twice, it is easy enough to knit in pattern from left to right,  when the carriages have reached the right side, simply use a ribber comb to push all needles back to B.

when the carriages have reached the right side, simply use a ribber comb to push all needles back to B.

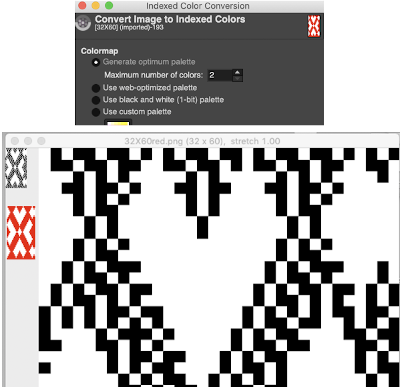

Speeding things up with color separation, beginning with the method that will have each color, each design row knitting twice. The repeat is 10 rows high, so it is expanded X6 to 10 by 60 rows. In the final result, the second row for each color in the separation is in turn erased. The red was added to make all 3 colors visible while working the separation, avoiding confusion with the white ground. The knittable result as usual is in a black and white png

Speeding things up with color separation, beginning with the method that will have each color, each design row knitting twice. The repeat is 10 rows high, so it is expanded X6 to 10 by 60 rows. In the final result, the second row for each color in the separation is in turn erased. The red was added to make all 3 colors visible while working the separation, avoiding confusion with the white ground. The knittable result as usual is in a black and white png

The ribber can also be set to knit every row, resulting in elongation on the knit side, while creating an interesting striper backing

The ribber can also be set to knit every row, resulting in elongation on the knit side, while creating an interesting striper backing

Comparing this version to the birdseye backed one for repeat height

Comparing this version to the birdseye backed one for repeat height  Comparisons: HoP, pushing back needles to B, and color separation results. In the latter, the design is likely elongated in part due to a change in the distribution of thinner yarns to larger design areas with no tension adjustments

Comparisons: HoP, pushing back needles to B, and color separation results. In the latter, the design is likely elongated in part due to a change in the distribution of thinner yarns to larger design areas with no tension adjustments

a partial illustration of

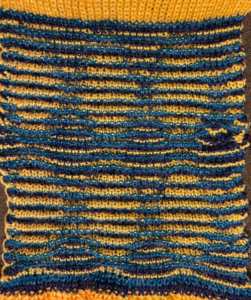

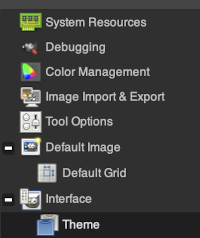

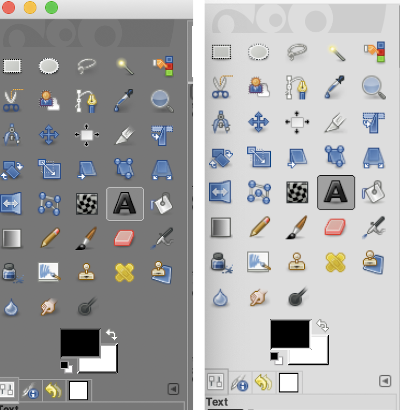

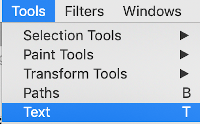

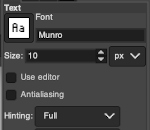

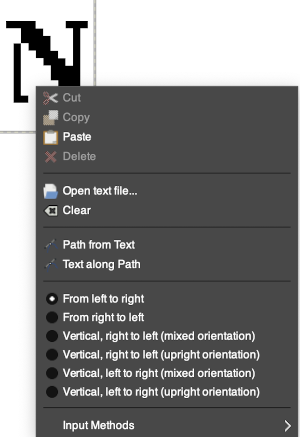

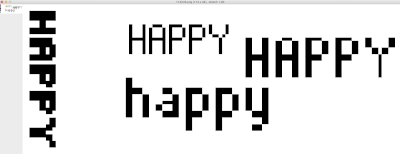

a partial illustration of  Text may be activated by choosing text in the image/ tools menu

Text may be activated by choosing text in the image/ tools menu  by clicking on the tool icon A in the toolbox

by clicking on the tool icon A in the toolbox  or by using t as the keyboard shortcut, then clicking anywhere on the canvas.

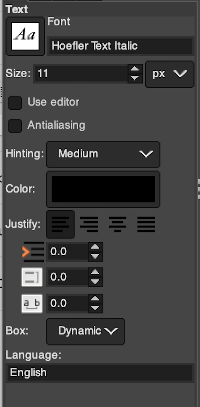

or by using t as the keyboard shortcut, then clicking anywhere on the canvas. At the top of the Text tool dialog, the current Text Size, 11 in above, is shown in either pixels or points. A pixel is the smallest component in a bitmap image, and all measures in pixels depend on the screen resolution. A point is a fixed value, one inch is the same as 72 points. Standard screen resolution is often 72 pixels per inch, in which case text in pixels will be the same size as text measured in points.

At the top of the Text tool dialog, the current Text Size, 11 in above, is shown in either pixels or points. A pixel is the smallest component in a bitmap image, and all measures in pixels depend on the screen resolution. A point is a fixed value, one inch is the same as 72 points. Standard screen resolution is often 72 pixels per inch, in which case text in pixels will be the same size as text measured in points.

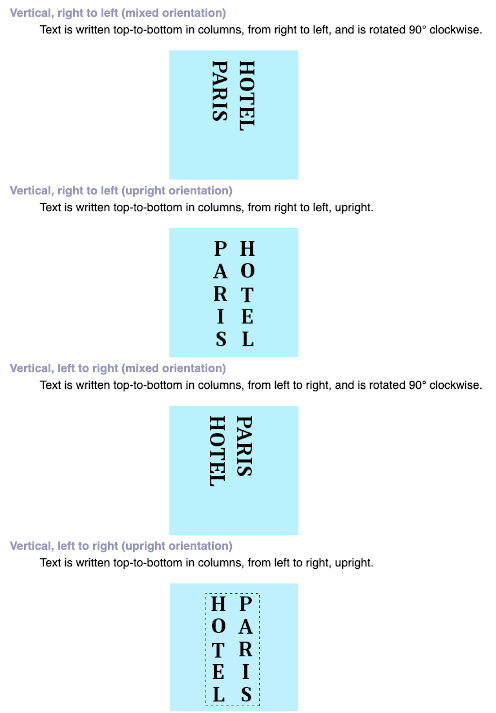

The choices listed at

The choices listed at  After the text is entered on the canvas, right-click on the inside of the text box to change text direction

After the text is entered on the canvas, right-click on the inside of the text box to change text direction

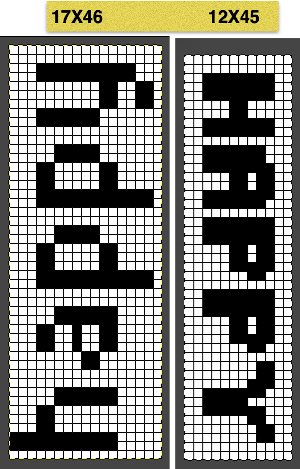

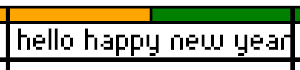

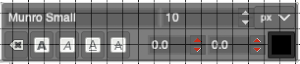

After the chosen text is placed change its mode from RGB to B/W indexed, then crop the image to your chosen size. Export.bmp, the result loaded into img2track and Ayab

After the chosen text is placed change its mode from RGB to B/W indexed, then crop the image to your chosen size. Export.bmp, the result loaded into img2track and Ayab

The usual text alignment rules apply in text boxes as well, left to right

The usual text alignment rules apply in text boxes as well, left to right

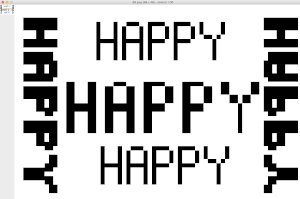

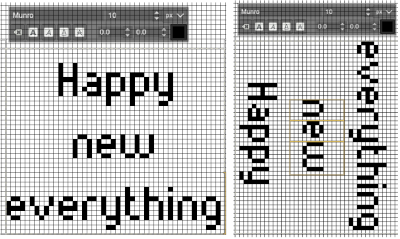

Getting more control of the process: after the text tool is highlighted and clicking anywhere on your canvas two things appear automatically. The four little boxes represent the text box, which is dynamic by default and grows in size to accommodate typed text. Anytime you click on the canvas a new text box is created.

Getting more control of the process: after the text tool is highlighted and clicking anywhere on your canvas two things appear automatically. The four little boxes represent the text box, which is dynamic by default and grows in size to accommodate typed text. Anytime you click on the canvas a new text box is created.

The spacing between the lines and between the letters may be adjusted as well. Clicking on the arrows to change the values here is one option, negative or positive numbers may be used

The spacing between the lines and between the letters may be adjusted as well. Clicking on the arrows to change the values here is one option, negative or positive numbers may be used  or what appeared easier to me, the same may be done here

or what appeared easier to me, the same may be done here

Very small fonts are likely not to have any room for decreased spacing in the between letters in strings of text.

Very small fonts are likely not to have any room for decreased spacing in the between letters in strings of text.

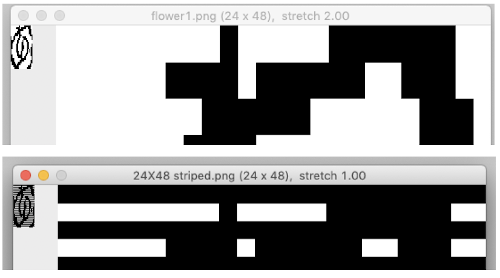

The “striped” repeat produces essentially the same fabric. The knit carriage may be set to slip in both directions when using it since the row of all punched holes or black pixels will knit every stitch on every needle selected while in the previous samples the cam button set to knit in one direction performed that function regardless of any markings on the design repeat. The ribber is set to knit in one direction, slip in the other. Reversing sides for cam button settings produces the same fabric

The “striped” repeat produces essentially the same fabric. The knit carriage may be set to slip in both directions when using it since the row of all punched holes or black pixels will knit every stitch on every needle selected while in the previous samples the cam button set to knit in one direction performed that function regardless of any markings on the design repeat. The ribber is set to knit in one direction, slip in the other. Reversing sides for cam button settings produces the same fabric

The

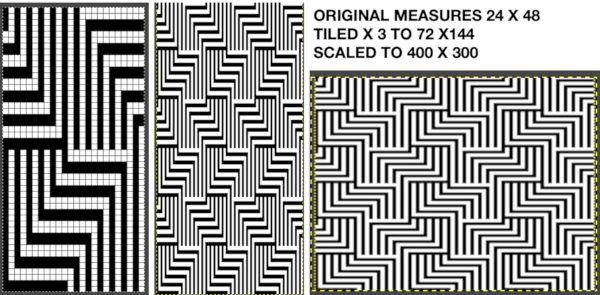

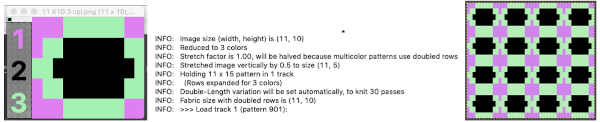

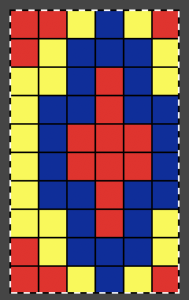

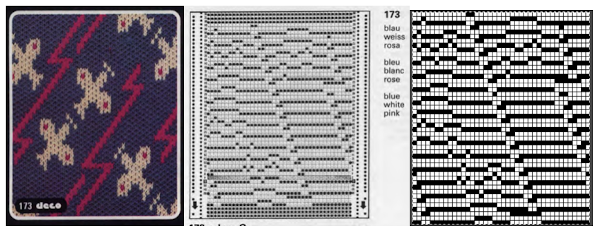

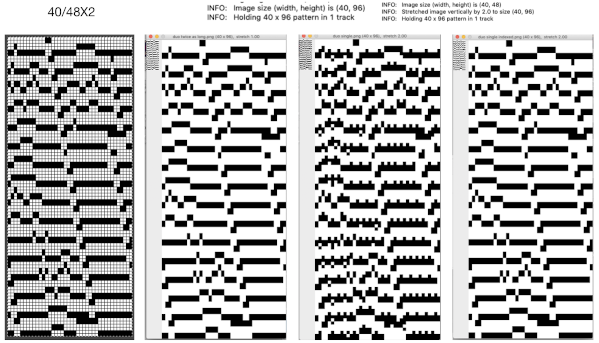

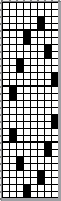

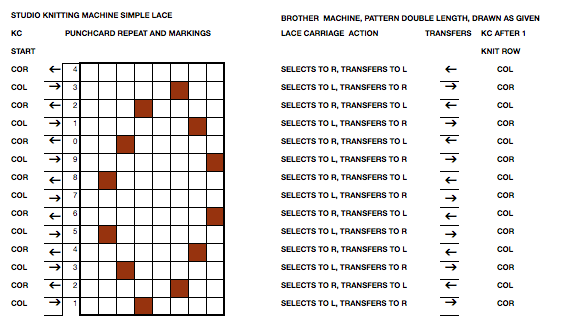

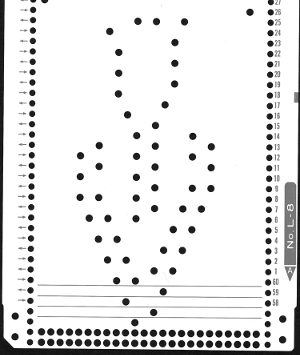

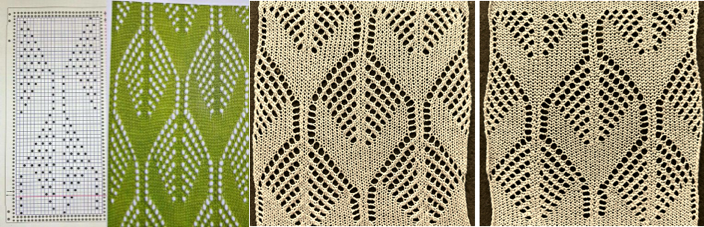

The  The repeat I chose is designated as suitable for the Garter Carriage. It is 24 stitches wide by 48 rows high, shown below as provided, charted in Gimp as .png for download, and tiled to help visualize how continuous repeats might line up. The image .png was downloaded with img2track to my 930, with a stretch factor of 1.0, retaining the original repeat size

The repeat I chose is designated as suitable for the Garter Carriage. It is 24 stitches wide by 48 rows high, shown below as provided, charted in Gimp as .png for download, and tiled to help visualize how continuous repeats might line up. The image .png was downloaded with img2track to my 930, with a stretch factor of 1.0, retaining the original repeat size

The design is automatically flipped vertically, so it will appear as intended on the knit side of the fabric. Yarn colors may be placed in the color changer matching the order in the assigned color numbers to match the placements in the original image. The program automatically adjusts for the vertical stretch, which changes the aspect ratio of the shapes. On my 930 I received prompts on which color to change to prior to doing so, eliminating any confusion. With no such prompts generally one can tell which color was knit last because it will appear on top of the previously used one on the left of the knit. With a stretch factor of 1 selected in img2track, the image height was reduced by half.

The design is automatically flipped vertically, so it will appear as intended on the knit side of the fabric. Yarn colors may be placed in the color changer matching the order in the assigned color numbers to match the placements in the original image. The program automatically adjusts for the vertical stretch, which changes the aspect ratio of the shapes. On my 930 I received prompts on which color to change to prior to doing so, eliminating any confusion. With no such prompts generally one can tell which color was knit last because it will appear on top of the previously used one on the left of the knit. With a stretch factor of 1 selected in img2track, the image height was reduced by half.

In the past, I have preferred to elongate the design prior to importing with plans for download rather than to rely on memory for changing settings either in the download program or in the machine itself in future uses of the same design.

In the past, I have preferred to elongate the design prior to importing with plans for download rather than to rely on memory for changing settings either in the download program or in the machine itself in future uses of the same design.

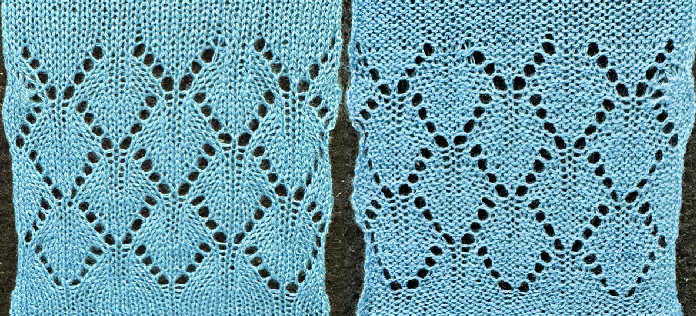

The same yarns, tension, the total number of carriage passes, and settings were used showing the difference in aspect ratio between single color per row knitting and the img2track built-in color separation.

The same yarns, tension, the total number of carriage passes, and settings were used showing the difference in aspect ratio between single color per row knitting and the img2track built-in color separation.  The width of both swatches is essentially identical.

The width of both swatches is essentially identical.

The 930 will provide prompts for the next color to be selected by pushing the matching number button on the color changer, avoiding any confusion in terms of what should be picked up next. img2track will also flip the design horizontally automatically so the image will appear as originally drawn on the knit side. Images are loaded as single motifs, so the change in the selector needs to be made manually for an all-over pattern.

The 930 will provide prompts for the next color to be selected by pushing the matching number button on the color changer, avoiding any confusion in terms of what should be picked up next. img2track will also flip the design horizontally automatically so the image will appear as originally drawn on the knit side. Images are loaded as single motifs, so the change in the selector needs to be made manually for an all-over pattern.

Obviously a success in terms of the single row for each color reducing elongation of the design shape. While knitting occurs using the same yarns, at the same tensions, there is a clear difference in the length of each stitch on the main bed and their appearance. The reverse. Checking the ribber carriage I noticed on the left side it was set to knit only, not to slip: OOPS!

Obviously a success in terms of the single row for each color reducing elongation of the design shape. While knitting occurs using the same yarns, at the same tensions, there is a clear difference in the length of each stitch on the main bed and their appearance. The reverse. Checking the ribber carriage I noticed on the left side it was set to knit only, not to slip: OOPS!  N is king, so the ribber set as shown is knitting every other needle when moving to the right, but even with lili buttons in use, it knits on every needle when moving back to the left. Every other needle on the ribber will then be knitting for 2 rows as a result. The more knitting on the ribber for each pair of rows, the longer the stitches on the opposite bed. The backing is an interesting variation (half) birdseye. The elongated stitches on the main bed show more of the backing in between their shapes, it is referred to as bleedthrough. In some instances, the result can make the knit surface resemble weaving and its appearance far less familiar in a surprising, pleasant way. Beauty is in the eye of the beholder.

N is king, so the ribber set as shown is knitting every other needle when moving to the right, but even with lili buttons in use, it knits on every needle when moving back to the left. Every other needle on the ribber will then be knitting for 2 rows as a result. The more knitting on the ribber for each pair of rows, the longer the stitches on the opposite bed. The backing is an interesting variation (half) birdseye. The elongated stitches on the main bed show more of the backing in between their shapes, it is referred to as bleedthrough. In some instances, the result can make the knit surface resemble weaving and its appearance far less familiar in a surprising, pleasant way. Beauty is in the eye of the beholder. The images could be replicated as given in a paint program, using only one color for the squares, but “should be reduced to black and white”. Attempting to import an indexed 2 color image drawn in a color other than BW may result in strange results.

The images could be replicated as given in a paint program, using only one color for the squares, but “should be reduced to black and white”. Attempting to import an indexed 2 color image drawn in a color other than BW may result in strange results.  That said, if glitched knits are the goal, the above could work just fine. Curiously, here is the same process, using a different color, and a successful import. Checking again, I had forgotten to save the image after indexing it from RGB mode to 2 colors.

That said, if glitched knits are the goal, the above could work just fine. Curiously, here is the same process, using a different color, and a successful import. Checking again, I had forgotten to save the image after indexing it from RGB mode to 2 colors.

Note to self: if you are determined to use a punchcard carriage on your electronic machine remember there is no KCII to cancel end needle selection!

Note to self: if you are determined to use a punchcard carriage on your electronic machine remember there is no KCII to cancel end needle selection!

Getting that first row to knit twice instead of a single time if that matters in your technique or is your preference:

Getting that first row to knit twice instead of a single time if that matters in your technique or is your preference:

pick up color 1 in yarn changer

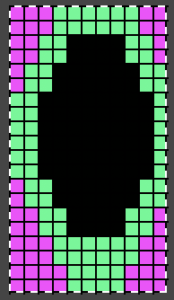

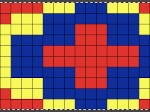

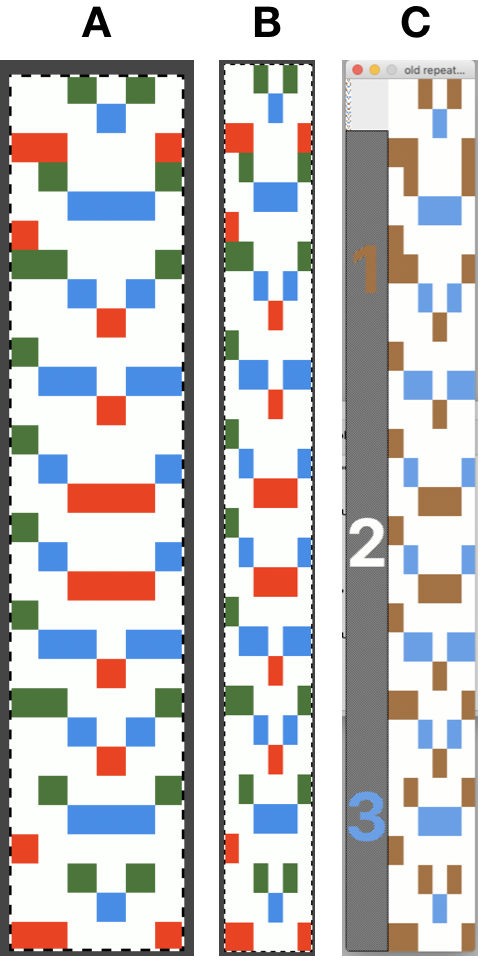

pick up color 1 in yarn changer If black and white repeats are already in your library, one may easily recycle them adding a third color. Here I did so with a repeat intended for a very different topic in future posts. The image was altered and tiled in Gimp for a repeat alignment test and is also shown imported into img2track for possible knitting.

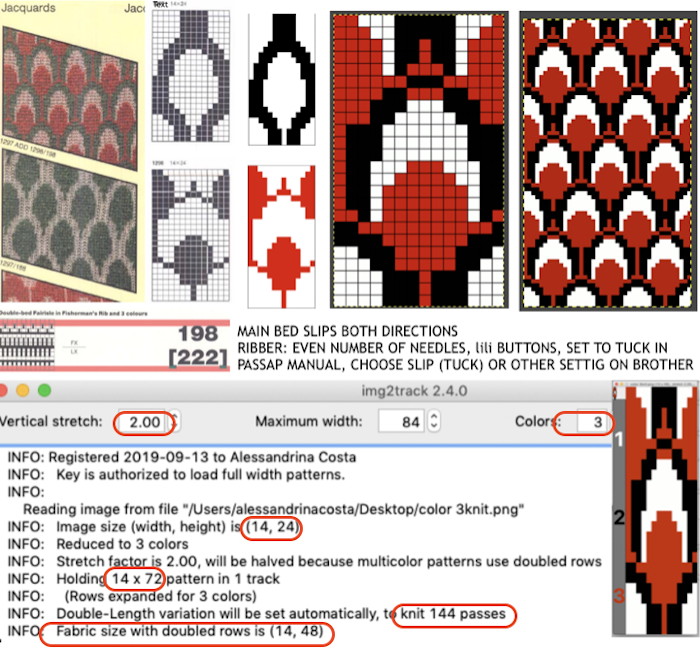

If black and white repeats are already in your library, one may easily recycle them adding a third color. Here I did so with a repeat intended for a very different topic in future posts. The image was altered and tiled in Gimp for a repeat alignment test and is also shown imported into img2track for possible knitting.

The image of the separation on the above right has not been proofed for accuracy. If it were, the next step would be to elongate it X 2 for color changes every 2 rows. One method is to elongate the original in a paint or photo processing program. The width is fixed (40), the height is scaled X 2. The resulting BW indexed image may be imported, using a 1.0 stretch factor, it remains unchanged. When I tried to elongate the unstretched image in img2track by 2.0 my first try failed. It turned out the reason was I had saved the import without first indexing it to 2 colors. With that corrected, the result matched the one from scaling X 2 in height in the paint program

The image of the separation on the above right has not been proofed for accuracy. If it were, the next step would be to elongate it X 2 for color changes every 2 rows. One method is to elongate the original in a paint or photo processing program. The width is fixed (40), the height is scaled X 2. The resulting BW indexed image may be imported, using a 1.0 stretch factor, it remains unchanged. When I tried to elongate the unstretched image in img2track by 2.0 my first try failed. It turned out the reason was I had saved the import without first indexing it to 2 colors. With that corrected, the result matched the one from scaling X 2 in height in the paint program

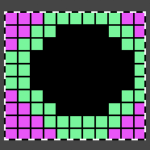

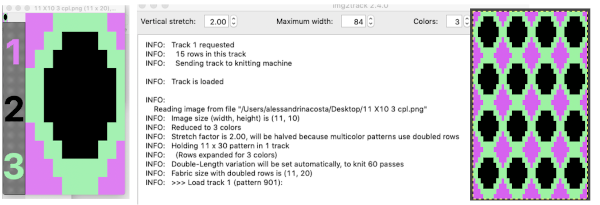

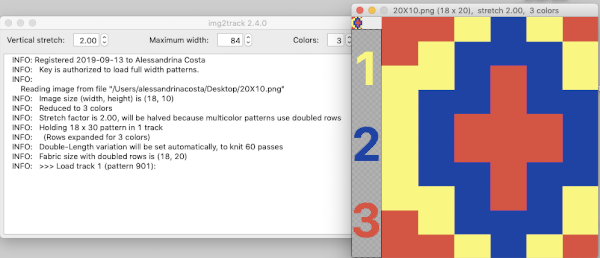

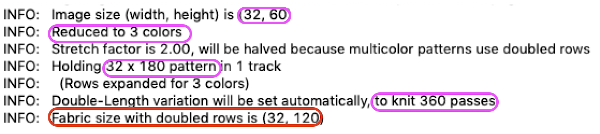

Here the image is scaled properly for each color represented for a single row in height, and also scaled again for double-height for possible knitting in Gimp. The Gimp scaling failed to be accurate for me (second image from left) until I indexed the original to 4 colors as well instead of 3. The no color rows as we view them actually serve as a fourth color in the separations. Importing the proper size png into img2track for separation of 4 colors per row now gives results that make sense: note the daunting estimate for the total number of carriage passes for a single repeat height

Here the image is scaled properly for each color represented for a single row in height, and also scaled again for double-height for possible knitting in Gimp. The Gimp scaling failed to be accurate for me (second image from left) until I indexed the original to 4 colors as well instead of 3. The no color rows as we view them actually serve as a fourth color in the separations. Importing the proper size png into img2track for separation of 4 colors per row now gives results that make sense: note the daunting estimate for the total number of carriage passes for a single repeat height If the ribber has knit on every needle by its return to the color changer and the machine is set to slip both ways with no needle selection on the main bed, the “no color” can be executed as an empty yarn holder in the color changer combined with no yarn in the feeder. The rows involved should simply not knit on the top bed, with no dropping of any of its stitches since no needles will have been selected thus coming forward with the yarn in the hooks and traveling behind the latches and in turn, slipping off the needles as a carriage with no yarn pushes the needles with now empty hooks back to B position.

If the ribber has knit on every needle by its return to the color changer and the machine is set to slip both ways with no needle selection on the main bed, the “no color” can be executed as an empty yarn holder in the color changer combined with no yarn in the feeder. The rows involved should simply not knit on the top bed, with no dropping of any of its stitches since no needles will have been selected thus coming forward with the yarn in the hooks and traveling behind the latches and in turn, slipping off the needles as a carriage with no yarn pushes the needles with now empty hooks back to B position.

Punchcard knitters may have the easiest knitting variable color sequences since cards may be visually marked up with colored pencils matching needed change locations and taking into account your eyes are a number of rows above the row being read by the card reader. This number depends on the machine’s brand and model.

Punchcard knitters may have the easiest knitting variable color sequences since cards may be visually marked up with colored pencils matching needed change locations and taking into account your eyes are a number of rows above the row being read by the card reader. This number depends on the machine’s brand and model.

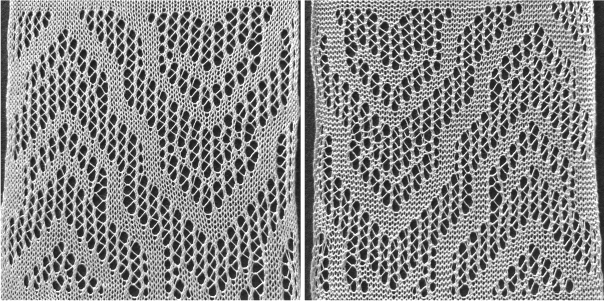

A comparison of my repeat using a single LC and the Knitlabo pattern expansion including memo options for use with 2 lace carriages

A comparison of my repeat using a single LC and the Knitlabo pattern expansion including memo options for use with 2 lace carriages

Back to the original method used in the previous post where ribber settings are changed from knit to tuck <– –> every 2 rows along with color changes. I chose a design that would make it easy to identify the location of non-selected needles on the main bed in rows where the ribber will be set to tuck in both directions. The result is interesting, but the solid areas, narrower than the remaining knit, are in the opposite color to the dominant one on each side, the reverse of the inspiration fabric.

Back to the original method used in the previous post where ribber settings are changed from knit to tuck <– –> every 2 rows along with color changes. I chose a design that would make it easy to identify the location of non-selected needles on the main bed in rows where the ribber will be set to tuck in both directions. The result is interesting, but the solid areas, narrower than the remaining knit, are in the opposite color to the dominant one on each side, the reverse of the inspiration fabric.

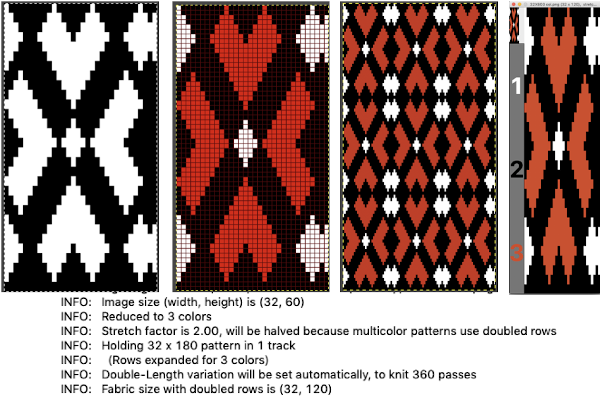

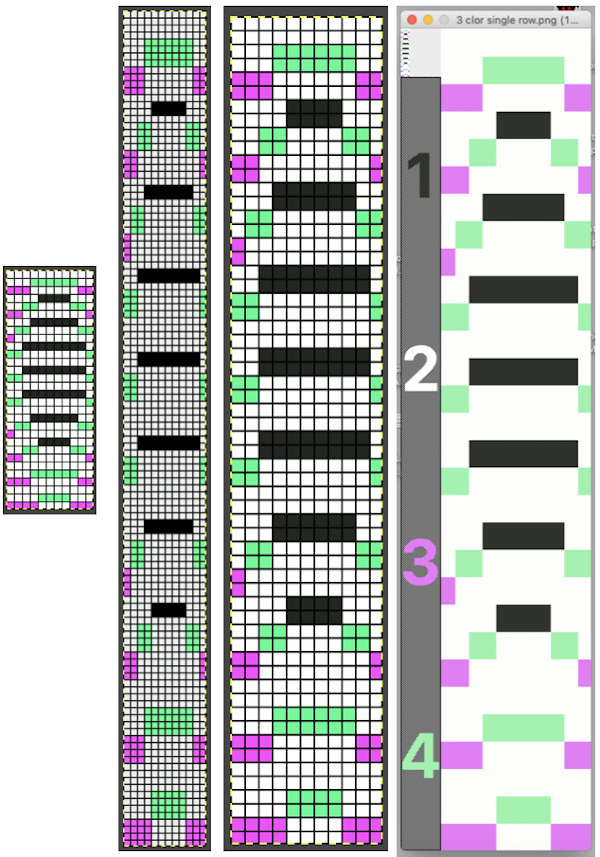

The single 14X84 png

The single 14X84 png  Each of the 2 colors tucks for 2 rows and in turn, knits for 2 rows alternately. Settings are changed manually as shown below after every 2 rows knit, following each color change on the left.

Each of the 2 colors tucks for 2 rows and in turn, knits for 2 rows alternately. Settings are changed manually as shown below after every 2 rows knit, following each color change on the left.  Making things a little easier: the top bed may be programmed on any machine, including punchcard models to avoid cam button changes in the knit carriage every 2 rows. With the main bed set to tuck <– —> throughout, black squares will knit for 2 rows, white squares will tuck, also for 2 rows. The first preselection row is toward the color changer. When no needles are selected on the top bed (white squares) the top bed will tuck every needle, the ribber is set to knit.

Making things a little easier: the top bed may be programmed on any machine, including punchcard models to avoid cam button changes in the knit carriage every 2 rows. With the main bed set to tuck <– —> throughout, black squares will knit for 2 rows, white squares will tuck, also for 2 rows. The first preselection row is toward the color changer. When no needles are selected on the top bed (white squares) the top bed will tuck every needle, the ribber is set to knit.

Another attempt at cabling, 1X1 and 2X2. That white line in the bottom image on the right was caused by the color changer picking up and knitting both colors for part of the row before I noticed it. I got rid of the “wrong” color from the feeder and continued on. The wider 2X2 cables require “special handling” and eyelets are formed on columns aside from them after transfers are made.

Another attempt at cabling, 1X1 and 2X2. That white line in the bottom image on the right was caused by the color changer picking up and knitting both colors for part of the row before I noticed it. I got rid of the “wrong” color from the feeder and continued on. The wider 2X2 cables require “special handling” and eyelets are formed on columns aside from them after transfers are made.

The situation is different when working on single bed vertically striped fair isle designs. One of my ancient machine-knit demo FI swatches:

The situation is different when working on single bed vertically striped fair isle designs. One of my ancient machine-knit demo FI swatches:

The charted repeat on the left below when tiled shows the area of a patterning error, on the right with the missing blank rows added the problem is shown to be resolved, the repeat is now 24 X 84.

The charted repeat on the left below when tiled shows the area of a patterning error, on the right with the missing blank rows added the problem is shown to be resolved, the repeat is now 24 X 84.

Adding complexity, there is the possibility of

Adding complexity, there is the possibility of

Other related fabrics may be found in posts:

Other related fabrics may be found in posts: