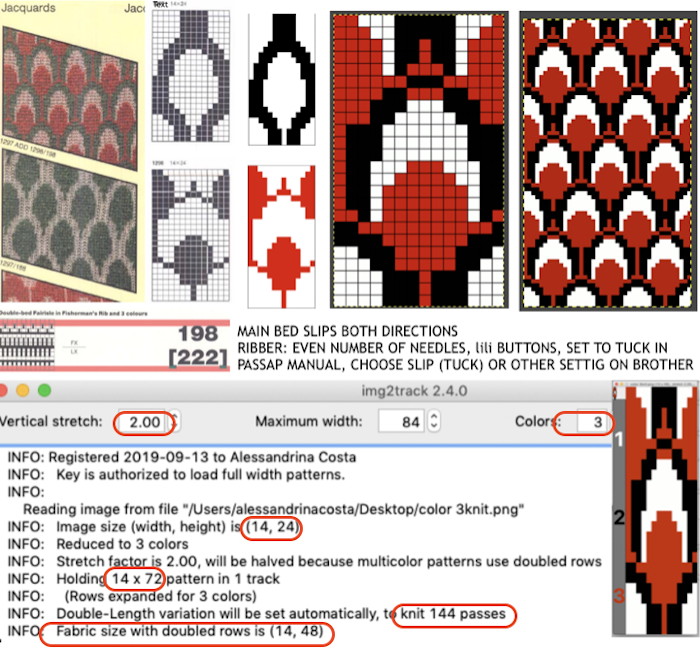

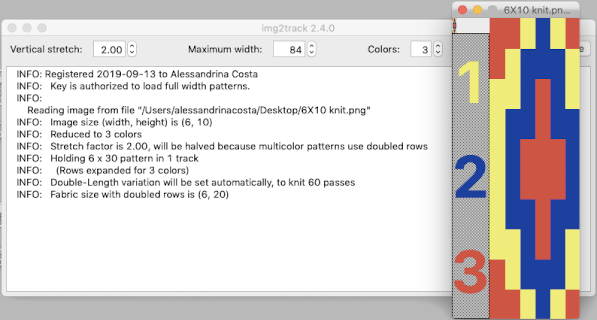

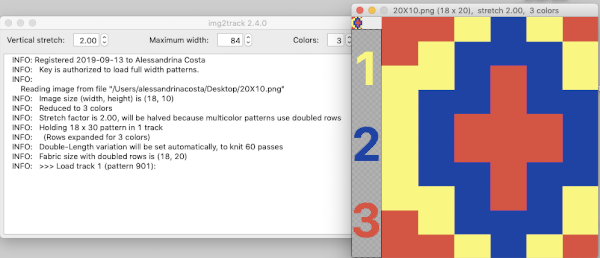

My first attempt to use a 3 color automatic separation was with img2track.

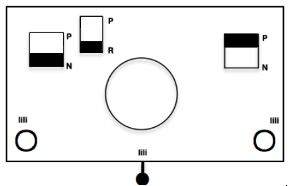

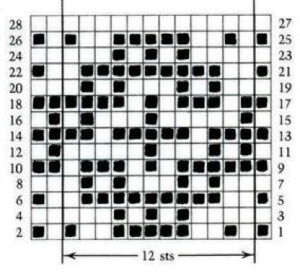

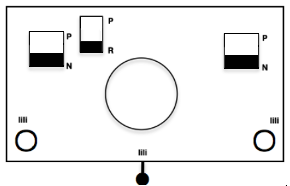

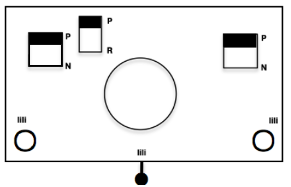

The default selector setting is for a single motif, perhaps on the assumption that the main use would primarily be for large-scale, nonrepetitive images.

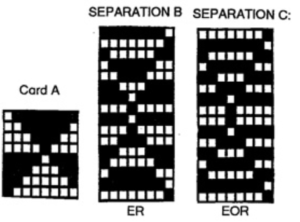

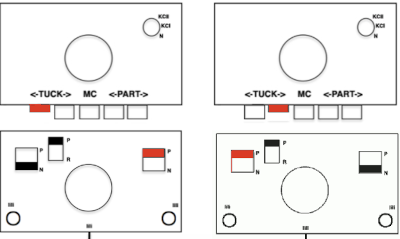

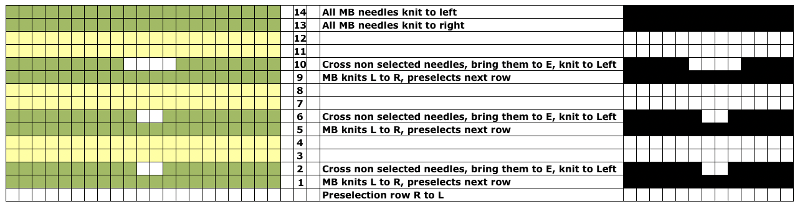

In standard dbj the built-in separation, when KRC is activated, the first preselection row is made from left to right, and the first color knits for only one row on moving from the right side to the left, but if 2 colors with the same selection are required at the start, one row of the 2 rows is technically eliminated as a result, resulting in patterning errors.

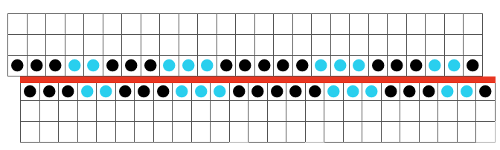

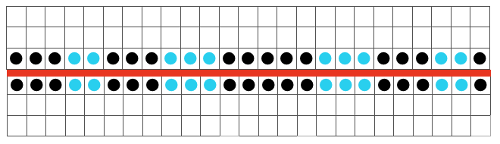

The first preselection row in these knits is made from right to left, each color in each row will be knit twice.

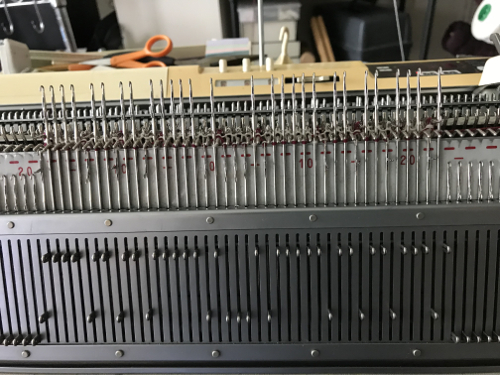

As soon as a row begins to be knit, the numbers change in the memo window, indicating that the machine is using this pass to select the needles for the next row. As the carriage passes the midpoint of the bed, the row number will begin flashing indicating that this is the row you will be knitting next. The process is repeated as the carriage reverses direction.

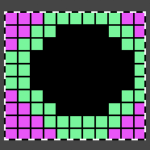

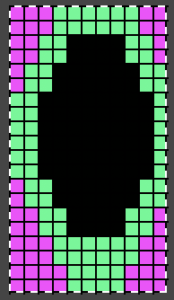

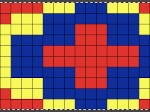

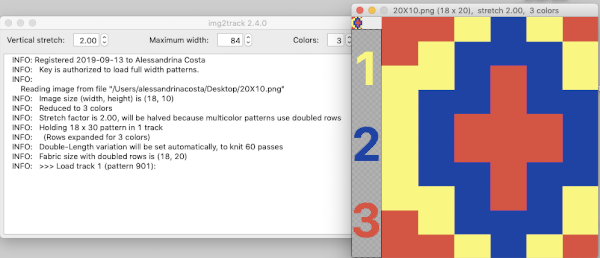

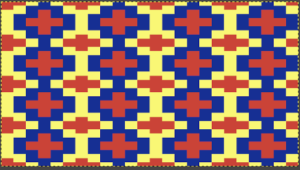

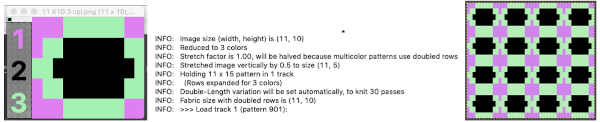

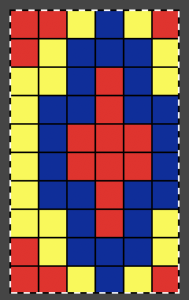

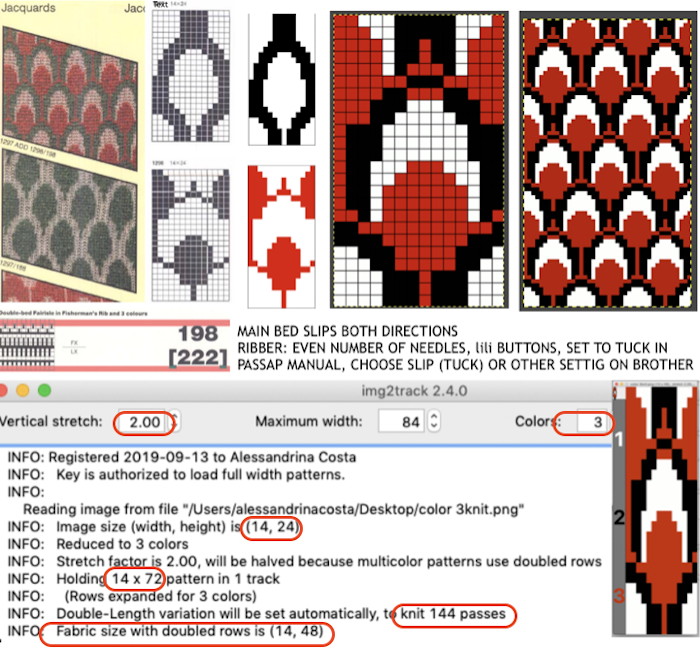

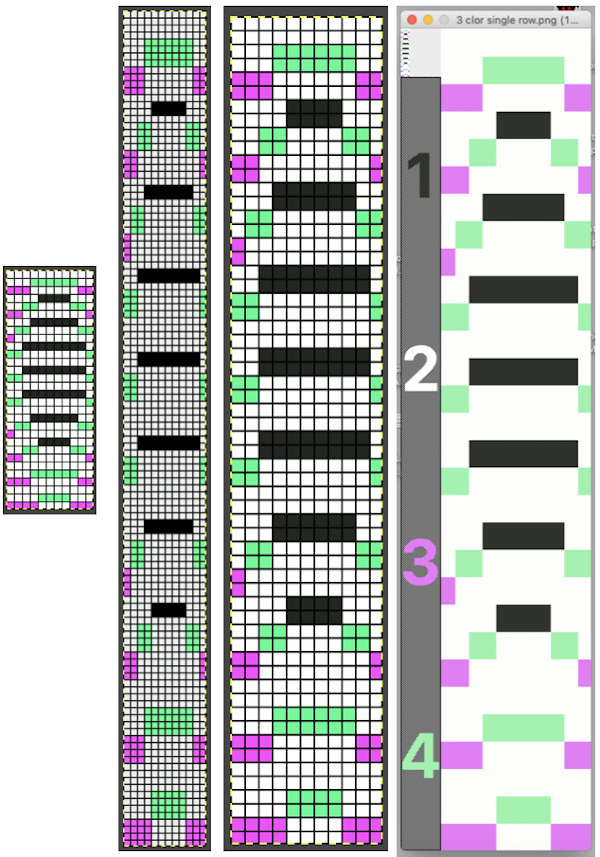

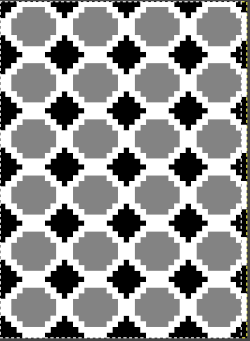

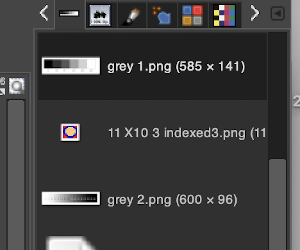

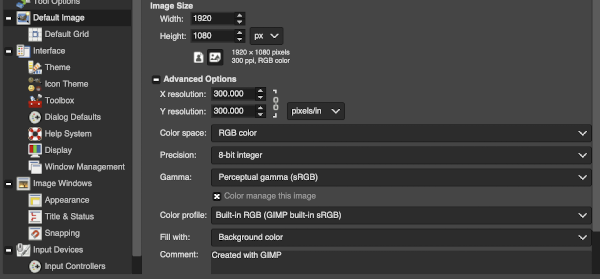

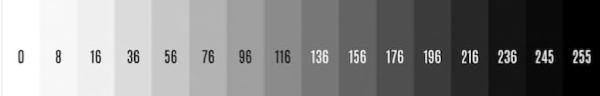

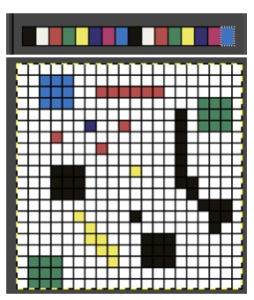

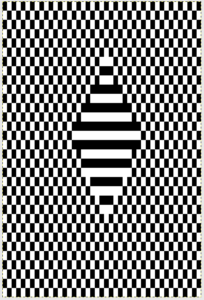

I had expected to use 3 shades of grey, a pleasant surprise: the program can import 3 colors other than grays. The test was using the 11-stitch repeat

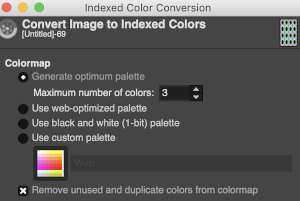

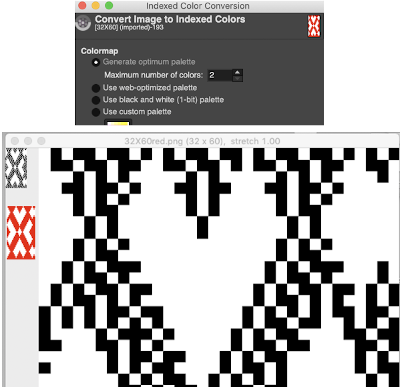

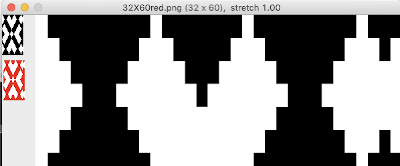

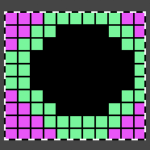

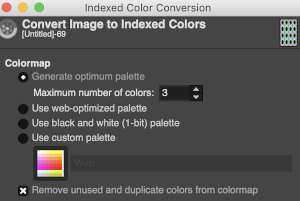

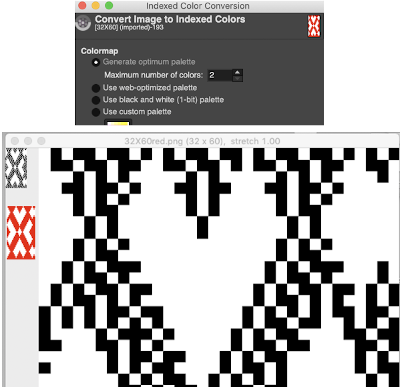

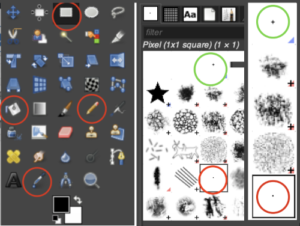

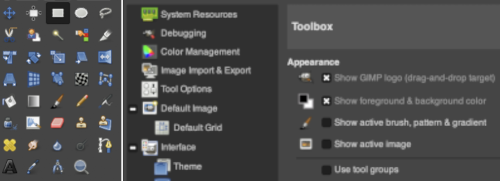

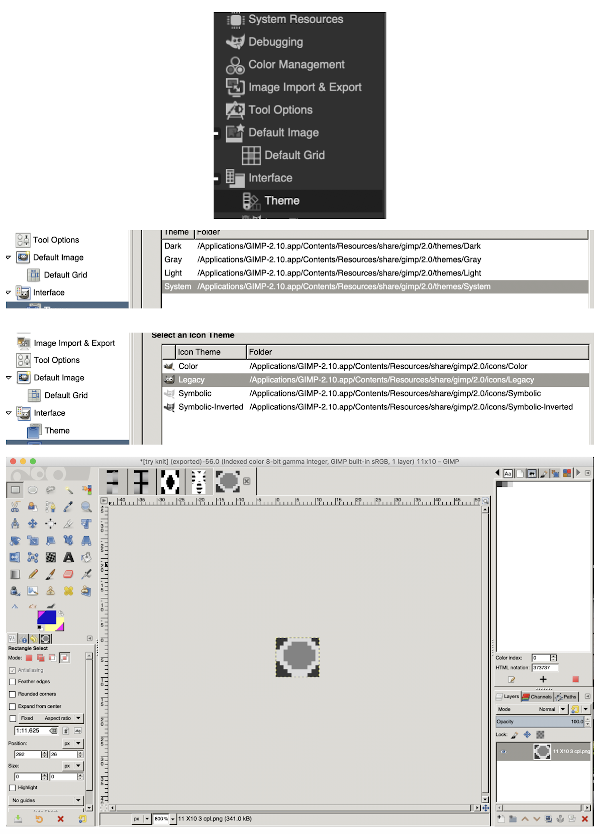

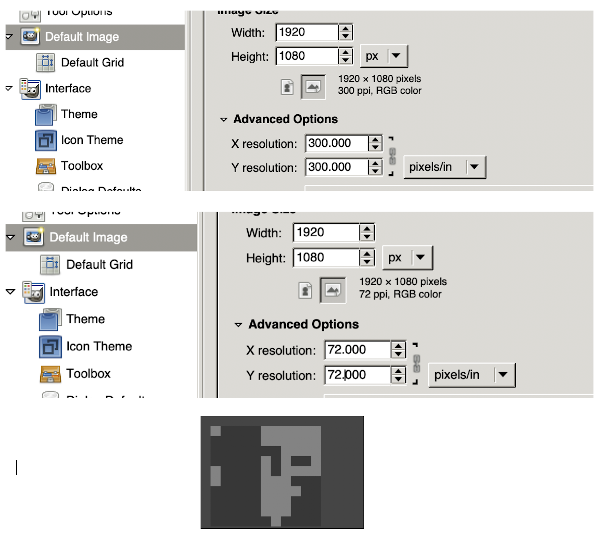

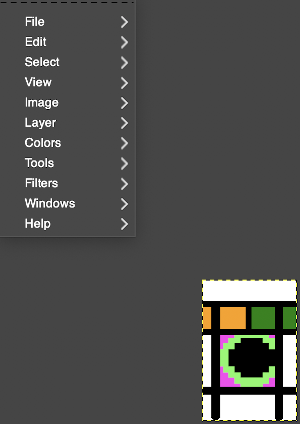

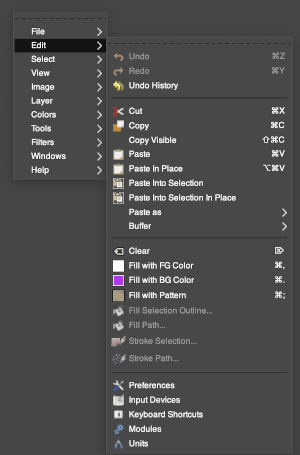

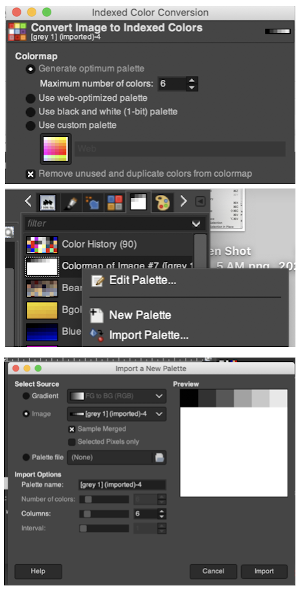

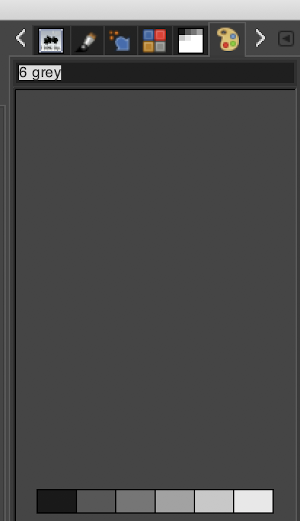

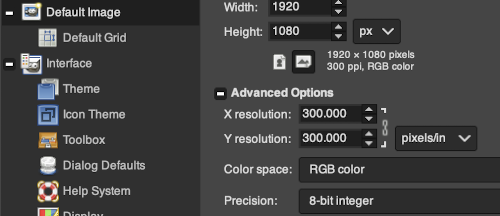

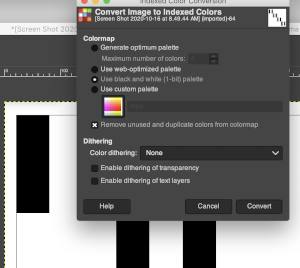

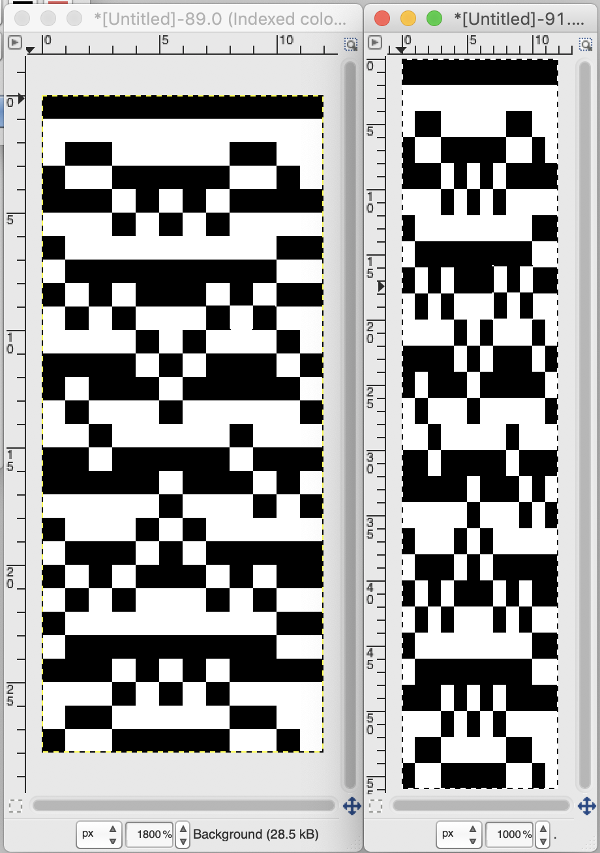

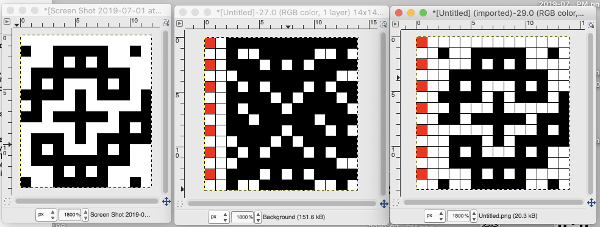

Using Gimp, images worked in RGB can be reduced to indexed 3 colors for this purpose. If there are rows where no color is represented, then as explained later in the post, the indexing should be to 4 colors, not 3 for the planned import to work properly.

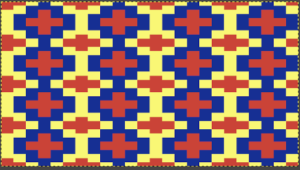

Using Gimp, images worked in RGB can be reduced to indexed 3 colors for this purpose. If there are rows where no color is represented, then as explained later in the post, the indexing should be to 4 colors, not 3 for the planned import to work properly.  The design is automatically flipped vertically, so it will appear as intended on the knit side of the fabric.

The design is automatically flipped vertically, so it will appear as intended on the knit side of the fabric.

Yarn colors may be placed in the color changer matching the order in the assigned color numbers to match the placements in the original image.

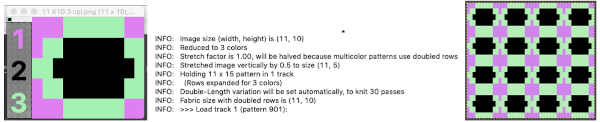

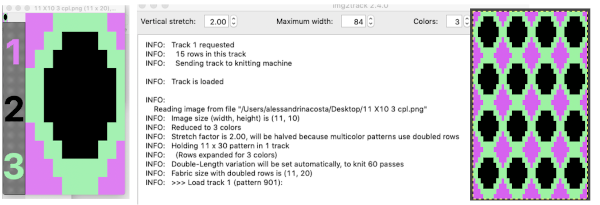

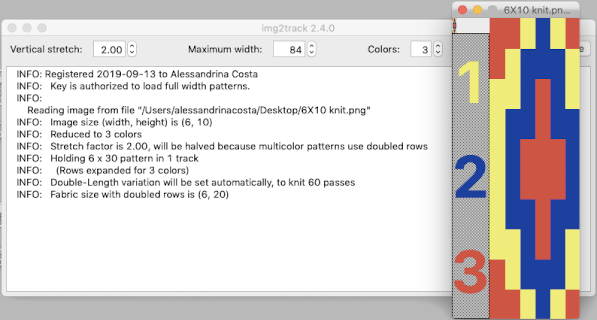

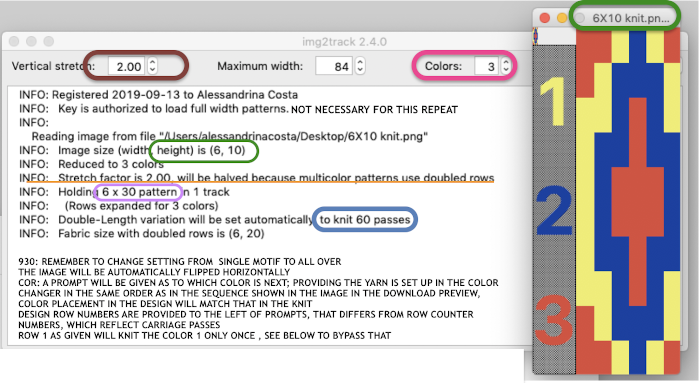

The program automatically adjusts for the vertical stretch, which changes the aspect ratio of the shapes.

The double height variation button is activated automatically.

On my 930 I received prompts on which color to change to before doing so, eliminating any confusion.

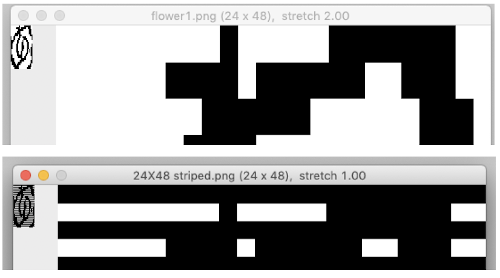

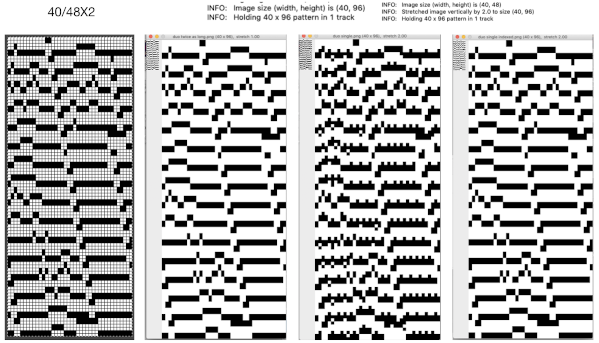

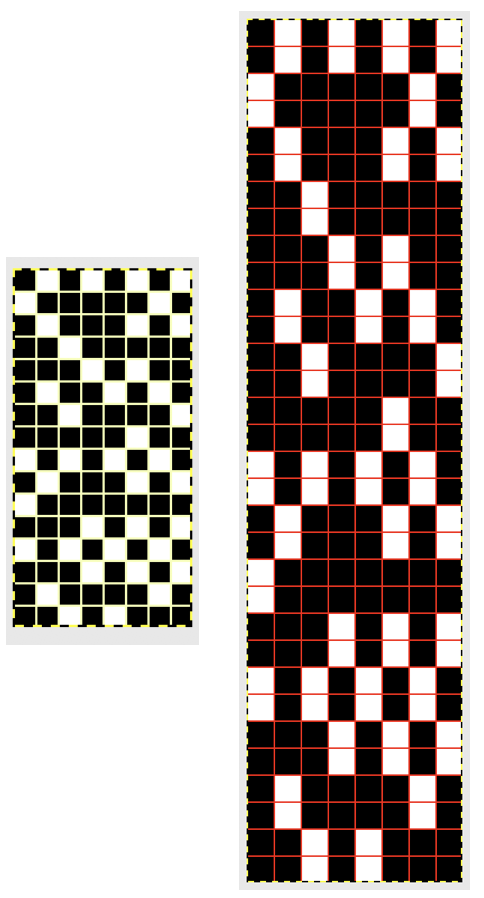

With no such prompts generally one can tell which color was knit last because it will appear on top of the previously used one on the left of the knit. With a stretch factor of 1 selected in img2track, the image height was reduced by half.

To achieve a look closer to the intended shape, the repeat needs to be rendered twice as long, or the stretch factor can be adjusted in the program itself to 2.0

To achieve a look closer to the intended shape, the repeat needs to be rendered twice as long, or the stretch factor can be adjusted in the program itself to 2.0

In the past, I have preferred to elongate the design prior to importing with plans for download rather than to rely on memory for changing settings either in the download program or in the machine itself in future uses of the same design.

In the past, I have preferred to elongate the design prior to importing with plans for download rather than to rely on memory for changing settings either in the download program or in the machine itself in future uses of the same design.

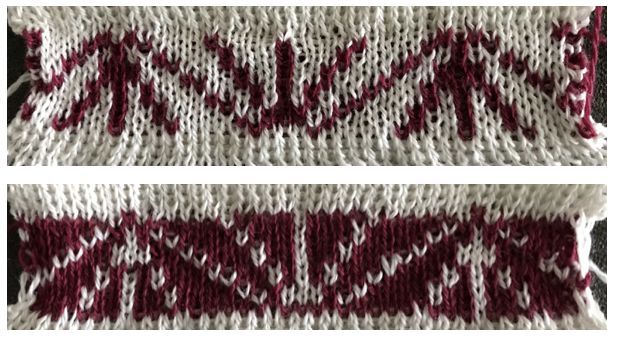

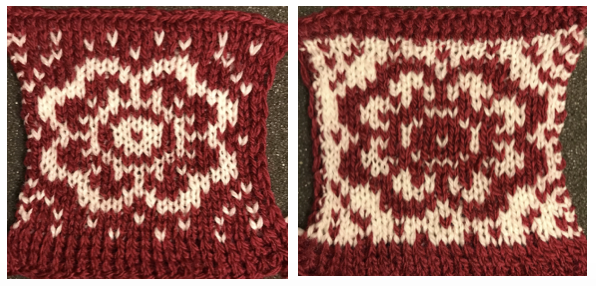

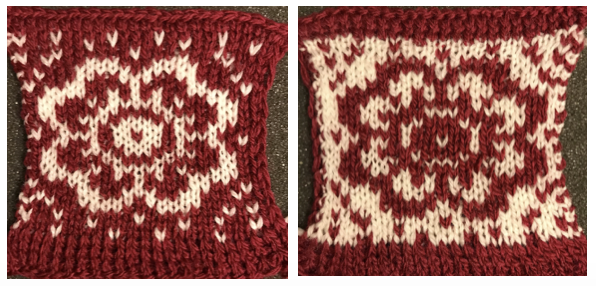

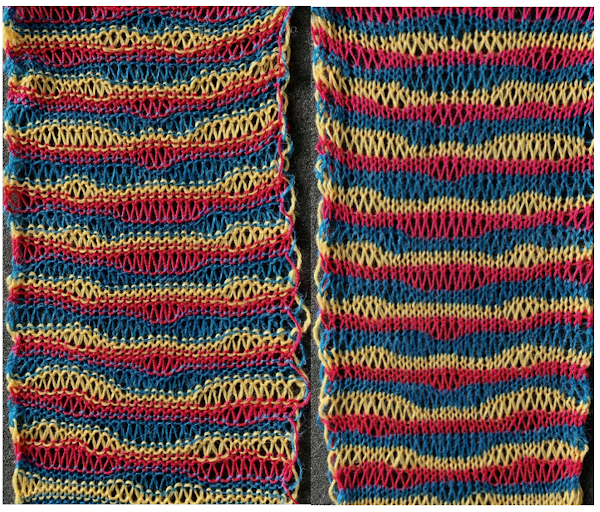

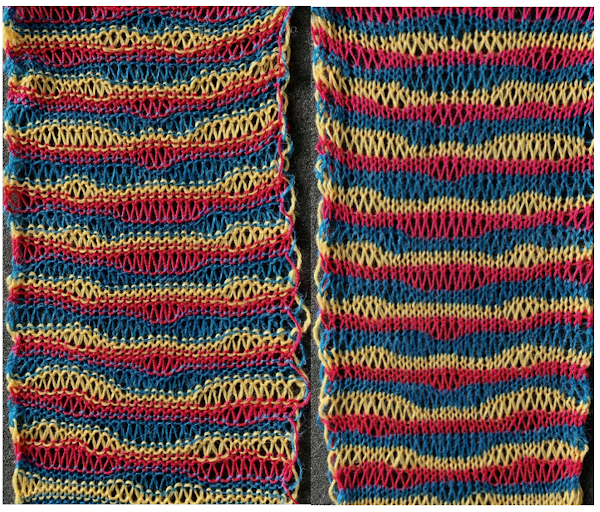

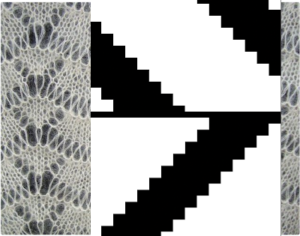

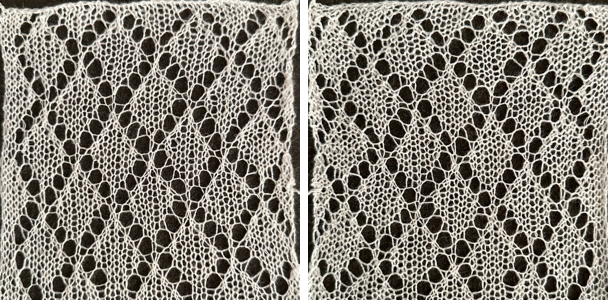

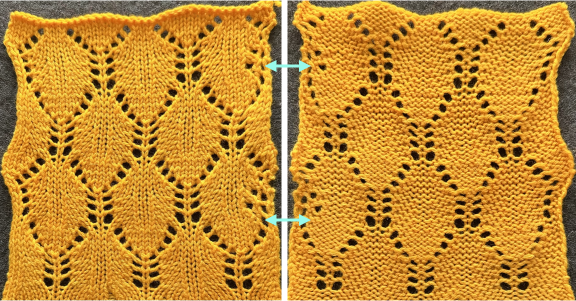

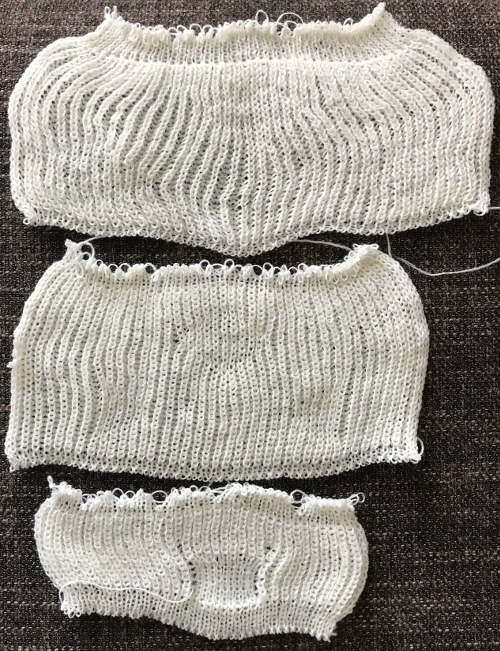

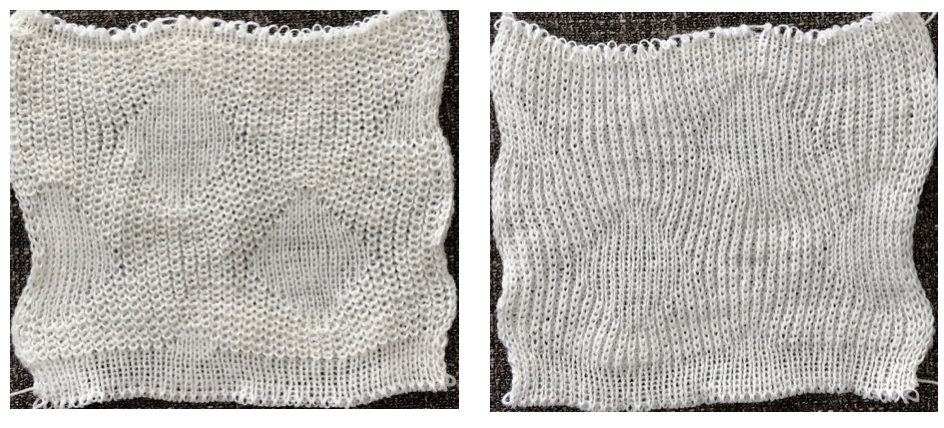

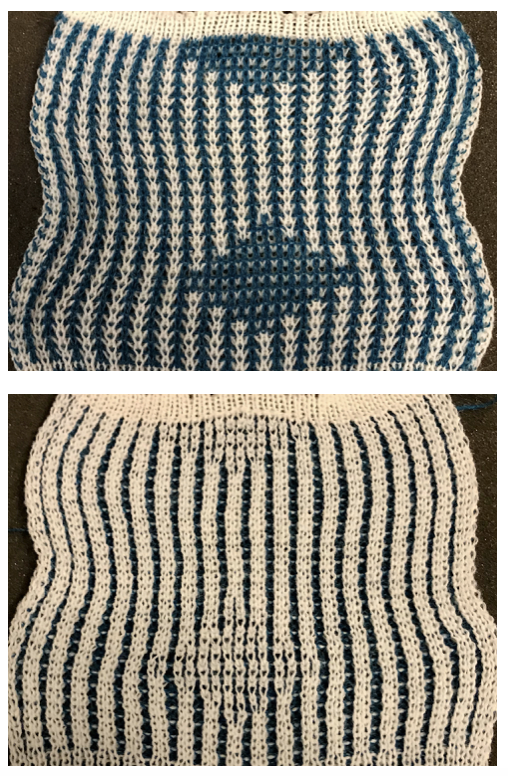

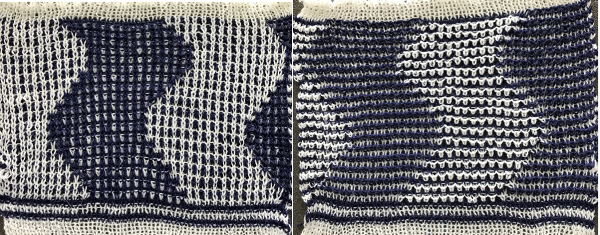

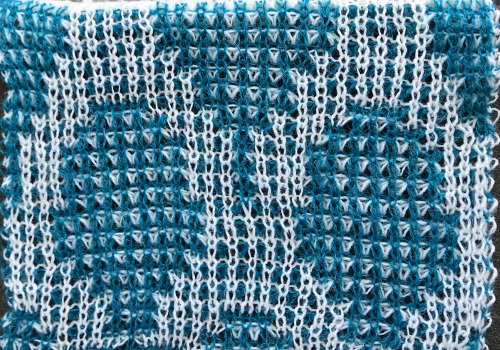

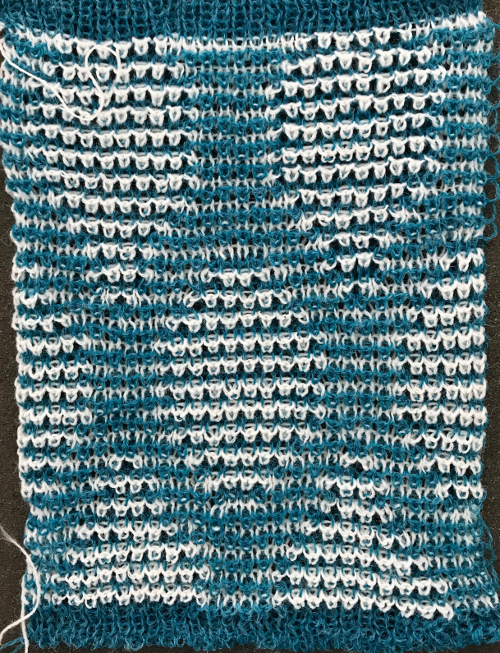

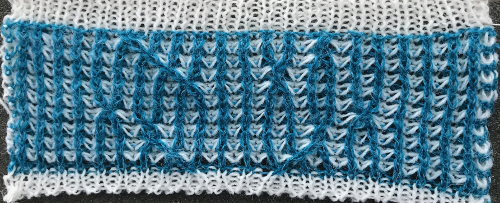

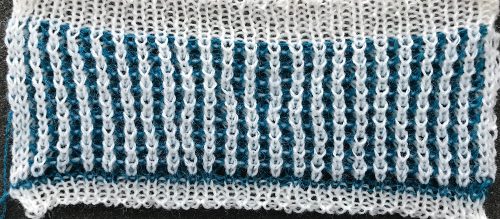

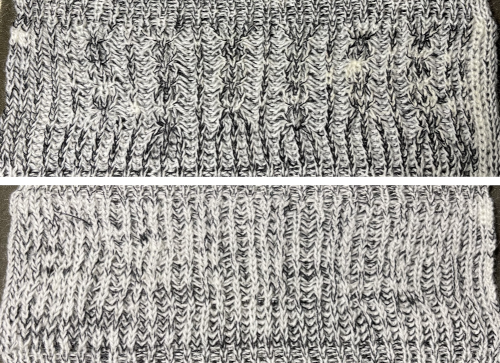

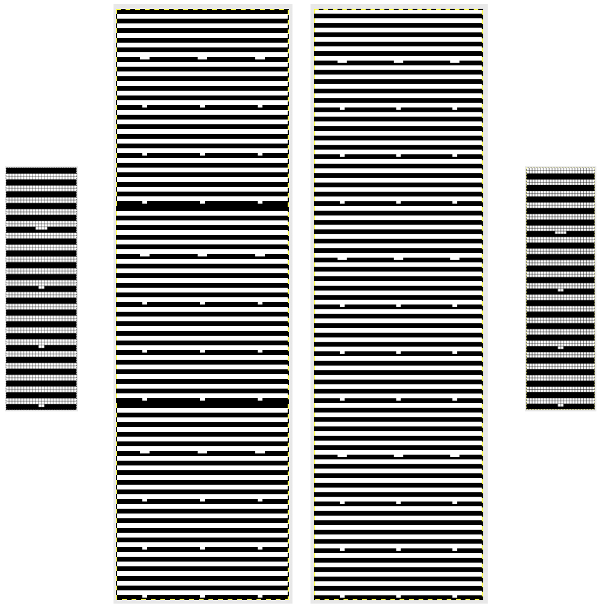

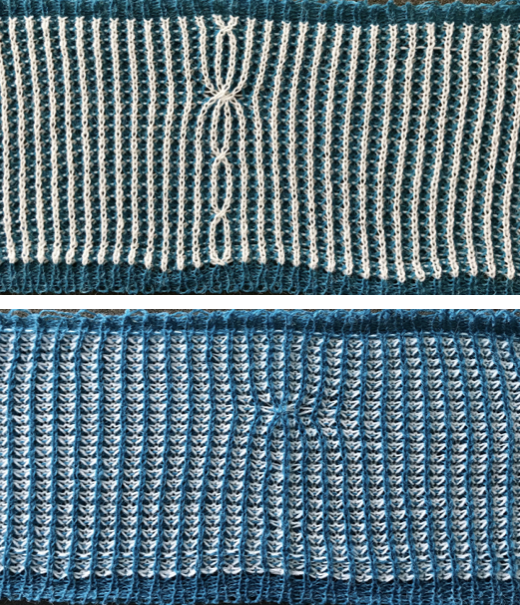

The same yarns, tension, the total number of carriage passes, and settings were used showing the difference in aspect ratio between single color per row knitting and the img2track built-in color separation.

The same yarns, tension, the total number of carriage passes, and settings were used showing the difference in aspect ratio between single color per row knitting and the img2track built-in color separation.  The width of both swatches is essentially identical.

The width of both swatches is essentially identical.

Images may be loaded into the program without the cable being connected to the machine. Error messages do appear with download attempts if the cable is not properly in place. The machine also needs to be powered on before the program is launched if a download is planned. I am working in Mac OS Mojave 10.14.6, have no present desire to upgrade to Catalina.

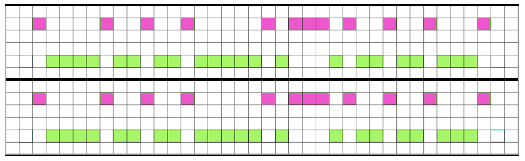

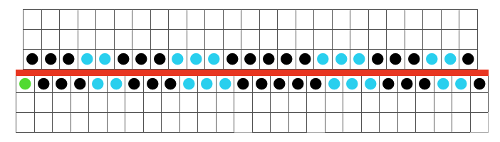

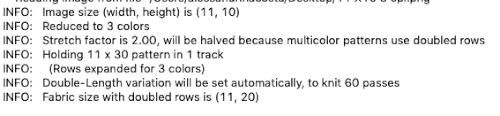

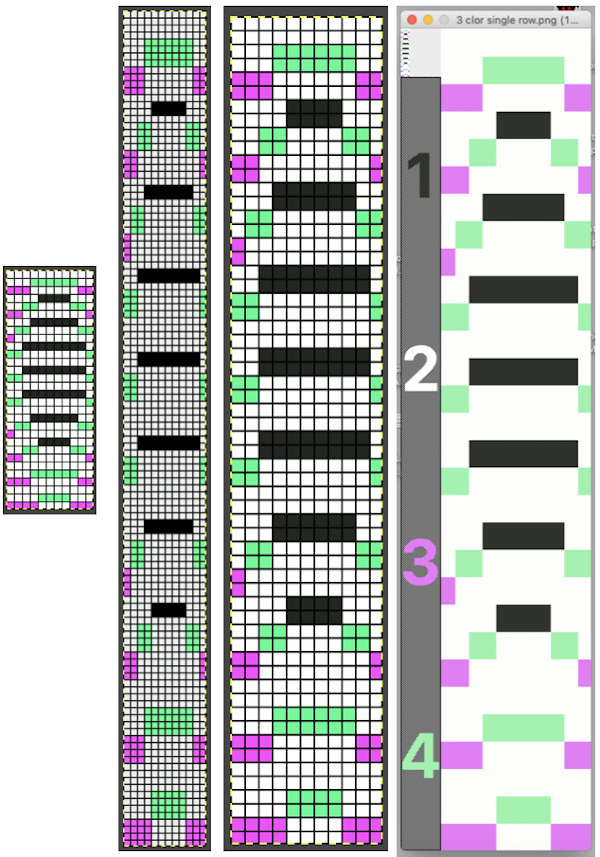

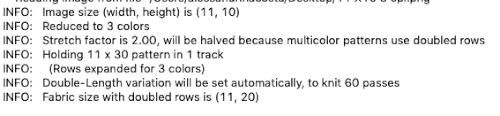

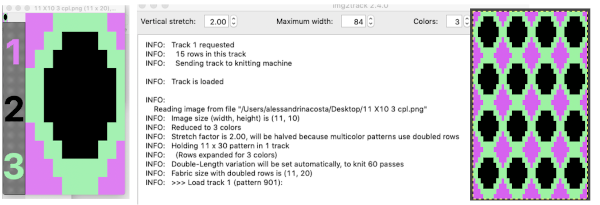

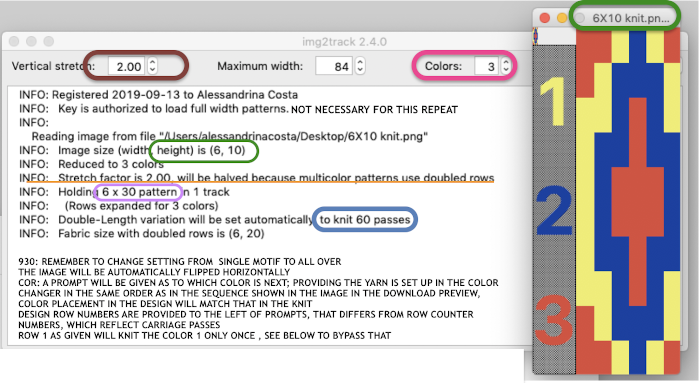

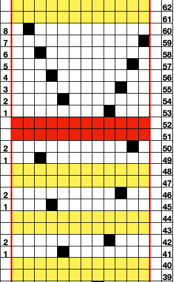

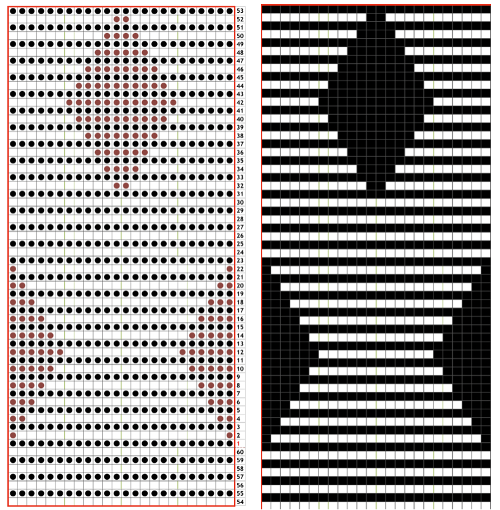

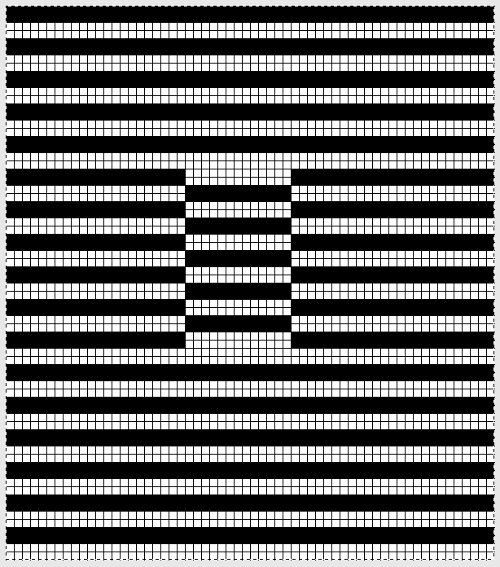

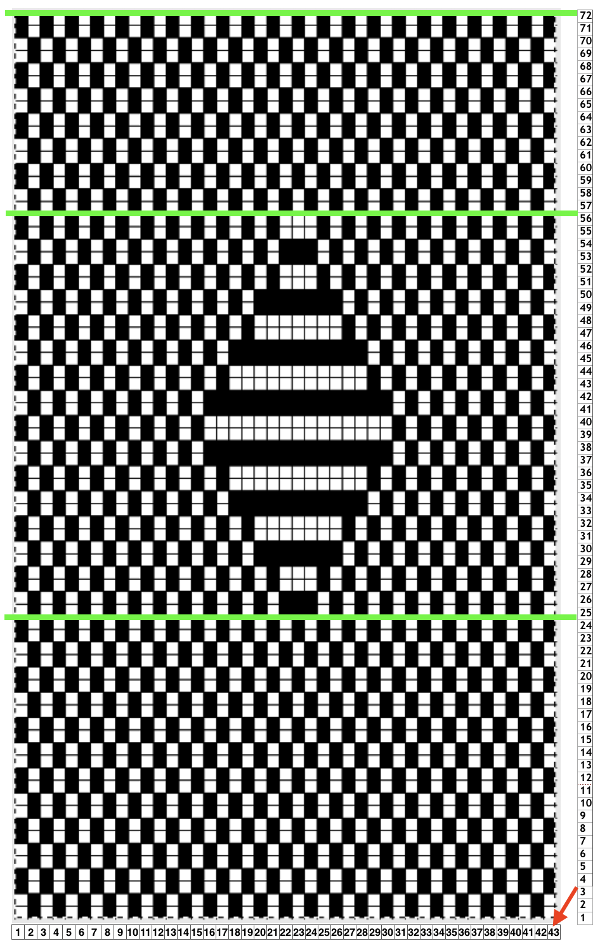

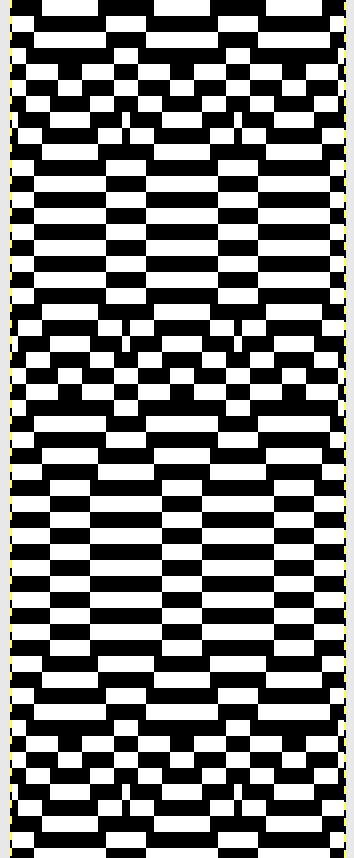

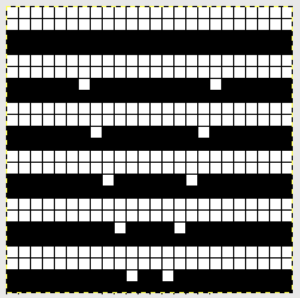

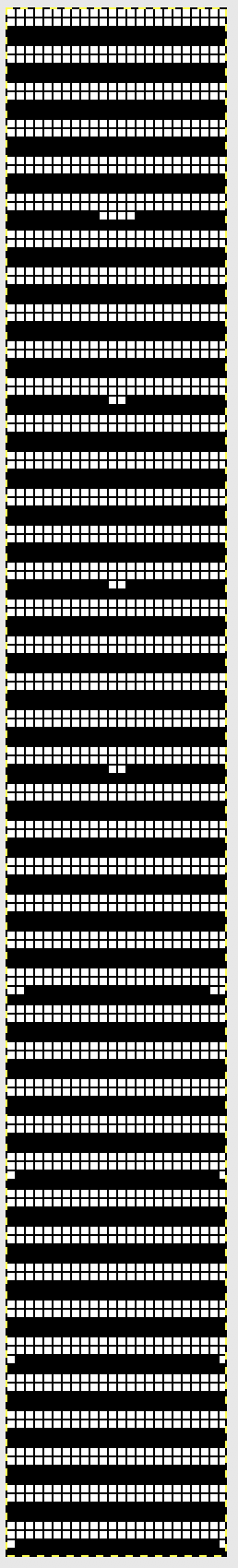

Executing fabrics that will knit each color in each row only once for every 2 passes on the main bed: back to that original repeat  Here it is used as drawn, note vertical stretch set at 2, will be cut in half by the software, getting the image back to the original height l0 X 3 = 30 rows required for all colors to knit in turn; there will be 60 carriage passes to complete one single repeat.

Here it is used as drawn, note vertical stretch set at 2, will be cut in half by the software, getting the image back to the original height l0 X 3 = 30 rows required for all colors to knit in turn; there will be 60 carriage passes to complete one single repeat.  The 930 will provide prompts for the next color to be selected by pushing the matching number button on the color changer, avoiding any confusion in terms of what should be picked up next. img2track will also flip the design horizontally automatically so the image will appear as originally drawn on the knit side. Images are loaded as single motifs, so the change in the selector needs to be made manually for an all-over pattern.

The 930 will provide prompts for the next color to be selected by pushing the matching number button on the color changer, avoiding any confusion in terms of what should be picked up next. img2track will also flip the design horizontally automatically so the image will appear as originally drawn on the knit side. Images are loaded as single motifs, so the change in the selector needs to be made manually for an all-over pattern.

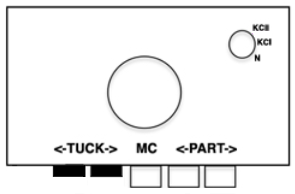

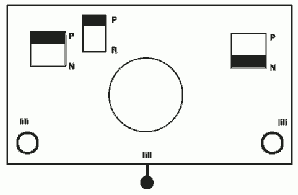

To have each color in each row knit only once: cast on with preferred method and color. Set up the machine so that the yarn colors are placed in the color shown in the image presented by the program to match your design. End with the machine on the left-hand side for the first preselection row.

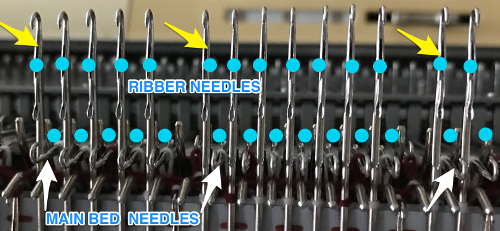

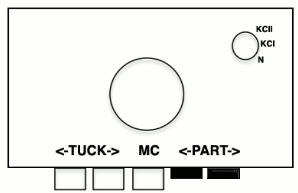

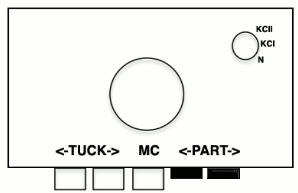

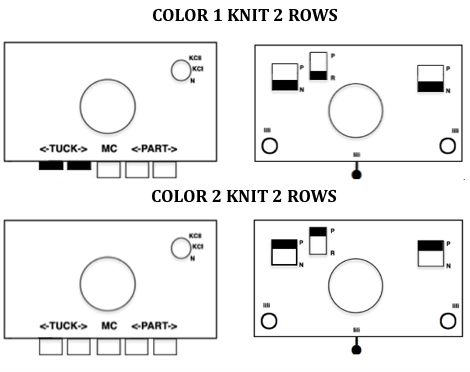

COL: set both carriages to slip in both directions and all its needles in the B position, set lili buttons if not already in use, and pick up color 1

knit one row to the right

COR: knit to the left, color 1 will knit for a single row

**COL: change color, STOP! Push back any needles on the top bed back to B position, as you knit to the right the ribber only will be knitting, knit one row to the right

COR: preselected needles will be knit in the color last picked up on the way back to the color changer, knitting only one row in that color on the main bed as you return to the left**

repeat the last ** 2 steps throughout. One can get into a rhythm. A cast-on comb, part of a garter bar, or any tool of adequate width can make it a quick process of pushing needles back to B when needed to

trust the software, not the selection expected by your eyes.

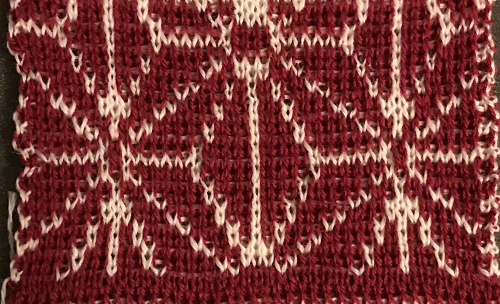

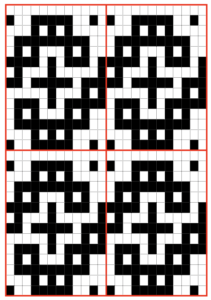

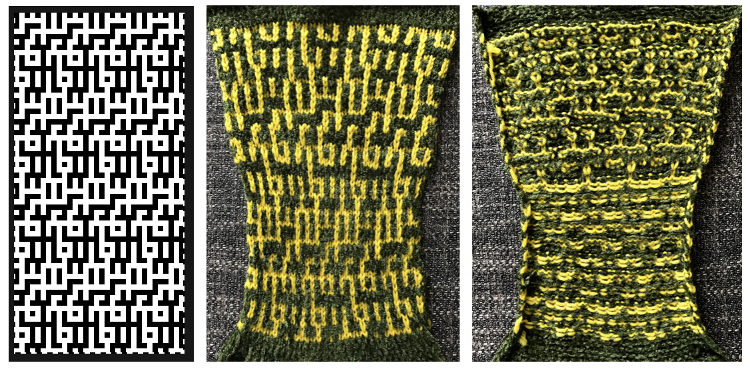

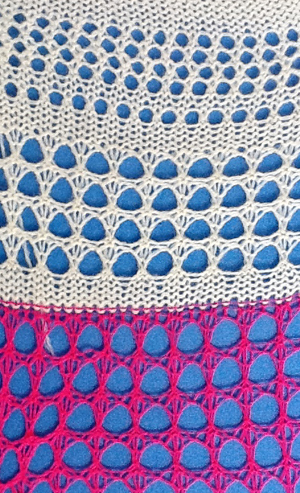

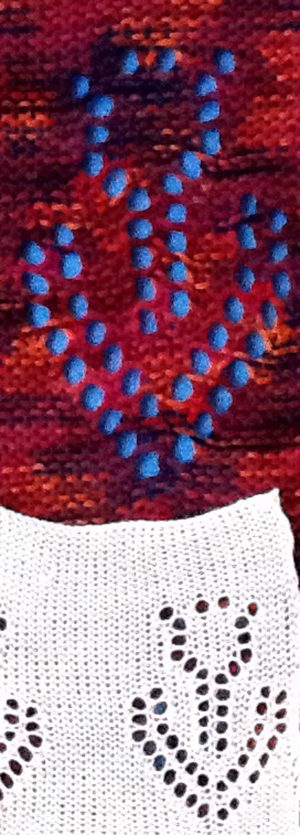

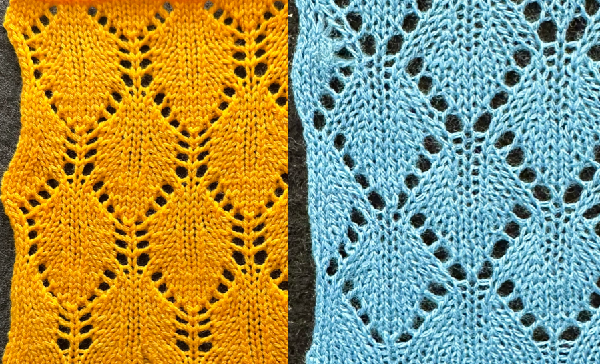

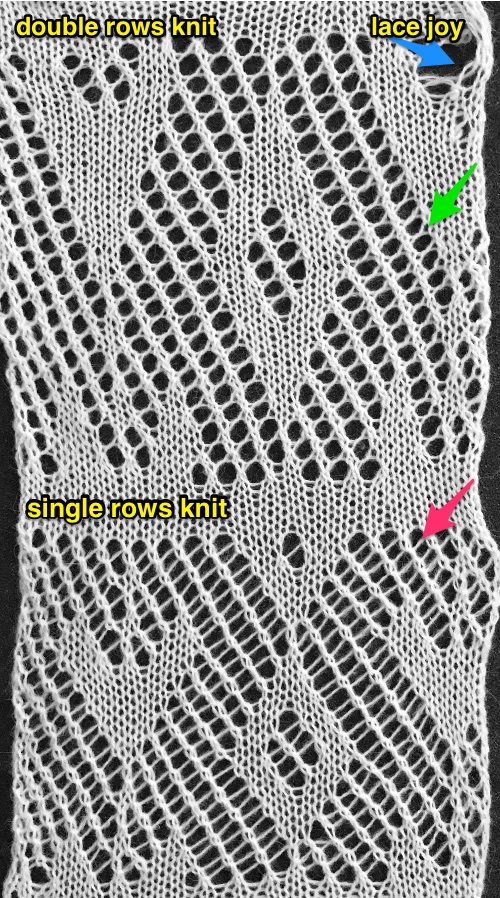

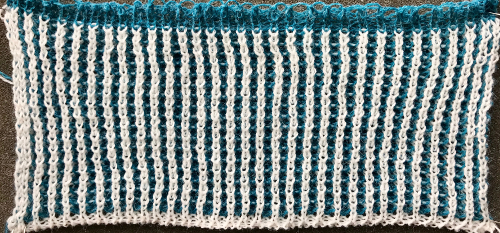

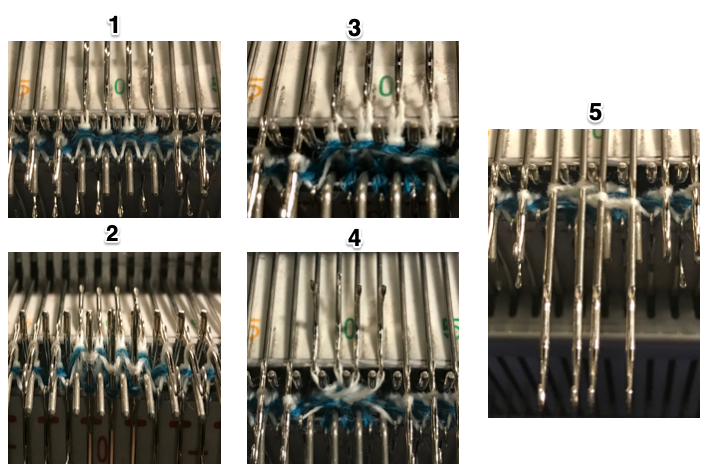

My swatch seemed to be growing in length at a faster rate than I remembered in the last exercise, here the results are shown side by side with the fabric executed previously

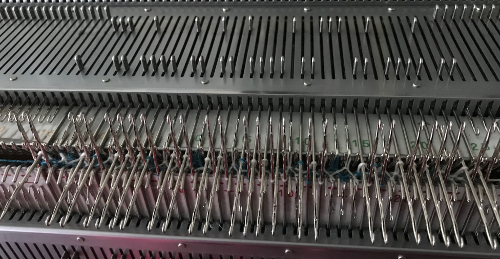

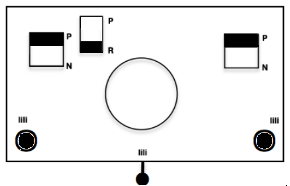

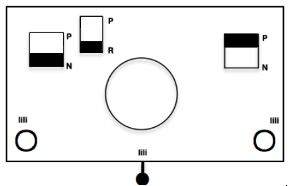

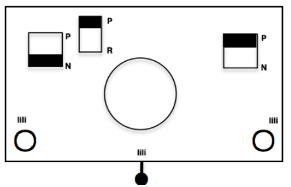

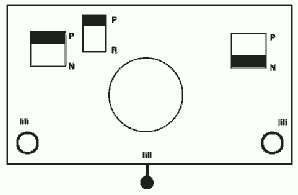

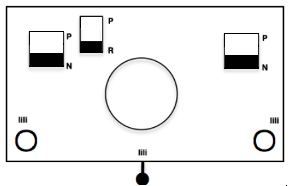

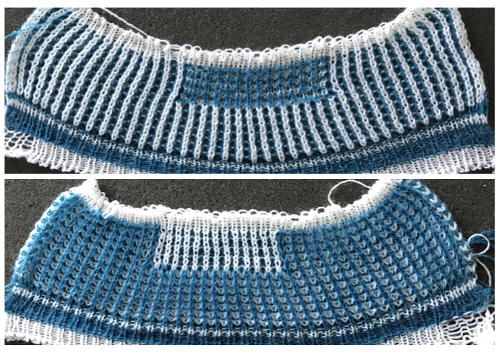

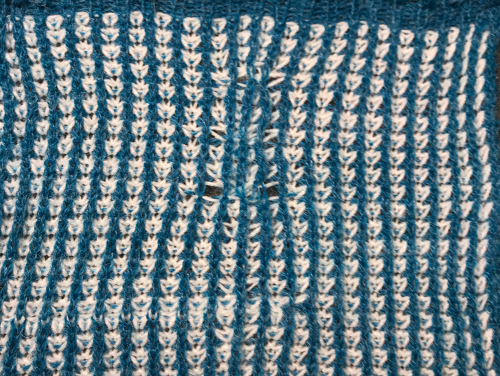

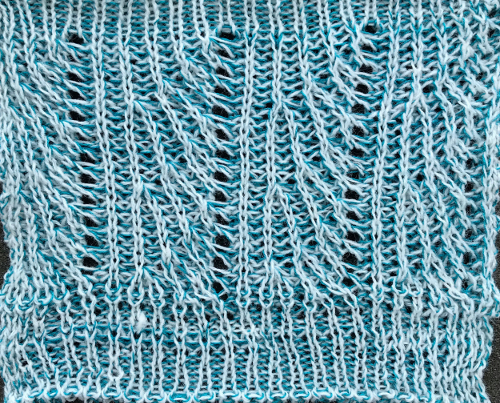

Obviously a success in terms of the single row for each color reducing elongation of the design shape. While knitting occurs using the same yarns, at the same tensions, there is a clear difference in the length of each stitch on the main bed and their appearance. The reverse. Checking the ribber carriage I noticed on the left side it was set to knit only, not to slip: OOPS!

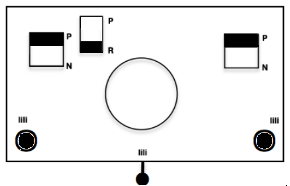

Obviously a success in terms of the single row for each color reducing elongation of the design shape. While knitting occurs using the same yarns, at the same tensions, there is a clear difference in the length of each stitch on the main bed and their appearance. The reverse. Checking the ribber carriage I noticed on the left side it was set to knit only, not to slip: OOPS!  N is king, so the ribber set as shown is knitting every other needle when moving to the right, but even with lili buttons in use, it knits on every needle when moving back to the left. Every other needle on the ribber will then be knitting for 2 rows as a result. The more knitting on the ribber for each pair of rows, the longer the stitches on the opposite bed. The backing is an interesting variation (half) birdseye. The elongated stitches on the main bed show more of the backing in between their shapes, it is referred to as bleedthrough. In some instances, the result can make the knit surface resemble weaving and its appearance far less familiar in a surprising, pleasant way. Beauty is in the eye of the beholder.

N is king, so the ribber set as shown is knitting every other needle when moving to the right, but even with lili buttons in use, it knits on every needle when moving back to the left. Every other needle on the ribber will then be knitting for 2 rows as a result. The more knitting on the ribber for each pair of rows, the longer the stitches on the opposite bed. The backing is an interesting variation (half) birdseye. The elongated stitches on the main bed show more of the backing in between their shapes, it is referred to as bleedthrough. In some instances, the result can make the knit surface resemble weaving and its appearance far less familiar in a surprising, pleasant way. Beauty is in the eye of the beholder.

Remember always to double-check all settings at the start of any process in case something was missed or magically moved, and keep notes.

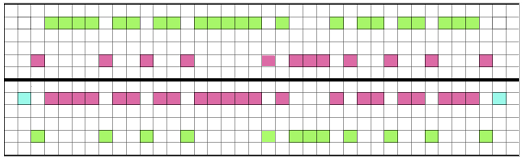

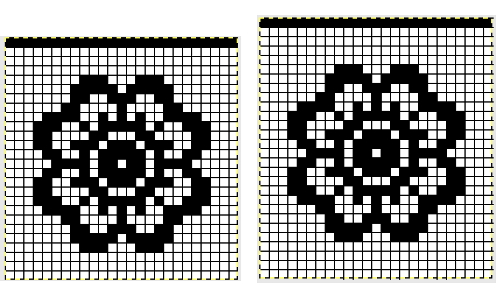

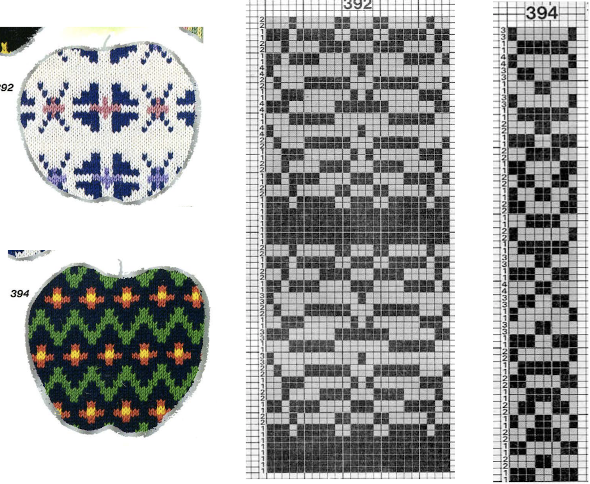

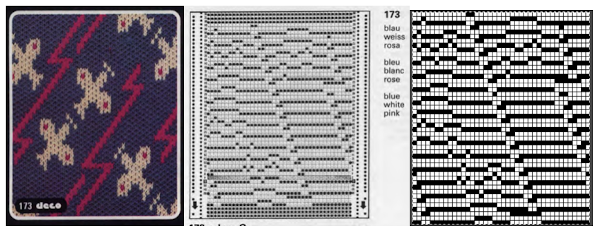

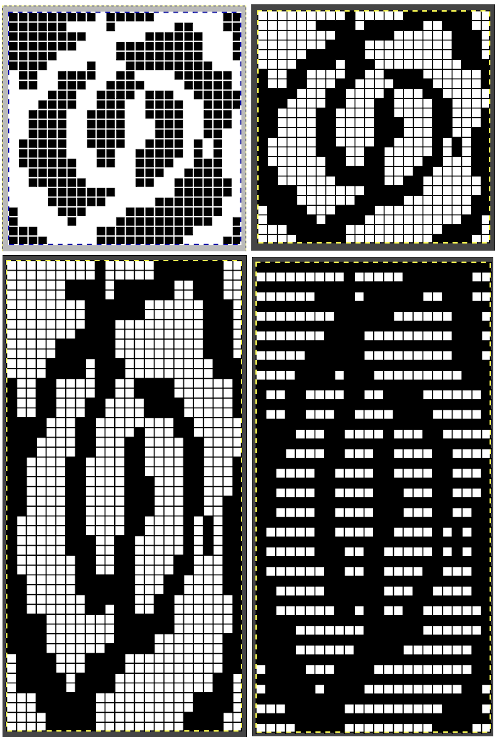

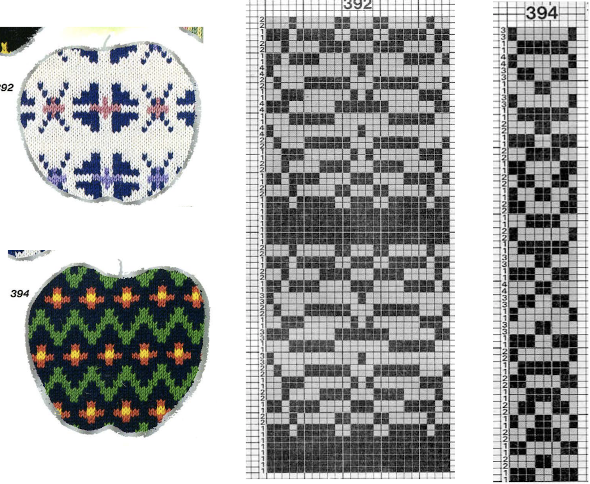

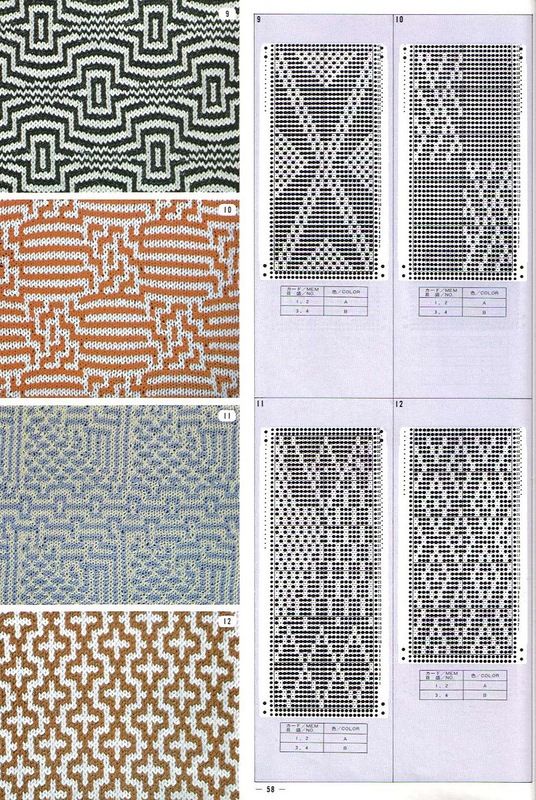

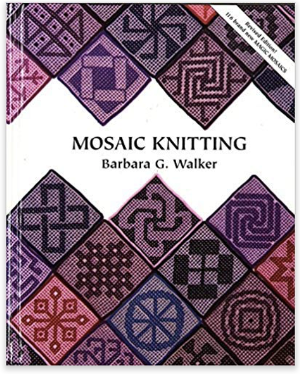

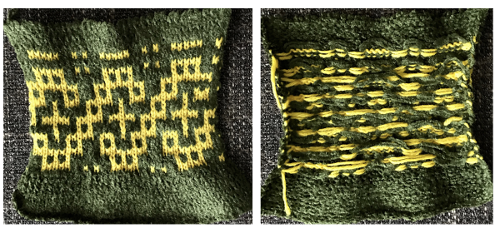

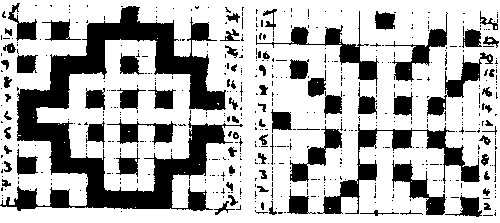

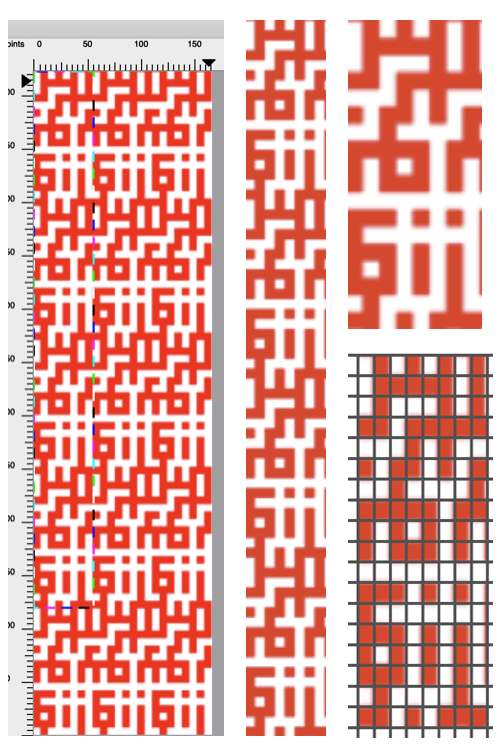

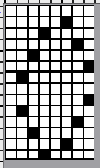

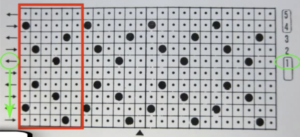

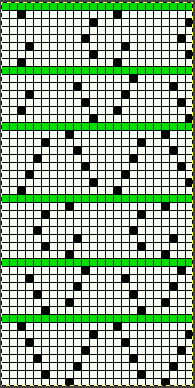

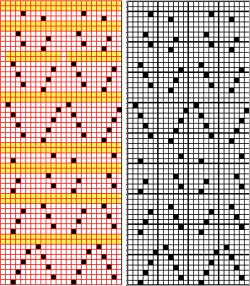

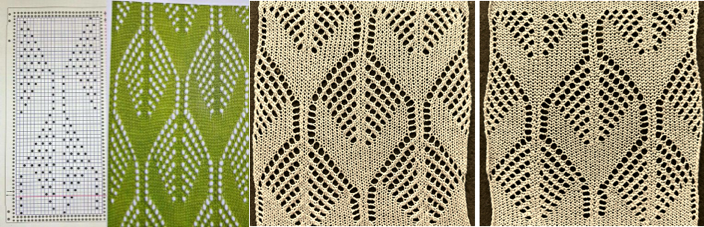

I was asked on Facebook whether the technique shown here is the same as the 3 color slip (skip) stitch patterns in the Stitchworld pattern book, my response: some of the StitchWorld patterns for 3 color slip are designed for or may be used on the double bed (often single bed as well). For instance, patterns 392 and 394. The original designs are rendered color-separated. The numbers on the left suggest the order for color changes to achieve a look similar to that in the swatch photos. Assuming the pattern is not easily accessible because of its being built-in your machine’s memory, it would have to be entered into a paint program manually to make it available for import and in turn for download. Note that the color-changing sequence may change throughout knitting the image, so prompts or notes of some sort would be needed to keep it correct. Each color in each row knits twice after each color change. My goals in my blog posts so far have been to keep a constant color-changing sequence with each color in each row of any personal design knitting only once. I did it first with my color separation, then, in turn, used the 3 color separation feature in img2track to achieve my desired result. Here are 2 images from the Stitchworld section in question  The images could be replicated as given in a paint program, using only one color for the squares, but “should be reduced to black and white”. Attempting to import an indexed 2-color image drawn in a color other than BW may result in strange results.

The images could be replicated as given in a paint program, using only one color for the squares, but “should be reduced to black and white”. Attempting to import an indexed 2-color image drawn in a color other than BW may result in strange results.  That said, if glitched knits are the goal, the above could work just fine. Curiously, here is the same process, using a different color, and a successful import. Checking again, I had forgotten to save the image after indexing it from RGB mode to 2 colors.

That said, if glitched knits are the goal, the above could work just fine. Curiously, here is the same process, using a different color, and a successful import. Checking again, I had forgotten to save the image after indexing it from RGB mode to 2 colors.  and a test with another color

and a test with another color

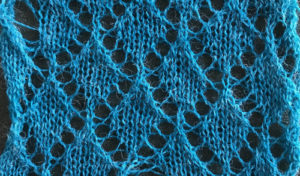

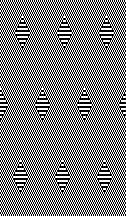

Drop stitch lace periodically comes up, I have written several posts on the technique, now considered the possibility of producing it in 3 colors. The resulting fabric tends to be long, thin, and in need of blocking. There is no way to avoid the striped ground. Passap knitters often refer to this type of knitting as “summer fair isle”. I adjusted the repeat width

Note to self: if you are determined to use a punchcard carriage on your electronic machine remember there is no KCII to cancel end needle selection!

Note to self: if you are determined to use a punchcard carriage on your electronic machine remember there is no KCII to cancel end needle selection!

To knit this fabric, stitches must be cast on in whatever method you prefer, but before any patterning, all stitches must be transferred down to the ribber, and the main bed needles are placed in the work position but are empty. Because of the single-row knit for the first 2 design rows of color one, the start is a bit finicky. Alternative start follows lower in post

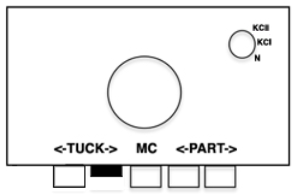

COL: KC II, main bed set to slip <– –>, ribber stays on N throughout, no lili buttons. Knit one row with color 1 (ribber only)

COR: as you knit to return to the left, the color 1 preselected needles will knit, while the ones corresponding to color 2 will preselect

COL: carefully drop any stitches on needles with color 1 on them without disturbing the new needle selection for color 2

**COL: change color, knit to right

COR: drop the stitches knit in the new color, make certain all needles are empty and in B position, knit back to left, and needles will be pre-selected for the next color**

Repeat the ** to**

Again, the resulting fabric is narrow and long, so it may take a bit of squinting to recognize the design.

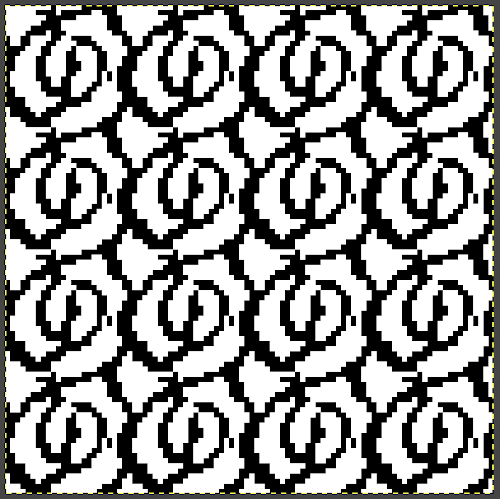

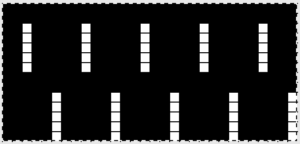

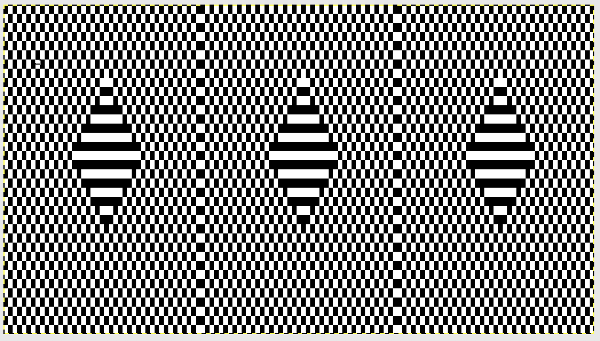

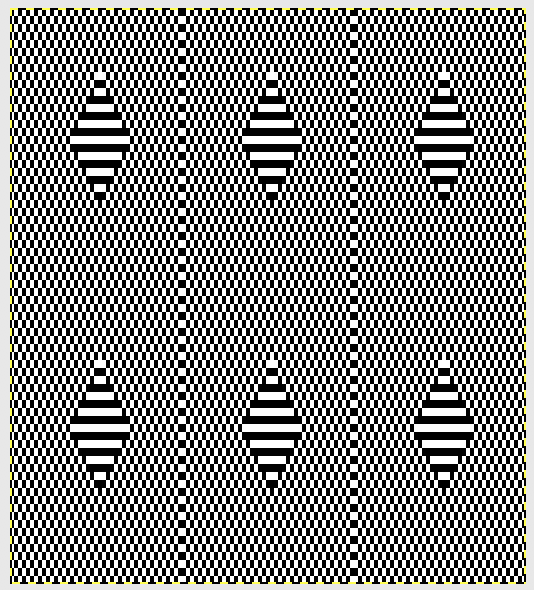

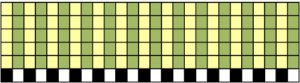

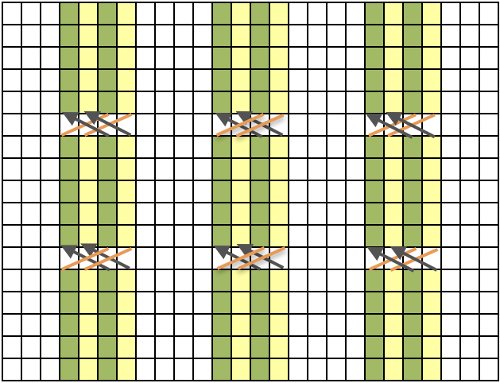

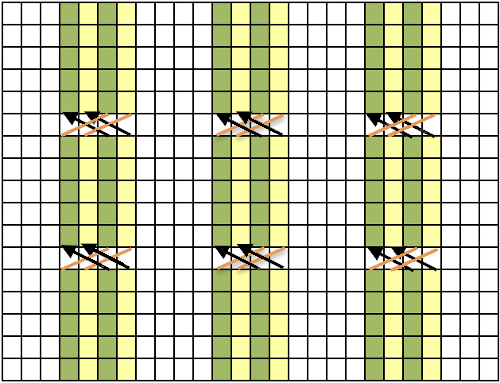

If each color is not represented in each design row, the ribber only will knit with no selection on the top bed corresponding to those no-pixel rows.  A single repeat results in about 3.5 by 9 inches of knitting, a far cry from what might have resulted in a single row per color design row dbj virtually shown here in a tiled format

A single repeat results in about 3.5 by 9 inches of knitting, a far cry from what might have resulted in a single row per color design row dbj virtually shown here in a tiled format

The question then comes up about dropping only one of the 3 colors. Using the manual selection described above, the knitting on the top bed would need to be canceled on every color, every row except for the single row in the chosen drop stitch color. To my mind, that is too much to keep track of for any length of time. It would be easier achieved with specific self-drawn color separations.

There is a lot of testing that can go into developing any fabric in unfamiliar techniques that may or may not meet our expectations or our “like”, it all contributes to learning regardless of whether the tests evolve into projects.

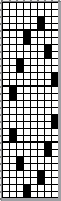

My last post on drop stitch lace from single color to two: revisiting the techniques on brother machines

2022: returning to the topic, exploring drop stitch lace in multiple colors

Reviewing what happens within the program one more time, highlighting significant items to verify before beginning to knit  Getting that first row to knit twice instead of a single time if that matters in your technique or is your preference:

Getting that first row to knit twice instead of a single time if that matters in your technique or is your preference:

advance design row to last one in the sequence, in this case, 30

in the 930 when the pattern is loaded, using the down arrow key gets to the last row in the downloaded pattern more quickly

COL: set machine to preselect pattern, the next 2 passes would need to not knit, so both carriages are set to slip in both directions

knit one row to the right

COR: number 30 design row flashes

knit one more free pass to the left, row 1 of color 1 will preselect as you knit

COL: number 1 design row flashes

check all settings, main bed set to slip <– –>, ribber set to slip <– –> with lili buttons, and with an even number of needles in work for standard dbj

pick up color 1 in yarn changer

pick up color 1 in yarn changer

the resulting knit design will be elongated

COL: knit one row to the right.

As you knit the first row of color 1 design row 1 will knit, row 2 of color one design row 1 will preselect

COR: knit back to the left

as you knit back to left row 2 of color 1 design row 1 will knit, row 1 of color 2 design row 1 will preselect

COL: pick up color 2,

continue in pattern changing colors every 2 rows

In designing your own, small repeats can easily be rendered even in a simple paint program. Larger, more complex ones, may best be worked using layers and masking in a variety of programs ie. Photoshop or Gimp. It is possible to combine 2 color dbj and 3 color dbj in the same piece simply by using different color separations for each segment, but the look of the fabric in terms of the length of each stitch on the knit side may be quite different when moving from one segment to the next. Of course, the backing will change as well. Though the aspect ratio of the design changes in terms of height when one knits 2 rows for each color in each design row, it remains the easiest separation method. Adding the hand selection as described above so that the main bed knits in one direction only helps reduce some of the extra height, making the original image more recognizable. There is no option within img2track to perform the action automatically in terms of adding the necessary blank rows to replace some of the colored ones in the separation.

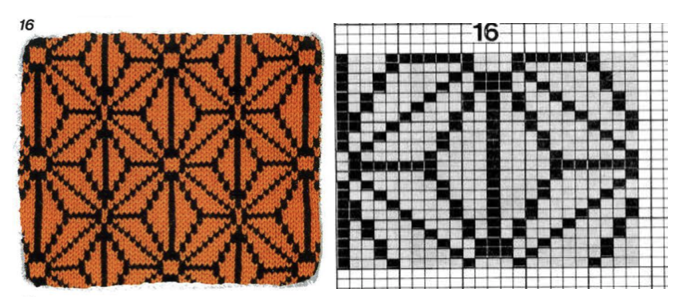

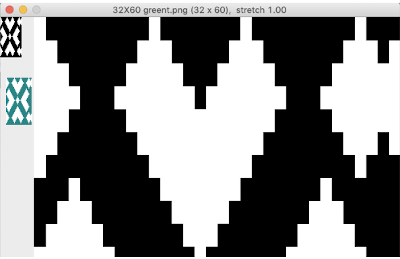

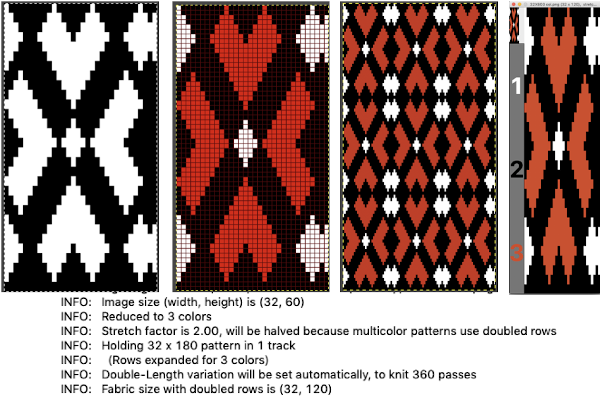

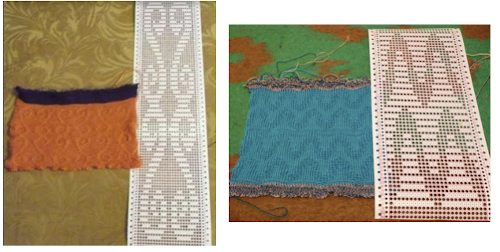

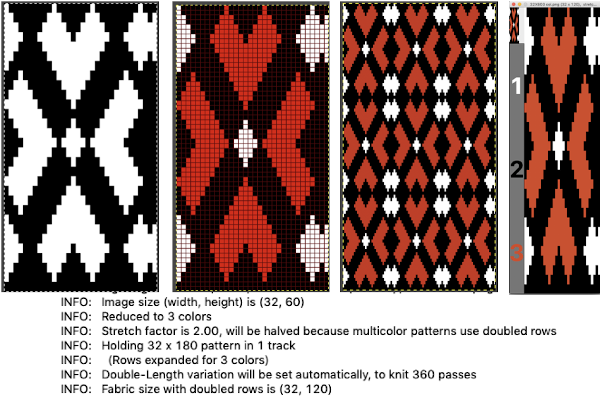

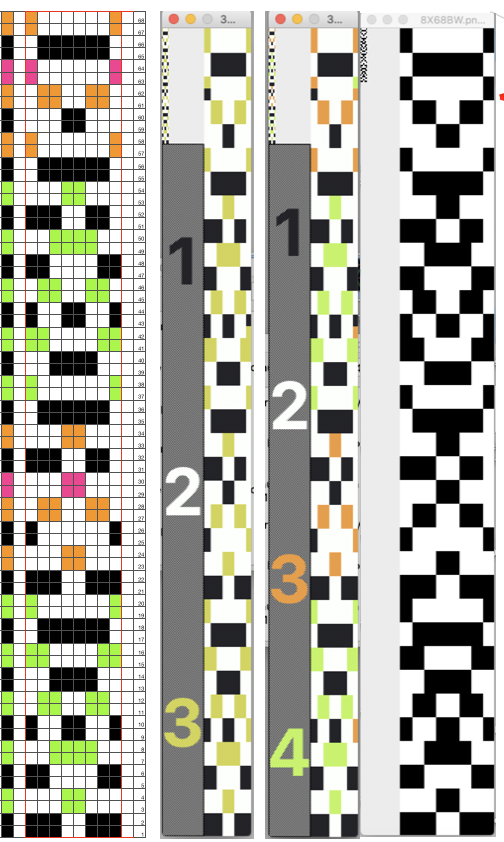

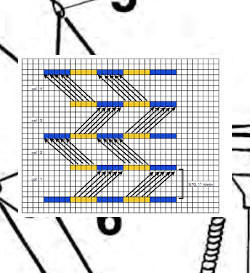

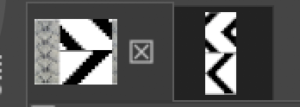

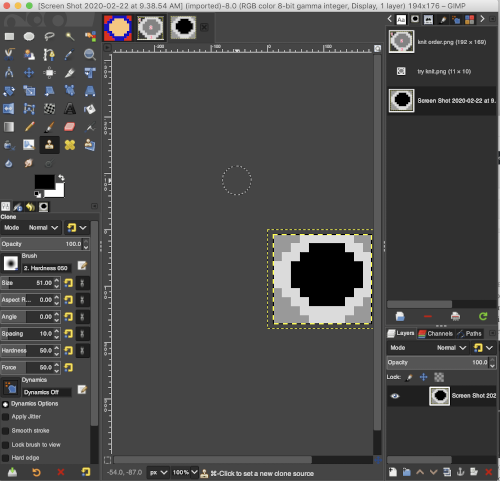

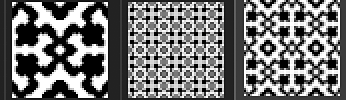

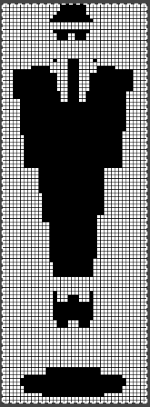

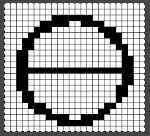

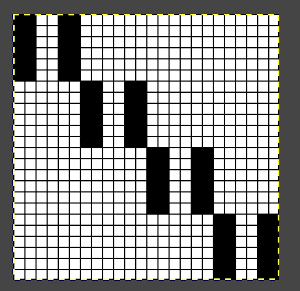

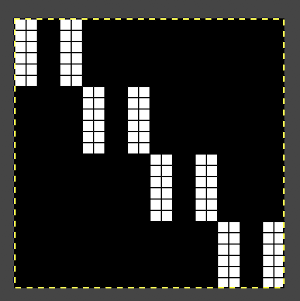

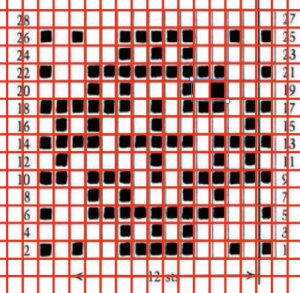

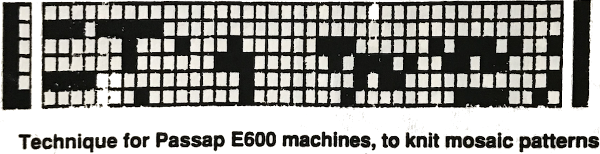

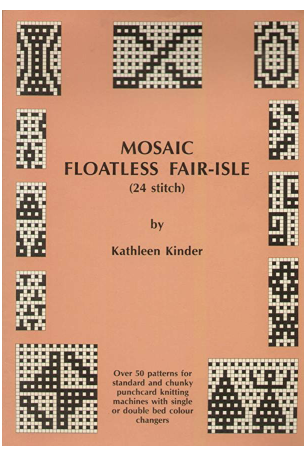

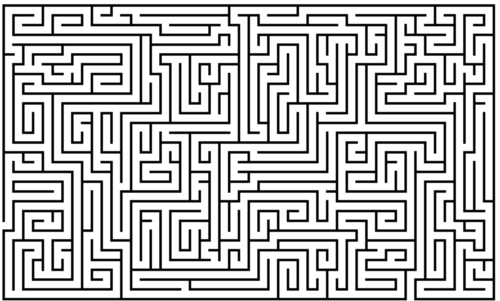

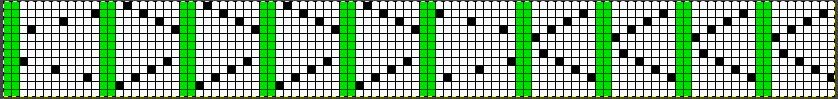

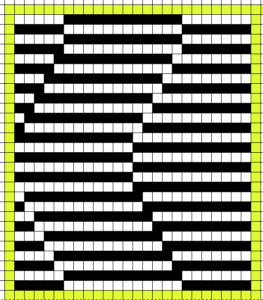

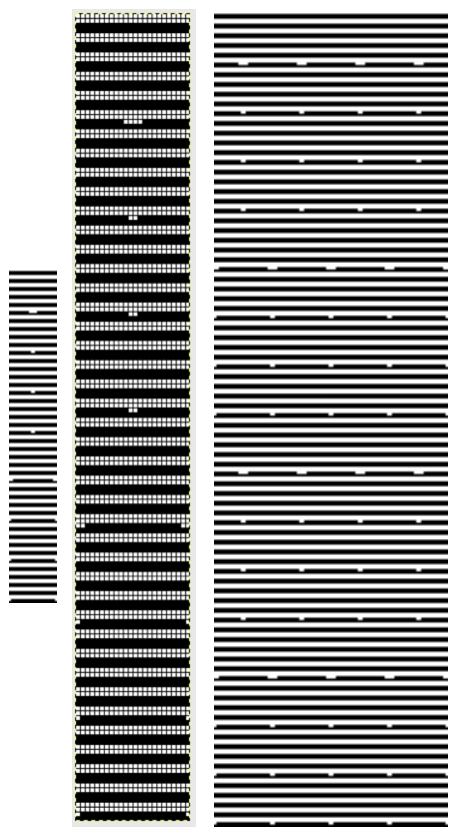

Passap knitters are not left out of this idea. Passap preselects pushers. On the E 6000 Tech 179 emulates the built-in KRC option in Japanese model machines. My guess was that technique 180 for 2 colors, perhaps 197 with both arrow keys on the back may work for 3 colors. TBD in my next spurt of knitting activity on it. That said, the console’s built-in designs may be used cross-brand. It is possible in Passap to layer repeats in order to add the third color to the mix. Here is one sample reworked for use on Brother and downloaded into img2track.  If black and white repeats are already in your library, one may easily recycle them adding a third color. Here I did so with a repeat intended for a very different topic in future posts. The image was altered and tiled in Gimp for a repeat alignment test and is also shown imported into img2track for possible knitting.

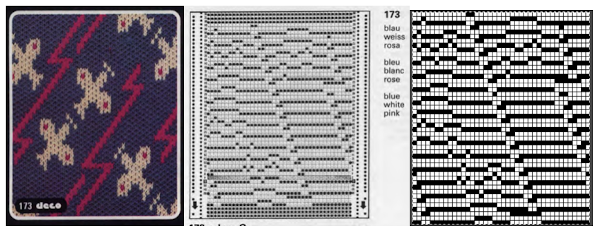

If black and white repeats are already in your library, one may easily recycle them adding a third color. Here I did so with a repeat intended for a very different topic in future posts. The image was altered and tiled in Gimp for a repeat alignment test and is also shown imported into img2track for possible knitting.  What about using images published in punchcard machine references? It is probably best to start with smaller repeats. That said, this is from a Deco pattern book. Deco punchcards were 40 stitches wide, and could be joined together in length as can those for the Japanese models

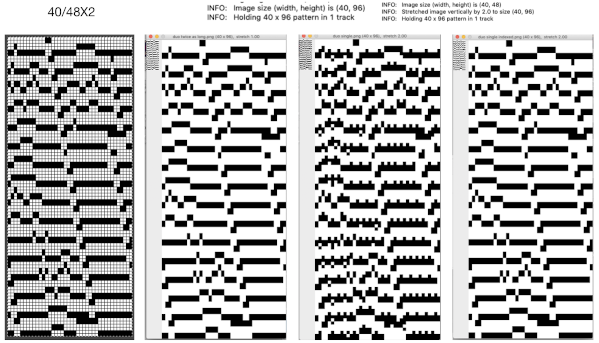

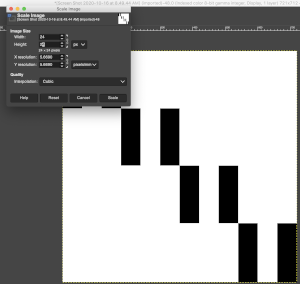

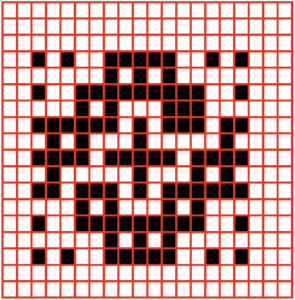

What about using images published in punchcard machine references? It is probably best to start with smaller repeats. That said, this is from a Deco pattern book. Deco punchcards were 40 stitches wide, and could be joined together in length as can those for the Japanese models  The image of the separation on the above right has not been proofed for accuracy. If it were, the next step would be to elongate it X 2 for color changes every 2 rows. One method is to elongate the original in a paint or photo processing program. The width is fixed (40), the height is scaled X 2. The resulting BW indexed image may be imported, using a 1.0 stretch factor, it remains unchanged. When I tried to elongate the unstretched image in img2track by 2.0 my first try failed. It turned out the reason was I had saved the import without first indexing it to 2 colors. With that corrected, the result matched the one from scaling X 2 in height in the paint program

The image of the separation on the above right has not been proofed for accuracy. If it were, the next step would be to elongate it X 2 for color changes every 2 rows. One method is to elongate the original in a paint or photo processing program. The width is fixed (40), the height is scaled X 2. The resulting BW indexed image may be imported, using a 1.0 stretch factor, it remains unchanged. When I tried to elongate the unstretched image in img2track by 2.0 my first try failed. It turned out the reason was I had saved the import without first indexing it to 2 colors. With that corrected, the result matched the one from scaling X 2 in height in the paint program

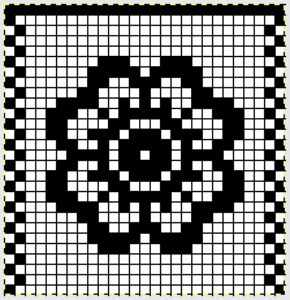

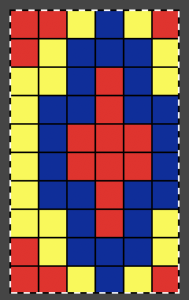

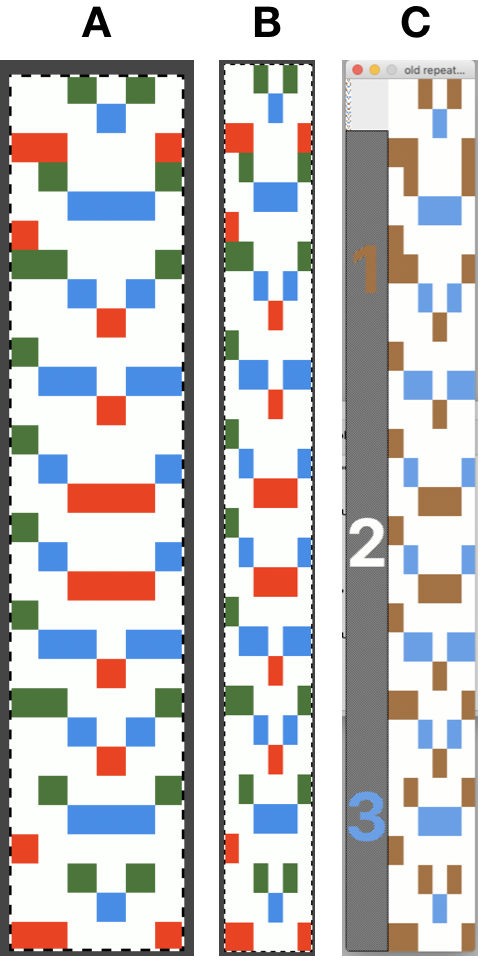

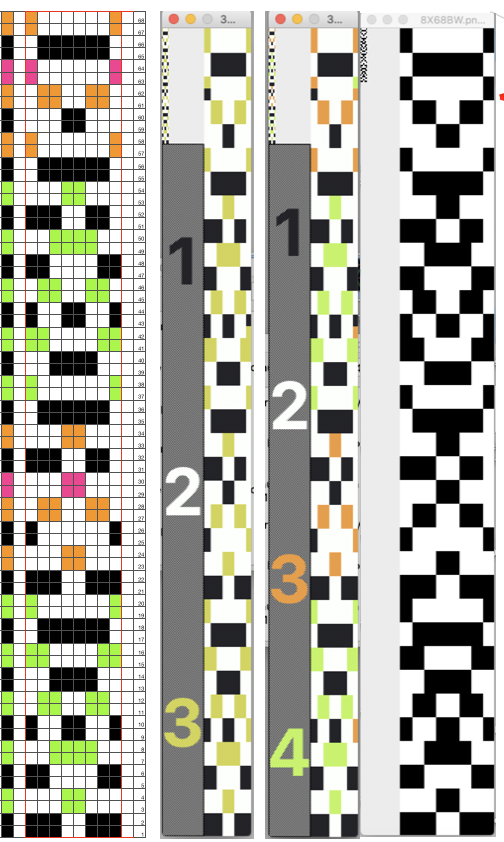

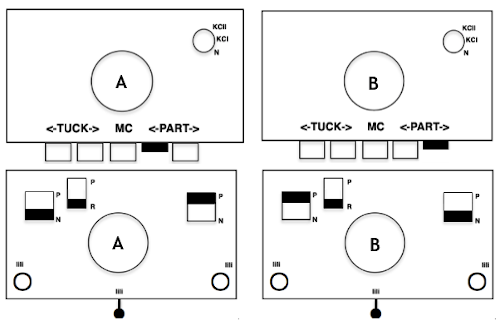

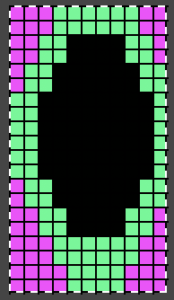

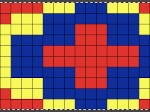

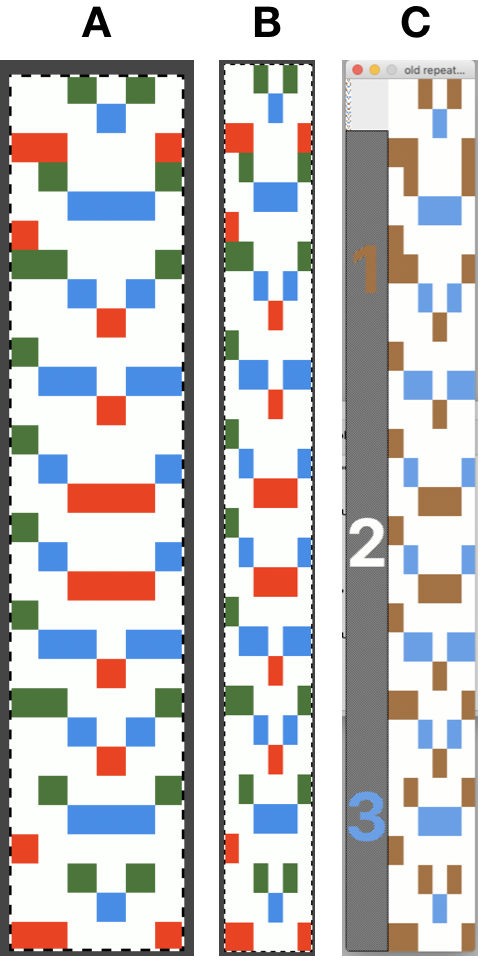

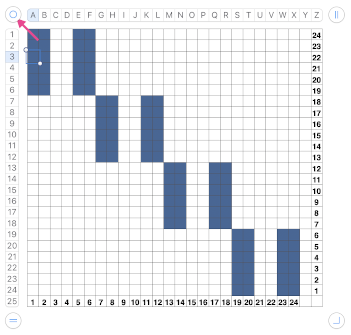

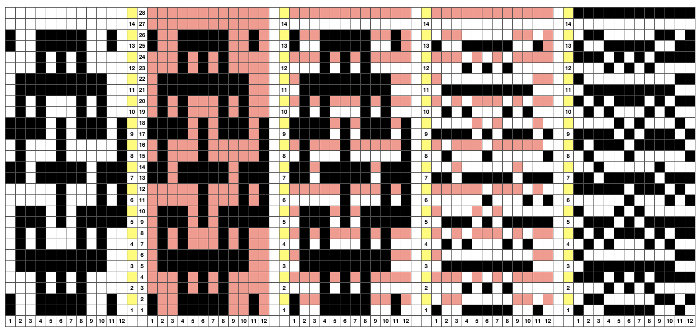

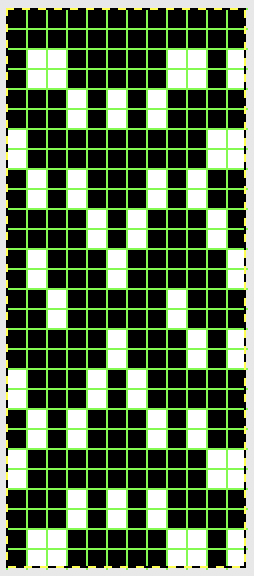

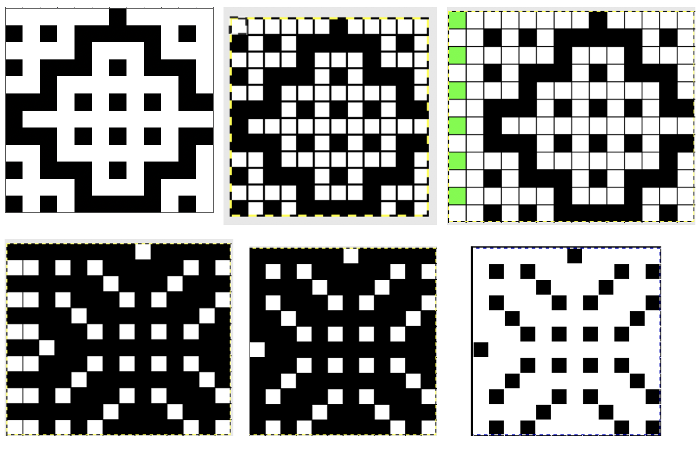

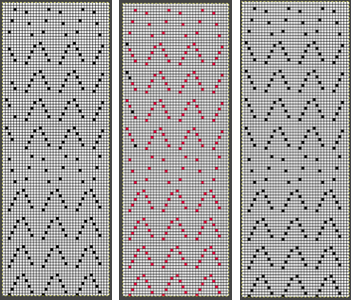

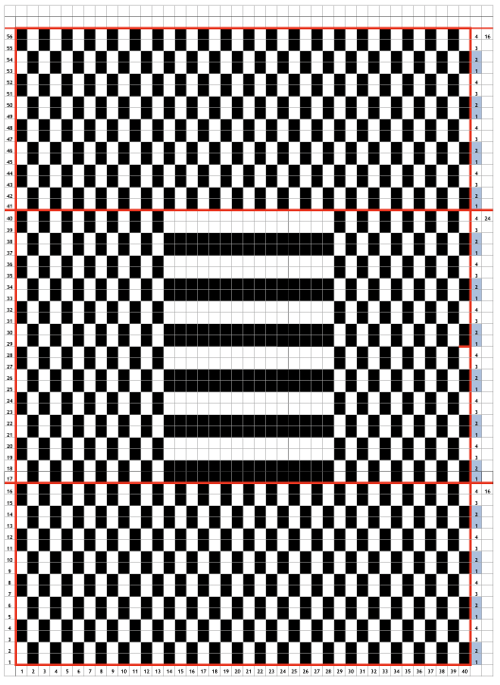

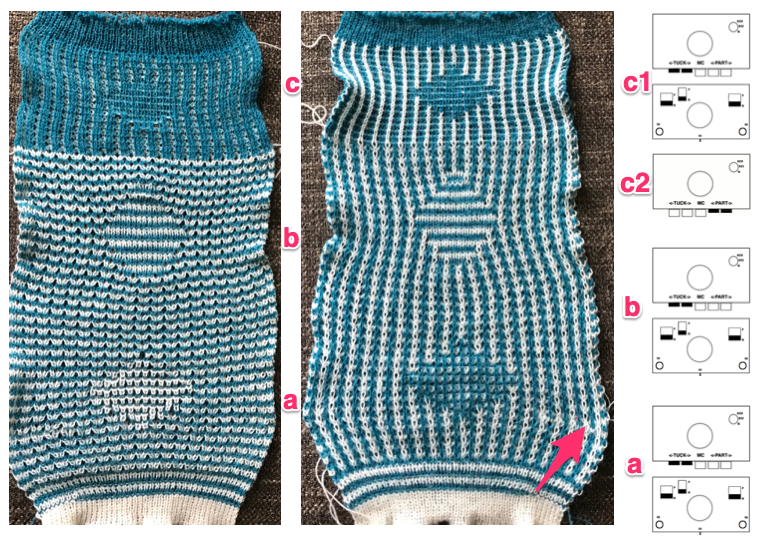

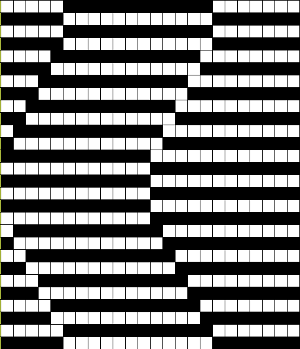

For years now I have been doing color separations which at first could be extremely slow, one pixel at a time. With increasing familiarity with Gimp and Mac Numbers over time, I have been able to decrease the speed to achieve them immensely. So here, with img2track I now have a program that can work with and separate multiple colors at a time (up to 6 in its pull-down menu option). Here I returned to my first separation in 3 colors for the now-familiar repeat A, elongated it in the paint program B and imported A into img2track choosing 2.0 stretch and 3 colors C. I can totally live with the fact the colors are not the same. The color changer can be set up with my chosen colors in any order I choose

For years now I have been doing color separations which at first could be extremely slow, one pixel at a time. With increasing familiarity with Gimp and Mac Numbers over time, I have been able to decrease the speed to achieve them immensely. So here, with img2track I now have a program that can work with and separate multiple colors at a time (up to 6 in its pull-down menu option). Here I returned to my first separation in 3 colors for the now-familiar repeat A, elongated it in the paint program B and imported A into img2track choosing 2.0 stretch and 3 colors C. I can totally live with the fact the colors are not the same. The color changer can be set up with my chosen colors in any order I choose

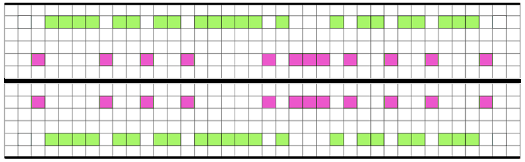

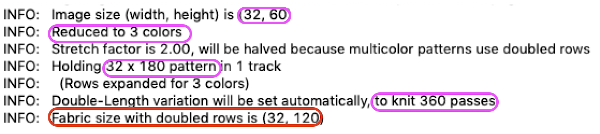

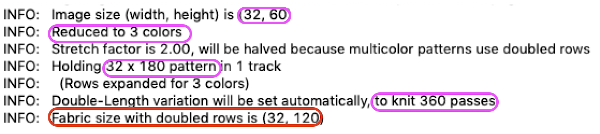

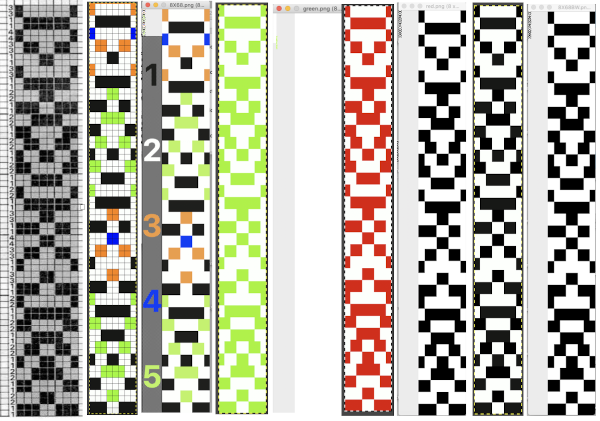

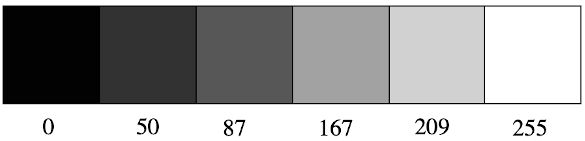

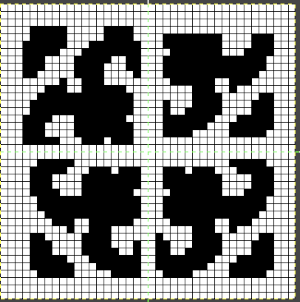

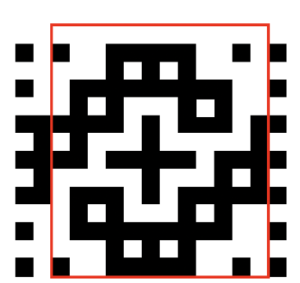

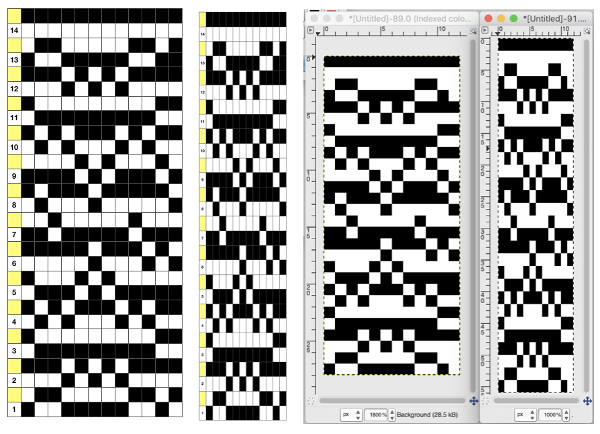

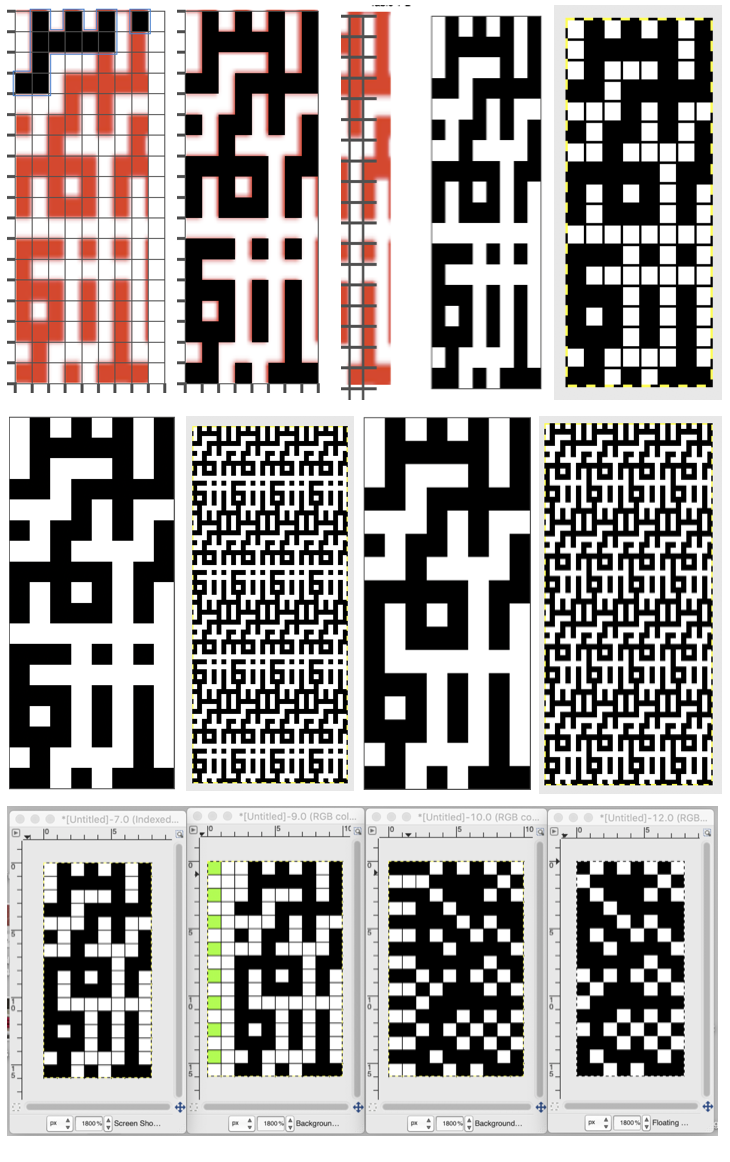

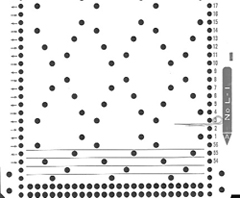

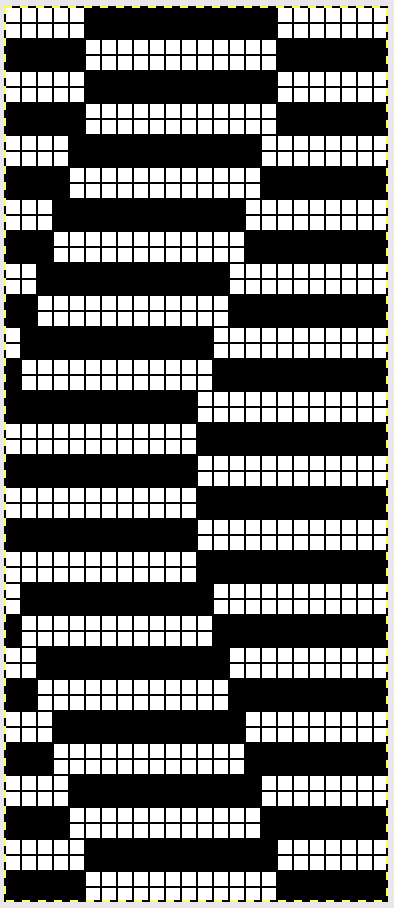

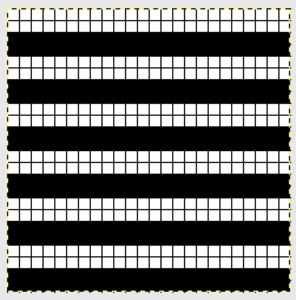

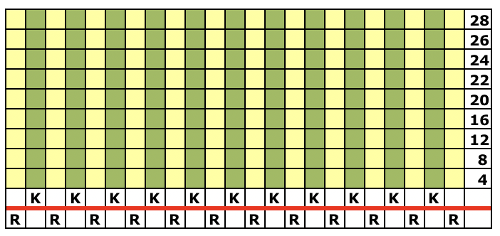

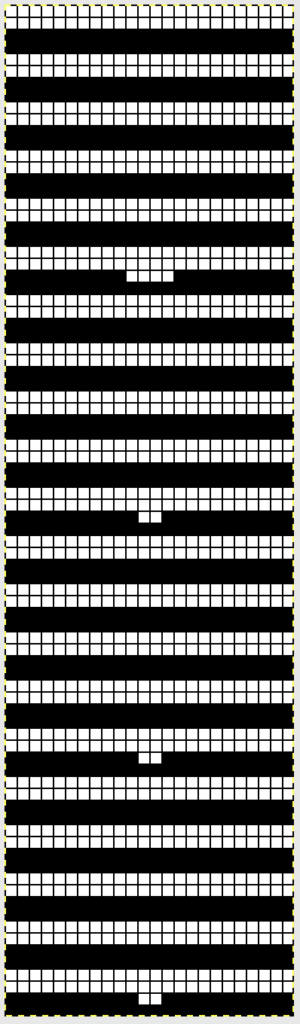

In my first tests with charting a repeat missing any color in some rows, I had scaled the original image taken from a spreadsheet to the wrong size in Gimp, so operator error resulted in crazy results in img2track.  Here the image is scaled properly for each color represented for a single row in height and also scaled again for double height for possible knitting in Gimp. The Gimp scaling failed to be accurate for me (second image from left) until I indexed the original to 4 colors as well instead of 3. The no-color rows as we view them serve as a fourth color in the separations. Importing the proper size PNG into img2track for the separation of 4 colors per row now gives results that make sense: note the daunting estimate for the total number of carriage passes for a single repeat height

Here the image is scaled properly for each color represented for a single row in height and also scaled again for double height for possible knitting in Gimp. The Gimp scaling failed to be accurate for me (second image from left) until I indexed the original to 4 colors as well instead of 3. The no-color rows as we view them serve as a fourth color in the separations. Importing the proper size PNG into img2track for the separation of 4 colors per row now gives results that make sense: note the daunting estimate for the total number of carriage passes for a single repeat height

If the ribber has knit on every needle by its return to the color changer and the machine is set to slip both ways with no needle selection on the main bed, the “no color” can be executed as an empty yarn holder in the color changer combined with no yarn in the feeder. The rows involved should simply not knit on the top bed, with no dropping of any of its stitches since no needles will have been selected thus coming forward with the yarn in the hooks and traveling behind the latches and in turn, slipping off the needles as a carriage with no yarn pushes the needles with now empty hooks back to B position.

If the ribber has knit on every needle by its return to the color changer and the machine is set to slip both ways with no needle selection on the main bed, the “no color” can be executed as an empty yarn holder in the color changer combined with no yarn in the feeder. The rows involved should simply not knit on the top bed, with no dropping of any of its stitches since no needles will have been selected thus coming forward with the yarn in the hooks and traveling behind the latches and in turn, slipping off the needles as a carriage with no yarn pushes the needles with now empty hooks back to B position.

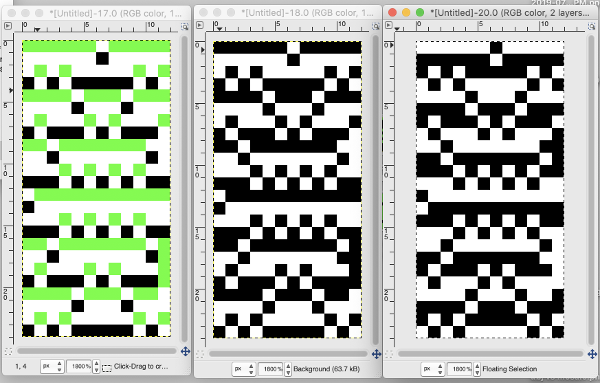

In testing concepts, I prefer to work initially with small repeats. Punchcard books can be an excellent source, but the Stitchworld books have the advantage of actually showing a single repeat for each design, so an 8 stitch repeat, for example, would be shown as such and it would not be up to the person using it shown in a 24 stitch card one to isolate it. I randomly chose pattern 394. I realize that if used from a built-in library of patterns in any machine model the prompts may be provided by the machine, but here I am looking at simply duplicating the pattern for import into img2track.

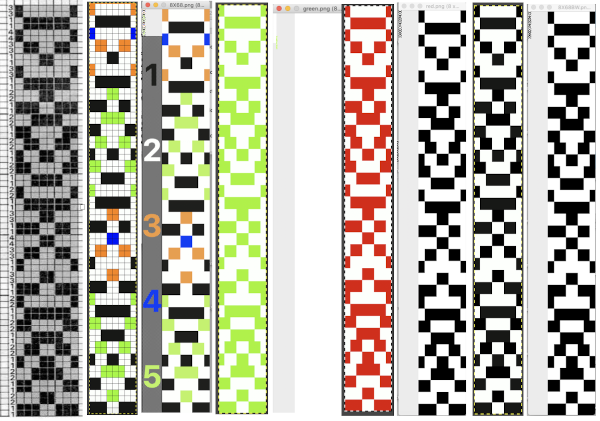

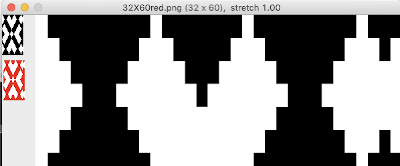

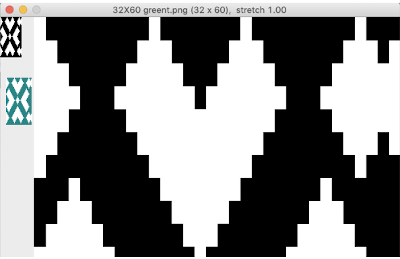

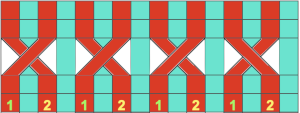

After duplicating the repeat and associated numbering using Numbers, these were some of my results. A pleasing surprise was that colors in the 2 color import need not be only black and white. That said, the pale green failed, the red did not, and the results from importing both the red/white and the black/white were identical. Another future time saver for me to keep in mind.

After duplicating the repeat and associated numbering using Numbers, these were some of my results. A pleasing surprise was that colors in the 2 color import need not be only black and white. That said, the pale green failed, the red did not, and the results from importing both the red/white and the black/white were identical. Another future time saver for me to keep in mind.

If colors were assigned to each pair rows representing each color used, the white squares were read as an added color on import, and the only way to have those few blocks for the 4th color to show up in the visual representation in an imported repeat was to assign a 5 color separation, resulting in a scrambled pattern. Removing the few squares in color 4 will produce inaccurate separations for actual knitting of the given pattern whether imported to be rendered for 3 colors or 4. The black and white on the right is the “correct” match, leaving any prompts for use of shifting color changers to be tracked somehow by the knitter.  Punchcard knitters may have the easiest knitting variable color sequences since cards may be visually marked up with colored pencils matching needed change locations and taking into account your eyes are several rows above the row being read by the card reader. This number depends on the machine’s brand and model.

Punchcard knitters may have the easiest knitting variable color sequences since cards may be visually marked up with colored pencils matching needed change locations and taking into account your eyes are several rows above the row being read by the card reader. This number depends on the machine’s brand and model.

Some spreadsheets that may help with tracking row color changes or other regular actions on paper: 2018/04/tracking-rows-1.pdf

I have been asked about the position of the slide lever being fixed in my dbj illustrations. I have found the alternate positions can be wild cards, would rather make adjustments in carriage settings if needed rather than let the factory settings do some of the work for me. If the settings are accidentally in the wrong place as multiple pieces are knit, or in knitting ribber bands for garment pieces, the gauge is changed if the alternate setting is not adjusted and kept constant, and that may not be noticed until the piece of knitting in question is completed, needing a restart. With 15-20 machines active in each studio class and lab session, I tried to reduce as many variables as possible.

A video resource on using img2knit for 3 colors per row knitting with blank color rows in the design by Tanya Cunningham, and a Ravelry thread on the topic

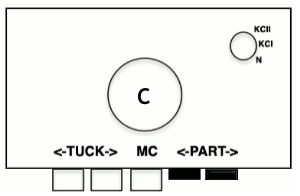

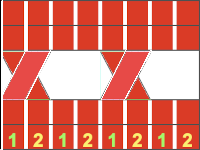

My starting samples were knit on 32 stitches, not enough to get a sense of or a good view of the horizontal repeat of 24 stitches. At first, I used the design version with no horizontal black lines in the download. The difference between the every needle rib at the bottom of the pieces and the slip stitch blister fabric is easily seen. Slip stitches are short and thin whether single or double bed. On the left, I used the tensions of 4/4, as for the particular yarn in past experiments. On the right, the switch was made to 4/2. The tighter ribber tension made the blisters more pronounced. The non selected needles on the main bed create the pockets. Because functions repeat for pairs of rows in this design, the first preselection row can happen from either side and cam buttons may be reversed with similar results as seen in top vs bottom below. Opposite part buttons are used as in option A or B.

My starting samples were knit on 32 stitches, not enough to get a sense of or a good view of the horizontal repeat of 24 stitches. At first, I used the design version with no horizontal black lines in the download. The difference between the every needle rib at the bottom of the pieces and the slip stitch blister fabric is easily seen. Slip stitches are short and thin whether single or double bed. On the left, I used the tensions of 4/4, as for the particular yarn in past experiments. On the right, the switch was made to 4/2. The tighter ribber tension made the blisters more pronounced. The non selected needles on the main bed create the pockets. Because functions repeat for pairs of rows in this design, the first preselection row can happen from either side and cam buttons may be reversed with similar results as seen in top vs bottom below. Opposite part buttons are used as in option A or B. As I have explained in the past, I tend to leave the slide lever permanently in the center position. It becomes one less variable, forgetting to reset it can result in errors in gauge and more mishaps when knitting multiple pieces where gauge matters significantly or in reproducing previous work.

As I have explained in the past, I tend to leave the slide lever permanently in the center position. It becomes one less variable, forgetting to reset it can result in errors in gauge and more mishaps when knitting multiple pieces where gauge matters significantly or in reproducing previous work.

The “striped” repeat produces essentially the same fabric. The knit carriage may be set to slip in both directions when using it since the row of all punched holes or black pixels will knit every stitch on every needle selected while in the previous samples the cam button set to knit in one direction performed that function regardless of any markings on the design repeat. The ribber is set to knit in one direction, slip in the other. Reversing sides for cam button settings produces the same fabric

The “striped” repeat produces essentially the same fabric. The knit carriage may be set to slip in both directions when using it since the row of all punched holes or black pixels will knit every stitch on every needle selected while in the previous samples the cam button set to knit in one direction performed that function regardless of any markings on the design repeat. The ribber is set to knit in one direction, slip in the other. Reversing sides for cam button settings produces the same fabric

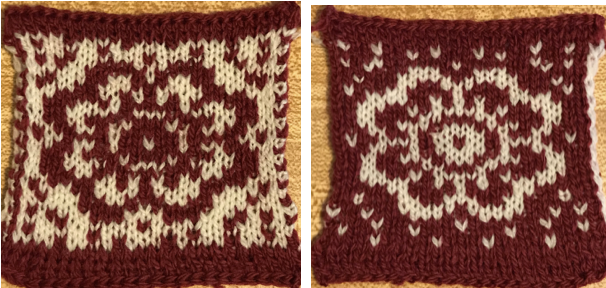

To my mind, the best shapes for this sort of surface design are clearly geometric ones. My eye sees them as more easily identified on the surface of the resulting knit. Sticking with the original “flower” however, here it is after a bit of editing of just a few pixels followed by a larger swatch

To my mind, the best shapes for this sort of surface design are clearly geometric ones. My eye sees them as more easily identified on the surface of the resulting knit. Sticking with the original “flower” however, here it is after a bit of editing of just a few pixels followed by a larger swatch

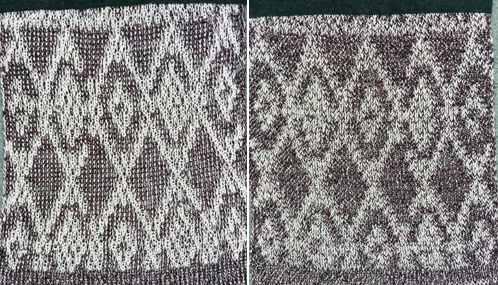

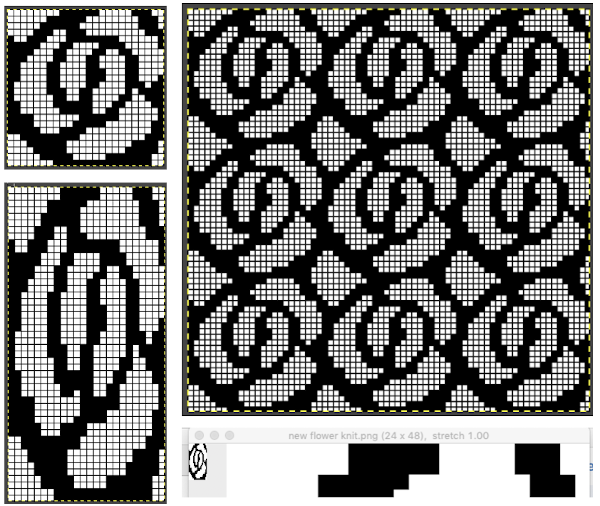

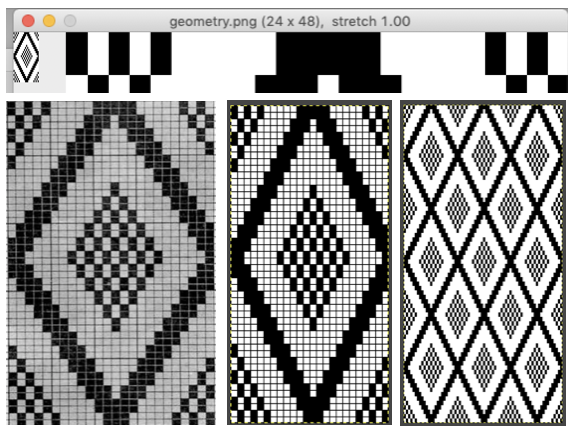

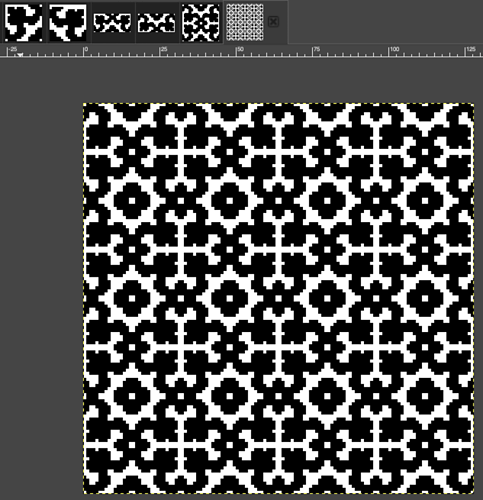

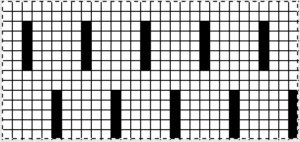

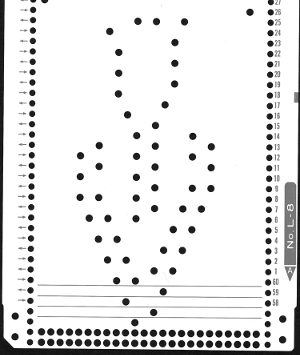

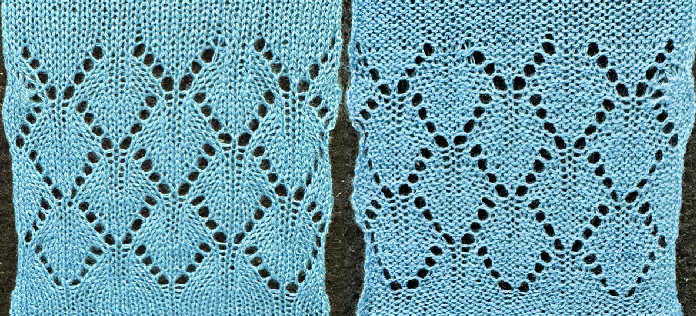

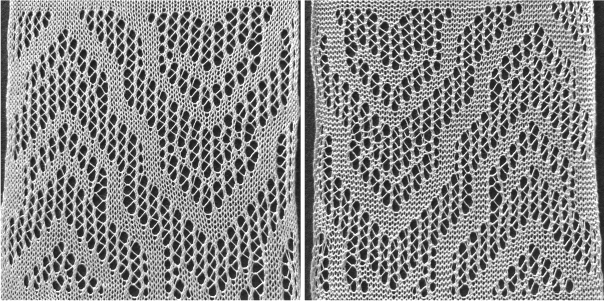

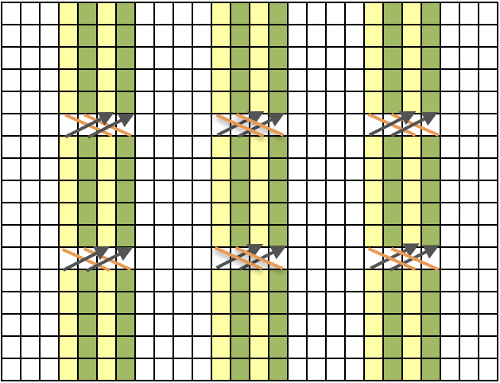

The Stitchworld Pattern Book is another good source for predesigned repeats, many in units suitable for punchcards as well. I was attracted to the possible geometry in this particular pattern

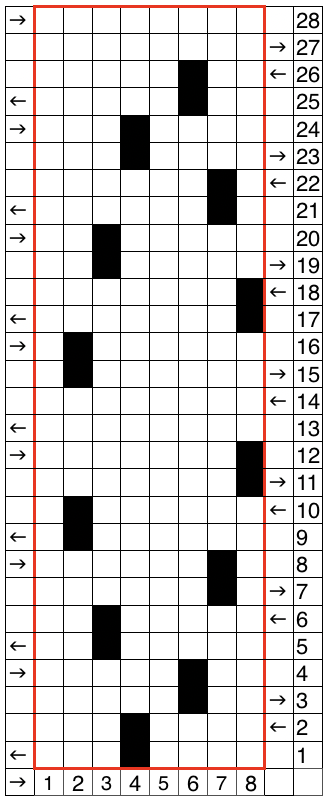

The Stitchworld Pattern Book is another good source for predesigned repeats, many in units suitable for punchcards as well. I was attracted to the possible geometry in this particular pattern The repeat I chose is designated as suitable for the Garter Carriage. It is 24 stitches wide by 48 rows high, shown below as provided, charted in Gimp as .png for download, and tiled to help visualize how continuous repeats might line up. The image .png was downloaded with img2track to my 930, with a stretch factor of 1.0, retaining the original repeat size

The repeat I chose is designated as suitable for the Garter Carriage. It is 24 stitches wide by 48 rows high, shown below as provided, charted in Gimp as .png for download, and tiled to help visualize how continuous repeats might line up. The image .png was downloaded with img2track to my 930, with a stretch factor of 1.0, retaining the original repeat size The resulting knit is interesting on both its knit and the purl sides, clearly shows how the “image” is shortened in slip stitch techniques, elongation would be required to create more of the diamond shape

The resulting knit is interesting on both its knit and the purl sides, clearly shows how the “image” is shortened in slip stitch techniques, elongation would be required to create more of the diamond shape

Final decisions are often best made after a period of rest for both the knit and for our eyes. It is only in the actual knitting that the shapes can be finally evaluated, worked on further, or abandoned. One of my own best selling felted items for more than a decade was born from an accidental effect on a large swatch that nearly landed in the trashcan after it became something different than what I had planned or expected.

Final decisions are often best made after a period of rest for both the knit and for our eyes. It is only in the actual knitting that the shapes can be finally evaluated, worked on further, or abandoned. One of my own best selling felted items for more than a decade was born from an accidental effect on a large swatch that nearly landed in the trashcan after it became something different than what I had planned or expected.

The design is automatically flipped vertically, so it will appear as intended on the knit side of the fabric.

The design is automatically flipped vertically, so it will appear as intended on the knit side of the fabric.

In the past, I have preferred to elongate the design prior to importing with plans for download rather than to rely on memory for changing settings either in the download program or in the machine itself in future uses of the same design.

In the past, I have preferred to elongate the design prior to importing with plans for download rather than to rely on memory for changing settings either in the download program or in the machine itself in future uses of the same design.

The same yarns, tension, the total number of carriage passes, and settings were used showing the difference in aspect ratio between single color per row knitting and the img2track built-in color separation.

The same yarns, tension, the total number of carriage passes, and settings were used showing the difference in aspect ratio between single color per row knitting and the img2track built-in color separation.  The width of both swatches is essentially identical.

The width of both swatches is essentially identical.

The 930 will provide prompts for the next color to be selected by pushing the matching number button on the color changer, avoiding any confusion in terms of what should be picked up next. img2track will also flip the design horizontally automatically so the image will appear as originally drawn on the knit side. Images are loaded as single motifs, so the change in the selector needs to be made manually for an all-over pattern.

The 930 will provide prompts for the next color to be selected by pushing the matching number button on the color changer, avoiding any confusion in terms of what should be picked up next. img2track will also flip the design horizontally automatically so the image will appear as originally drawn on the knit side. Images are loaded as single motifs, so the change in the selector needs to be made manually for an all-over pattern.

Obviously a success in terms of the single row for each color reducing elongation of the design shape. While knitting occurs using the same yarns, at the same tensions, there is a clear difference in the length of each stitch on the main bed and their appearance. The reverse. Checking the ribber carriage I noticed on the left side it was set to knit only, not to slip: OOPS!

Obviously a success in terms of the single row for each color reducing elongation of the design shape. While knitting occurs using the same yarns, at the same tensions, there is a clear difference in the length of each stitch on the main bed and their appearance. The reverse. Checking the ribber carriage I noticed on the left side it was set to knit only, not to slip: OOPS!  N is king, so the ribber set as shown is knitting every other needle when moving to the right, but even with lili buttons in use, it knits on every needle when moving back to the left. Every other needle on the ribber will then be knitting for 2 rows as a result. The more knitting on the ribber for each pair of rows, the longer the stitches on the opposite bed. The backing is an interesting variation (half) birdseye. The elongated stitches on the main bed show more of the backing in between their shapes, it is referred to as bleedthrough. In some instances, the result can make the knit surface resemble weaving and its appearance far less familiar in a surprising, pleasant way. Beauty is in the eye of the beholder.

N is king, so the ribber set as shown is knitting every other needle when moving to the right, but even with lili buttons in use, it knits on every needle when moving back to the left. Every other needle on the ribber will then be knitting for 2 rows as a result. The more knitting on the ribber for each pair of rows, the longer the stitches on the opposite bed. The backing is an interesting variation (half) birdseye. The elongated stitches on the main bed show more of the backing in between their shapes, it is referred to as bleedthrough. In some instances, the result can make the knit surface resemble weaving and its appearance far less familiar in a surprising, pleasant way. Beauty is in the eye of the beholder. The images could be replicated as given in a paint program, using only one color for the squares, but “should be reduced to black and white”. Attempting to import an indexed 2-color image drawn in a color other than BW may result in strange results.

The images could be replicated as given in a paint program, using only one color for the squares, but “should be reduced to black and white”. Attempting to import an indexed 2-color image drawn in a color other than BW may result in strange results.  That said, if glitched knits are the goal, the above could work just fine. Curiously, here is the same process, using a different color, and a successful import. Checking again, I had forgotten to save the image after indexing it from RGB mode to 2 colors.

That said, if glitched knits are the goal, the above could work just fine. Curiously, here is the same process, using a different color, and a successful import. Checking again, I had forgotten to save the image after indexing it from RGB mode to 2 colors.

Note to self: if you are determined to use a punchcard carriage on your electronic machine remember there is no KCII to cancel end needle selection!

Note to self: if you are determined to use a punchcard carriage on your electronic machine remember there is no KCII to cancel end needle selection!

Getting that first row to knit twice instead of a single time if that matters in your technique or is your preference:

Getting that first row to knit twice instead of a single time if that matters in your technique or is your preference:

pick up color 1 in yarn changer

pick up color 1 in yarn changer If black and white repeats are already in your library, one may easily recycle them adding a third color. Here I did so with a repeat intended for a very different topic in future posts. The image was altered and tiled in Gimp for a repeat alignment test and is also shown imported into img2track for possible knitting.

If black and white repeats are already in your library, one may easily recycle them adding a third color. Here I did so with a repeat intended for a very different topic in future posts. The image was altered and tiled in Gimp for a repeat alignment test and is also shown imported into img2track for possible knitting.

The image of the separation on the above right has not been proofed for accuracy. If it were, the next step would be to elongate it X 2 for color changes every 2 rows. One method is to elongate the original in a paint or photo processing program. The width is fixed (40), the height is scaled X 2. The resulting BW indexed image may be imported, using a 1.0 stretch factor, it remains unchanged. When I tried to elongate the unstretched image in img2track by 2.0 my first try failed. It turned out the reason was I had saved the import without first indexing it to 2 colors. With that corrected, the result matched the one from scaling X 2 in height in the paint program

The image of the separation on the above right has not been proofed for accuracy. If it were, the next step would be to elongate it X 2 for color changes every 2 rows. One method is to elongate the original in a paint or photo processing program. The width is fixed (40), the height is scaled X 2. The resulting BW indexed image may be imported, using a 1.0 stretch factor, it remains unchanged. When I tried to elongate the unstretched image in img2track by 2.0 my first try failed. It turned out the reason was I had saved the import without first indexing it to 2 colors. With that corrected, the result matched the one from scaling X 2 in height in the paint program

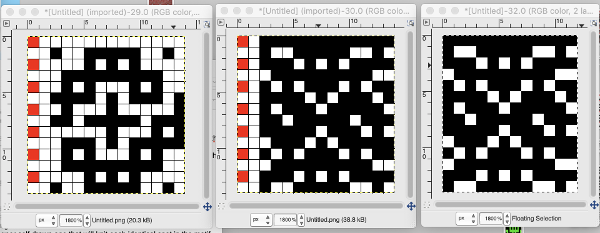

Here the image is scaled properly for each color represented for a single row in height and also scaled again for double height for possible knitting in Gimp. The Gimp scaling failed to be accurate for me (second image from left) until I indexed the original to 4 colors as well instead of 3. The no-color rows as we view them serve as a fourth color in the separations. Importing the proper size PNG into img2track for the separation of 4 colors per row now gives results that make sense: note the daunting estimate for the total number of carriage passes for a single repeat height

Here the image is scaled properly for each color represented for a single row in height and also scaled again for double height for possible knitting in Gimp. The Gimp scaling failed to be accurate for me (second image from left) until I indexed the original to 4 colors as well instead of 3. The no-color rows as we view them serve as a fourth color in the separations. Importing the proper size PNG into img2track for the separation of 4 colors per row now gives results that make sense: note the daunting estimate for the total number of carriage passes for a single repeat height If the ribber has knit on every needle by its return to the color changer and the machine is set to slip both ways with no needle selection on the main bed, the “no color” can be executed as an empty yarn holder in the color changer combined with no yarn in the feeder. The rows involved should simply not knit on the top bed, with no dropping of any of its stitches since no needles will have been selected thus coming forward with the yarn in the hooks and traveling behind the latches and in turn, slipping off the needles as a carriage with no yarn pushes the needles with now empty hooks back to B position.

If the ribber has knit on every needle by its return to the color changer and the machine is set to slip both ways with no needle selection on the main bed, the “no color” can be executed as an empty yarn holder in the color changer combined with no yarn in the feeder. The rows involved should simply not knit on the top bed, with no dropping of any of its stitches since no needles will have been selected thus coming forward with the yarn in the hooks and traveling behind the latches and in turn, slipping off the needles as a carriage with no yarn pushes the needles with now empty hooks back to B position.

Punchcard knitters may have the easiest knitting variable color sequences since cards may be visually marked up with colored pencils matching needed change locations and taking into account your eyes are several rows above the row being read by the card reader. This number depends on the machine’s brand and model.

Punchcard knitters may have the easiest knitting variable color sequences since cards may be visually marked up with colored pencils matching needed change locations and taking into account your eyes are several rows above the row being read by the card reader. This number depends on the machine’s brand and model.

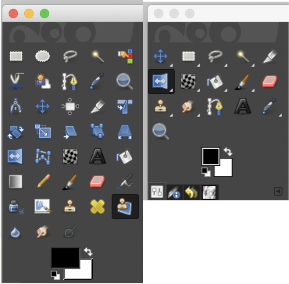

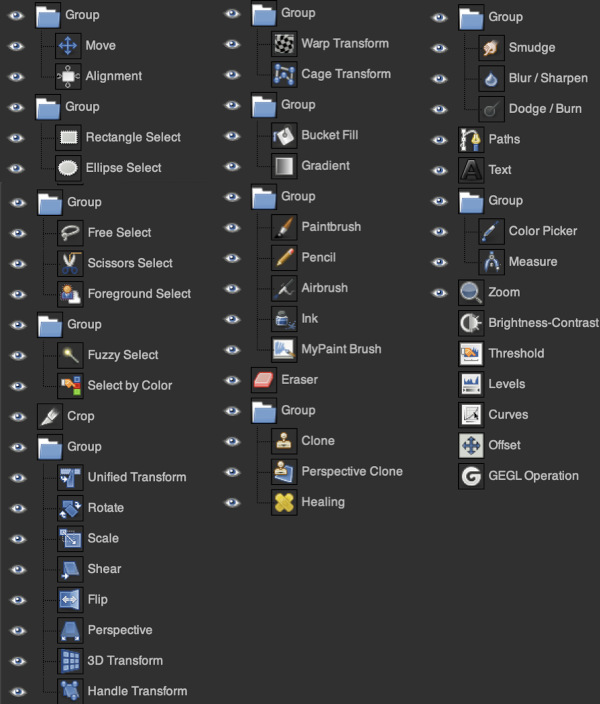

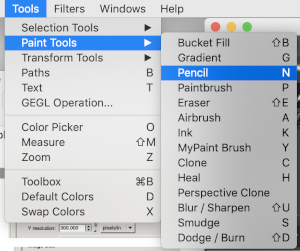

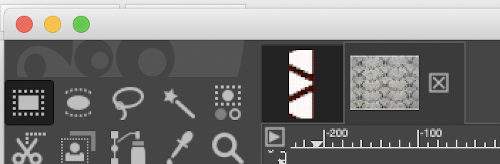

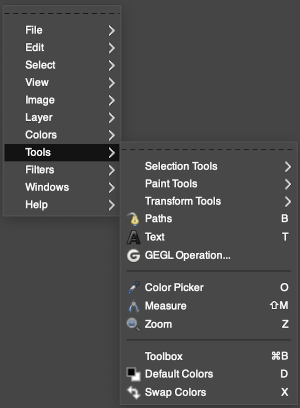

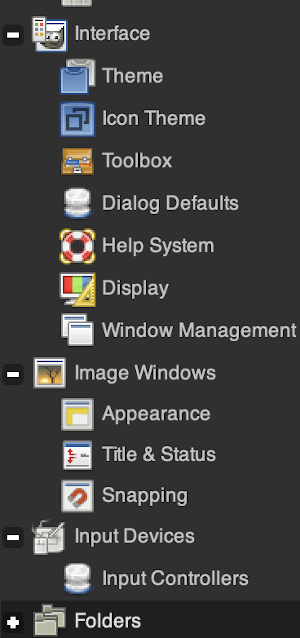

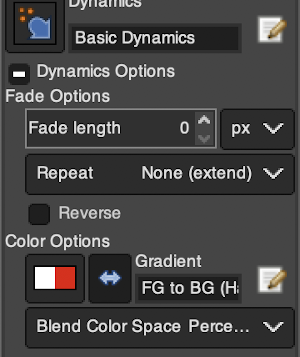

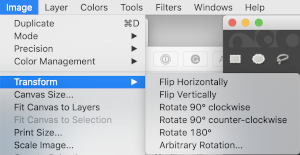

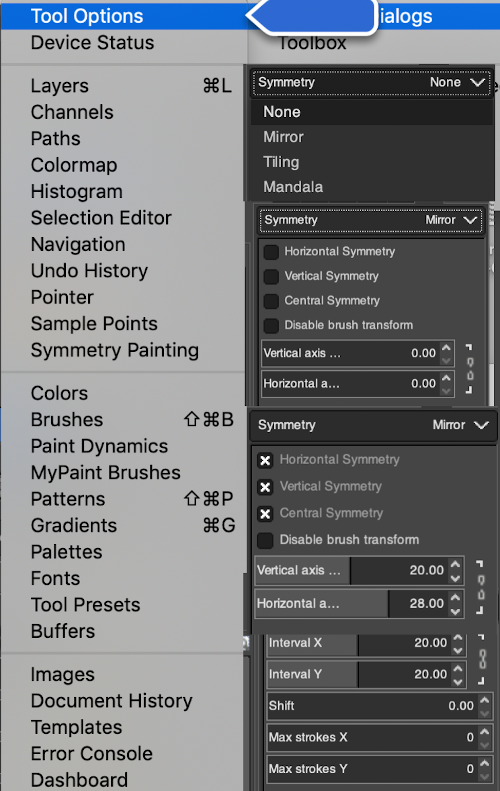

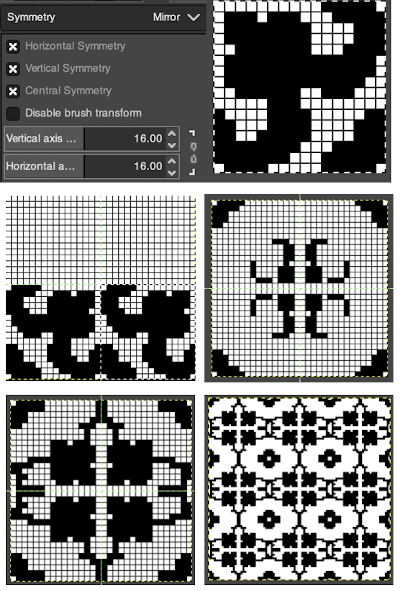

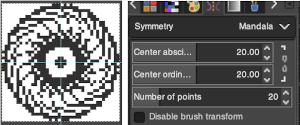

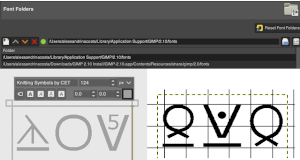

The symmetry tool is greatly improved and more user-friendly, allowing the distribution of patterns in varied repeats across canvases ie garment pieces.

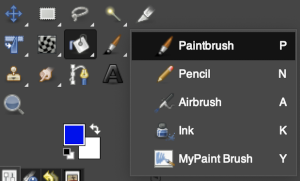

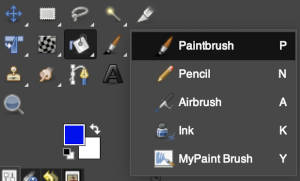

The symmetry tool is greatly improved and more user-friendly, allowing the distribution of patterns in varied repeats across canvases ie garment pieces. Right-click on the tool icon to reveal other choices

Right-click on the tool icon to reveal other choices

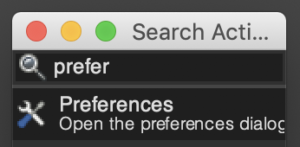

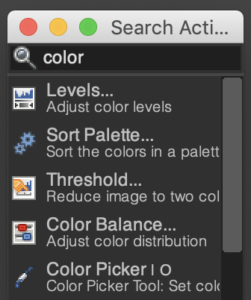

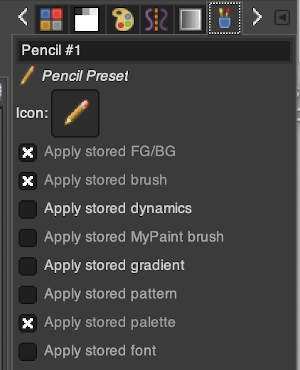

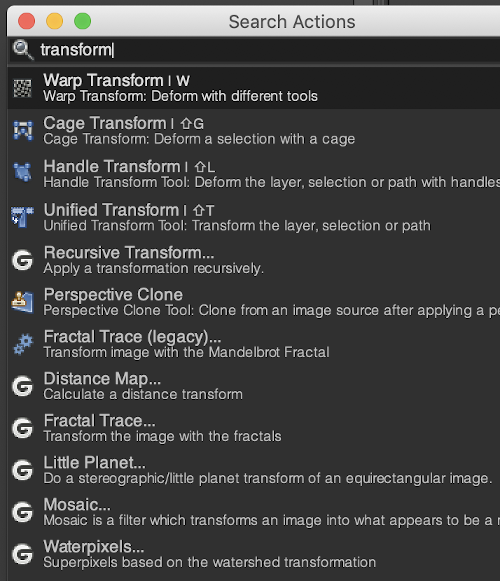

An option for selecting specific tools that include keyboard shortcuts to do so

An option for selecting specific tools that include keyboard shortcuts to do so  or right-click on the chosen tool

or right-click on the chosen tool

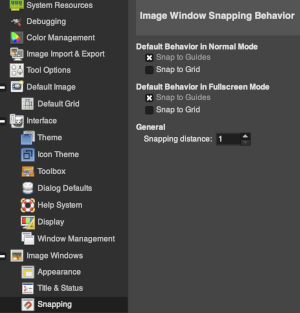

The jury is out as to whether changing the snapping preference value solves the problem long term

The jury is out as to whether changing the snapping preference value solves the problem long term A FB friend with a lot of experience with the program offered this as a possible cause “sometimes I accidentally activate commands with key combinations. It happens if you use the keyboard a lot (I have not used the mouse, for years). I work on a large Mac desktop and prefer the mouse to any keyboard commands.

A FB friend with a lot of experience with the program offered this as a possible cause “sometimes I accidentally activate commands with key combinations. It happens if you use the keyboard a lot (I have not used the mouse, for years). I work on a large Mac desktop and prefer the mouse to any keyboard commands. and here with a portrait size image

and here with a portrait size image

A new

A new

Previously clicking on the red X dot would ask if the image was to be discarded, and on the acknowledgment of the fact, the program would continue to stay open,

Previously clicking on the red X dot would ask if the image was to be discarded, and on the acknowledgment of the fact, the program would continue to stay open,  now that same action will quit the program completely. Clicking on the X beside the image will bring up the discard option, quitting the image and working on it as opposed to quitting the program. It is possible to work on multiple images at the same time. Drag and drop superimpose the new image fixed onto the center of first.

now that same action will quit the program completely. Clicking on the X beside the image will bring up the discard option, quitting the image and working on it as opposed to quitting the program. It is possible to work on multiple images at the same time. Drag and drop superimpose the new image fixed onto the center of first.

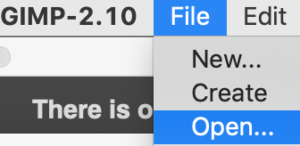

Working on 2 images again, copy the smaller image on its own screen,

Working on 2 images again, copy the smaller image on its own screen,  return to the screen with the larger image intended to be in the background, paste the smaller image for a floating selection that can be anchored anywhere on the ground, edit/ undo may be used repeatedly if need be, and done

return to the screen with the larger image intended to be in the background, paste the smaller image for a floating selection that can be anchored anywhere on the ground, edit/ undo may be used repeatedly if need be, and done

click on the gimp icon again to restore the view.

click on the gimp icon again to restore the view.

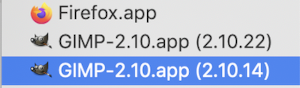

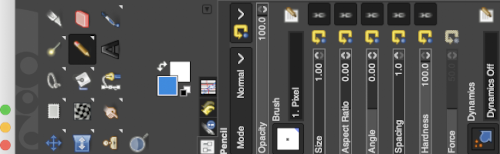

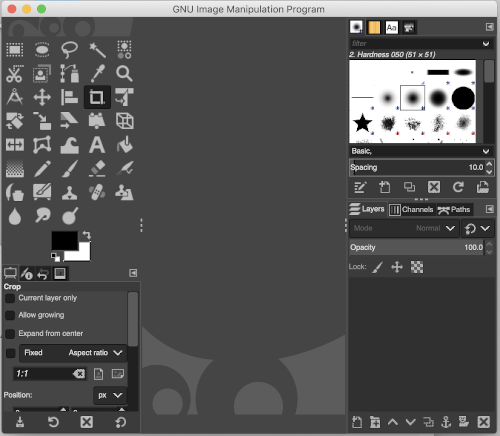

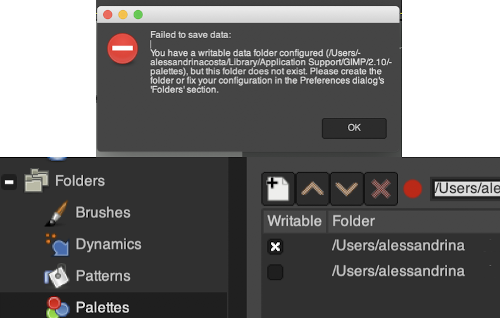

A word of caution: after choosing the 8-bit option and not liking the quality of my imported images, I tried restoring the original 32-bit floating one without success even after saving, quitting the program, and restarting it several times. I then chose to reinstall the program and continue working in the default settings for now. The download turned out to be for version 2.10.14, this is the new default appearance after launch on my computer

A word of caution: after choosing the 8-bit option and not liking the quality of my imported images, I tried restoring the original 32-bit floating one without success even after saving, quitting the program, and restarting it several times. I then chose to reinstall the program and continue working in the default settings for now. The download turned out to be for version 2.10.14, this is the new default appearance after launch on my computer

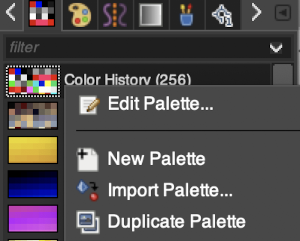

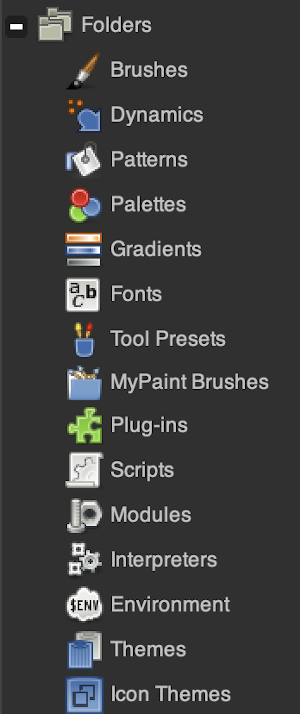

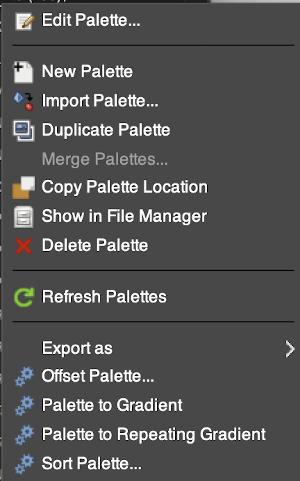

What about saving the color information as easy access palettes? Doing so in this release is fairly intuitive.

What about saving the color information as easy access palettes? Doing so in this release is fairly intuitive.

Selecting any one of the colors will automatically change the foreground color for working on the image ie choosing color 3 of the 6

Selecting any one of the colors will automatically change the foreground color for working on the image ie choosing color 3 of the 6

Using this feature with palettes containing multiple colors makes far quicker work when designing in RGB. Set pencil to desired pixel size, click on the desired color in any sequence to choose it, and then click again to place it on the working canvas

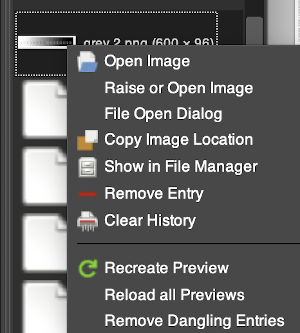

Using this feature with palettes containing multiple colors makes far quicker work when designing in RGB. Set pencil to desired pixel size, click on the desired color in any sequence to choose it, and then click again to place it on the working canvas  Right-click on any of the palette icons, for this dialogue menu

Right-click on any of the palette icons, for this dialogue menu

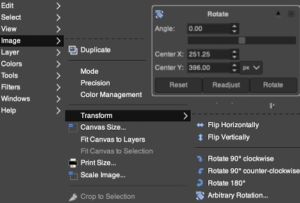

A sample in Mac, with the rotate dialogue which now appears as a separate window copied and pasted on the upper right of the image below

A sample in Mac, with the rotate dialogue which now appears as a separate window copied and pasted on the upper right of the image below  and another view from the image menu selection in the top dialogue

and another view from the image menu selection in the top dialogue

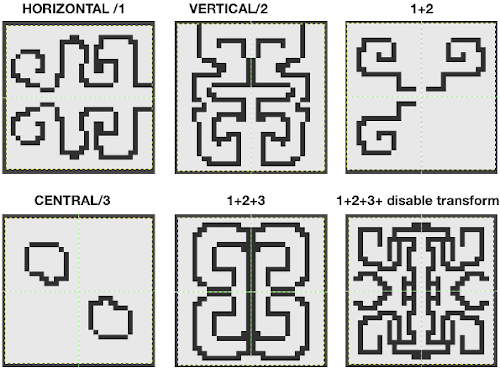

Some quick doodles using a single-pixel brush note the lags in some of the mirroring

Some quick doodles using a single-pixel brush note the lags in some of the mirroring Other than drawing freehand I have had no luck working predictably with larger designs, even if saved as brushes or patterns. One problem is that the pivot point is 2 pixels in each direction, not one, so repeats with single stitches/rows along their center axis would still need editing. In a previous attempt to explain mirroring in a forum post, I used Passap 1273 as my sample pattern. Copying and pasting the image on a larger canvas leaves one unable to change the direction of the newly pasted image alone, the whole potential repeat is affected by the command. The image in question here was 16 pixels wide by 16 high, the goal to mirror it to a 32 by 32 repeat.

Other than drawing freehand I have had no luck working predictably with larger designs, even if saved as brushes or patterns. One problem is that the pivot point is 2 pixels in each direction, not one, so repeats with single stitches/rows along their center axis would still need editing. In a previous attempt to explain mirroring in a forum post, I used Passap 1273 as my sample pattern. Copying and pasting the image on a larger canvas leaves one unable to change the direction of the newly pasted image alone, the whole potential repeat is affected by the command. The image in question here was 16 pixels wide by 16 high, the goal to mirror it to a 32 by 32 repeat. There was no problem with transforming the original and pasting each in place, here it is also scaled twice as high and wide

There was no problem with transforming the original and pasting each in place, here it is also scaled twice as high and wide tiling is compared for both the original repeat and the same scaled X2, with both the final tiled images 128 pixels in width and height

tiling is compared for both the original repeat and the same scaled X2, with both the final tiled images 128 pixels in width and height

The mandala option reminds me of spirograph drawings, the number of points can easily be changed

The mandala option reminds me of spirograph drawings, the number of points can easily be changed  Tiling may be useful in brick or offset repeats, but my limited experiments did not produce anything worth saving or sharing.

Tiling may be useful in brick or offset repeats, but my limited experiments did not produce anything worth saving or sharing.

and the 8-bit precision option

and the 8-bit precision option  I have previously written on using Numbers (similarly done in Excel) to create charts, then importing them into Gimp to create .bmps for download. This is a review of a method that seems to work well with smaller repeats: the working chart. Make certain the table is formatted so that all cells are the same size, with equal height and width

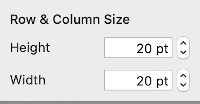

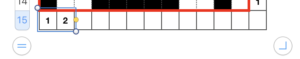

I have previously written on using Numbers (similarly done in Excel) to create charts, then importing them into Gimp to create .bmps for download. This is a review of a method that seems to work well with smaller repeats: the working chart. Make certain the table is formatted so that all cells are the same size, with equal height and width

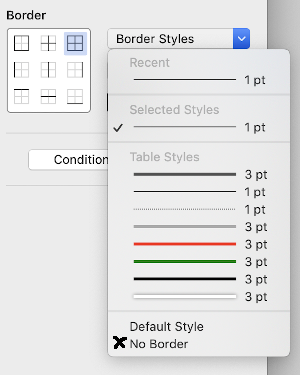

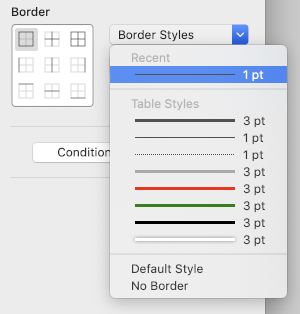

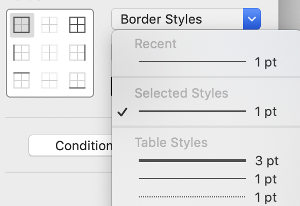

Use the border option to eliminate the interior cell borders, selecting no border,

Use the border option to eliminate the interior cell borders, selecting no border,

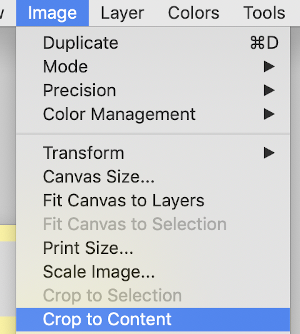

Use the bucket fill tool to make each color segment black, change the mode to indexed,

Use the bucket fill tool to make each color segment black, change the mode to indexed,

magnify to at least 800X, show grid, check that no clean up is needed,

magnify to at least 800X, show grid, check that no clean up is needed,  the image needs to be color reversed in order to be used for slip-stitch knitting,

the image needs to be color reversed in order to be used for slip-stitch knitting,

the numbering system reflects every other row worked alternating sides of the work

the numbering system reflects every other row worked alternating sides of the work  it is shown here with a superimposed table grid with its cells outlined in a thick border and positioned in front of a scaled screen grab of the original motif (arrange/ aspect ratio turned off)

it is shown here with a superimposed table grid with its cells outlined in a thick border and positioned in front of a scaled screen grab of the original motif (arrange/ aspect ratio turned off)

the cell borders can be edited as wished. Here borders were removed by selecting none, then, in turn, the outer border was highlighted in an easy to identify a thicker red line

the cell borders can be edited as wished. Here borders were removed by selecting none, then, in turn, the outer border was highlighted in an easy to identify a thicker red line

the last image needs to be once again converted to BW mode. The 2 extra rows of pixels on left are cropped off, the image is scaled to twice as long for use with the color changer, and the original 12X14 repeat is now 12X56

the last image needs to be once again converted to BW mode. The 2 extra rows of pixels on left are cropped off, the image is scaled to twice as long for use with the color changer, and the original 12X14 repeat is now 12X56 the actual BMP

the actual BMP

a “pretend” longer repeat

a “pretend” longer repeat

is compared here with the earlier

is compared here with the earlier

Back to the drawing board: row height is as in the original repeat

Back to the drawing board: row height is as in the original repeat  being extra careful, not necessary, the process can be inverted once more to check the repeat color separation

being extra careful, not necessary, the process can be inverted once more to check the repeat color separation

the corresponding proof of concept swatch, with shorter floats than when the DBJ separation is used single bed

the corresponding proof of concept swatch, with shorter floats than when the DBJ separation is used single bed

the repeat of the design separation on the right is intended for use in electronics with color reverse and double length

the repeat of the design separation on the right is intended for use in electronics with color reverse and double length

for knitting purposes

for knitting purposes

The repeat (8X16) is then doubled in length for knitting after that single all-white row was edited out (middle images). The repeat is now 8 rows wide by 32 rows in height

The repeat (8X16) is then doubled in length for knitting after that single all-white row was edited out (middle images). The repeat is now 8 rows wide by 32 rows in height One of the yarns is chenille, the other a wool. The chenille is slightly thicker and fuzzy, so some of the yellow rows are almost hidden but the pattern is definitely there. Here the design is knit using both slip (bottom) and tuck (top) settings. Again, there is a noticeable difference in width produced by each stitch type.

One of the yarns is chenille, the other a wool. The chenille is slightly thicker and fuzzy, so some of the yellow rows are almost hidden but the pattern is definitely there. Here the design is knit using both slip (bottom) and tuck (top) settings. Again, there is a noticeable difference in width produced by each stitch type.  Observations: make certain that after the image is isolated in Numbers cell size is converted to square/ equal measurements in width and height before importing and scaling its screen grab in GIMP if not already so. It will likely load in RGB mode, convert to Indexed before scaling. Added colored squares are only possible if you return to RGB mode. After rows with colored squares are cut, return the image to indexed before saving as BMP for knitting. If any pairs of rows do not have 2 consecutive rows of cells in either color check your pattern. In DBJ the final repeat should be 4 times in numbers of rows in height to the original one, and thus divisible by four. The separation first doubles height for each row for 2 colors. Then height is doubled once more to allow for color changes every 2 rows. In Mosaics and Mazes, the color reversal happens on every other row in the original design. When that is completed, the height will be doubled for actual knitting to allow for color changes every 2 rows, with the final row count double that of the original motif. Rules for tuck knitting apply here as in any other technique. If white squares in the final chart have black ones on either side of them, the appearance is that tuck would be possible. Examining needle preselection is an easy way to assess that possibility.

Observations: make certain that after the image is isolated in Numbers cell size is converted to square/ equal measurements in width and height before importing and scaling its screen grab in GIMP if not already so. It will likely load in RGB mode, convert to Indexed before scaling. Added colored squares are only possible if you return to RGB mode. After rows with colored squares are cut, return the image to indexed before saving as BMP for knitting. If any pairs of rows do not have 2 consecutive rows of cells in either color check your pattern. In DBJ the final repeat should be 4 times in numbers of rows in height to the original one, and thus divisible by four. The separation first doubles height for each row for 2 colors. Then height is doubled once more to allow for color changes every 2 rows. In Mosaics and Mazes, the color reversal happens on every other row in the original design. When that is completed, the height will be doubled for actual knitting to allow for color changes every 2 rows, with the final row count double that of the original motif. Rules for tuck knitting apply here as in any other technique. If white squares in the final chart have black ones on either side of them, the appearance is that tuck would be possible. Examining needle preselection is an easy way to assess that possibility.

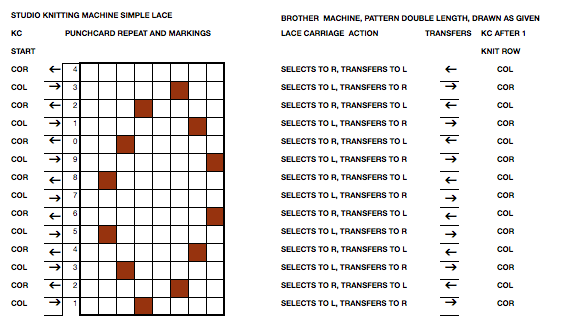

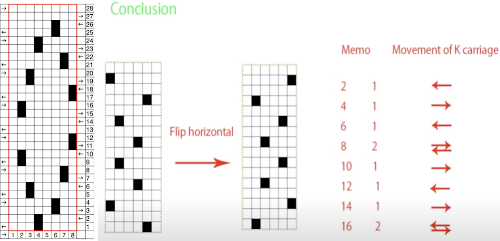

A comparison of my repeat using a single LC and the Knitlabo pattern expansion including memo options for use with 2 lace carriages

A comparison of my repeat using a single LC and the Knitlabo pattern expansion including memo options for use with 2 lace carriages

Back to the original method used in the previous post where ribber settings are changed from knit to tuck <– –> every 2 rows along with color changes. I chose a design that would make it easy to identify the location of non-selected needles on the main bed in rows where the ribber will be set to tuck in both directions. The result is interesting, but the solid areas, narrower than the remaining knit, are in the opposite color to the dominant one on each side, the reverse of the inspiration fabric.

Back to the original method used in the previous post where ribber settings are changed from knit to tuck <– –> every 2 rows along with color changes. I chose a design that would make it easy to identify the location of non-selected needles on the main bed in rows where the ribber will be set to tuck in both directions. The result is interesting, but the solid areas, narrower than the remaining knit, are in the opposite color to the dominant one on each side, the reverse of the inspiration fabric.

The ribber remains set for knitting in both directions throughout, with the main bed set to tuck in both directions.

The ribber remains set for knitting in both directions throughout, with the main bed set to tuck in both directions.

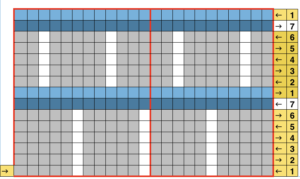

The single 14X84 png

The single 14X84 png  Each of the 2 colors tucks for 2 rows and in turn, knits for 2 rows alternately. Settings are changed manually as shown below after every 2 rows knit, following each color change on the left.

Each of the 2 colors tucks for 2 rows and in turn, knits for 2 rows alternately. Settings are changed manually as shown below after every 2 rows knit, following each color change on the left.  Making things a little easier: the top bed may be programmed on any machine, including punchcard models to avoid cam button changes in the knit carriage every 2 rows. With the main bed set to tuck <– —> throughout, black squares will knit for 2 rows, white squares will tuck, also for 2 rows. The first preselection row is toward the color changer. When no needles are selected on the top bed (white squares) the top bed will tuck every needle, the ribber is set to knit.

Making things a little easier: the top bed may be programmed on any machine, including punchcard models to avoid cam button changes in the knit carriage every 2 rows. With the main bed set to tuck <– —> throughout, black squares will knit for 2 rows, white squares will tuck, also for 2 rows. The first preselection row is toward the color changer. When no needles are selected on the top bed (white squares) the top bed will tuck every needle, the ribber is set to knit.

Another attempt at cabling, 1X1 and 2X2. That white line in the bottom image on the right was caused by the color changer picking up and knitting both colors for part of the row before I noticed it. I got rid of the “wrong” color from the feeder and continued on. The wider 2X2 cables require “special handling” and eyelets are formed on columns aside from them after transfers are made.

Another attempt at cabling, 1X1 and 2X2. That white line in the bottom image on the right was caused by the color changer picking up and knitting both colors for part of the row before I noticed it. I got rid of the “wrong” color from the feeder and continued on. The wider 2X2 cables require “special handling” and eyelets are formed on columns aside from them after transfers are made.

The situation is different when working on single bed vertically striped fair isle designs. One of my ancient machine-knit demo FI swatches:

The situation is different when working on single bed vertically striped fair isle designs. One of my ancient machine-knit demo FI swatches:

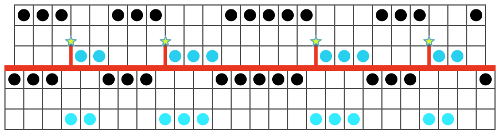

The charted repeat on the left below when tiled shows the area of a patterning error, on the right with the missing blank rows added the problem is shown to be resolved, the repeat is now 24 X 84.

The charted repeat on the left below when tiled shows the area of a patterning error, on the right with the missing blank rows added the problem is shown to be resolved, the repeat is now 24 X 84.

Adding complexity, there is the possibility of

Adding complexity, there is the possibility of

Other related fabrics may be found in posts:

Other related fabrics may be found in posts: