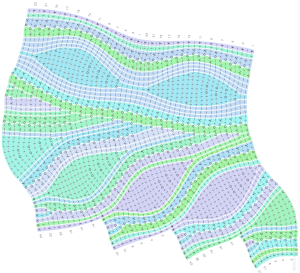

In 2012 I had a sort of leaf obsession, which led to my exploring a range of shapes created in both hand and machine knitting, including a series of shawls that were machine knit, using the lace carriage, intended for both gifts and sale.

Online resources were not as abundant back then, searches are more productive now via browser searches, pinboards, and Ravelry.

I have always been interested in holding techniques and automating them on both punchcard and electronic machines. In recently revisiting shell shapes I was reminded of leaves once more and thought I would return to working with them.

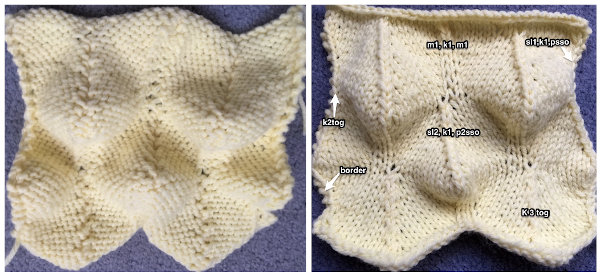

An early abandoned effort in trying to construct leaf shapes automating their shaping using holding in combination with slip stitch followed other earlier posts is shown below. In all honesty, I have been blogging long enough so I often do not recall previous writings on a recent spark of interest and execute a personal version of reinventing the wheel, starting from scratch, or executed poor note-keeping which in turn requires it.

A variety of lozenge and “leaf”-shaped forms may be found in previous posts on holding intarsia, some are strictly hand-selected, others are automated. There is a series of 5:

2016/06/21/a-bit-of-holding-1/

2016/06/29/a-bit-of-holding-2-moving-shapes-around/

2016/07/12/a-bit-of-holding-3-shape-variations-and-more/

2016/07/24/a-bit-of-holding-4-intarsia-and-more/

/2016/08/13/a-bit-of-holding-5-intarsia-and-more-2/

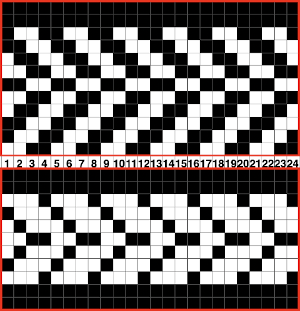

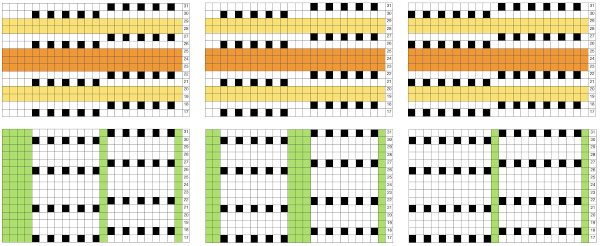

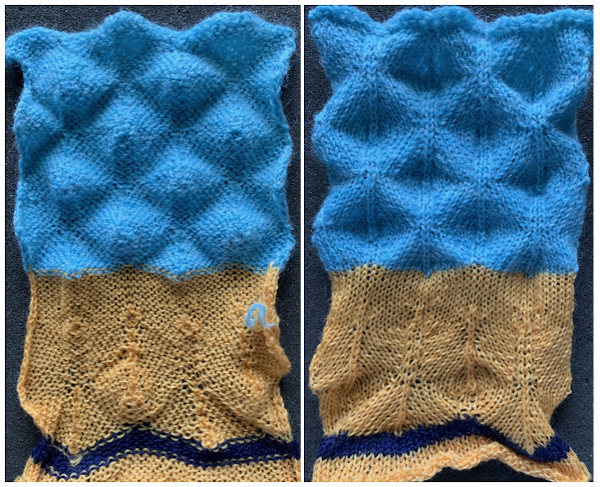

Checking the repeat for a single shape  Adding a second color and reversing directions of shapes brings lots of yarn ends and its “price to pay”

Adding a second color and reversing directions of shapes brings lots of yarn ends and its “price to pay”

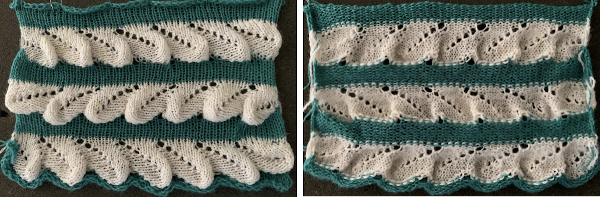

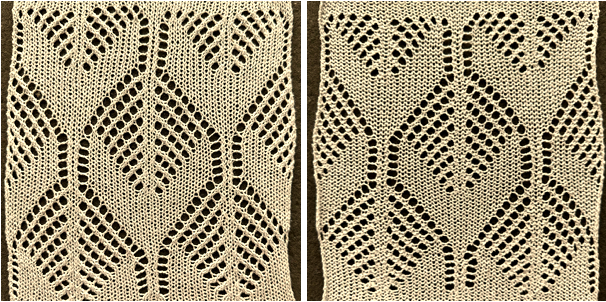

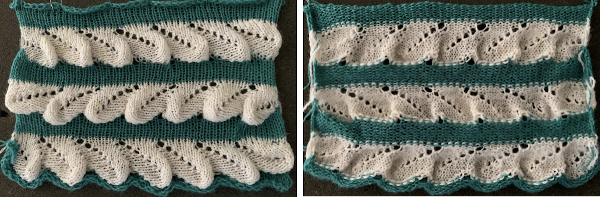

Some handknit large scale inspiration to begin my revisit to MKing them: Garnstudio 1

Some handknit large scale inspiration to begin my revisit to MKing them: Garnstudio 1  and Garnstudio 2, which introduces lace transfer stripes between leaf forms

and Garnstudio 2, which introduces lace transfer stripes between leaf forms  A free hand knitting pattern, “Papagena“, that takes similar shapes to a triangular layout for shawl shaping

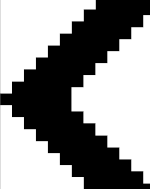

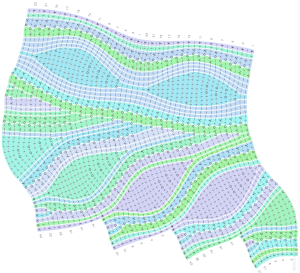

A free hand knitting pattern, “Papagena“, that takes similar shapes to a triangular layout for shawl shaping  Stitch Maps is an online source for hand knitters with interesting graphics that include some for held shapes, such as this

Stitch Maps is an online source for hand knitters with interesting graphics that include some for held shapes, such as this  The chart is actually rotated 90 degrees counterclockwise, could serve as inspiration for an electronic pattern.

The chart is actually rotated 90 degrees counterclockwise, could serve as inspiration for an electronic pattern.

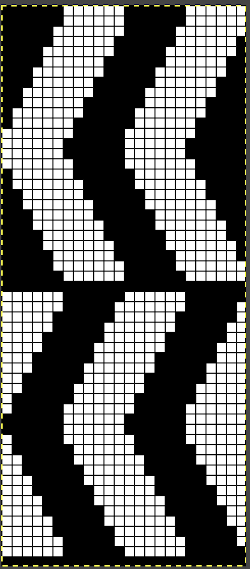

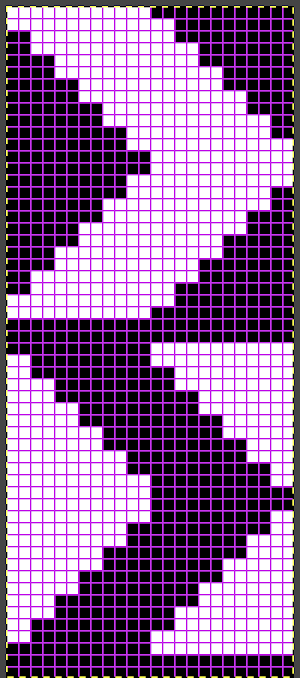

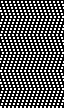

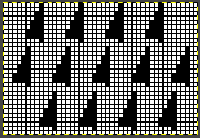

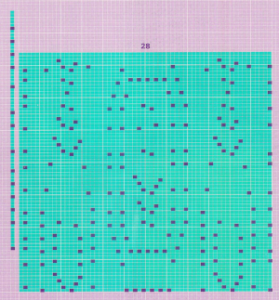

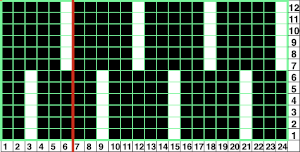

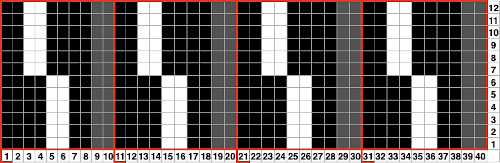

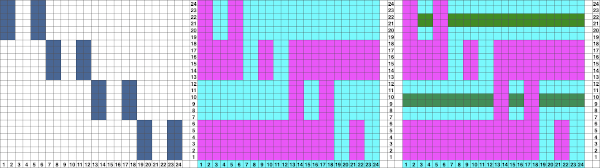

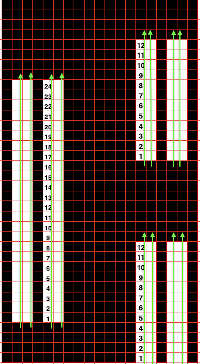

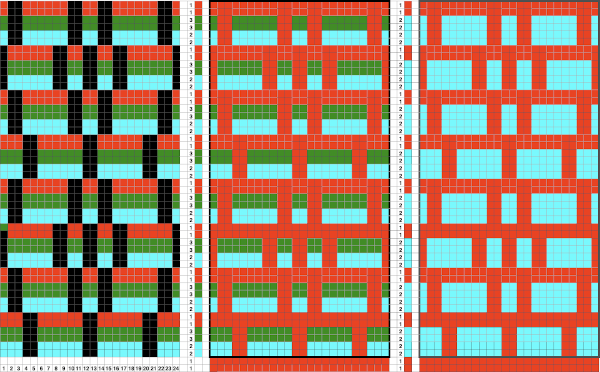

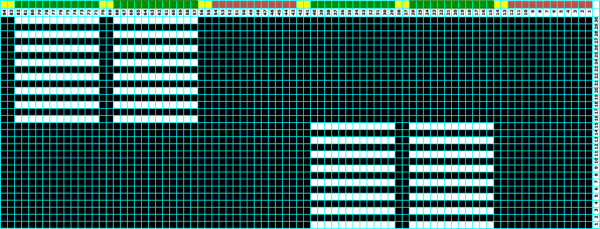

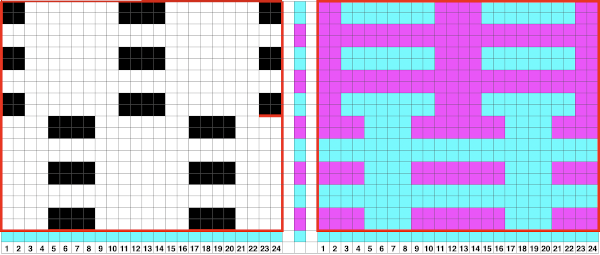

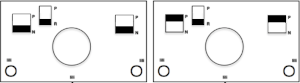

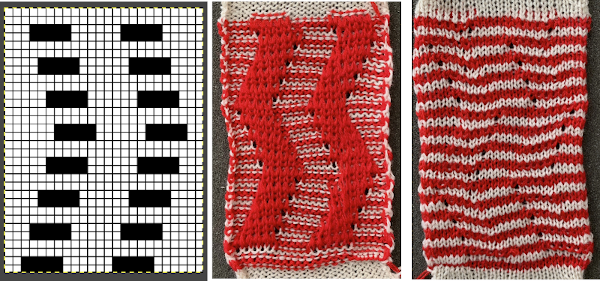

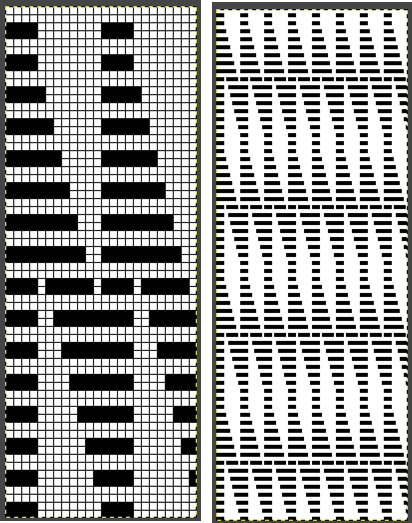

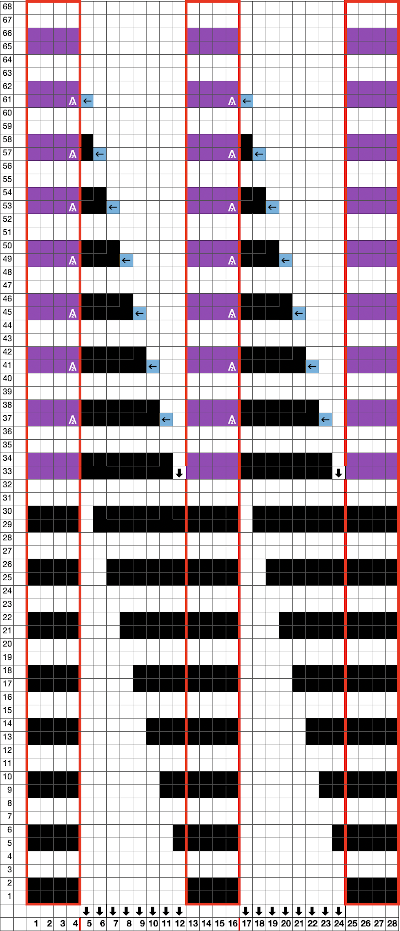

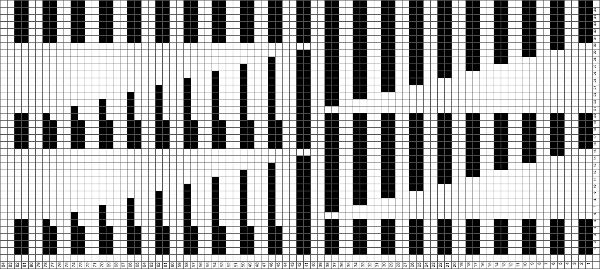

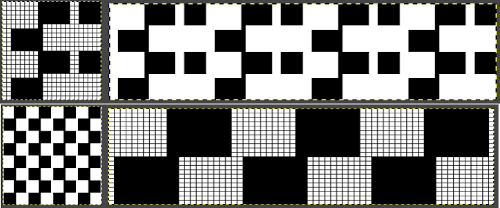

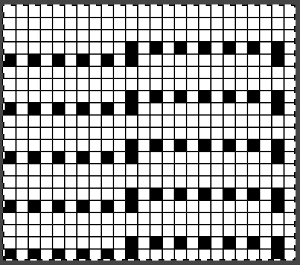

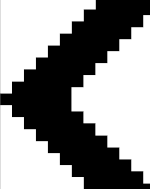

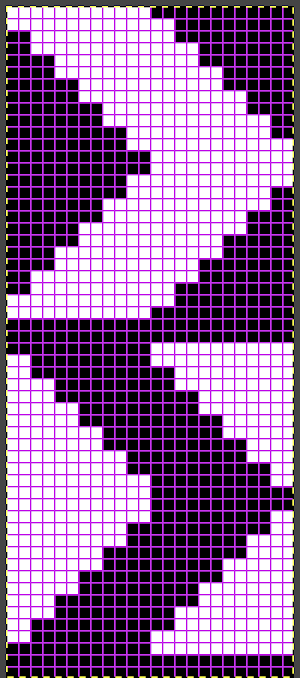

Returning to a possible far smaller repeat that may be executable on a punchcard machine as well. The central vein in the forms is created by having held stitches with no wraps along and up to its center in height, creating 2 continuous shapes that mirror horizontally and repeat Automated holding sequences may be planned for single or multiple stitches in width, as well as for single and multiple rows in height. For the new initial test, which proved to need editing, this was my repeat

Automated holding sequences may be planned for single or multiple stitches in width, as well as for single and multiple rows in height. For the new initial test, which proved to need editing, this was my repeat A tiny test in too thin a yarn

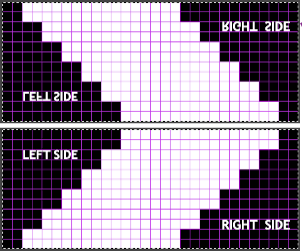

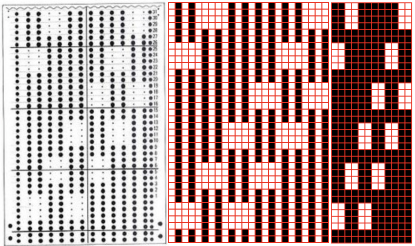

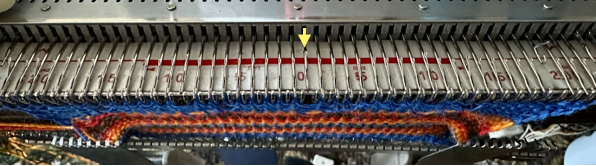

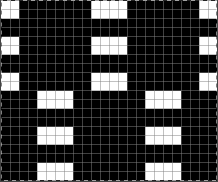

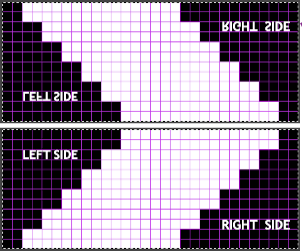

A tiny test in too thin a yarn  I am knitting on a 930, the image needs to be mirrored in order for it to appear in the direction I intend on the knit side. The above repeat did not work properly when knitting a whole row of shapes. With some patience, a final, edited, and mirrored repeat was developed that enabled a completed a full row of shapes using the slip setting and holding, and starting with working it from right to left. Sometimes differences are subtle, especially in designing using single-pixel units. The new repeat proved to also work for rows of shapes in the reverse direction after horizontal mirroring and restarting the pattern or design row 1. When working from right to left, the initial preselection row is from left to right, while when working from left to right, the first preselection row is from right to left. After a full row of repeats is completed, the pattern is rolled back to row 1 and mirrored. Punchcard knitters could turn the card over and start again on the proper row. I used contrast color knit rows initially in between rows of shapes to help me note transitions more clearly. The “leaf” is not pointy enough for me, but at times what was not planned may lead to a pleasing result of a different sort.

I am knitting on a 930, the image needs to be mirrored in order for it to appear in the direction I intend on the knit side. The above repeat did not work properly when knitting a whole row of shapes. With some patience, a final, edited, and mirrored repeat was developed that enabled a completed a full row of shapes using the slip setting and holding, and starting with working it from right to left. Sometimes differences are subtle, especially in designing using single-pixel units. The new repeat proved to also work for rows of shapes in the reverse direction after horizontal mirroring and restarting the pattern or design row 1. When working from right to left, the initial preselection row is from left to right, while when working from left to right, the first preselection row is from right to left. After a full row of repeats is completed, the pattern is rolled back to row 1 and mirrored. Punchcard knitters could turn the card over and start again on the proper row. I used contrast color knit rows initially in between rows of shapes to help me note transitions more clearly. The “leaf” is not pointy enough for me, but at times what was not planned may lead to a pleasing result of a different sort.

The amended, corrected repeat is shown on the right

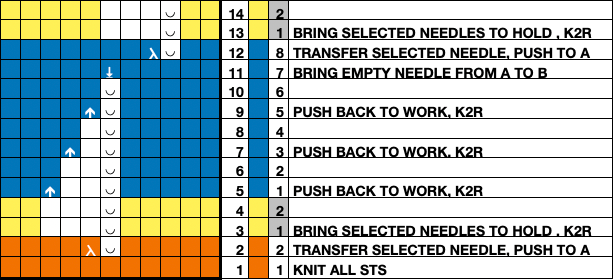

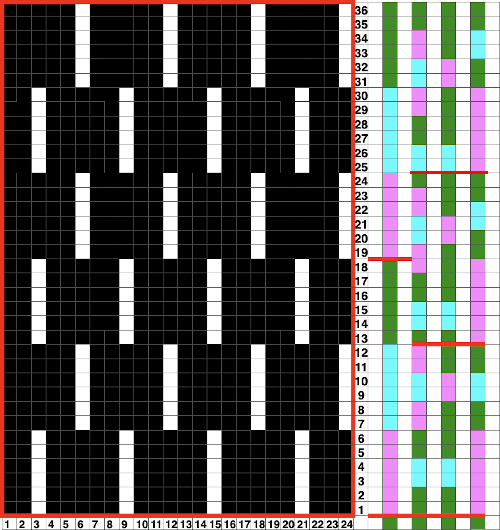

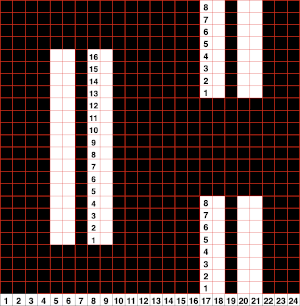

To knit: cast on with a multiple of 12 stitches on each side of the center 24 on the needle bed

To knit: cast on with a multiple of 12 stitches on each side of the center 24 on the needle bed

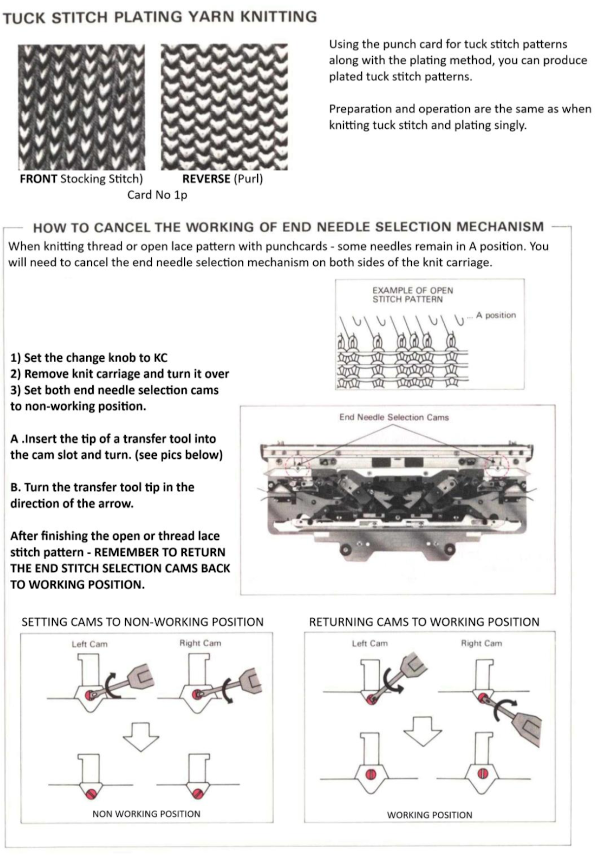

Cancel end needle selection

COL: first preselection row from left to right

COR: set machine for both slip <– –> and hold

all needles will have been preselected, knitting every stitch, knit 2 rows, return to the right, as the row is knit, patterned preselection occurs

COR: bring all needles to the left of the first 12 on the right into hold position, knit until all needles in the group of 12 are preselected again, the carriage will be on the right

*COR: bring a group of 6 needles to the left of the 12 stitch group just completed into work, knit one row to left

COL: bring 6 stitches from the completed shape on the right to hold, continue in the pattern on the new 12 stitch group until all 12 stitches are once again preselected, stopping with COR***

repeat * to *** end working the full last group of 12 stitches on the left, including the last 12 stitch preselection

At the completion of a row of shapes COL: make a decision about the transition, whether any extra rows knit are a problem or not, and whether added rows in contrasting colors are wanted. To proceed with no changes in cam settings and 4 rows of knitting between the rows of shapes remembering that the first preselection row needs to be made from right to left.

COL: manually return all needles to upper work position (D). They will knit row 1 of the stripe

COR: manually push all needles to D again, return program to design row one, check settings, as the first design row pattern is preselected an all knit row 2 will be added. As patterning resumes from the left another 2 all knit rows will be produced before selective patterning occurs.

If any extra all knit rows are wanted cancel patterning on the knit carriage, set it to N, knit the extra rows, remember to end on the proper side for the first preselection row, and what options may be necessary to complete that row correctly.

To reverse patterns without extra knit rows:

COL: store yarn. The carriage can be removed and brought to the opposite side, or stitches need to be manually be placed in the B position for a free pass to the right. This involves placing the cam selector button on N, returning the cams set to slip in both directions.

COR, all needles also need to be in work in B position, no yarn, in order to make a free pass to preselect from right to left, ending COL

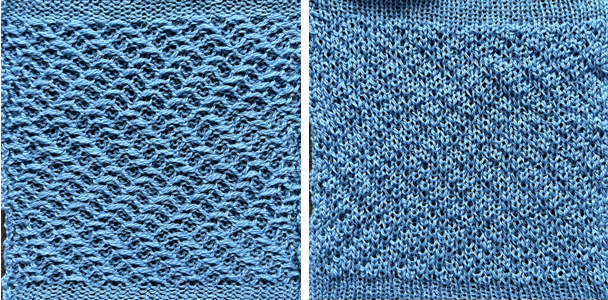

COL: pick up yarn and continue in pattern. These textures require a lot of carriage passes, which tend to fuzz up the yarn on the purl side of the knit a bit. The shape I created was not very leafy to my mind, but still interesting, especially on the purl side. The yarn used in a 2/15 wool, knit on Tension 5

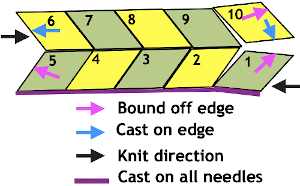

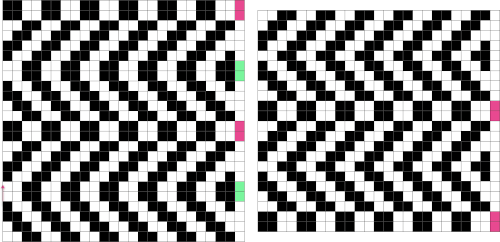

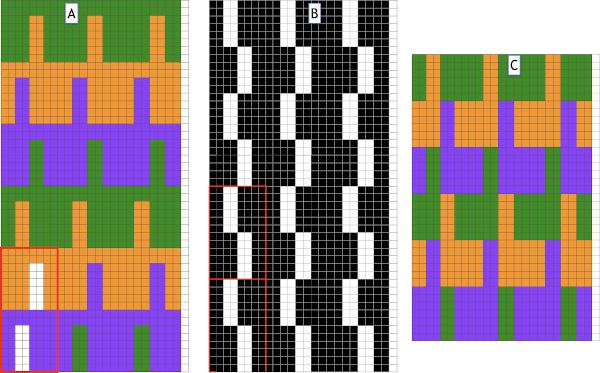

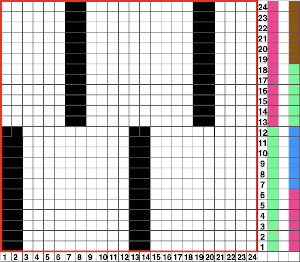

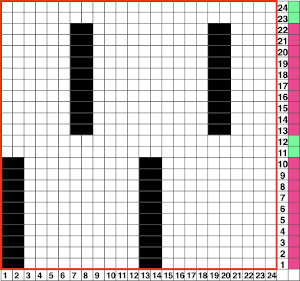

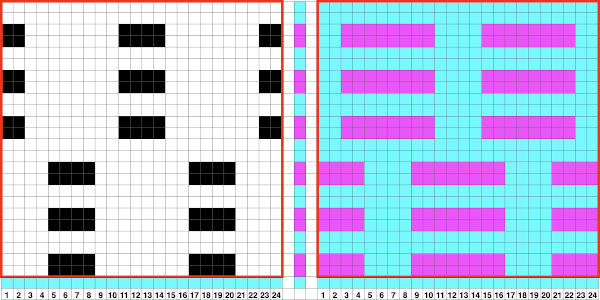

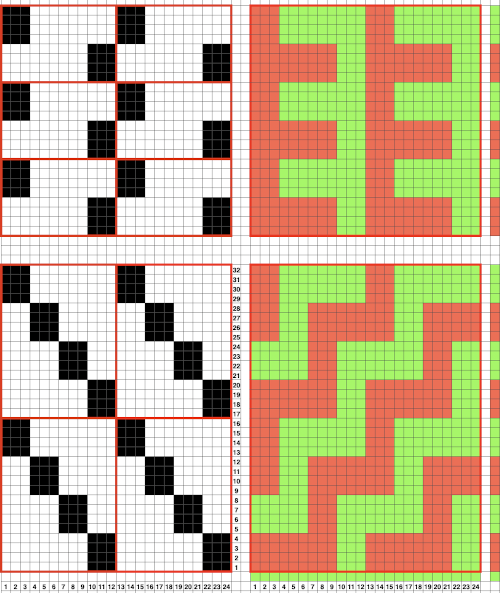

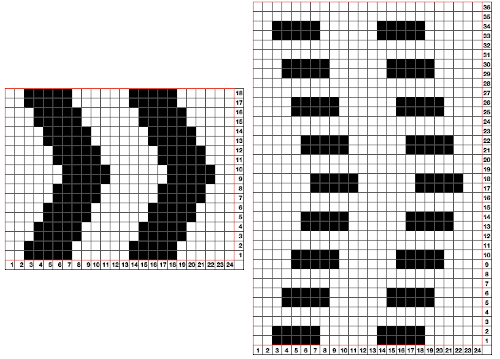

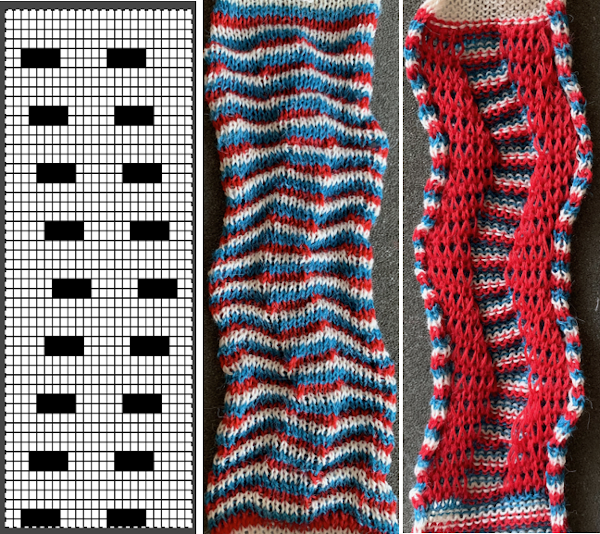

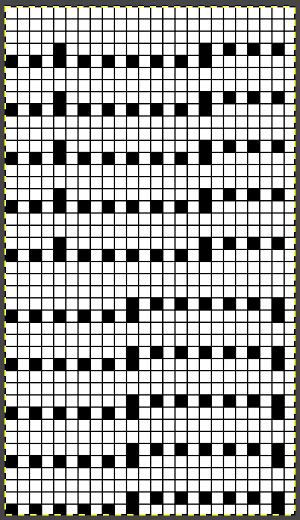

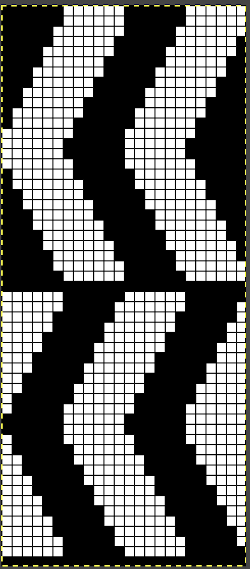

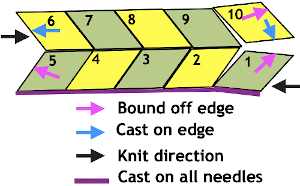

Moving on to a wider version, using 24 stitches in width to allow for using the pattern on a punchcard: this repeats works both as-is and mirrored, the groups of stitches moved in and out of work is now half of the new design repeat = 12.

Moving on to a wider version, using 24 stitches in width to allow for using the pattern on a punchcard: this repeats works both as-is and mirrored, the groups of stitches moved in and out of work is now half of the new design repeat = 12.  Making the repeat work in any number for this shape involves lining up the needle selection in each group of needles and constant counts for holding sequences. Punchard knitters would need 2 separate cards.

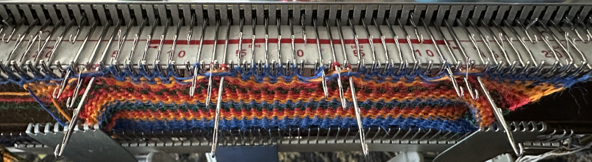

Making the repeat work in any number for this shape involves lining up the needle selection in each group of needles and constant counts for holding sequences. Punchard knitters would need 2 separate cards.  The lovely mess in the swatch happened when I stopped paying attention to everything but what was happening on the needle bed and missed the tangle of yarns in my yarn mast. There is enough knitting, however, to note that the repeat is sound and that the edges on both sides are formed by the narrowest part of the shapes in each direction. One way to solve that is by casting on and binding off along tops and bottoms of shapes as seen in the yellow and green swatch at the top of the post.

The lovely mess in the swatch happened when I stopped paying attention to everything but what was happening on the needle bed and missed the tangle of yarns in my yarn mast. There is enough knitting, however, to note that the repeat is sound and that the edges on both sides are formed by the narrowest part of the shapes in each direction. One way to solve that is by casting on and binding off along tops and bottoms of shapes as seen in the yellow and green swatch at the top of the post.  Planning things out to release those edges as seen at the top of the post

Planning things out to release those edges as seen at the top of the post

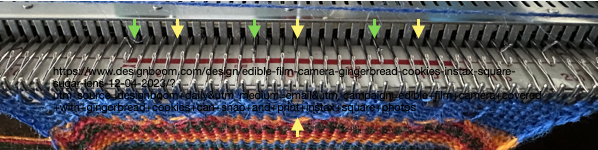

Working on outlining the shapes with contrast color:

Problems to solve: maintaining an even number of rows in-between shapes and a straight edge along both sides. The latter could happen with triangles prior to knitting full shapes at either or both ends, the first sample failed on the left side due to both triangles being knit in the same sequence;

Problems to solve: maintaining an even number of rows in-between shapes and a straight edge along both sides. The latter could happen with triangles prior to knitting full shapes at either or both ends, the first sample failed on the left side due to both triangles being knit in the same sequence;

that may be solved by beginning shaping on 2 stitches on the left rather than the full 12, mirrored. The proper sequence for actual knit stitches for the first, bottom set, and mirrored for the second, top set

that may be solved by beginning shaping on 2 stitches on the left rather than the full 12, mirrored. The proper sequence for actual knit stitches for the first, bottom set, and mirrored for the second, top set  still only partway there

still only partway there

I am presently knitting with my left hand in a splint that has exposed velcro teeth, which has caused some interesting issues with actual knitting and with yarn snags. To end this latest effort, in yet another knitting aaargh! moment, it appears my iron is now overheating and burned the wool! From observing the above swatch on the purl side it looks as though each row of shapes needs to have a triangular shape at each end. Also, the contrasting color line thickness is not constant. The purpose of automation should be to make things easier, not confounding. After yet another trial, I decided to give up on attempting to use the automated repeat to produce an effect that was consistent and made me happy.

I am presently knitting with my left hand in a splint that has exposed velcro teeth, which has caused some interesting issues with actual knitting and with yarn snags. To end this latest effort, in yet another knitting aaargh! moment, it appears my iron is now overheating and burned the wool! From observing the above swatch on the purl side it looks as though each row of shapes needs to have a triangular shape at each end. Also, the contrasting color line thickness is not constant. The purpose of automation should be to make things easier, not confounding. After yet another trial, I decided to give up on attempting to use the automated repeat to produce an effect that was consistent and made me happy.

Setup for a leaf in each color is far less fiddly and simpler to execute. A tentative layout and knitting sequence:

Begin on waste yarn, decide on the color of the cast on, and any additional knit rows prior to beginning in the pattern. Each of the side triangles is shaped using manual holding techniques over 12 stitches. If starting on the right, the first preselection row needs to be made moving from left to right as above on the first 24 stitches. With knit carriage set to both slip in both directions and holding with COL make certain the first 24 stitches on the right in B position make a free pass to the right.

Begin on waste yarn, decide on the color of the cast on, and any additional knit rows prior to beginning in the pattern. Each of the side triangles is shaped using manual holding techniques over 12 stitches. If starting on the right, the first preselection row needs to be made moving from left to right as above on the first 24 stitches. With knit carriage set to both slip in both directions and holding with COL make certain the first 24 stitches on the right in B position make a free pass to the right.

COR: cut yarn, change color, knit the first shape repeat, end COR

COR: when all needles in the group are preselected, push the first 12 needles on the carriage side out to holding position, push 12 stitches on their left back into upper work position as you would in any holding pattern, they will knit in the slip setting as well. Cut the yarn, change color, repeat across the row of shapes

COR: when the last group of 12 needles on the left is preselected with all needles out to hold or removing the carriage and positioning it on the other side, begin knitting COL.

COL: manually knit triangle at top of the previous row of shapes

If a contrasting color stripe or any other pattern is intended between a full row of shapes, execute them and end COL

COL: shape the second triangle for the start of the reversed row of shapes, get the carriage to the right side by a pass over all needles in holding position or removing the carriage and bringing it to the opposite side

COR: the second pattern is programmed. Punchcard knitters use the second card, electronics mirror the shape. With the first 24 stitches on the left in B position and the knit carriage set for holding and to slip in both directions, make a preselection pass to left.

COL: change color, knit shape, and continue on as described above reversing shaping

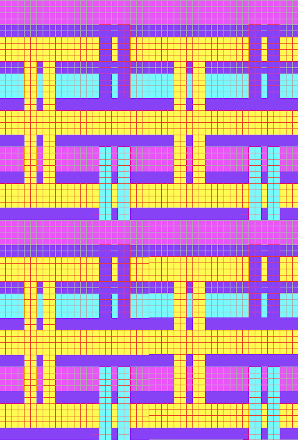

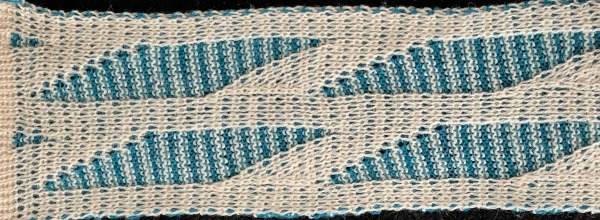

As with intarsia, there will be lots of yarn ends to weave in and clean up those eyelets at the start of each color change. The swatch after a quick pressing

The possibilities could be endless. Electronic machines do not have the limitation of working within the 24 stitches maximum design width. Shapes can be fully automated using only slip stitch setting, no holding, but repeats become exponentially wide and long. The technique merits its own post.

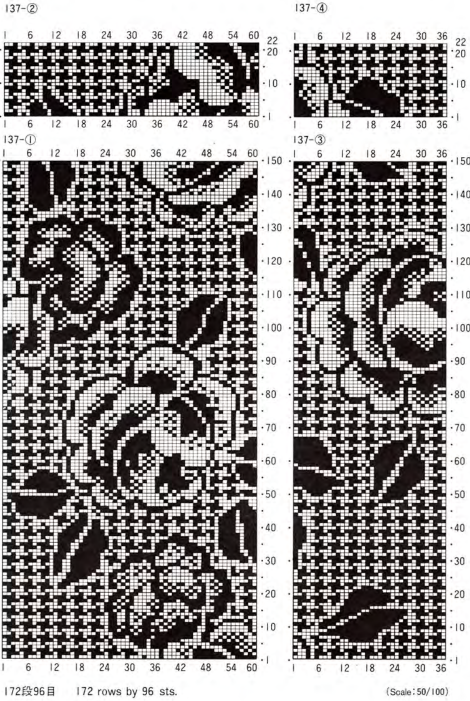

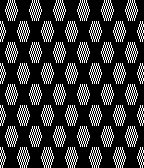

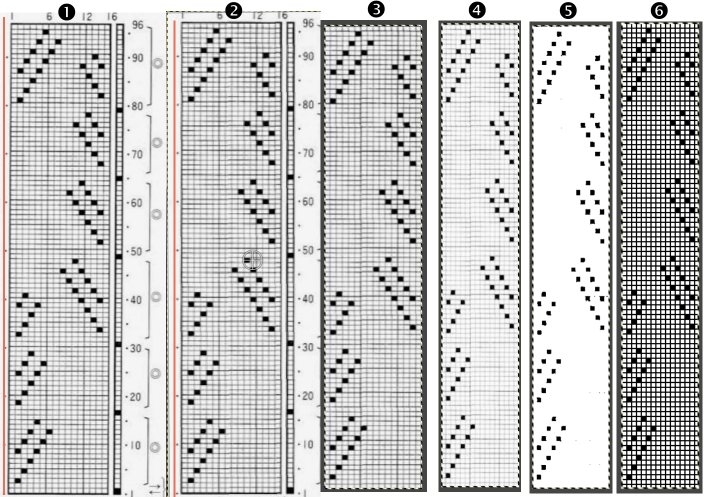

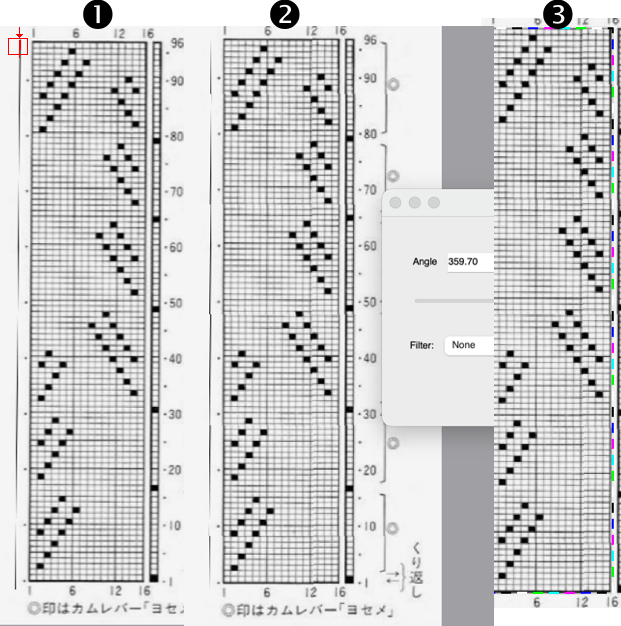

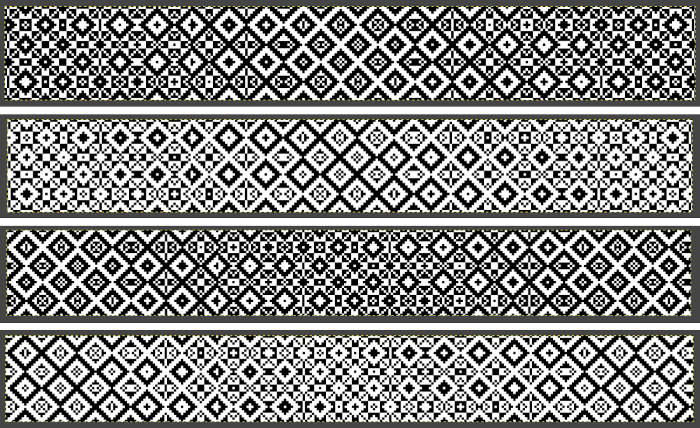

Conversion to the full 96X172 file.

Conversion to the full 96X172 file. Visualizing the potential large piece knit, it was not an instant favorite.

Visualizing the potential large piece knit, it was not an instant favorite.  Working towards a DIY design and examining varied methods and steps:

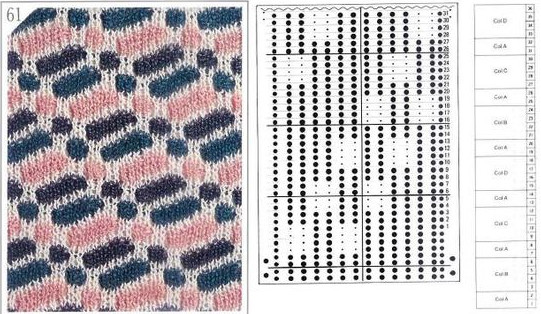

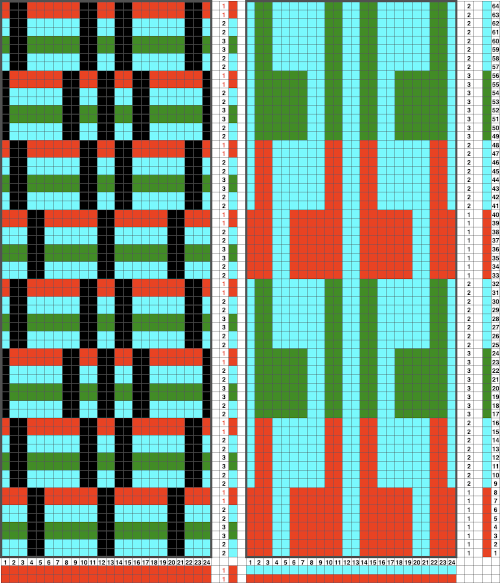

Working towards a DIY design and examining varied methods and steps: a small “rose” from a punchcard repeat, 24X24

a small “rose” from a punchcard repeat, 24X24![]() the first approach uses color to alpha to place the design on a pattern-filled ground, the file is adjusted to 30X30 to allow for outlining the rose in a third color

the first approach uses color to alpha to place the design on a pattern-filled ground, the file is adjusted to 30X30 to allow for outlining the rose in a third color ![]() the result, in turn, is centered on a 44X44 new image.

the result, in turn, is centered on a 44X44 new image.![]() in a new window, fill a new picture, 44X44, with pattern

in a new window, fill a new picture, 44X44, with pattern ![]() copy and paste the flower, anchoring it in place after rendering the cyan transparent

copy and paste the flower, anchoring it in place after rendering the cyan transparent ![]() and change the magenta outline to white,

and change the magenta outline to white, ![]() tile to 132X132

tile to 132X132 playing with the movement of the shapes to change the overall placement, the brick repeat immediately shows patterning problems, and the shapes appear small

playing with the movement of the shapes to change the overall placement, the brick repeat immediately shows patterning problems, and the shapes appear small  the 30-pixel file is doubled in size to 60X60,

the 30-pixel file is doubled in size to 60X60,  check that the number of colors is set to 3, fill the white background with pattern

check that the number of colors is set to 3, fill the white background with pattern  magenta pixels to white

magenta pixels to white

the intersection problem in a standard brick repeat reoccurs

the intersection problem in a standard brick repeat reoccurs  if the white outline is considered too thick, reduce it to one pixel from 2.

if the white outline is considered too thick, reduce it to one pixel from 2. Changing the approach: the above is drawn in repeat on a white ground. Rotating any individual elements becomes possible with no disruption in the yet-to-be brush-filled design.

Changing the approach: the above is drawn in repeat on a white ground. Rotating any individual elements becomes possible with no disruption in the yet-to-be brush-filled design.

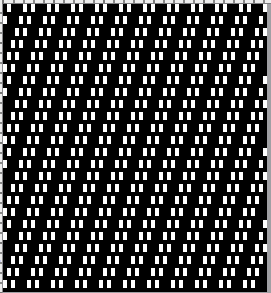

Filling in the white ground with the pattern results in no tiling errors

Filling in the white ground with the pattern results in no tiling errors  eliminating the third color, BW brick, it is not possible to isolate a smaller repeat

eliminating the third color, BW brick, it is not possible to isolate a smaller repeat  keeping directions constant in alternate rows of the pattern

keeping directions constant in alternate rows of the pattern  makes isolating the smallest repeat possible, 60X120.

makes isolating the smallest repeat possible, 60X120.

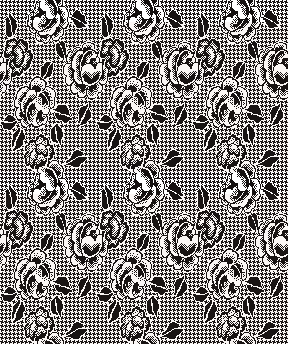

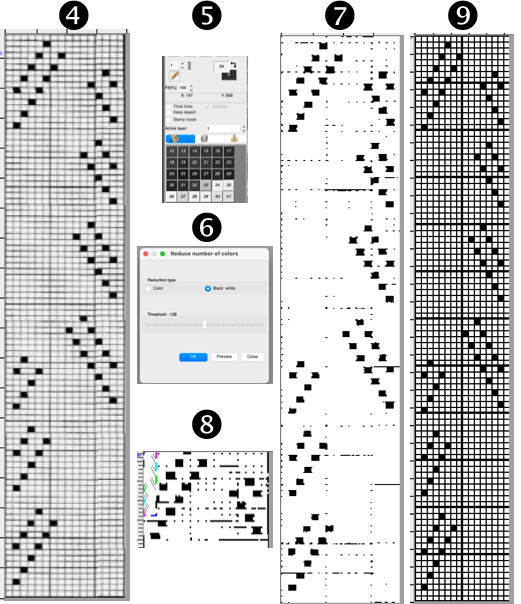

Back to the inspiration florals, isolating one of the roses, 61X59, note that the shape is not symmetrical

Back to the inspiration florals, isolating one of the roses, 61X59, note that the shape is not symmetrical  with a single-pixel third color outline, on a white ground, 64X64

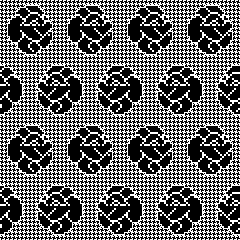

with a single-pixel third color outline, on a white ground, 64X64 tiled in a simple brick repeat to 128X192 on a white ground

tiled in a simple brick repeat to 128X192 on a white ground  with the background pattern-filled

with the background pattern-filled 64X128 isolated smallest repeat

64X128 isolated smallest repeat

tiled in BW with colored outline removed

tiled in BW with colored outline removed  testing random placements

testing random placements

produce a design with the smallest programmable repeat

produce a design with the smallest programmable repeat  note that the horizontal distance between the flower shapes is not fixed

note that the horizontal distance between the flower shapes is not fixed

scaled to 58X58

scaled to 58X58 planning added borders 64X64

planning added borders 64X64  outlined

outlined  a full single repeat 192X256 using the same random arrangement

a full single repeat 192X256 using the same random arrangement

building the smallest straightforward single brick repeat if there are limitations on the size of the programmed image ie to avoid multiple tracks in machines such as the 930 using img2track

building the smallest straightforward single brick repeat if there are limitations on the size of the programmed image ie to avoid multiple tracks in machines such as the 930 using img2track

the slightly scaled design reduced to an 80X80 repeat to play with in any configuration of your choice.

the slightly scaled design reduced to an 80X80 repeat to play with in any configuration of your choice.  The test swatch for the full single repeat

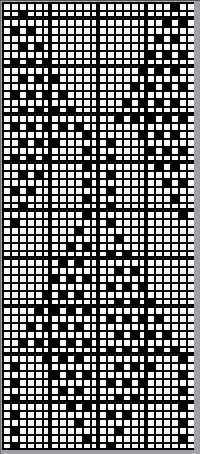

The test swatch for the full single repeat Continuing on a floral theme, inspired by a filet crochet design, 30X90

Continuing on a floral theme, inspired by a filet crochet design, 30X90 ![]() its half drop version, 60X90

its half drop version, 60X90 drawing both in repeat to 180X180 helps to determine whether further editing is needed, and if the shift in vertical/horizontal vs diagonal striping is preferred

drawing both in repeat to 180X180 helps to determine whether further editing is needed, and if the shift in vertical/horizontal vs diagonal striping is preferred

the 60X74 png

the 60X74 png

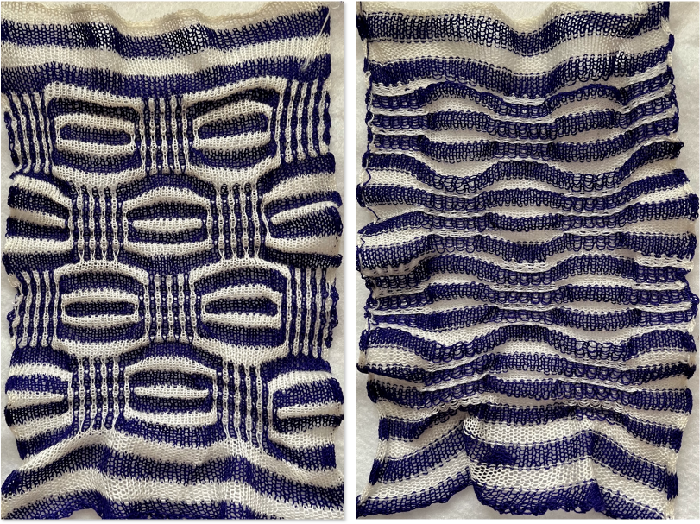

What may be firing in one piece could provide a tube for insertions on either side of the knit.

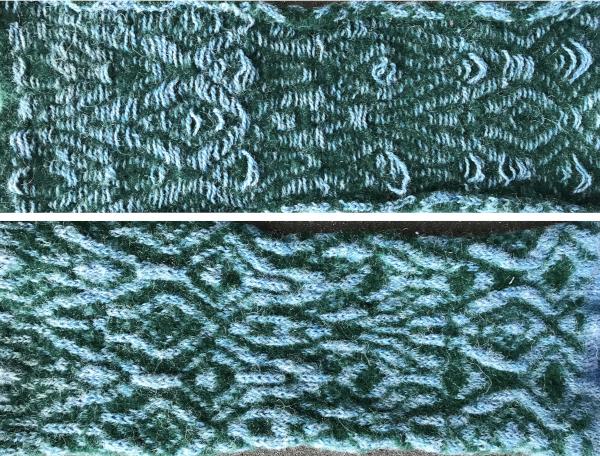

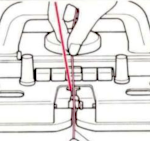

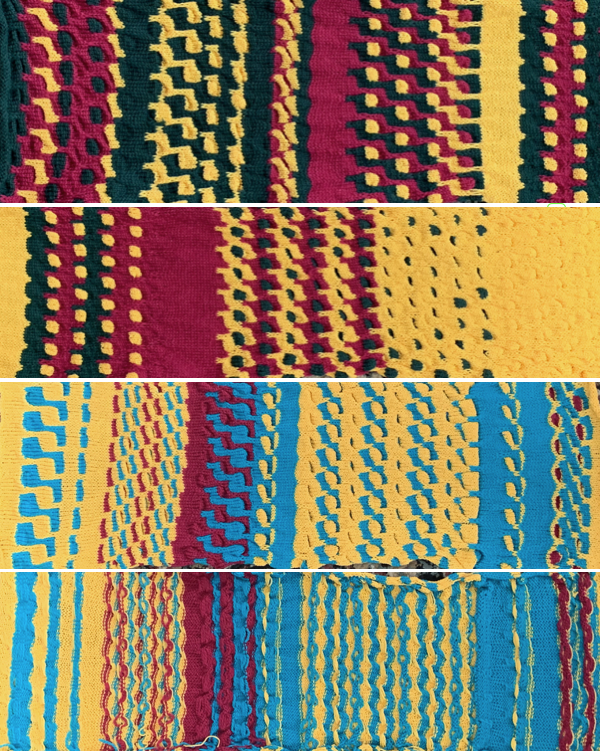

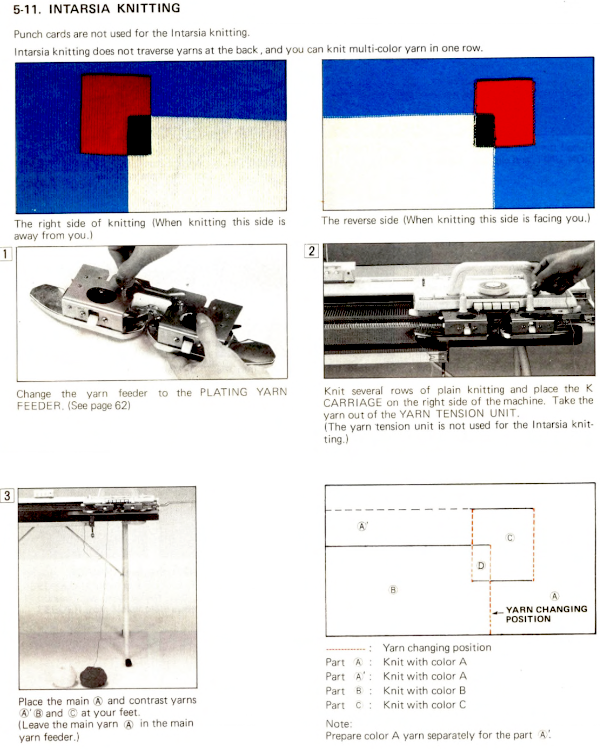

What may be firing in one piece could provide a tube for insertions on either side of the knit. Creating blistered surfaces the easy way, leaf pattern variations: poly-cotton and raffia on the bottom, fishing line as the second yarn line on top. I have found the line for 6lb or fewer works best. The knit is flat.

Creating blistered surfaces the easy way, leaf pattern variations: poly-cotton and raffia on the bottom, fishing line as the second yarn line on top. I have found the line for 6lb or fewer works best. The knit is flat.  Felted rayon chainette and wool; when the main color is wool and the rayon renders the floats there is minimal blistering

Felted rayon chainette and wool; when the main color is wool and the rayon renders the floats there is minimal blistering  the result from reversing the yarn positions creates more bubbling

the result from reversing the yarn positions creates more bubbling Here elastic is used as the second color in the thread lace setting.

Here elastic is used as the second color in the thread lace setting.

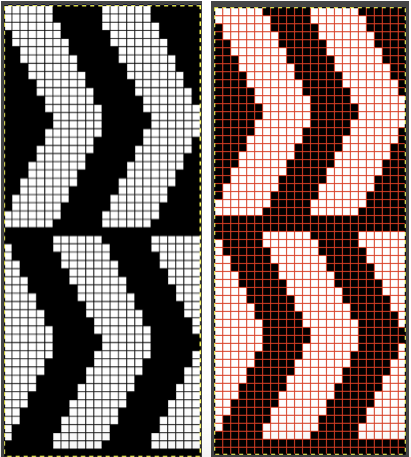

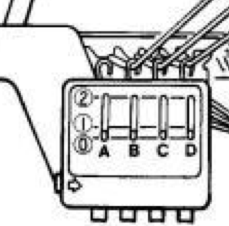

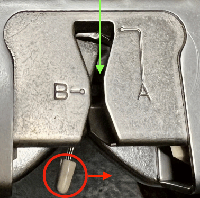

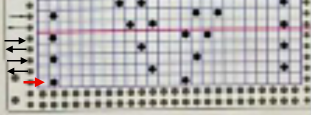

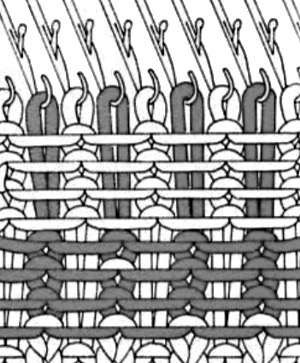

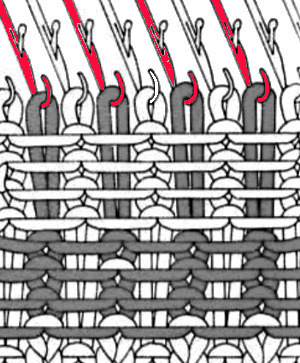

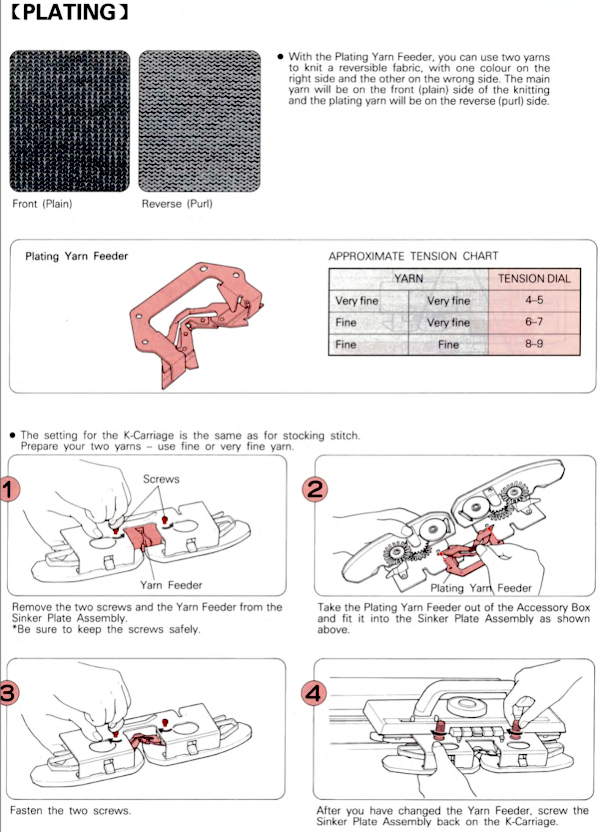

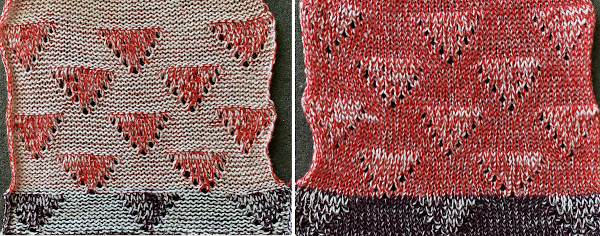

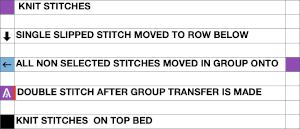

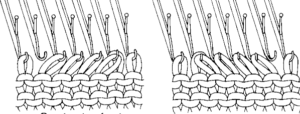

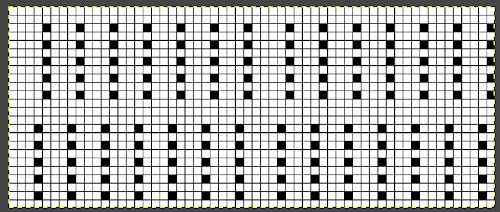

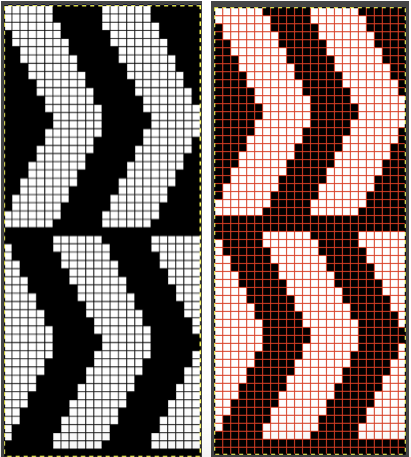

The yarn positions in two color single-pass knitting, remain fixed in their relationship to punched holes. In fair isle patterning, the back feeder, usually labeled A, knits the ground on non-selected needles in the B position. The yarn (red) in the forward, B feeder, knits the stitches on needles selected to the D position which correspond to punched holes or black squares in a mylar, black pixels in a computer file for download. In thread lace, the back A position yarn knit both yarns together, while the forward B position yarn, red thread, knits the forward yarn/color, with the other yarn creating the single set of floats behind it.

The yarn positions in two color single-pass knitting, remain fixed in their relationship to punched holes. In fair isle patterning, the back feeder, usually labeled A, knits the ground on non-selected needles in the B position. The yarn (red) in the forward, B feeder, knits the stitches on needles selected to the D position which correspond to punched holes or black squares in a mylar, black pixels in a computer file for download. In thread lace, the back A position yarn knit both yarns together, while the forward B position yarn, red thread, knits the forward yarn/color, with the other yarn creating the single set of floats behind it.

In addition, large thin fabric shapes can be stiffened over enclosures to create permanent effects in sculptural pieces.

In addition, large thin fabric shapes can be stiffened over enclosures to create permanent effects in sculptural pieces. Nearly all my previous dbj pieces have been knit on a Passap E6000. The 930 experience for such repeats is new to me. With some help from Tanya Cunnigham in reviewing the steps required when using img2track, I returned to cellular automata repeat saved years ago.

Nearly all my previous dbj pieces have been knit on a Passap E6000. The 930 experience for such repeats is new to me. With some help from Tanya Cunnigham in reviewing the steps required when using img2track, I returned to cellular automata repeat saved years ago. That provided an opportunity to decide I preferred the reverse color placement as well as wanting a thicker ply for the white, resulting in twice the fun with 2 colors, and another scrapped sample

That provided an opportunity to decide I preferred the reverse color placement as well as wanting a thicker ply for the white, resulting in twice the fun with 2 colors, and another scrapped sample

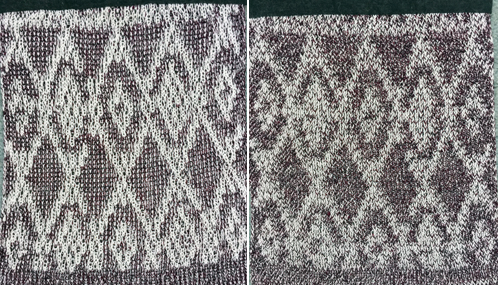

I was able to achieve a reasonable repair on the knit side, but the birdseye pattern on the reverse is a bit scrambled.

I was able to achieve a reasonable repair on the knit side, but the birdseye pattern on the reverse is a bit scrambled.

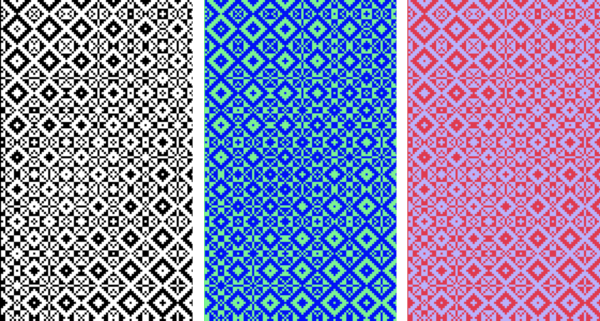

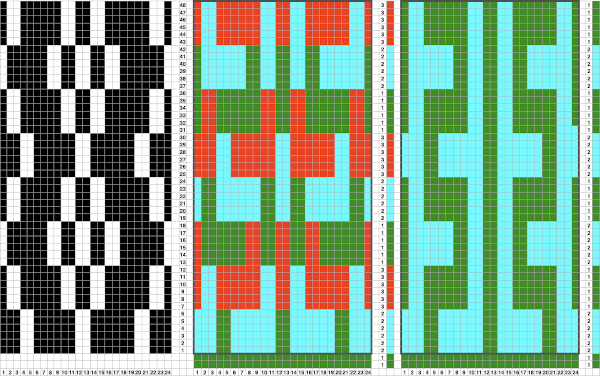

There is also potential for exchanging colors to get a sense of how the pattern might appear in different colorways

There is also potential for exchanging colors to get a sense of how the pattern might appear in different colorways

a planned color change on the next row would require needles that had been skipped, marked in red, being pre-selected forward for knitting back toward the color changer and returning to the previous or next planned color selection

a planned color change on the next row would require needles that had been skipped, marked in red, being pre-selected forward for knitting back toward the color changer and returning to the previous or next planned color selection

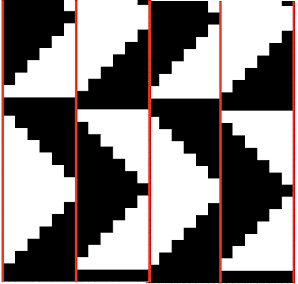

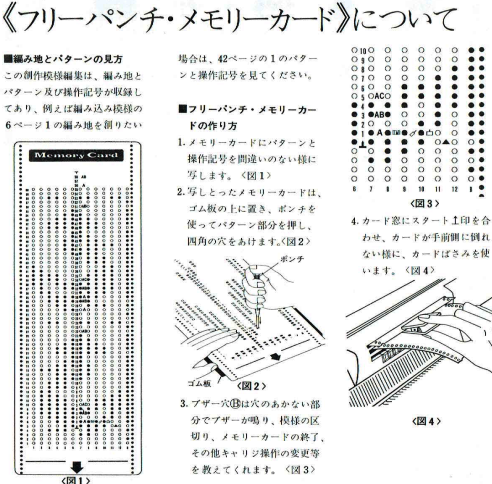

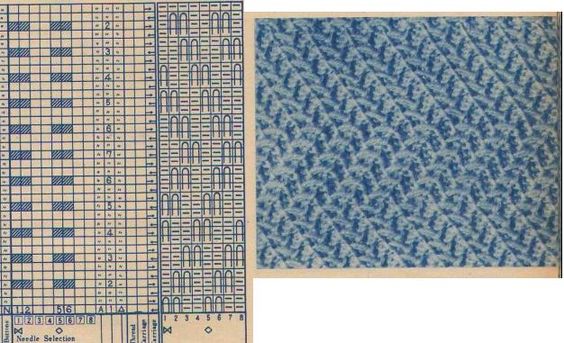

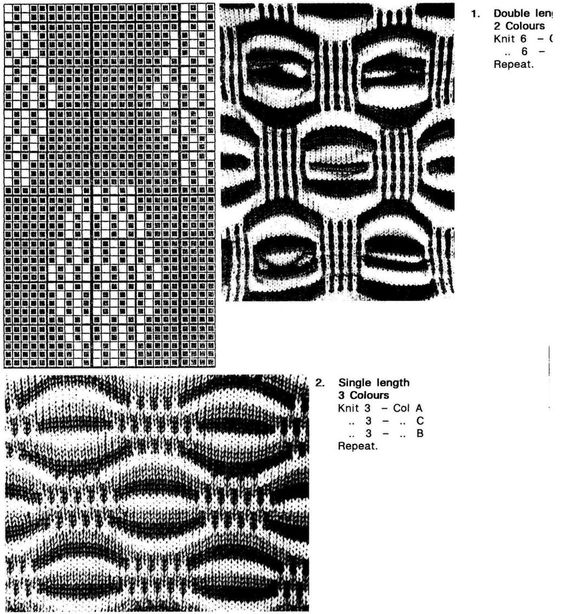

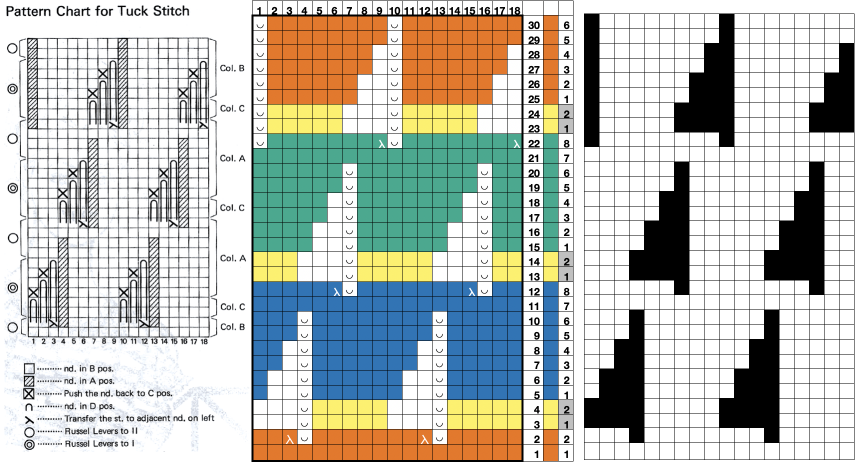

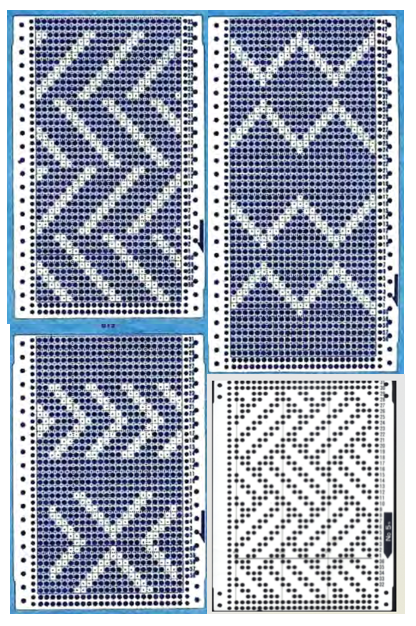

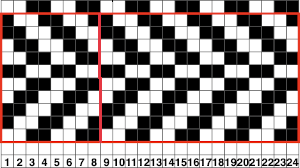

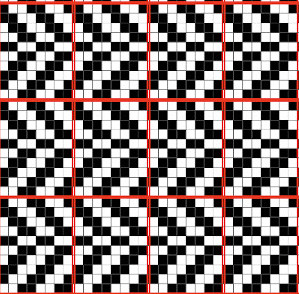

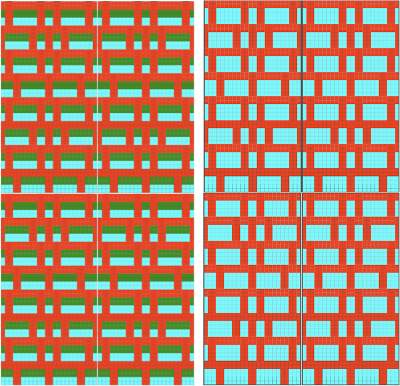

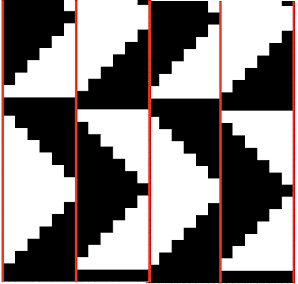

Remember that punchcards knit the image as viewed on the purl side of the fabric, so to match any swatch photos given in published pattern books, the exact repeat unless it is perfectly symmetrical, will usually need to be mirrored horizontally for use in electronic machines.

Remember that punchcards knit the image as viewed on the purl side of the fabric, so to match any swatch photos given in published pattern books, the exact repeat unless it is perfectly symmetrical, will usually need to be mirrored horizontally for use in electronic machines.

tiling to check the alignment of the 8X10 repeat.

tiling to check the alignment of the 8X10 repeat.

other possibilities using checks rather than solid lines

other possibilities using checks rather than solid lines  When evaluating published repeats, keep in mind the basics; these are suitable for electronic KMs that will allow for color reverse

When evaluating published repeats, keep in mind the basics; these are suitable for electronic KMs that will allow for color reverse  punchcard knitters would have to punch white squares, resulting in this arrangement

punchcard knitters would have to punch white squares, resulting in this arrangement  The knit side is not necessarily always interesting. With knit stripes in a different color breaking up the textured segments a secondary pattern will begin to emerge. A closer look at the samples below reveals one repeat is actually the other, drawn double length. This is an easy option, even in punch card machines. When knitting long pieces especially, however, I prefer not to use double-length built-in features, finding it easier to sort out where I am in terms of design rows if errors occur.

The knit side is not necessarily always interesting. With knit stripes in a different color breaking up the textured segments a secondary pattern will begin to emerge. A closer look at the samples below reveals one repeat is actually the other, drawn double length. This is an easy option, even in punch card machines. When knitting long pieces especially, however, I prefer not to use double-length built-in features, finding it easier to sort out where I am in terms of design rows if errors occur.

Depending on your machine ie Passap Duo requires 40 stitches punched repeats or modifying for electronics, vertical black columns or additional white squares may be added to the original design repeat units. The corresponding cells are filled with the color gray

Depending on your machine ie Passap Duo requires 40 stitches punched repeats or modifying for electronics, vertical black columns or additional white squares may be added to the original design repeat units. The corresponding cells are filled with the color gray

I have begun including .pngs with some of my posts. Check that your import method does not automatically change the mode to RGB. It is a common problem with such grabs from FB. If that happens, index the image to B/W and save it again before using it in download to KM software.

I have begun including .pngs with some of my posts. Check that your import method does not automatically change the mode to RGB. It is a common problem with such grabs from FB. If that happens, index the image to B/W and save it again before using it in download to KM software.

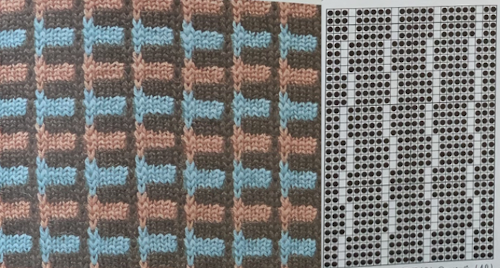

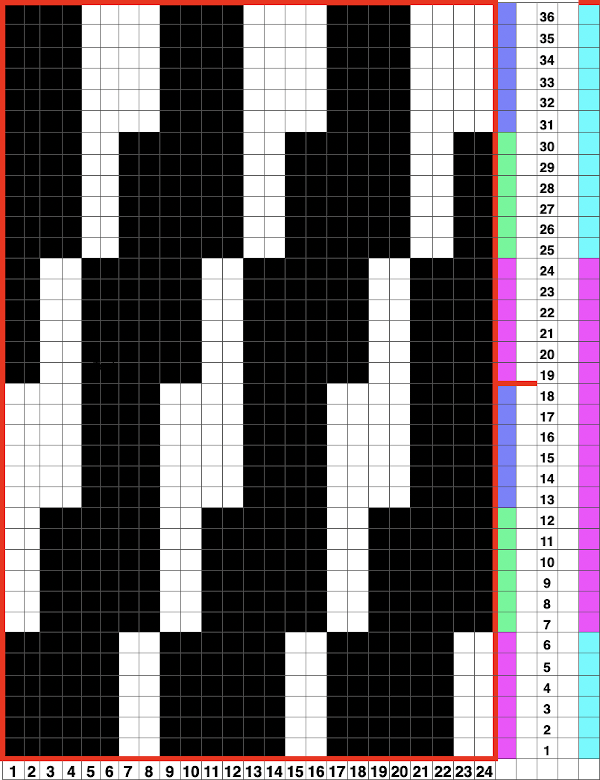

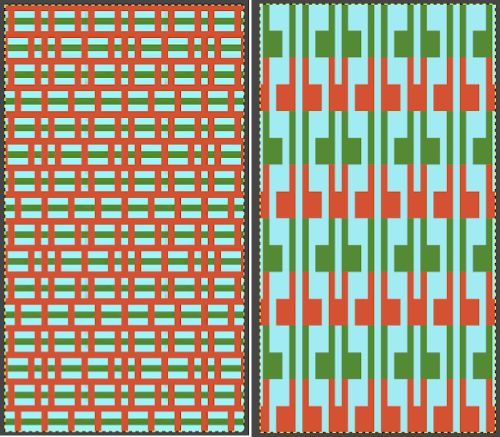

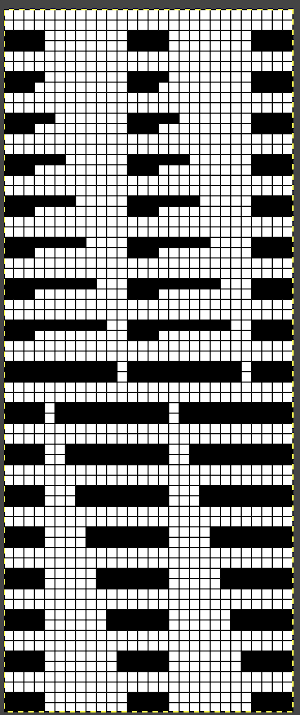

From long design studio inspiration swatches: the secondary shapes are created by varying the number of rows in the color change rotation and placement, the bottom swatch shows the purl side of part of the completed length. Float counts can help duplicate the repeat or color placements if notes are skipped during knitting.

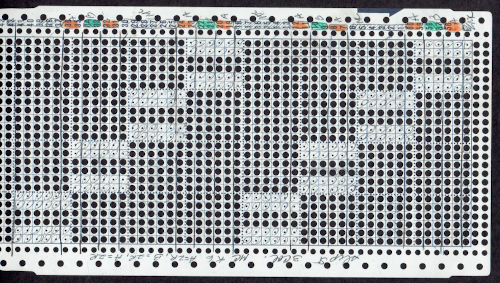

From long design studio inspiration swatches: the secondary shapes are created by varying the number of rows in the color change rotation and placement, the bottom swatch shows the purl side of part of the completed length. Float counts can help duplicate the repeat or color placements if notes are skipped during knitting.  Working with multiple slip stitch “bars”: this shows my punchcard, marked with color changes once the final rotation was decided, remembering to begin markings 7 rows up from the bottom for Brother (5 for Studio).

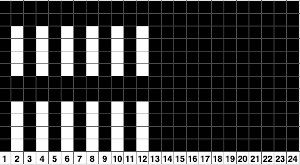

Working with multiple slip stitch “bars”: this shows my punchcard, marked with color changes once the final rotation was decided, remembering to begin markings 7 rows up from the bottom for Brother (5 for Studio).  This design produces a fabric that is fairly flat on both sides: the .png is in the same orientation as the punchcard repeat, which you can see is produced with shapes reversed on the knit side in the swatches below it. Instructions on how the repeat was converted to .bmp for download using Gimp in

This design produces a fabric that is fairly flat on both sides: the .png is in the same orientation as the punchcard repeat, which you can see is produced with shapes reversed on the knit side in the swatches below it. Instructions on how the repeat was converted to .bmp for download using Gimp in

This swatch segment illustrates the possibility of removing the slipped stitches from the needle bed and bringing them to the purl side, rehanging them on the same needles, bringing all needles out to hold before executing the next all knit row. The “floats” at the bottom of the swatch are from threads that were missed and not brought to the back of the slipped stitches

This swatch segment illustrates the possibility of removing the slipped stitches from the needle bed and bringing them to the purl side, rehanging them on the same needles, bringing all needles out to hold before executing the next all knit row. The “floats” at the bottom of the swatch are from threads that were missed and not brought to the back of the slipped stitches

Reducing the number of slipped rows

Reducing the number of slipped rows  reducing columns to produce a trim, being certain as to placement on the needle bed

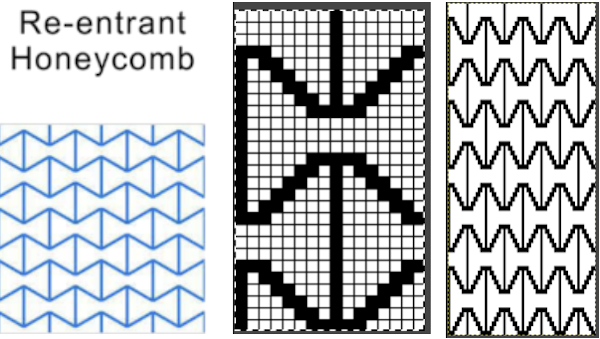

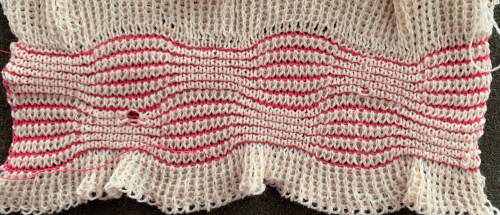

reducing columns to produce a trim, being certain as to placement on the needle bed  This repeat produces a ruched fabric when no all knit rows are included, and a sort of “honeycomb” effect when additional color changes on all knit rows are added. The first long swatch

This repeat produces a ruched fabric when no all knit rows are included, and a sort of “honeycomb” effect when additional color changes on all knit rows are added. The first long swatch

Shifting slip stitch units to form shapes

Shifting slip stitch units to form shapes

If the slip stitch units begin and end with the same color knitting just before them and immediately after, the color carried on the knit side will be consistent throughout.

If the slip stitch units begin and end with the same color knitting just before them and immediately after, the color carried on the knit side will be consistent throughout.  A sure way to get the shapes to match your design is to assign a number matching the number sequence in the color changer for your machine to each of the yarn colors. Imagining the results in a spreadsheet or even graph paper

A sure way to get the shapes to match your design is to assign a number matching the number sequence in the color changer for your machine to each of the yarn colors. Imagining the results in a spreadsheet or even graph paper  Expanding each section to 8 rows, the repeat now becomes 64 rows high and allows for 3 colors to show behind the slipped stitches in the chart on the left. On the right, the color-changing order shifts to 6 rows at a time in sequences 1,2,3,2,1,2,3. Design row 1 would begin the piece using the color red, the last row in the repeat is blue, shifting the color then carried up the front of the piece to blue.

Expanding each section to 8 rows, the repeat now becomes 64 rows high and allows for 3 colors to show behind the slipped stitches in the chart on the left. On the right, the color-changing order shifts to 6 rows at a time in sequences 1,2,3,2,1,2,3. Design row 1 would begin the piece using the color red, the last row in the repeat is blue, shifting the color then carried up the front of the piece to blue.

Once the basics are understood, changes in scale and amount of ruched textures along with fiber content are easier to execute

Once the basics are understood, changes in scale and amount of ruched textures along with fiber content are easier to execute  The chart for the sample below is 30 stitches wide by 84 rows high, and is shown turned counterclockwise

The chart for the sample below is 30 stitches wide by 84 rows high, and is shown turned counterclockwise

This fabric has a more compressed shape, the blocks of slipped stitches are in a vertical arrangement directly above each other. A possible building unit for similar structures:

This fabric has a more compressed shape, the blocks of slipped stitches are in a vertical arrangement directly above each other. A possible building unit for similar structures:

An all-knit border on either edge automatically creates a ruffle on each side.

An all-knit border on either edge automatically creates a ruffle on each side.

The 24X20 repeat for the swatch on the above right, with the floats easily identified on the purl side of the swatch

The 24X20 repeat for the swatch on the above right, with the floats easily identified on the purl side of the swatch

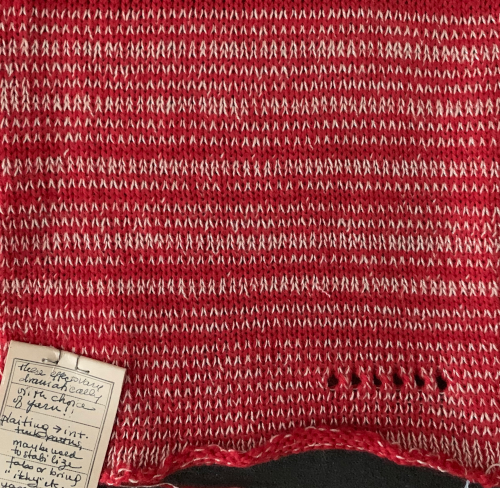

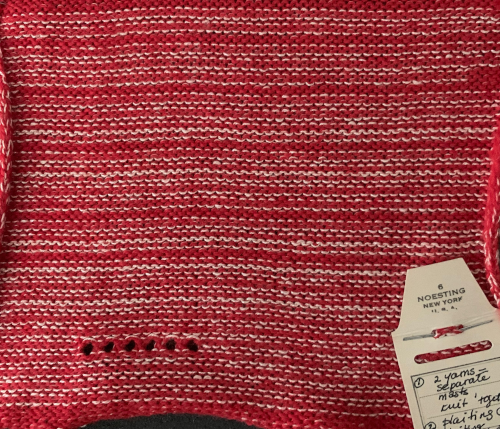

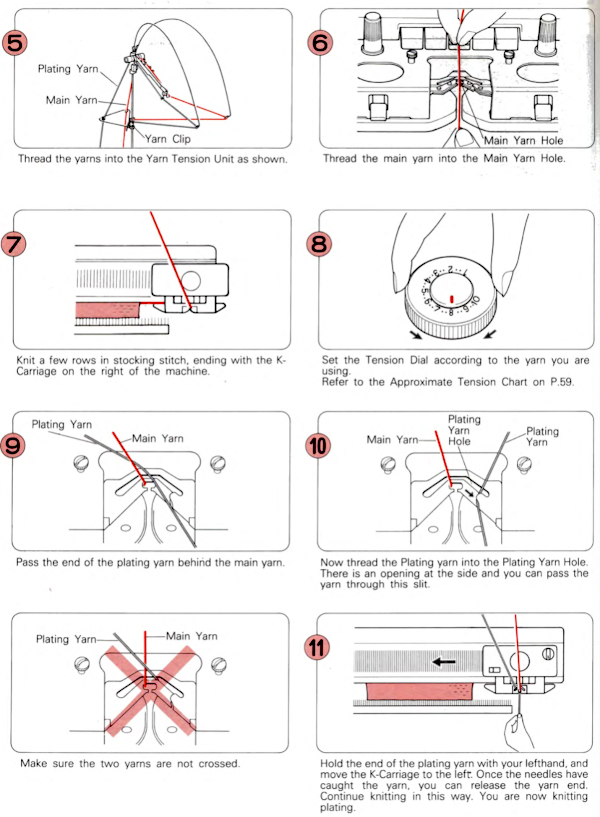

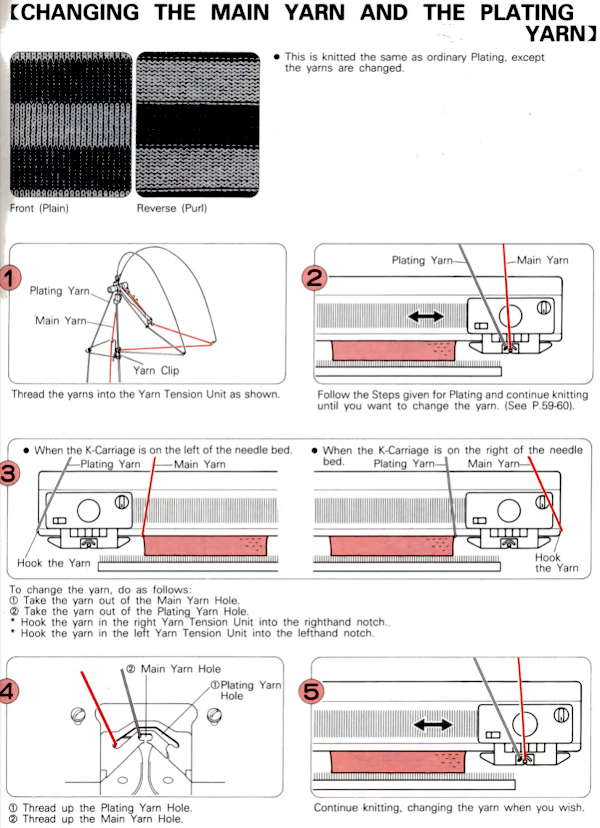

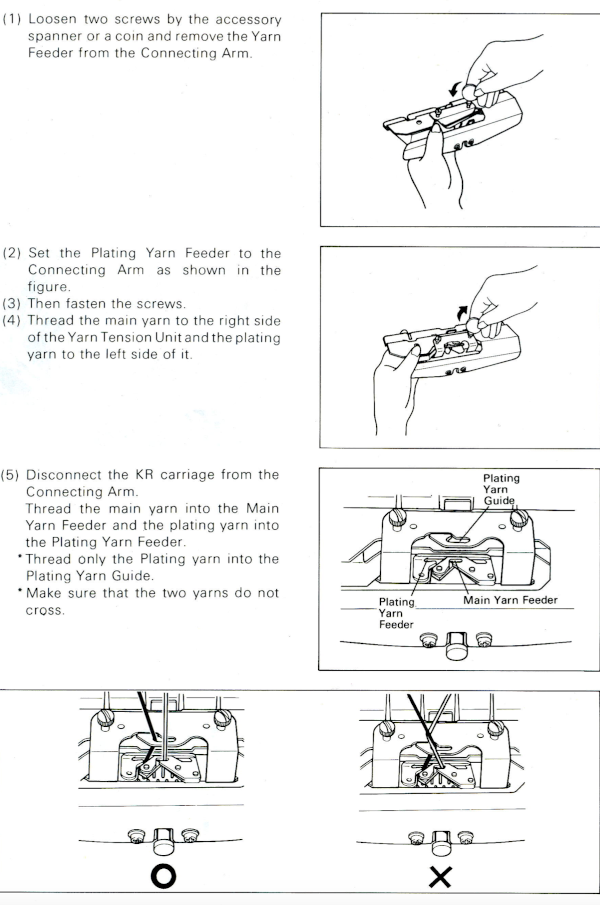

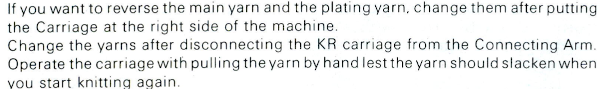

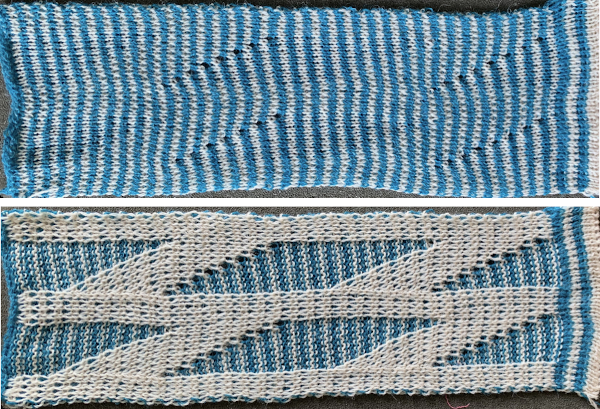

plaiting with yarns swapped in feeders for reversible striped effect

plaiting with yarns swapped in feeders for reversible striped effect

Striping created by reversing yarn positions in plaiting feeder

Striping created by reversing yarn positions in plaiting feeder

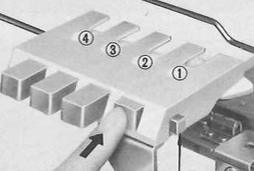

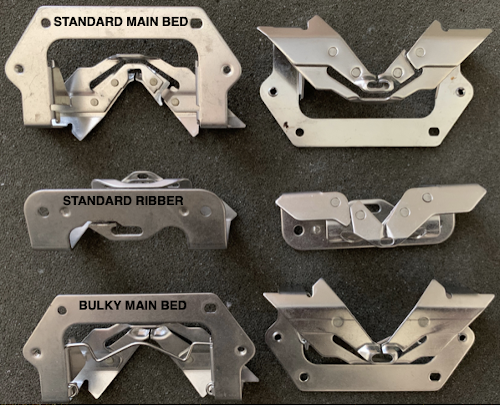

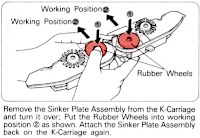

If your sinker plate has rubber wheels, check them and move them to the proper position if needed.

If your sinker plate has rubber wheels, check them and move them to the proper position if needed.

More random, ancient swatches: stocking stitch using equal-weight yarns in a single bed tuck stitch

More random, ancient swatches: stocking stitch using equal-weight yarns in a single bed tuck stitch

double bed every needle rib tuck stitch using the same pattern repeat

double bed every needle rib tuck stitch using the same pattern repeat

Shadow lace

Shadow lace  Pleated pattern

Pleated pattern

An experimental double bed fabric using the plaiting feeder and thread lace setting double bed

An experimental double bed fabric using the plaiting feeder and thread lace setting double bed

The suitable dbj separation is the one where each color in each row knits for 2 rows, whether performed by hand, using the 3 colors per row separation in img2track or the default separation in Passap. The Ayab HOP separation is awesome, works for any 3 color design with as little elongation as possible, but is not suited for this purpose. How-tos for DIY separations and their automated versions by programs for knitting more than 2 colors per row have been discussed in other posts.

The suitable dbj separation is the one where each color in each row knits for 2 rows, whether performed by hand, using the 3 colors per row separation in img2track or the default separation in Passap. The Ayab HOP separation is awesome, works for any 3 color design with as little elongation as possible, but is not suited for this purpose. How-tos for DIY separations and their automated versions by programs for knitting more than 2 colors per row have been discussed in other posts.

A similar process on the Passap allows for playing easily with both racked colors because of the possible arrow and pusher settings on the back bed, but on Brother, this would require hand selection on the ribber on every row or a specific color separation for needle selection on the top bed

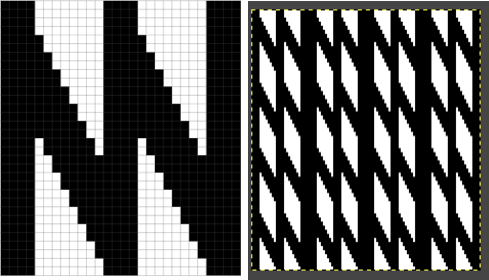

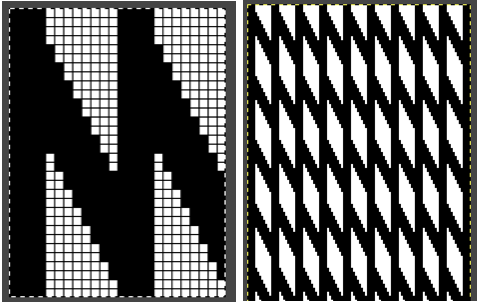

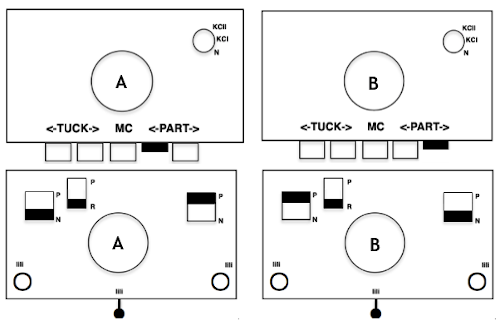

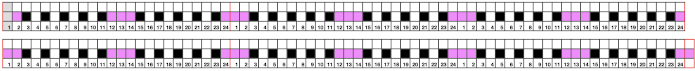

A similar process on the Passap allows for playing easily with both racked colors because of the possible arrow and pusher settings on the back bed, but on Brother, this would require hand selection on the ribber on every row or a specific color separation for needle selection on the top bed Seeking automation, keeping things simple, here is a basic zigzag pattern in a repeat also executable on punchcard machines. The ribber is now set to knit throughout (N/N), the main bed to slip in both directions. End needle selection must be canceled when using the slip setting selectively or when working patterning with needles completely out of work

Seeking automation, keeping things simple, here is a basic zigzag pattern in a repeat also executable on punchcard machines. The ribber is now set to knit throughout (N/N), the main bed to slip in both directions. End needle selection must be canceled when using the slip setting selectively or when working patterning with needles completely out of work

The process using 3 colors: the patterning color will be knit on needles preselected on the top bed. As shaping is about to begin, in this pattern, one needle preselected out indicates the location for an “increase”, one preselected back to B position a decrease

The process using 3 colors: the patterning color will be knit on needles preselected on the top bed. As shaping is about to begin, in this pattern, one needle preselected out indicates the location for an “increase”, one preselected back to B position a decrease  To perform the decrease, using a double eye tool to transfer the B position stitch down onto the ribber needle adjacent to the first needle in D position on the top bed

To perform the decrease, using a double eye tool to transfer the B position stitch down onto the ribber needle adjacent to the first needle in D position on the top bed

The repeat and the knit shown on both sides:

The repeat and the knit shown on both sides:  Comparing the 2 color and 3 color versions: aside from the obvious increase in length, note that the slipped segments in red on the 3 color swatch are now composed of longer stitches since they are held for 2 additional rows, and the overall fabric is more puckered than the 2 color version. The curling at the sides is the nature of edge stitches, especially if the yarn used is wool. At times that may be used intentionally, as a decorative edge.

Comparing the 2 color and 3 color versions: aside from the obvious increase in length, note that the slipped segments in red on the 3 color swatch are now composed of longer stitches since they are held for 2 additional rows, and the overall fabric is more puckered than the 2 color version. The curling at the sides is the nature of edge stitches, especially if the yarn used is wool. At times that may be used intentionally, as a decorative edge.

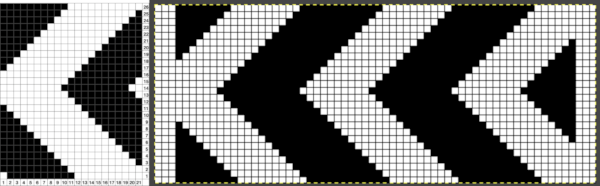

Using the same color separation as for the simple zig-zag shape, the design is expanded to include knit bed rows that will be skipped completely, resulting in the ribber alone knitting in the second color for those rows. It is now twice as long as the original, 24X64

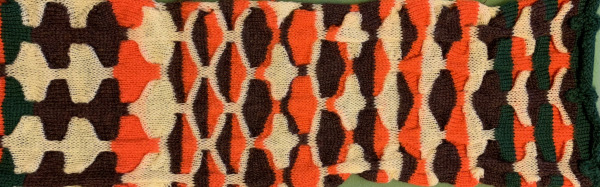

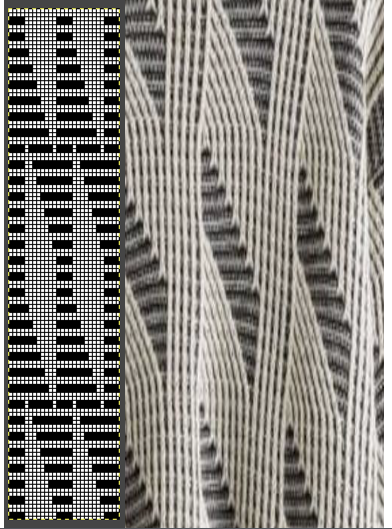

Using the same color separation as for the simple zig-zag shape, the design is expanded to include knit bed rows that will be skipped completely, resulting in the ribber alone knitting in the second color for those rows. It is now twice as long as the original, 24X64 The planned proof of concept added a 4 stitch border on the right for a 28 stitch swatch centered with 14 stitches either side of 0. Tiling the repeat X2 again in height made it easier for me to plan how to manage transfers to expose the varying stripes in the ground. Visual comparison to the movement in the inspiration knit:

The planned proof of concept added a 4 stitch border on the right for a 28 stitch swatch centered with 14 stitches either side of 0. Tiling the repeat X2 again in height made it easier for me to plan how to manage transfers to expose the varying stripes in the ground. Visual comparison to the movement in the inspiration knit:  As the number of needles in work on either of the 2 beds is increased, it is likely tension or yarn changes may be required. The first preselection row is from the right, toward the color changer. The stitches on the non selected needles are transferred to the bottom bed

As the number of needles in work on either of the 2 beds is increased, it is likely tension or yarn changes may be required. The first preselection row is from the right, toward the color changer. The stitches on the non selected needles are transferred to the bottom bed

with the color change, only preselected needles will knit on both the top and bottom beds moving to the right

with the color change, only preselected needles will knit on both the top and bottom beds moving to the right  and will do so again on the return to the left while preselecting an all blank row

and will do so again on the return to the left while preselecting an all blank row  on the next pass to the right only the ribber knits in the ground color;

on the next pass to the right only the ribber knits in the ground color;

Back to the drawing board in order to reduce the number of hand manipulations involved, with a shift in the center transition, the repeat in my spreadsheet is now 24 stitches wide, plus an additional 4 stitch border, and gets marked up with colors. I prefer to program the width of my knitting as opposed to a single repeat for all over patterning

Back to the drawing board in order to reduce the number of hand manipulations involved, with a shift in the center transition, the repeat in my spreadsheet is now 24 stitches wide, plus an additional 4 stitch border, and gets marked up with colors. I prefer to program the width of my knitting as opposed to a single repeat for all over patterning

The choice can be made based upon the preference of moving stitch groups to the right or to the left with the horizontal direction of the repeat adjusted for your KM model or software used.

The choice can be made based upon the preference of moving stitch groups to the right or to the left with the horizontal direction of the repeat adjusted for your KM model or software used.  I planned the transfers in this swatch toward the color changer after picking up the proper color, white, and before knitting the next row using it. The 930 png:

I planned the transfers in this swatch toward the color changer after picking up the proper color, white, and before knitting the next row using it. The 930 png:

When the top of the repeat is reached, row 68, the only needles selected will be those of the 4 stitch vertical columns and the design repeat will return to its start

When the top of the repeat is reached, row 68, the only needles selected will be those of the 4 stitch vertical columns and the design repeat will return to its start My proof of concept swatch is 3.75 inches wide

My proof of concept swatch is 3.75 inches wide  The inspiration sweater was knit using a wider repeat and significantly thicker yarn, reflected here in the small number of repeats composing the sweater body front

The inspiration sweater was knit using a wider repeat and significantly thicker yarn, reflected here in the small number of repeats composing the sweater body front

The off white yarn used here was the same thickness but not fiber content as in the previous swatch, 2/18 wool-silk vs Australian wool in the former. It is not as smoothly spun. The result shows an interesting similarity in length, though there are 16 additional rows in the pattern repeat. This time I programmed my repeat for stitch transfers on the knit bed to move away from the color changer.

The off white yarn used here was the same thickness but not fiber content as in the previous swatch, 2/18 wool-silk vs Australian wool in the former. It is not as smoothly spun. The result shows an interesting similarity in length, though there are 16 additional rows in the pattern repeat. This time I programmed my repeat for stitch transfers on the knit bed to move away from the color changer.  Eliminating the border on one side, a double repeat (30 stitches) measure 4 inches in width. To put the difference in scale to the sweater in perspective, an oversize garment with 40 inches in chest diameter would require 20 inches in width for the front piece. Ten single repeats, as opposed to the inspiration’s sweater 4, bring the total required the number of stitches to 150. With the added border of 5 stitches for matching side edges, the fabric is in the realm of possibility for producing a garment on the home knitting machine. My tension was set at 3/3 for all the swatches, with some teasing required on occasion to encourage stitches on the main bed to knit off properly. Ribber height adjustment can also have an effect on those numbers. I tend to do all my knitting with the slide lever in the center position. The double 30X84 repeat with no added border

Eliminating the border on one side, a double repeat (30 stitches) measure 4 inches in width. To put the difference in scale to the sweater in perspective, an oversize garment with 40 inches in chest diameter would require 20 inches in width for the front piece. Ten single repeats, as opposed to the inspiration’s sweater 4, bring the total required the number of stitches to 150. With the added border of 5 stitches for matching side edges, the fabric is in the realm of possibility for producing a garment on the home knitting machine. My tension was set at 3/3 for all the swatches, with some teasing required on occasion to encourage stitches on the main bed to knit off properly. Ribber height adjustment can also have an effect on those numbers. I tend to do all my knitting with the slide lever in the center position. The double 30X84 repeat with no added border

Here the same pattern was executed on the same number of stitches with the white wool used above, but the elastic was plied with a 2/24 acrylic yarn and knit as DBJ with the blue, stretchy combination creating the solid color backing.

Here the same pattern was executed on the same number of stitches with the white wool used above, but the elastic was plied with a 2/24 acrylic yarn and knit as DBJ with the blue, stretchy combination creating the solid color backing.

The same pattern repeat knit with striper backing is far less interesting

The same pattern repeat knit with striper backing is far less interesting

The appearance of the fabric when stretched and weighted, still between the beds

The appearance of the fabric when stretched and weighted, still between the beds  and off

and off  Going the far more traditional route of traditional dbj with the use of the color changer, striper backing with the ribber set to N/N yields a wider, flatter fabric with an interesting purl side

Going the far more traditional route of traditional dbj with the use of the color changer, striper backing with the ribber set to N/N yields a wider, flatter fabric with an interesting purl side

The birdseye version had more of a bent on

The birdseye version had more of a bent on

Adding a third ply of elastic was disastrous at any tension. Better results occurred simply by increasing the ribber tension by 2 whole numbers, the knit tension by 1, and reverting to the previous yarn usage. There is a single dropped stitch in the elastic, and the result has much more of a 3D effect.

Adding a third ply of elastic was disastrous at any tension. Better results occurred simply by increasing the ribber tension by 2 whole numbers, the knit tension by 1, and reverting to the previous yarn usage. There is a single dropped stitch in the elastic, and the result has much more of a 3D effect.

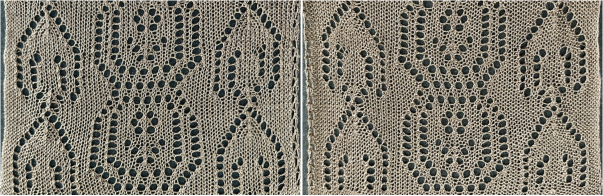

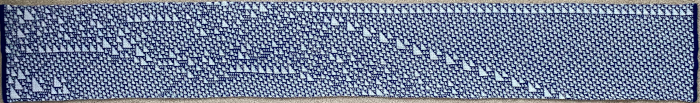

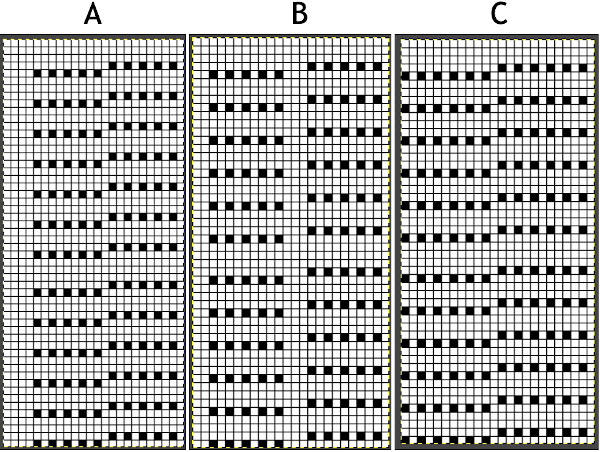

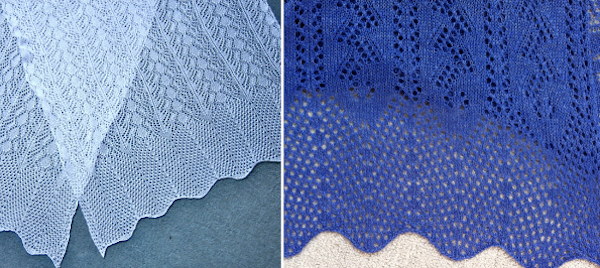

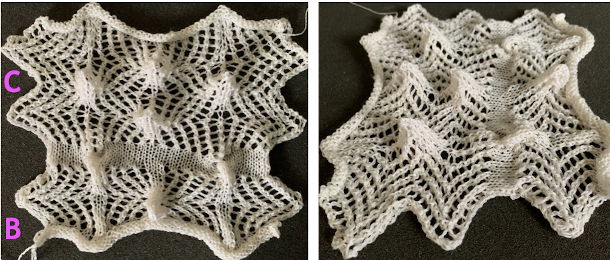

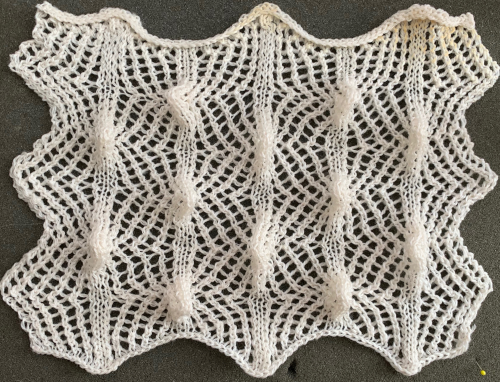

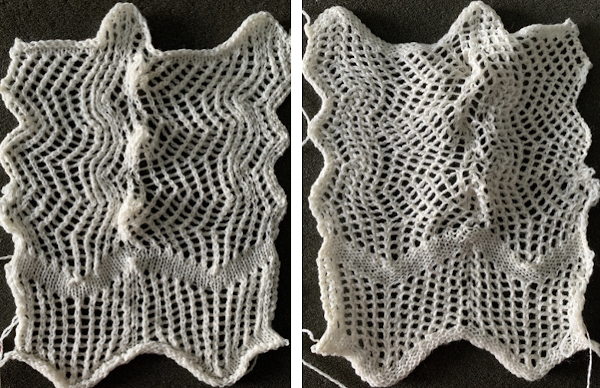

A variation of Card C, with 2 rows blank after each pair of transfers throughout was used in borders in some of my lace shawls including these, made in 2011.

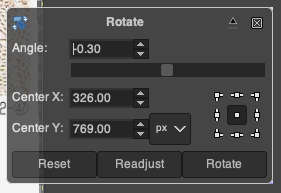

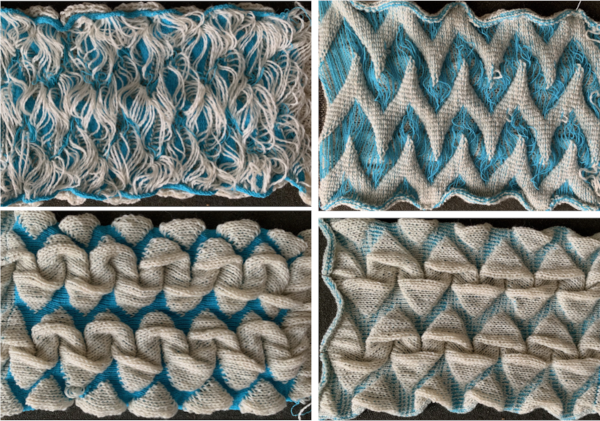

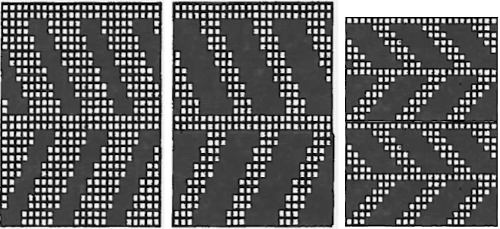

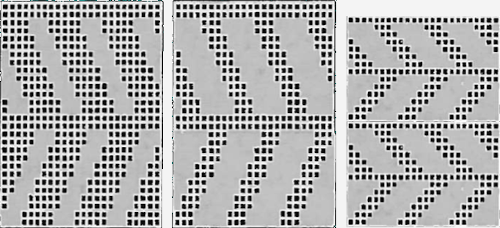

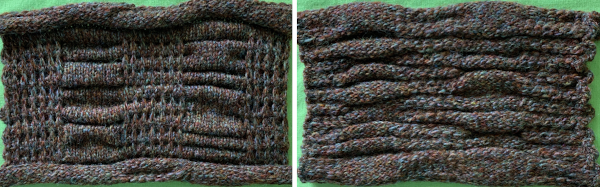

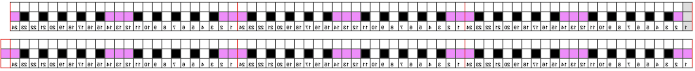

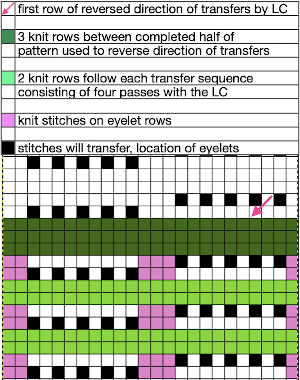

A variation of Card C, with 2 rows blank after each pair of transfers throughout was used in borders in some of my lace shawls including these, made in 2011.  All 3 card designs share the fact that the lace carriage (LC) makes 4 passes followed by 2 rows using the knit carriage set for normal knit to complete the eyelets with exceptions. The exceptions are in areas where there are extra blank rows, where the lace carriage will make 6 passes in order to reverse the direction of transfers. Brother lace cards usually start with punched holes on the very first row, have 2 blank rows between LC passes that complete one sequence (here each sequence is 2 rows in height), and 2 blank rows at the top of the card. Lace markings are few and far between, errors are easy to make when punching long cards and working in designings with pixels in particular. In this case, I did not notice until I began composing the post, and after I had completed the first test swatches that the repeat on the left has an extra 4-row segment in the top half, making it 24 stitches X 54 rows as opposed to the other two at 24 X 50.

All 3 card designs share the fact that the lace carriage (LC) makes 4 passes followed by 2 rows using the knit carriage set for normal knit to complete the eyelets with exceptions. The exceptions are in areas where there are extra blank rows, where the lace carriage will make 6 passes in order to reverse the direction of transfers. Brother lace cards usually start with punched holes on the very first row, have 2 blank rows between LC passes that complete one sequence (here each sequence is 2 rows in height), and 2 blank rows at the top of the card. Lace markings are few and far between, errors are easy to make when punching long cards and working in designings with pixels in particular. In this case, I did not notice until I began composing the post, and after I had completed the first test swatches that the repeat on the left has an extra 4-row segment in the top half, making it 24 stitches X 54 rows as opposed to the other two at 24 X 50. The knit side of the fabric is the most interesting. The swatches were first photographed as they were immediately after their removal from the knitting machine. I also tried to photograph them at an angle to show the protrusions from the surface. Pattern A:

The knit side of the fabric is the most interesting. The swatches were first photographed as they were immediately after their removal from the knitting machine. I also tried to photograph them at an angle to show the protrusions from the surface. Pattern A:

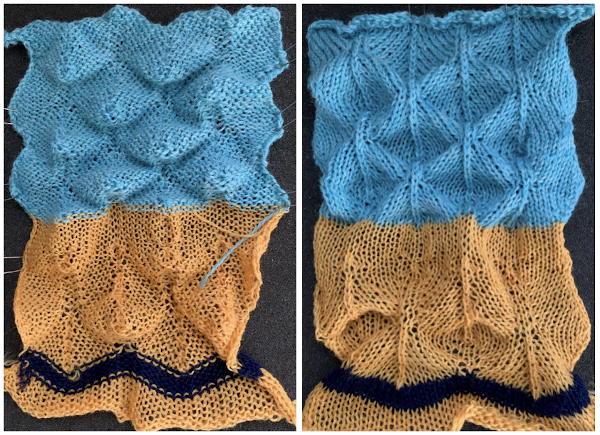

When using card A, the shapes alternate vertically between all mesh ones with all knit rows at the outer edge of the folds. Using Card B, all protrusions have a fixed number of knit stitch rows at the outer fold. Card C produces an all-mesh fabric that made me think of ocean waves somehow. Turned sideways, and pressed to set the folds, the resulting fabric could provide a springboard for a host of other, different ideas:

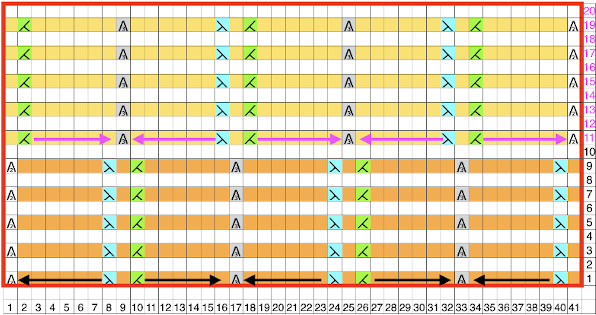

When using card A, the shapes alternate vertically between all mesh ones with all knit rows at the outer edge of the folds. Using Card B, all protrusions have a fixed number of knit stitch rows at the outer fold. Card C produces an all-mesh fabric that made me think of ocean waves somehow. Turned sideways, and pressed to set the folds, the resulting fabric could provide a springboard for a host of other, different ideas:  A larger swatch started on waste yarn, with 2 rows of knitting at the bottom and at the top before binding off. The design is card B, with 4 rows added to each half of the design. I am still working with the constraints of a punchcard machine, and for the moment, of retaining symmetry in the width of the “scales”. The working chart, turned counterclockwise to save space

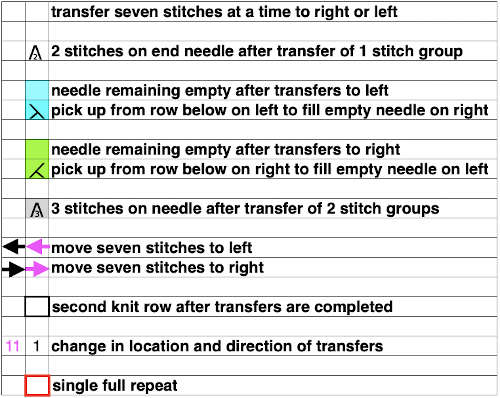

A larger swatch started on waste yarn, with 2 rows of knitting at the bottom and at the top before binding off. The design is card B, with 4 rows added to each half of the design. I am still working with the constraints of a punchcard machine, and for the moment, of retaining symmetry in the width of the “scales”. The working chart, turned counterclockwise to save space

the above arrangement will, in turn, need to be mirrored for the lace pattern. My sample was knit using 2/15 wool at tension 7, using needles 36 left to 35 right

the above arrangement will, in turn, need to be mirrored for the lace pattern. My sample was knit using 2/15 wool at tension 7, using needles 36 left to 35 right

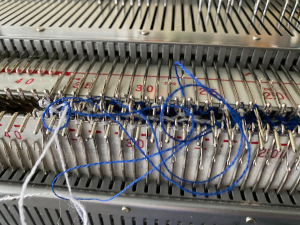

The knitting in progress

The knitting in progress

Often the question of what fine lace is and how it is made comes up. Fine lace is a fabric against which I have a personal bias. It seems to involve a lot of work for the result unless one is using a light-colored yarn with a smooth surface to show the subtle and at times hard to observe surface changes. It fares better visually when mixed with eyelets. The yarn is shared between the needle that would normally be left empty and the one with the formed stitch already on it to its right or left depending on the direction of the transfer. If the shared yarn is dropped instead of staying in the hook of the transfer needle, as the next 2 rows are knit there will be eyelets on the ground lacking them anywhere else. Card C, knit using only the fine lace setting on the LC, looks very different from the previous fabrics, both knit and purl sides are shown, with a couple of spots where the yarn was not shared by 2 adjacent needles, forming eyelets

Often the question of what fine lace is and how it is made comes up. Fine lace is a fabric against which I have a personal bias. It seems to involve a lot of work for the result unless one is using a light-colored yarn with a smooth surface to show the subtle and at times hard to observe surface changes. It fares better visually when mixed with eyelets. The yarn is shared between the needle that would normally be left empty and the one with the formed stitch already on it to its right or left depending on the direction of the transfer. If the shared yarn is dropped instead of staying in the hook of the transfer needle, as the next 2 rows are knit there will be eyelets on the ground lacking them anywhere else. Card C, knit using only the fine lace setting on the LC, looks very different from the previous fabrics, both knit and purl sides are shown, with a couple of spots where the yarn was not shared by 2 adjacent needles, forming eyelets Now evaluating the possibility of mimicking my

Now evaluating the possibility of mimicking my  Planning out a repeat in chart form:

Planning out a repeat in chart form:

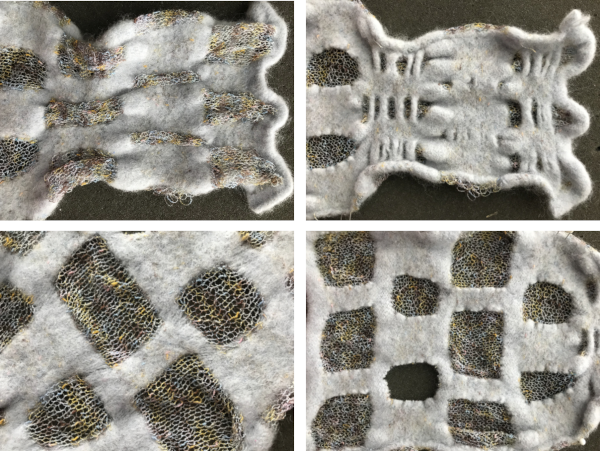

Knitting began with working in a 2/15 wool, tension 6, using a 7 prong tool with all prongs engaged to transfer groups of stitches onto their new positions on the needle bed. The first two images review picking up from the row below to fill in needles emptied by transfers. It is one of the machine-knit equivalents for the M1 direction in hand-knitting patterns. As a result, the number of stitches being knit remains constant throughout the piece.

Knitting began with working in a 2/15 wool, tension 6, using a 7 prong tool with all prongs engaged to transfer groups of stitches onto their new positions on the needle bed. The first two images review picking up from the row below to fill in needles emptied by transfers. It is one of the machine-knit equivalents for the M1 direction in hand-knitting patterns. As a result, the number of stitches being knit remains constant throughout the piece.

The stitch structure so far appeared too loose to me, so I then switched to a 2/8 wool, at tension 7 with the intent to test knitting as tightly as possible while still facilitating the multiple moves of stitch groups on each row. The resulting fabric was stiff and wanted to curl strongly to the purl side, needed pins to help it lie flatter. The shapes refused to stay poked out to the knit side.

The stitch structure so far appeared too loose to me, so I then switched to a 2/8 wool, at tension 7 with the intent to test knitting as tightly as possible while still facilitating the multiple moves of stitch groups on each row. The resulting fabric was stiff and wanted to curl strongly to the purl side, needed pins to help it lie flatter. The shapes refused to stay poked out to the knit side.

On electronic machines, one does not have the same limitations in terms of the width of the repeat maxing out at 24. For example, the number of eyelets on either side of the block components of the repeats may differ, the greater the number of eyelets, the wider the spacing between the 3D shapes. Graduations may be planned in height and width of repeat blocks across the full needle bed, limited only by patience in designing, the capacity to download, and the tolerance for both the yarn and the operator to complete wide, long pieces using the technique.

On electronic machines, one does not have the same limitations in terms of the width of the repeat maxing out at 24. For example, the number of eyelets on either side of the block components of the repeats may differ, the greater the number of eyelets, the wider the spacing between the 3D shapes. Graduations may be planned in height and width of repeat blocks across the full needle bed, limited only by patience in designing, the capacity to download, and the tolerance for both the yarn and the operator to complete wide, long pieces using the technique. and in a staggered one, tested at the top of the swatch

and in a staggered one, tested at the top of the swatch

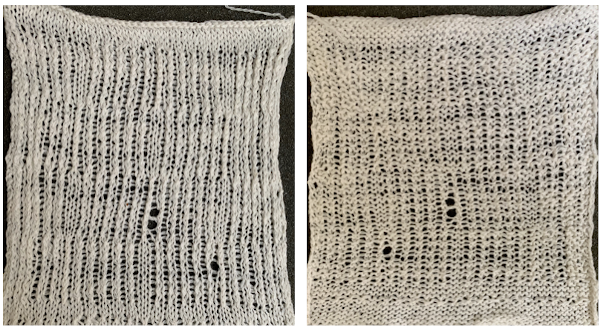

The “scales” were more like twisty bumps, with subtle variations vertically in some of the stitch groups. That said the results were dramatically different when color changes were added to the pattern knitting in the shorter repeat. Blocking may make an even more marked difference depending on whether the mesh (lightly steamed) or the tighter knit (vertically pulled, should be washed) produces the preferred effect. The looser stitches at the top outside edge ie at the top left corner are the result of a stitch that got away from me. The cast on was a bit too loose, I knit 4 rows at the bottom after the cast on and 4 rows at the top of the repeat before binding off.

The “scales” were more like twisty bumps, with subtle variations vertically in some of the stitch groups. That said the results were dramatically different when color changes were added to the pattern knitting in the shorter repeat. Blocking may make an even more marked difference depending on whether the mesh (lightly steamed) or the tighter knit (vertically pulled, should be washed) produces the preferred effect. The looser stitches at the top outside edge ie at the top left corner are the result of a stitch that got away from me. The cast on was a bit too loose, I knit 4 rows at the bottom after the cast on and 4 rows at the top of the repeat before binding off.  The differences in the width of the same fabric are dramatic. Any overall mesh/ lace fabric blocked for openness such as on the left will grow in length over time, is best stored flat, and will benefit from episodic pressing/ steaming to reset the width. Then I began counting eyelets, which were equal in number in the schematic for the repeat, but not equal in number on either side of the center pivot for the bend in the herringbone shape when the piece was finished. Any extra eyelet rows in the same direction will result in increased biasing in those sections.

The differences in the width of the same fabric are dramatic. Any overall mesh/ lace fabric blocked for openness such as on the left will grow in length over time, is best stored flat, and will benefit from episodic pressing/ steaming to reset the width. Then I began counting eyelets, which were equal in number in the schematic for the repeat, but not equal in number on either side of the center pivot for the bend in the herringbone shape when the piece was finished. Any extra eyelet rows in the same direction will result in increased biasing in those sections. Adding a second color and reversing directions of shapes brings lots of yarn ends and its “price to pay”

Adding a second color and reversing directions of shapes brings lots of yarn ends and its “price to pay”

Some handknit large scale inspiration to begin my revisit to MKing them:

Some handknit large scale inspiration to begin my revisit to MKing them:

The chart is actually rotated 90 degrees counterclockwise, could serve as inspiration for an electronic pattern.

The chart is actually rotated 90 degrees counterclockwise, could serve as inspiration for an electronic pattern. Automated holding sequences may be planned for single or multiple stitches in width, as well as for single and multiple rows in height. For the new initial test, which proved to need editing, this was my repeat

Automated holding sequences may be planned for single or multiple stitches in width, as well as for single and multiple rows in height. For the new initial test, which proved to need editing, this was my repeat A tiny test in too thin a yarn

A tiny test in too thin a yarn  I am knitting on a 930, the image needs to be mirrored in order for it to appear in the direction I intend on the knit side. The above repeat did not work properly when knitting a whole row of shapes. With some patience, a final, edited, and mirrored repeat was developed that enabled a completed a full row of shapes using the slip setting and holding, and starting with working it from right to left. Sometimes differences are subtle, especially in designing using single-pixel units. The new repeat proved to also work for rows of shapes in the reverse direction after horizontal mirroring and restarting the pattern or design row 1. When working from right to left, the initial preselection row is from left to right, while when working from left to right, the first preselection row is from right to left. After a full row of repeats is completed, the pattern is rolled back to row 1 and mirrored. Punchcard knitters could turn the card over and start again on the proper row. I used contrast color knit rows initially in between rows of shapes to help me note transitions more clearly. The “leaf” is not pointy enough for me, but at times what was not planned may lead to a pleasing result of a different sort.

I am knitting on a 930, the image needs to be mirrored in order for it to appear in the direction I intend on the knit side. The above repeat did not work properly when knitting a whole row of shapes. With some patience, a final, edited, and mirrored repeat was developed that enabled a completed a full row of shapes using the slip setting and holding, and starting with working it from right to left. Sometimes differences are subtle, especially in designing using single-pixel units. The new repeat proved to also work for rows of shapes in the reverse direction after horizontal mirroring and restarting the pattern or design row 1. When working from right to left, the initial preselection row is from left to right, while when working from left to right, the first preselection row is from right to left. After a full row of repeats is completed, the pattern is rolled back to row 1 and mirrored. Punchcard knitters could turn the card over and start again on the proper row. I used contrast color knit rows initially in between rows of shapes to help me note transitions more clearly. The “leaf” is not pointy enough for me, but at times what was not planned may lead to a pleasing result of a different sort.

To knit: cast on with a multiple of 12 stitches on each side of the center 24 on the needle bed

To knit: cast on with a multiple of 12 stitches on each side of the center 24 on the needle bed

Moving on to a wider version, using 24 stitches in width to allow for using the pattern on a punchcard: this repeats works both as-is and mirrored, the groups of stitches moved in and out of work is now half of the new design repeat = 12.

Moving on to a wider version, using 24 stitches in width to allow for using the pattern on a punchcard: this repeats works both as-is and mirrored, the groups of stitches moved in and out of work is now half of the new design repeat = 12.

The lovely mess in the swatch happened when I stopped paying attention to everything but what was happening on the needle bed and missed the tangle of yarns in my yarn mast. There is enough knitting, however, to note that the repeat is sound and that the edges on both sides are formed by the narrowest part of the shapes in each direction. One way to solve that is by casting on and binding off along tops and bottoms of shapes as seen in the yellow and green swatch at the top of the post.

The lovely mess in the swatch happened when I stopped paying attention to everything but what was happening on the needle bed and missed the tangle of yarns in my yarn mast. There is enough knitting, however, to note that the repeat is sound and that the edges on both sides are formed by the narrowest part of the shapes in each direction. One way to solve that is by casting on and binding off along tops and bottoms of shapes as seen in the yellow and green swatch at the top of the post.  Planning things out to release those edges as seen at the top of the post

Planning things out to release those edges as seen at the top of the post

Problems to solve: maintaining an even number of rows in-between shapes and a straight edge along both sides. The latter could happen with triangles prior to knitting full shapes at either or both ends, the first sample failed on the left side due to both triangles being knit in the same sequence;

Problems to solve: maintaining an even number of rows in-between shapes and a straight edge along both sides. The latter could happen with triangles prior to knitting full shapes at either or both ends, the first sample failed on the left side due to both triangles being knit in the same sequence;

Begin on waste yarn, decide on the color of the cast on, and any additional knit rows prior to beginning in the pattern. Each of the side triangles is shaped using manual holding techniques over 12 stitches. If starting on the right, the first preselection row needs to be made moving from left to right as above on the first 24 stitches. With knit carriage set to both slip in both directions and holding with COL make certain the first 24 stitches on the right in B position make a free pass to the right.

Begin on waste yarn, decide on the color of the cast on, and any additional knit rows prior to beginning in the pattern. Each of the side triangles is shaped using manual holding techniques over 12 stitches. If starting on the right, the first preselection row needs to be made moving from left to right as above on the first 24 stitches. With knit carriage set to both slip in both directions and holding with COL make certain the first 24 stitches on the right in B position make a free pass to the right.