Very little has been written on this topic.

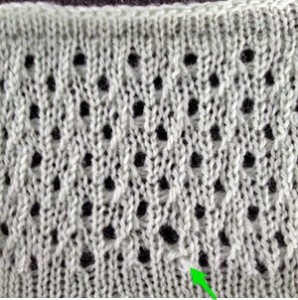

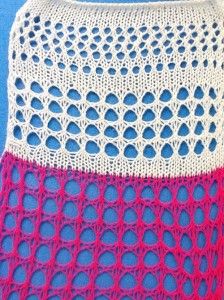

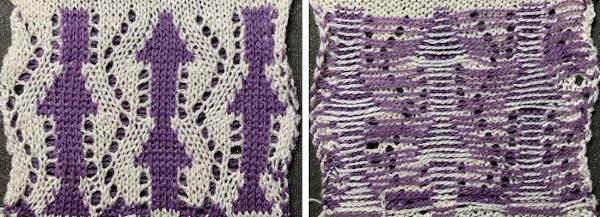

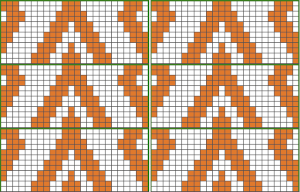

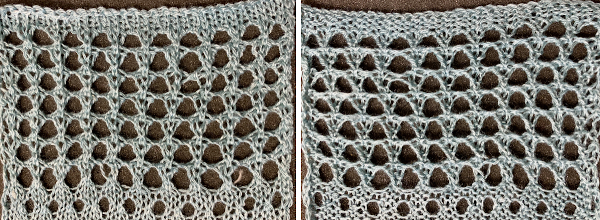

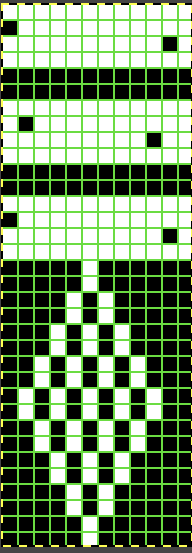

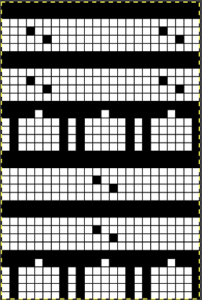

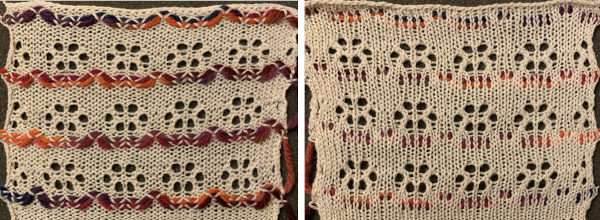

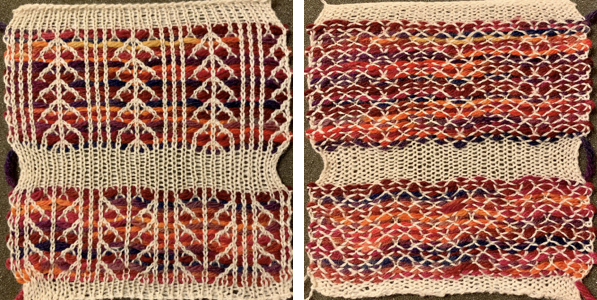

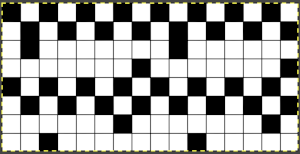

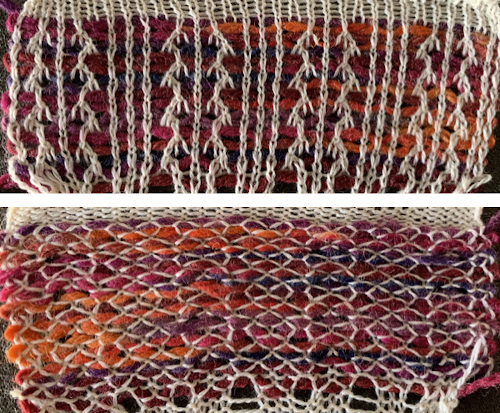

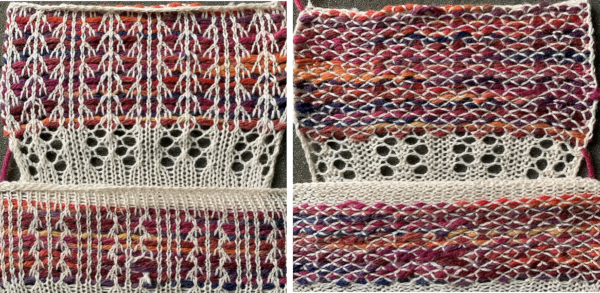

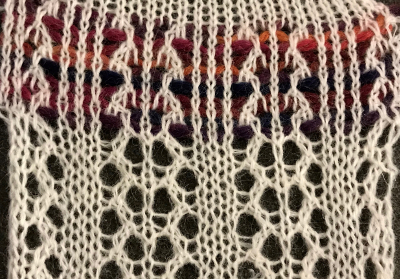

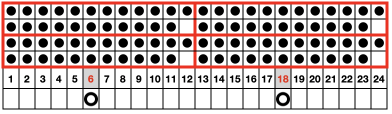

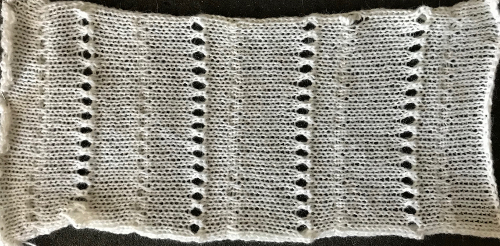

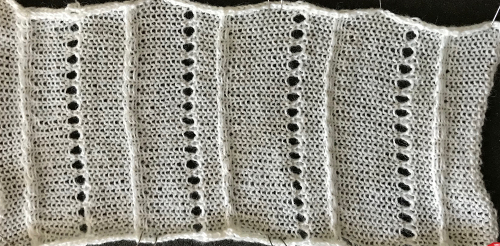

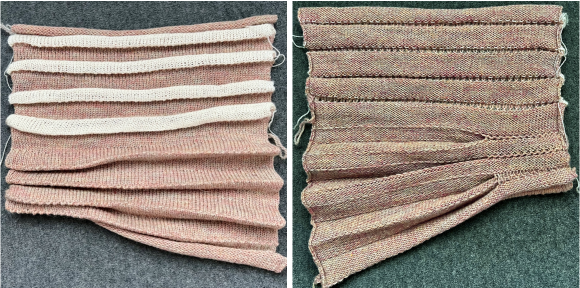

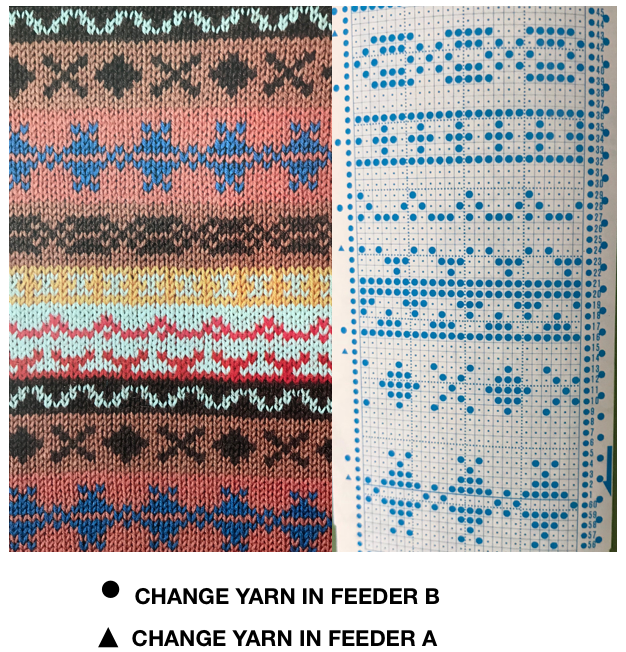

The easiest method to produce the eyelet and fair isle combination is to create ladders in spaces between vertical FI motifs. The end needle selection is canceled. The swatches show the transitions in the development of the final design

Susanna in her Machine Knitter’s Guide offers a version knit in combination with the ribber on page 218, and a small amount of information on single bed versions on pp, 220-221.

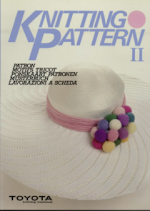

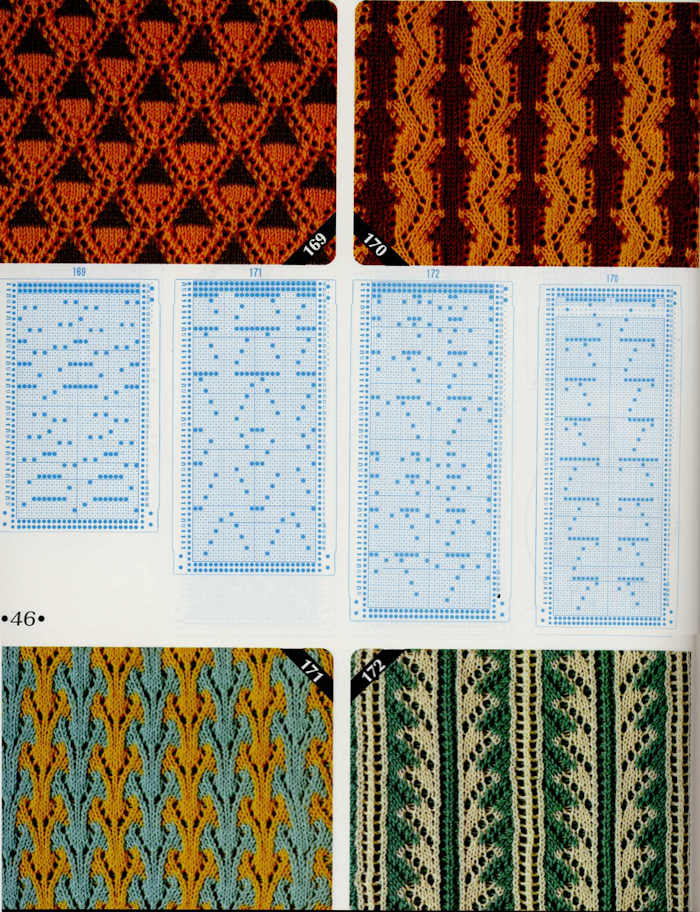

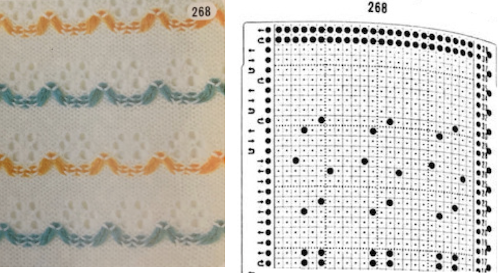

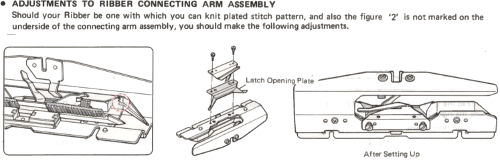

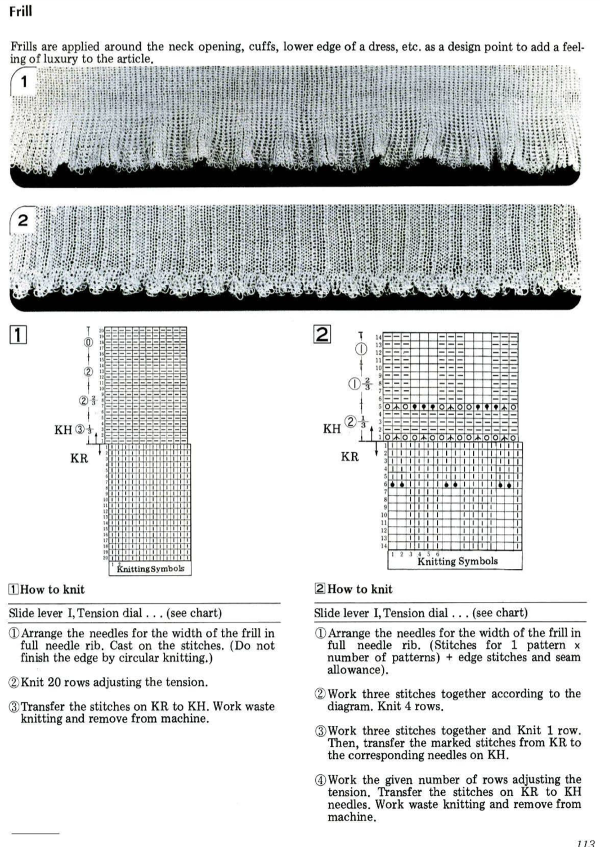

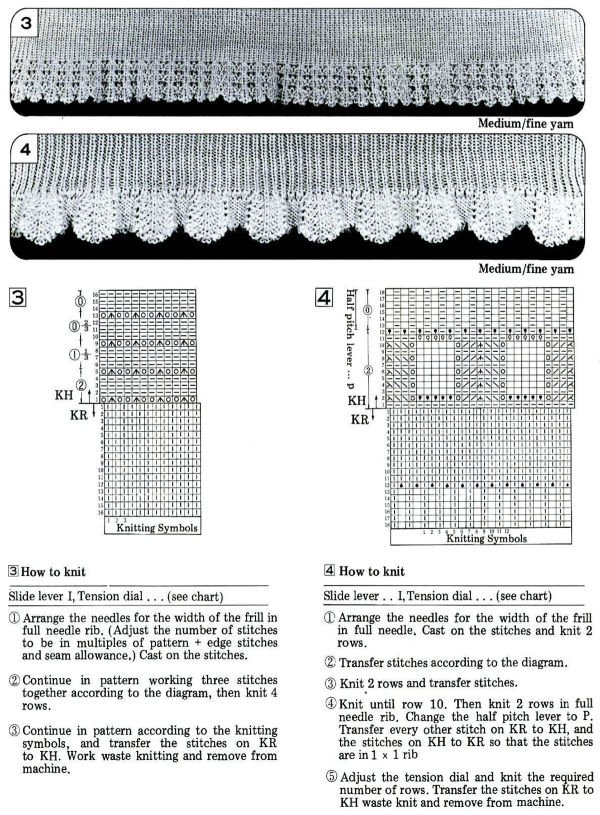

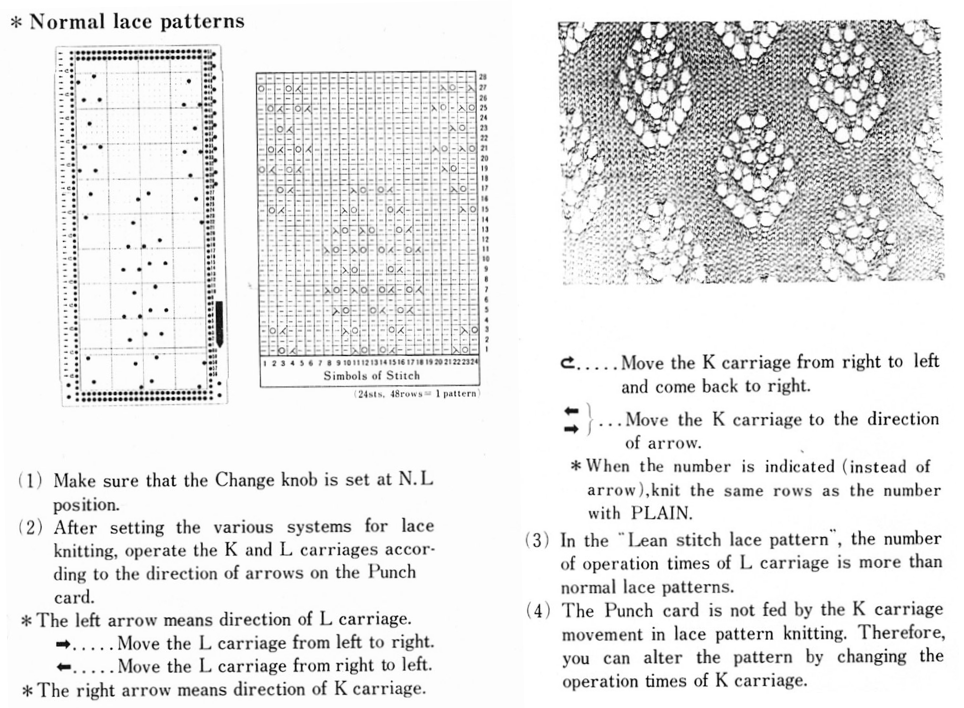

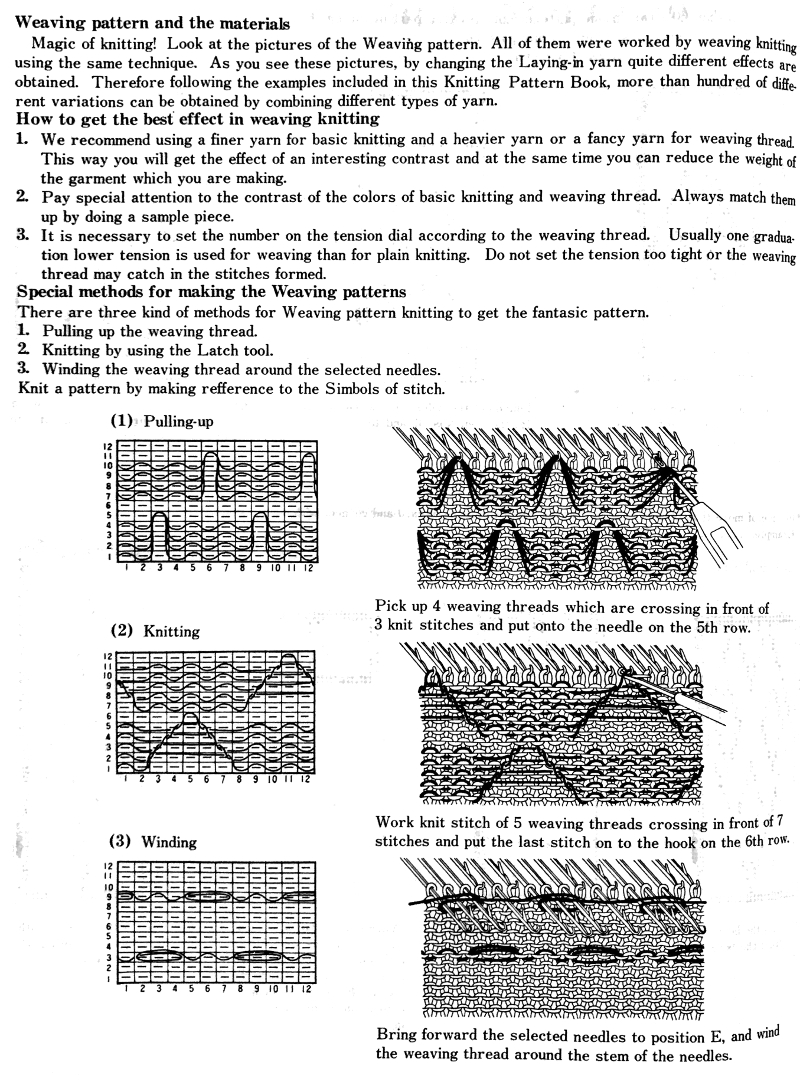

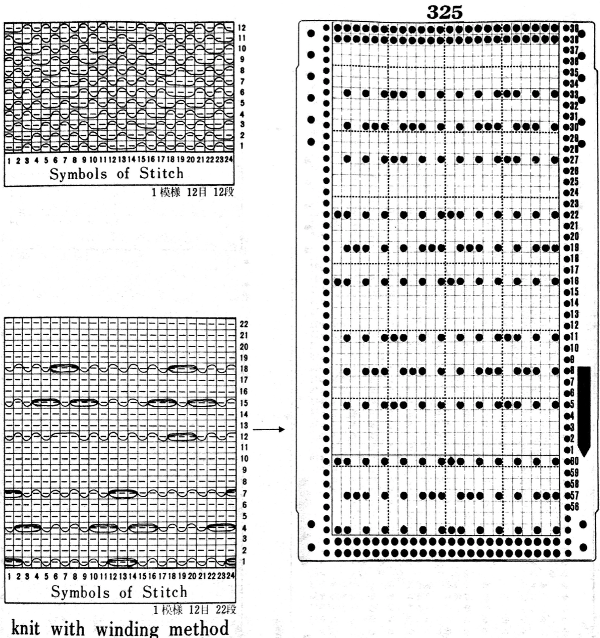

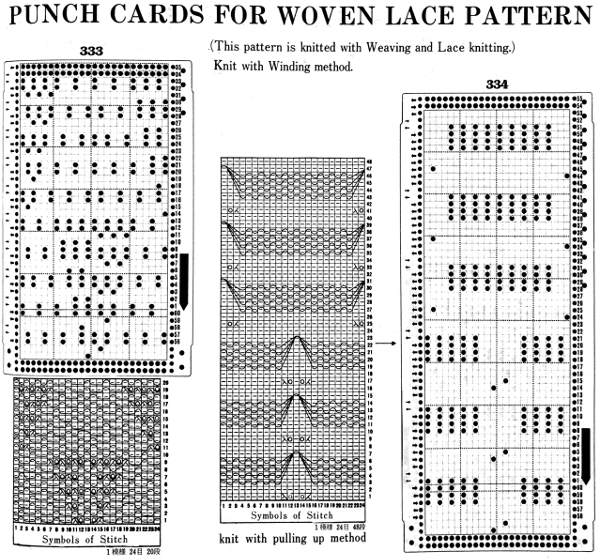

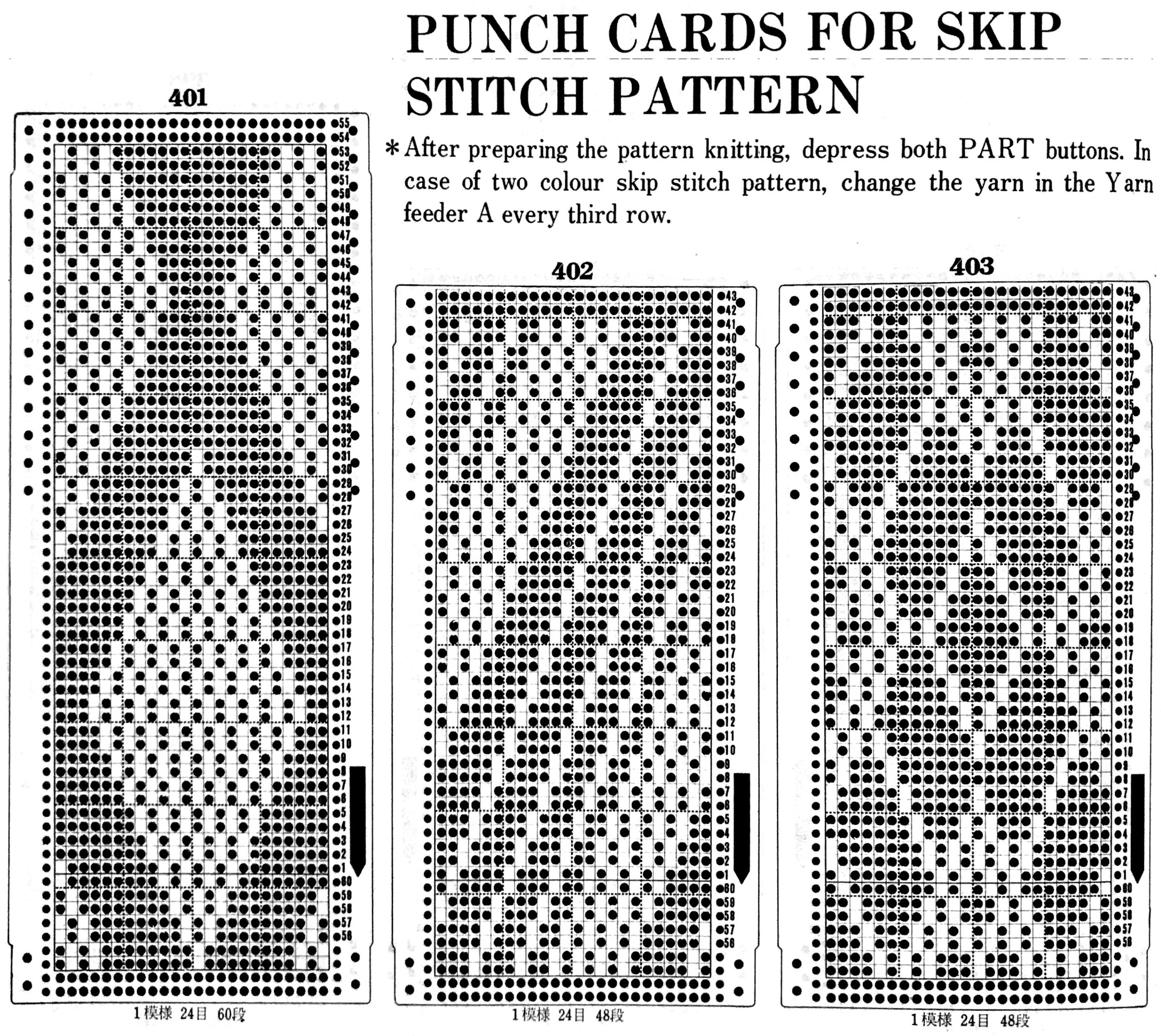

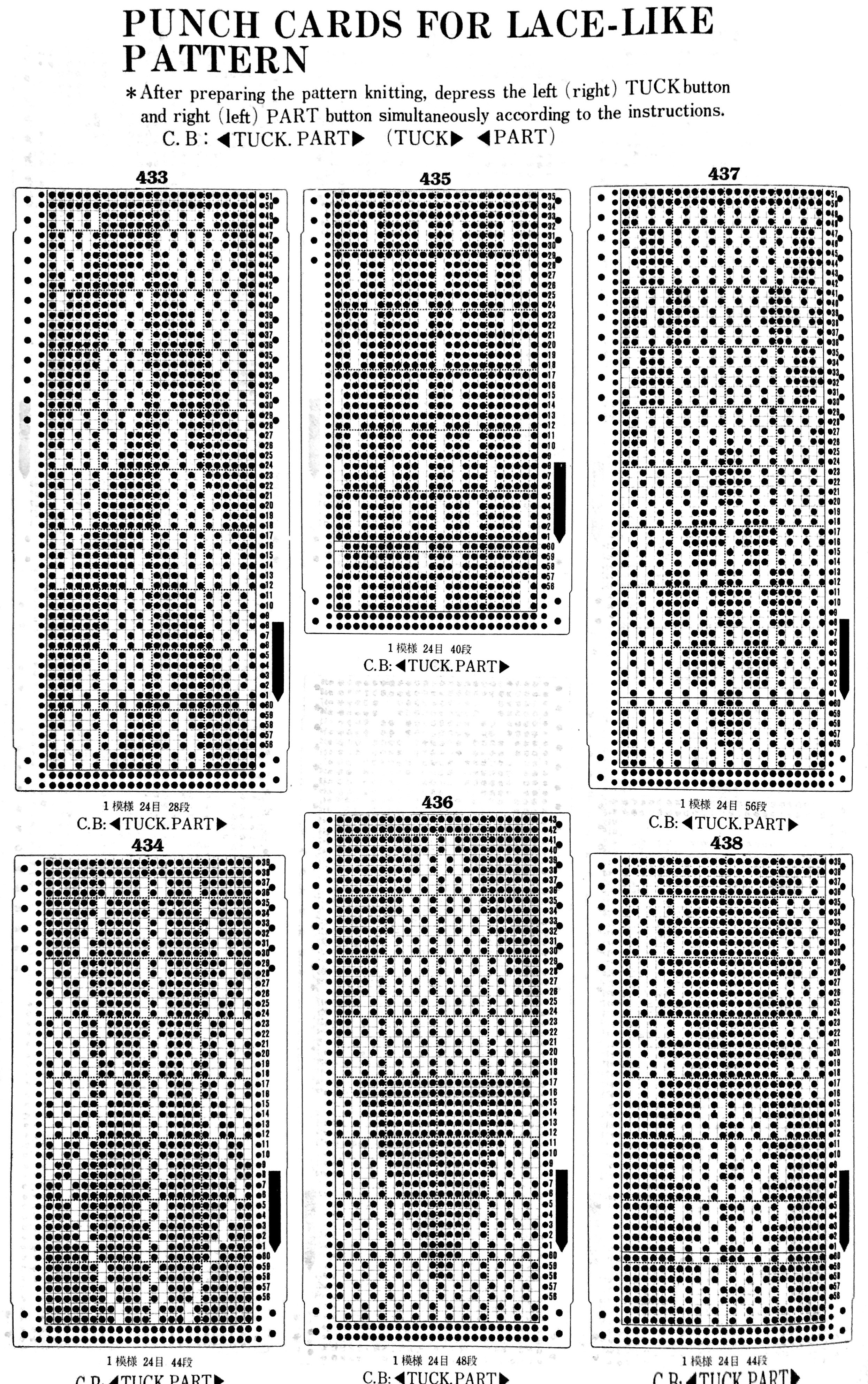

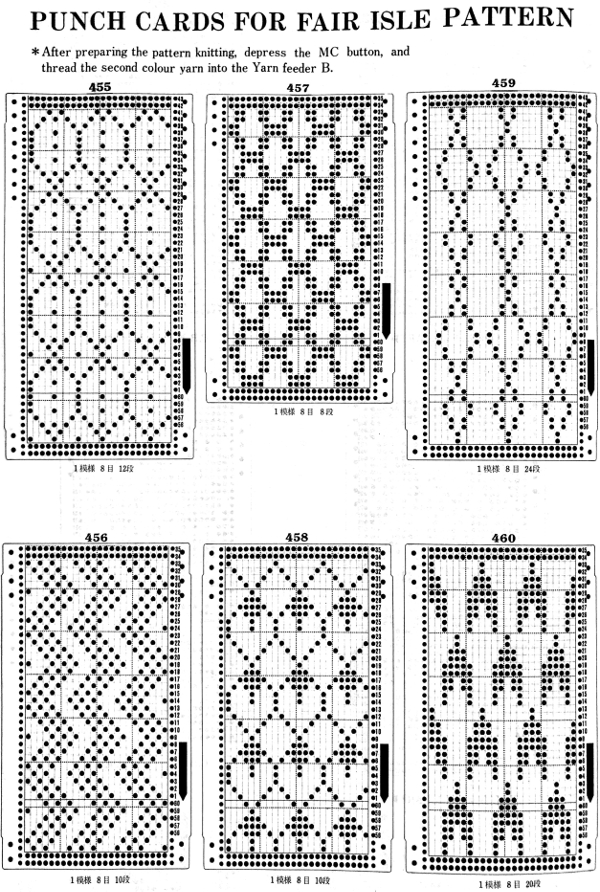

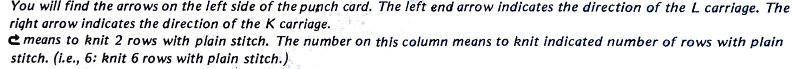

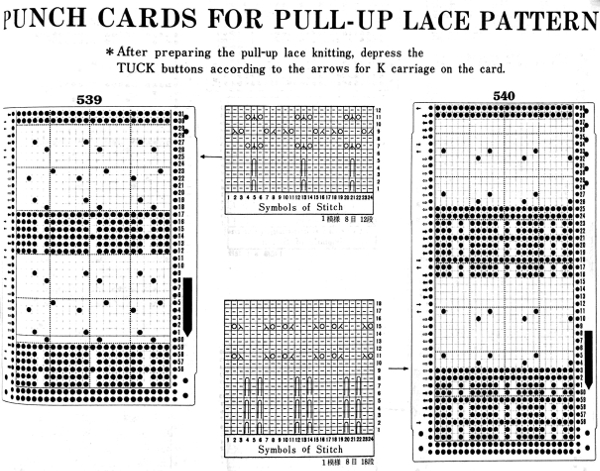

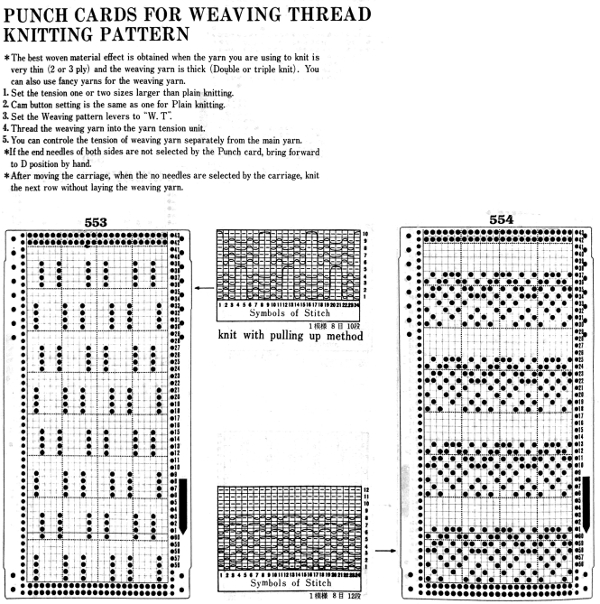

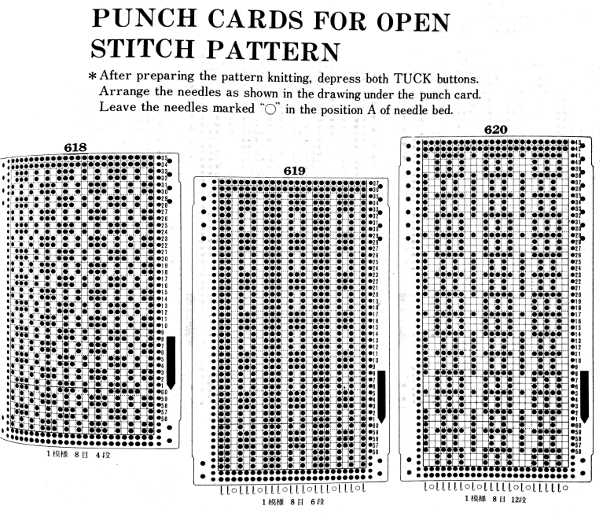

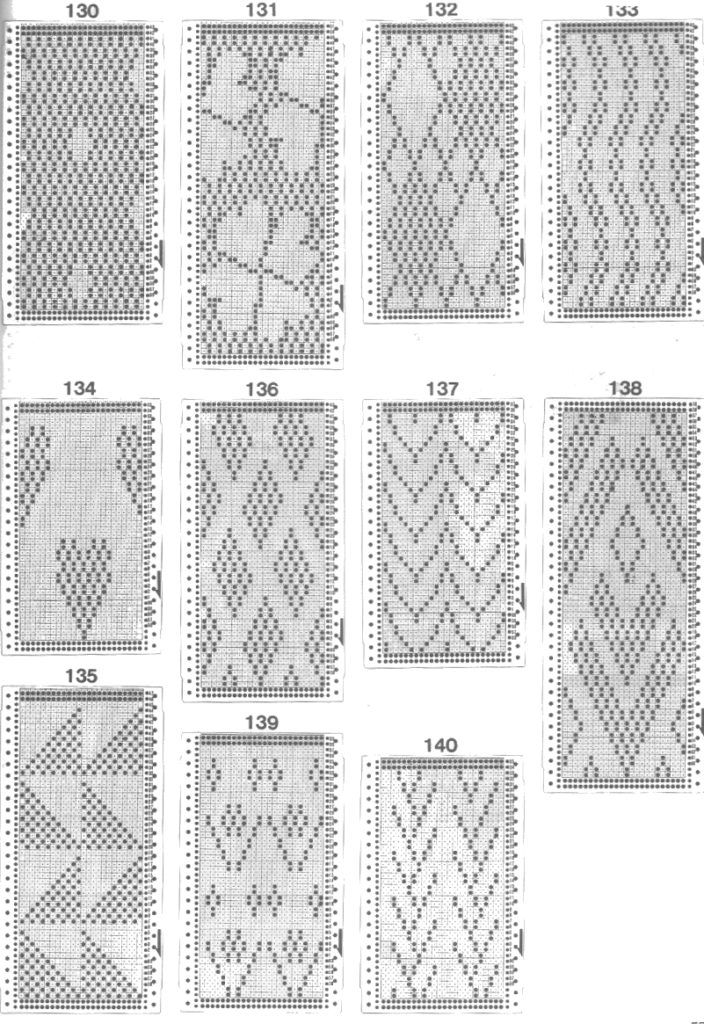

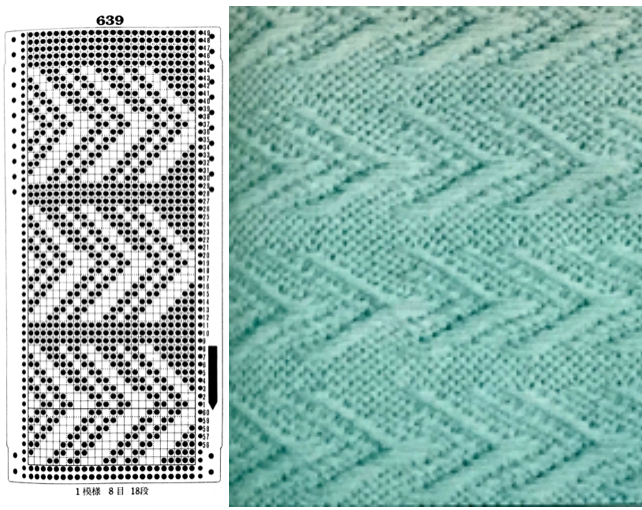

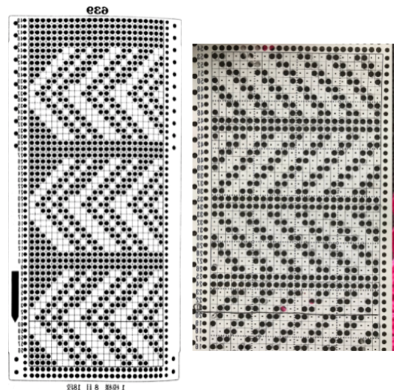

Before any DIY, I like to start with a published pattern. Toyota, in this volume,  offers 4 punchcards for use with this technique

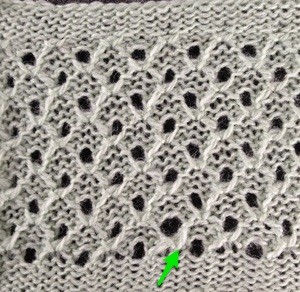

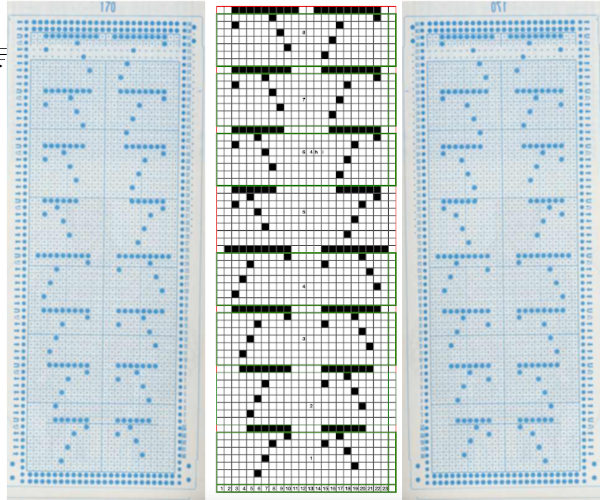

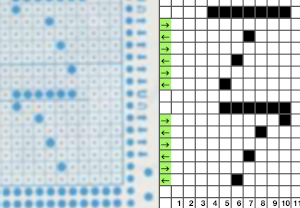

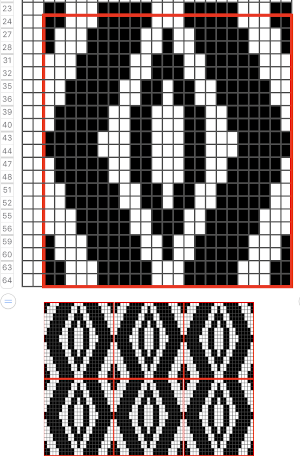

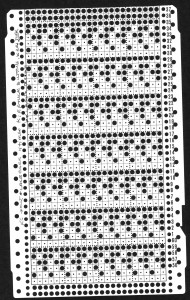

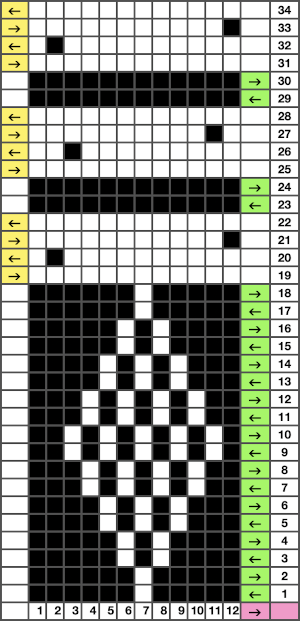

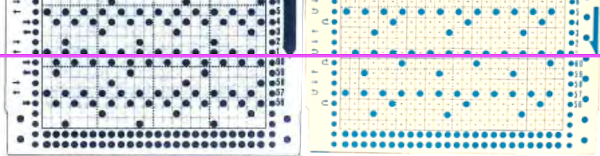

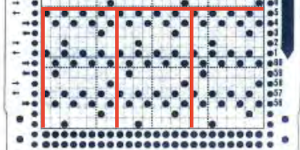

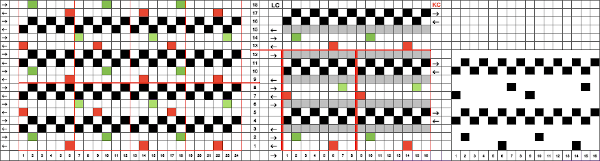

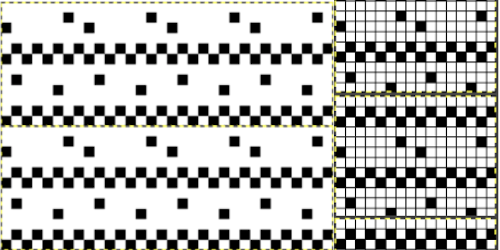

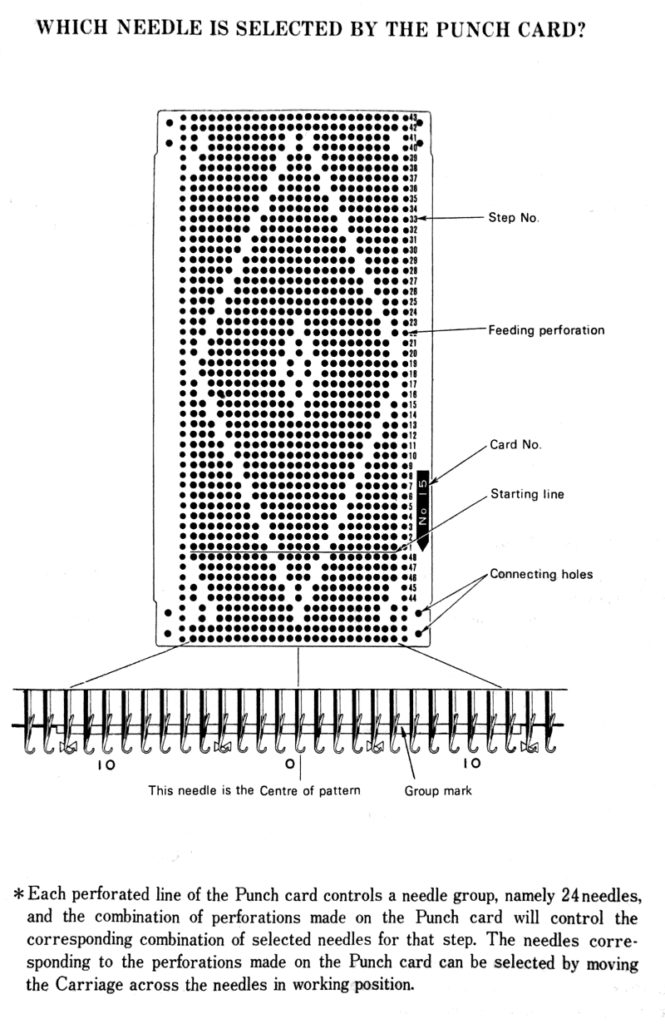

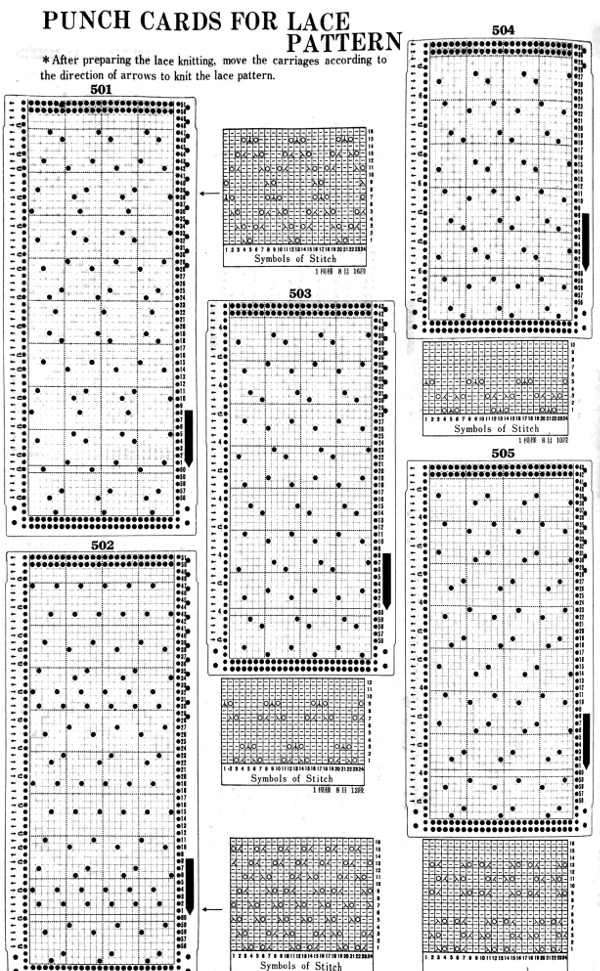

offers 4 punchcards for use with this technique  I chose to work with #170. The lace carriage in the Toyota models operates from the right side rather than the left as in Brother. The direction of the arrows marked on the card actually indicates movements for the carriage operating from that side. That fact is taken into consideration planning a possible Brother punchcard repeat. Lace direction arrows are matched based on the punchcard image being mirrored horizontally. The card in its original version is imaged on the left, mirrored on the far right, the proposed Brother punchcard in the center

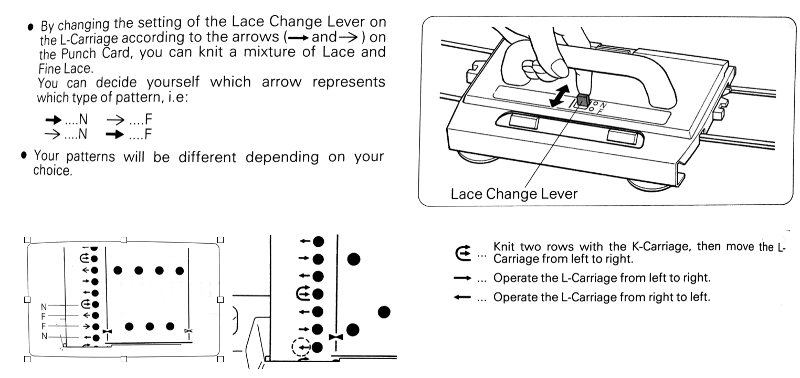

I chose to work with #170. The lace carriage in the Toyota models operates from the right side rather than the left as in Brother. The direction of the arrows marked on the card actually indicates movements for the carriage operating from that side. That fact is taken into consideration planning a possible Brother punchcard repeat. Lace direction arrows are matched based on the punchcard image being mirrored horizontally. The card in its original version is imaged on the left, mirrored on the far right, the proposed Brother punchcard in the center

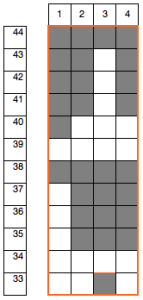

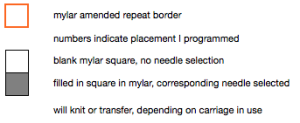

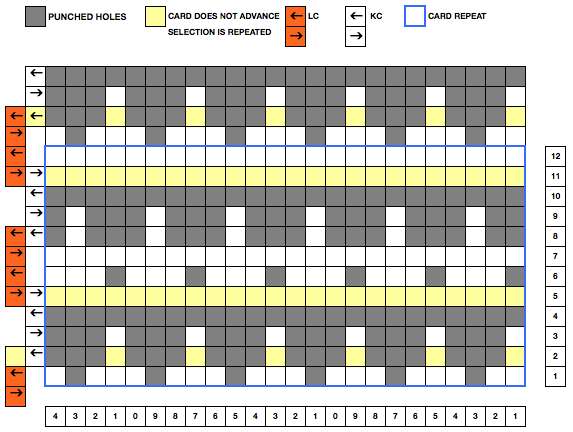

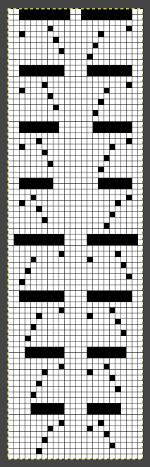

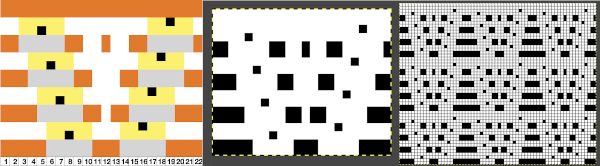

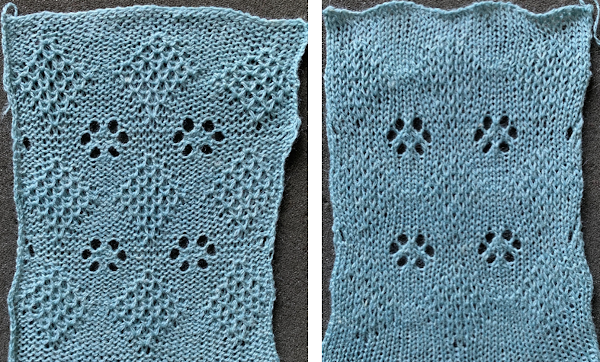

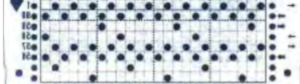

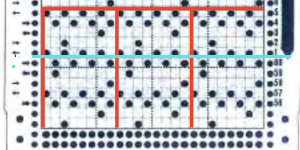

The proposed Brother punchcard repeat is now expanded for use on the electronic machine, ready for converting to .bmp in Gimp. Numbers in the middle of the chart on the left helped keep track of repeat segments. I also used red dots initially to mark segments as I had completed in the expanded the repeat, then erased them

The proposed Brother punchcard repeat is now expanded for use on the electronic machine, ready for converting to .bmp in Gimp. Numbers in the middle of the chart on the left helped keep track of repeat segments. I also used red dots initially to mark segments as I had completed in the expanded the repeat, then erased them

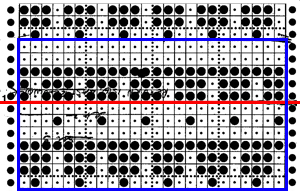

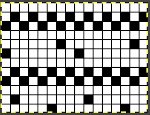

The Gimp magnified punchcard repeat

The Gimp magnified punchcard repeat  in turn in need of mirroring for the .bmp to be used in the 930

in turn in need of mirroring for the .bmp to be used in the 930![]() the resulting fabric

the resulting fabric  Observations and settings:

Observations and settings:

The knit carriage is set to FI patterning for the knit rows, the typical floats will be created. Commonly, when floats are wider than 5 pixels, anchoring the longer ones may become a preference or even a necessity. This would add time to an already complex fabric. Each FI design row is repeated twice.

The transfers in this design are made on the yarn in the color in the B feeder. I began my swatch using the light color yarn, failed to switch its position to the B with color 2 for the shape in A, accounting for the dark stripe at the swatch bottom

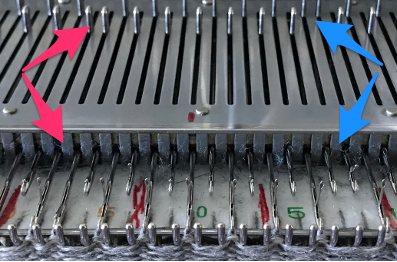

If KCI is used, end needle selection will be made prior to the lace carriage passes. Those preselected needles will have to be pushed back to B position by hand prior to using the LC or they will transfer on one side and drop on the other.

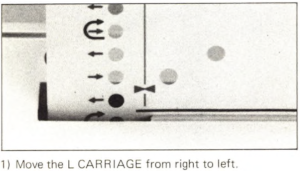

In this pattern, the LC operates for 8 passes, followed by 2 rows of FI throughout the piece. The first preselection row is made with the KC from the left as it moves toward its home on the right.

What of DIY? From working on the repeats for transfer lace combined with weaving, I understand patterns beginning with transfers to the right rather than the familiar to the left, are shortened considerably and carriage changes may be made as often as every 2 rows, saving many carriage passes. In order to understand the choices that need to be made, I began with a lace transfer pattern, thinking I could add contrasting color shapes in FI.  I expected something like this

I expected something like this  however, the swatch had issues. The eyelets were not occurring in the same spot in both directions, the color transition at the repeat intersections was clumsy

however, the swatch had issues. The eyelets were not occurring in the same spot in both directions, the color transition at the repeat intersections was clumsy  Regrouping: the easiest place to insert eyelets is in the dominant, background-color

Regrouping: the easiest place to insert eyelets is in the dominant, background-color  The 930 .png

The 930 .png![]() A quick test: rows with no needle pre-selection will knit in only one color, end needle selection must be canceled before knitting to the other side

A quick test: rows with no needle pre-selection will knit in only one color, end needle selection must be canceled before knitting to the other side  Can the exchange of the color positions in the yarn feeder create colored shapes with eyelets on the white ground? not only does it not do so in a way I liked, but my machine was having none of it as well

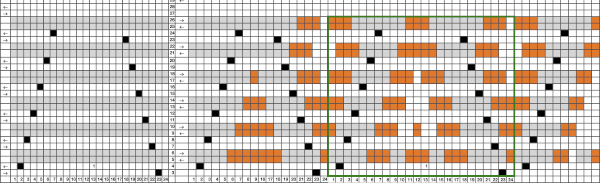

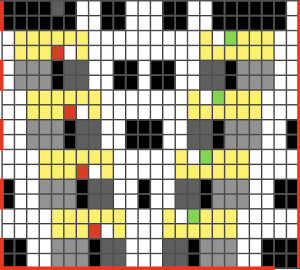

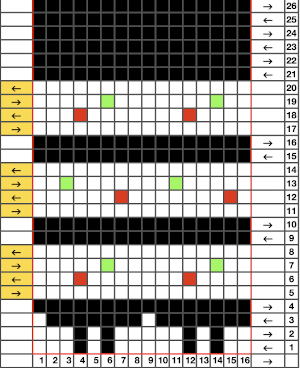

Can the exchange of the color positions in the yarn feeder create colored shapes with eyelets on the white ground? not only does it not do so in a way I liked, but my machine was having none of it as well  Coming up with a better plan resulted in the following repeat. The transfers are made in the wanted direction on the purl side of the fabric, so their location becomes easy to check and identify during knitting. In this exercise, they will be placed in the center or the previously knit fair isle rows. Magenta cells marking the doubled stitch after transfers to the right, the cyan one the doubled stitch after transfers to the left. The two blank rows at the top of the design will knit in the background only.

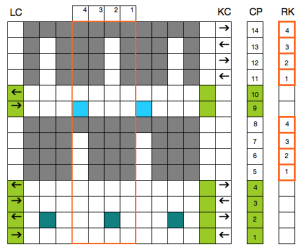

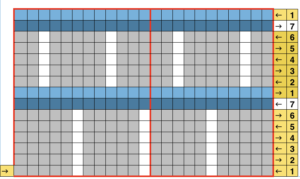

Coming up with a better plan resulted in the following repeat. The transfers are made in the wanted direction on the purl side of the fabric, so their location becomes easy to check and identify during knitting. In this exercise, they will be placed in the center or the previously knit fair isle rows. Magenta cells marking the doubled stitch after transfers to the right, the cyan one the doubled stitch after transfers to the left. The two blank rows at the top of the design will knit in the background only.

![]()

Building the repeat in Numbers: the eyelets within the shapes in the contrast color need to begin and end with a pair of FI rows. They are placed taking into consideration the black cell blocks immediately below them, not the ones directly above

Building the repeat in Numbers: the eyelets within the shapes in the contrast color need to begin and end with a pair of FI rows. They are placed taking into consideration the black cell blocks immediately below them, not the ones directly above  It’s good to start with a small repeat.

It’s good to start with a small repeat.

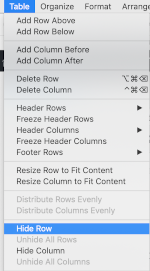

A: one may begin with a planned repeat, in this case, 20 rows in height

B: create a table at least twice the planned height or start with a long template that in turn will have half its rows hidden. Holding the command key select every other pair of rows beginning with 2 blank ones at the top of the table, and hide them. The location for the options to hide and unhide rows and columns:  C: Once the rows are hidden, the black cells are filled in

C: Once the rows are hidden, the black cells are filled in

D: the repeat is tiled to check its alignment

E: the hidden rows are unhidden, I like to add colored cells as shown to ensure proper placement of eyelets

F: place black cells for stitches to be transferred where desired

Previous posts describe the steps to isolate the repeat as a screengrab and importing it into GIMP. The grab is cropped to content, image mode to indexed, scale to the proper size, mirror for use on the electronic if needed, save, and use the final image to download to the knitting machine for testing.

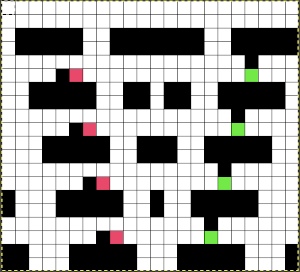

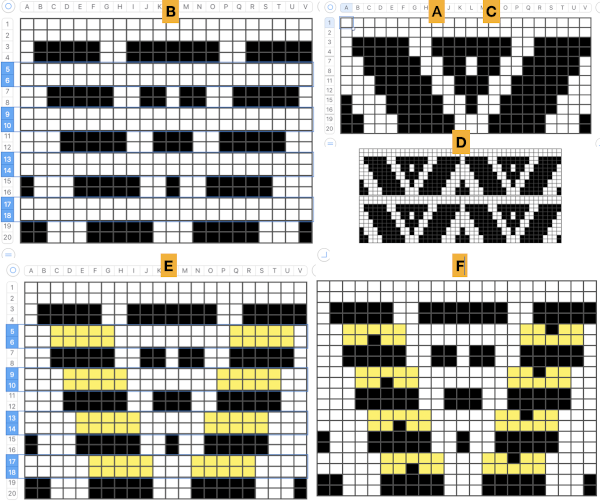

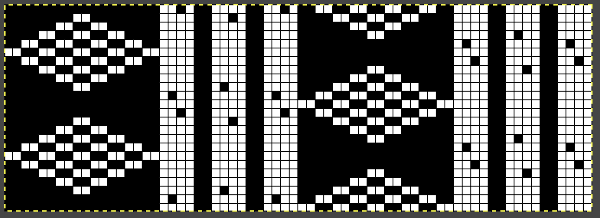

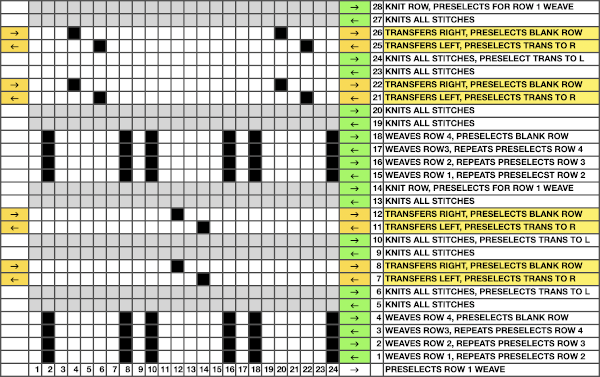

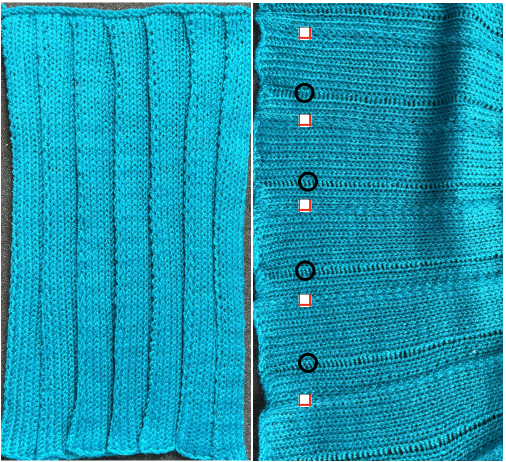

The first pair of rows are knit in FI, so the preselection for design row 1 is from left to right. The KCI setting will bring end needles out to D prior to lace rows, those needles need to be pushed back to B position prior to moving the LC from left to right. Continue with switching carriages every 2 rows. This repeat is 20 rows high. When knitting the last 2 rows, no needles will have been preselected, except for first and last. Push them back to B for those two rows, so only the color in the A feeder knits, and the preselected needles do not drop off the bed. The second color does not need to be removed from its location, but in executing a wide piece of knitting, the extra yarn pulled down from the tension mast as the knit carriage makes its passes may cause issues. If the yarn is removed and held aside, be sure to place it back after the 2 passes with the ground color so as to avoid forgetting to do so prior to resuming patterning using 2 colors per row.  Taking it to continuous shapes and checking them in repeat: red cells represent transfers to the right, cyan ones the transfers to the left. The empty cells adjoining each of both colors represent the location of the doubled-up stitch after the transfer is made

Taking it to continuous shapes and checking them in repeat: red cells represent transfers to the right, cyan ones the transfers to the left. The empty cells adjoining each of both colors represent the location of the doubled-up stitch after the transfer is made

I like to check tiling for the repats along the whole process

I like to check tiling for the repats along the whole process

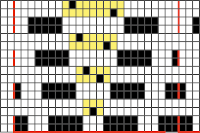

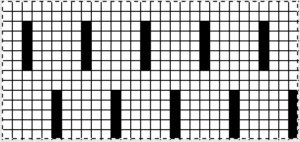

Though the repeat is 24 stitches wide, it is not suitable for use on the punchcard machines in this format, its tiled test

Though the repeat is 24 stitches wide, it is not suitable for use on the punchcard machines in this format, its tiled test and .png

and .png![]() The one area where the white got picked up with the contrast is not due to programming, but likely to operator error in “correcting” a dropped stitch

The one area where the white got picked up with the contrast is not due to programming, but likely to operator error in “correcting” a dropped stitch  Adding another contrast color stitch to shapes will make the number of stitches on either side of the eyelets consistent

Adding another contrast color stitch to shapes will make the number of stitches on either side of the eyelets consistent  Adding lace shapes in the ground can follow the same concept

Adding lace shapes in the ground can follow the same concept  The repeat does was not planned as a continuing pattern, but here it is knit and repeated in height X 2

The repeat does was not planned as a continuing pattern, but here it is knit and repeated in height X 2  and with the addition of two blank rows at the top of each segment.

and with the addition of two blank rows at the top of each segment.

The possibilities are endless, with some patience, they can be manipulated to meet personal preferences and taste.

The possibilities are endless, with some patience, they can be manipulated to meet personal preferences and taste.

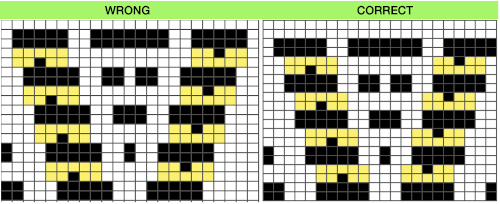

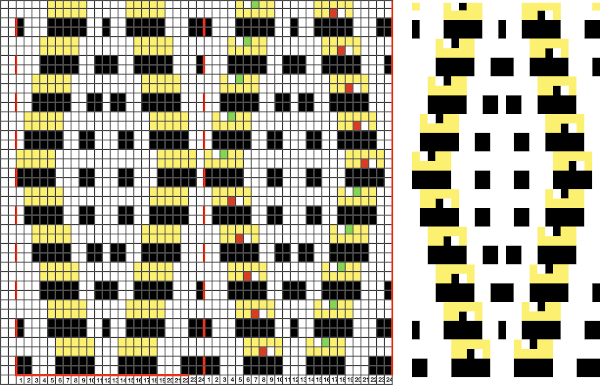

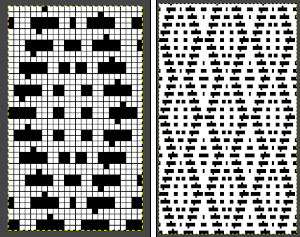

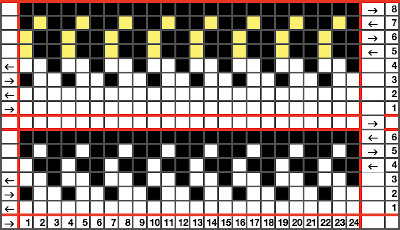

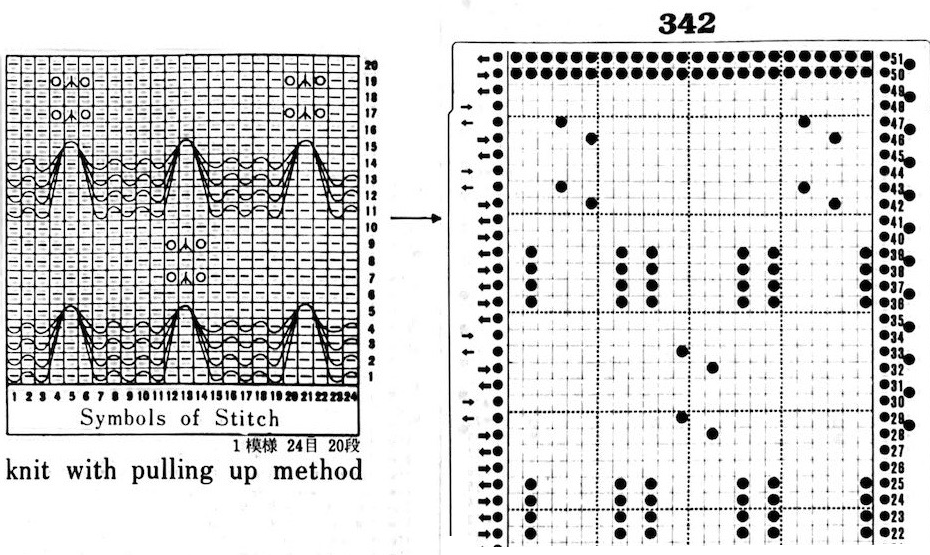

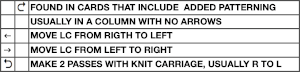

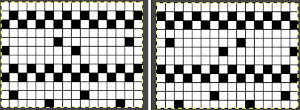

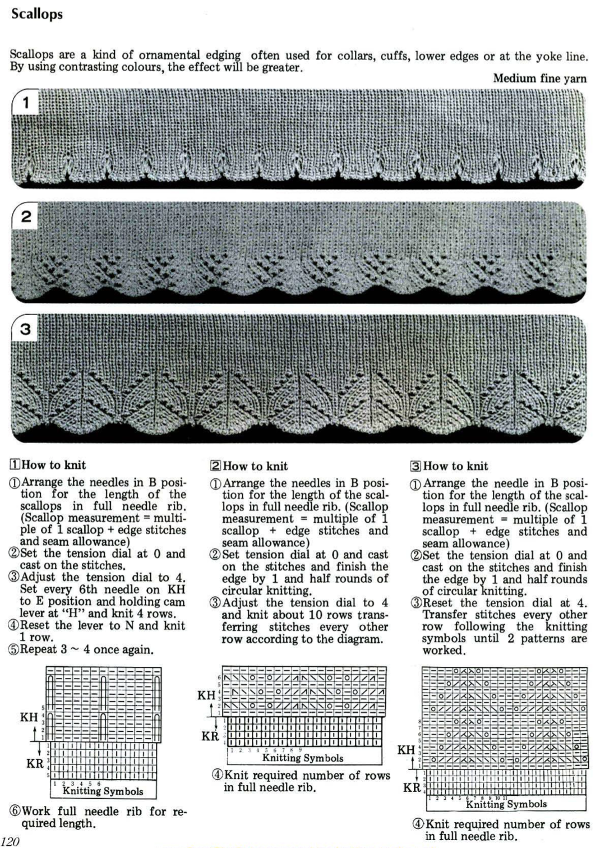

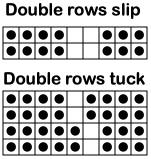

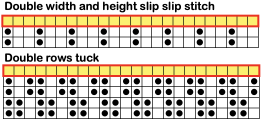

Working out an electronic repeat: the punchcard repeat is on the bottom, the expanded electronic one on top, yellow cells highlight rows with tuck stitches

Working out an electronic repeat: the punchcard repeat is on the bottom, the expanded electronic one on top, yellow cells highlight rows with tuck stitches

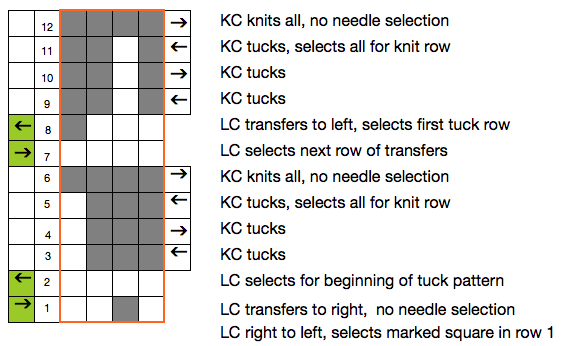

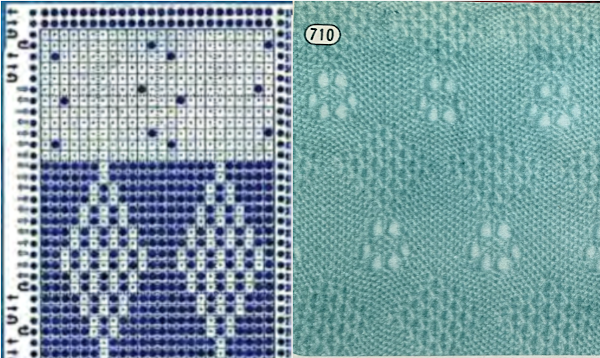

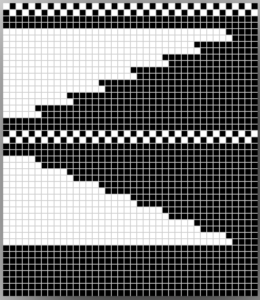

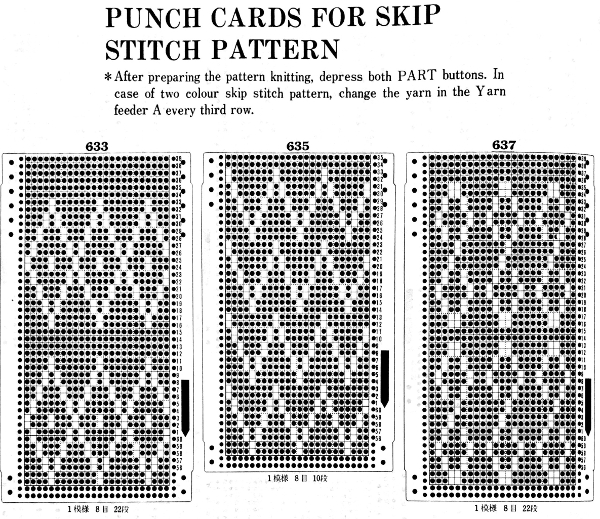

Returning to Volume 4, here is a combination of lace and tuck repeat that appealed to me. I am repeating a process akin to that used in programming the

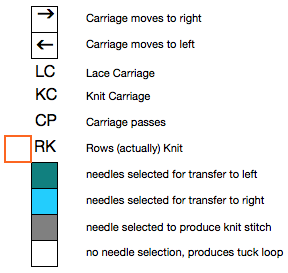

Returning to Volume 4, here is a combination of lace and tuck repeat that appealed to me. I am repeating a process akin to that used in programming the  The actions of the 2 carriages on the electronic, the repeat prior to mirroring

The actions of the 2 carriages on the electronic, the repeat prior to mirroring  mirrored for use on the 930

mirrored for use on the 930

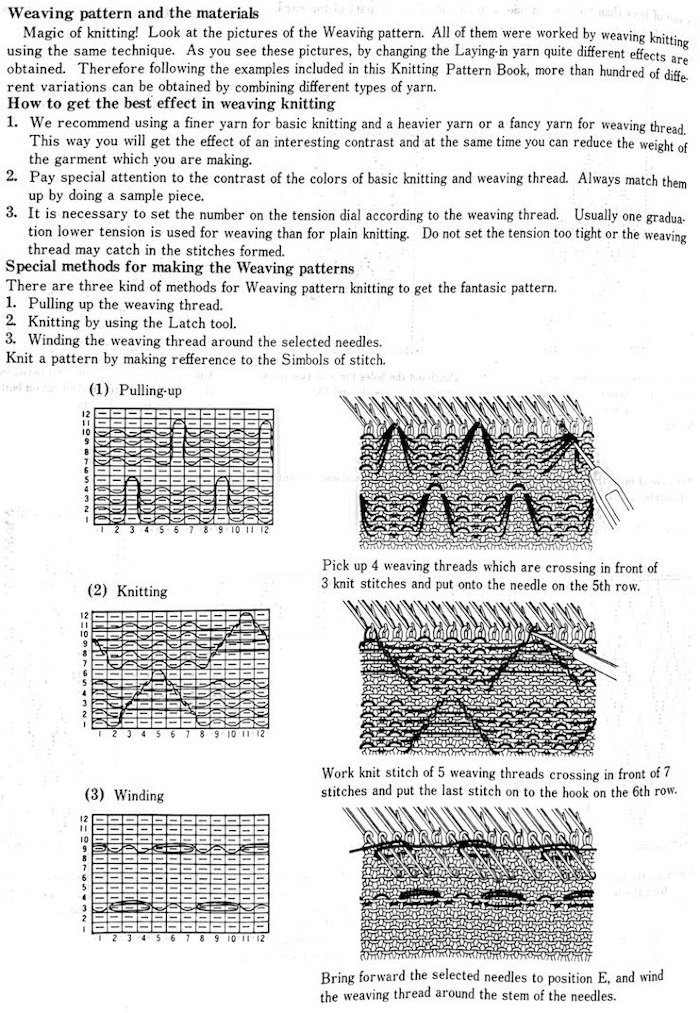

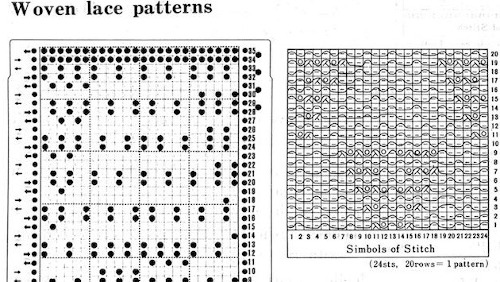

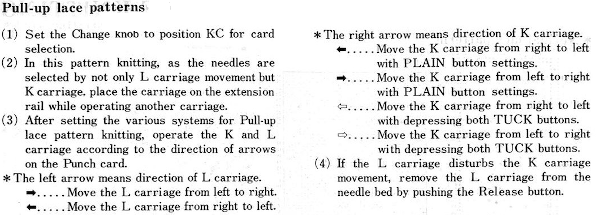

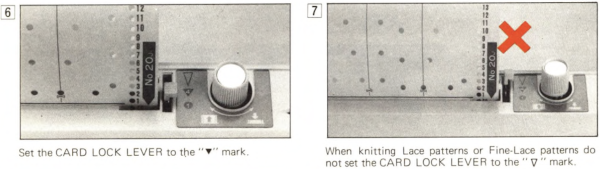

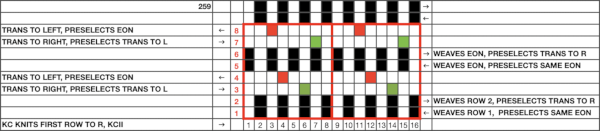

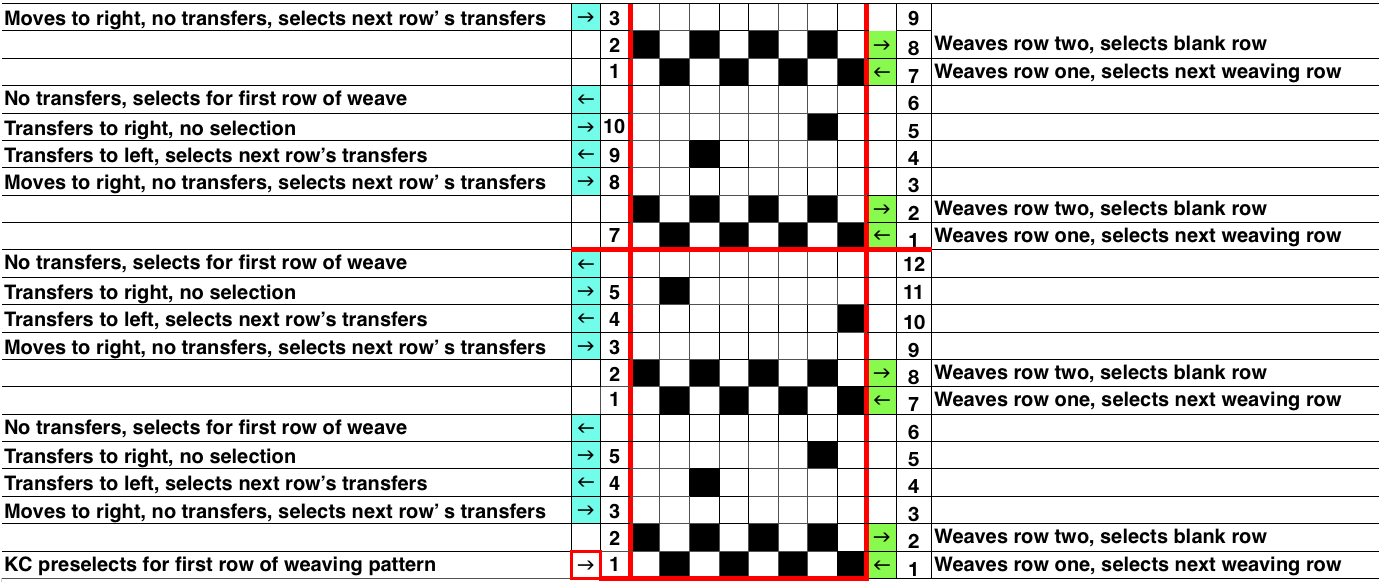

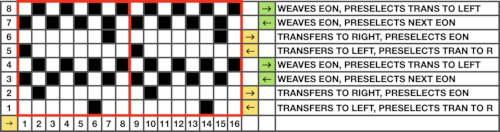

It has the added data on how each of the fabrics might look visualized in a chart prior to its expansion as a card in full repeat. This is the top half repeat of a card for pull up weaving combined with lace along with the directions for execiting the knit

It has the added data on how each of the fabrics might look visualized in a chart prior to its expansion as a card in full repeat. This is the top half repeat of a card for pull up weaving combined with lace along with the directions for execiting the knit

My experience with trying to knit

My experience with trying to knit  Taking carriages on and off the same side of the machine is nothing I would be inclined to do for any length on any machine. In theory, the identical repeat above could be used on an electronic KM in that way, but I did not get very far with that method before giving up.

Taking carriages on and off the same side of the machine is nothing I would be inclined to do for any length on any machine. In theory, the identical repeat above could be used on an electronic KM in that way, but I did not get very far with that method before giving up.

Volume 4 offers only this advice: “the empty needles are selected at the second lace pattern, but this is not a trouble, and you may pass the L carriage to the side which is indicated on the punchcard”. I take that to mean that after a transfer if the same needle is selected again, don’t be concerned, keep moving the carriage in the direction of the arrows.

Volume 4 offers only this advice: “the empty needles are selected at the second lace pattern, but this is not a trouble, and you may pass the L carriage to the side which is indicated on the punchcard”. I take that to mean that after a transfer if the same needle is selected again, don’t be concerned, keep moving the carriage in the direction of the arrows.  Because the weaving is for only 2 rows, the use of laid in, thicker yarn is well tolerated. The punchcard repeat amended for use on electronic, shown prior to mirroring

Because the weaving is for only 2 rows, the use of laid in, thicker yarn is well tolerated. The punchcard repeat amended for use on electronic, shown prior to mirroring

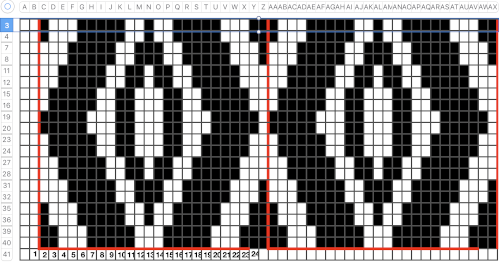

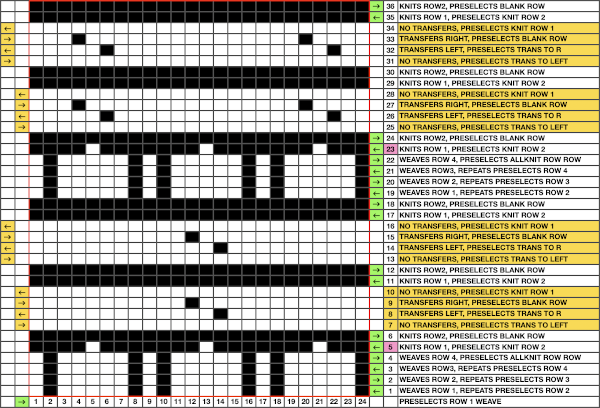

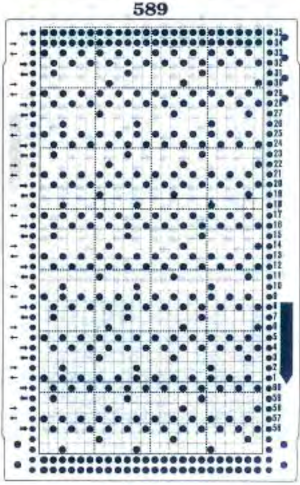

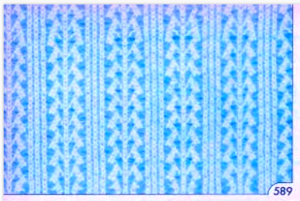

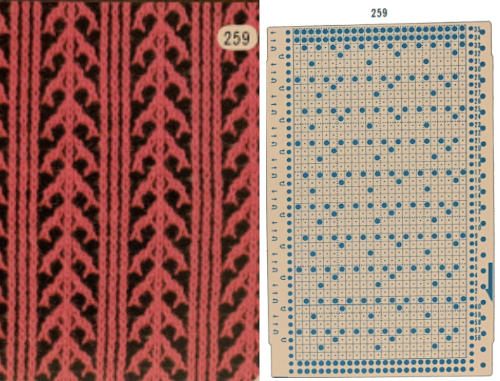

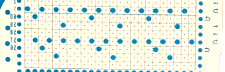

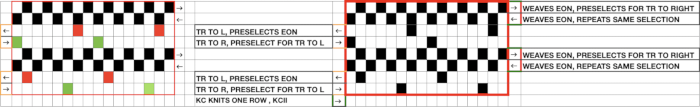

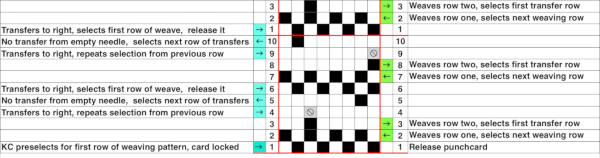

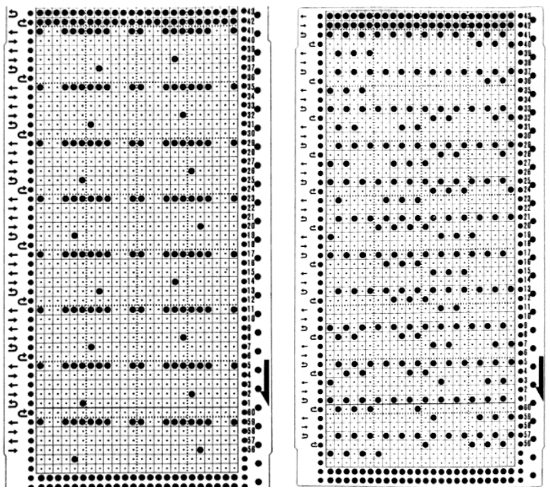

At the time, I made a long, convoluted effort to produce the fabric. I am returning to the topic and comparing 2 cards in this post, the original 589, and a new-found cousin, 259. Looking to the published cards for clues, remember that markings for carriage movements related to the first design row at the bottom of the card begin on the left of the card, above the Brother line numbered 1 on the right. The start of both cards:

At the time, I made a long, convoluted effort to produce the fabric. I am returning to the topic and comparing 2 cards in this post, the original 589, and a new-found cousin, 259. Looking to the published cards for clues, remember that markings for carriage movements related to the first design row at the bottom of the card begin on the left of the card, above the Brother line numbered 1 on the right. The start of both cards:

As the carriage moves to the right, the card will advance a row.

As the carriage moves to the right, the card will advance a row.

259 shows the traditional approach combining the two techniques that take into account the fact that when the second selecting carriage starts to move from the opposite side, the punchcard does not advance, repeating the same preselection. Added discussion of the differences in repeats for both machine types may be found in the post: Doilies:

259 shows the traditional approach combining the two techniques that take into account the fact that when the second selecting carriage starts to move from the opposite side, the punchcard does not advance, repeating the same preselection. Added discussion of the differences in repeats for both machine types may be found in the post: Doilies:

The pattern is simply not workable as given using both carriages selecting needles from opposite sides of a punchcard machine, each moving for 2 rows.

The pattern is simply not workable as given using both carriages selecting needles from opposite sides of a punchcard machine, each moving for 2 rows. the smallest, single repeated in width X 2 for use on my 930

the smallest, single repeated in width X 2 for use on my 930 its .png

its .png

comparing the sequences for both starts, weaving on left, lace on the right

comparing the sequences for both starts, weaving on left, lace on the right

a sample using 2 different weight yarns; irregular weaving may require changing the yarn, or adjusting the tension used for the background yarn

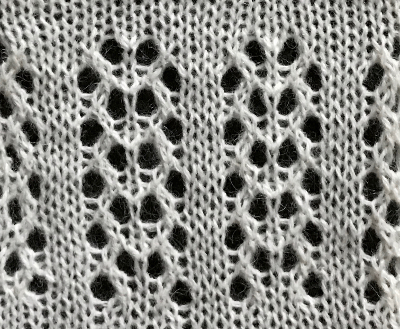

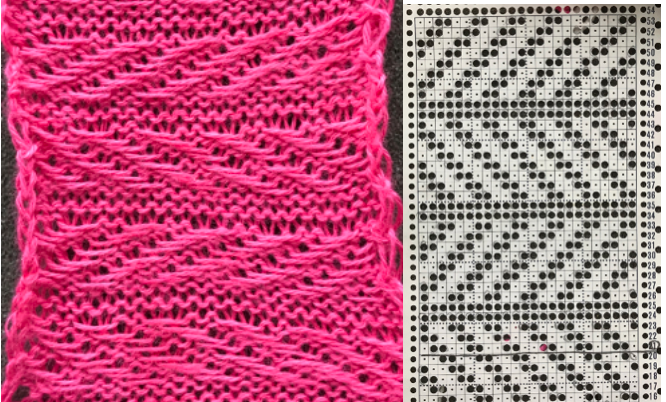

a sample using 2 different weight yarns; irregular weaving may require changing the yarn, or adjusting the tension used for the background yarn  I like to test these repeats first in transfer lace, to sort out the best tension and yarn to use, errors in programming,

I like to test these repeats first in transfer lace, to sort out the best tension and yarn to use, errors in programming,  Taking another look at the original punchcard and those arrows on the left-hand side, a detail I had originally missed, they all start from and return to the right, the line thickness changing marking the alternate carriage

Taking another look at the original punchcard and those arrows on the left-hand side, a detail I had originally missed, they all start from and return to the right, the line thickness changing marking the alternate carriage

As I was trying to understand what was happening, I was also able to produce a swatch using the original #589 card, using a method that, however, produced all lace transfers to the right, and differed from the desired effect:

As I was trying to understand what was happening, I was also able to produce a swatch using the original #589 card, using a method that, however, produced all lace transfers to the right, and differed from the desired effect: the knit, produced at the time on both my punchcard machine and with my 910 also requiring an LC release on its third pass,

the knit, produced at the time on both my punchcard machine and with my 910 also requiring an LC release on its third pass,

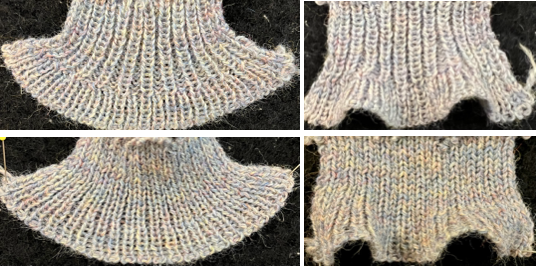

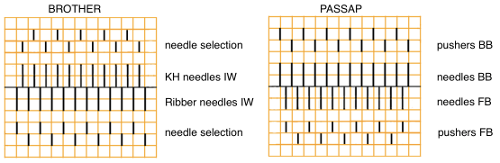

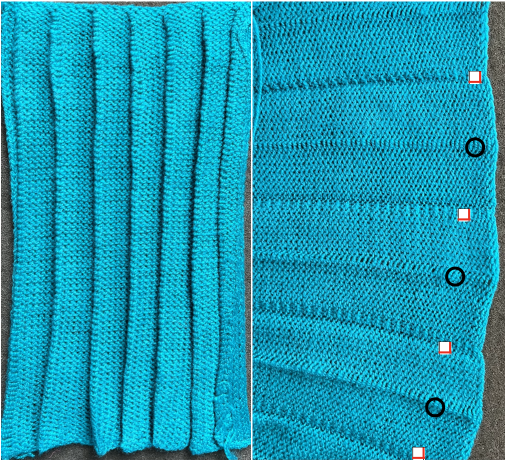

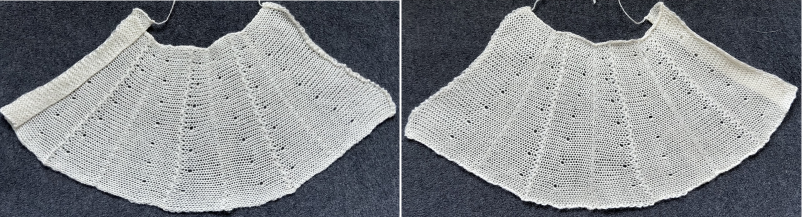

Working it on Brother becomes a bit fiddly. Whether working on a punchcard or electronic KM, it is possible to introduce patterning on either or both beds as seen below. I preferred the look obtained with the racked cast on at the start. Setting up the Brother machine: program the repeat, half pitch for every needle rib, air knit to place the pattern on the bed so that the first needle on the left (or right if you prefer) is preselected forward and will produce a knit stitch on the first row knit. The yarn used is a 2/24 acrylic

Working it on Brother becomes a bit fiddly. Whether working on a punchcard or electronic KM, it is possible to introduce patterning on either or both beds as seen below. I preferred the look obtained with the racked cast on at the start. Setting up the Brother machine: program the repeat, half pitch for every needle rib, air knit to place the pattern on the bed so that the first needle on the left (or right if you prefer) is preselected forward and will produce a knit stitch on the first row knit. The yarn used is a 2/24 acrylic

now another needle on the ribber is brought in to work on the far left, it will tuck with lili selection when moving from left to right

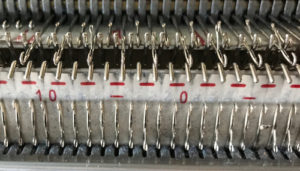

now another needle on the ribber is brought in to work on the far left, it will tuck with lili selection when moving from left to right  remember the ribber rule with lili buttons: an even number of needles must be in work, this shows the start and end of selection on the ribber on alternate needle tape markings, as required

remember the ribber rule with lili buttons: an even number of needles must be in work, this shows the start and end of selection on the ribber on alternate needle tape markings, as required

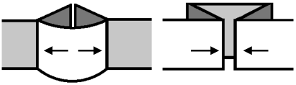

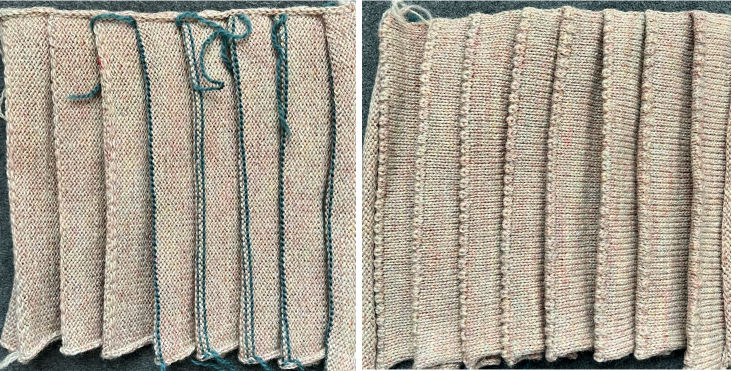

Both pieces compared for width and rippling

Both pieces compared for width and rippling

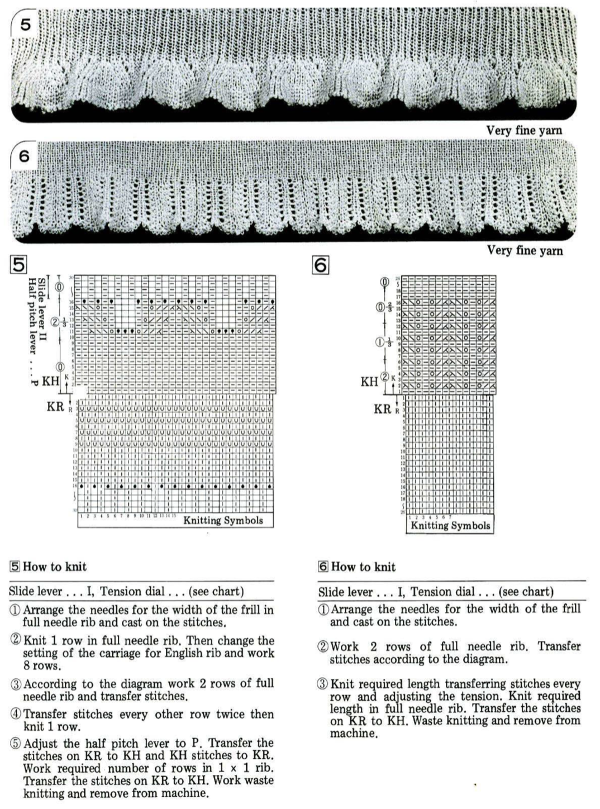

An intro to scallops: p.120

An intro to scallops: p.120

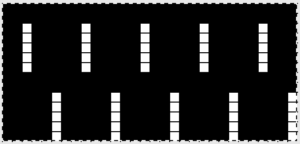

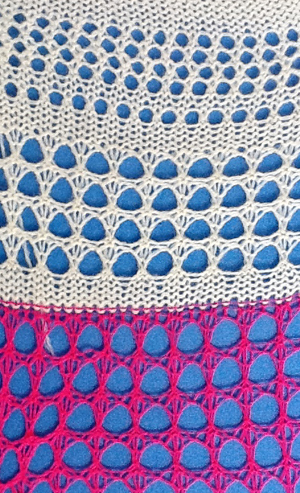

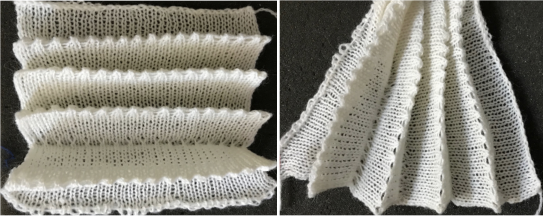

The fabric narrows considerably as it is stretched lengthwise to set the stitches. Several panels would be required for a garment such as a skirt. Such an item would need to be pulled into shape, pinned, and hot pressed. Fiber content will determine the crispness of the pleats after blocking, and their retention after cleaning. The swatch below is turned sideways for the sake of space.

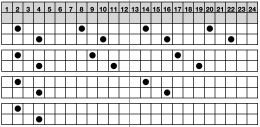

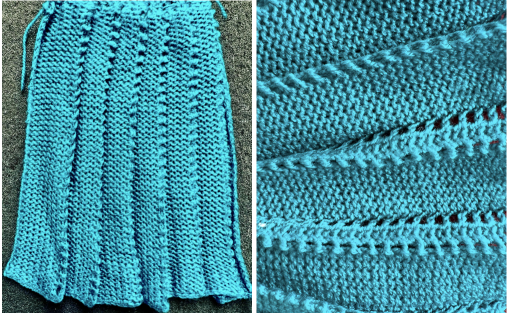

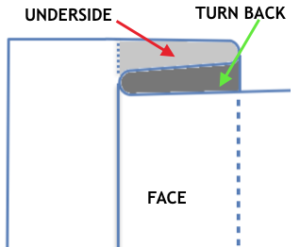

The fabric narrows considerably as it is stretched lengthwise to set the stitches. Several panels would be required for a garment such as a skirt. Such an item would need to be pulled into shape, pinned, and hot pressed. Fiber content will determine the crispness of the pleats after blocking, and their retention after cleaning. The swatch below is turned sideways for the sake of space.  More variations with folds can be made by varying the “rules” commonly recognized for creases. Working sideways once more: on a punchcard machine, using card # 1 locked, cast on making certain every other needle as well as the first and last are selected.

More variations with folds can be made by varying the “rules” commonly recognized for creases. Working sideways once more: on a punchcard machine, using card # 1 locked, cast on making certain every other needle as well as the first and last are selected. Cancel the slip setting, complete the next knit section, and transfer every other needle to the adjacent one on either the right or left.

Cancel the slip setting, complete the next knit section, and transfer every other needle to the adjacent one on either the right or left.  The needles holding 2 stitches may be brought out to the hold position as each transfer is made, or pushed out to hold after the fact to insure the stitches have been transferred and will knit off properly. The number of needles in work remains constant.

The needles holding 2 stitches may be brought out to the hold position as each transfer is made, or pushed out to hold after the fact to insure the stitches have been transferred and will knit off properly. The number of needles in work remains constant.

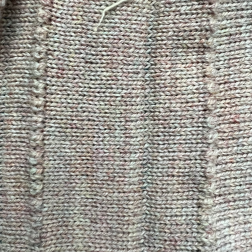

The slipped stitches form the inside folds in the pressed swatch, while eyelets and tuck stitches fold a picot edge to the outside.

The slipped stitches form the inside folds in the pressed swatch, while eyelets and tuck stitches fold a picot edge to the outside.

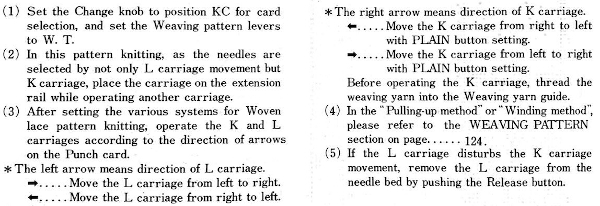

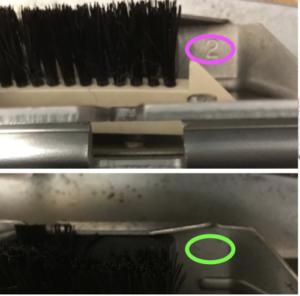

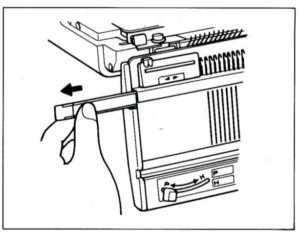

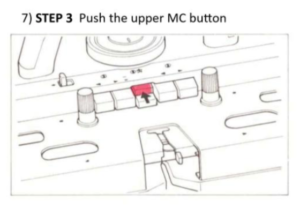

the punchcard change knob has selections for single motif and pattern knitting (KC)

the punchcard change knob has selections for single motif and pattern knitting (KC)