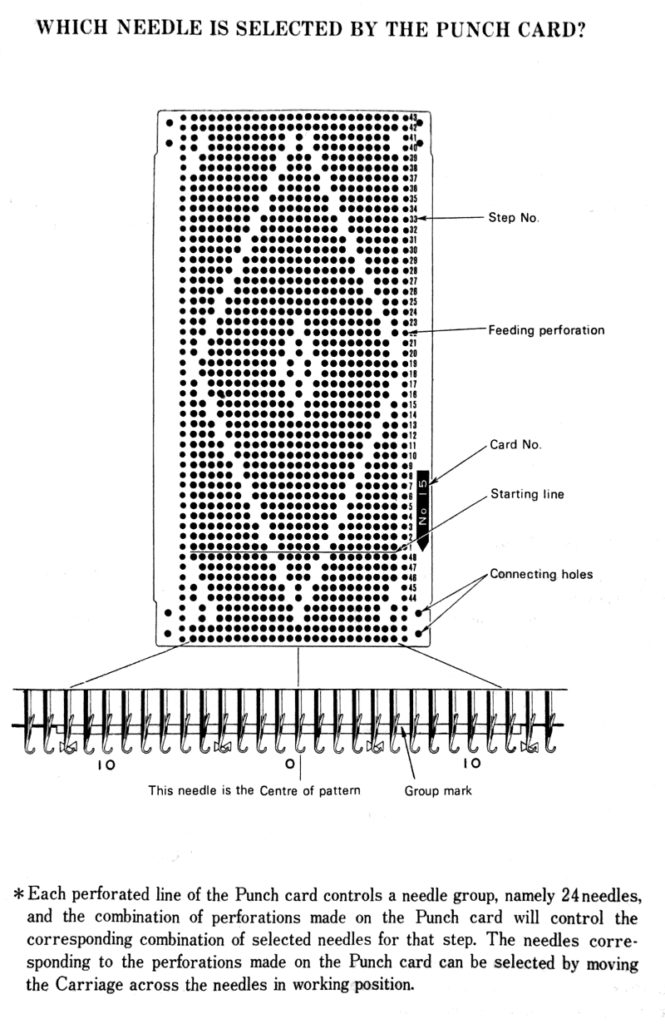

A number of variables need to be considered when adapting punchcard patterns for use on electronic knitting machines. These images pertain to Brother use, but the principles are shared between KM brands. I will add more information as time goes on. Online free downloads for magazines, manuals, etc. may be found at

http://knittsings.com/knitting-machine-manuals/

http://toyotaknitting.blogspot.com/

machineknittingetc.com

https://www.knititnow.com/ManualAndDocuments/

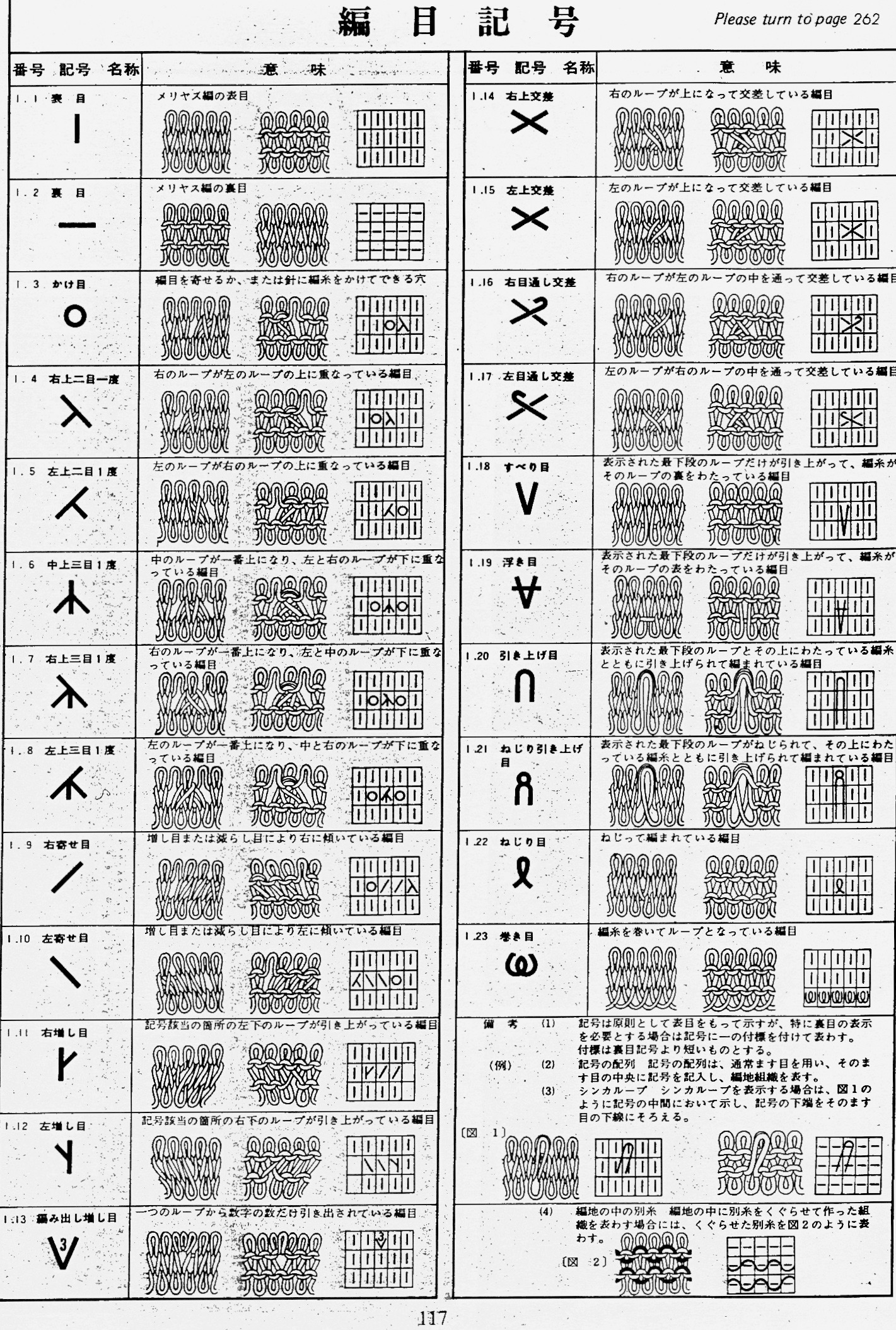

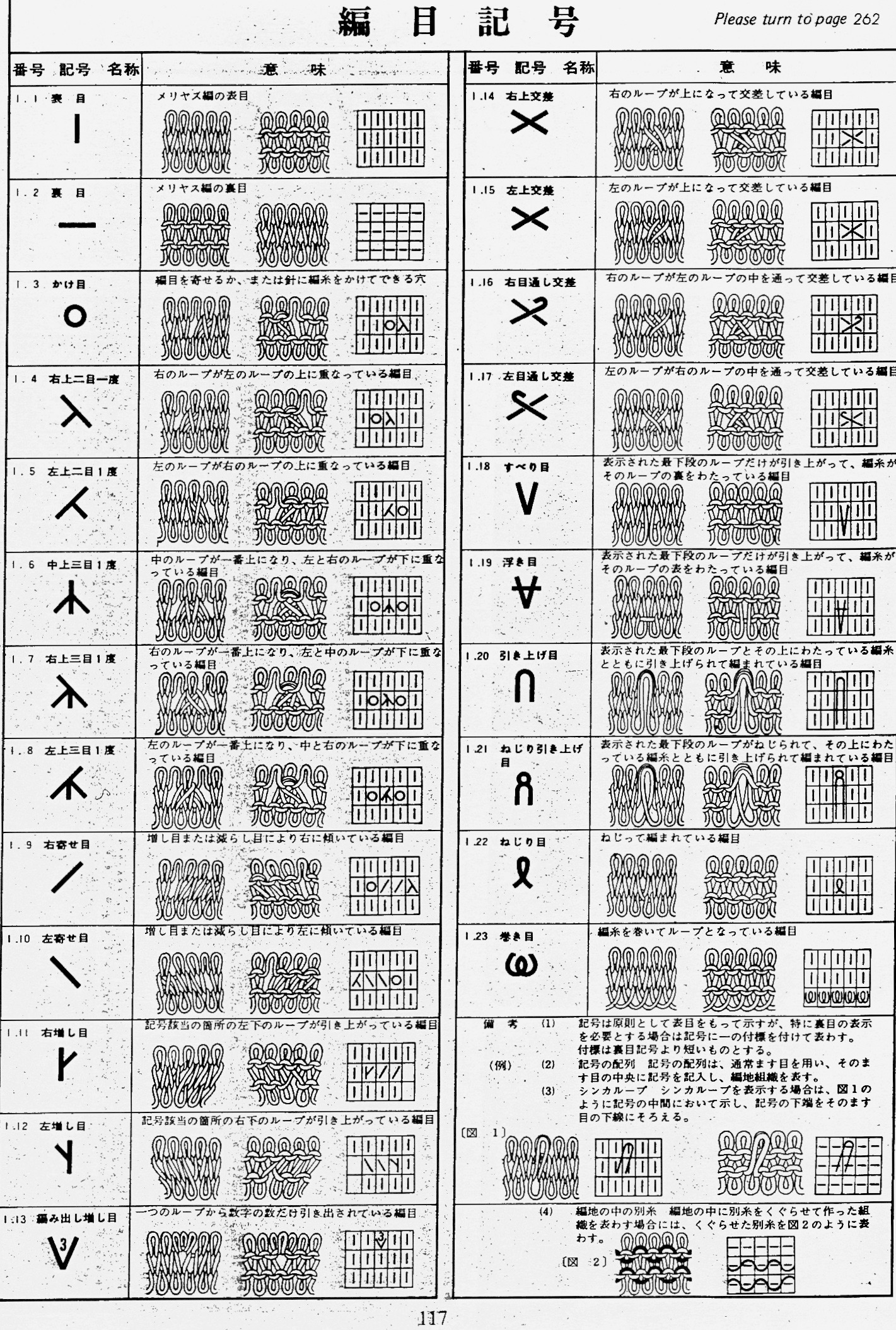

some additions of late include designs in 12, 18, and 30 stitch repeats in addition to the familiar 24 and 40 ones, and to help with interpretations of symbols: Japanese symbols for machine knitters

Punchcard collections for all brands @ needles of steel

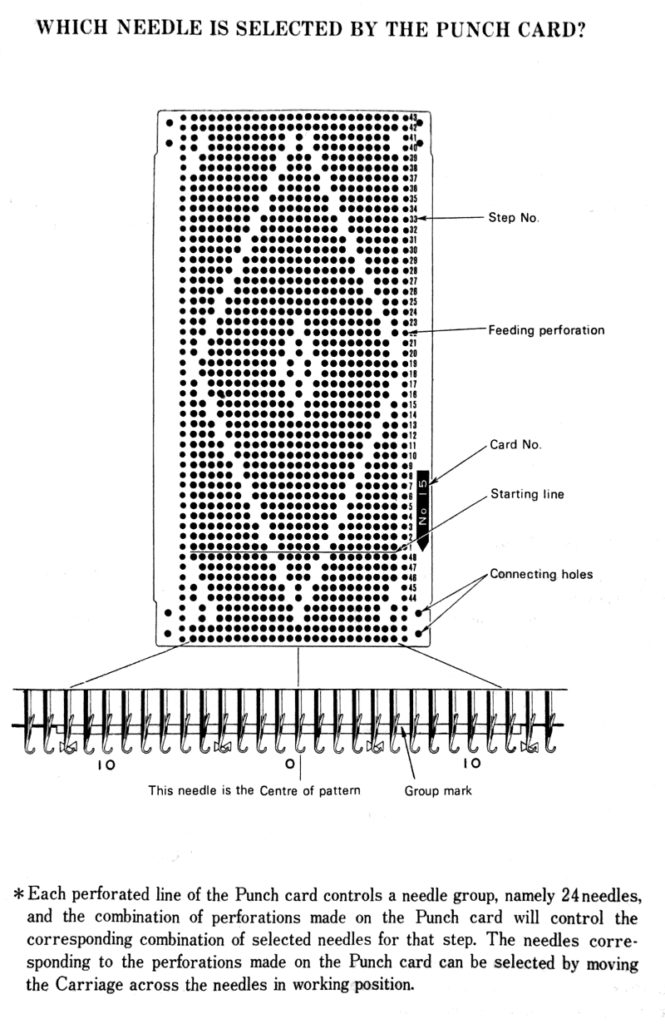

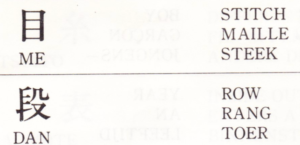

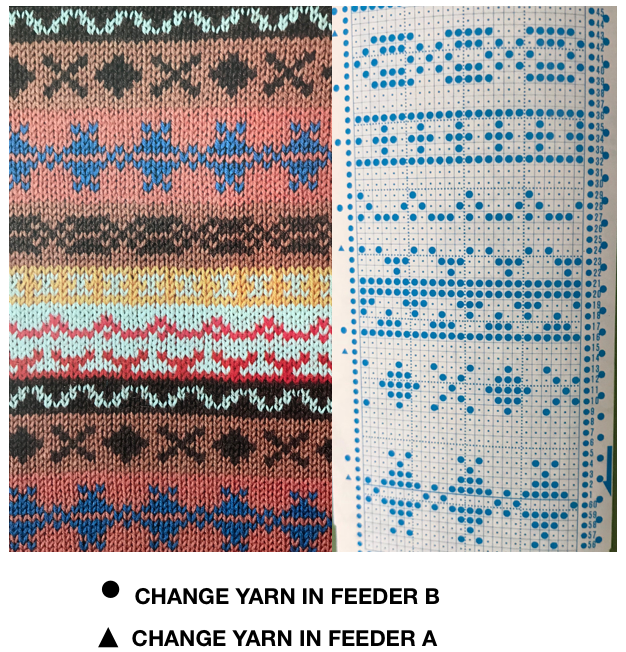

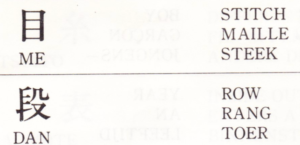

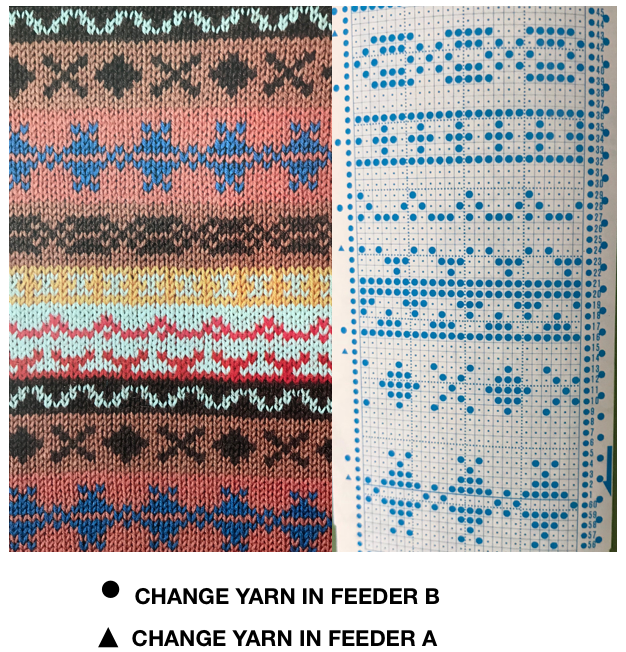

As the transition was made from manual machines to push-button, and then to punchcard selection systems, the early collections included diagrams of symbols familiar to hand knitters, and interestingly worded text that disappeared or was reduced in later punchcard books. I am presenting information in the order in which it appeared in this particular collection’s paper version, I have not found this volume in the above-mentioned sources for free download. Images are gathered from more than one source, so there is some repetition of information

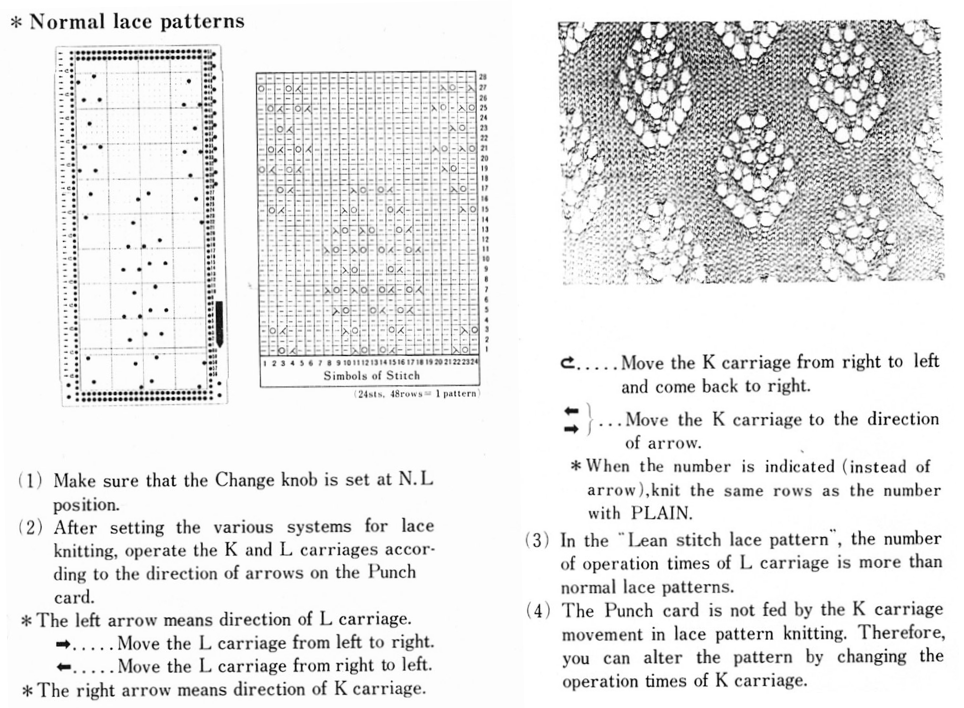

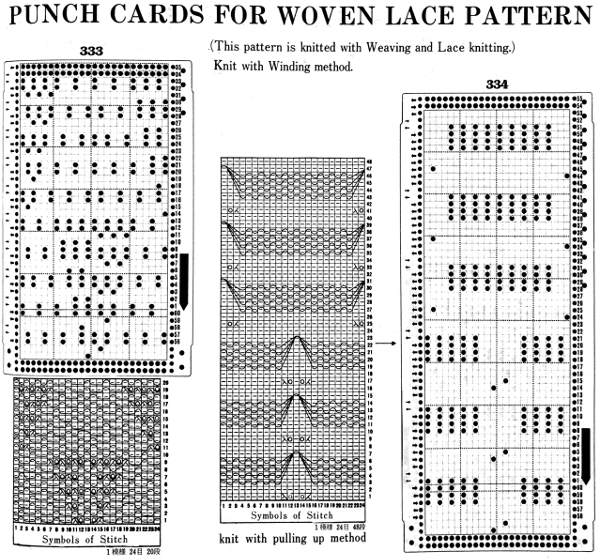

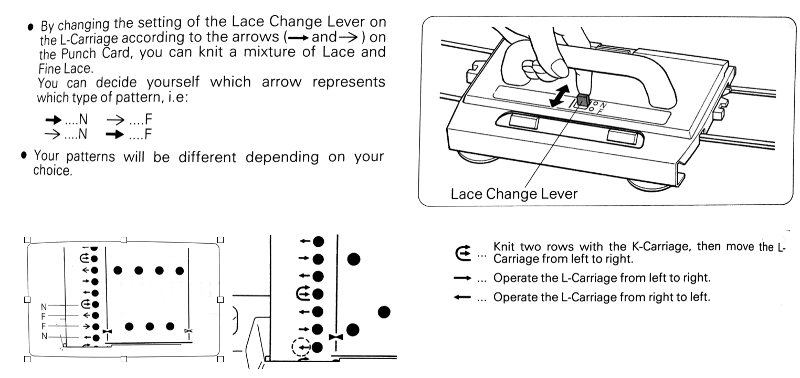

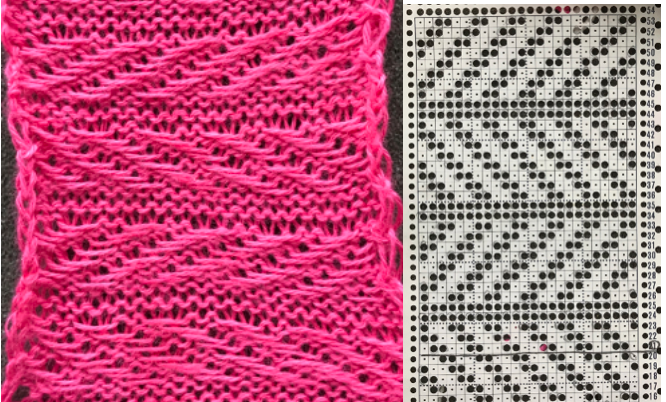

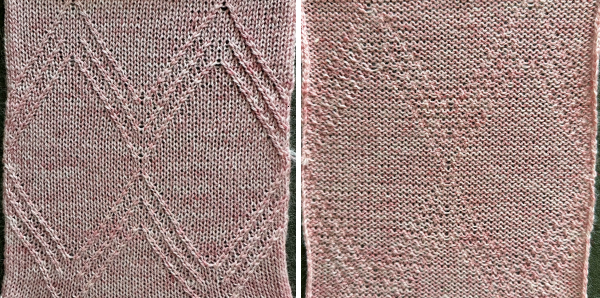

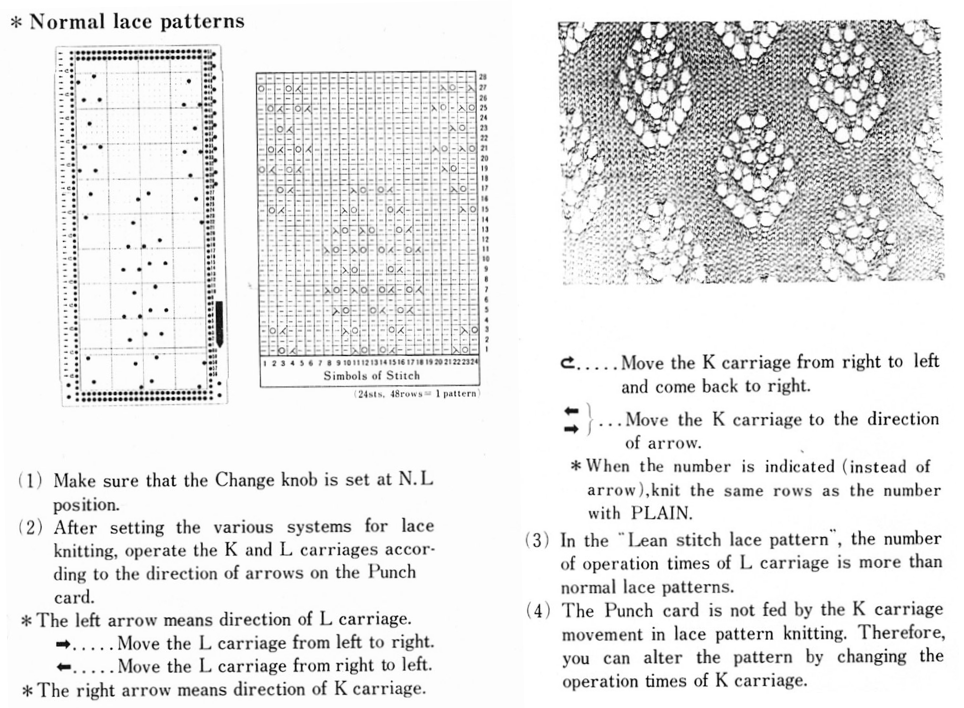

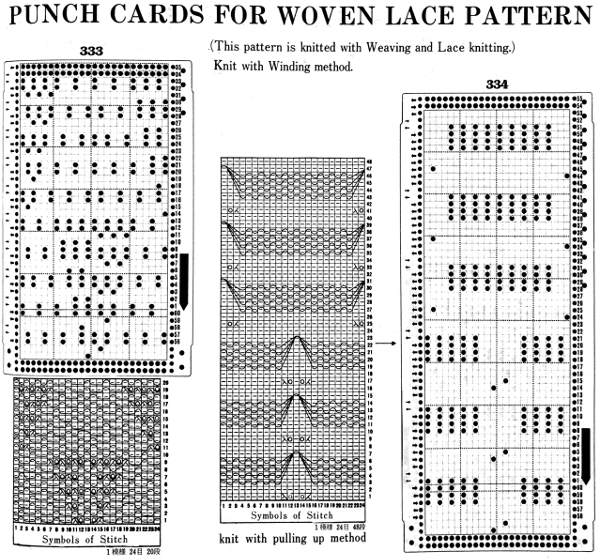

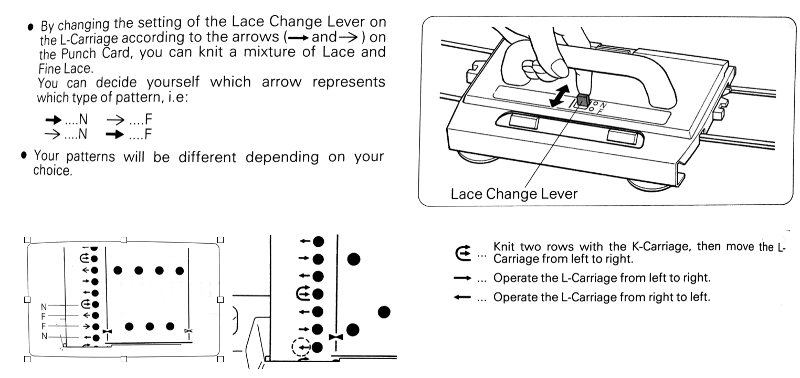

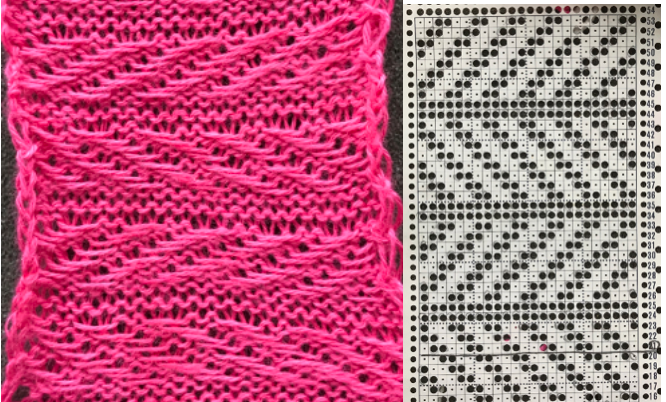

LACE KNITTING

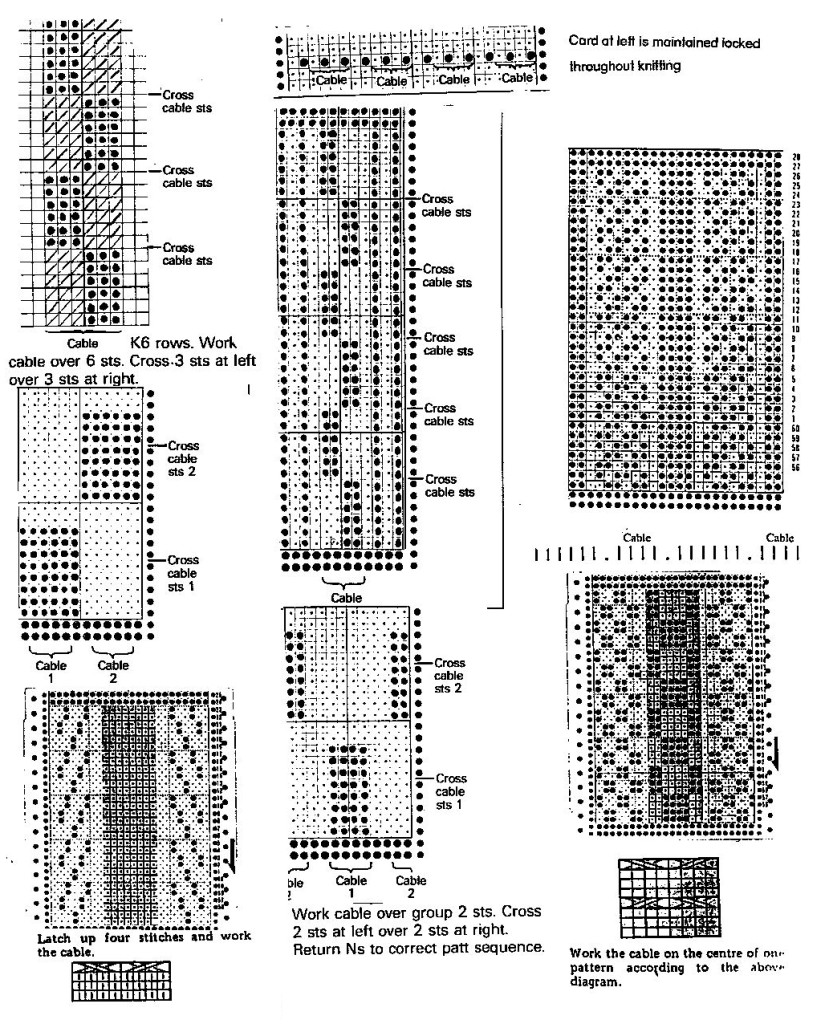

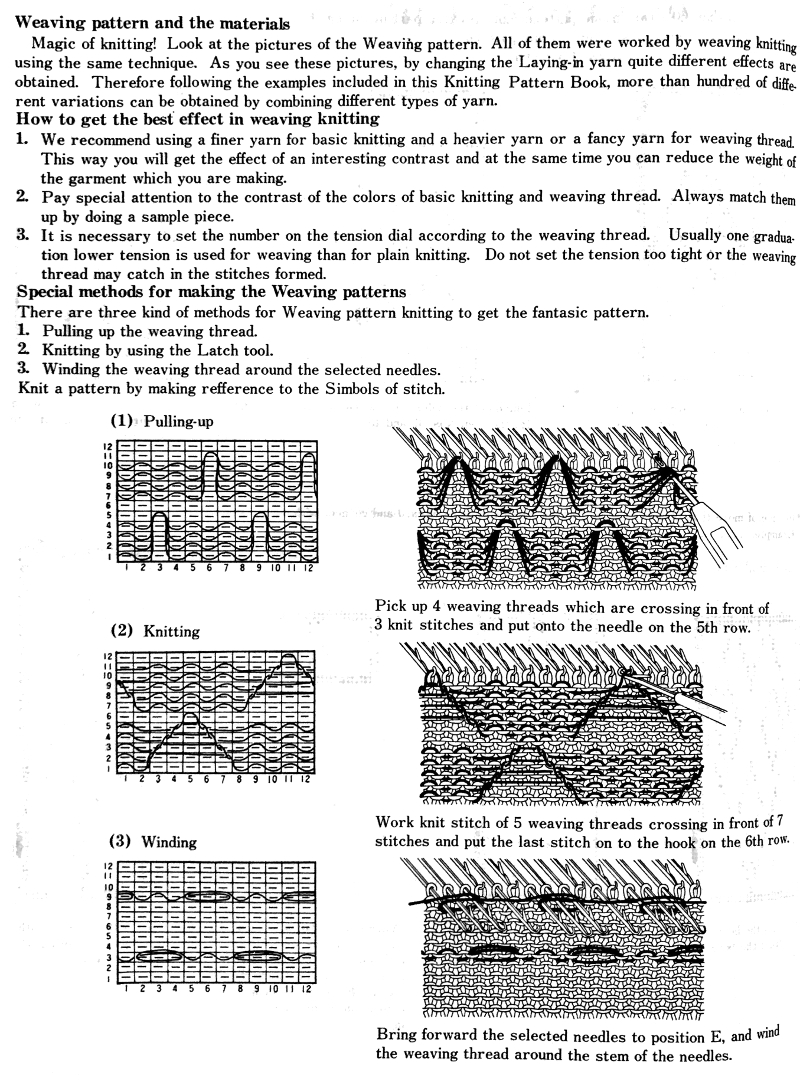

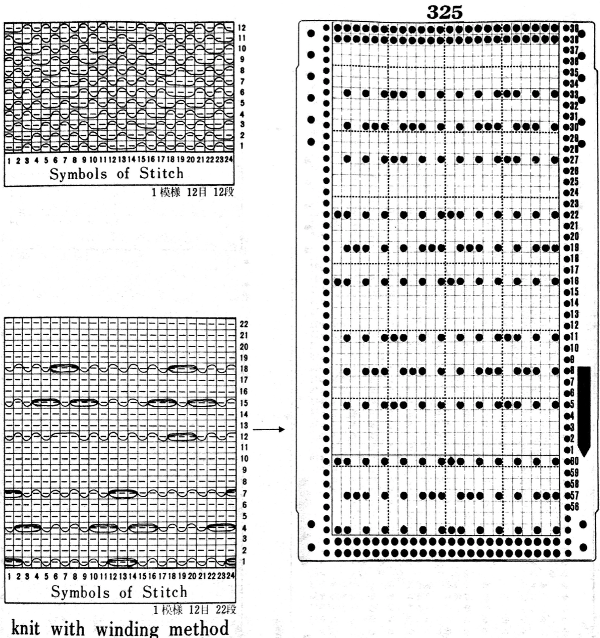

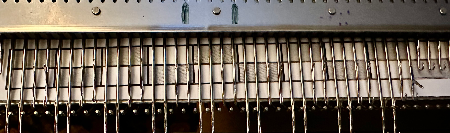

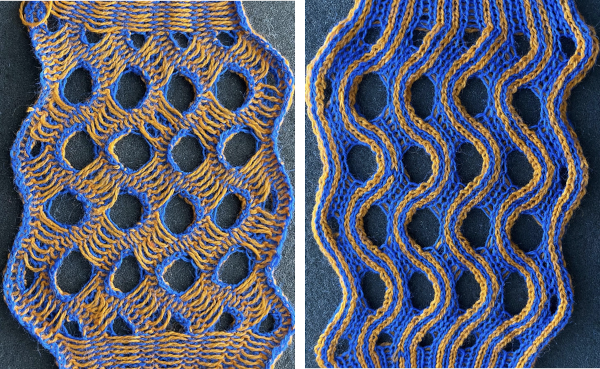

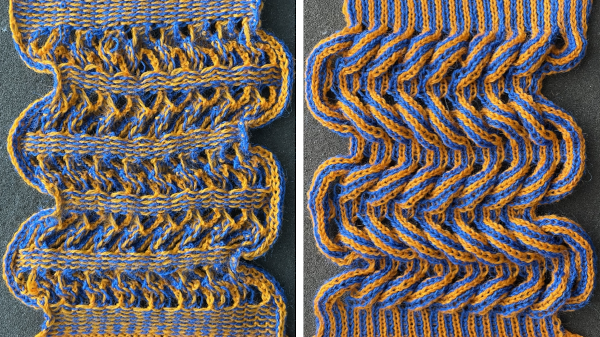

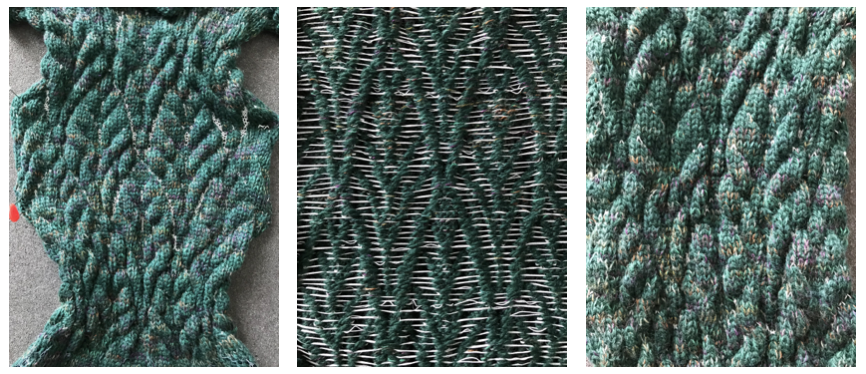

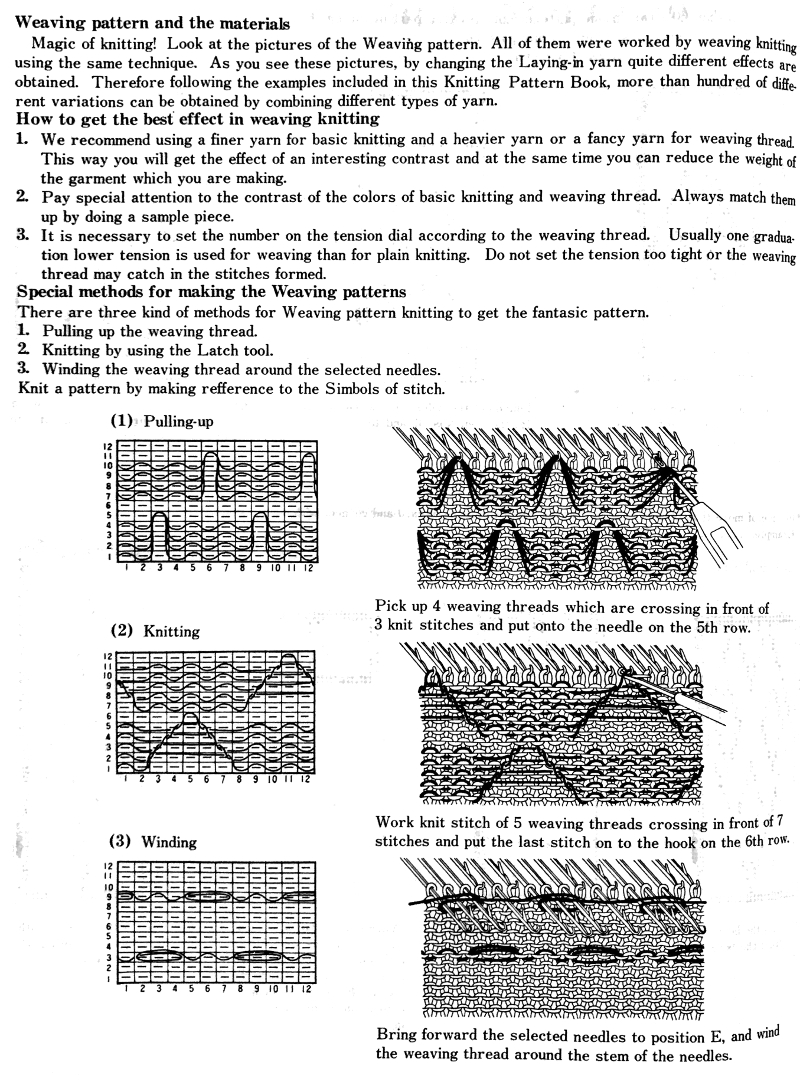

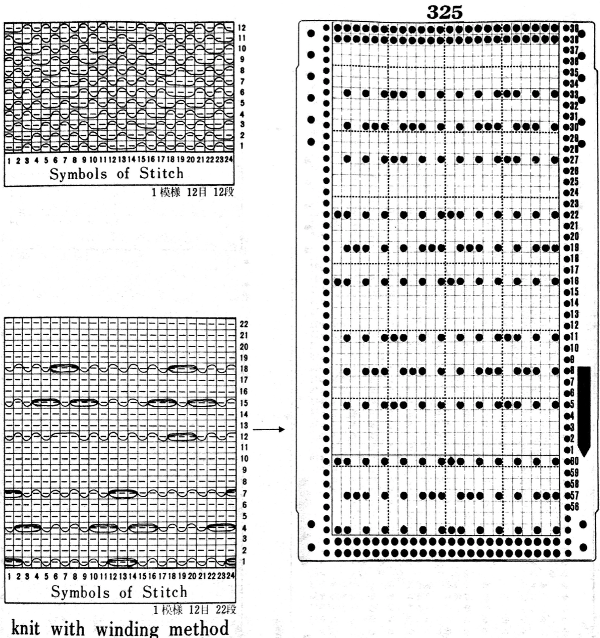

Punchcards may be used to guide one for hand techniques, here a version of e-wrap is used on selected needles for weaving effect, and the diagram on the upper left is for a different fabric. Punchcards may also be used to help track twisted stitches, cables, and racking  This is a 2 carriages patterning operation, lace extension rails must be used, with each carriage disengaged from the belt while the other is moving across the knitting and back to its resting place.

This is a 2 carriages patterning operation, lace extension rails must be used, with each carriage disengaged from the belt while the other is moving across the knitting and back to its resting place.

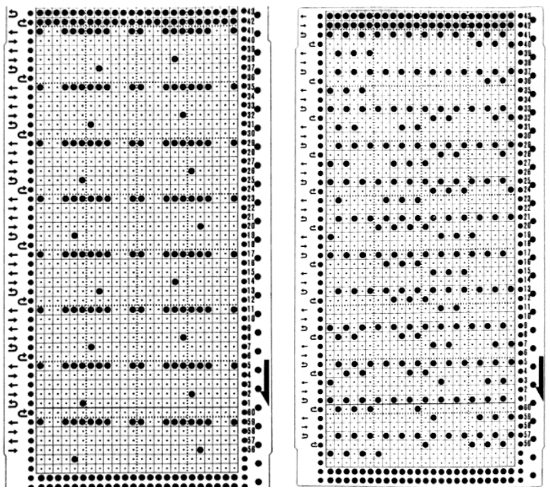

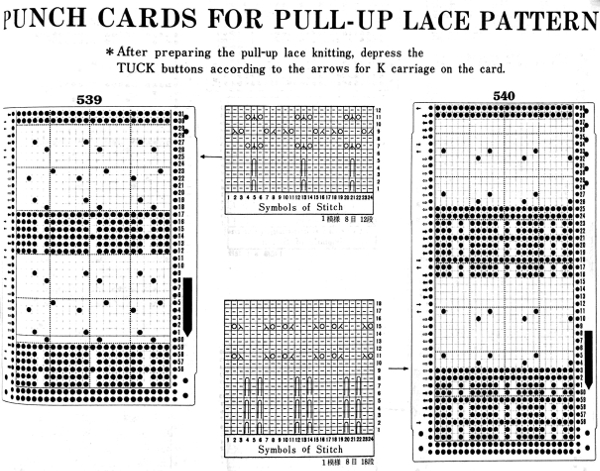

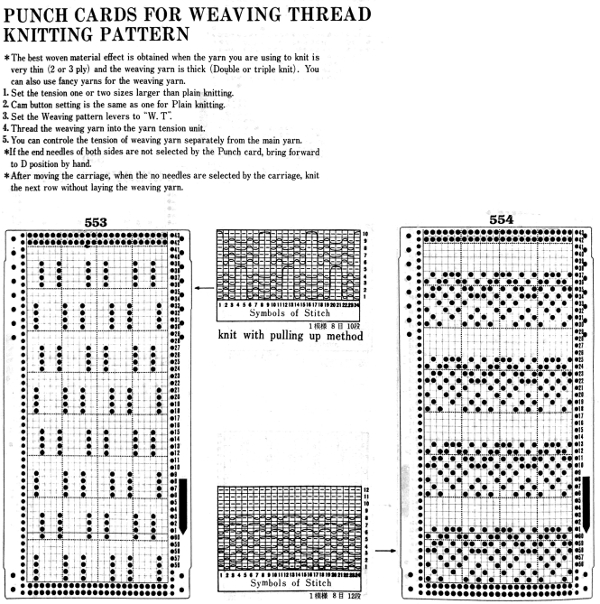

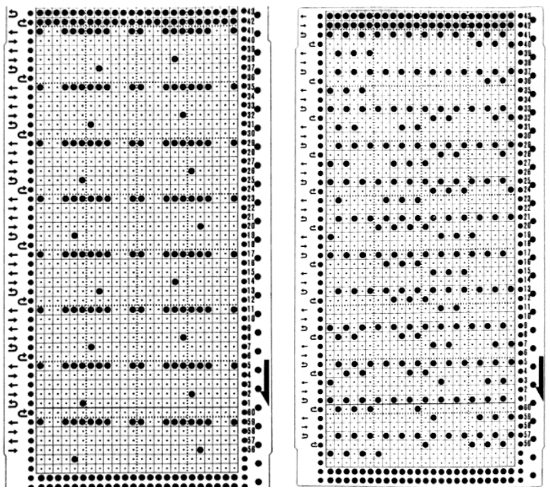

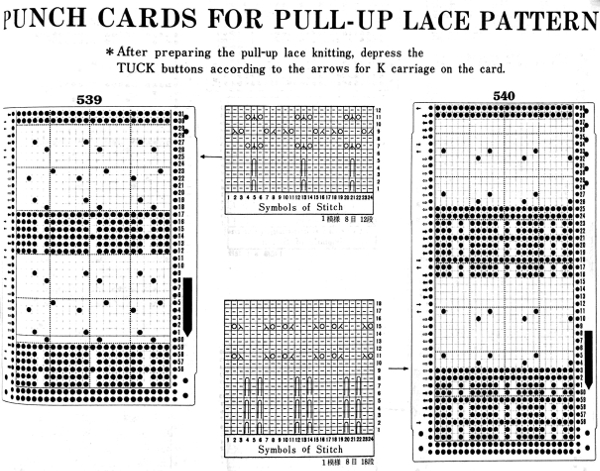

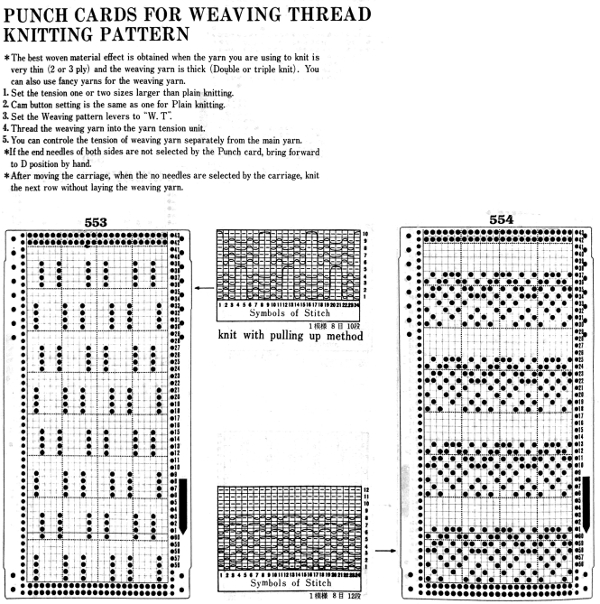

SYMBOLS IN PATTERN KNITTING

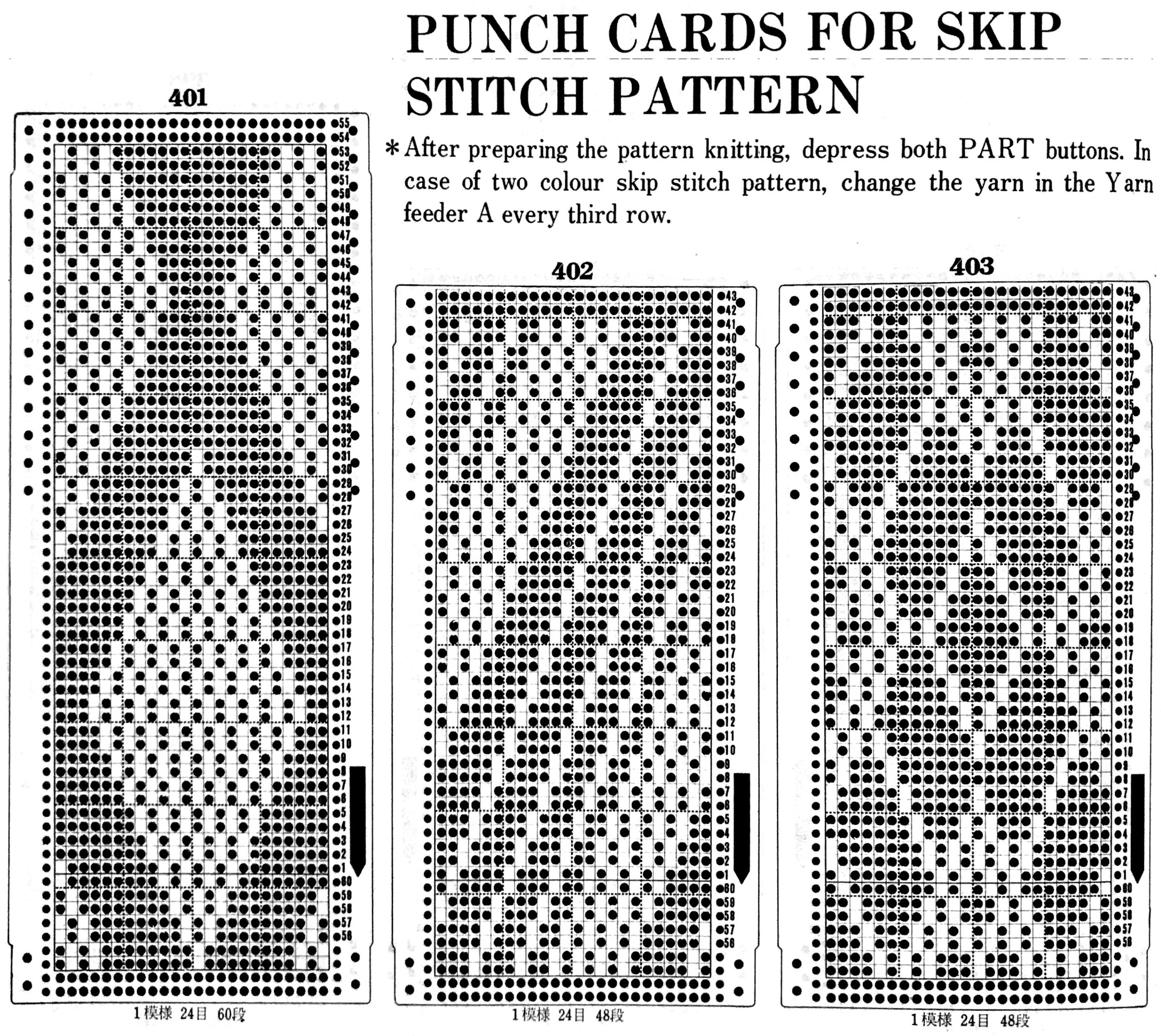

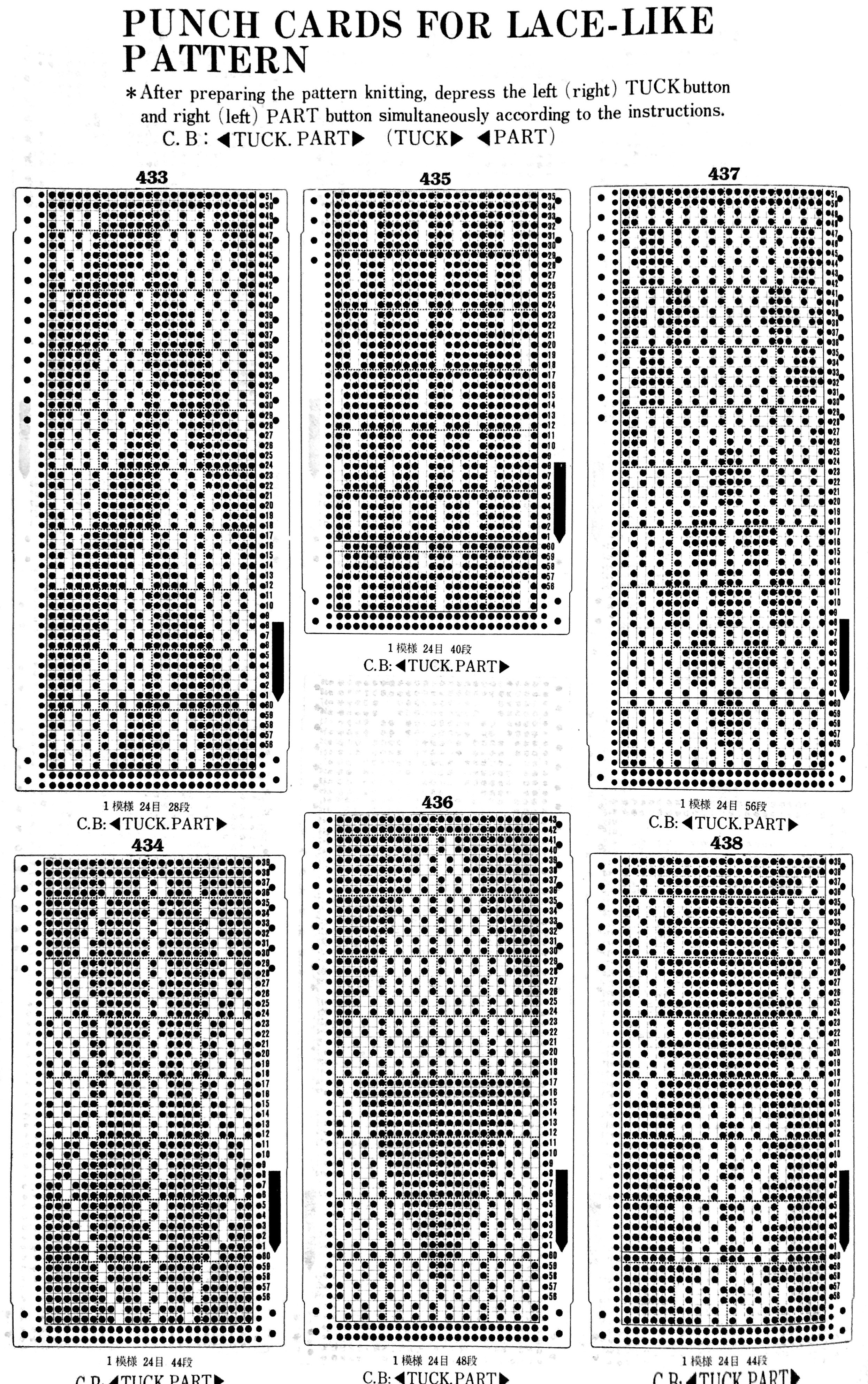

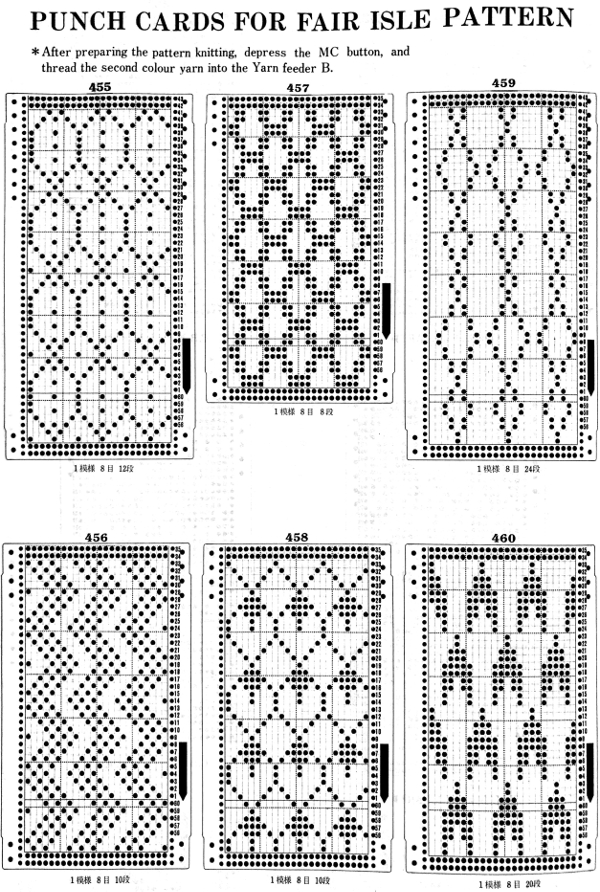

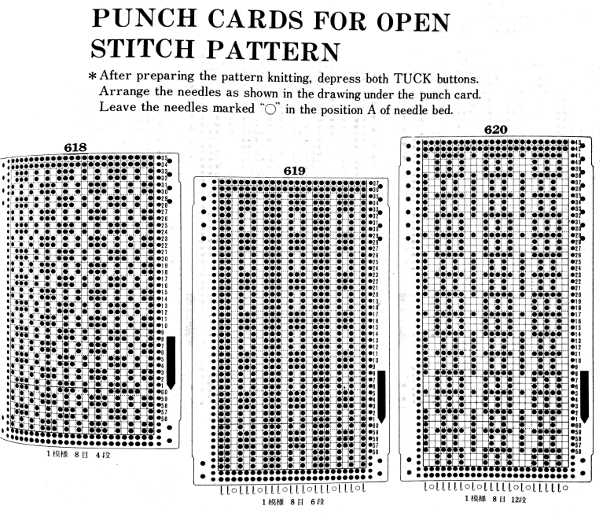

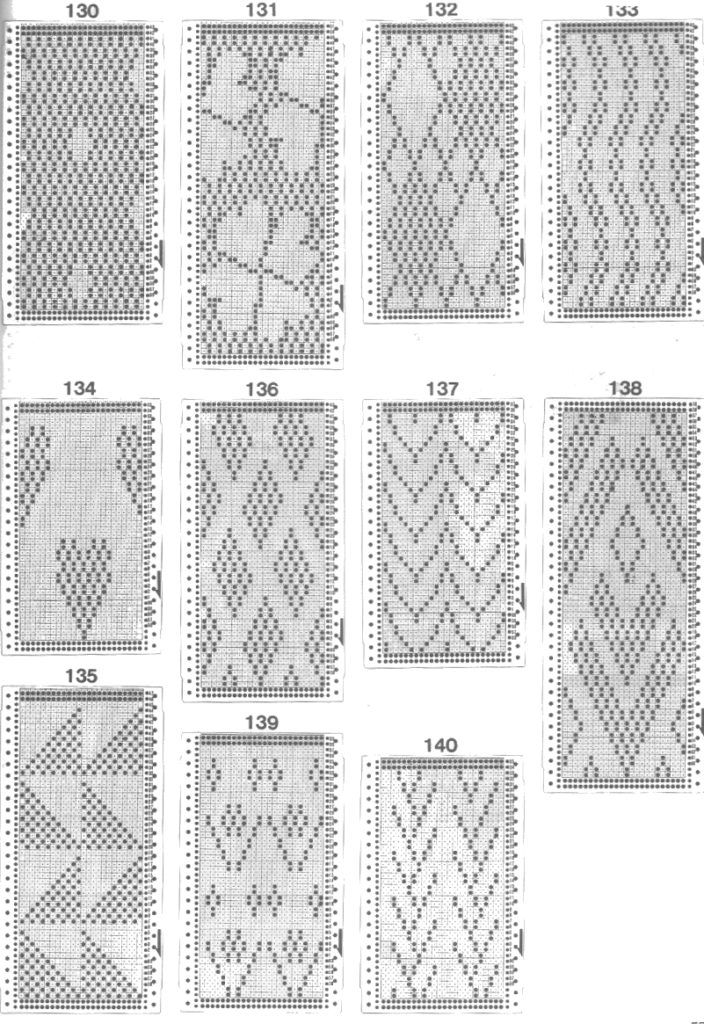

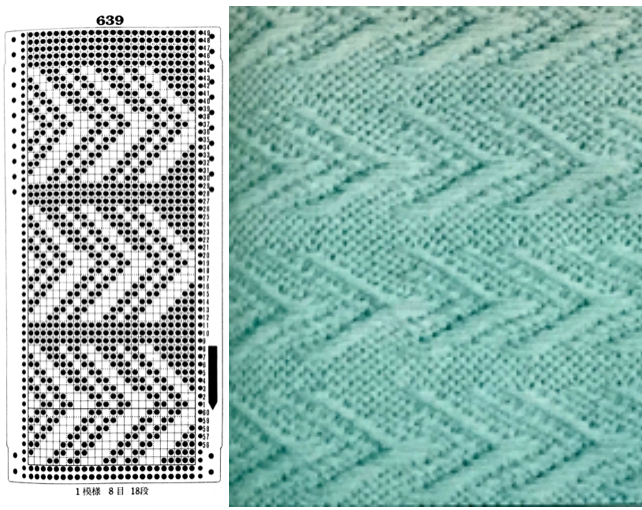

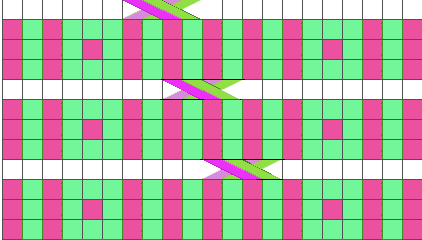

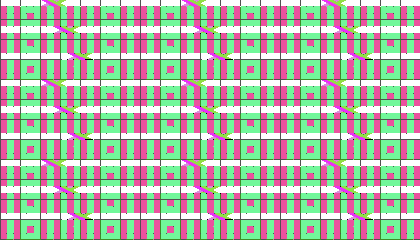

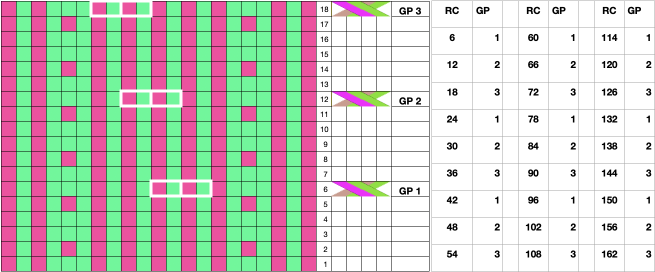

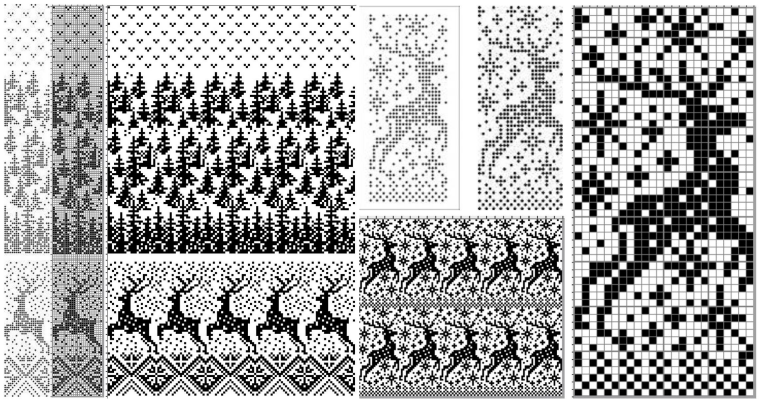

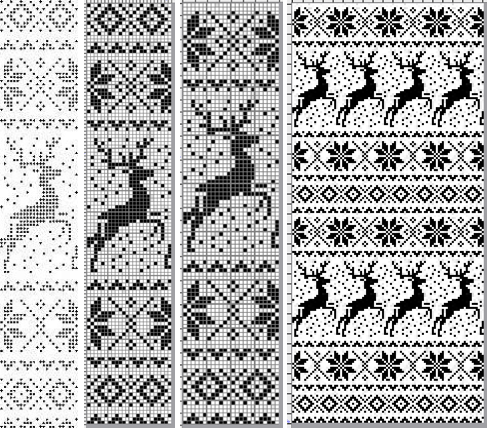

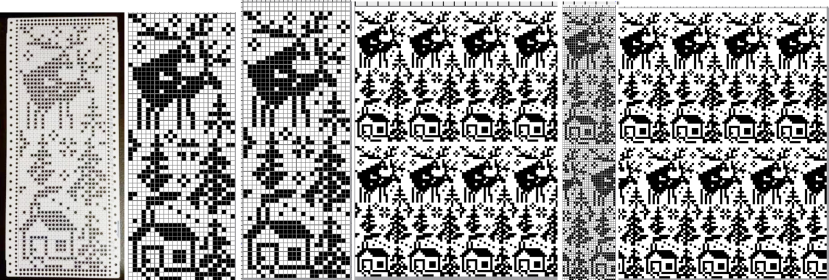

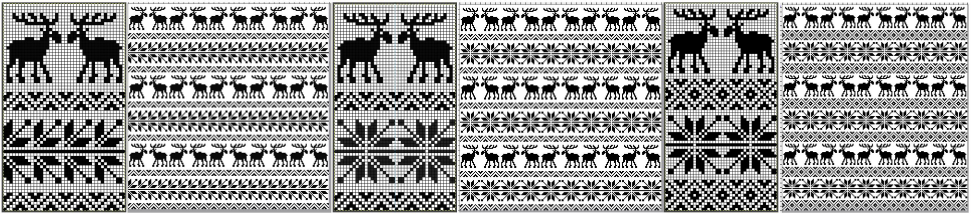

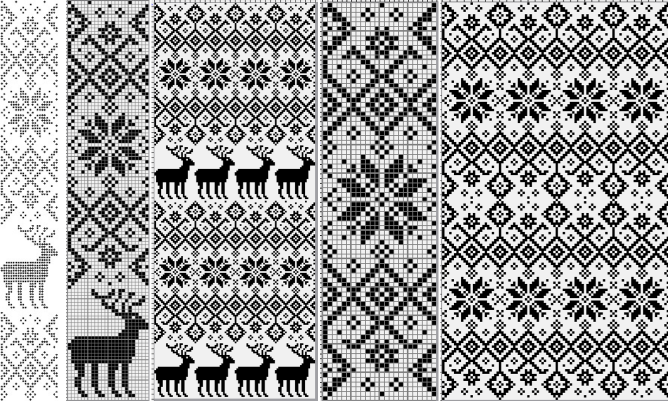

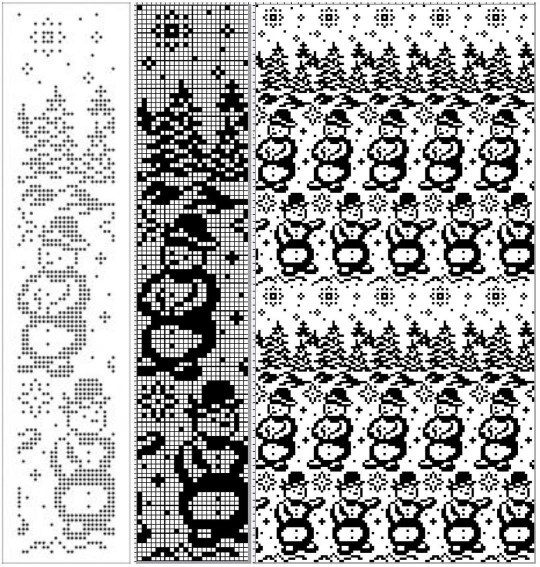

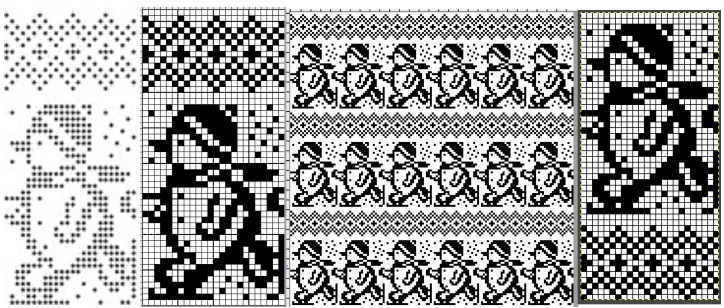

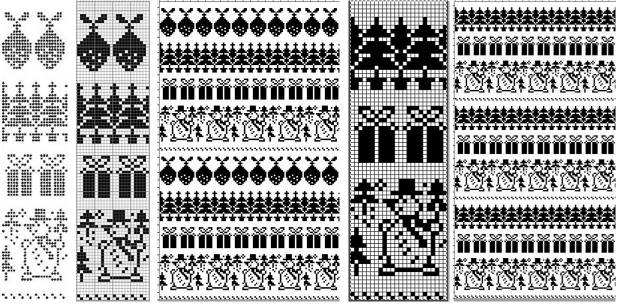

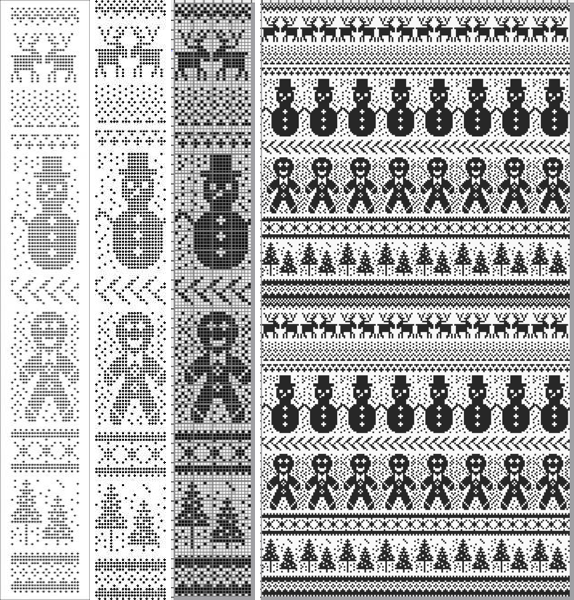

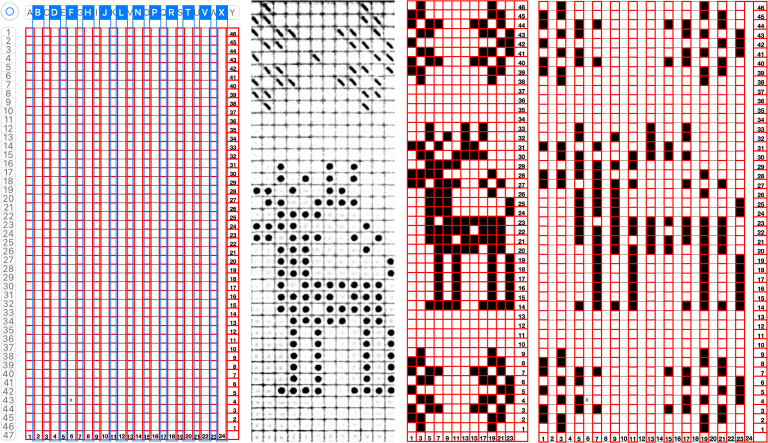

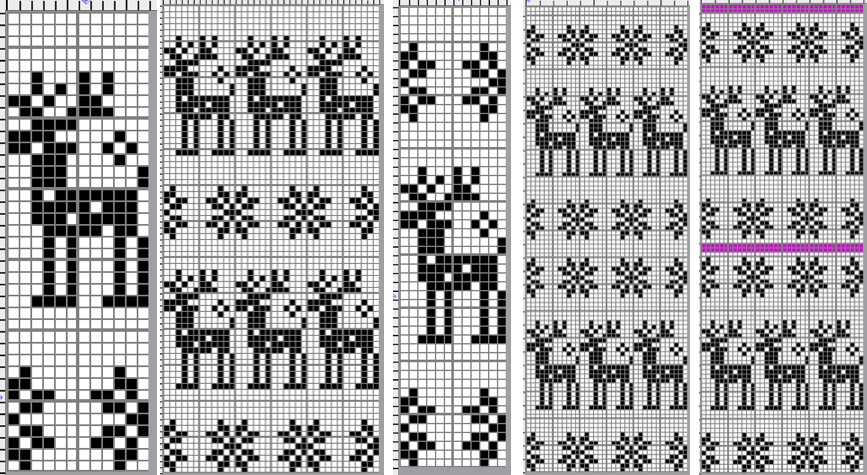

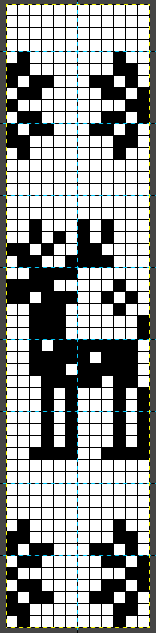

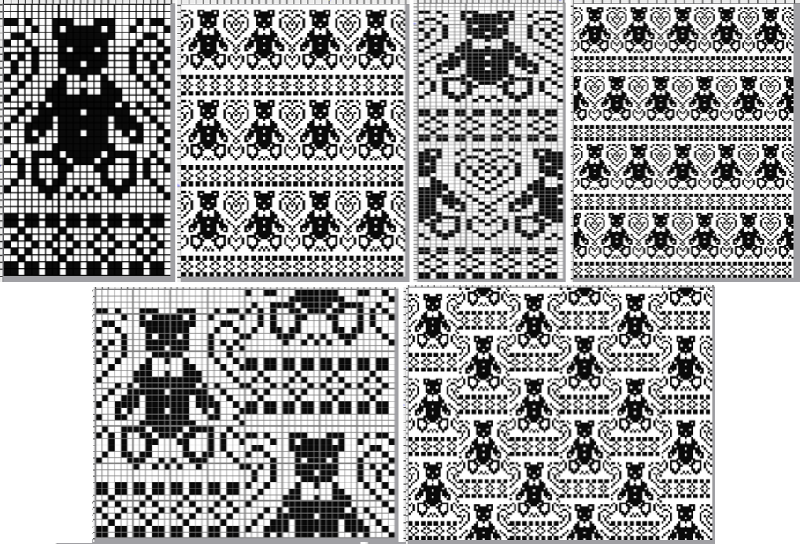

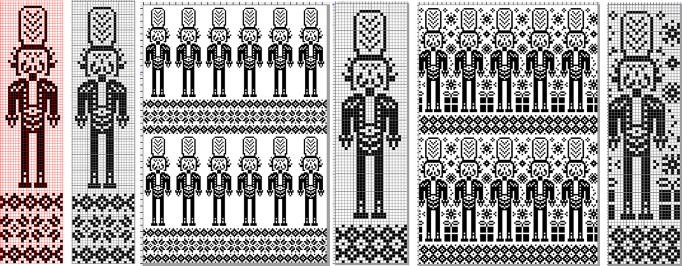

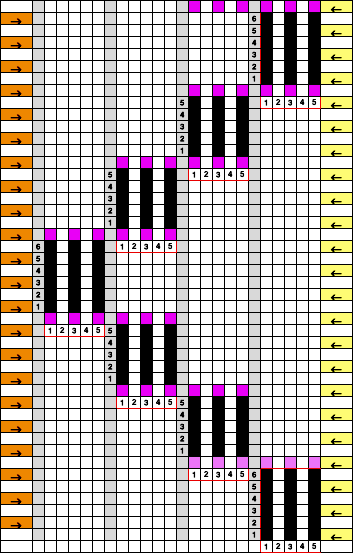

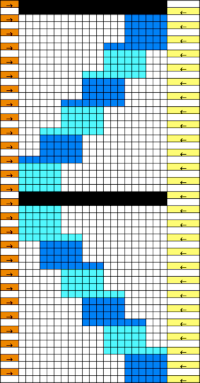

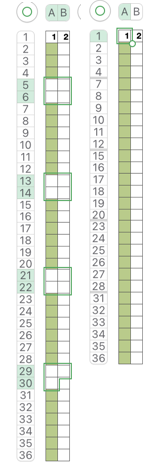

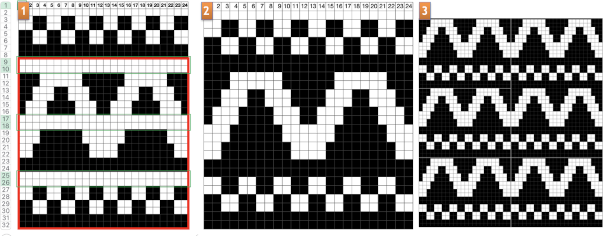

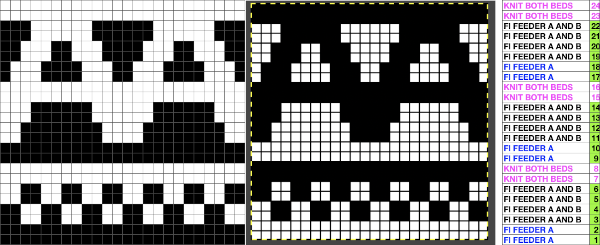

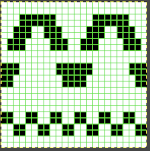

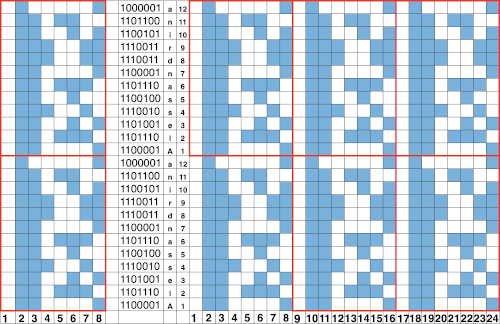

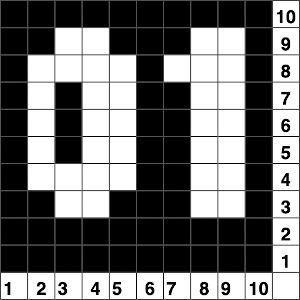

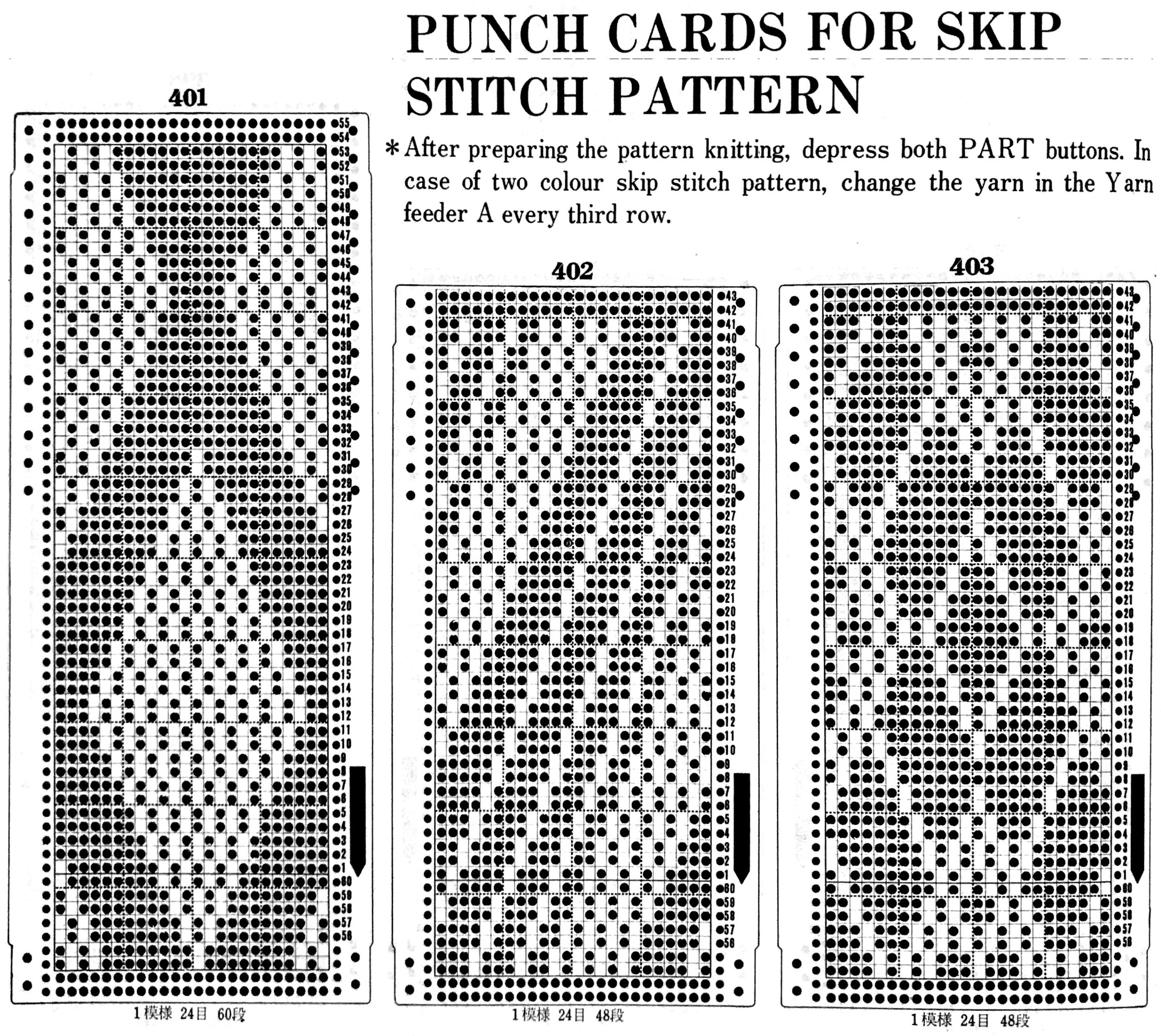

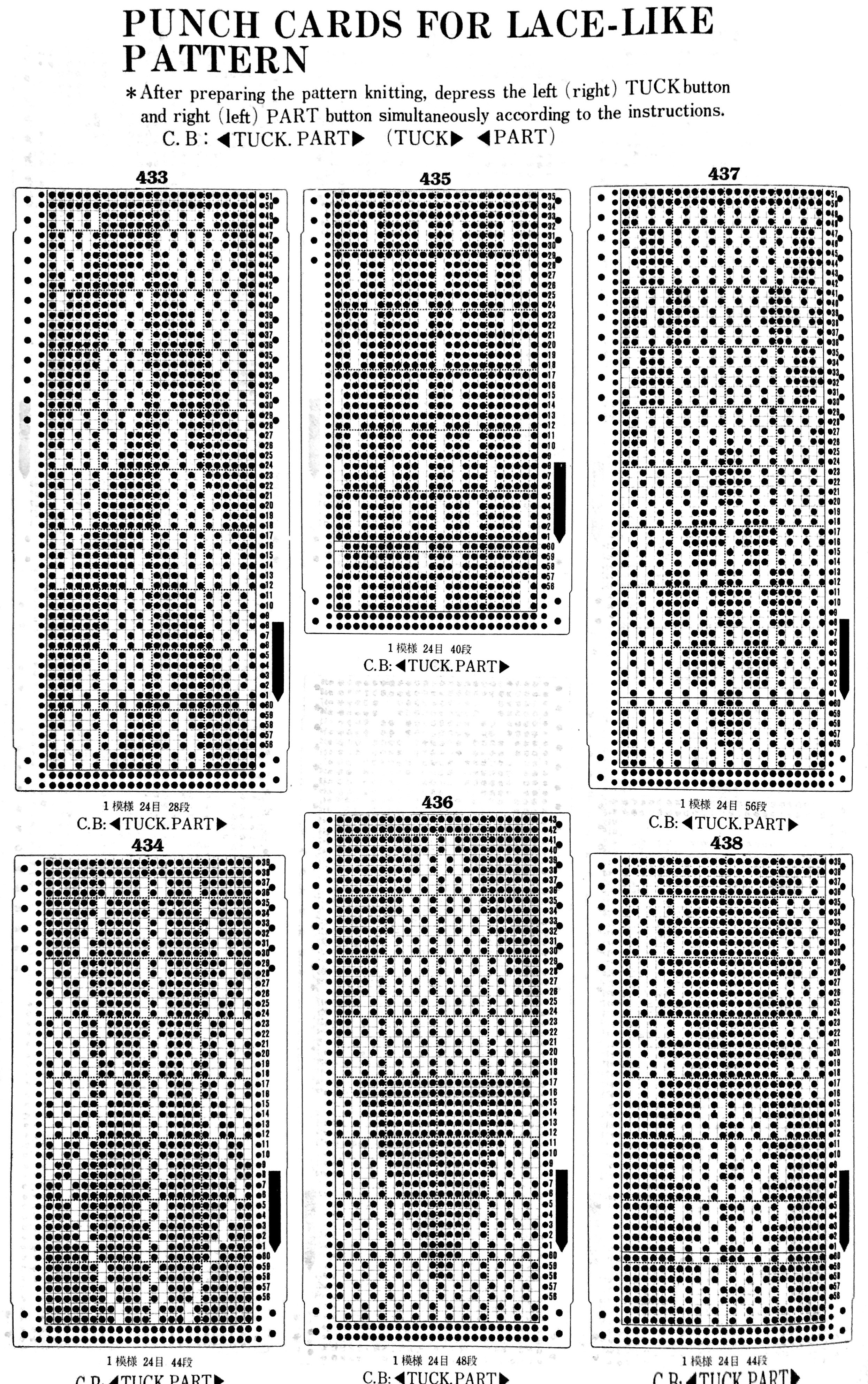

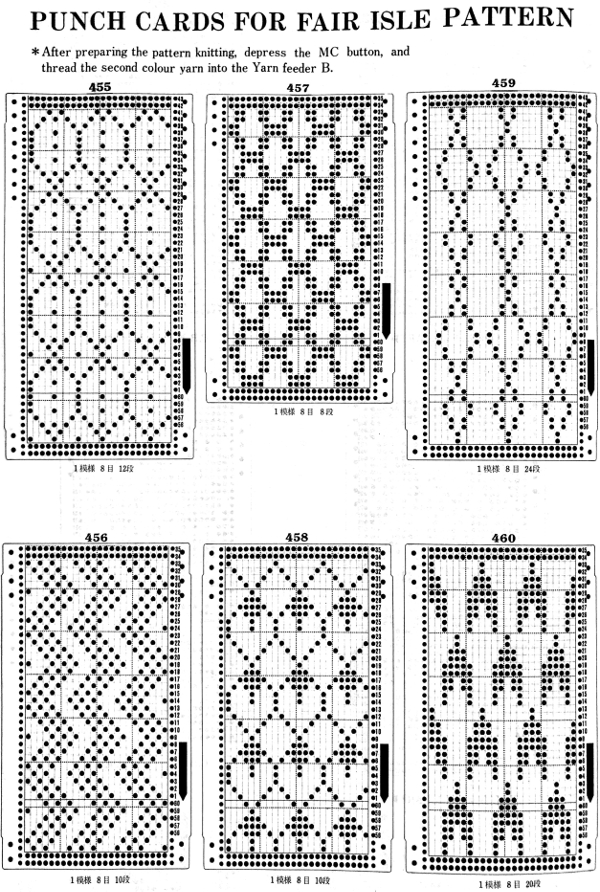

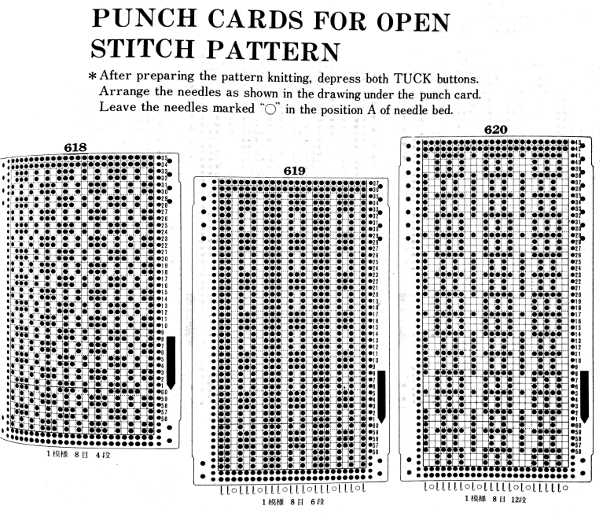

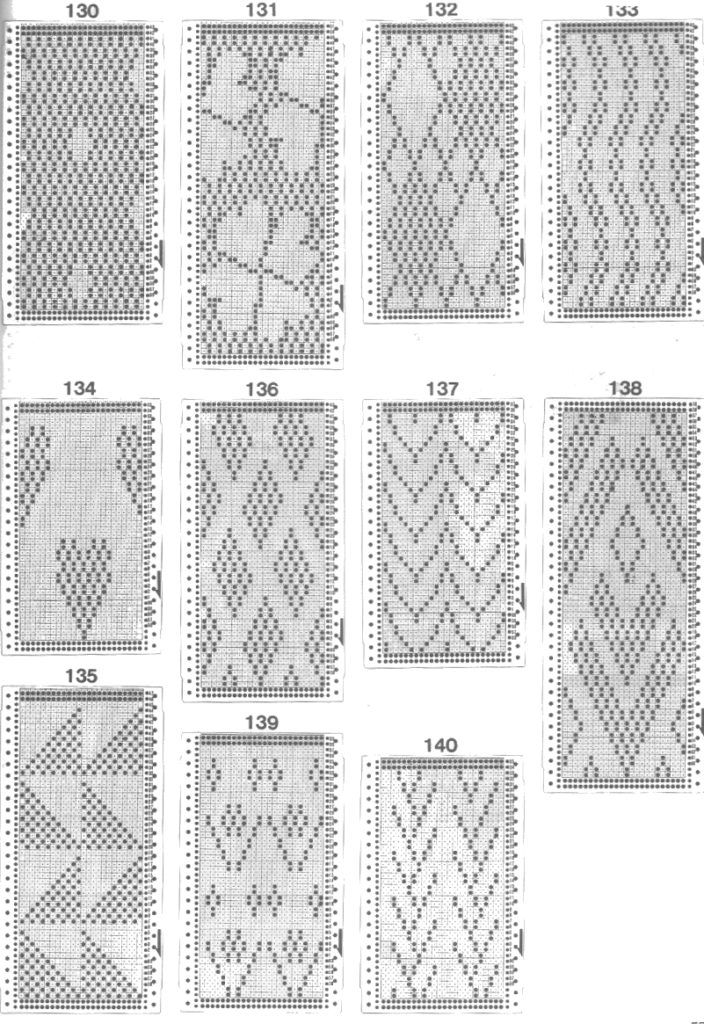

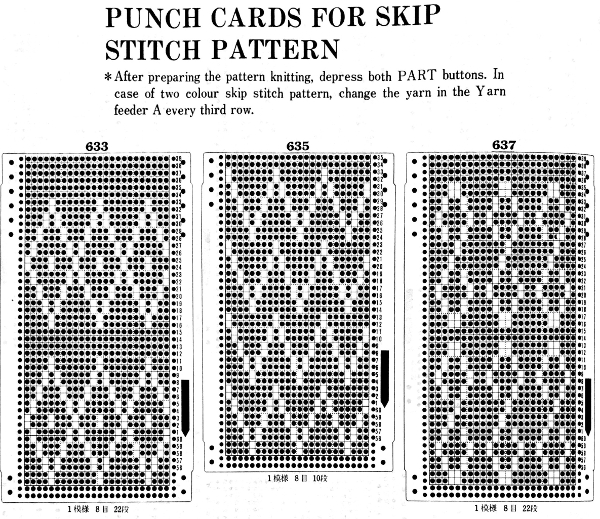

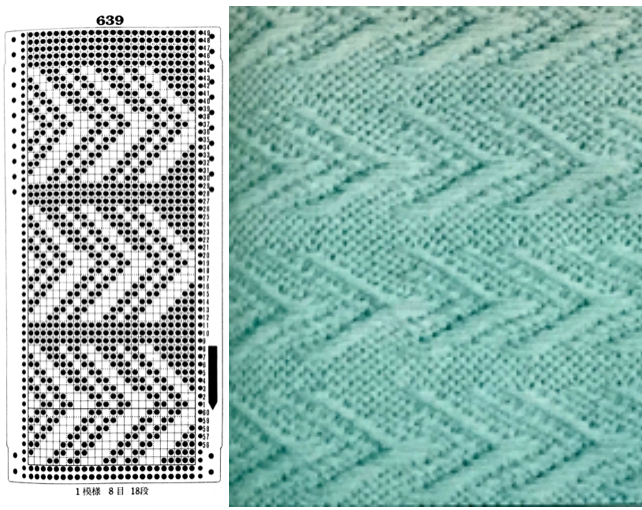

Below each punchcard, the repeat is identified in numbers for stitches and rows. The cards presented are the minimum length required for the card to roll smoothly within the reader when joined for continuous knitting (at least 36 rows). Electronic knitters may isolate the individual, smallest repeat, draw only the squares that appear as white in the cards, enter them via mylar or download, and use color reverse.

Below each punchcard, the repeat is identified in numbers for stitches and rows. The cards presented are the minimum length required for the card to roll smoothly within the reader when joined for continuous knitting (at least 36 rows). Electronic knitters may isolate the individual, smallest repeat, draw only the squares that appear as white in the cards, enter them via mylar or download, and use color reverse.

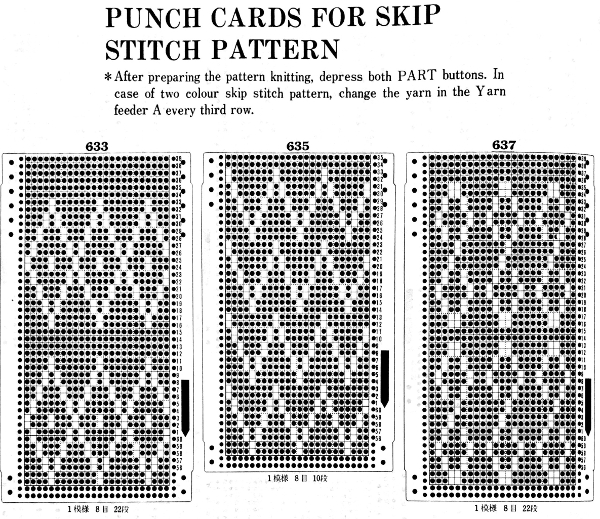

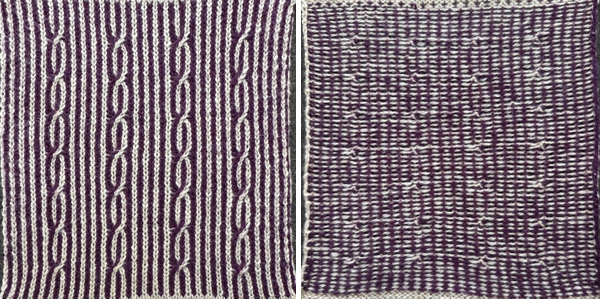

Skip is aka slip or part. These cards would work for tuck stitch as well, may even tolerate elongation, depending on yarn thickness.

Opposite cam buttons are in use, the fabric changes appearance depending on which of the 2 stitch types is forward, so if instructions with cards are to be followed, then the starting side for the attern in this instance should be COR. Both tuck buttons (or slip) may be used as well, for a different fabric. If the tuck or slip texture is created over an even number of rows (2, 4), changing colors for each paired row sequence can create some interesting color patterns with very short floats akin to planned mosaics and mazes.

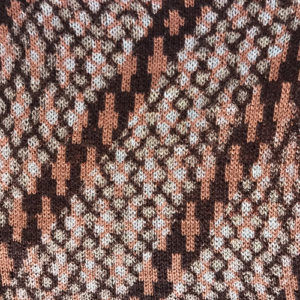

The fair isle patterns below are actually poor choices in terms of float control, pushing its limits. It is usually recommended that floats be no wider than 5 stitches, and even then, they may have to be controlled to make the finished garment easier to wear.

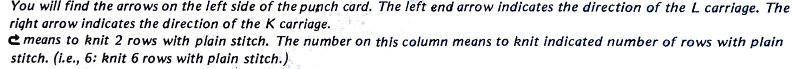

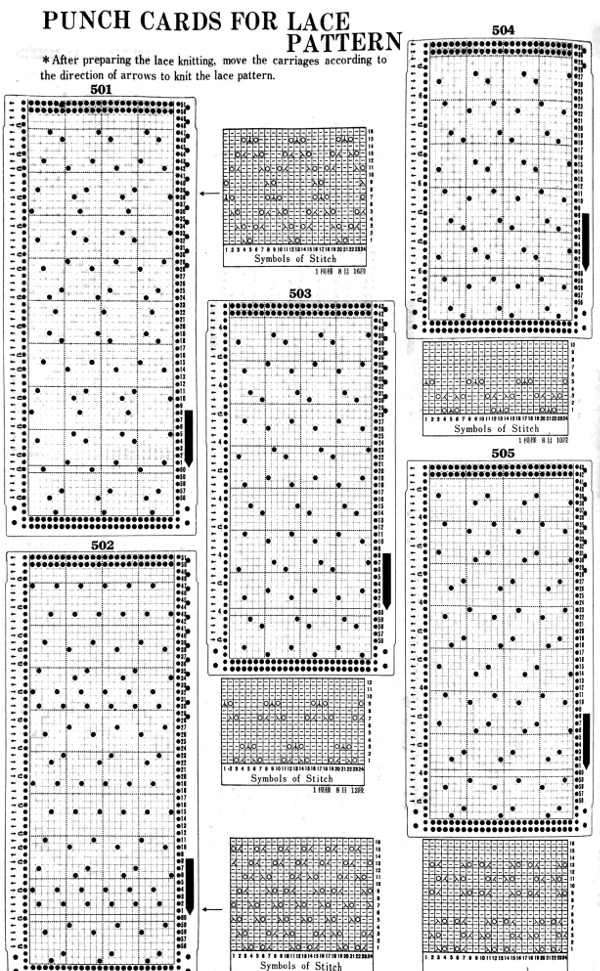

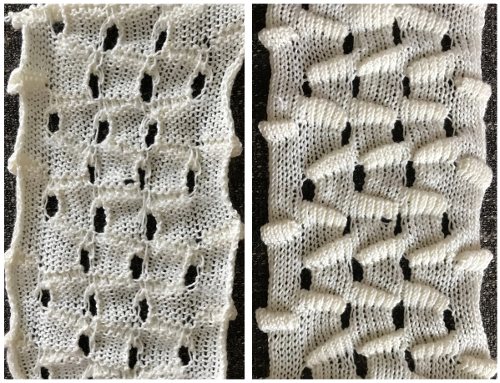

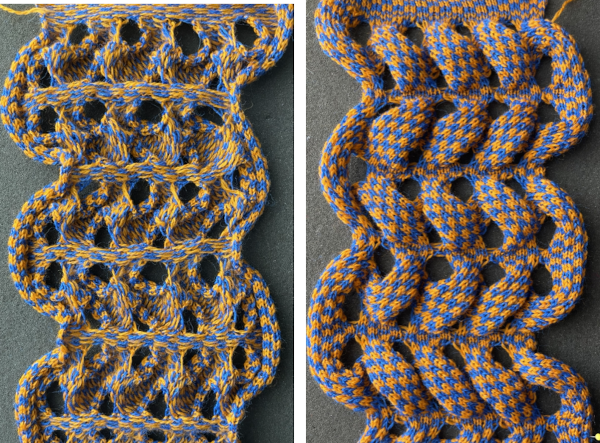

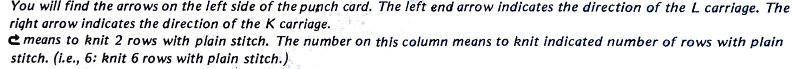

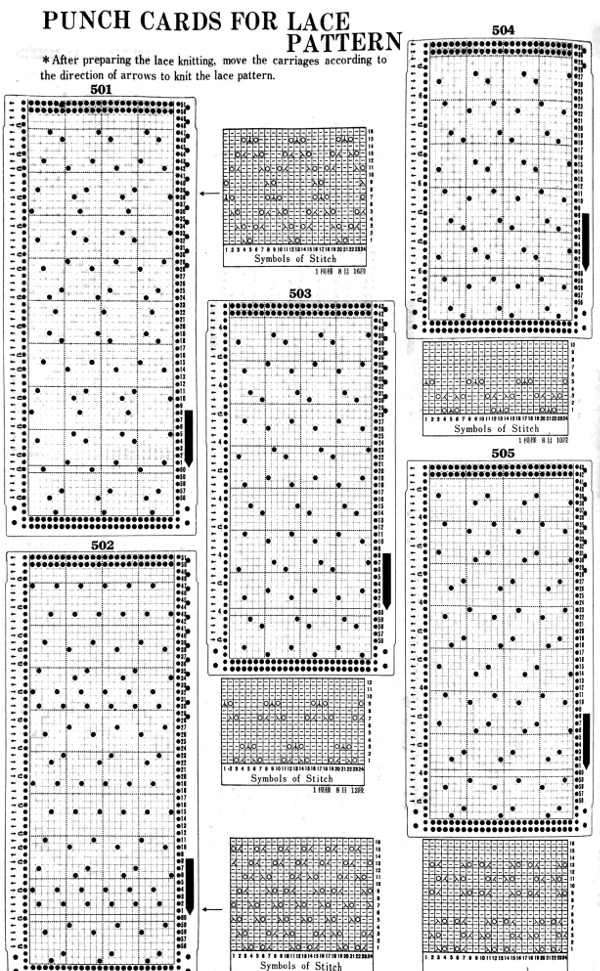

Brother only produces a transfer lace (as opposed to studio simple lace, where the carriage transfers and knits with each pass of the carriage). The lace carriage is the one advancing the punch card. The knit carriage does not select needles, but rather, knits 2 (or more) plain knit rows

Lace card markings, including those for fine lace: in the latter, stitches are transferred and shared between pairs of needles, best knit in a light color, with smooth yarn so the surface texture becomes more noticeable.

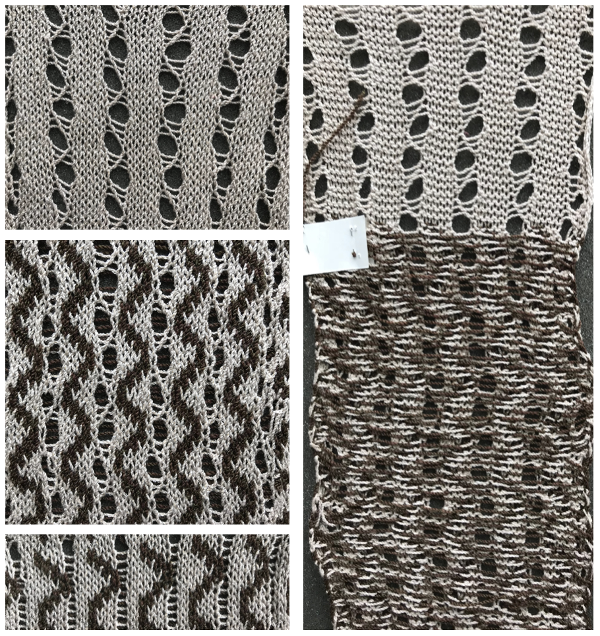

Lace point cams may be used on the punchcard machine to create vertical bands of lace. This is also achievable on the electronic by programming for knit stitches between vertical (or horizontal bands).

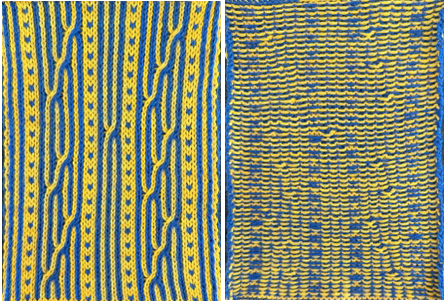

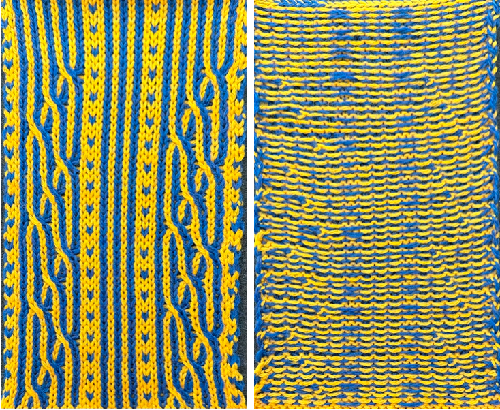

Tuck (left) and weaving (right) may be combined with lace. In these fabrics both carriages are selecting needles, so extension rails must be used. The two-column on the left of the cards indicate movements for the lace carriage on left and the knit carriage on right. Straight arrows indicate single carriage passes, curved ones 2.

Yet another fabric using 2 carriages selecting needles for patterning

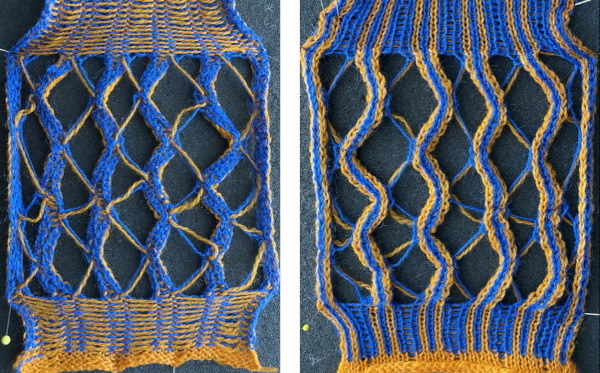

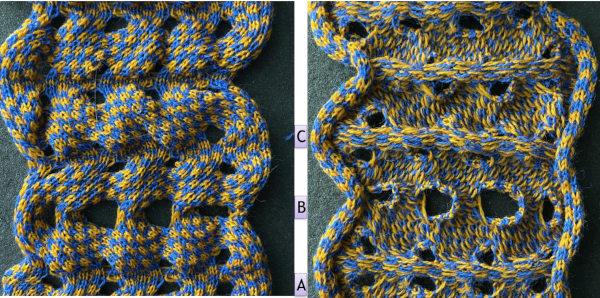

Here the “openness” is created by having the appropriate needles out of work, creating ladders in those spaces. Some interesting results can be obtained by transferring the recommended out of work needles’ stitches to the ribber. “air knitting” can help with verifying proper needle placement is in use

to match the location of the out of work needles to markings for punchcards, which are often given with lines delineating 0 needle position, the image will need to be mirrored horizontally

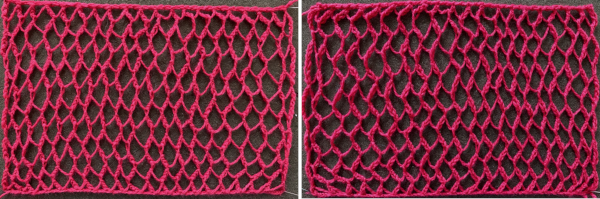

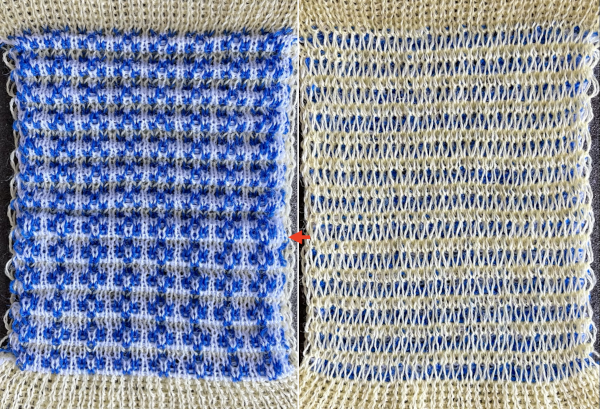

THREAD OR PUNCH LACE is possible only on machine models that have 2 buttons in mc position  The thicker yarn knits along with the thinner one where there are unpunched areas or white squares, the thinner yarn knits alone where the punched holes or black squares occur, with the thicker yarn floating behind it

The thicker yarn knits along with the thinner one where there are unpunched areas or white squares, the thinner yarn knits alone where the punched holes or black squares occur, with the thicker yarn floating behind it  more information on this fabric

more information on this fabric

Suitable for tuck and possibly tolerant of elongation as well:

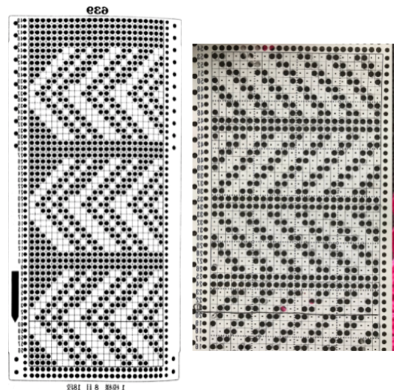

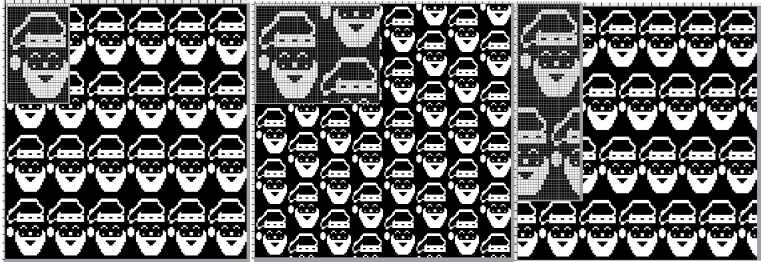

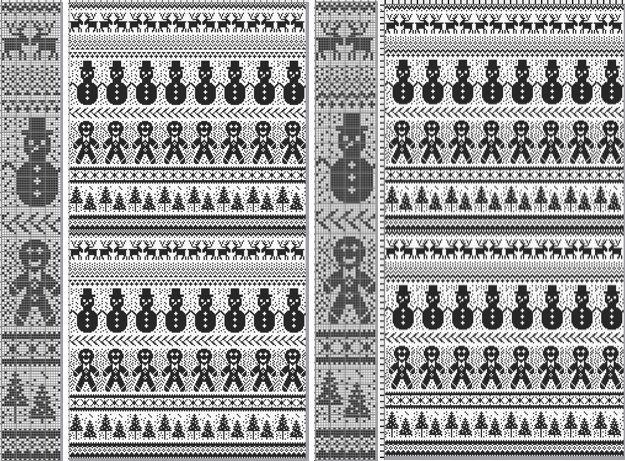

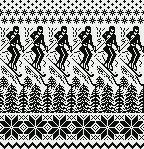

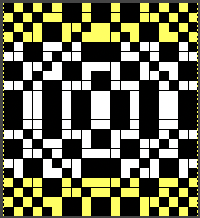

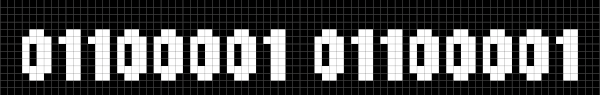

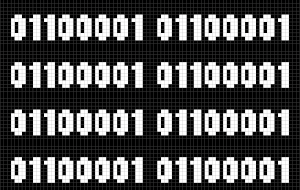

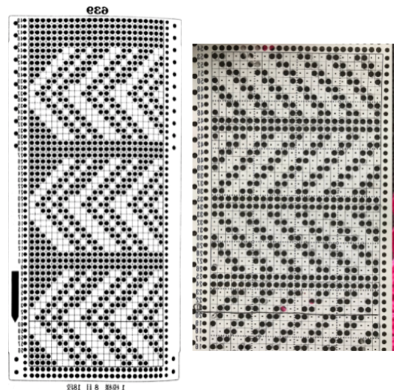

Punchcard machines mirror motifs when knit. This may not be noticed when copying small repeats, but it becomes more evident in larger ones. For knitting on the 910, the supplied motif would need to be mirrored when programmed to retain the intended direction. With other machine models, one needs to know whether the “image” on the card will appear on the purl side, matching punchcard pattern and needle selection, or the knit side, thus reversing it.

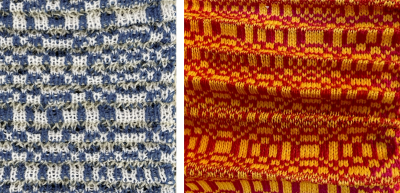

Here are 2 FI samples: the one on the left is fairly evenly distributed, so little if any difference is noticed, the one on the right sends the biker to a different forest

reversal of lettering

reversal of lettering

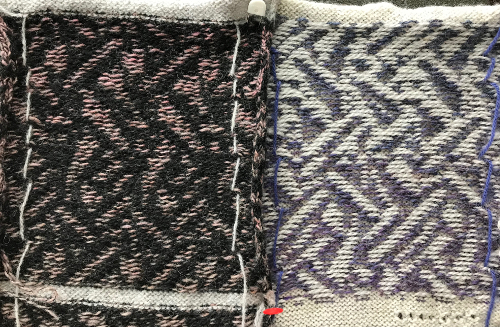

When you think that that is all sorted out in your head, there are these in slip stitch, the direction of stitches matches, because the purl side is used, images are reversed on the knit side.

When you think that that is all sorted out in your head, there are these in slip stitch, the direction of stitches matches, because the purl side is used, images are reversed on the knit side.

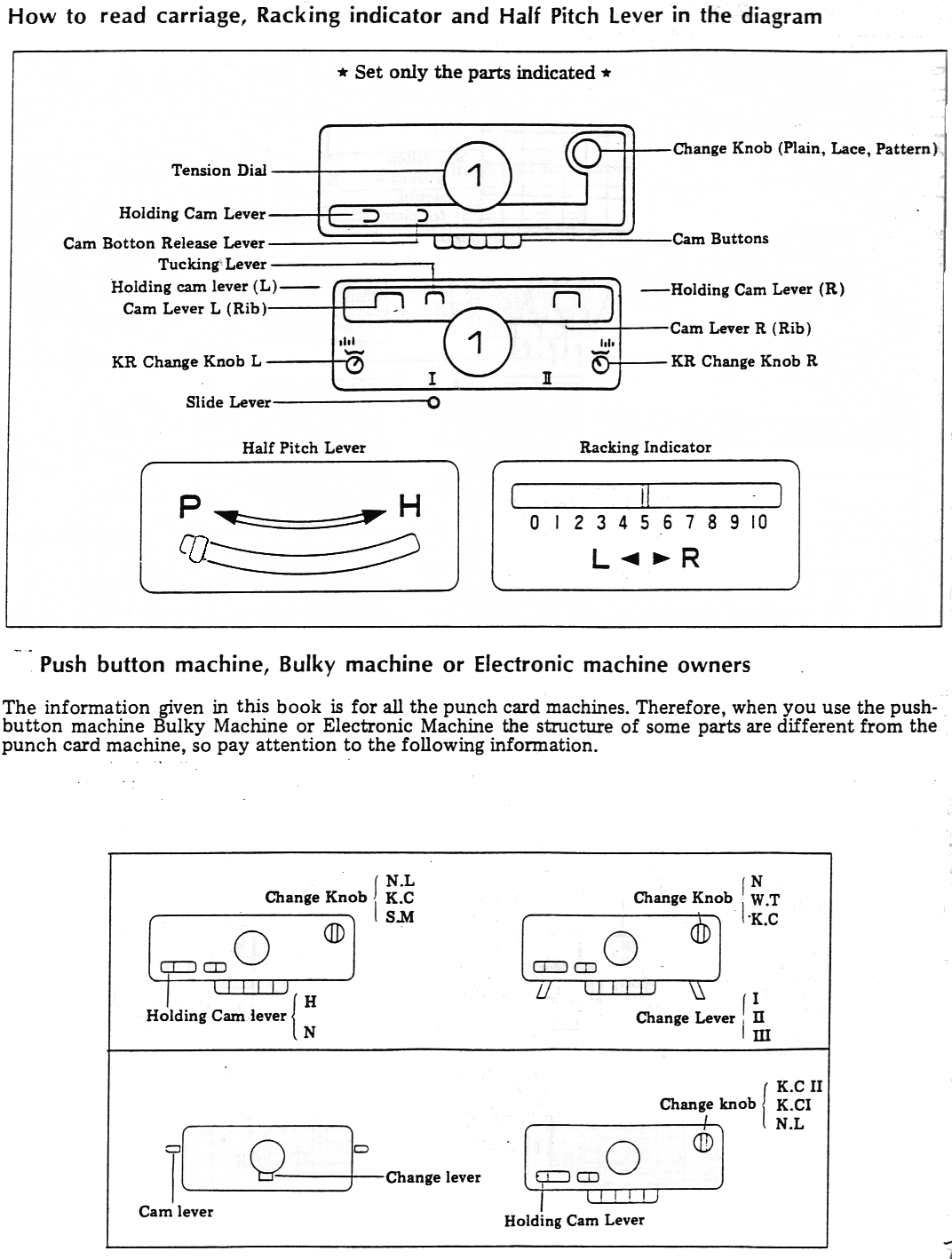

the mirrored punchcards  the punchcard change knob has selections for single motif and pattern knitting (KC)

the punchcard change knob has selections for single motif and pattern knitting (KC)

the 910 has settings KC I and II, KC II cancels end needle selection, while in punchcard machines this has to be done manually if the pattern stitch requires it. One such example is when any patterns are made with needles out of work. End needle selection would make the needles on each side of the empty space select forward and create a knit stitch. In tuck or slip, that would be an out-of-pattern knit stitch, in FI, a vertical line of the color in the B feeder would appear along on each side of the OOW needles.

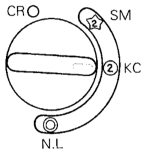

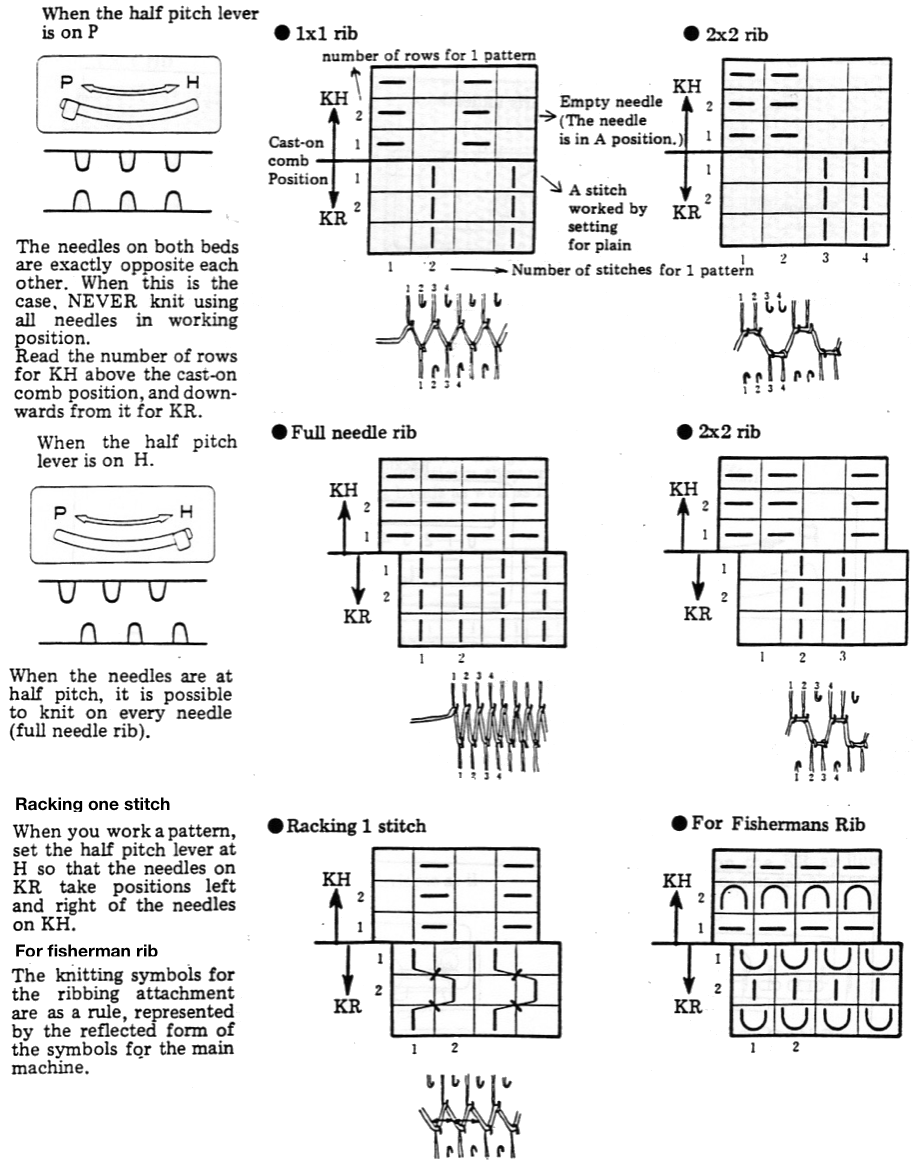

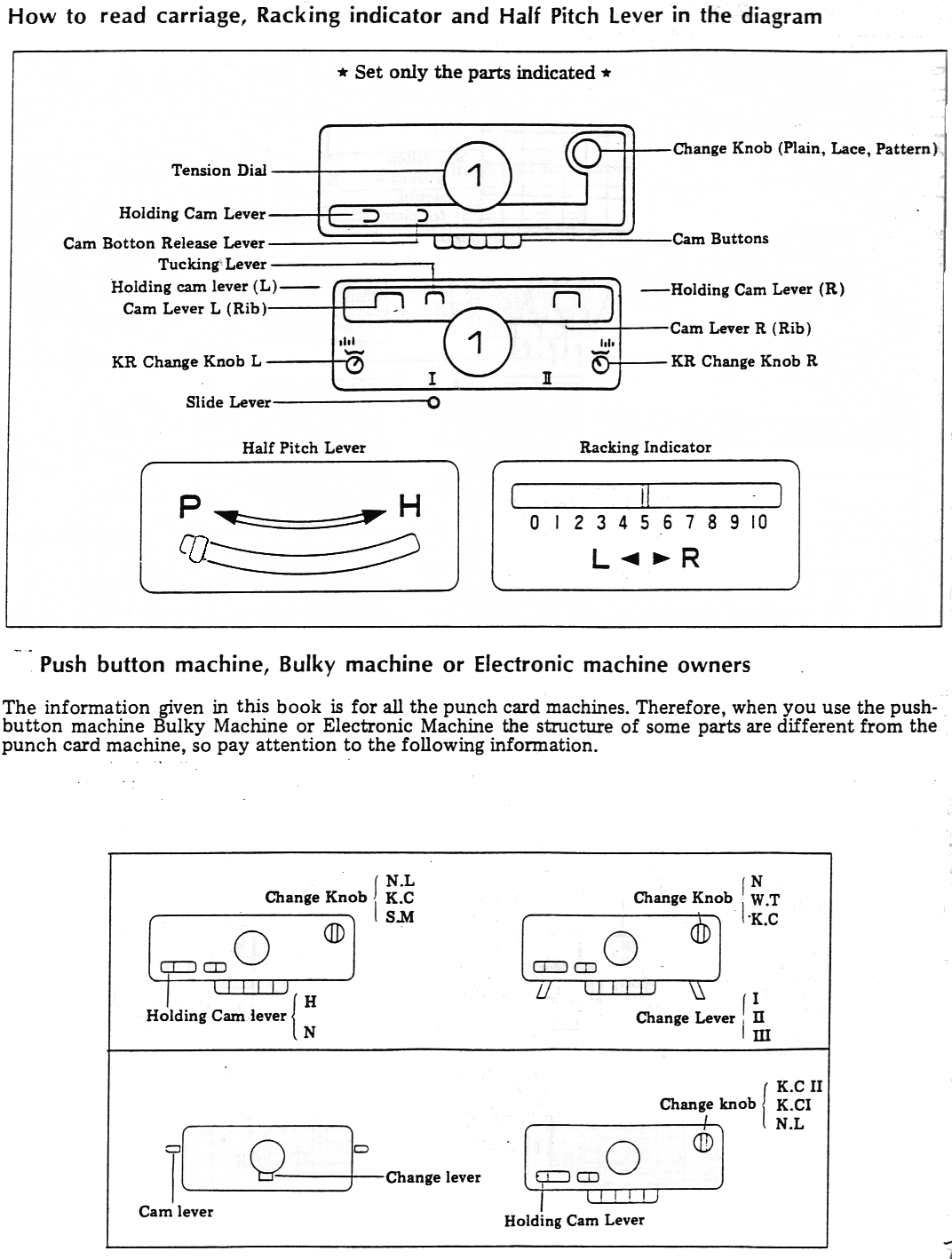

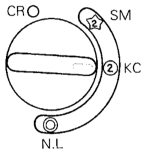

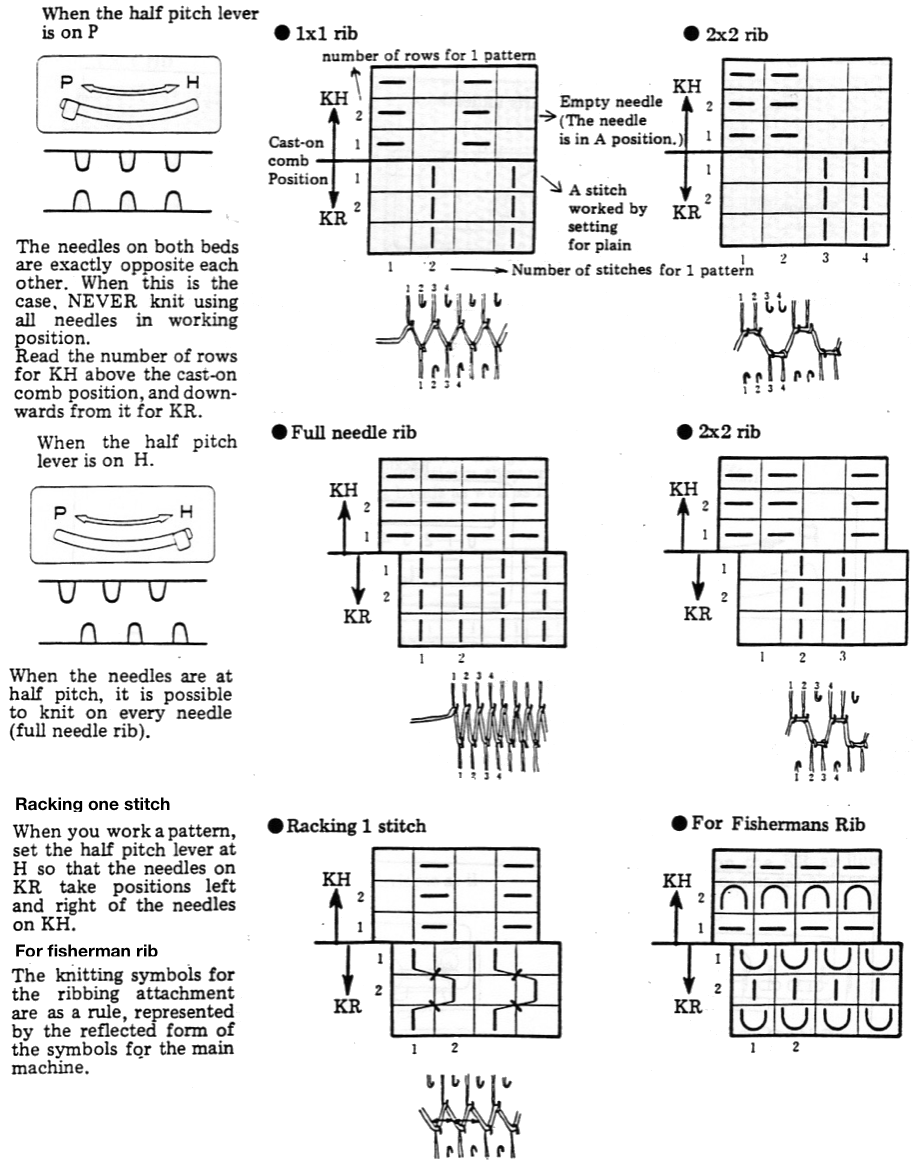

Ribber settings and symbols for Brother machines

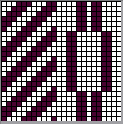

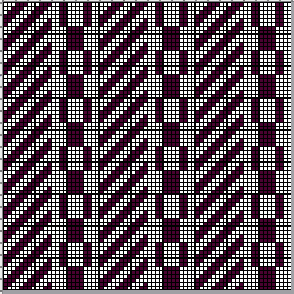

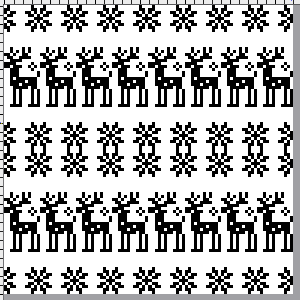

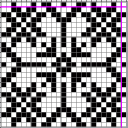

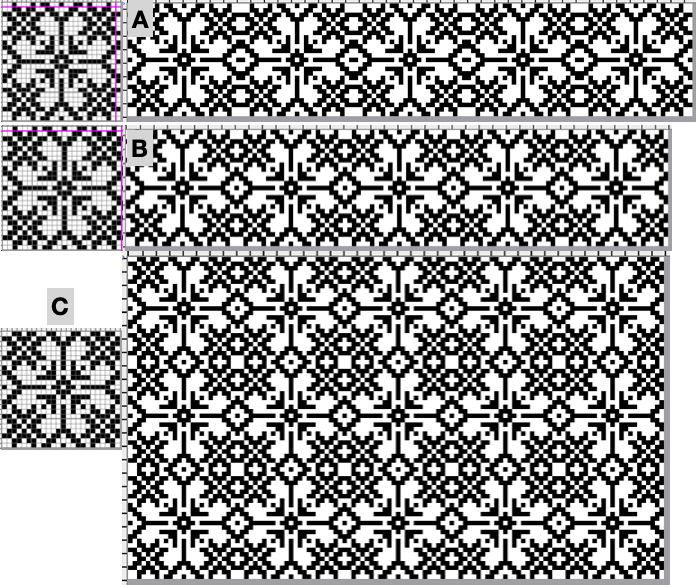

![]() tiled

tiled 16X17

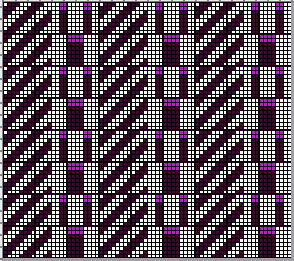

16X17 ![]() tiled

tiled  16X34

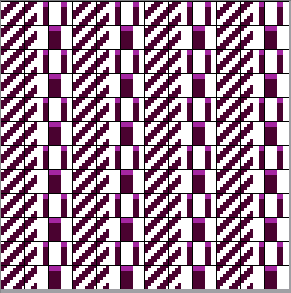

16X34 ![]() tiled

tiled  16X32

16X32![]() tiled

tiled  16X20

16X20 ![]() tiled

tiled  16X40

16X40![]()

18X40

18X40![]() tiled

tiled  20X28

20X28 ![]() tiled

tiled  20X40

20X40![]() tiled

tiled 20X56

20X56 ![]() tiled

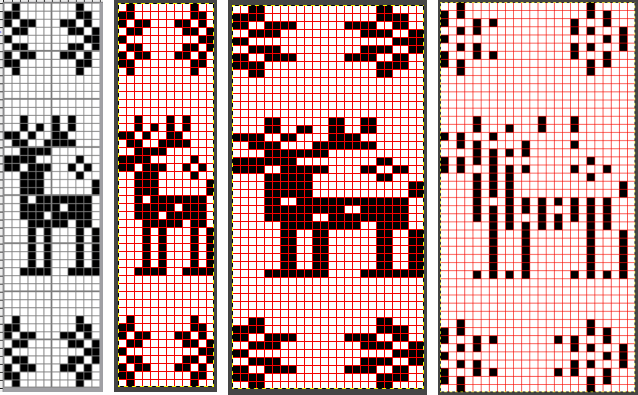

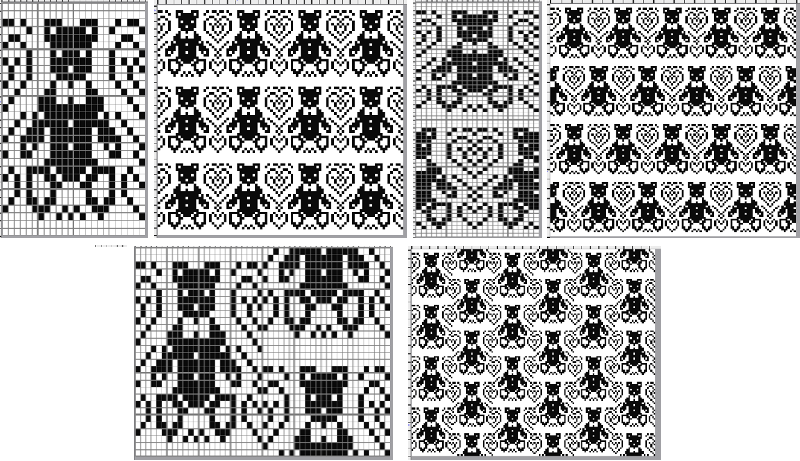

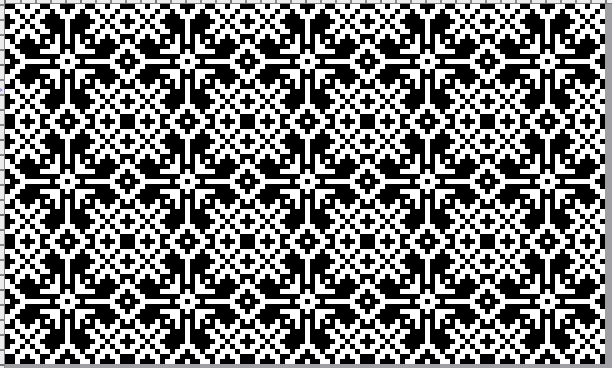

tiled 24X24

24X24![]() tiled

tiled  24X40

24X40![]() tiled

tiled 24X44

24X44![]() tiled

tiled 24X48

24X48![]() tiled

tiled 24X48

24X48![]() tiled

tiled 24X48

24X48![]() tiled

tiled 24X48

24X48![]() tiled

tiled 24X48

24X48 ![]() tiled

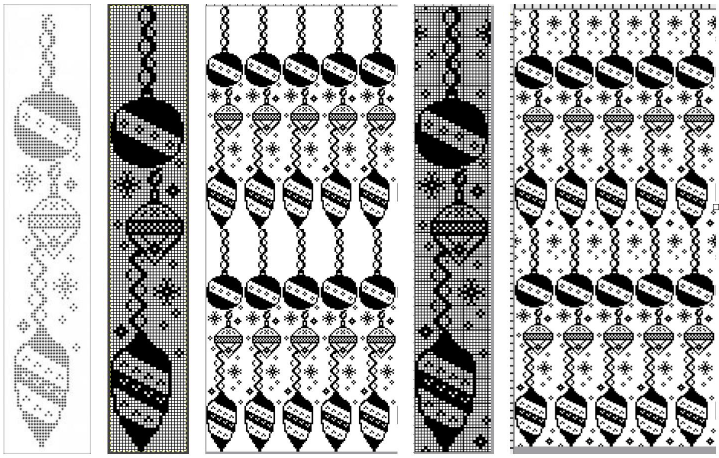

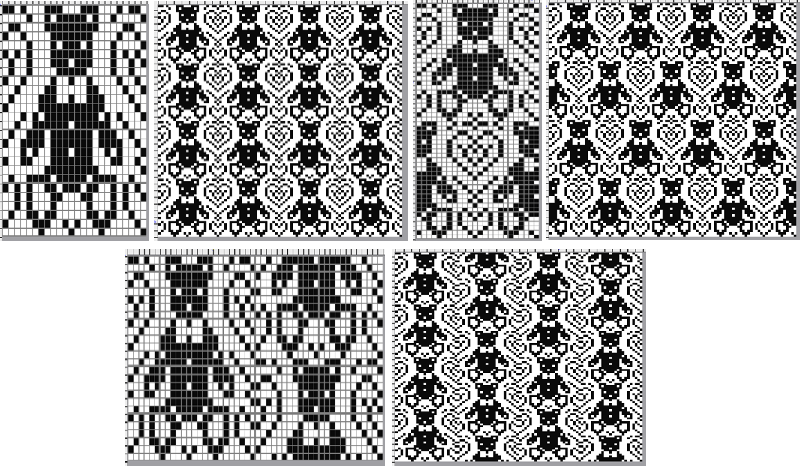

tiled 24X60 for border or horizontal bands of design

24X60 for border or horizontal bands of design ![]()

trimmed to 24X52 for all-over patterning

trimmed to 24X52 for all-over patterning ![]()

24X96

24X96 ![]() tiled

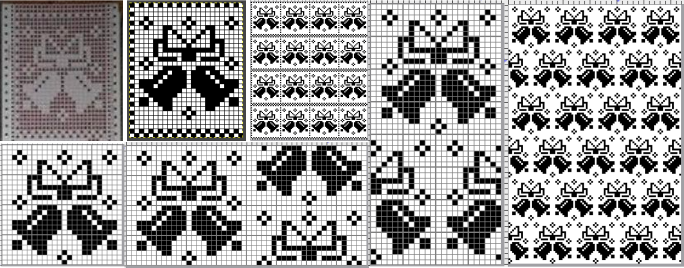

tiled  32X44

32X44![]() tiled

tiled  32X64

32X64![]() tiled

tiled 36X80

36X80![]() tiled

tiled 42X32

42X32![]() tiled

tiled Passap 257 40X40

Passap 257 40X40 40X80

40X80![]()

Working in multiple colors

Working in multiple colors![]()

36X72

36X72 ![]()

32X32

32X32![]()

![]()

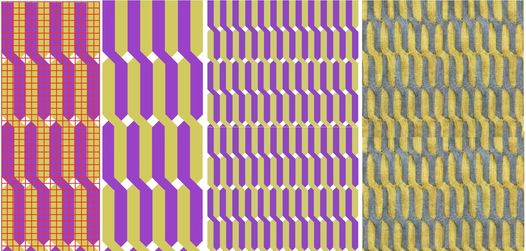

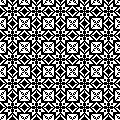

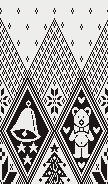

A coloring book approach can be used to develop DIY designs by filling in segments in any repeats provided expanding the color palettes,

A coloring book approach can be used to develop DIY designs by filling in segments in any repeats provided expanding the color palettes, ![]()

![]()

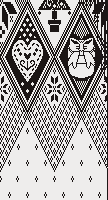

or creating custom-sized diamond outlines and filling in individual shapes between lines with colors.

or creating custom-sized diamond outlines and filling in individual shapes between lines with colors.![]() visualization of patterns becomes easier on a larger canvas than one simply doubling the original to 48X48

visualization of patterns becomes easier on a larger canvas than one simply doubling the original to 48X48![]() 96X96

96X96

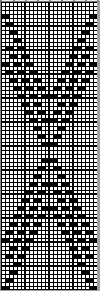

![]() the smallest repeat segment, 12X24 for quick color changes to custom

the smallest repeat segment, 12X24 for quick color changes to custom ![]() A 24X48 repeat with all white outlines for filling in shapes

A 24X48 repeat with all white outlines for filling in shapes ![]()

![]()

reducing the number of colors

reducing the number of colors  shifting shapes: 12X48

shifting shapes: 12X48![]()

It is possible to form related shapes with hand-transferred stitches, as seen in Using punchcards to track small cables in pattern (1)

It is possible to form related shapes with hand-transferred stitches, as seen in Using punchcards to track small cables in pattern (1)

maintaining diagonals with cable crossing blocks,

maintaining diagonals with cable crossing blocks,

Changing the holding sequence to eliminate the long threads between held shapes, beginning once more to sort out the how-to before adding fair isle patterning: cast on 36 stitches, with every sixth out of work moving from left to right, knit several rows.

Changing the holding sequence to eliminate the long threads between held shapes, beginning once more to sort out the how-to before adding fair isle patterning: cast on 36 stitches, with every sixth out of work moving from left to right, knit several rows.

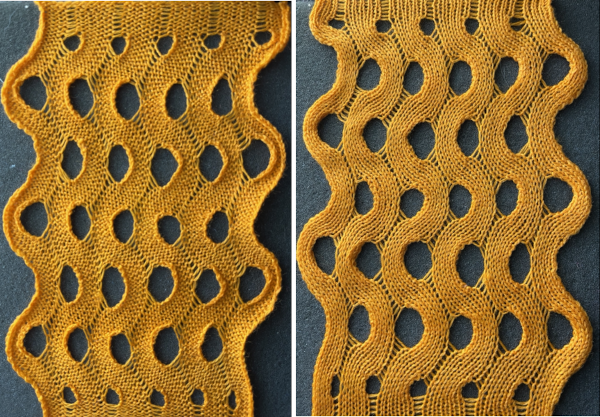

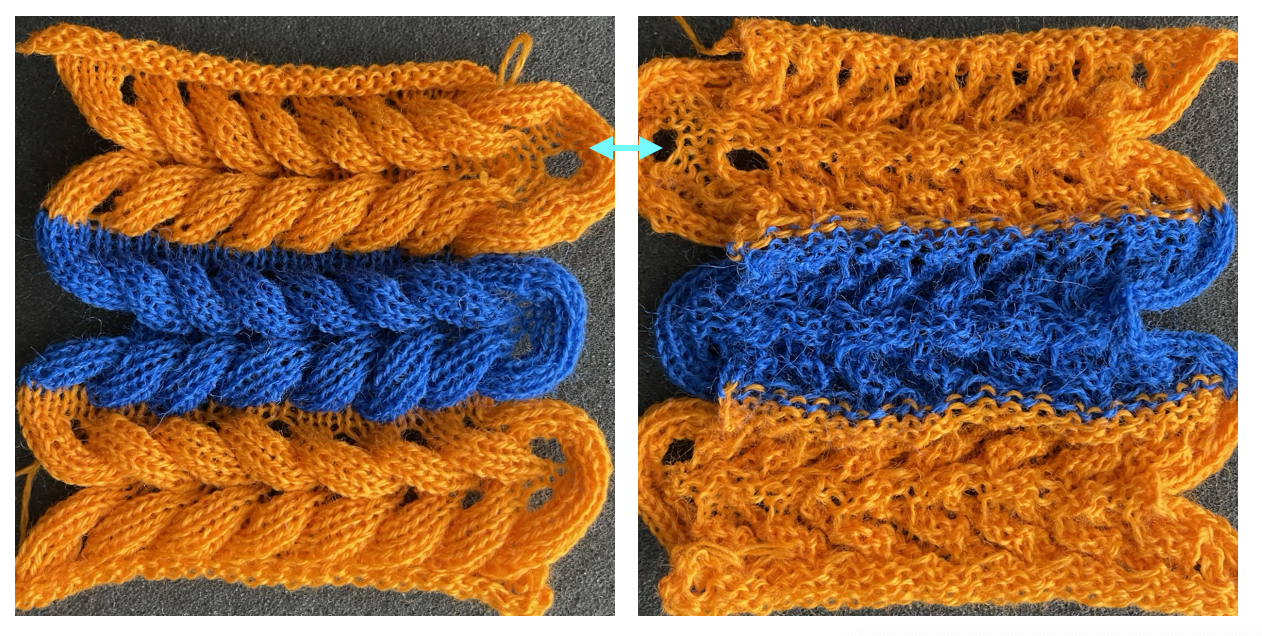

A large variety of pleats may be knit on the single bed as well, one being shadow pleats. The resulting knits also need to be gathered on one of the 2 edges in items like skirts at waistlines, and the number of knit rows needed for the volume required can be daunting and a large commitment of time if not effort.

A large variety of pleats may be knit on the single bed as well, one being shadow pleats. The resulting knits also need to be gathered on one of the 2 edges in items like skirts at waistlines, and the number of knit rows needed for the volume required can be daunting and a large commitment of time if not effort.

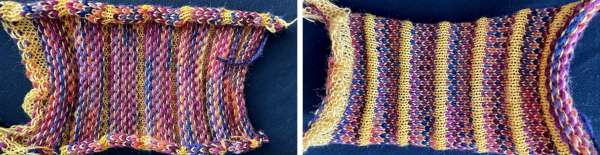

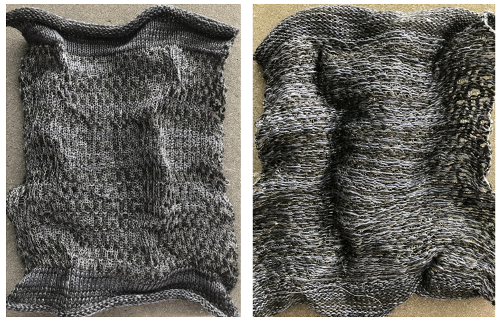

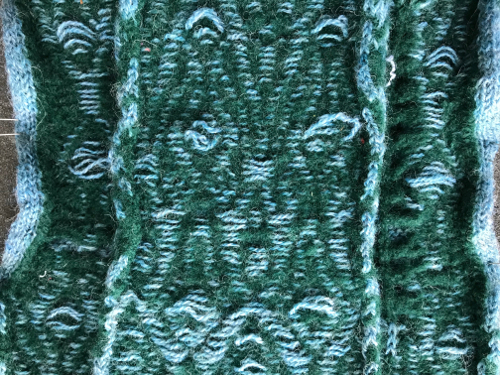

Both yarns used are wool, a yarn that has memory and spring-back. In the potential fold rows, the red color was replaced with a thin ply with the same fiber content. The first folds were knit in an *8 with thin, 14 with thick, 8 with thin** color sequence. Watching the knit as it progressed showed the thicker fair isle areas folding inward, with the thinner areas folding outward. The remainder of the swatch used a 4 thin, 8 thick sequence. The knit was steamed and pressed, the folds are soft but permanently present with the lower edge of the piece lying quite flat after a considerable amount of time.

Both yarns used are wool, a yarn that has memory and spring-back. In the potential fold rows, the red color was replaced with a thin ply with the same fiber content. The first folds were knit in an *8 with thin, 14 with thick, 8 with thin** color sequence. Watching the knit as it progressed showed the thicker fair isle areas folding inward, with the thinner areas folding outward. The remainder of the swatch used a 4 thin, 8 thick sequence. The knit was steamed and pressed, the folds are soft but permanently present with the lower edge of the piece lying quite flat after a considerable amount of time.

The blocking saga: I do own blocking pins but honestly have only used them in demos, and on rare occasions such as this, or to cut them down when I needed a fast replacement for a ribber cast on comb lost wire.

The blocking saga: I do own blocking pins but honestly have only used them in demos, and on rare occasions such as this, or to cut them down when I needed a fast replacement for a ribber cast on comb lost wire.

after steaming and pressing

after steaming and pressing

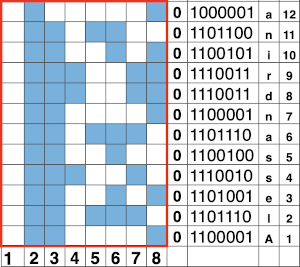

The related swatch, knit nearly 4 years later, forgetting that the 930 automatically mirrors text and motifs, so my repeat is mirrored horizontally 🙁

The related swatch, knit nearly 4 years later, forgetting that the 930 automatically mirrors text and motifs, so my repeat is mirrored horizontally 🙁

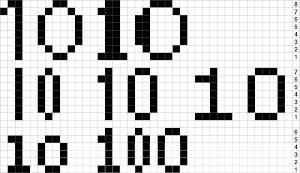

going a bit bolder, the 8 individual letters as numbers could repeat horizontally across each design row.

going a bit bolder, the 8 individual letters as numbers could repeat horizontally across each design row.  A repeat for the letter AX2 planned for the first segment of an 82 stitch wide scarf,

A repeat for the letter AX2 planned for the first segment of an 82 stitch wide scarf,

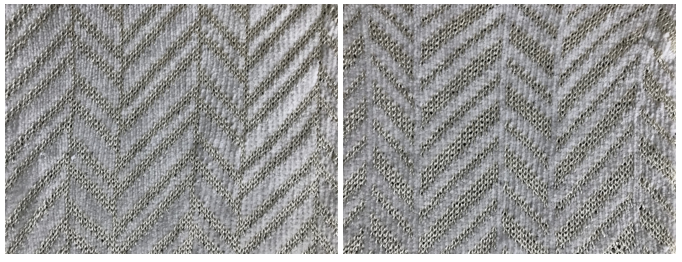

G carriages may be used to knit the same patterns in knit and purl stitch combinations.

G carriages may be used to knit the same patterns in knit and purl stitch combinations.

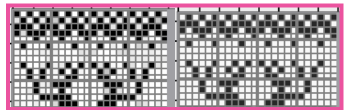

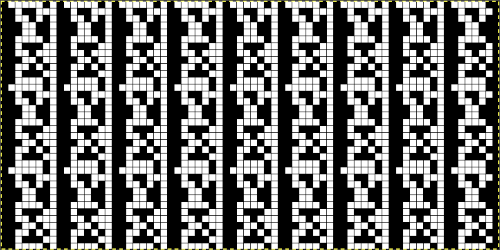

These repeats are very simple. They are commonly associated with card #1 and card #2 in basic factory packs supplied with knitting machines purchases. Card #2 is reproducible by using card #1 elongated X2. A reminder: if using either repeat in pieces of garments ie baby leggings, etc. take note of which yarn feeder each color is in. Even if the repeat is correct and placed properly, the surface of the knit will appear different to the eye if the color placement is reversed in alternate pieces. The repeats may be used as backgrounds for a variety of other more complex fabrics in DIY designing.

These repeats are very simple. They are commonly associated with card #1 and card #2 in basic factory packs supplied with knitting machines purchases. Card #2 is reproducible by using card #1 elongated X2. A reminder: if using either repeat in pieces of garments ie baby leggings, etc. take note of which yarn feeder each color is in. Even if the repeat is correct and placed properly, the surface of the knit will appear different to the eye if the color placement is reversed in alternate pieces. The repeats may be used as backgrounds for a variety of other more complex fabrics in DIY designing.

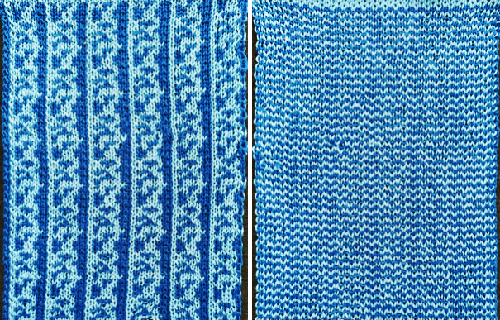

The longer floats seem manageable in these yarns, there is a bit of hooking up on the bottom right. The yarn traveling up the swatch on the right is an alternative way to mark for gauge measurements. A previous post provides some information on

The longer floats seem manageable in these yarns, there is a bit of hooking up on the bottom right. The yarn traveling up the swatch on the right is an alternative way to mark for gauge measurements. A previous post provides some information on

Tone on tone chenille and all rayon, with “color reverse” by switching yarn positions in feeder

Tone on tone chenille and all rayon, with “color reverse” by switching yarn positions in feeder  less effective with a flat yarn as the alternative to the chenille

less effective with a flat yarn as the alternative to the chenille

Hooked-up floats are not just for float control; note puckering on the knit side where they have been hung up in groups.

Hooked-up floats are not just for float control; note puckering on the knit side where they have been hung up in groups.

Combined with

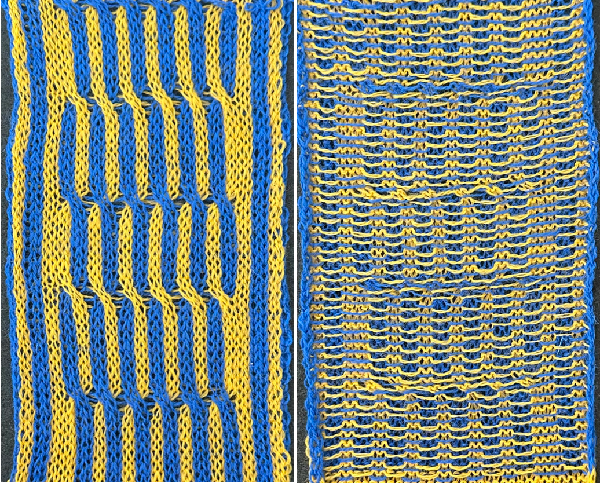

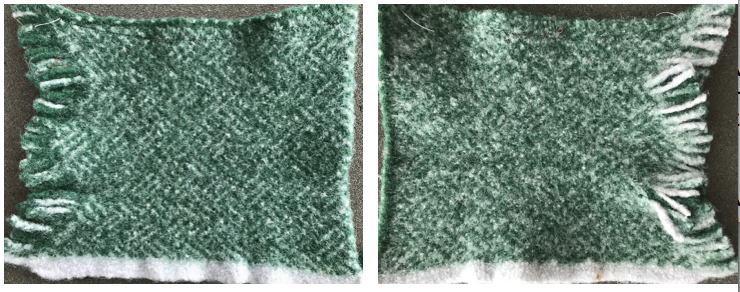

Combined with With using a sewing machine: there is a vertical, single stitch line due to end needle selection in the contrast color formed on either side of any needle(s) out of work which provides a visual guide for altering the fabric. This swatch was knit with wide NOOW spaces, then sewing machine stitching joined the contrasting vertical lines to form a 2 color “fringe” on the knit side (left) and purl side (right)

With using a sewing machine: there is a vertical, single stitch line due to end needle selection in the contrast color formed on either side of any needle(s) out of work which provides a visual guide for altering the fabric. This swatch was knit with wide NOOW spaces, then sewing machine stitching joined the contrasting vertical lines to form a 2 color “fringe” on the knit side (left) and purl side (right)

reversing color positions

reversing color positions

A punchcard can be further manipulated by masking areas with tape. It is not a good solution for production knitting, but adequate for testing out ideas before committing to punching a full, new card. The surface blisters here are much more dramatic. The green floats do not felt as much as in the previous swatch, and are considerably wider. On the right, far side you can see some of them were latched up, creating yet another design detail.

A punchcard can be further manipulated by masking areas with tape. It is not a good solution for production knitting, but adequate for testing out ideas before committing to punching a full, new card. The surface blisters here are much more dramatic. The green floats do not felt as much as in the previous swatch, and are considerably wider. On the right, far side you can see some of them were latched up, creating yet another design detail.

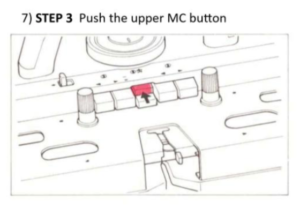

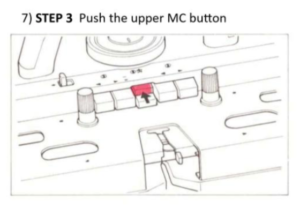

the punchcard change knob has selections for single motif and pattern knitting (KC)

the punchcard change knob has selections for single motif and pattern knitting (KC)