A collection of previous posts exploring some variations on the topic:

Ladders with lace, (leaf) “making things work” 1 3/15

Ladders with lace, (leaf) “making things work” 2 3/15

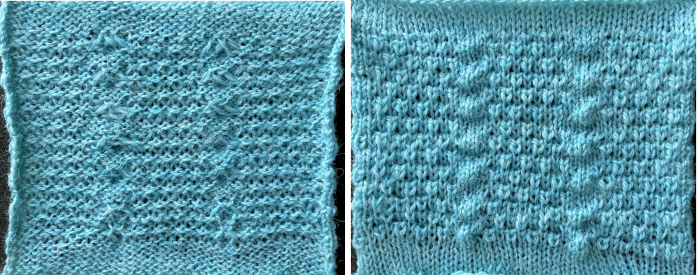

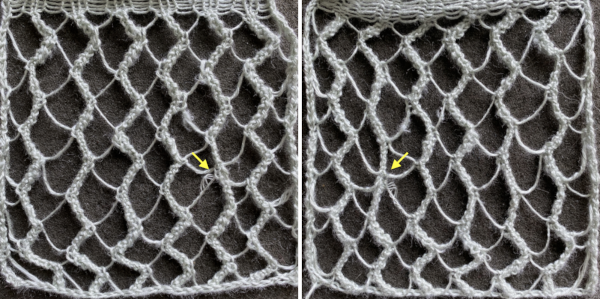

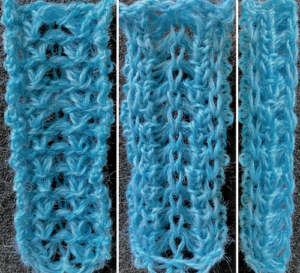

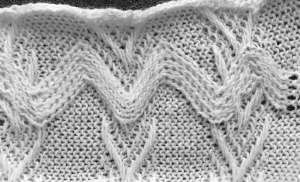

Ladder lace 8/13 Instructions reviewed in 2022, one of the accompanying swatches:  Ladders and Lace 8/13. MK ladders, and a bit of crochet 12/16

Ladders and Lace 8/13. MK ladders, and a bit of crochet 12/16

Tuck “lace” trims (and fabrics 1) 6/17

Tuck “lace” trims (and fabrics 2) 6/17

Tuck “lace” trims or fabrics 312/17

Automating tuck stitches combined with “lace” 2 6/17

Combining tuck stitches with “lace” 1 3/15

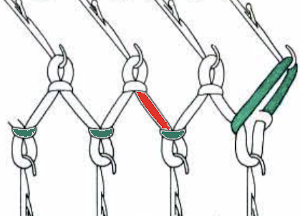

Many fabrics other than the traditional ones familiar to hand knitters and machine knitters that create eyelet patterns by transferring and combining stitches with yarnovers often include the term lace in their name, one such is ladder lace.

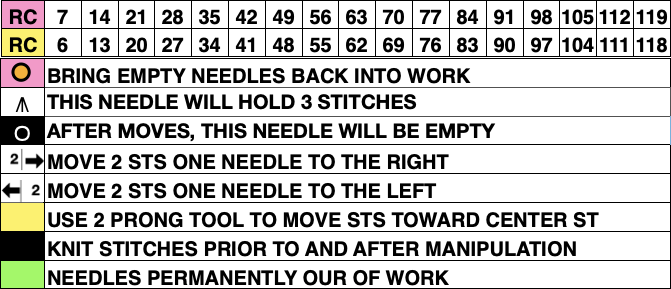

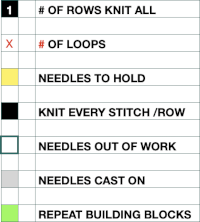

No matter what machine is in use, charts may be developed and followed that include row-by-row directions for needles out of work and any movement of stitches to alter the look of the floats created in the resulting spaces.

Knitology offers endless video inspiration for lovers of hand techniques including ones relying on patterns including ladders.

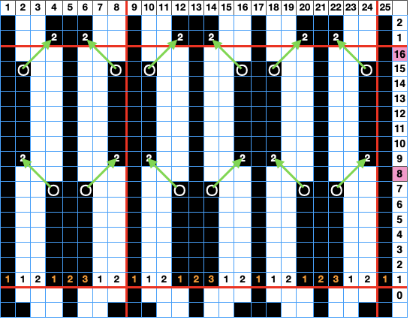

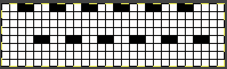

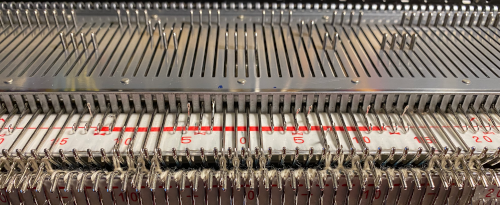

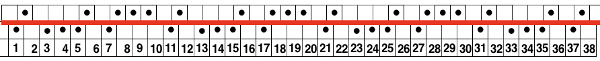

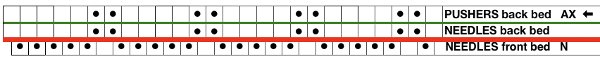

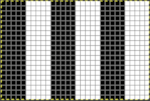

There are several aids in maintaining the desired repeat in NOOW (needles out of work). When establishing the initial needle configuration, punchcard knitters can punch a single row to match the required needle selection if the repeat works within the 24-stitch constraint, and use locked preselection to make transfers in base knitting.

Electronic knitters may use the same concept, I prefer if doing so to plan for programming the width of the stitches in use on the needle bed, adding pixels for knit borders on either side. Punchcard users may need to disregard some needle selections to form them.

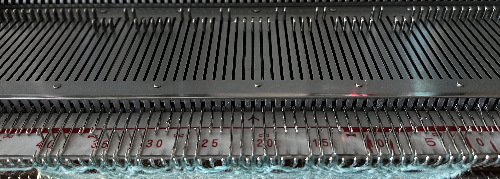

Another option for hand technique tracking in addition to marking the needle tape or even the needle bed is to print custom needle tapes created in a spreadsheet.  They can be marked as needed to guide hand technique selections, with colors added if preferred, and are easily swapped out if corrected or additional tapes are needed for different segments of the same technique.

They can be marked as needed to guide hand technique selections, with colors added if preferred, and are easily swapped out if corrected or additional tapes are needed for different segments of the same technique.

A variety of printable tapes for multiple gauge knitting machines is offered by Claudia Scarpa in her blog post.

A series of printable sheets for tracking row counts at even intervals may be found at the bottom of this post.

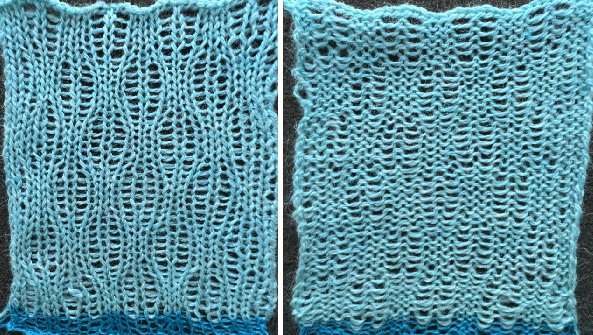

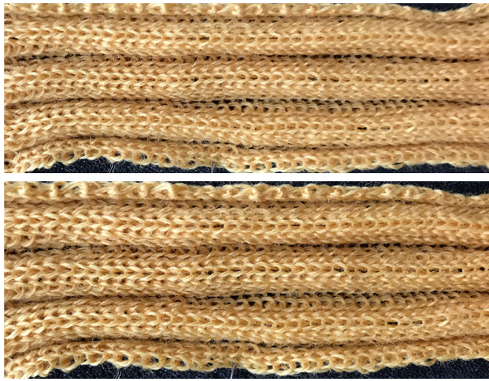

In laddered fabrics, the edge stitch on either side of the float may widen and grow in size over time.

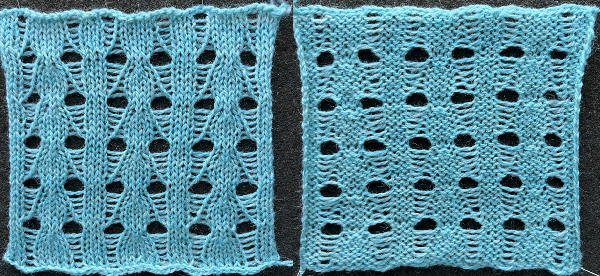

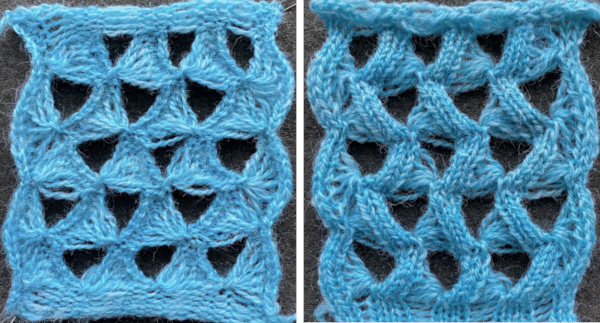

The 8/13 swatch uses lace transfers that produce doubled-up stitches to help with stitch stability.

Adding hand techniques serves a similar purpose in wide or varying ladder space designs created on the knit bed.

The length of the item produced combined with the added weight in the finished piece as it is hung or worn may quicken any lengthening and narrowing of the piece, requiring blocking again or at the very least pressing and steaming.

The fiber used makes a difference in the retention of the blocked shapes, in this case, man-made fibers may serve better than wool with its spring back.

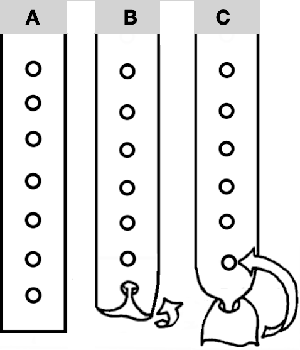

If a needle is emptied, if left forward or brought back to the B position, it will pick up a loop on the next pass, and when followed by a second knit row, an eyelet is formed in the loop location.

If a loop on a previously empty needle is dropped after it is formed, the resulting ladder grows in width.

Latching ladders while on the machine creates knit stitches on the purl ground.

Stitches may be removed and returned to the needle bed, cable crossings may be involved.

Picking up the heels of specific stitches on designated rows below and placing them on the knit stitches to the right or left of the ladder space is a way of adding non-vertical shaping.

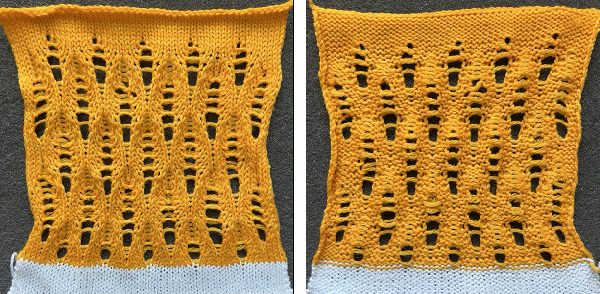

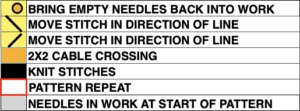

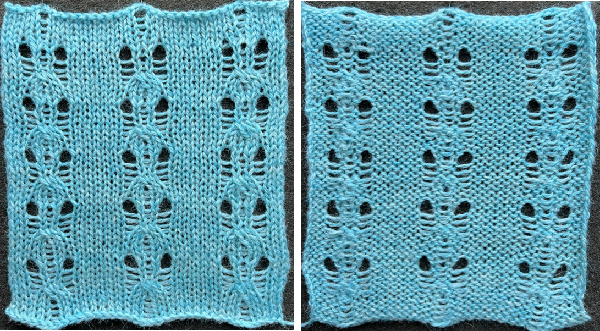

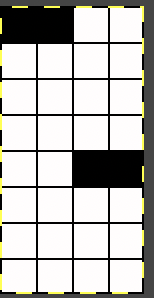

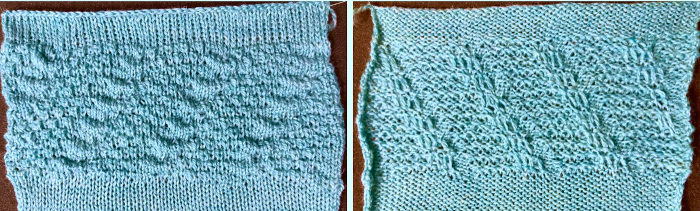

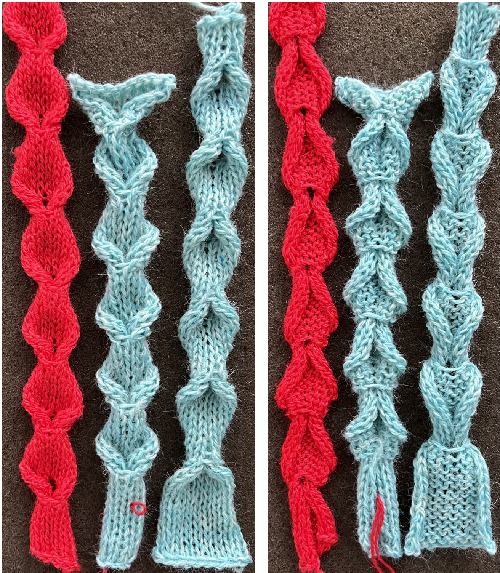

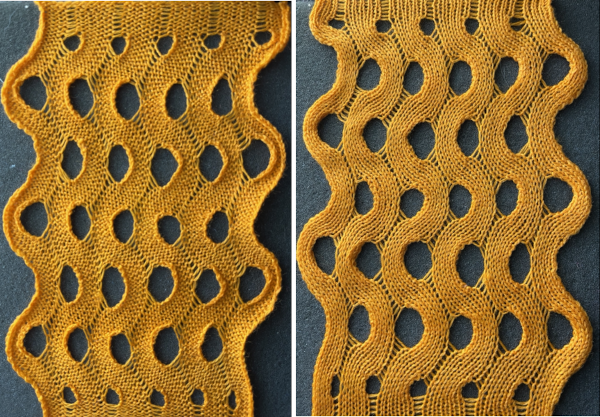

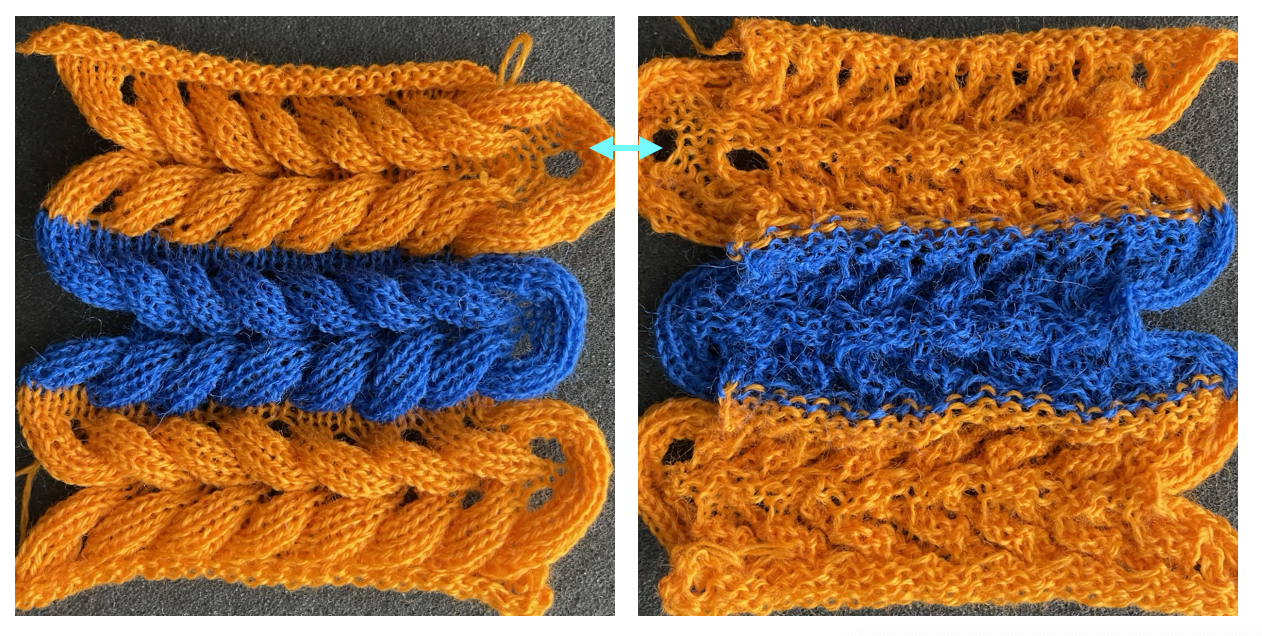

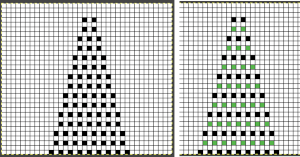

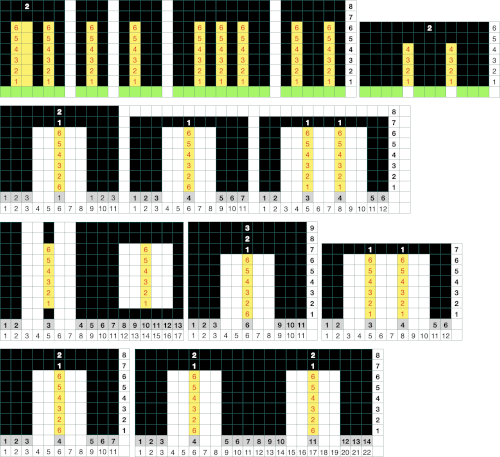

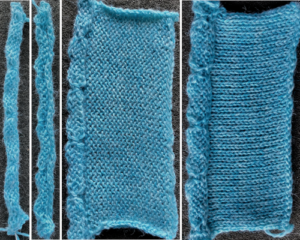

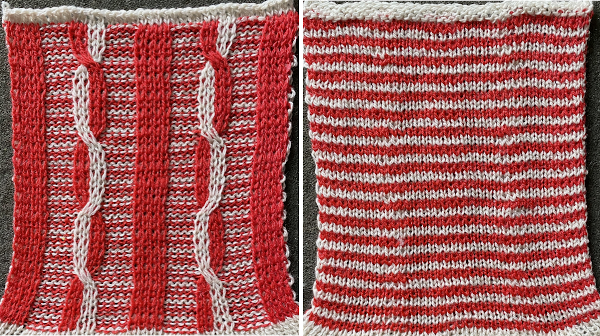

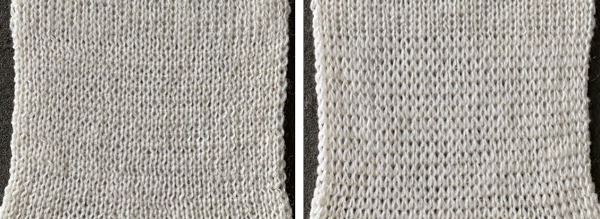

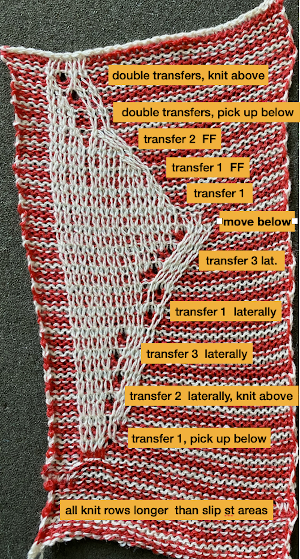

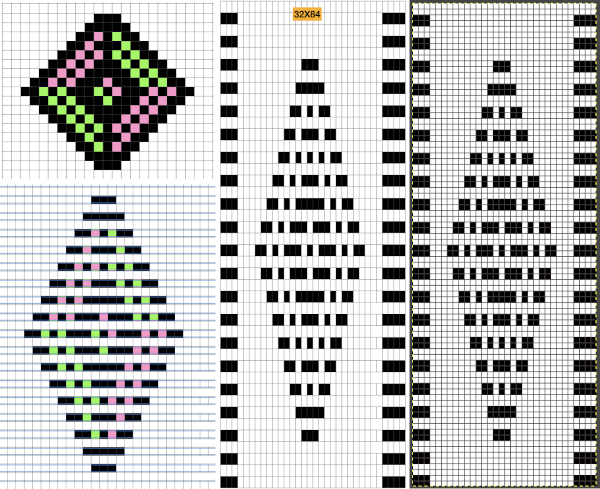

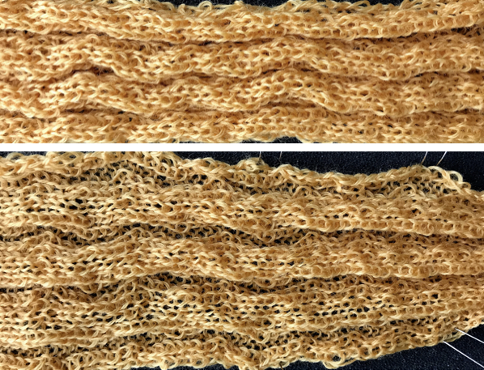

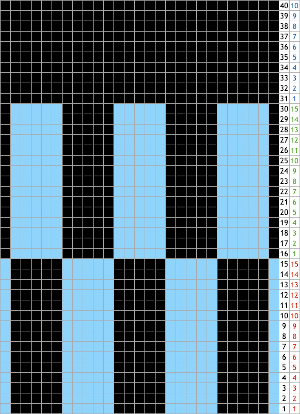

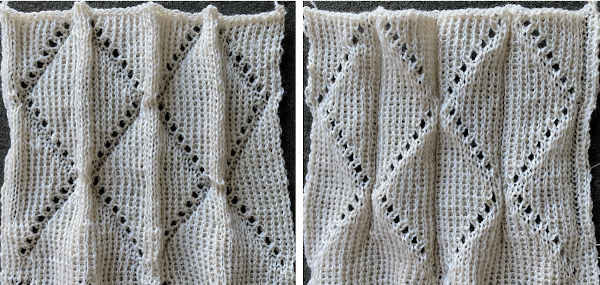

If experimenting with the number of rows knit before adding hand techniques, keep good notes in order to be able to reproduce segments in an all-over pattern. Beginning patterning with simple transfers in stocking stitch ground, here the needle configuration shifts but remains constant throughout. My proof of concept swatch is knit in 2/8 wool.  Visualizing the necessary actions:

Visualizing the necessary actions:

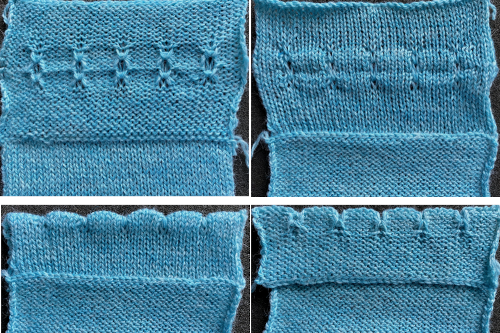

The proof of concept:

The proof of concept:

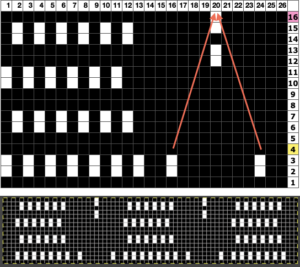

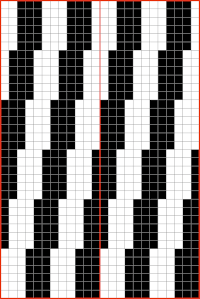

Adding 2X2 cable crossings: this repeat is 12 stitches wide.

Adding 2X2 cable crossings: this repeat is 12 stitches wide.

A chain cast-on allows for dropping the 2 chains in the location of the starting ladders, with some weight applied to the starting rows one may proceed to the first cable crossing.

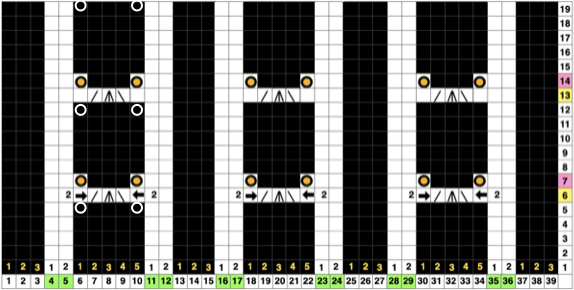

On row 6, and then again at 10-row intervals from there, the designated pairs of stitches are crossed consistently in the same direction. The needles aside from the crossing are pushed back to the A position.

Knit 4 rows.

On row 10, and then again at 10-row intervals from there move the left stitch of the pair of the center needles to its left, and the right stitch to its right, restoring the empty column at the center of the chart. Return the remaining empty needles to the B or E position

Knit 6 rows.

Repeat the process, ending with 6 knit rows. ![]()

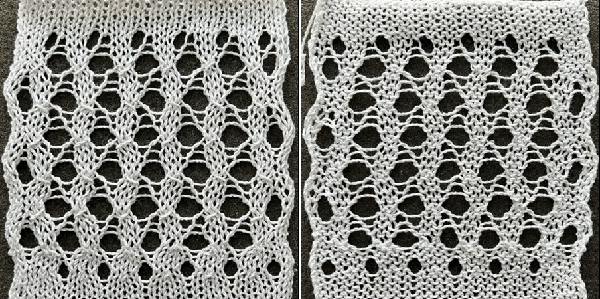

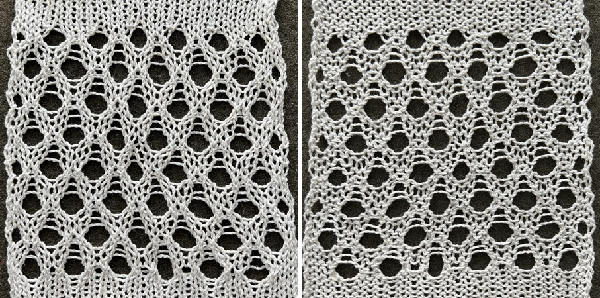

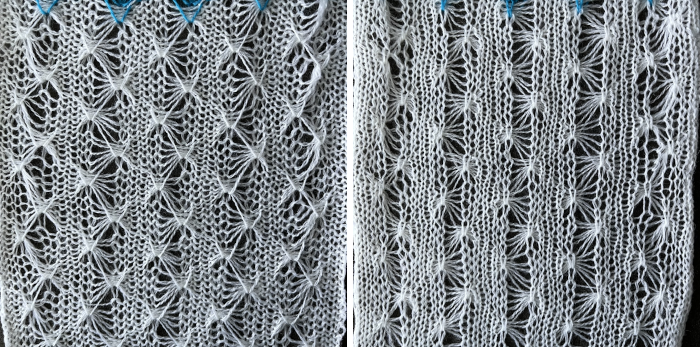

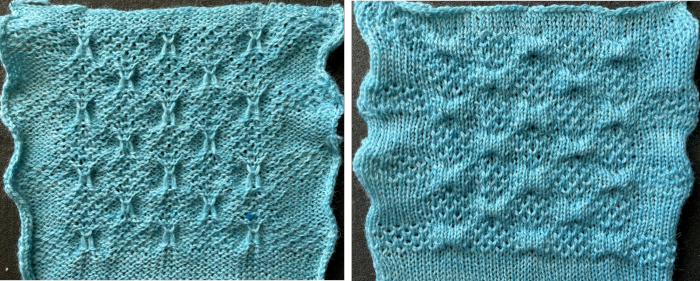

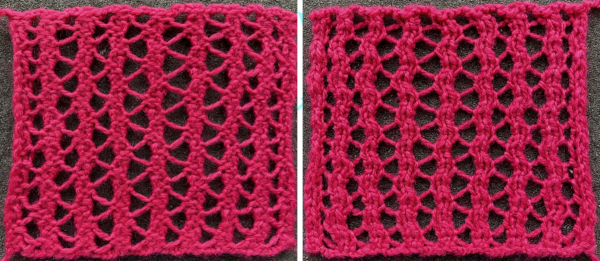

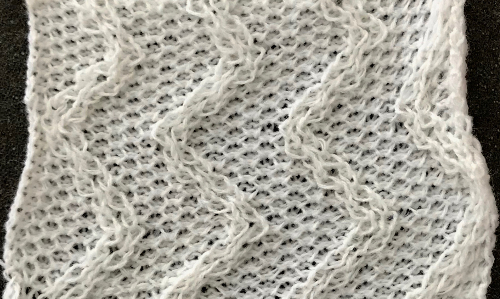

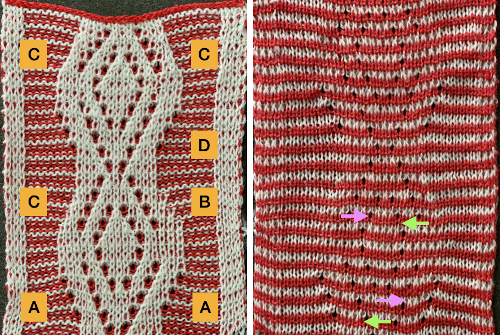

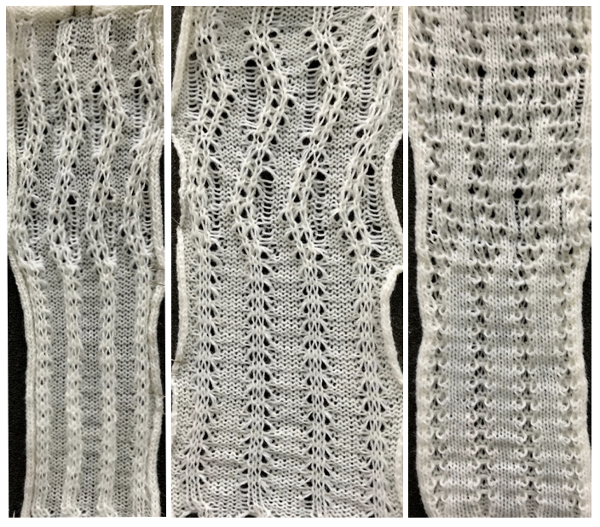

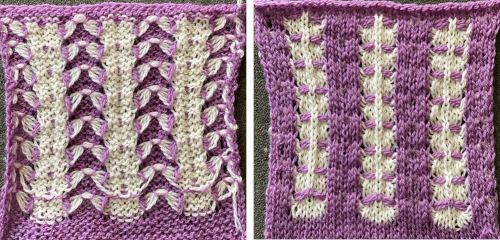

This variation uses transfer lace stitch crossings to produce larger eyelets than seen in the above swatch. Row counts for specific hand techniques can be tracked in a written or printed document if preferred.

This variation uses transfer lace stitch crossings to produce larger eyelets than seen in the above swatch. Row counts for specific hand techniques can be tracked in a written or printed document if preferred.

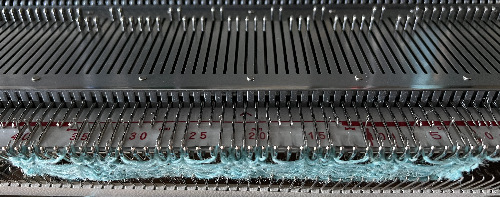

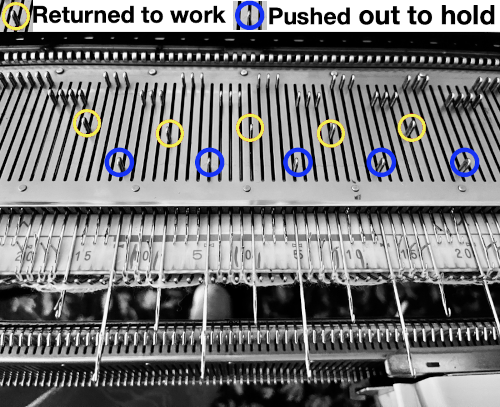

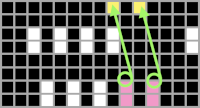

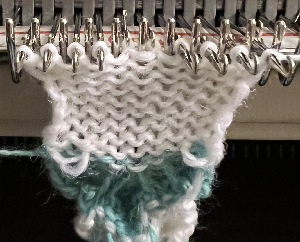

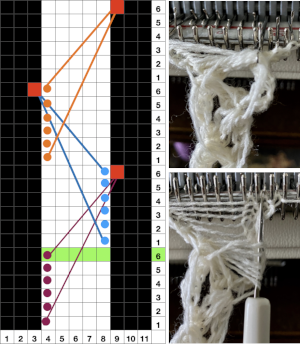

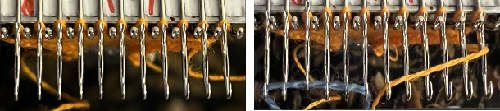

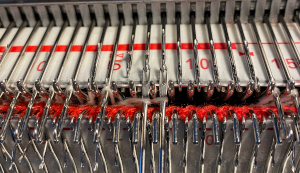

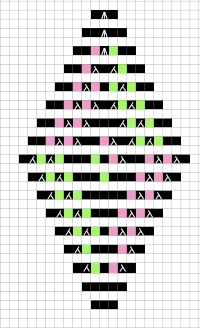

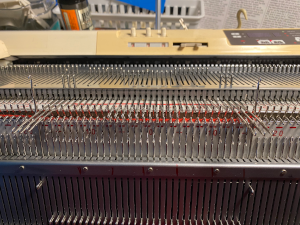

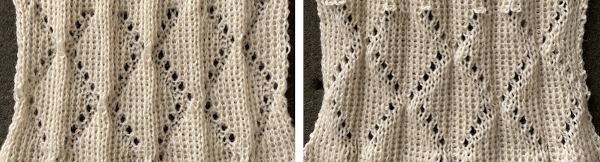

The knitting in progress: the initial needle spacing:

The knitting in progress: the initial needle spacing:  Emptied needles are in the process of being returned to work after the transfers to restore the initial setup, the first knit row will create loops on those needles, and the stitch is completed with the next knit pass from the opposite side

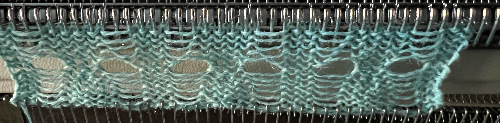

Emptied needles are in the process of being returned to work after the transfers to restore the initial setup, the first knit row will create loops on those needles, and the stitch is completed with the next knit pass from the opposite side  The growing pattern becoming apparent

The growing pattern becoming apparent

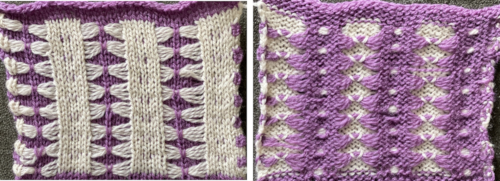

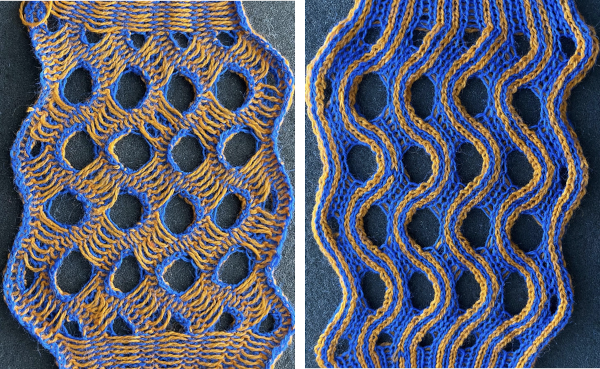

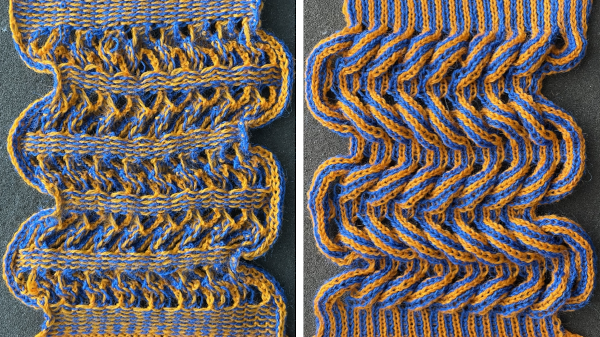

After updating the 8/13 post, these experiments continue exploring the above concept. The yarn now used is a wool rayon, which appeared not to split, and retains blocking if it is used.

After updating the 8/13 post, these experiments continue exploring the above concept. The yarn now used is a wool rayon, which appeared not to split, and retains blocking if it is used.

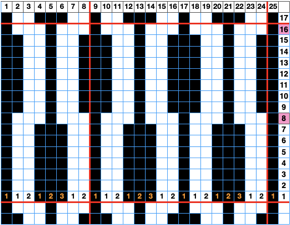

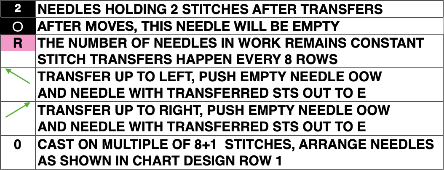

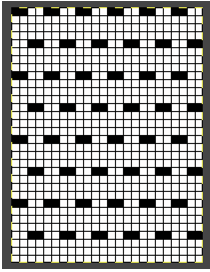

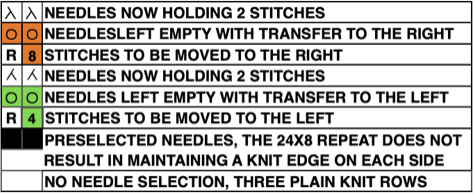

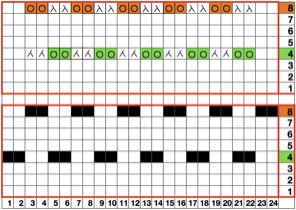

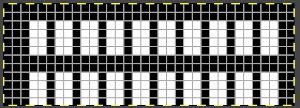

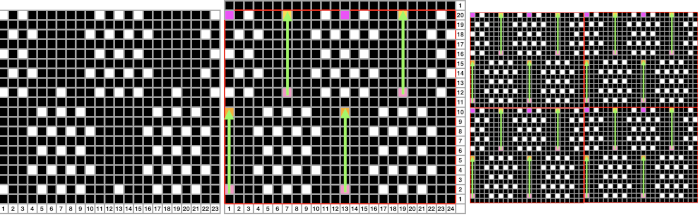

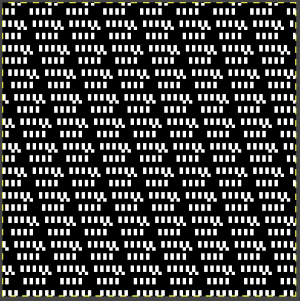

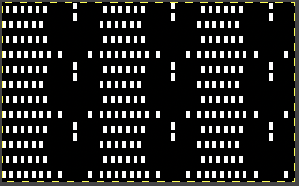

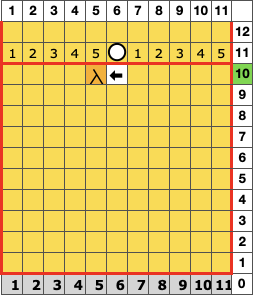

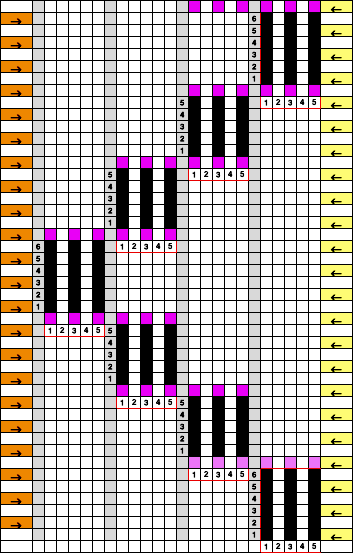

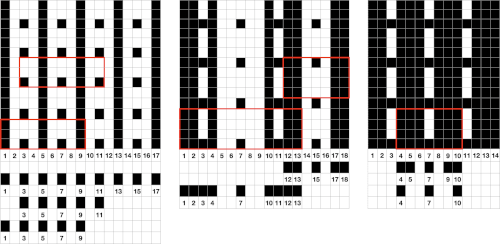

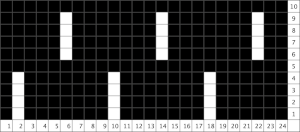

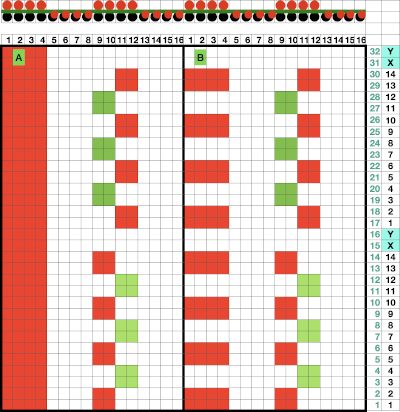

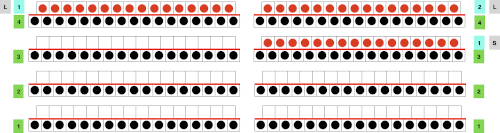

The samples use an 8-row repeat with different transfer methods. The first uses two-stitch transfers. The 24-stitch version is suitable for a punchcard, 48 rows in height.  the smallest electronic repeat

the smallest electronic repeat  tiled to a 28-stitch repeat for the electronic, in the width of my planned swatch, only for the required 8-row height

tiled to a 28-stitch repeat for the electronic, in the width of my planned swatch, only for the required 8-row height

![]()

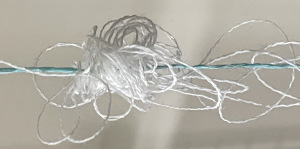

The now familiar double loops

The now familiar double loops  Beginning ladders

Beginning ladders  A partial row view of stitches moved 2 at a time toward the higher end stitch count, treating the loops as one would stitches

A partial row view of stitches moved 2 at a time toward the higher end stitch count, treating the loops as one would stitches

e-wrapping one of the two loops consistently in the same direction at the top of the piece will form equal eyelets on the next pass

e-wrapping one of the two loops consistently in the same direction at the top of the piece will form equal eyelets on the next pass

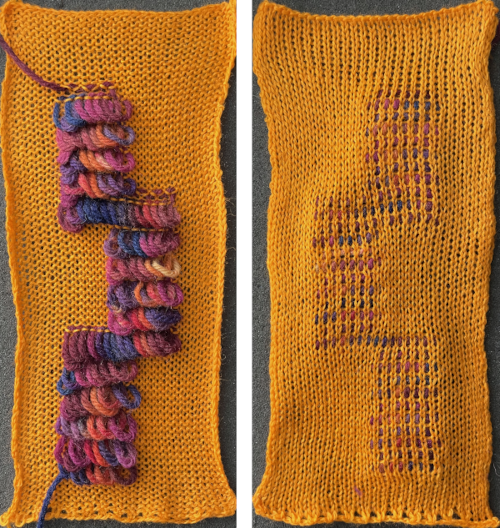

Working with multiple loops held in hooks of specific needles: the following swatches were actually the beginning for what became the above thread

Working with multiple loops held in hooks of specific needles: the following swatches were actually the beginning for what became the above thread

I tend to web surf in the early morning hours. Sometimes that includes coming across YouTube videos where contributors show fantastic dexterity at handling tools while developing complex fabrics using only hand techniques.

This is one example:

https://www.youtube.com/watch?v=IoJbbInlxck.

As usual, I attempted to automate as much as I could and failed to be able to execute a truly similar fabric.

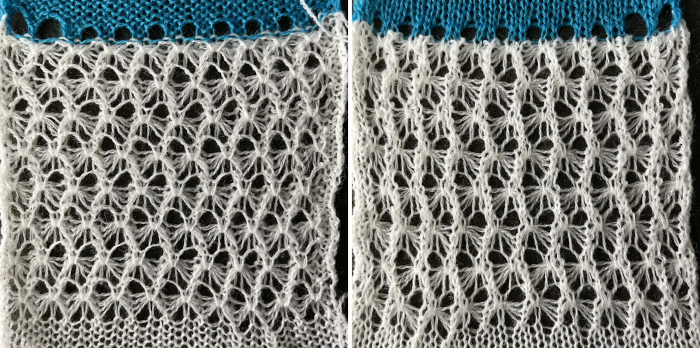

In my first modified version, I introduced knit rows as seen below to make tracking of hand techniques easier and to facilitate knitting stitches/ loops groups.

The result is of course quite different from the swatch in the video.

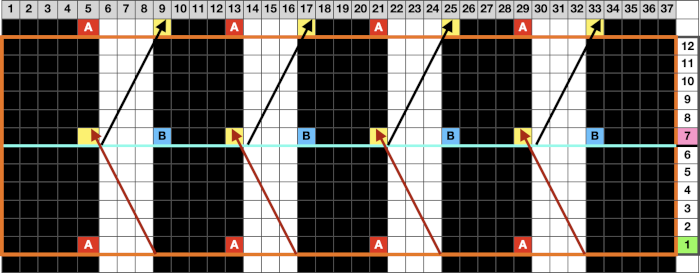

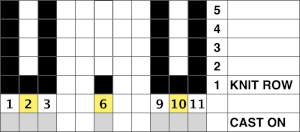

To knit: begin with a permanent cast on over the planned number of needles. In this case, 2 needles are included to form vertical all-knit borders on both sides.

I knit most of my proof of concept swatches on an electronic machine and download a plain design repeat with a stitch count equal to the entire width of the number of needles in use on the bed.

On a punchcard model, the all-knit border needles would have to be brought out to E on every row for them to knit with each carriage pass.

Using provided repeat pngs as shared may require mirroring the repeat horizontally depending on the download program and the knitting machine model used, as well as changing the image mode back to indexed BW since downloaded designs from the posts may be converted to RGB mode as they are copied.

If working on a finished piece, knit several rows of waste yarn, followed by a row of ravel cord and a permanent cast-on, otherwise simply knit enough to hang a comb and some weights, required for most tuck knitting.

I happen to have a 2/20 wool as my go-to for most experiments that result in 4 or more loops building up in the needle hooks.

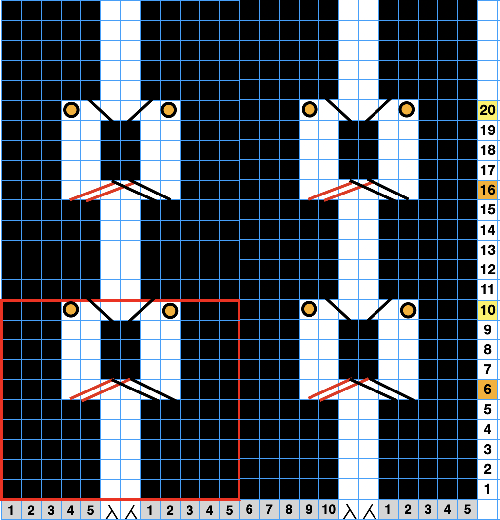

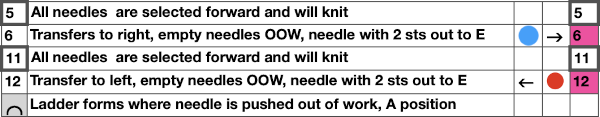

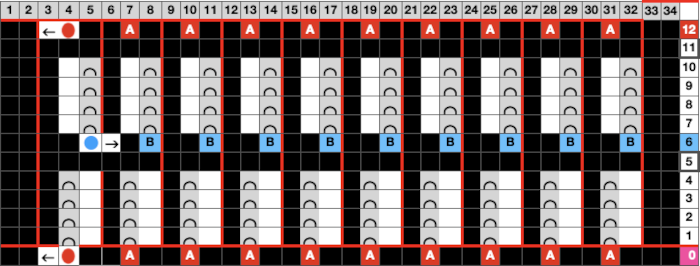

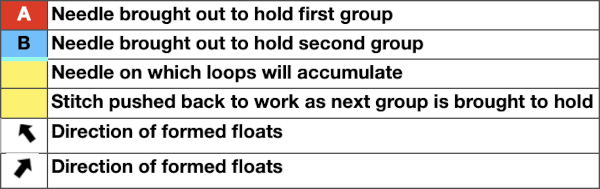

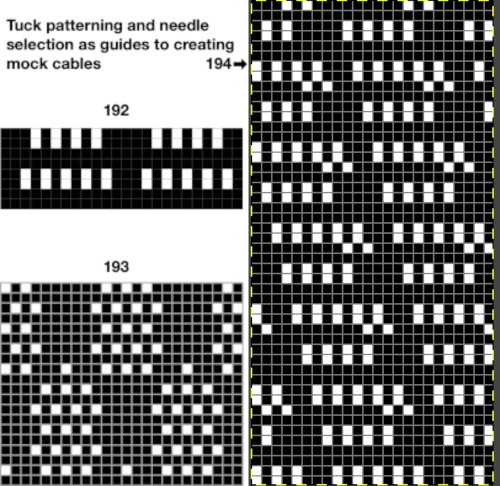

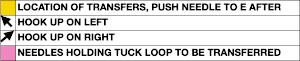

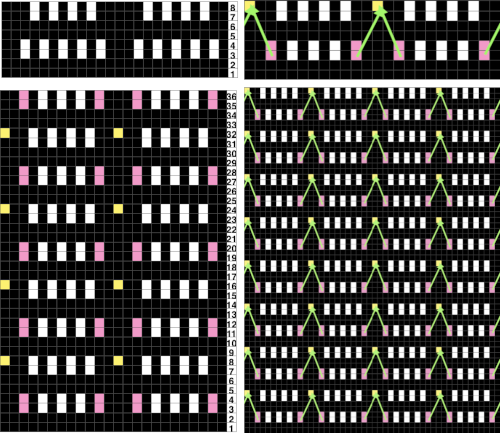

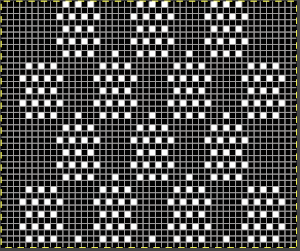

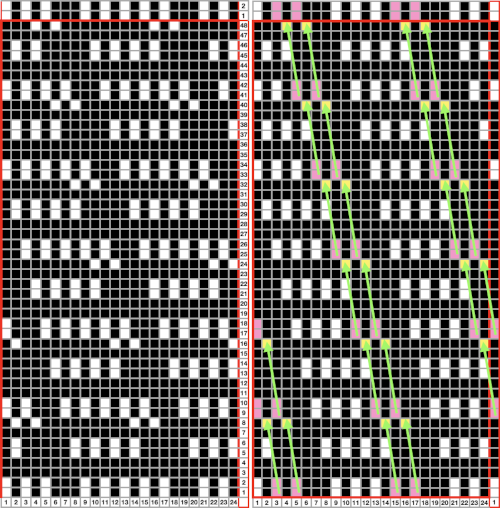

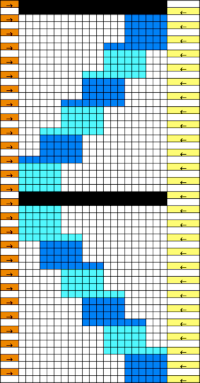

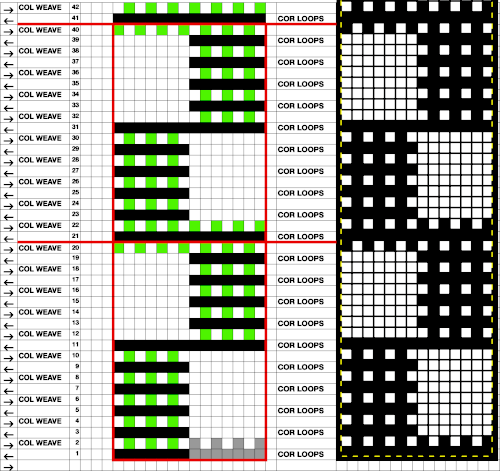

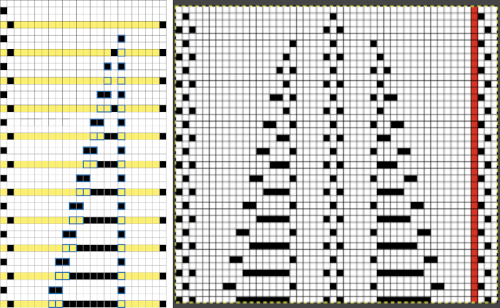

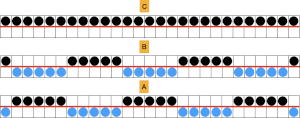

The beginning concept: hand transfers and automated tuck patterning

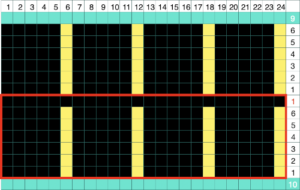

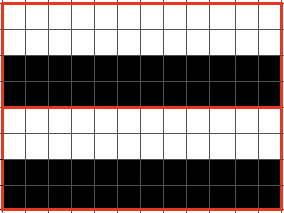

The programmed repeat is planned for two rows of knit stitches between sets of loops

The programmed repeat is planned for two rows of knit stitches between sets of loops

![]() After the cast-on and base knit rows, program the machine and preselect the first pattern row. The starting side does not matter unless the use of the color changer is planned, in which case, the first preselection row would need to move toward it.

After the cast-on and base knit rows, program the machine and preselect the first pattern row. The starting side does not matter unless the use of the color changer is planned, in which case, the first preselection row would need to move toward it.

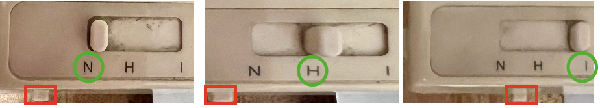

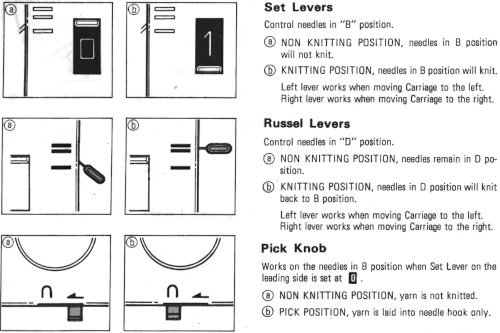

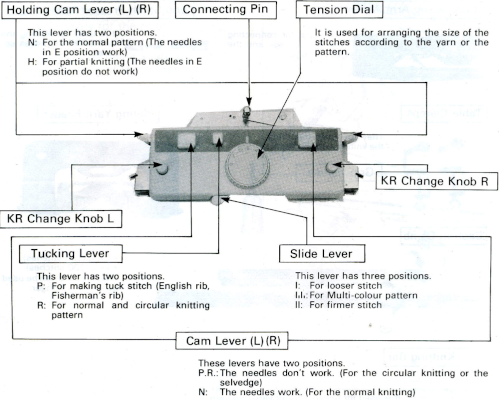

Because some needles are taken out of work, end needle selection is canceled.

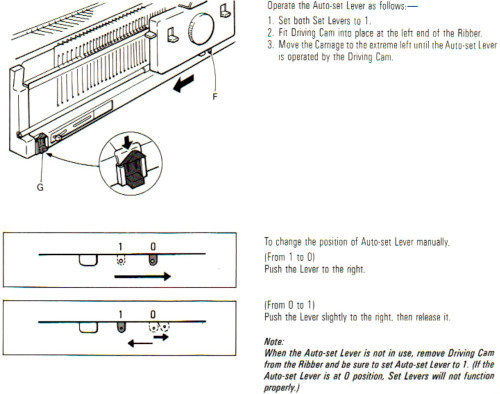

After the first preselection row, the machine is set to tuck in both directions.

My test repeat was programmed as a single motif on the 930, with the image mirrored horizontally.

Each pattern segment is 6 rows high, the full repeat is 12 rows tall. Color changes could be introduced every 6 rows.

Following the chart for the first segment, transfer the A marked nonselected location needles to the adjacent preselected ones on their left, push the emptied needles out to A position, OOW after each transfer, and its adjacent needle with the combined stitches/loops out to E position.

After 4 tuck stitch rows, push any needles previously placed out of work to A position out to E so they will knit appropriately on the next pass as part of an all-knit row.

As the carriage moves to the opposite side, the second all-knit row will preselect. As the carriage again moves once again to the previous side, it will knit the whole row, while preselecting for the first hand-technique row once more.

Prior to the next carriage pass, transfer each of the marked B location nonselected needles to the adjacent preselected ones on its right, push the emptied needles out to A, OOW after each transfer, and its adjacent needle with the combined stitches out to E.

Form loops for 4 more rows, and push any needles previously placed back to A position out to E so they will knit appropriately on the next pass, forming an all-knit row. As the carriage moves to the opposite side, the next all-knit row will preselect, followed by preselection for loops and transfers again as the carriage moves again to the previous side knitting every stitch.

Repeat the process for the desired length.

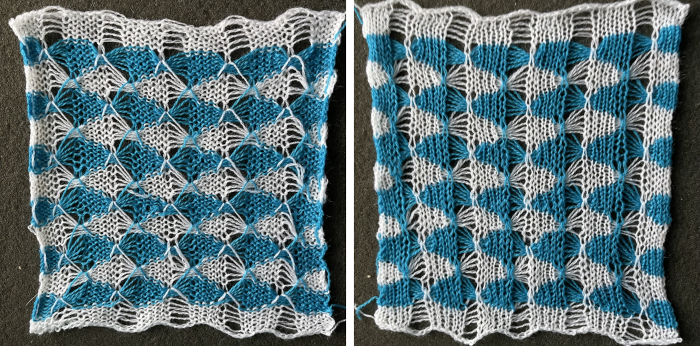

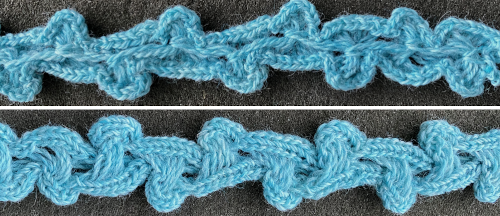

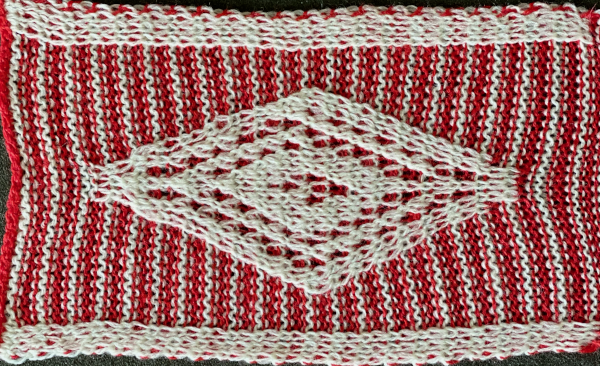

End the piece with at least 2 all-knit rows after a full or half design repeat. Cast off loosely to compensate for the widening due to the type of stitch formation.  This fabric is executed as a hand technique/ short rows with no automated tuck patterning assistance. I have found when using the tuck automated setting in Brother models there is often a limit for accumulating no more than 4 strands in the hooks of the needles, while in using holding, manually pushing needles out to hold and back to work can be far more forgiving.

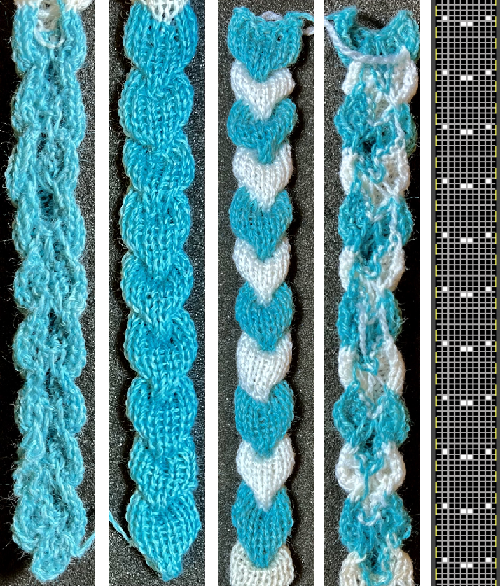

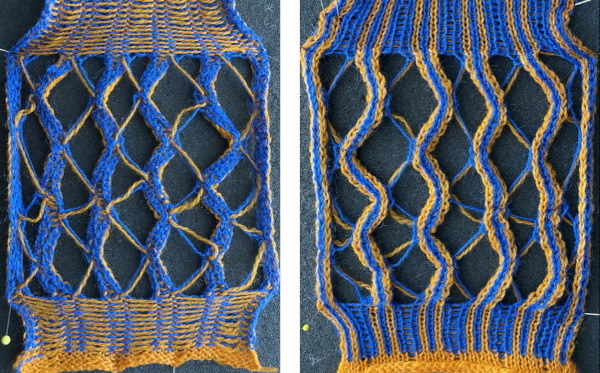

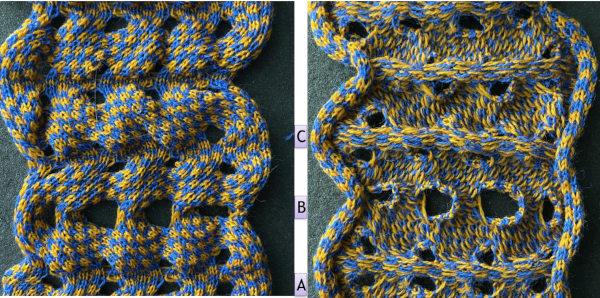

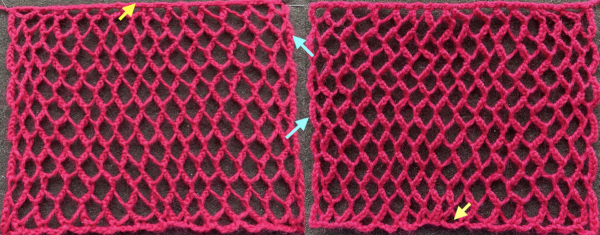

This fabric is executed as a hand technique/ short rows with no automated tuck patterning assistance. I have found when using the tuck automated setting in Brother models there is often a limit for accumulating no more than 4 strands in the hooks of the needles, while in using holding, manually pushing needles out to hold and back to work can be far more forgiving.

In this instance, loops are formed for 6 consecutive rows.

There are no all-knit rows. The color changes were made every 6 rows prior to knitting across the newly adjusted needle positions.

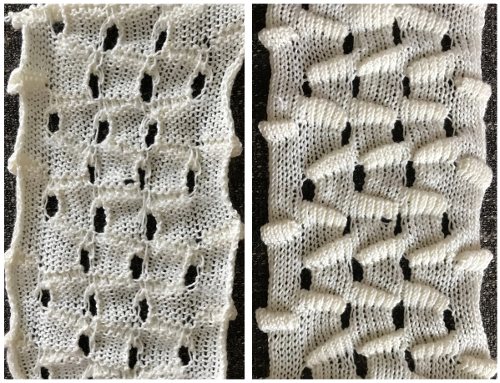

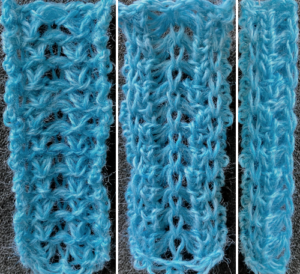

Changing the holding sequence to eliminate the long threads between held shapes, beginning once more to sort out the how-to before adding fair isle patterning: cast on 36 stitches, with every sixth out of work moving from left to right, knit several rows.

Changing the holding sequence to eliminate the long threads between held shapes, beginning once more to sort out the how-to before adding fair isle patterning: cast on 36 stitches, with every sixth out of work moving from left to right, knit several rows.

Chain cast on 2 in work, 2 out of work, end with 2 needles in work

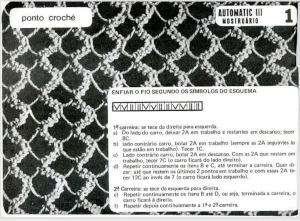

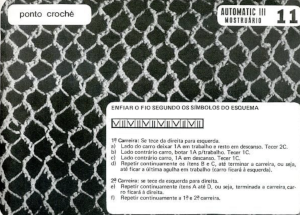

Chain cast on 2 in work, 2 out of work, end with 2 needles in work Number 11 is a close relative but worked on every other needle

Number 11 is a close relative but worked on every other needle

The rayon used in the previous sample, and a 2/8 wool, were less successful than a 2/11 acrylic in knitting the swatch. The stitches need to be as tight as possible while also needing to be able to knit off properly

The rayon used in the previous sample, and a 2/8 wool, were less successful than a 2/11 acrylic in knitting the swatch. The stitches need to be as tight as possible while also needing to be able to knit off properly

This knit begins on every needle

This knit begins on every needle

Eliminating those ladders or floats, here eyelets are created where stitches are held for two rows.

Eliminating those ladders or floats, here eyelets are created where stitches are held for two rows.

push first 2 of needles out to hold

push first 2 of needles out to hold

COL knit 10 rows, bring the third pair of needles into work, knit one row

COL knit 10 rows, bring the third pair of needles into work, knit one row

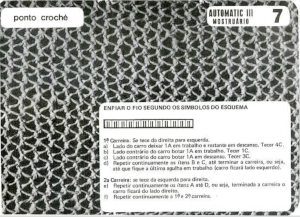

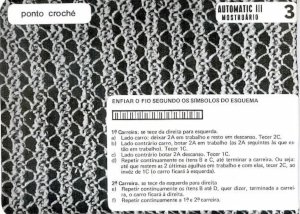

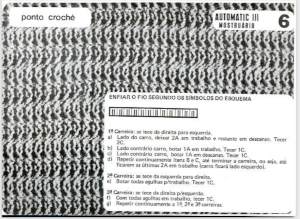

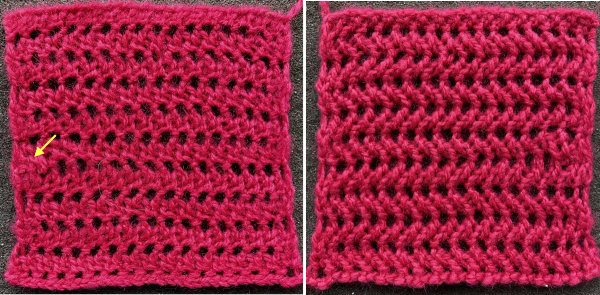

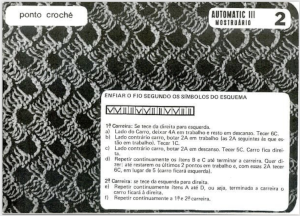

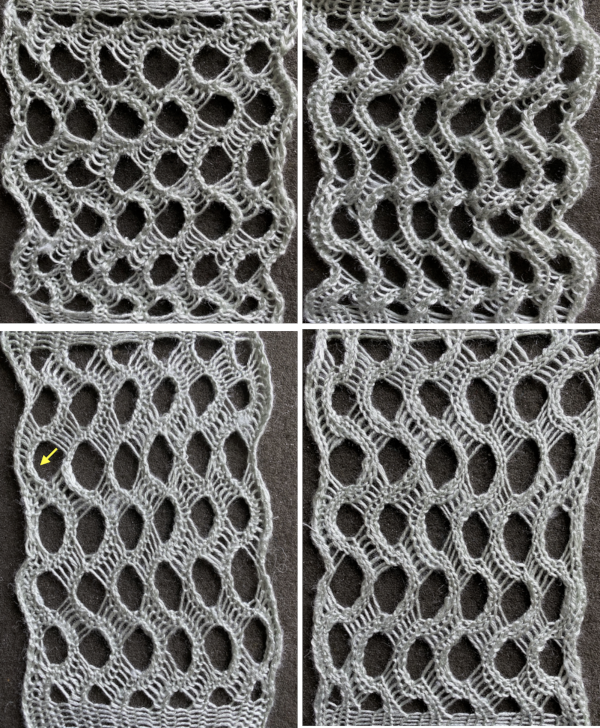

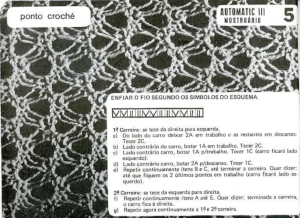

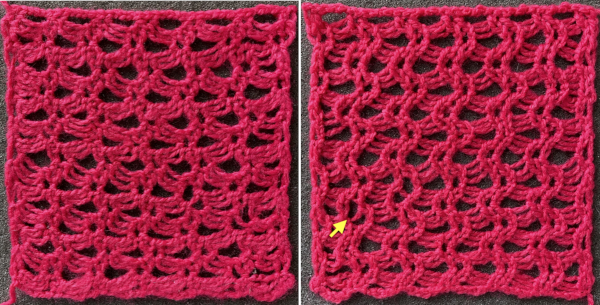

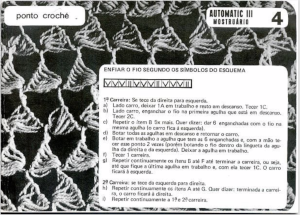

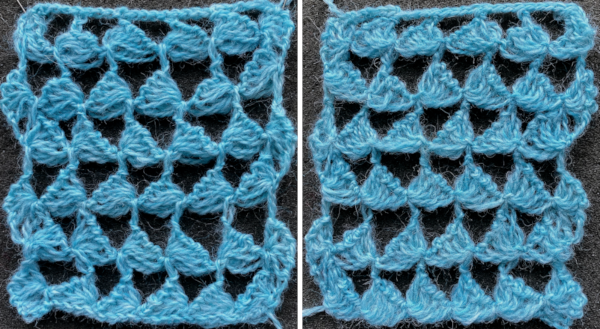

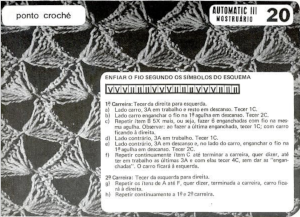

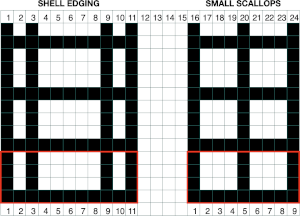

Shell shapes: #4 and # 20 directions are given in the 2017 blog post

Shell shapes: #4 and # 20 directions are given in the 2017 blog post

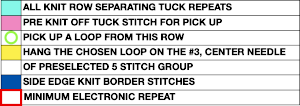

Some of the trims in this pub may be far more easily and quickly executed using tuck stitches.

Some of the trims in this pub may be far more easily and quickly executed using tuck stitches.

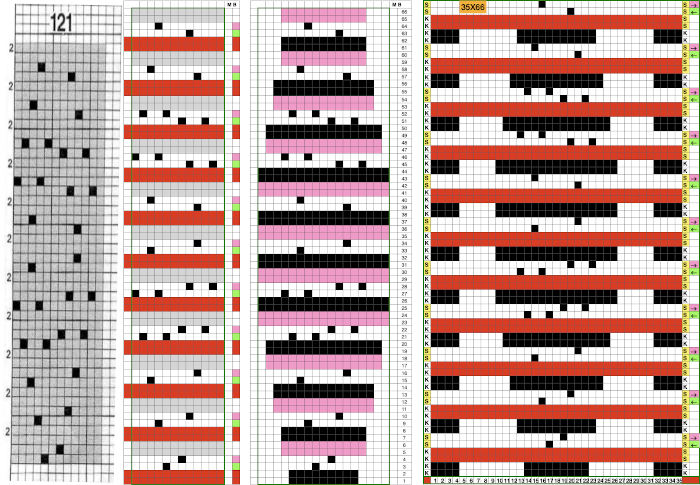

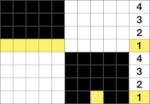

Segments marked with green cells may be grouped in a variety of ways to create repeats in different widths, asymmetrical ones are also a possible consideration

Segments marked with green cells may be grouped in a variety of ways to create repeats in different widths, asymmetrical ones are also a possible consideration

The usual single bed tension for this yarn might be 7 or 8, depending on stitch type. The greater the number of knit stitches on either bed, the closer the tension will have to be adjusted to that used in stocking stitch for the same yarn. Wool also has memory, will want to roll to knit side at the top and bottom, to the purl side along vertical edges, steps often need to be taken to reduce the rolls. Using this repeat

The usual single bed tension for this yarn might be 7 or 8, depending on stitch type. The greater the number of knit stitches on either bed, the closer the tension will have to be adjusted to that used in stocking stitch for the same yarn. Wool also has memory, will want to roll to knit side at the top and bottom, to the purl side along vertical edges, steps often need to be taken to reduce the rolls. Using this repeat

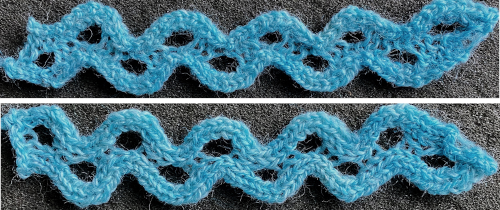

A variety of edgings may be produced by simply hooking up ladder floats created by leaving needles out of work after X number of rows. In this instance chain cast on over 11 needles, dropping the center 5 chains and taking the corresponding needles out of work.

A variety of edgings may be produced by simply hooking up ladder floats created by leaving needles out of work after X number of rows. In this instance chain cast on over 11 needles, dropping the center 5 chains and taking the corresponding needles out of work.

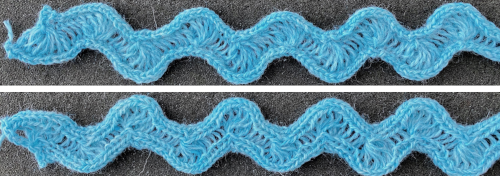

This variation uses the thicker blue yarn, knit at tension 4; 12 rows are knit before hooking up the lower groups of six ladders, which makes the floats easier to pick up or count using a single eye tool. Repeating selection on the same side allows the trim to be easily bent around corners

This variation uses the thicker blue yarn, knit at tension 4; 12 rows are knit before hooking up the lower groups of six ladders, which makes the floats easier to pick up or count using a single eye tool. Repeating selection on the same side allows the trim to be easily bent around corners

Trims using holding alone border on the possibility of automation using slip stitch programming. A simple one to start: cast on 7 stitches, with the center needle out of work. Knit a few rows, set knit carriage to hold.

Trims using holding alone border on the possibility of automation using slip stitch programming. A simple one to start: cast on 7 stitches, with the center needle out of work. Knit a few rows, set knit carriage to hold.

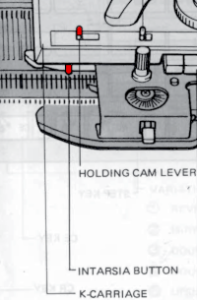

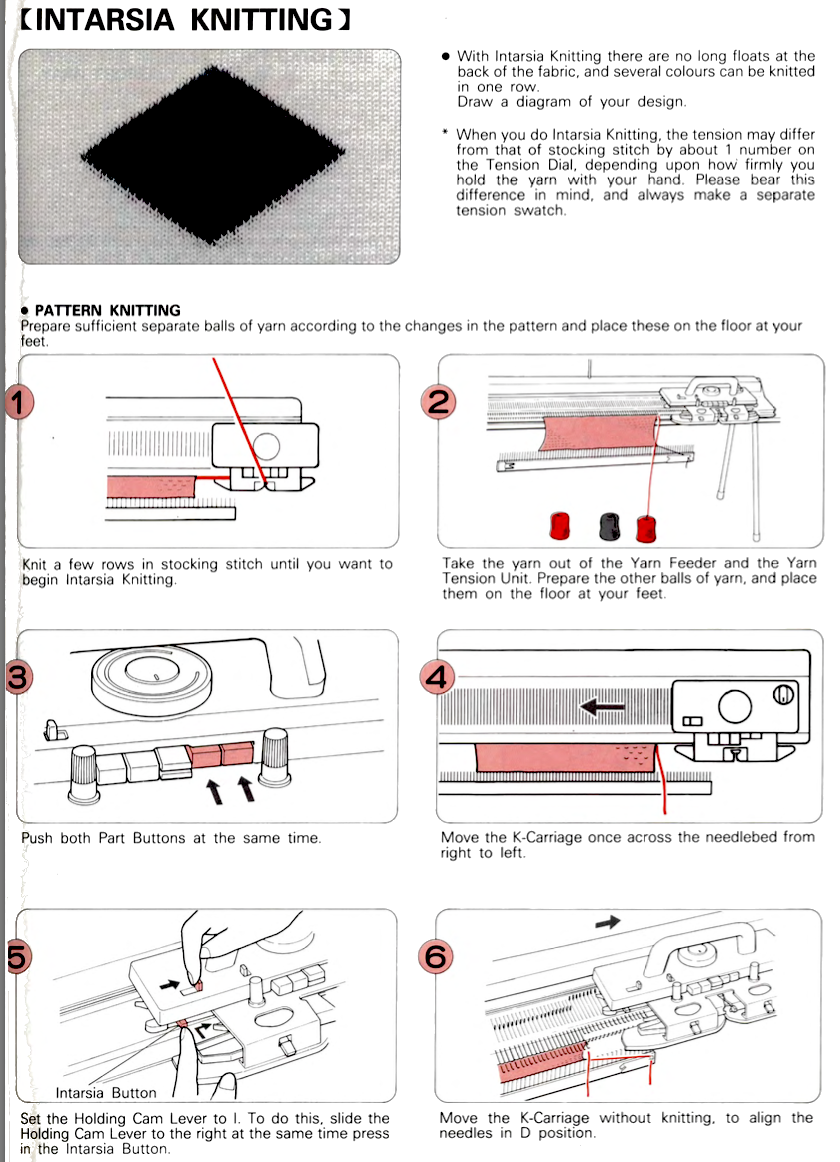

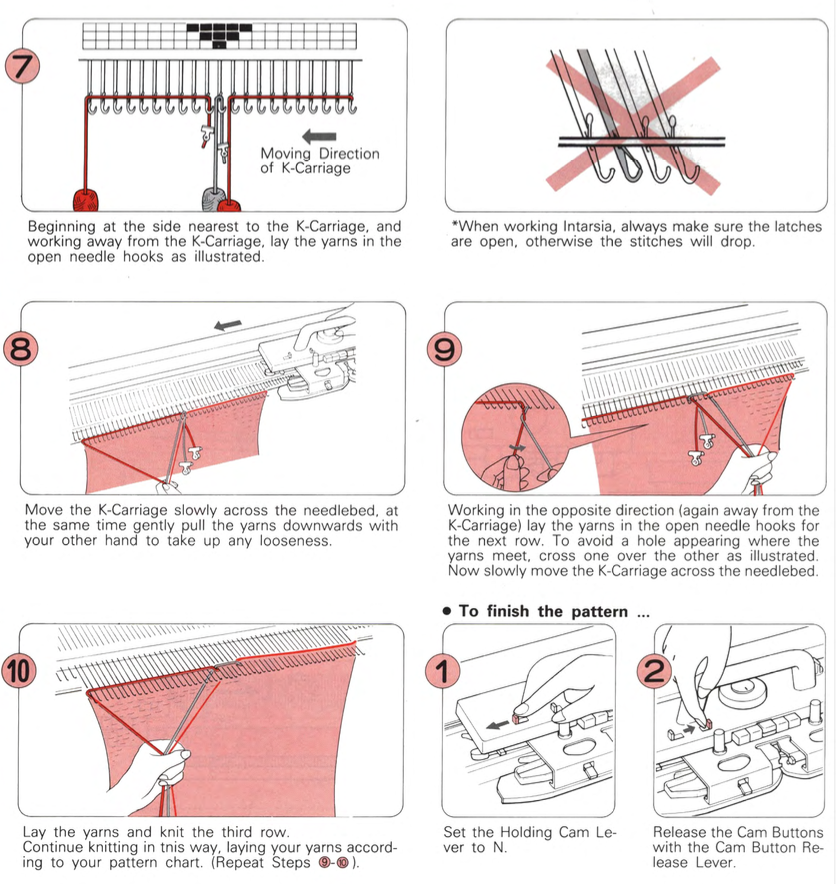

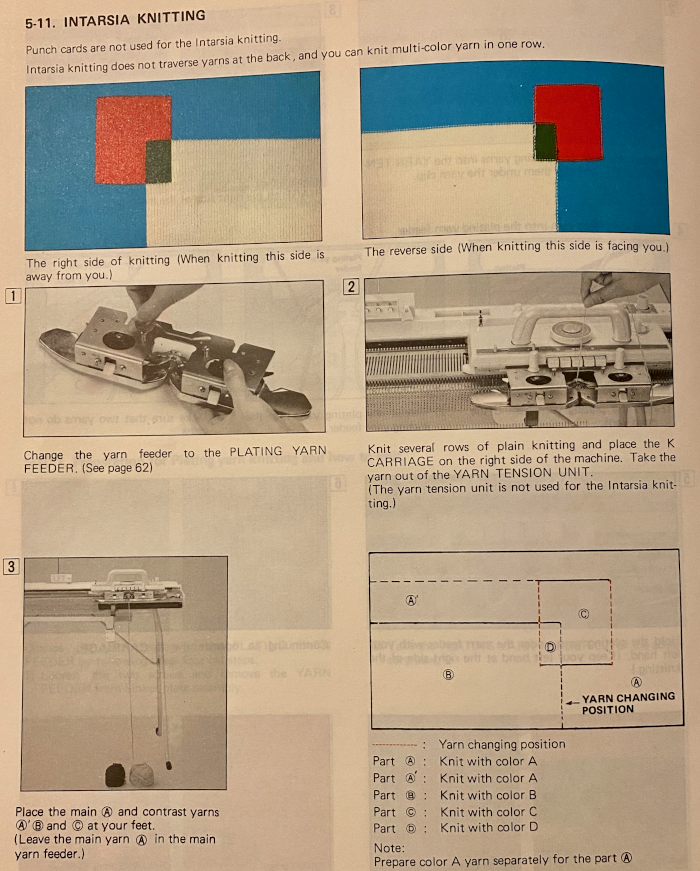

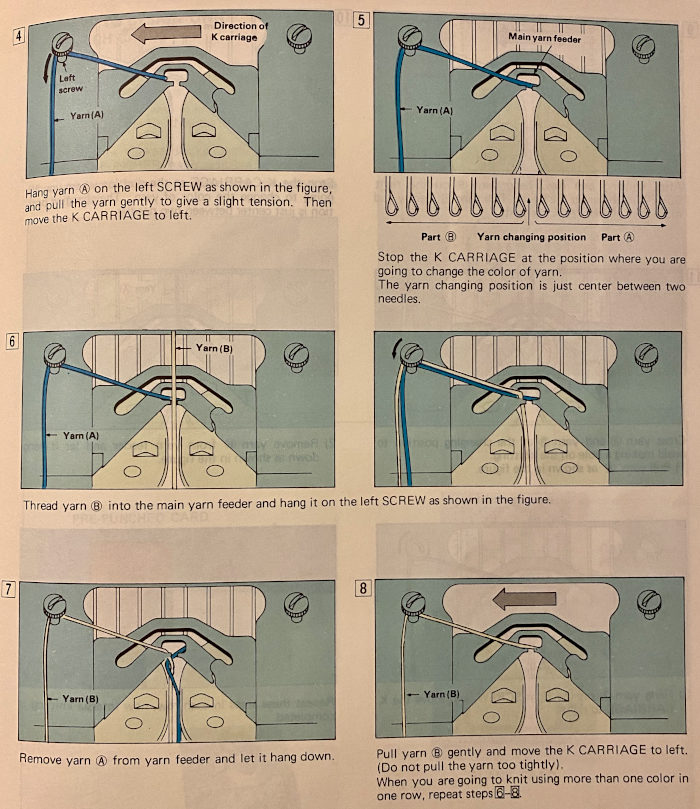

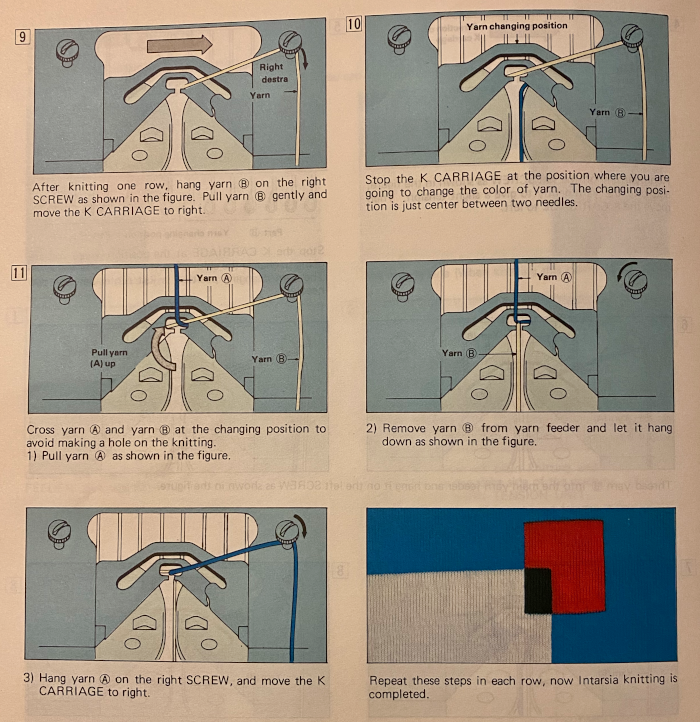

This is from a Japanese language manual for the 891(1987-89) punchcard machine, which appears to introduce the idea of replacing the use of the knit carriage and plaiting feeder with one specifically designed for intarsia

This is from a Japanese language manual for the 891(1987-89) punchcard machine, which appears to introduce the idea of replacing the use of the knit carriage and plaiting feeder with one specifically designed for intarsia

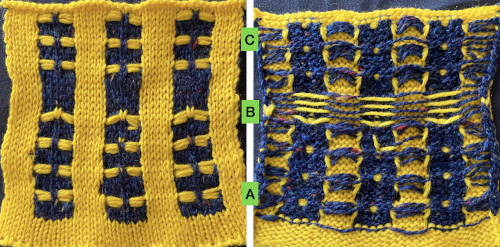

If the intent is to have solid vertical columns of color, those areas as in column marked A, need to be adjusted for using alternating colors as well. Using the repeat on the left of the chart

If the intent is to have solid vertical columns of color, those areas as in column marked A, need to be adjusted for using alternating colors as well. Using the repeat on the left of the chart

Half Milano stitch formation on the left, full on the right

Half Milano stitch formation on the left, full on the right

In executing the fabric as a hand technique, the main bed is still set to slip in both directions, the ribber to knit every row

In executing the fabric as a hand technique, the main bed is still set to slip in both directions, the ribber to knit every row Begin with simple shapes, examining the quality of increases and decreases, whether single or multiple, eyelet formation. Picking up from the row below before the next pass with the contrast color eliminates eyelets

Begin with simple shapes, examining the quality of increases and decreases, whether single or multiple, eyelet formation. Picking up from the row below before the next pass with the contrast color eliminates eyelets picking up from row below at any point during knitting

picking up from row below at any point during knitting

Simple increases or decreases are made by moving stitches laterally in either or both directions. Increases may be made by moving contrast color stitches laterally, followed by the choice as to whether to fill in the empty needle or allow it to create an eyelet.

Simple increases or decreases are made by moving stitches laterally in either or both directions. Increases may be made by moving contrast color stitches laterally, followed by the choice as to whether to fill in the empty needle or allow it to create an eyelet.

Fully fashioned increases or decreases are made by moving a stitch or a group of them to the adjacent needle/s to the left or the right and then taking the double stitches back to the original position, leaving a single empty needle for the planned eyelet formation. There should not be multiple needles with no stitches on them unless the goal is to expose a stripe of ground

Fully fashioned increases or decreases are made by moving a stitch or a group of them to the adjacent needle/s to the left or the right and then taking the double stitches back to the original position, leaving a single empty needle for the planned eyelet formation. There should not be multiple needles with no stitches on them unless the goal is to expose a stripe of ground  typically, in these exercises, there should be single empty needles after transfers, making certain proper needle selection for the pattern group is maintained

typically, in these exercises, there should be single empty needles after transfers, making certain proper needle selection for the pattern group is maintained  Combining eyelets with lateral increases

Combining eyelets with lateral increases

When transferring stitches, watch for any loops getting caught on gate pegs, as seen on the left below, increases and decreases may be pre-formed on more than single stitches

When transferring stitches, watch for any loops getting caught on gate pegs, as seen on the left below, increases and decreases may be pre-formed on more than single stitches

At the top of the single medallion, the stitches were transferred to the ribber prior to knitting with the same color once there was no needle preselection for it on the top bed.

At the top of the single medallion, the stitches were transferred to the ribber prior to knitting with the same color once there was no needle preselection for it on the top bed. The first preselection row after the chosen cast on is from right to left with end needle selection canceled and the knit carriage already set to slip in both directions, with all required needles on the top bed in the B position.

The first preselection row after the chosen cast on is from right to left with end needle selection canceled and the knit carriage already set to slip in both directions, with all required needles on the top bed in the B position.

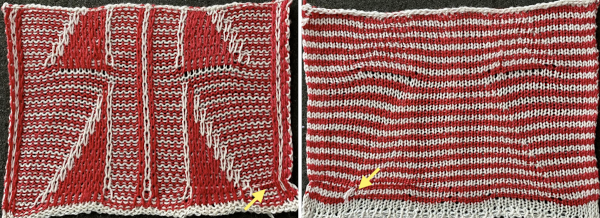

To eliminate the extra white rows, the main bed stays set to slip every row, the ribber settings alternate. It is set to slip for two rows immediately after knitting with the red yarn, then will be reset and knits for 4 consecutive rows. Transfers to create eyelets are made on selected needles on each of those two rows, always toward the carriage, even as the transfers themselves change directions as the angles of the shape decrease toward its center on the top half of the design. After the first transfer and the carriages travel to the right, a long float will be evident, will “disappear” on the return to the left.

To eliminate the extra white rows, the main bed stays set to slip every row, the ribber settings alternate. It is set to slip for two rows immediately after knitting with the red yarn, then will be reset and knits for 4 consecutive rows. Transfers to create eyelets are made on selected needles on each of those two rows, always toward the carriage, even as the transfers themselves change directions as the angles of the shape decrease toward its center on the top half of the design. After the first transfer and the carriages travel to the right, a long float will be evident, will “disappear” on the return to the left.  Patterning selection will reappear as the carriages return to the left.

Patterning selection will reappear as the carriages return to the left.

As with single bed lace, the first pass after transfers creates loops on empty needles, which here need to be kept in upper work, D position after transfers. For non Brother knitters, Brother positions are A, B, D, E, skipping C.

As with single bed lace, the first pass after transfers creates loops on empty needles, which here need to be kept in upper work, D position after transfers. For non Brother knitters, Brother positions are A, B, D, E, skipping C.

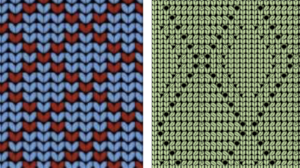

Knitting over the loops on the next pass on that bed completes the stitch. This design is knit as continuous, the striping at the bottom is wrong because the red was not picked up after the first 2 rows knit in pattern with white, most sequences for the remaining fabric are 4 passes with white in the feeder, followed by 2 in the red. All eyelets here are reduced in size by picking up from the row below, all transfers for decreases are made laterally, the border is set to a width of 4 stitches, the pivot point for the repeat has been narrowed

Knitting over the loops on the next pass on that bed completes the stitch. This design is knit as continuous, the striping at the bottom is wrong because the red was not picked up after the first 2 rows knit in pattern with white, most sequences for the remaining fabric are 4 passes with white in the feeder, followed by 2 in the red. All eyelets here are reduced in size by picking up from the row below, all transfers for decreases are made laterally, the border is set to a width of 4 stitches, the pivot point for the repeat has been narrowed

Many of the same principles may be applied to designs using tuck stitch settings, where the striping will appear vertically rather than horizontally

Many of the same principles may be applied to designs using tuck stitch settings, where the striping will appear vertically rather than horizontally

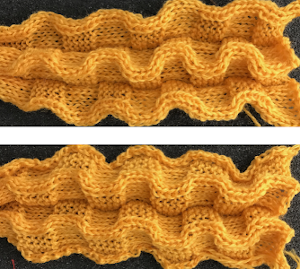

Here the fold is created by 2 stitches tucking for 2 consecutive, then knitting on the same needles for 2 rows on regularly spaced pairs of needles on either bed. Most knitting is on a single bed. A lacey series of eyelets begin to appear, and in some random racking at the top of the swatch, the possibility of developing a secondary pattern due to the combination of racking and tucking begins to show. The middle image is of the fabric slightly stretched. Passap

Here the fold is created by 2 stitches tucking for 2 consecutive, then knitting on the same needles for 2 rows on regularly spaced pairs of needles on either bed. Most knitting is on a single bed. A lacey series of eyelets begin to appear, and in some random racking at the top of the swatch, the possibility of developing a secondary pattern due to the combination of racking and tucking begins to show. The middle image is of the fabric slightly stretched. Passap

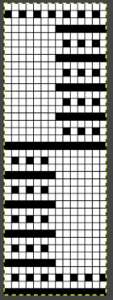

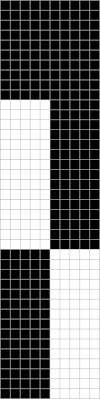

Brother: the ribber can do the stocking stitch background, every needle in work, carriage set to knit. The setup is the same as the Passap diagram. A repeat with 2 black rows of squares followed by 2 white can be programmed on the top bed. On every needle selected rows, pairs of needles will knit, on the white, no selection rows the same pairs of needles will tuck for 2 rows.

Brother: the ribber can do the stocking stitch background, every needle in work, carriage set to knit. The setup is the same as the Passap diagram. A repeat with 2 black rows of squares followed by 2 white can be programmed on the top bed. On every needle selected rows, pairs of needles will knit, on the white, no selection rows the same pairs of needles will tuck for 2 rows.  Moving away from vertical ribs becomes significantly easier if one has a G carriage. The alternative option is to create geometric folds that require transferring between beds. Any of these fabrics are best knit in a yarn that has memory and can spring back. Yarns such as acrylic can be permanently flattened by pressing, resulting in loss of texture. A quick experiment: black cells represent knit stitches, blue purl ones

Moving away from vertical ribs becomes significantly easier if one has a G carriage. The alternative option is to create geometric folds that require transferring between beds. Any of these fabrics are best knit in a yarn that has memory and can spring back. Yarns such as acrylic can be permanently flattened by pressing, resulting in loss of texture. A quick experiment: black cells represent knit stitches, blue purl ones  The needle setups: after casting on, transfer for a stitch configuration based in this case, of blocks that are 5 stitches wide. A single needle on the opposite bed is used on each outside edge of all needles in work.

The needle setups: after casting on, transfer for a stitch configuration based in this case, of blocks that are 5 stitches wide. A single needle on the opposite bed is used on each outside edge of all needles in work.

The repeat, 10 stitches by 40 rows.

The repeat, 10 stitches by 40 rows.

Pleated one color “shadow lace” in

Pleated one color “shadow lace” in

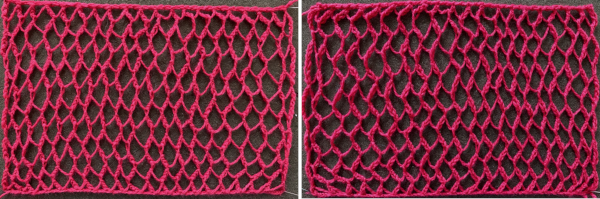

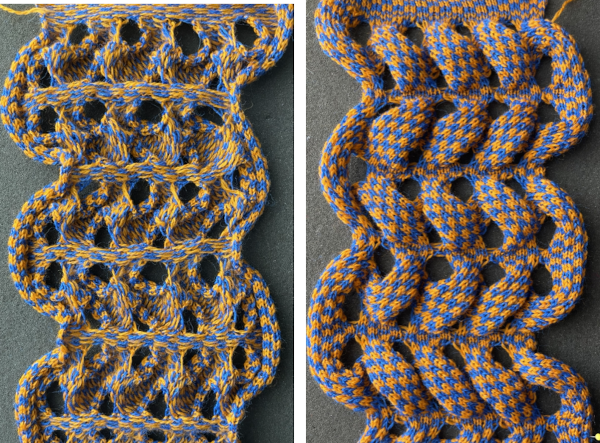

As stated, the process is easier and quicker working on non-selected groups. Above, the yellow yarn was thicker than the blue. To maintain proper color selection in the non-selected column, the center needle needs to remain in the B position, with the slipped stitch forming floats below it before the next row knits. If the needle is brought out to E, it will knit in the contrast color, forming floats in that color on the purl side, and a knit stitch in what was planned as an all-solid column on the knit. The results are seen at the top of the first sequence in the swatch. I chose to limit my number of floats to 4 to keep the process manageable, moved stitches on the left of the center needle to the front of the knit, and then followed with those to its right. One of the many things to explore in hand technique fabrics is finding a way to handle tools that may be more comfortable than others, practicing on single blocks of color first can help establish that. Below both yarns are equal in weight and thinner. The floats formed by the color in the B feeder are also hooked up on the center needle in each vertical group in that color, forming a pattern on the purl side as well.

As stated, the process is easier and quicker working on non-selected groups. Above, the yellow yarn was thicker than the blue. To maintain proper color selection in the non-selected column, the center needle needs to remain in the B position, with the slipped stitch forming floats below it before the next row knits. If the needle is brought out to E, it will knit in the contrast color, forming floats in that color on the purl side, and a knit stitch in what was planned as an all-solid column on the knit. The results are seen at the top of the first sequence in the swatch. I chose to limit my number of floats to 4 to keep the process manageable, moved stitches on the left of the center needle to the front of the knit, and then followed with those to its right. One of the many things to explore in hand technique fabrics is finding a way to handle tools that may be more comfortable than others, practicing on single blocks of color first can help establish that. Below both yarns are equal in weight and thinner. The floats formed by the color in the B feeder are also hooked up on the center needle in each vertical group in that color, forming a pattern on the purl side as well.  The needle position for selection for B feeder yarn also needs to be maintained. Bringing the needle out to E ensures it will knit on the next pass. In both of my tests, the slip stitch floats on the knit side lie more horizontally than the lifted-up floats on the purl.

The needle position for selection for B feeder yarn also needs to be maintained. Bringing the needle out to E ensures it will knit on the next pass. In both of my tests, the slip stitch floats on the knit side lie more horizontally than the lifted-up floats on the purl.

The transfers in the piece begin on row 5. Before the next row is knit in the alternate color, the slip stitch floats are reconfigured, bringing stitches 1 and 2, 4 and 5 in each group to the knit side of the fabric, leaving the center floats undisturbed.

The transfers in the piece begin on row 5. Before the next row is knit in the alternate color, the slip stitch floats are reconfigured, bringing stitches 1 and 2, 4 and 5 in each group to the knit side of the fabric, leaving the center floats undisturbed.  Bring the whole group out to the E position so they will form knit stitches with the first row of contrast as the carriage moves to the right.

Bring the whole group out to the E position so they will form knit stitches with the first row of contrast as the carriage moves to the right.