After a slow down in my blog posts for a variety of reasons I find myself playing catch up with the eternal list of knit fabrics that I wish to explore out of my own curiosity and the attempt to answer questions from knitters who contacted me directly via the blog or have asked them in the online forums in which I am a member.

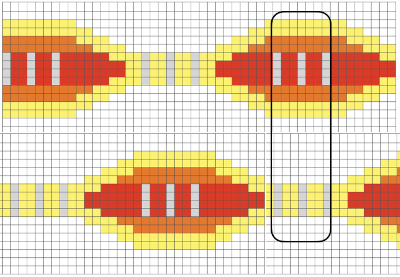

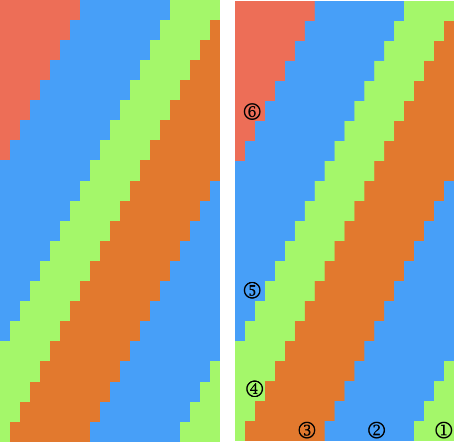

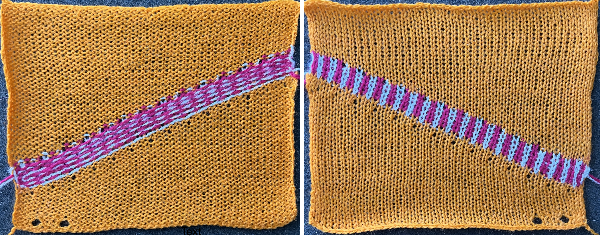

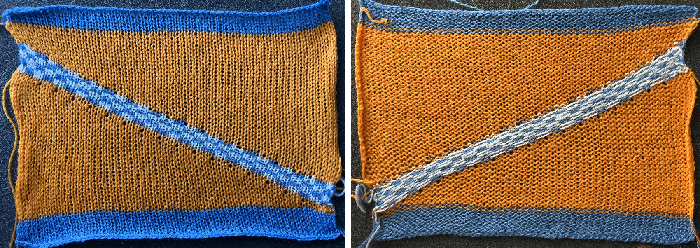

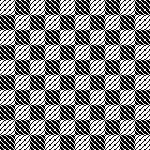

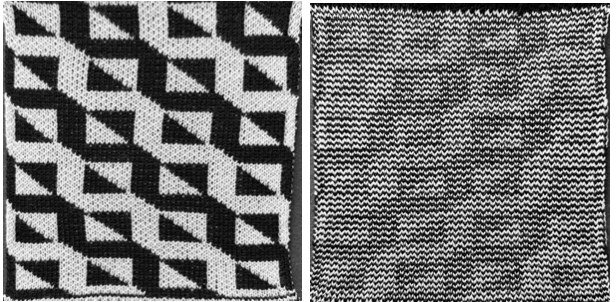

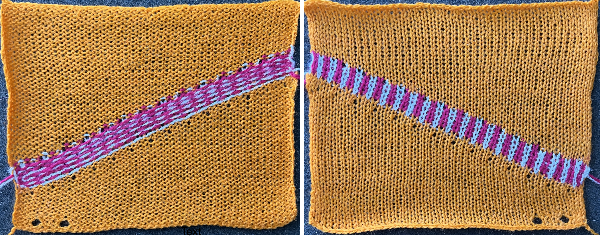

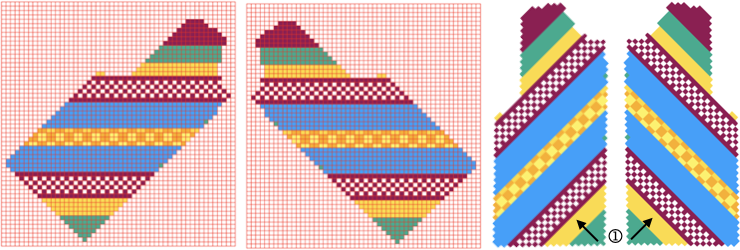

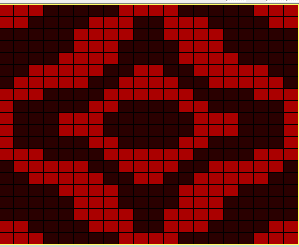

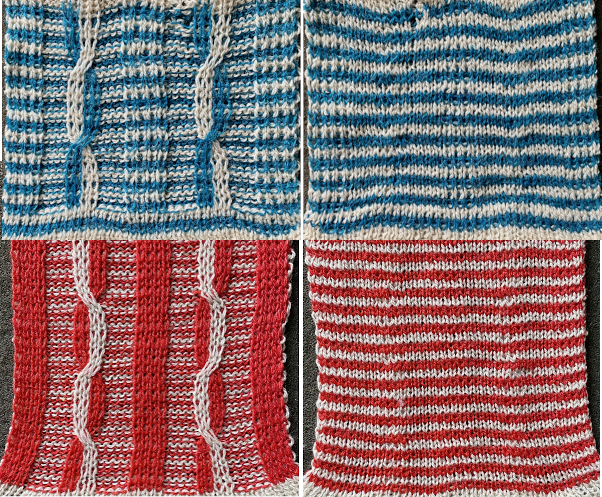

Stephen West is a prolific designer of colorful hand knits in a variety of techniques and complexity. This honey-striped scarf is an example.  Slip-stitch patterning is a likely way of knitting a similar effect combined with

Slip-stitch patterning is a likely way of knitting a similar effect combined with

the use of the concept familiar to many when making bias cast-on rags.

A fixed number of stitches is cast on and positioned as far to one side of the machine as possible. They are then decreased on a fixed side and increased on the opposite one.

The strip moves across the needle bed, when far enough on the side opposite to the starting one, it is returned to the original needle bed position and the process is repeated until the desired length is reached.

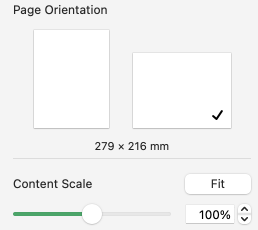

If the moves to and from are performed on solid color rows matching needle selections may not be an issue. If the repeats in other cam settings are to match, then proper needle placement can be assisted by marking the metal bed, the factory-supplied needle tape, or a custom-printed one, and hand-selection for the first design row may be required and planned.

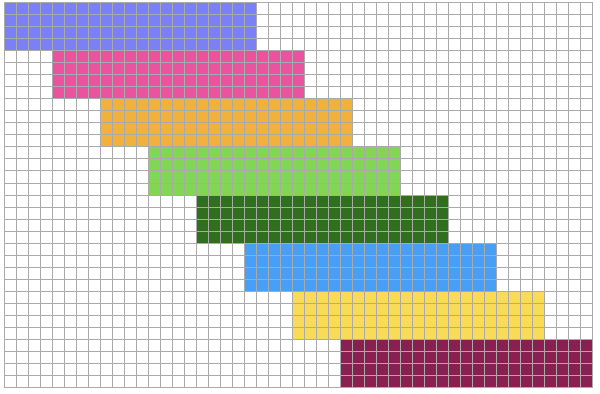

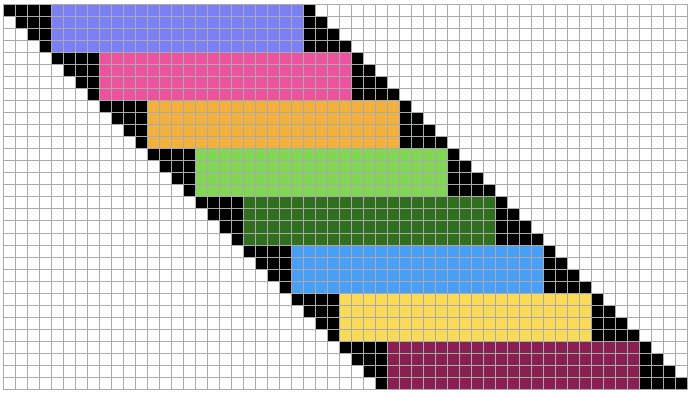

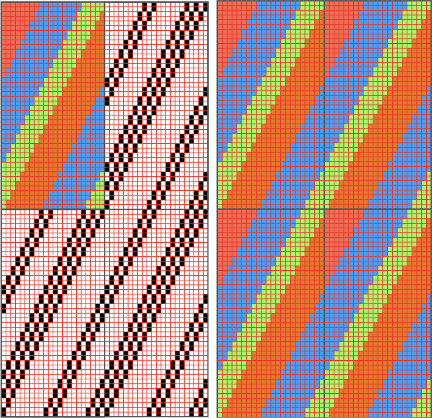

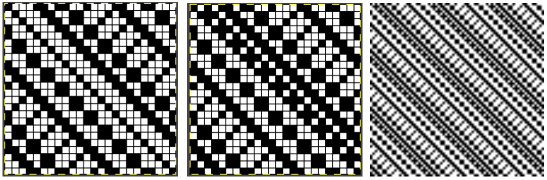

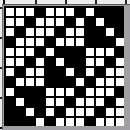

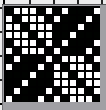

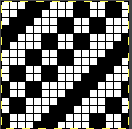

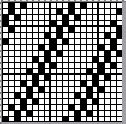

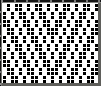

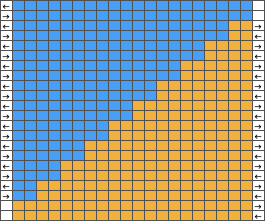

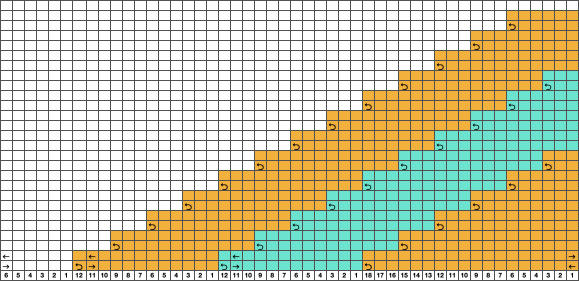

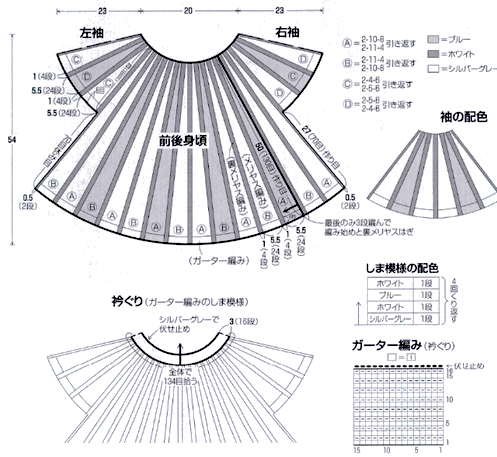

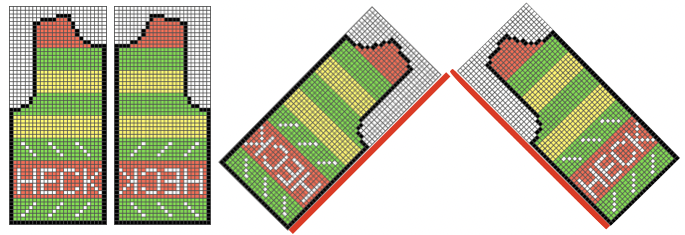

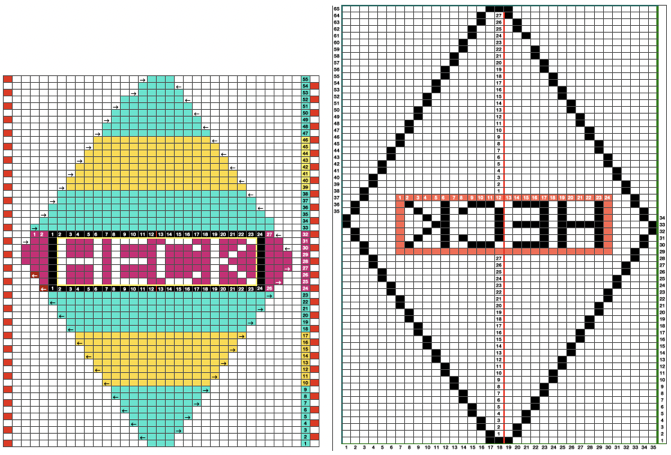

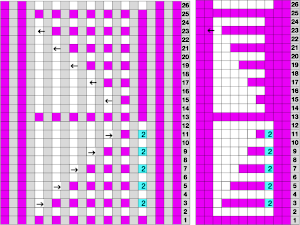

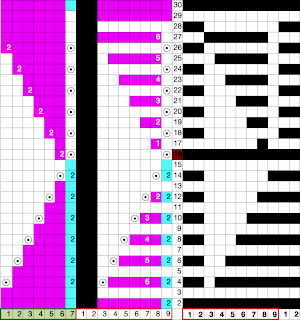

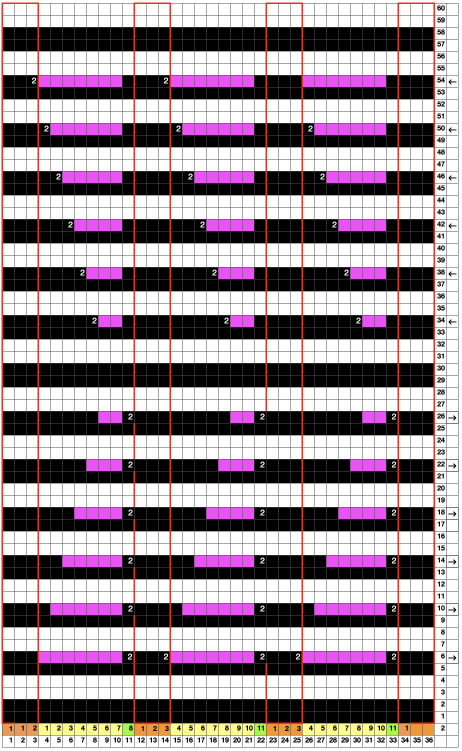

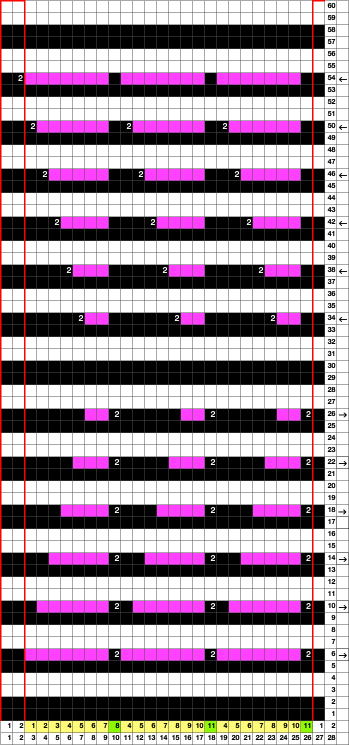

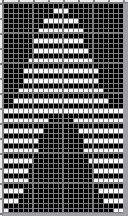

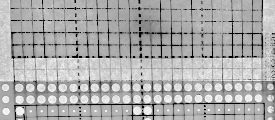

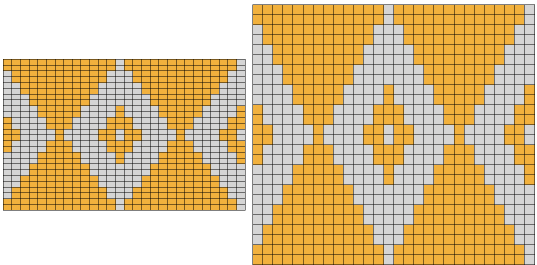

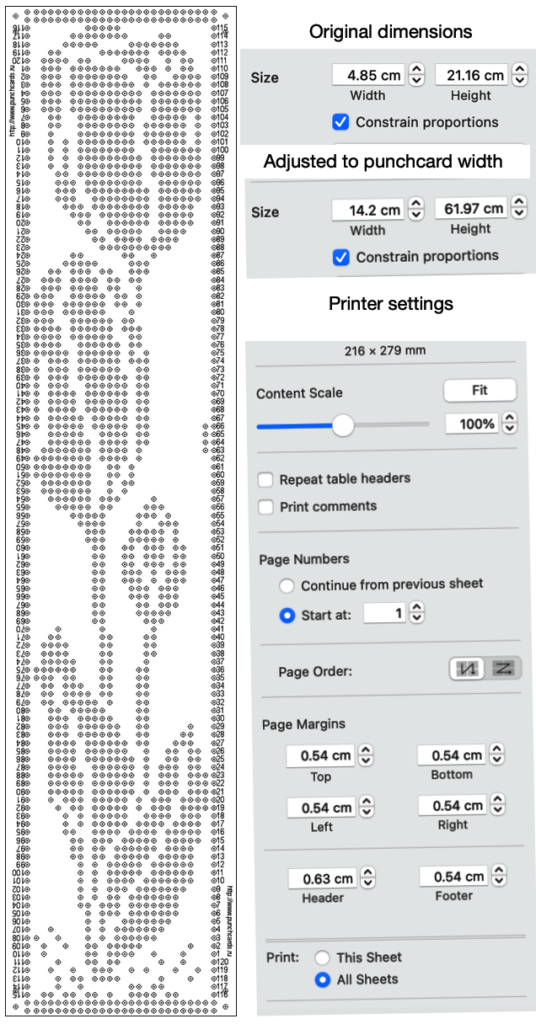

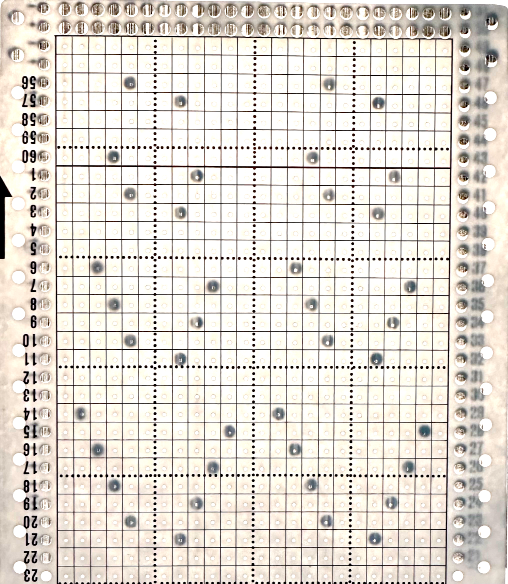

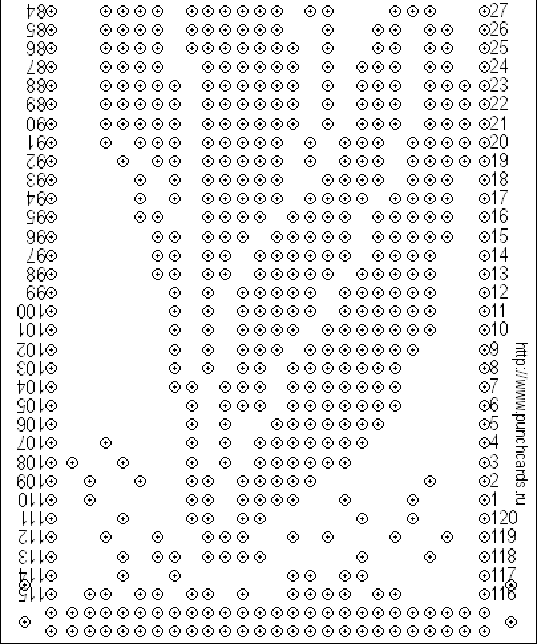

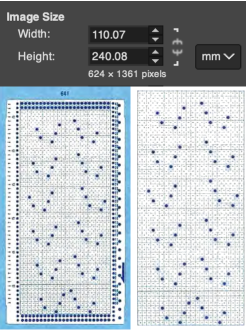

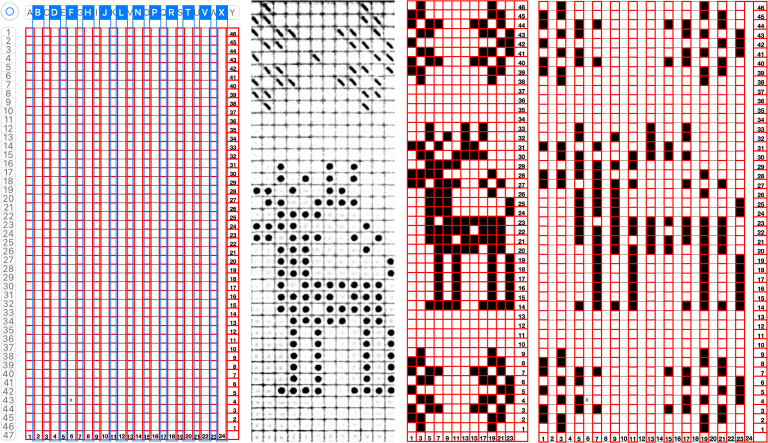

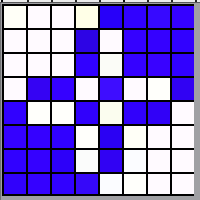

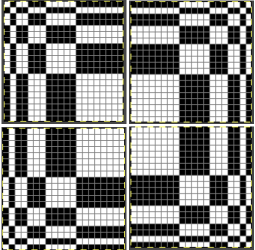

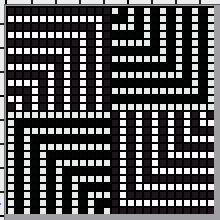

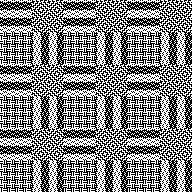

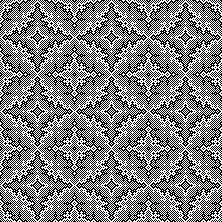

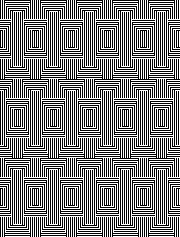

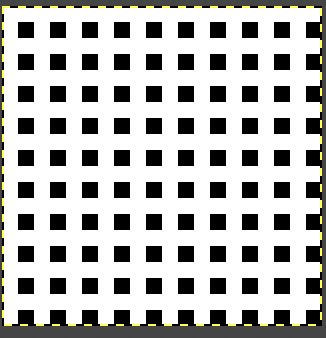

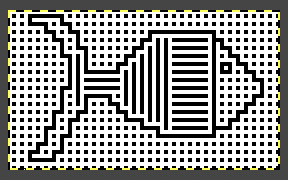

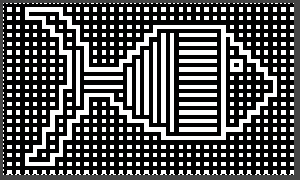

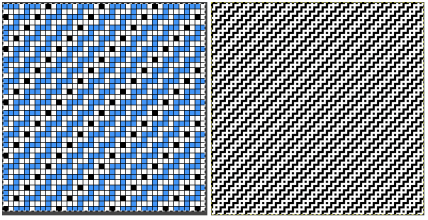

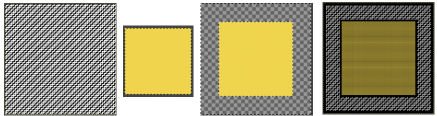

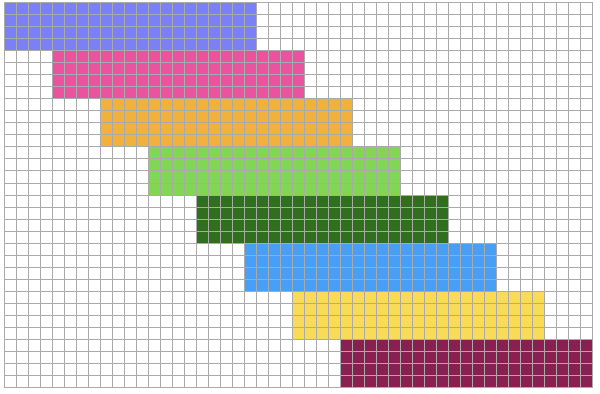

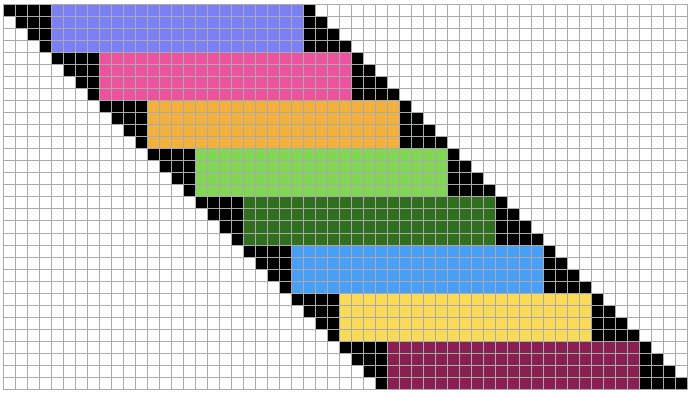

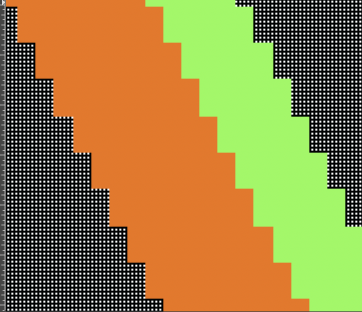

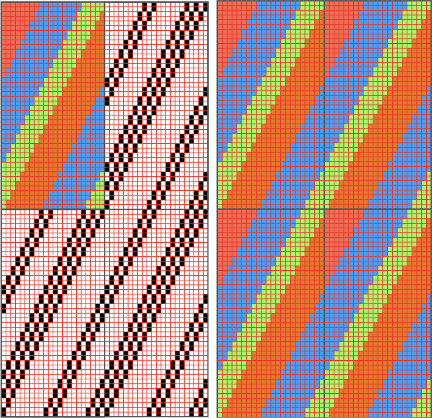

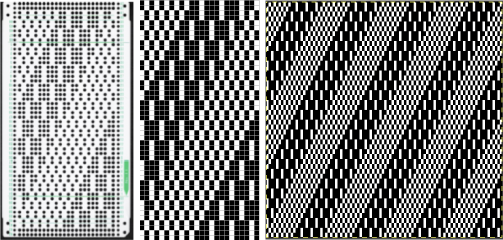

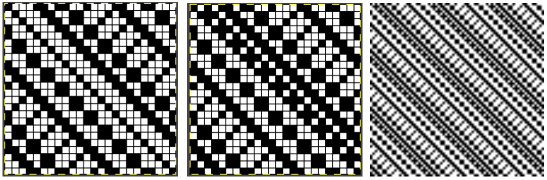

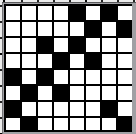

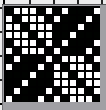

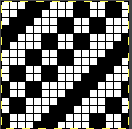

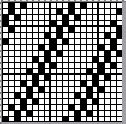

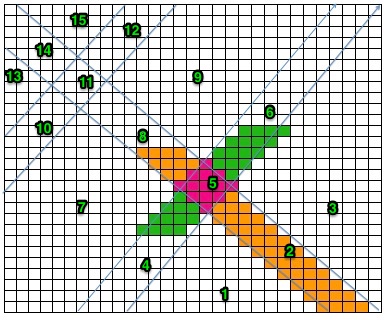

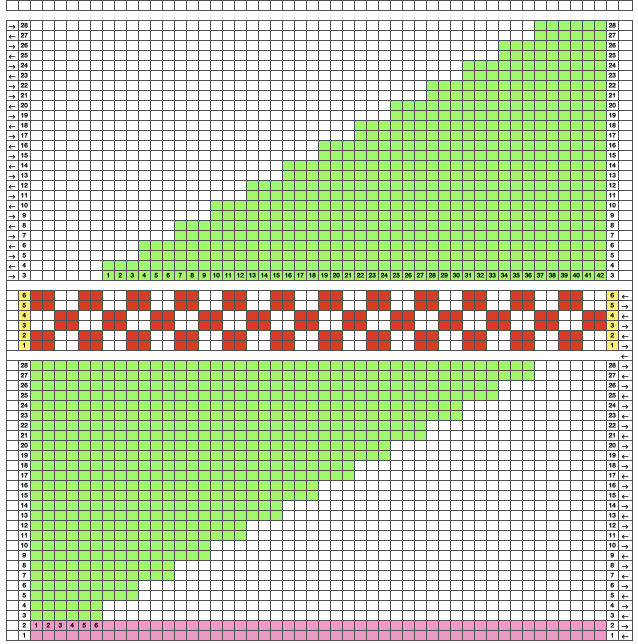

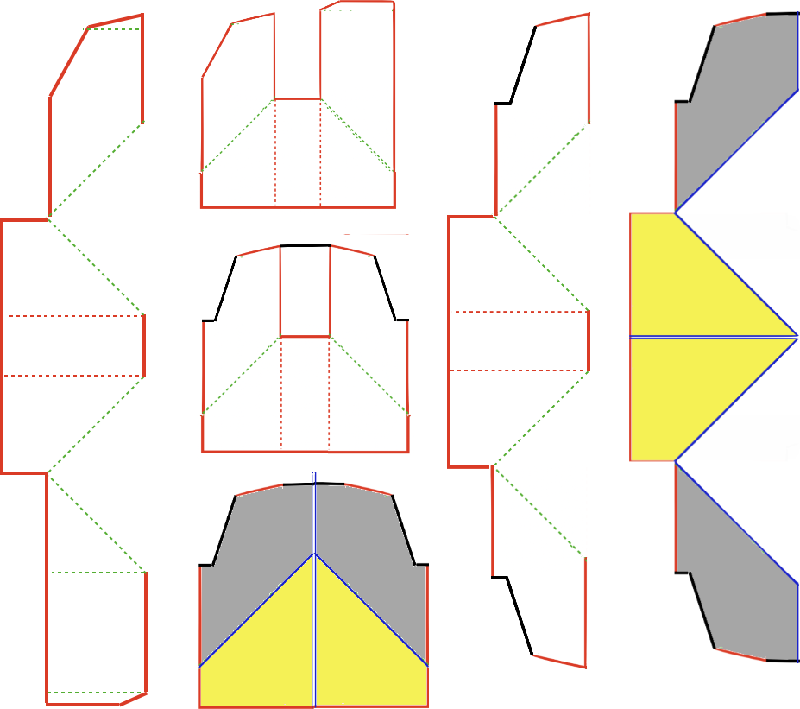

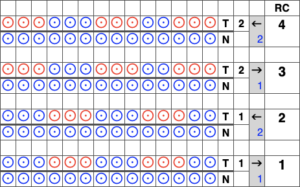

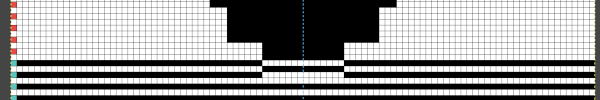

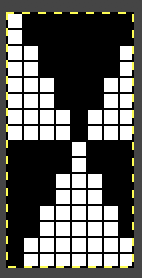

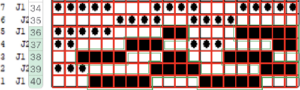

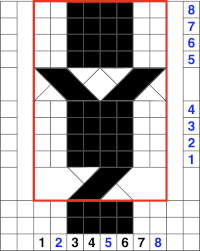

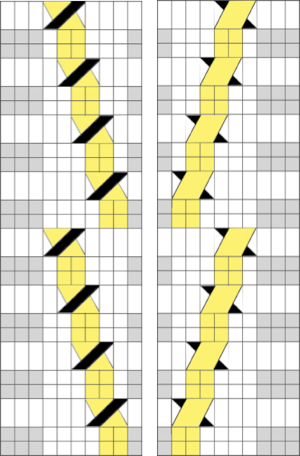

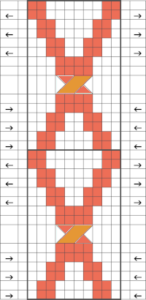

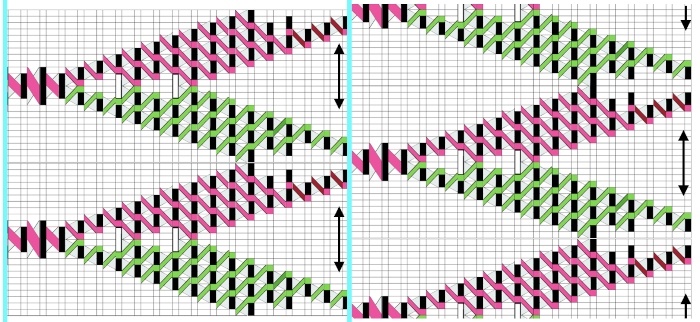

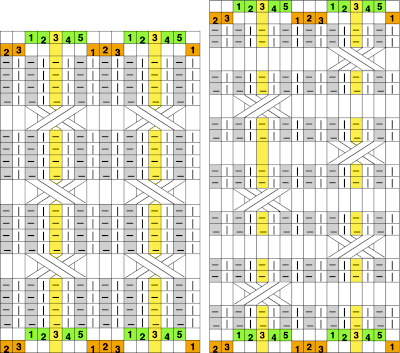

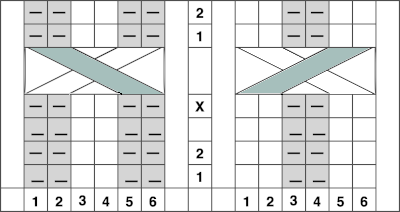

This chart attempts to visualize the proposed movement using colored stripes. Stitches are bound off on one side and cast-on on the other to maintain a fixed width with shaped edges.  If the goal is to maintain straight bias edges, the design repeat would need to be rendered wider in order to compensate for the shifts on the needle bed in turn modifying increases and decreases at a different rate The black cells represent the adjusted stitch counts needed for each pattern band.

If the goal is to maintain straight bias edges, the design repeat would need to be rendered wider in order to compensate for the shifts on the needle bed in turn modifying increases and decreases at a different rate The black cells represent the adjusted stitch counts needed for each pattern band.  When an item such as a scarf is worn, both options will appear as diagonals.

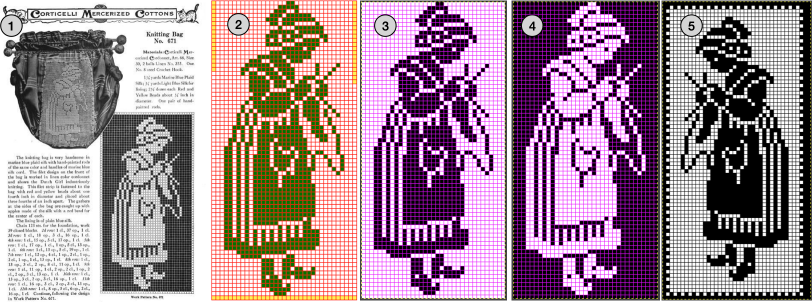

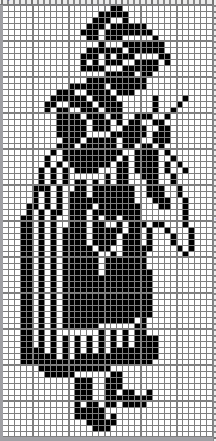

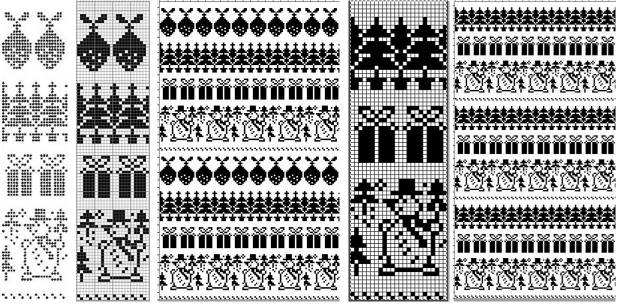

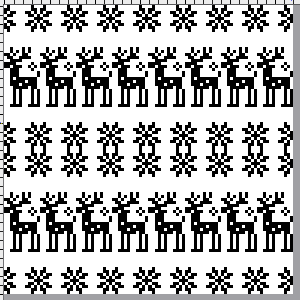

When an item such as a scarf is worn, both options will appear as diagonals.  If any picture knitting is included and the direction of it matters when the piece is worn, appreciated particularly in representational fair isle, such accessories are best knit as 2 pieces knit from the bottom up, and grafted together at their center after the fact.

If any picture knitting is included and the direction of it matters when the piece is worn, appreciated particularly in representational fair isle, such accessories are best knit as 2 pieces knit from the bottom up, and grafted together at their center after the fact.

Increases and decreases are calculated carefully based on the knit gauge for garments. The approach to accessories may be more casual.

Stripe heights are varied to accommodate specific design motifs or cam settings, and they are, in turn, added to the base visualization charts.

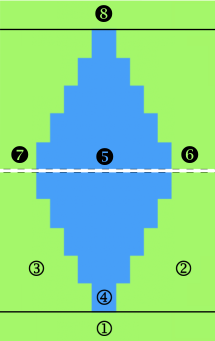

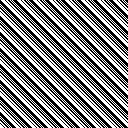

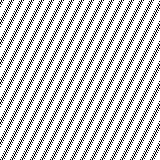

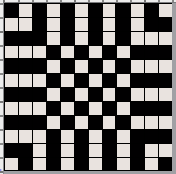

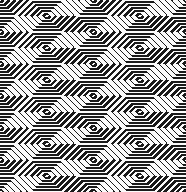

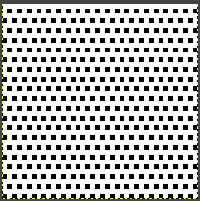

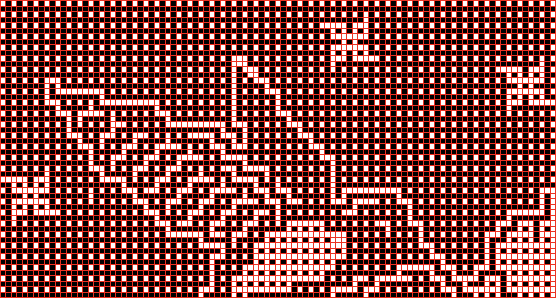

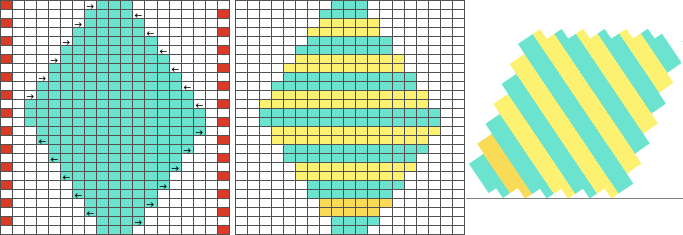

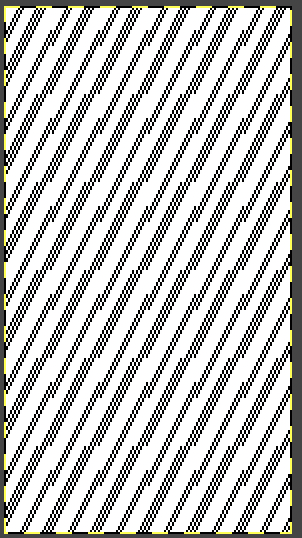

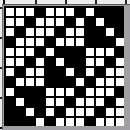

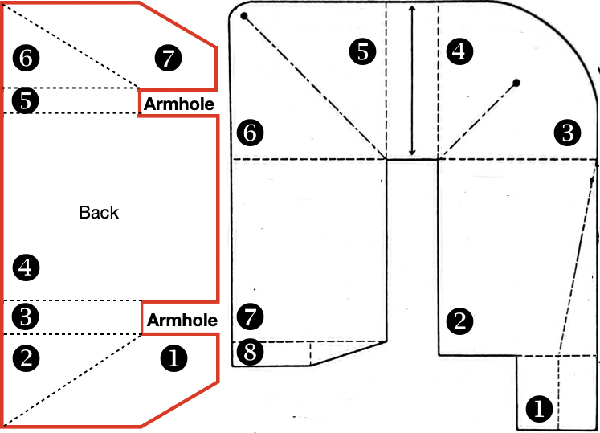

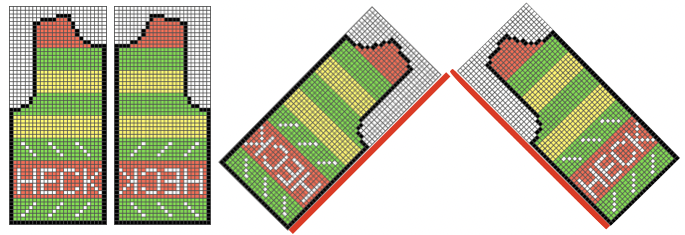

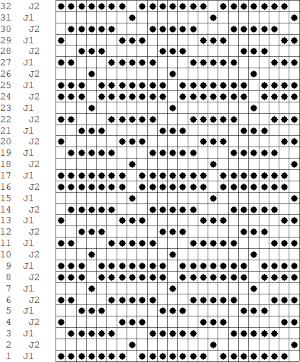

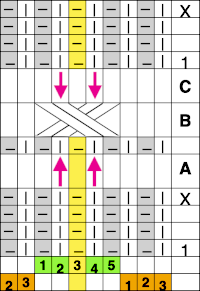

Here an attempt at 45-degree striping is made by beginning on a 3-stitch tab. Increasing on the carriage side creates loops, while those opposite the carriage form knots.

Increases and decreases are indicated by arrows.

Increases are made on alternating sides, opposite the carriage, to produce matching edges.

The red cells in the chart represent the carriage side before each pass.

Table cells have been rendered rectangular in a 4 to 3 ratio, estimating the difference in gauge between stitches and rows.

Striping for an even number of rows matters if color changes are made on a fixed side ie if a color changer is in use.  Yarn ends at color changes may be cut or the yarn can be carried up the side depending on preference and the number of rows involved. If carried up for long stretches, the alternate color yarn not in use may be secured by e wrapping it on the end needle periodically. Care needs to be taken that the float up the side is not so short as to have an effect on the swatch length and having an effort to remedy that will leave yarn ends too short to be secured.

Yarn ends at color changes may be cut or the yarn can be carried up the side depending on preference and the number of rows involved. If carried up for long stretches, the alternate color yarn not in use may be secured by e wrapping it on the end needle periodically. Care needs to be taken that the float up the side is not so short as to have an effect on the swatch length and having an effort to remedy that will leave yarn ends too short to be secured.

The result will not produce a proper square, garter stitch is the only knit stitch that results in approximately true square shapes.

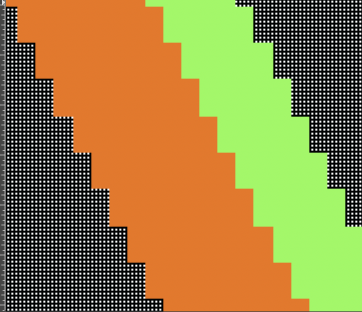

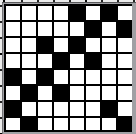

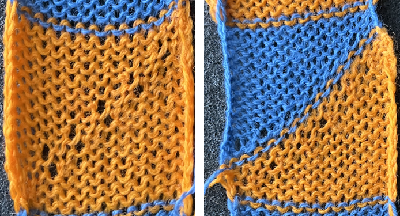

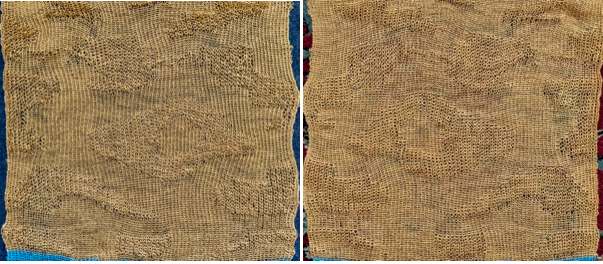

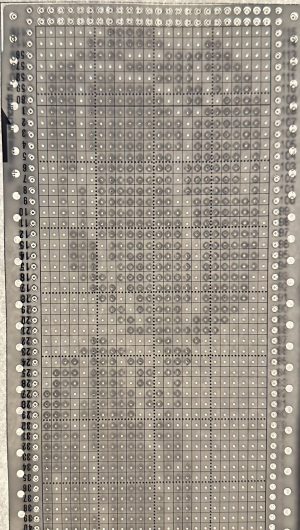

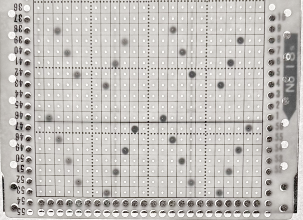

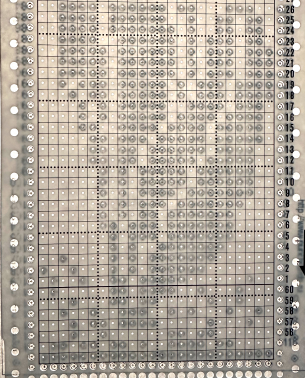

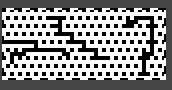

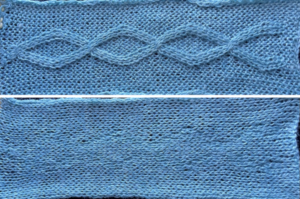

If the center of the needle bed is used for swatches while keeping an eye on the stitch formation. If loops are formed repeatedly on specific needles akin to tuck stitches or problem areas such as those in the center of this swatch are encountered, they can be caused by damaged needles or sticky latches that may result from frequent use.  Diagonal lines in knits that maintain straight sides are also achieved using short row/holding intarsia techniques. Segments are planned in specific orders

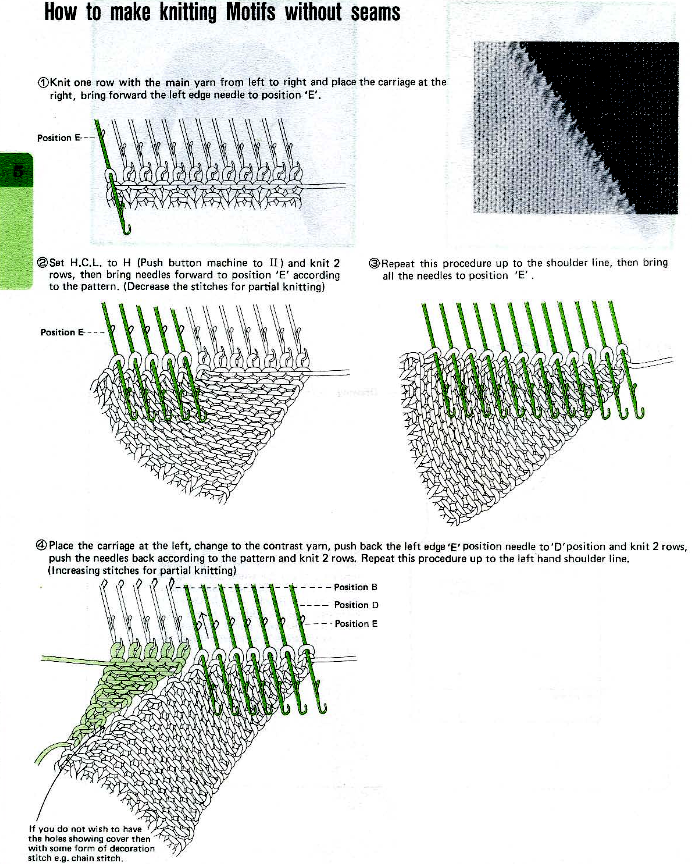

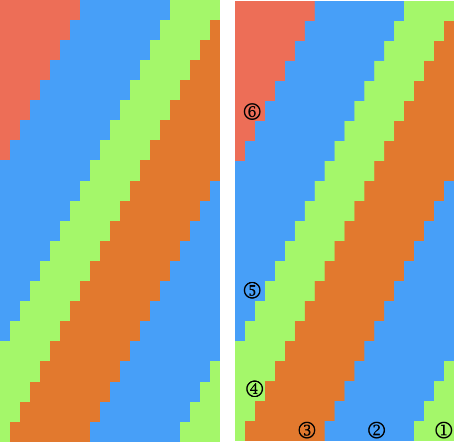

Diagonal lines in knits that maintain straight sides are also achieved using short row/holding intarsia techniques. Segments are planned in specific orders  which can be varied to form added shapes.

which can be varied to form added shapes.  Chevrons would be more easily created by knitting separate strips and seaming as you knit or after the fact.

Chevrons would be more easily created by knitting separate strips and seaming as you knit or after the fact.  The addition of small-repeat fair isle patterns is also possible. Keep in mind when bringing needles back into work to reverse shaping, needle preselection for accurate patterning in Brother machines needs to be maintained by hand selection.

The addition of small-repeat fair isle patterns is also possible. Keep in mind when bringing needles back into work to reverse shaping, needle preselection for accurate patterning in Brother machines needs to be maintained by hand selection.  Some of the published punchcard patterns can serve as a source for diagonal lines that may be tiled and programmed for the full design in addition to being used for their original intent. Numbers 52, 384, and 328 (published with error), are suitable for tuck, slip, and FI with moderately wide floats, while 335 would fail as a tuck stitch.

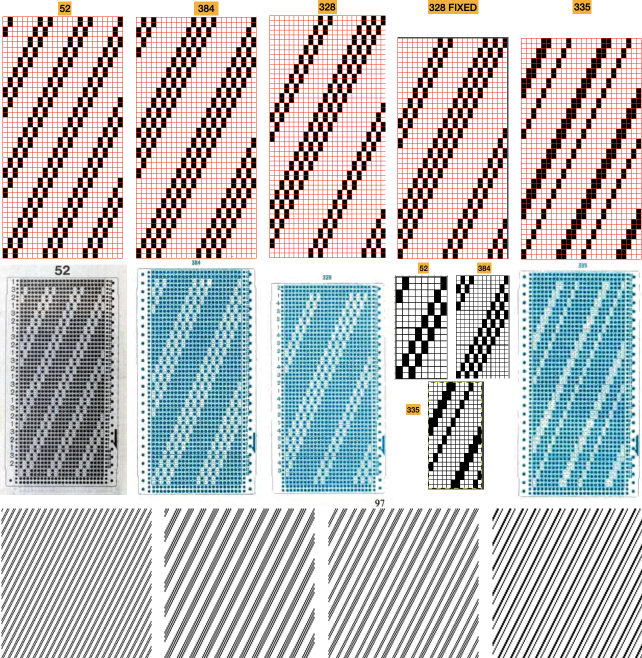

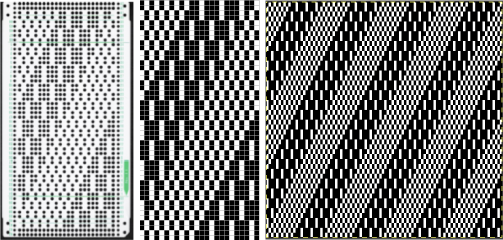

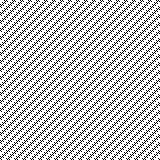

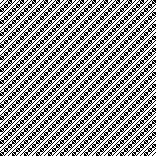

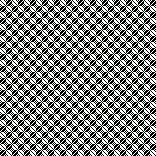

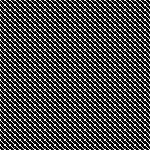

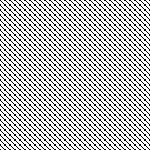

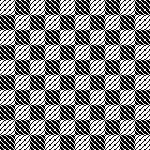

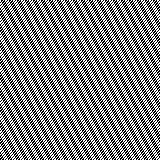

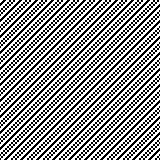

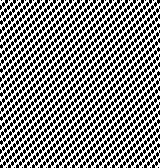

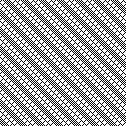

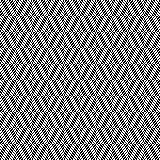

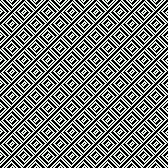

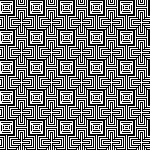

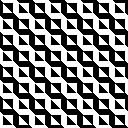

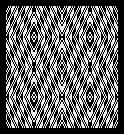

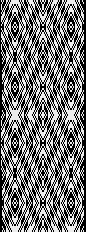

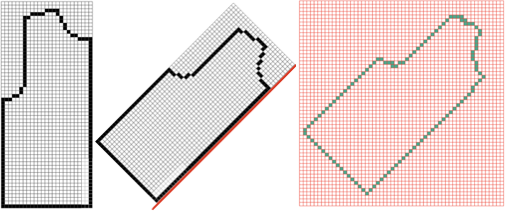

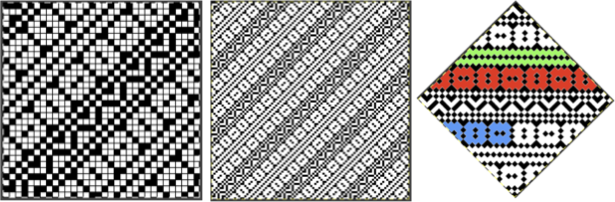

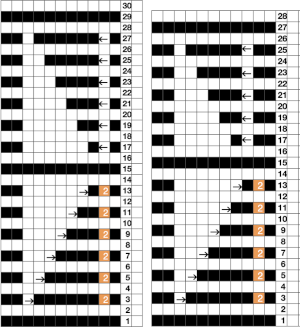

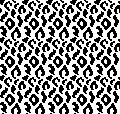

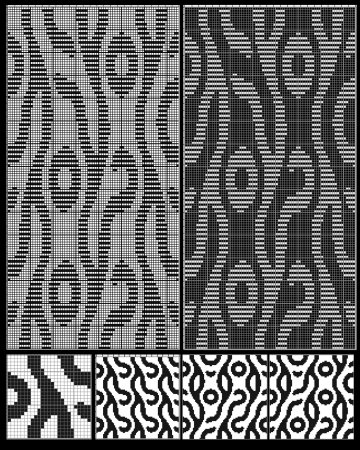

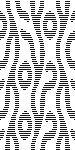

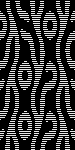

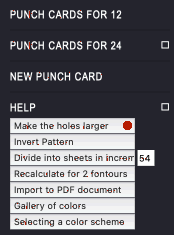

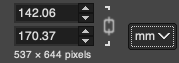

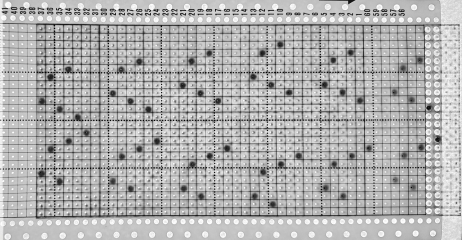

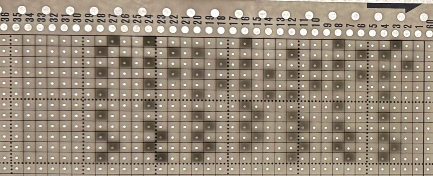

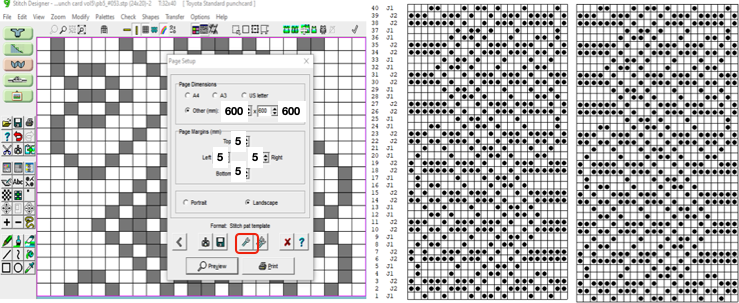

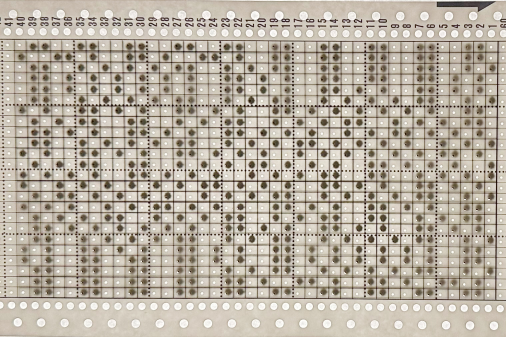

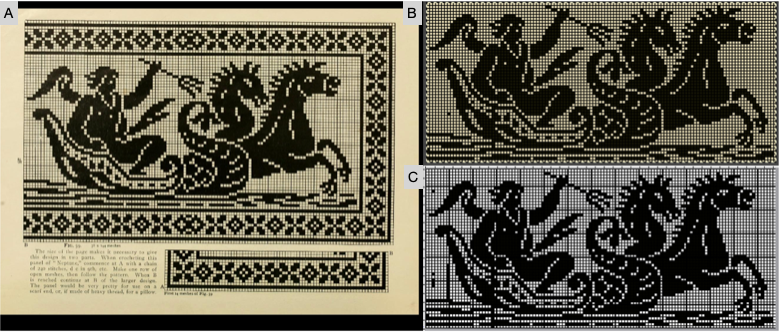

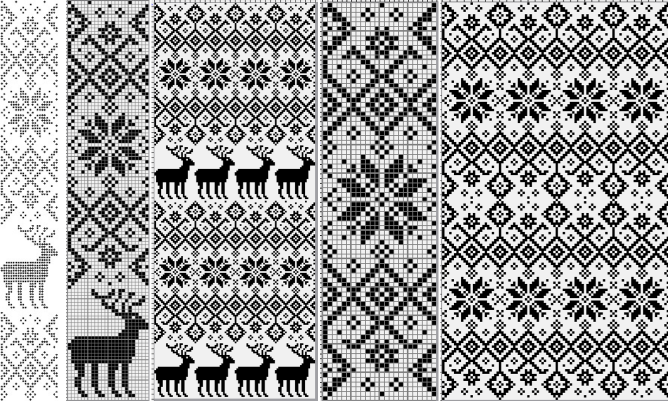

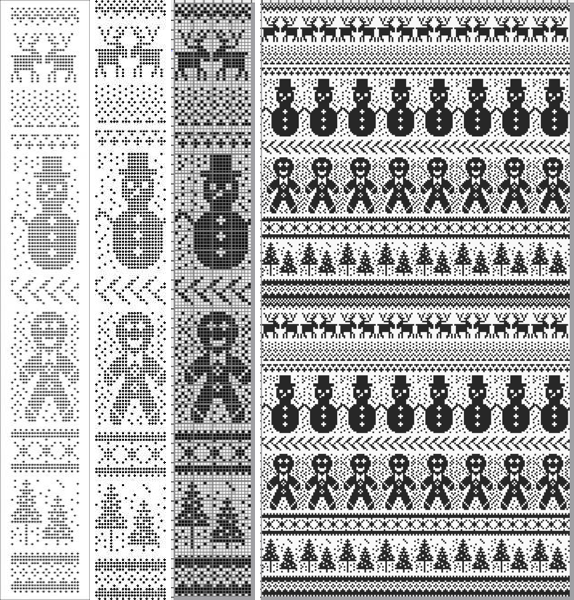

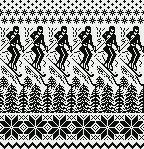

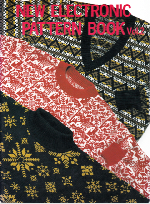

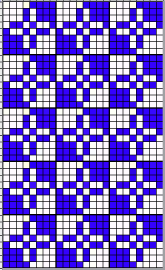

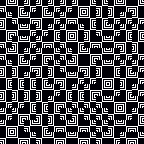

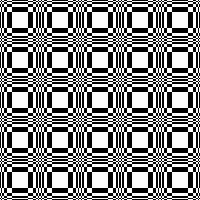

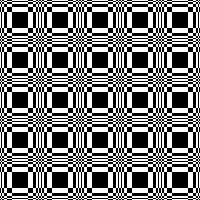

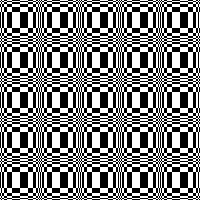

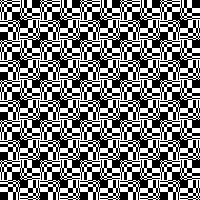

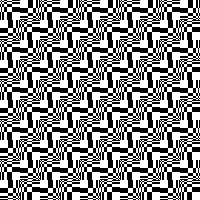

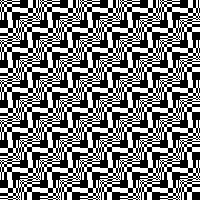

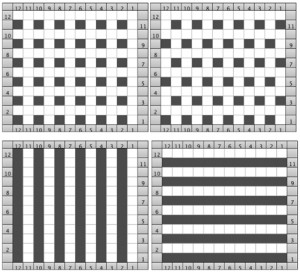

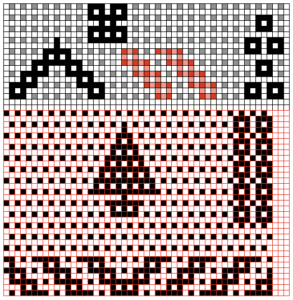

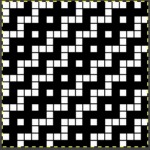

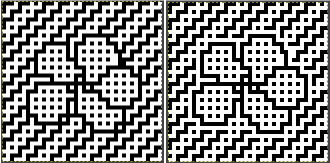

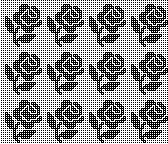

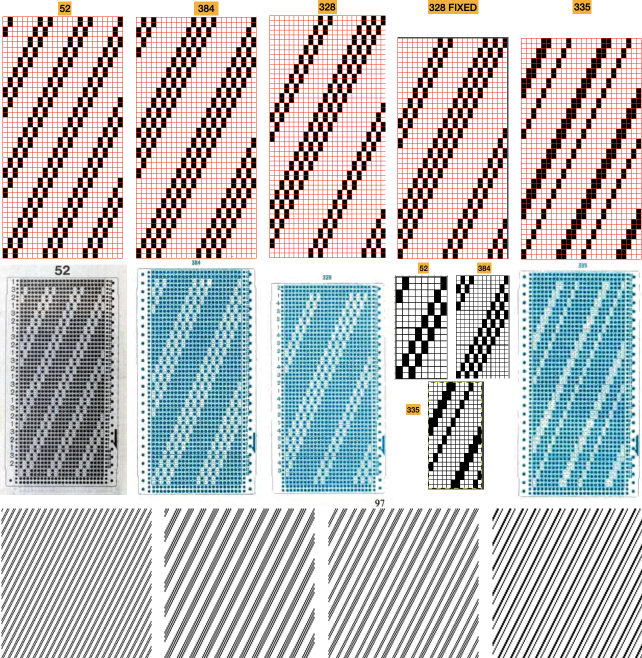

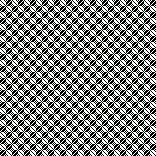

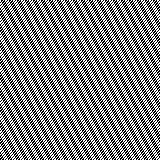

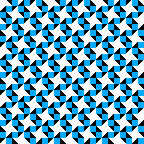

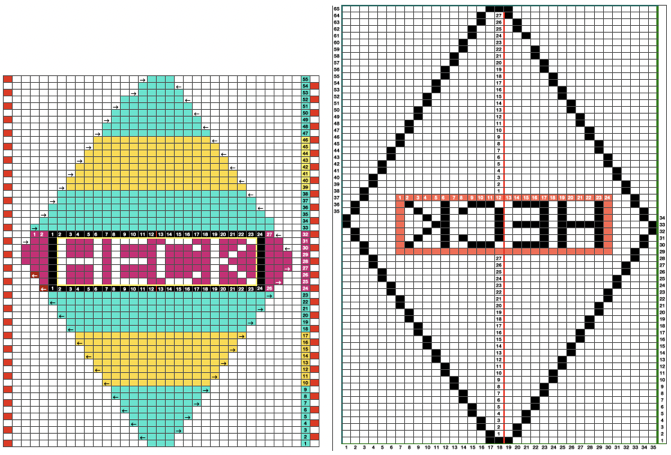

Some of the published punchcard patterns can serve as a source for diagonal lines that may be tiled and programmed for the full design in addition to being used for their original intent. Numbers 52, 384, and 328 (published with error), are suitable for tuck, slip, and FI with moderately wide floats, while 335 would fail as a tuck stitch.

For added ways to develop diagonal patterns using brush fill see post on developing designs using pattern fill for use on a range of machine models

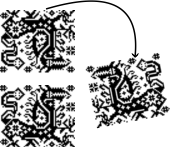

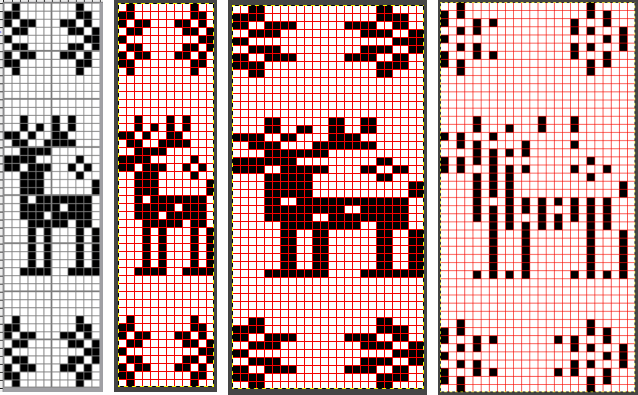

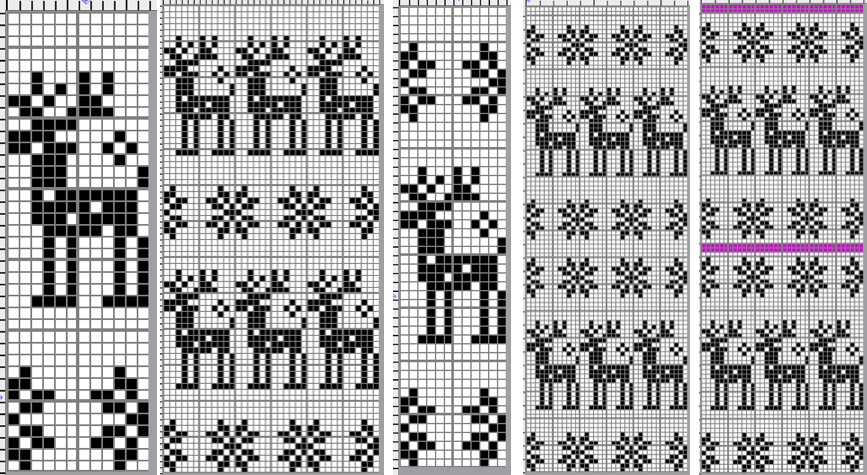

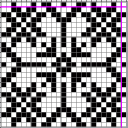

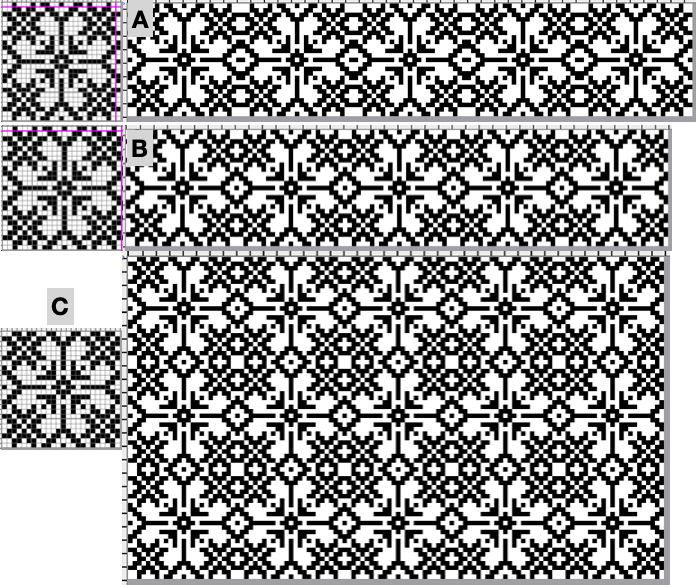

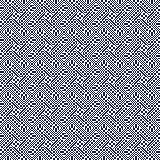

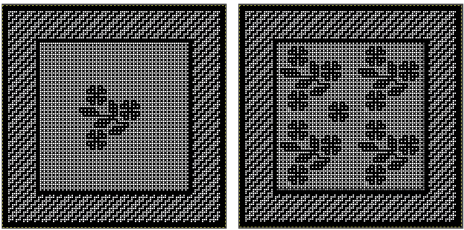

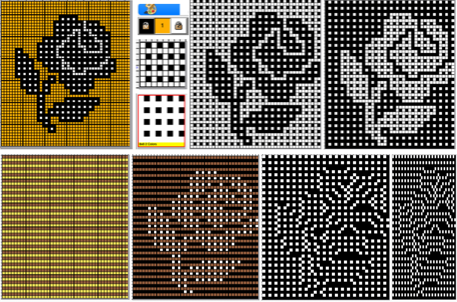

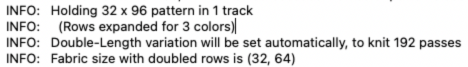

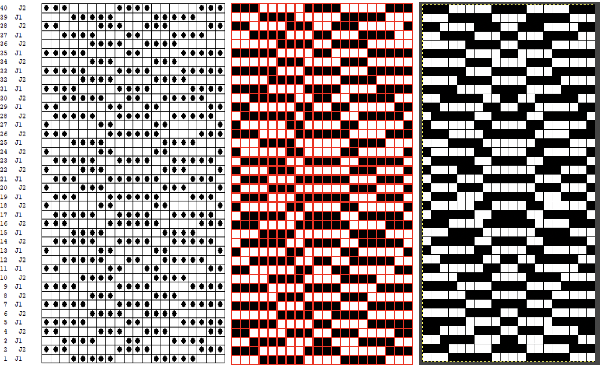

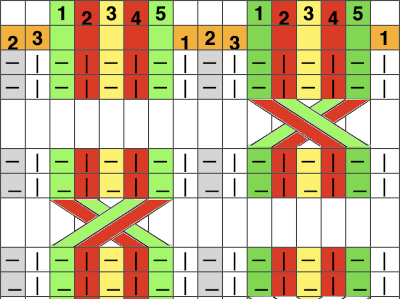

Tiling as in any patterning will reveal errors, such as here for 328.  The latter was edited to a 22-stitch wide repeat, becoming suitable for only electronic machine models.

The latter was edited to a 22-stitch wide repeat, becoming suitable for only electronic machine models.

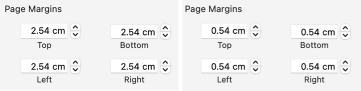

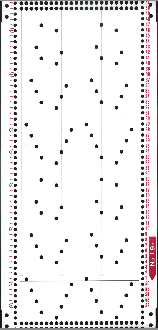

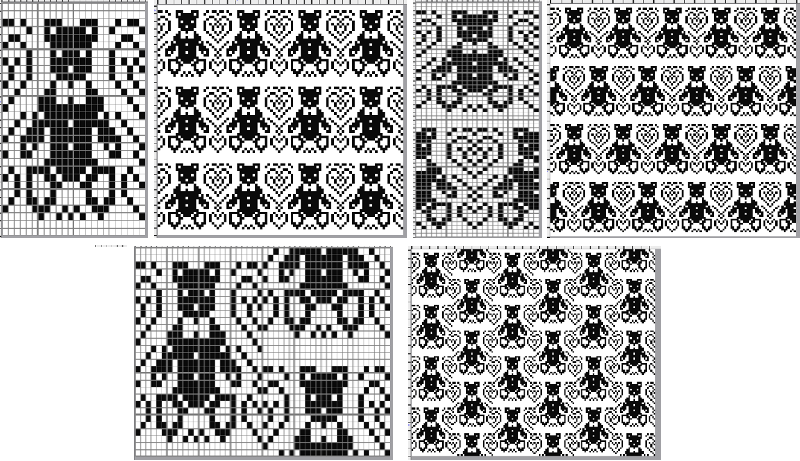

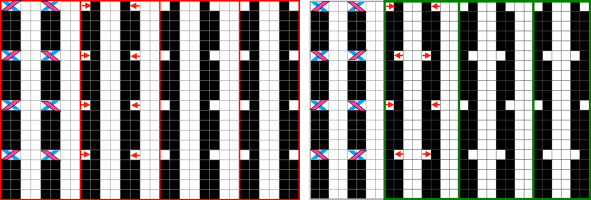

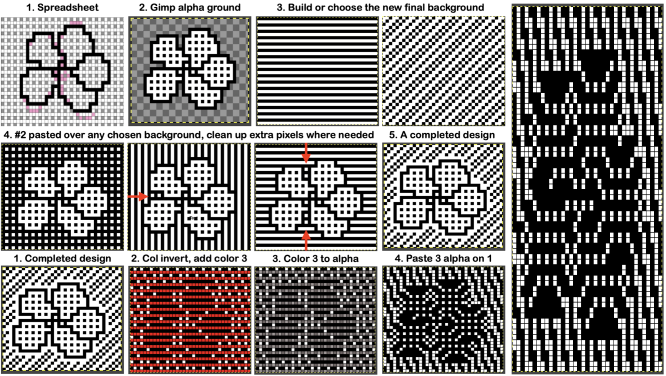

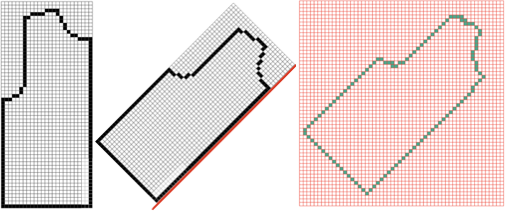

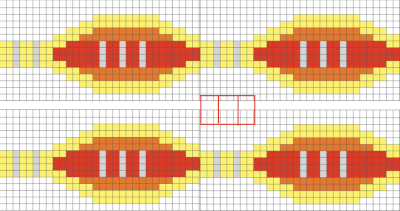

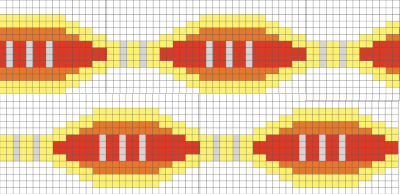

The charts with the red grid on the top row were rendered as tables in Numbers. Since their end use is different, they are the color-reversed version of the cards, whose screengrabs were in turn processed in Gimp to create knittable pngs.

The smallest repeats suitable for electronics are given in the center row of images, the amended 328 cannot be reduced in size. The last row illustrates tiling for all files as BW images that may be opened and amended to suit the size of the pieces planned.

Files in png formats for the group: if pngs generated by me in BW indexed mode are downloaded and opened in editors such as Gimp, they will open in RGB mode. To make them suitable for download programs, convert them to indexed BW mode again and save the result. There should be no loss of data.

Files in png formats for the group: if pngs generated by me in BW indexed mode are downloaded and opened in editors such as Gimp, they will open in RGB mode. To make them suitable for download programs, convert them to indexed BW mode again and save the result. There should be no loss of data.

384, 12X24 12X48

12X48  144X144

144X144 328, 22X44

328, 22X44

176X176

335, 12X24

24X48  144X144

144X144  52, 8X16

52, 8X16

24X48  192X192

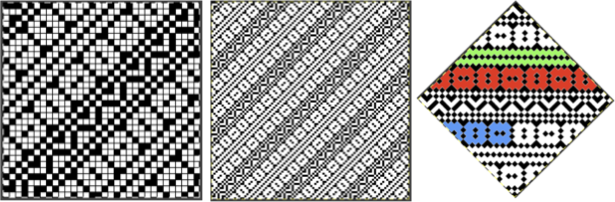

192X192  The black lines formed by units 2 rows in height can be followed or erased to establish short rows shaping a stitch at a time every two rows, given at least 2X2 full repeats to check color placement.

The black lines formed by units 2 rows in height can be followed or erased to establish short rows shaping a stitch at a time every two rows, given at least 2X2 full repeats to check color placement.  The method was used to isolate the previous ungridded color illustrations. Another instance of a published Toyota 901#11diagonal tuck card, in this case, incorporates a combination of 2 and 4-row tuck patterning. The repeat is 24X48

The method was used to isolate the previous ungridded color illustrations. Another instance of a published Toyota 901#11diagonal tuck card, in this case, incorporates a combination of 2 and 4-row tuck patterning. The repeat is 24X48

The previews may be used to replace color selections with those matching yarn colors used in the project to develop some idea as to how color shifts might affect the final piece.

The previews may be used to replace color selections with those matching yarn colors used in the project to develop some idea as to how color shifts might affect the final piece.

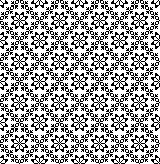

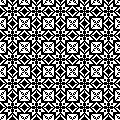

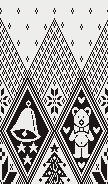

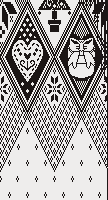

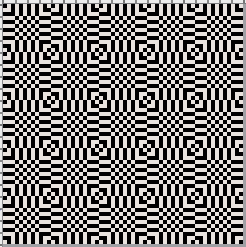

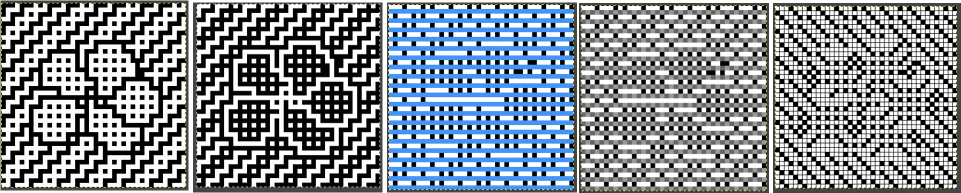

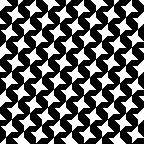

EON diagonal patterning surrounding blocks containing other shapes may be maintained with slight variations in the size of the shapes used to fill those blocks

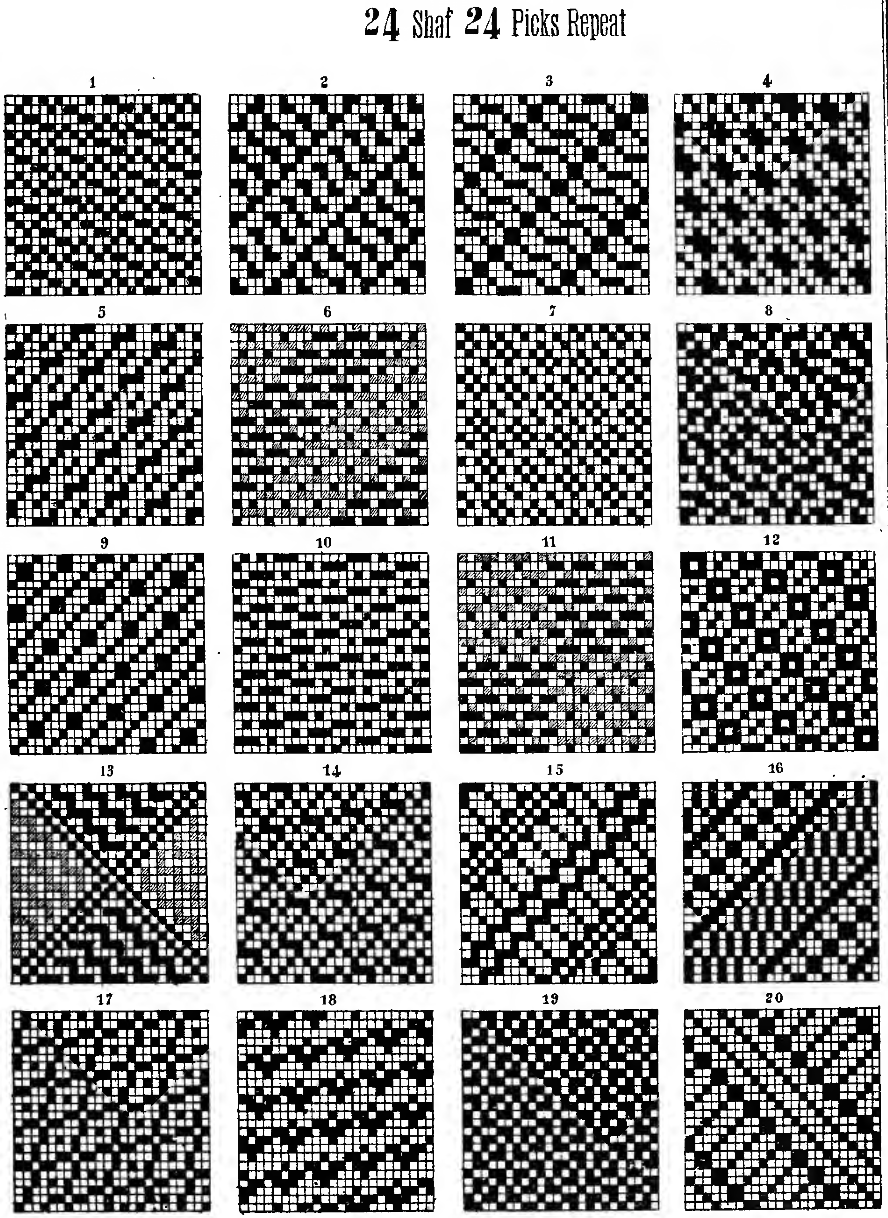

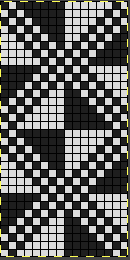

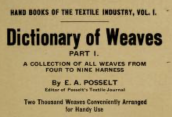

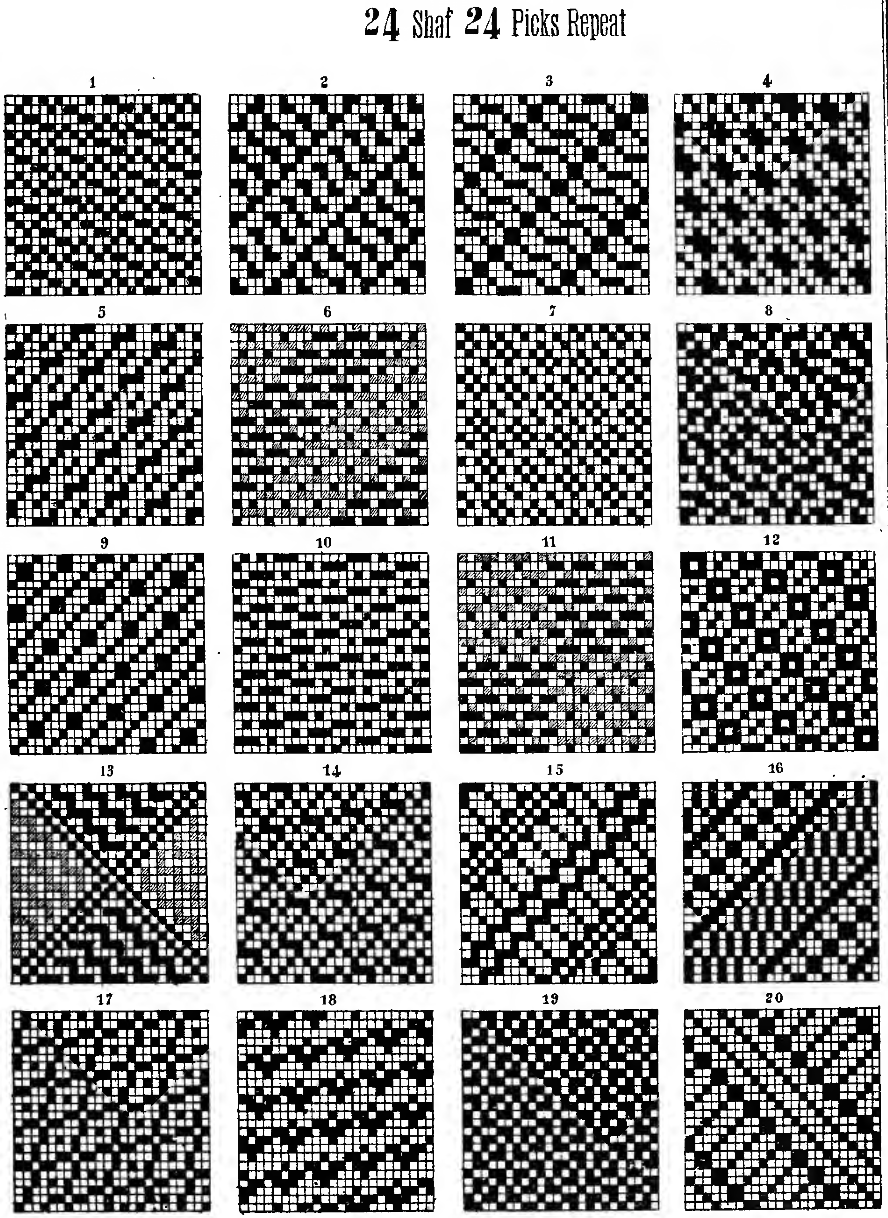

References published for weaving can be a source of charts usable for this type of design.

References published for weaving can be a source of charts usable for this type of design.

The repeats are provided regarding width (shafts) and height (picks). For proper alignments, the provided charts must be reproduced in full, or in DIY adaptations careful editing with erasures or additions can still maintain the proper tiling.

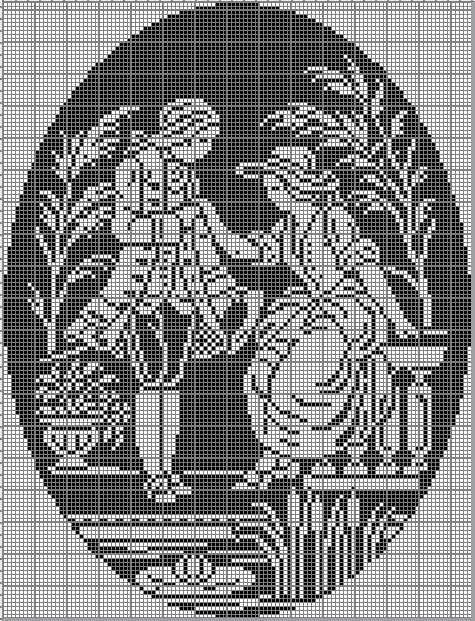

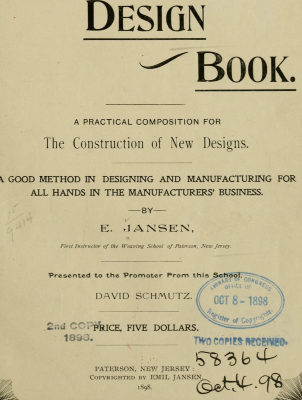

A full reference with varied size design inspirations A page from an 1898 pub

A page from an 1898 pub

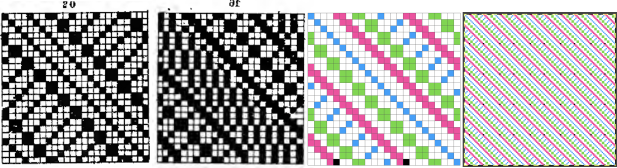

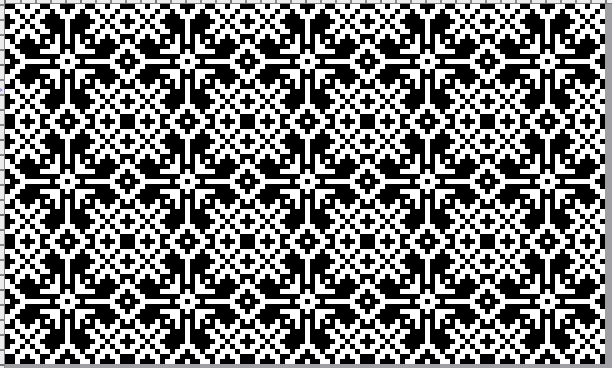

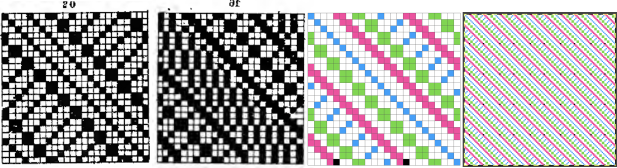

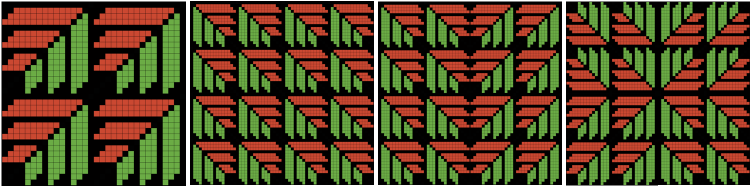

Playing with using #20 and #16 mirrored, isolating, erasing, or combining elements of each while keeping fixed some of the details that move diagonally to touch sides of the repeats, with the process illustrated in color.

Playing with using #20 and #16 mirrored, isolating, erasing, or combining elements of each while keeping fixed some of the details that move diagonally to touch sides of the repeats, with the process illustrated in color.

Consider the width of the floats if planning for fair isle patterning.

Check the original for any errors, marked in the color chart in black. They are often not noticeable until the design is drawn in repeat.

The editable PNG for the center 24X24 design is tiled on the far right above. It is also suitable for punchcards

The editable PNG for the center 24X24 design is tiled on the far right above. It is also suitable for punchcards  A 16X16 electronic repeat

A 16X16 electronic repeat  tiled to 128X128

tiled to 128X128

Handweaving drafts such as those found at handweaving. net provides endless inspiration for designs, including diagonals.

Handweaving drafts such as those found at handweaving. net provides endless inspiration for designs, including diagonals.

8X8

12X12

12X12

drawn in repeat X7

drawn in repeat X7 12X12

12X12

drawn in repeat X7

drawn in repeat X7 15X15

15X15

color reversed

color reversed  using color invert and quarter rotations to 30X30

using color invert and quarter rotations to 30X30

16X16

16X16

16X16

16X16

16X24

16X24

drawn in repeat to 160X168

drawn in repeat to 160X168  18X18

18X18  in repeat to 126X126

in repeat to 126X126 20X20

20X20

32X32 with rotated segments

32X32 with rotated segments

playing with rectangles, squares, and fill-ins24X24

playing with rectangles, squares, and fill-ins24X24

30X30

30X30

A 32X32 diagonal DBJ design built with small color-reversed blocks

A 32X32 diagonal DBJ design built with small color-reversed blocks

16X16  color-reversed

color-reversed

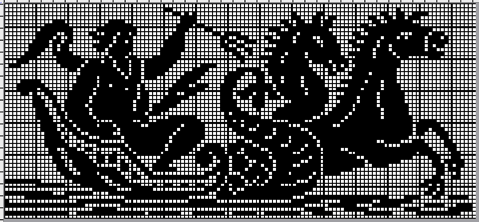

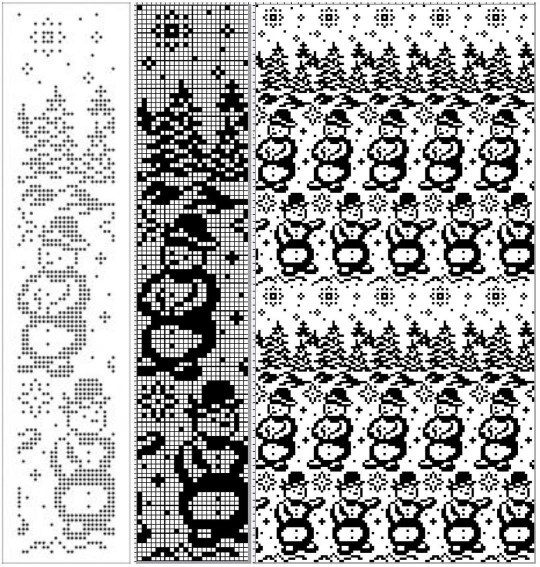

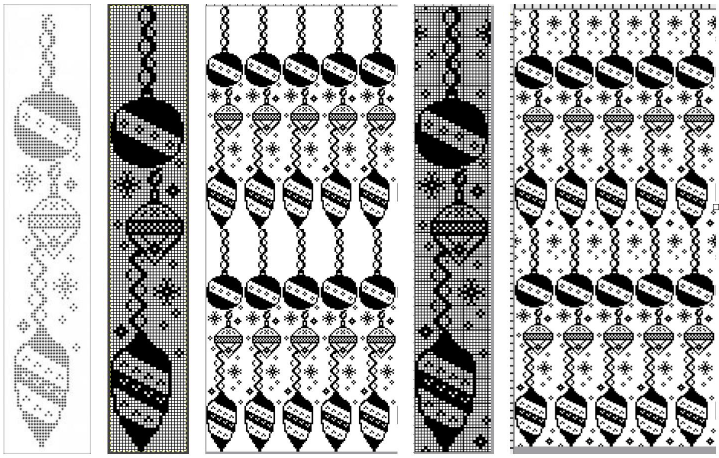

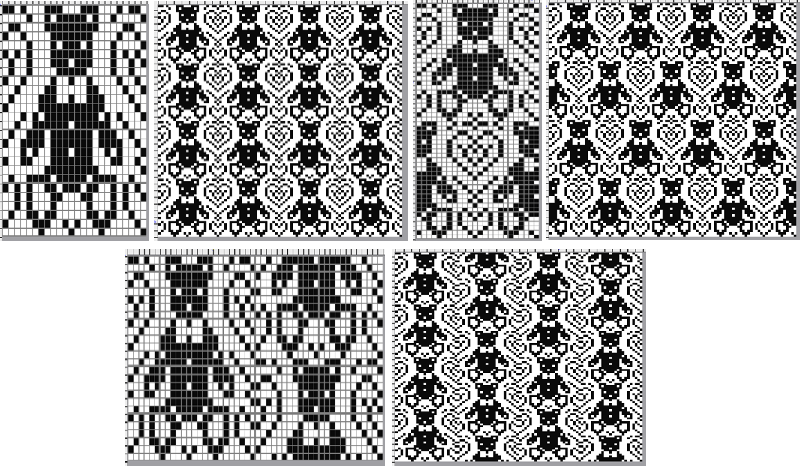

A seasonal sample, 40X41

A seasonal sample, 40X41

48X48

48X48

The movement is not as evident until the tiled repeat becomes quite large, the start, 168X150

The movement is not as evident until the tiled repeat becomes quite large, the start, 168X150

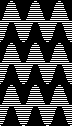

Chevrons can be developed from partial repeats. This is from Toyota 950#12, 24X20

Chevrons can be developed from partial repeats. This is from Toyota 950#12, 24X20

drawn in repeat to 144X140 Combined with added shapes 28X32

drawn in repeat to 144X140 Combined with added shapes 28X32  56X32

56X32  rotated 180 degrees

rotated 180 degrees  combined and trimmed to 56X62

combined and trimmed to 56X62  tiled and with an added frame, 124X134 for a blanket-sized project

tiled and with an added frame, 124X134 for a blanket-sized project  Cropping the frameless large design in different places vertically could provide a collection of accessories ie scarves, ie in this start, 86X132 png with 2 stitch vertical borders on both sides

Cropping the frameless large design in different places vertically could provide a collection of accessories ie scarves, ie in this start, 86X132 png with 2 stitch vertical borders on both sides  Whether in use for a punchcard model or an electronic one, the convention if the end goal is a tuck stitch fabric, is to color reverse the design

Whether in use for a punchcard model or an electronic one, the convention if the end goal is a tuck stitch fabric, is to color reverse the design

It is possible to generate DIY designs easily using ArahPaint.

It is possible to generate DIY designs easily using ArahPaint.

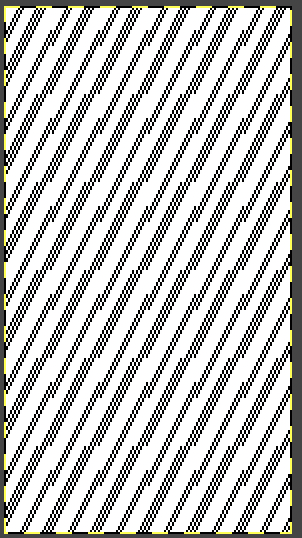

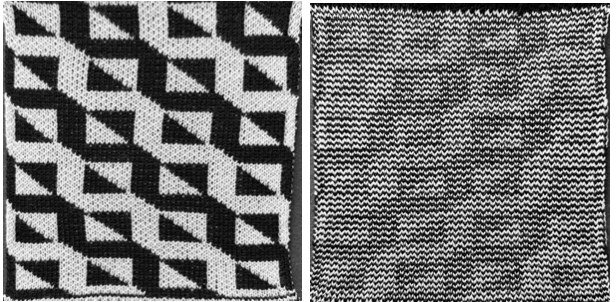

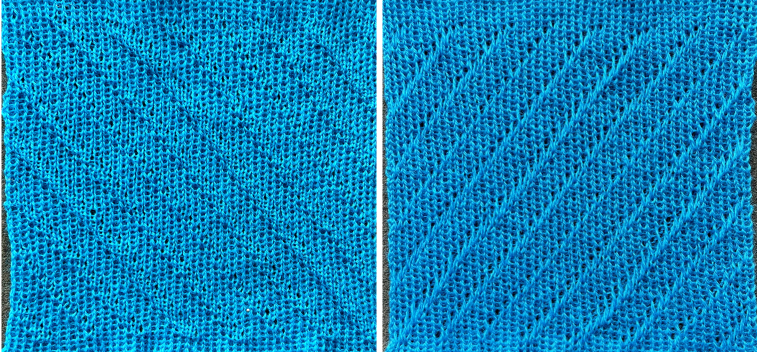

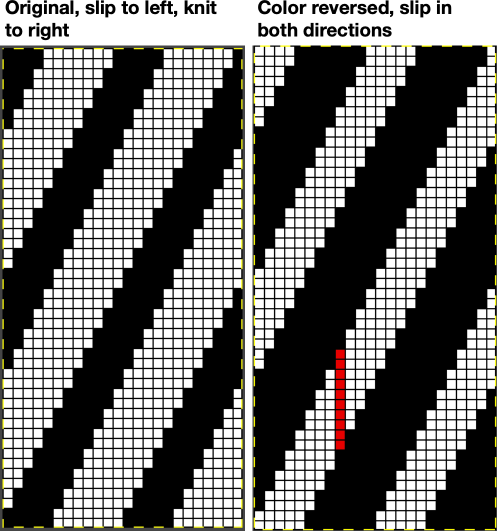

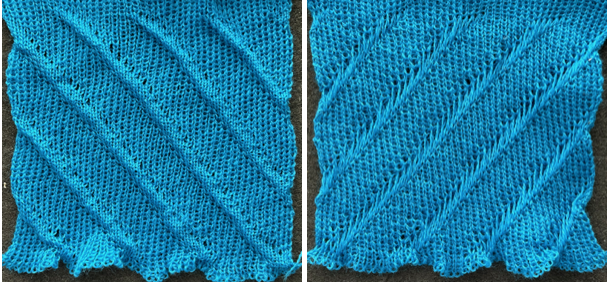

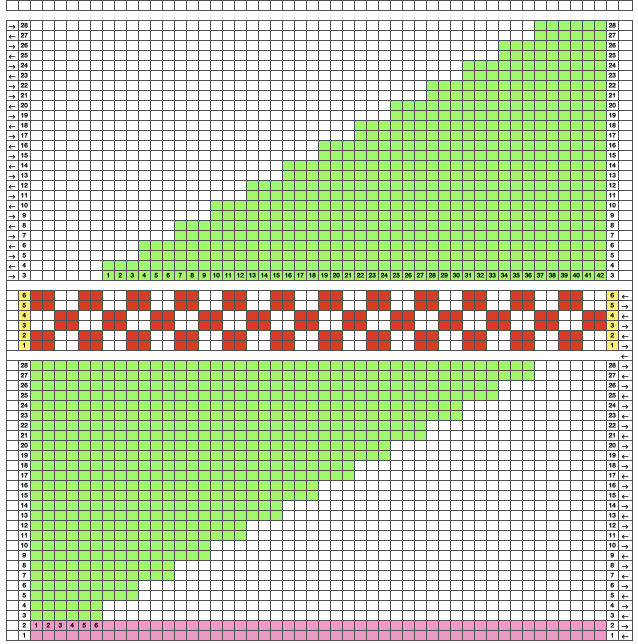

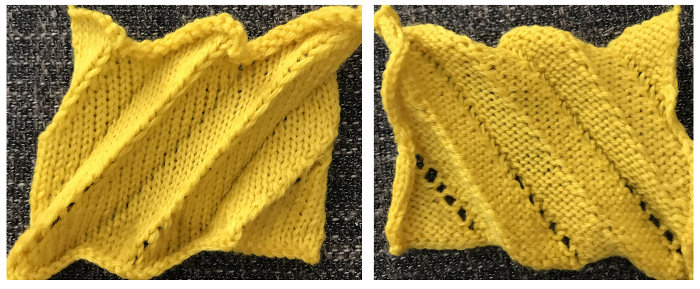

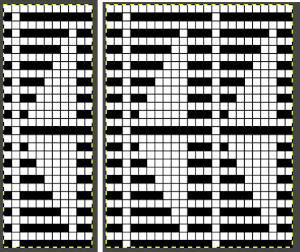

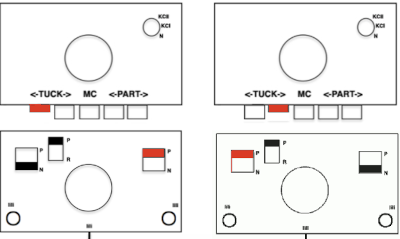

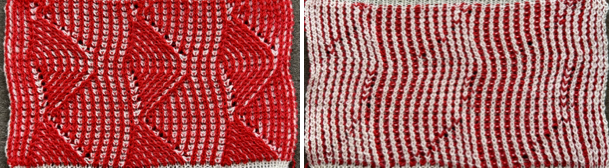

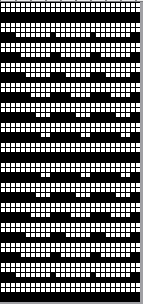

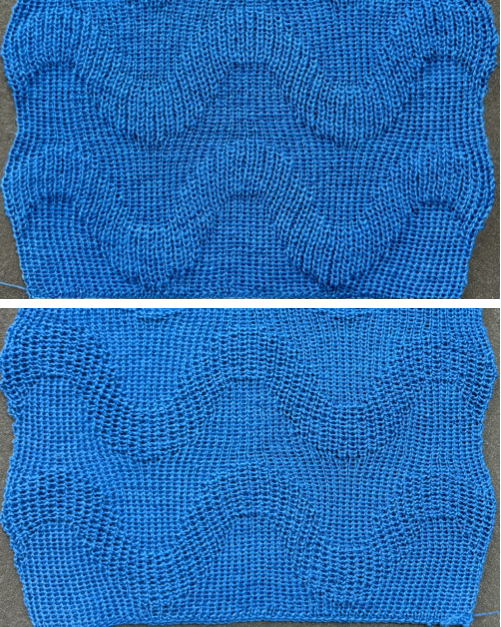

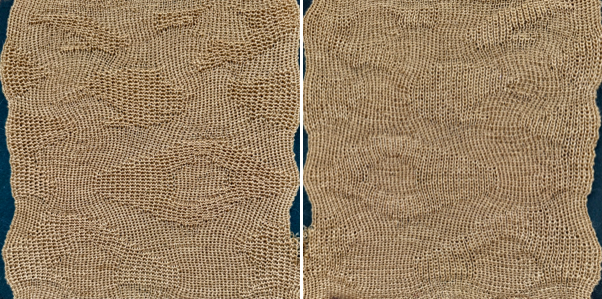

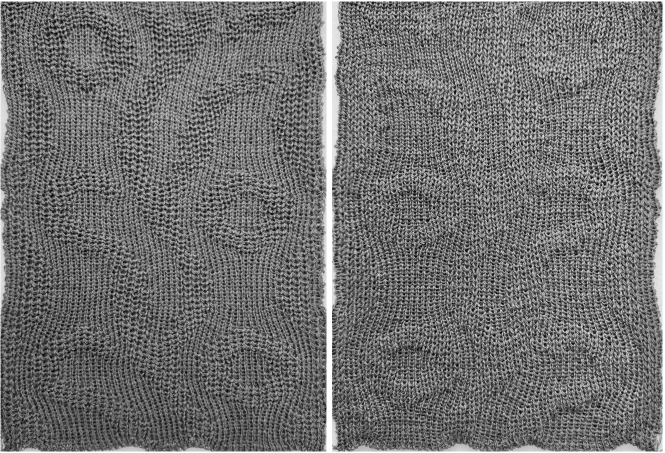

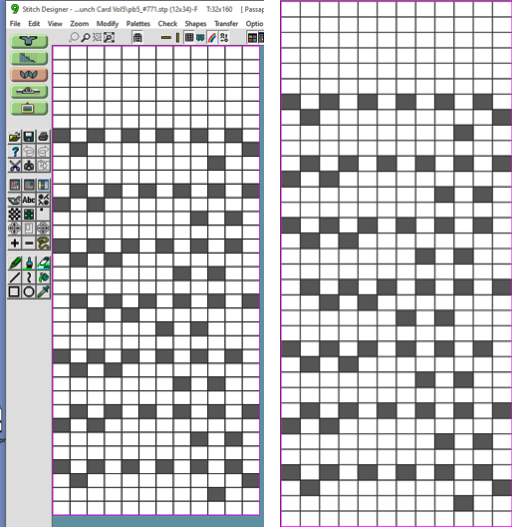

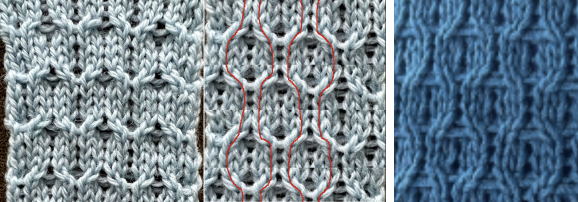

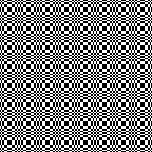

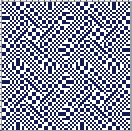

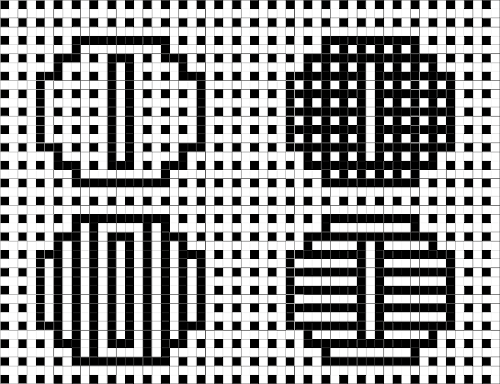

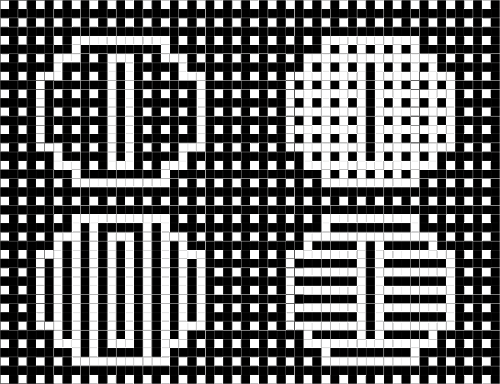

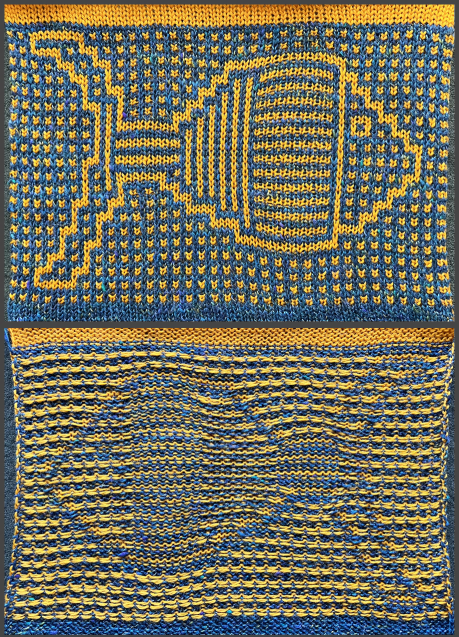

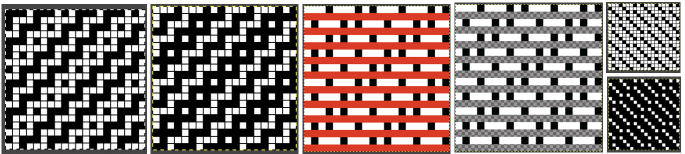

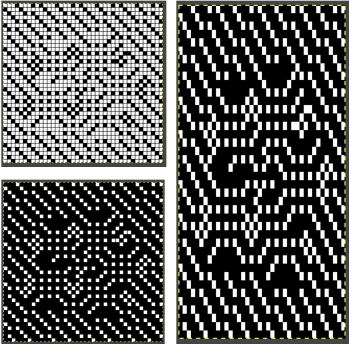

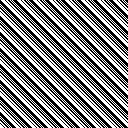

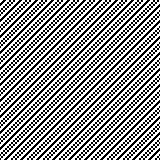

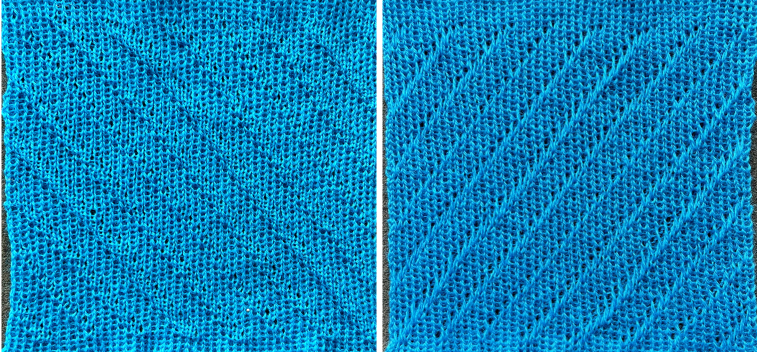

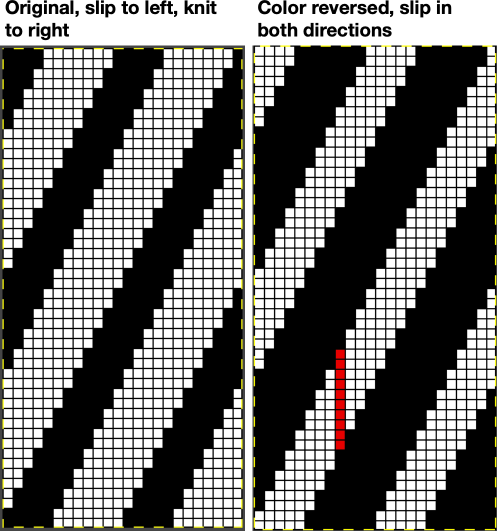

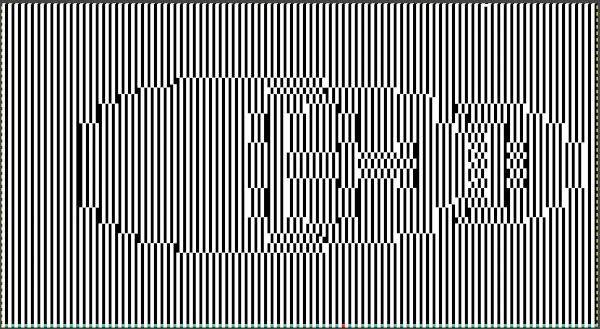

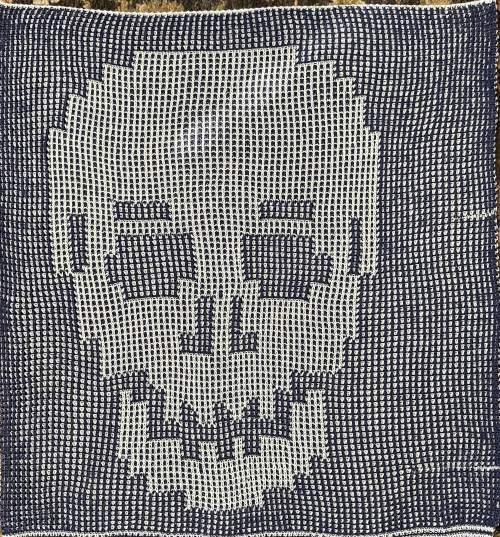

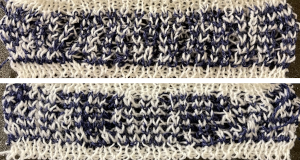

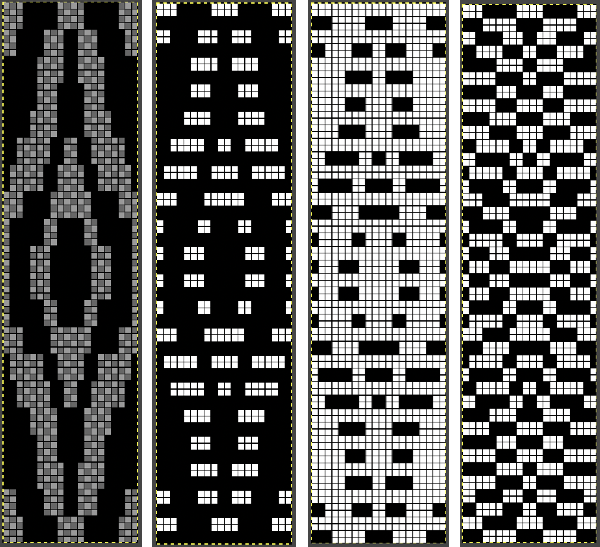

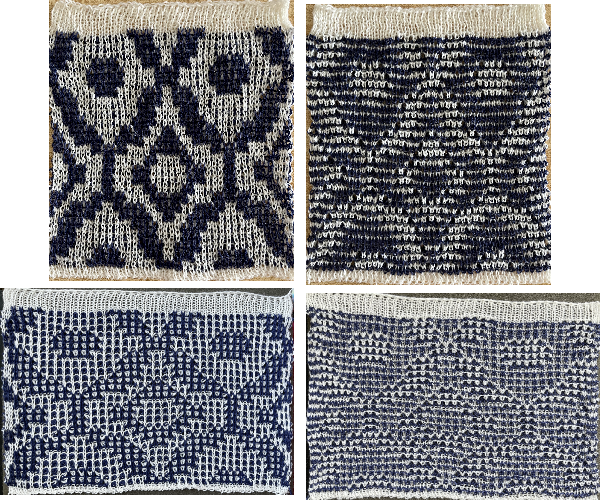

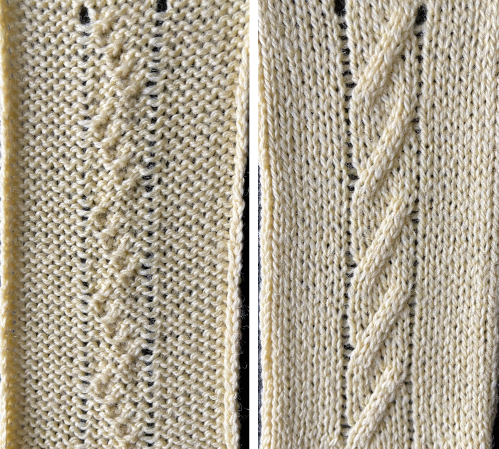

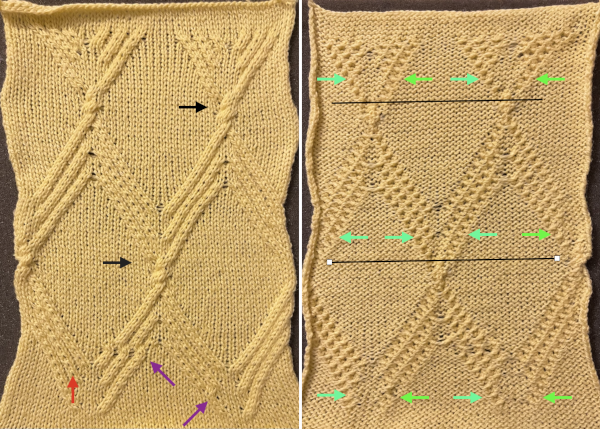

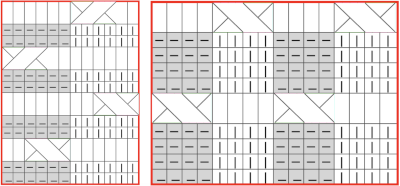

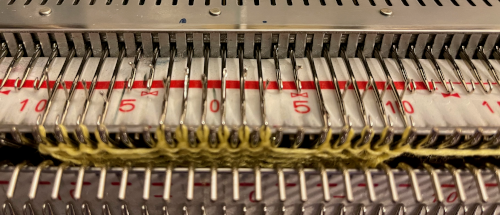

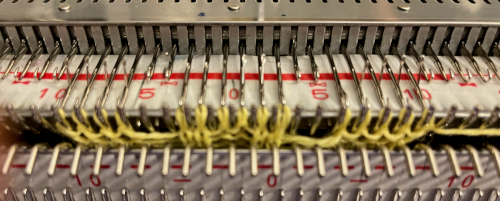

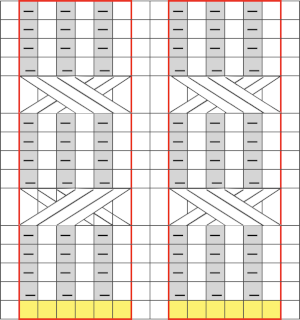

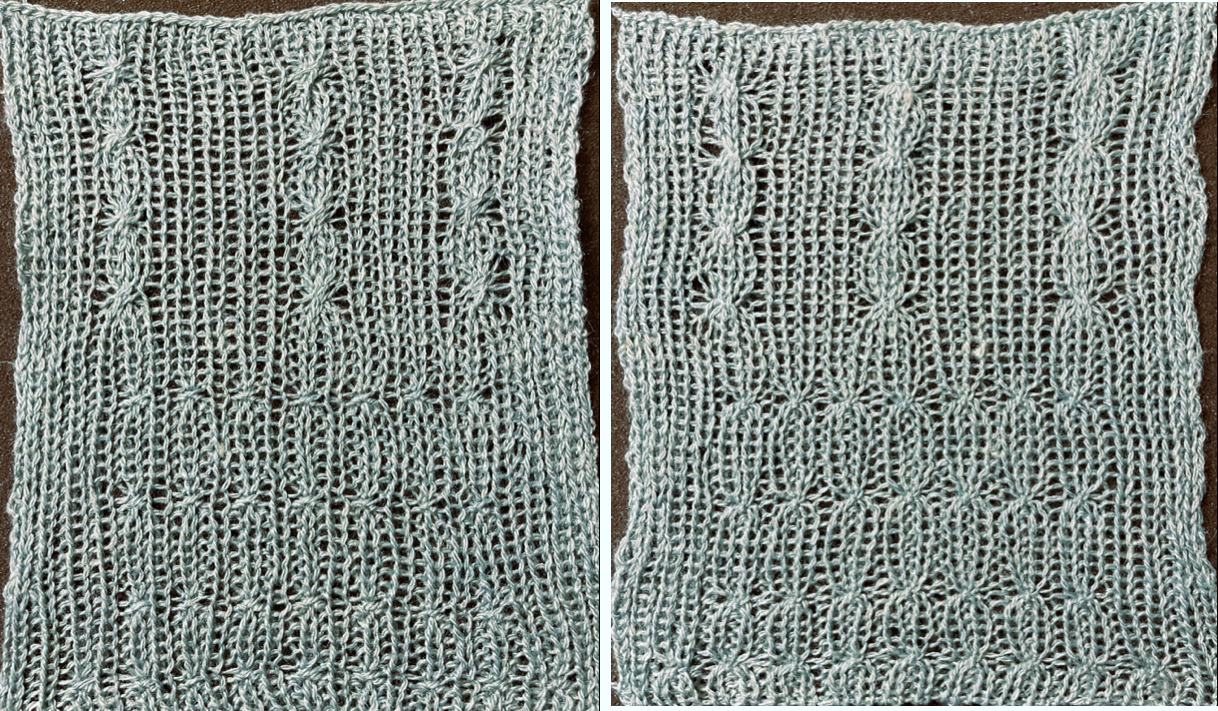

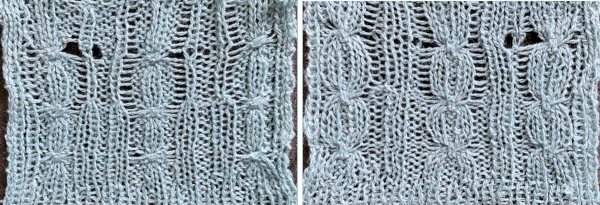

Taking diagonal patterning to the double bed for creating pintuck effects using the slip-stitch setting, this 24X48 repeat explores some of the potential spacings and the resulting ridges.

The next 2 repeats tested, both 24 stitches X 48 rows:

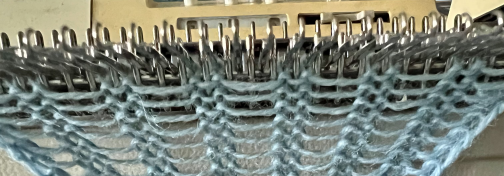

The next 2 repeats tested, both 24 stitches X 48 rows:  The red line is a reminder that the slipped stitches are being held for as many as 8 rows. It is best to use thin yarn that does not break easily and to watch for the knit stitches riding up.

The red line is a reminder that the slipped stitches are being held for as many as 8 rows. It is best to use thin yarn that does not break easily and to watch for the knit stitches riding up.

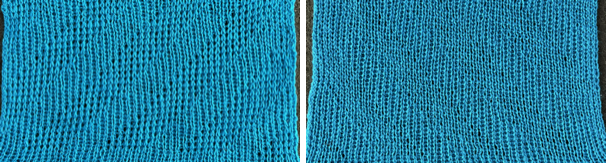

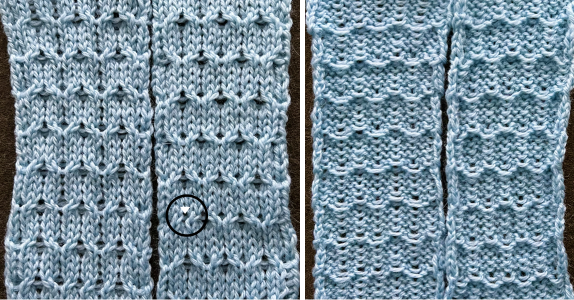

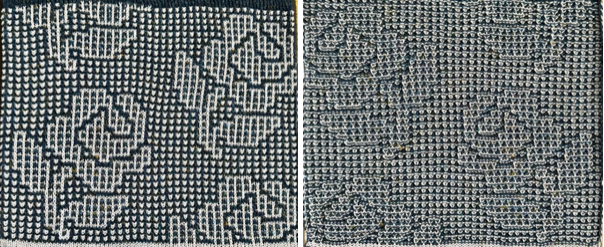

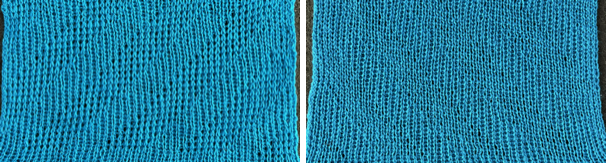

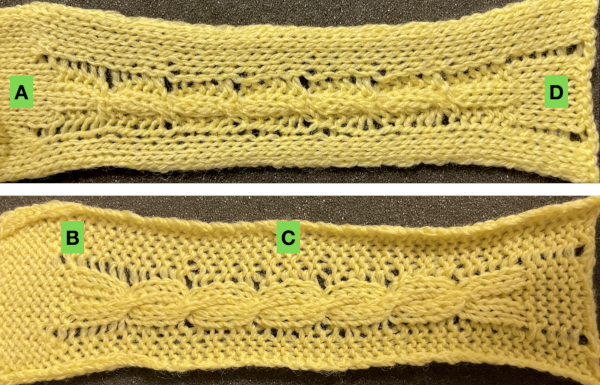

Slipping in one direction produces a very subtle texture,

while the color-reversed design produces even-sized identifiable folds

while the color-reversed design produces even-sized identifiable folds

Adding lettering or small shapes and maintaining the diagonal can result in distortion of the motifs.

Adding lettering or small shapes and maintaining the diagonal can result in distortion of the motifs.

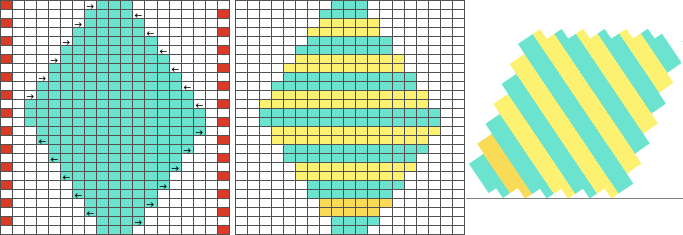

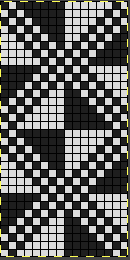

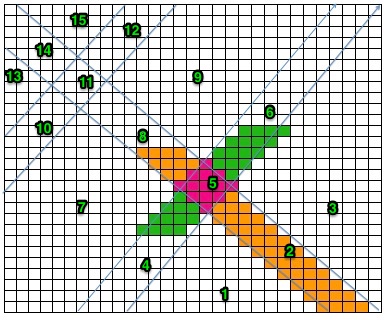

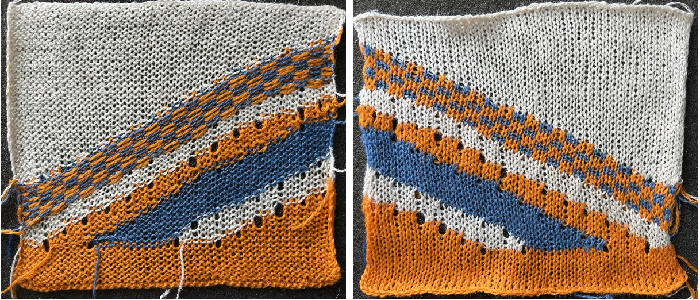

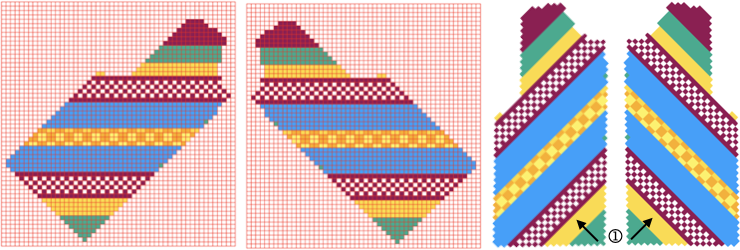

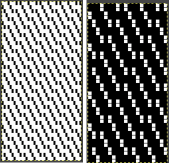

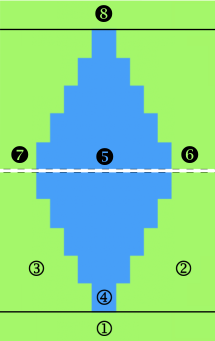

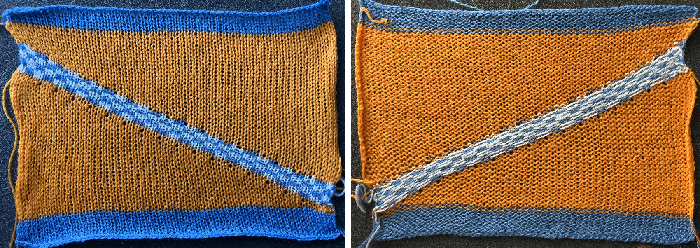

One option to add such motifs is to form the knit by beginning on 3 stitches as in this shared swatch and planning the stripes to heights and widths that accommodate adding designs or fonts.  Short-row intarsia will also produce diagonal striping, from simple to complex as seen in this chart, with knitting sequence numbered for each segment.

Short-row intarsia will also produce diagonal striping, from simple to complex as seen in this chart, with knitting sequence numbered for each segment.  A limited number of rows may be knit in stocking stitch in areas following shapes not simply to travel to the opposite side and reverse shaping, but also to add small rolls or hems.

A limited number of rows may be knit in stocking stitch in areas following shapes not simply to travel to the opposite side and reverse shaping, but also to add small rolls or hems.

Another use might be to add small vertical motif details or patterning in their usual orientation.

The limit appears to be a maximum of 8 rows of alternative patterns, in order to keep the short-rowed areas from developing into distorted edges, which may be variable depending on the yarn and pattern used.

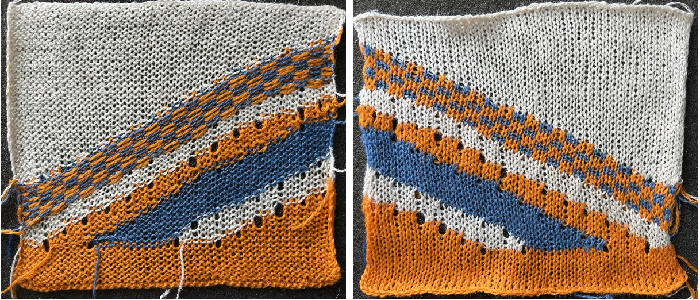

This first swatch was knit using progressively thinner yarns, wool, wool rayon, and a 2/24 acrylic in the FI segment. FI is a slip stitch that narrows the knit. The dark acrylic color stitch definition here gets lost. The band is seen pulling in the short-row segments on both sides. The shaping in both the top and bottom segments is by 2 stitches at a time.  The result in different yarns of equal thickness, with the FI band knit at a tension one full number looser than the stocking stitch areas, with the top and bottom solid color segments now shaped 3 stitches at a time.

The result in different yarns of equal thickness, with the FI band knit at a tension one full number looser than the stocking stitch areas, with the top and bottom solid color segments now shaped 3 stitches at a time.  There is a trick when making A-line skirts to change the triangles that would poke out normally at the bottom if shaping were to begin immediately used as a design feature in many runway knits recently. If between an inch or 2 are actually knit up straight before shaping starts, the problem is eliminated. Depending on the design this may be a solution or it may read as a patterning error.

There is a trick when making A-line skirts to change the triangles that would poke out normally at the bottom if shaping were to begin immediately used as a design feature in many runway knits recently. If between an inch or 2 are actually knit up straight before shaping starts, the problem is eliminated. Depending on the design this may be a solution or it may read as a patterning error.

There are some conventions and “rules” for short-row techniques, but they do not always apply.

Keeping good notes helps to make successful experiments reproducible.

Two more tries began to experiment with working on the first and last groups in the holding techniques on a different number of stitches than the remaining shapes, noting differences. In the first an all-knit row is made across the short-row eyelets, reducing the planned FI band from 6 rows to 5. A rough spot in maintaining even stitches on one side is noticeable.  Progress: holding happened at the start of the bottom wedge, the FI was knit at 2 tension numbers looser than the stocking stitch, for 6 rows.

Progress: holding happened at the start of the bottom wedge, the FI was knit at 2 tension numbers looser than the stocking stitch, for 6 rows.  The goal in the short row shaping for the triangles is to maintain vertical edges that appear as straight as possible to the eye. One need not work on large swatches, small ones can provide clues as to differences resulting from variations in the starting side of the short-row shapings.

The goal in the short row shaping for the triangles is to maintain vertical edges that appear as straight as possible to the eye. One need not work on large swatches, small ones can provide clues as to differences resulting from variations in the starting side of the short-row shapings.  Studying the results can lead to many variations. There are student theses and careers based on exploring limited techniques to the max.

Studying the results can lead to many variations. There are student theses and careers based on exploring limited techniques to the max.

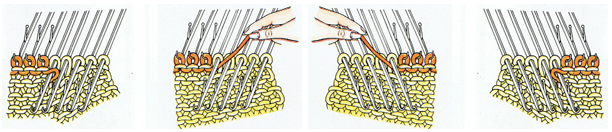

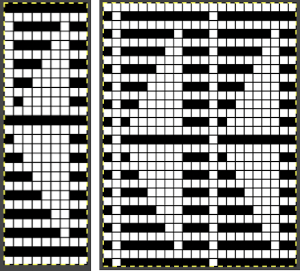

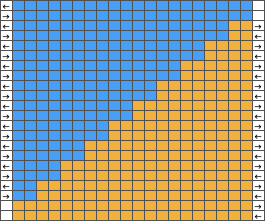

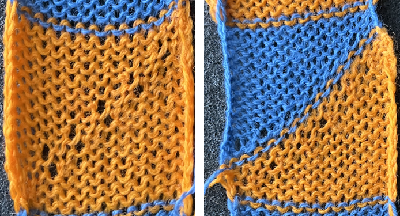

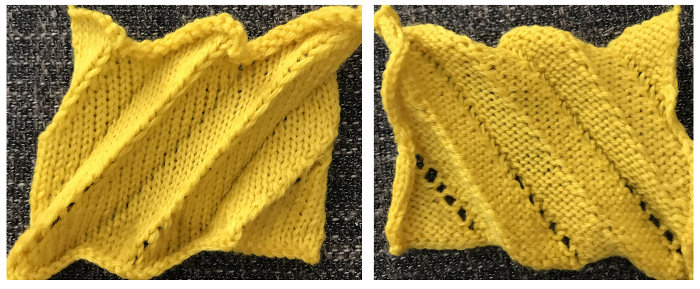

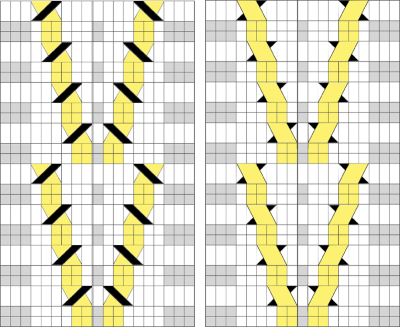

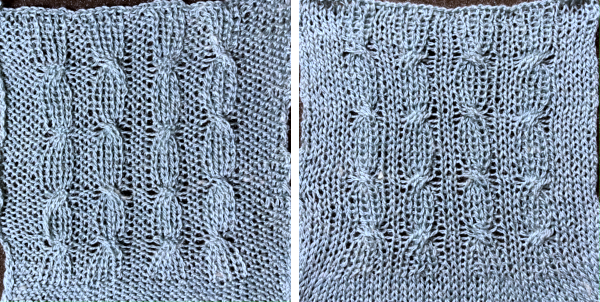

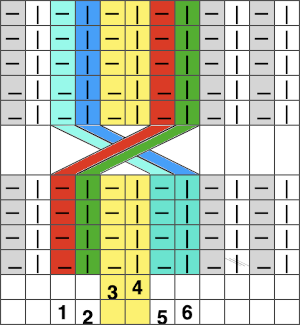

Building a theoretical true square or other predictable shapes is subject to the yarn and tension used. Beginning with a small sample, this shows the order of knitting 2 triangular shapes with the carriage beginning to knit each shape from alternate sides. In this case, 2 stitches are to be brought in and out of holding at a time.  Because each color knits for 2 rows, small slits happen in the fabric resulting in eyelets. They may be used as design features, or attempts can be made to reduce their size. One way to do so is to have plain knit rows between holding selections to keep the small slits from intersecting and becoming double height. On the left swatch, one yellow row was knit to the left before reverse shaping in the same color. In the swatch on the right, in addition, 2 rows were knit in the blue prior to reverse shaping.

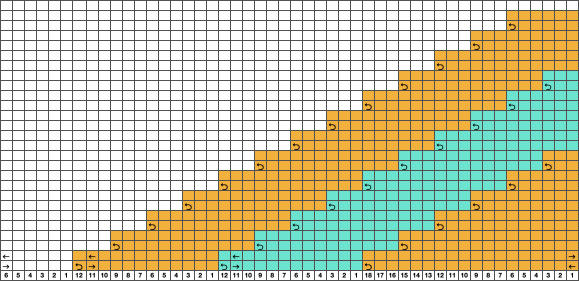

Because each color knits for 2 rows, small slits happen in the fabric resulting in eyelets. They may be used as design features, or attempts can be made to reduce their size. One way to do so is to have plain knit rows between holding selections to keep the small slits from intersecting and becoming double height. On the left swatch, one yellow row was knit to the left before reverse shaping in the same color. In the swatch on the right, in addition, 2 rows were knit in the blue prior to reverse shaping.  Reviewing the concept and developing a chart for larger swatches: the cyan color cells represent stitches in the hold position and the white cells stitches that will be knit.

Reviewing the concept and developing a chart for larger swatches: the cyan color cells represent stitches in the hold position and the white cells stitches that will be knit.

At the top of the first wedge, most needles will be in the hold position, return them all to the B position manually before knitting the next row.

With the carriage on either side, set it for KCI with the cam buttons to slip for a free pass to the opposite side, the first FI pattern row will pre-select. Holding need not be canceled, since no needles are brought far enough out for the technique.

Cancel the slip setting, change the cam setting for FI knitting, place the pairs of colors in their corresponding feeders, and knit 6-8 rows of pattern.

Bring all needles out to hold except for the first desired group, if the holding lever has been canceled, reset it and commence reverse shaping.  Merrily knitting along and you forget to loosen the tension for the fair isle stripe:

Merrily knitting along and you forget to loosen the tension for the fair isle stripe:  And what if the FI were to actually follow diagonal colored stripes? The approach is the same. I am right-handed, my default is often to begin on the right. Left-handed knitters can mirror charts as needed to make them easier to follow.

And what if the FI were to actually follow diagonal colored stripes? The approach is the same. I am right-handed, my default is often to begin on the right. Left-handed knitters can mirror charts as needed to make them easier to follow.

The first triangle is shaped from the right toward the left, subsequent ones begin on the left, then to wrap or not wrap becomes the question.  Review of wrapping, which does not disturb the stitch on or the position of the wrapped needle:

Review of wrapping, which does not disturb the stitch on or the position of the wrapped needle:  I obstinately use random yarns at hand, sometimes too thin for the task, true here. Any type of intarsia, of which holding is one, will be accompanied by lots of yarn ends that will require weaving in. Some of the stitches were wrapped here, some not, and maybe the eyelets could be considered a pleasing design feature. The 8 rows of FI, knit at 2 full tension numbers higher than that used for stocking stitch, minimizes the size of the eyelets all on their own on both sides of its stripe. Errors in bringing an added group or not into work may not always be immediately visible, frogging this type of knitting can be painful.

I obstinately use random yarns at hand, sometimes too thin for the task, true here. Any type of intarsia, of which holding is one, will be accompanied by lots of yarn ends that will require weaving in. Some of the stitches were wrapped here, some not, and maybe the eyelets could be considered a pleasing design feature. The 8 rows of FI, knit at 2 full tension numbers higher than that used for stocking stitch, minimizes the size of the eyelets all on their own on both sides of its stripe. Errors in bringing an added group or not into work may not always be immediately visible, frogging this type of knitting can be painful.

I would not use the last 6 stitch modification in any future swatches.  Elizabeth Zimmermann published many patterns for hand knitting utilizing garter stitch and striped diagonal wedges for garment shaping.

Elizabeth Zimmermann published many patterns for hand knitting utilizing garter stitch and striped diagonal wedges for garment shaping.

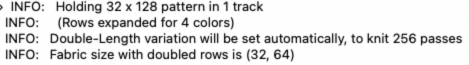

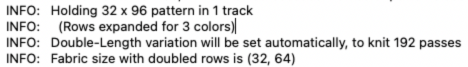

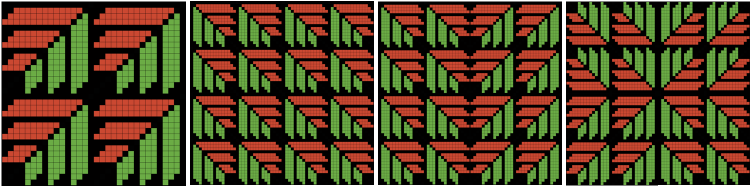

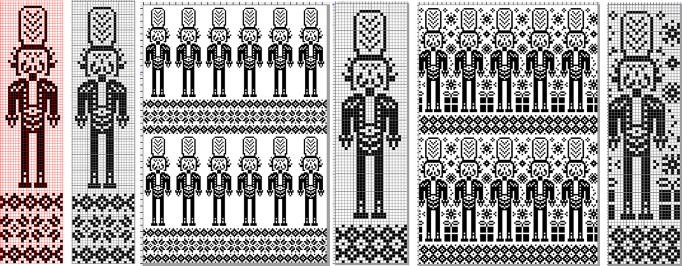

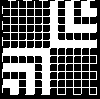

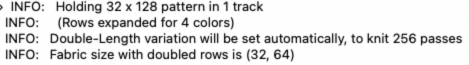

Multiple colors per row patterning may be maintained by beginning planning with diagonal straight lines, seen here in a 32X32 repeat.  Opened in img2track

Opened in img2track  The design will be elongated, and 256 passes are required to finish a single repeat

The design will be elongated, and 256 passes are required to finish a single repeat  Each color may be edited to suit. Quick visualizations of a few of the possible repeat arrangements using the file as is

Each color may be edited to suit. Quick visualizations of a few of the possible repeat arrangements using the file as is  Avoiding lots of extra knit rows by eliminating one of the colors.

Avoiding lots of extra knit rows by eliminating one of the colors.

The larger designs may need to be knit in sections depending on the available memory in the knitting machine model being used.

The larger designs may need to be knit in sections depending on the available memory in the knitting machine model being used.

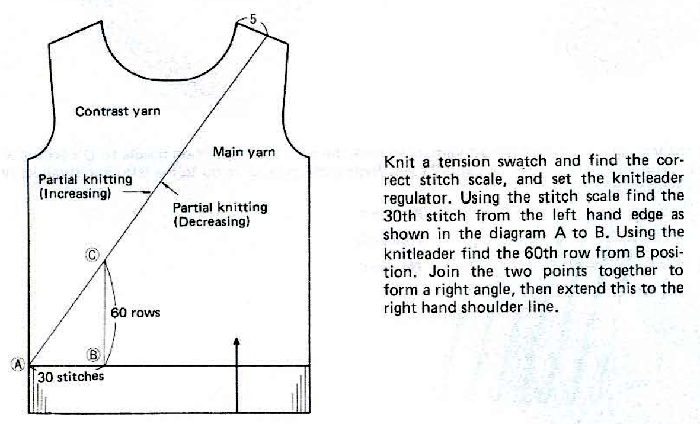

Machine-knit stitches do not form as close to square ones found in garter stitches. Rendering the full-scale garment on a knit leader would make knitting to gauge while avoiding tons of math calculations possible.

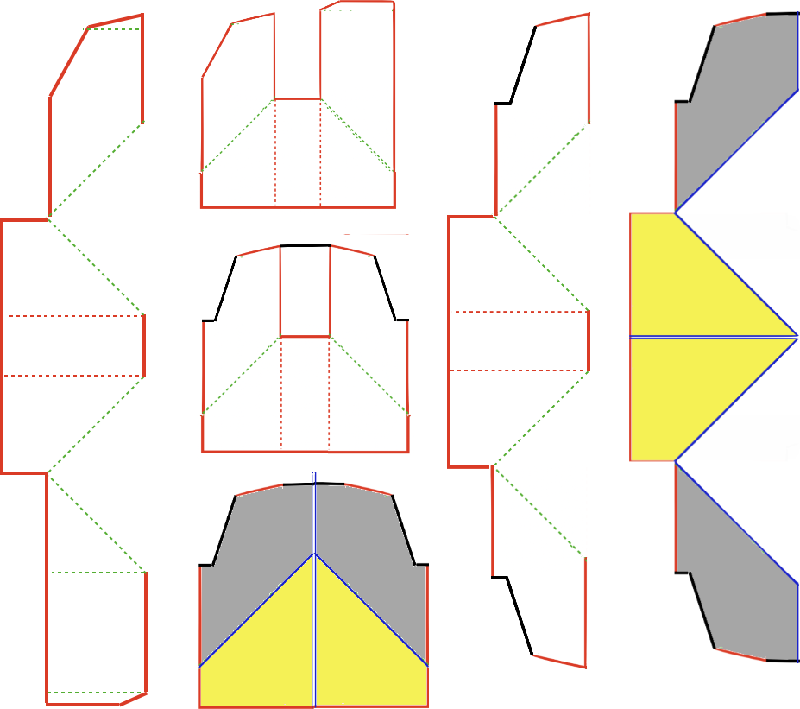

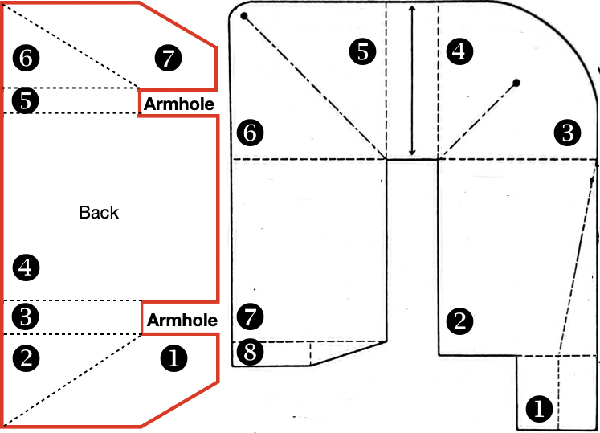

DIY is a bit like assembling paper cut-outs that are required to fit together, first attempts at planning do not always succeed. One may begin at different parts of the piece and seam two halves together if necessary in order to keep matching stitch formations in both directions. Stripes may be added to form secondary intersecting shapes.  On the left is a simple one-piece vest concept with no miters in the back panel, which may be knit from the bottom up or as two pieces with a center seam.

On the left is a simple one-piece vest concept with no miters in the back panel, which may be knit from the bottom up or as two pieces with a center seam.

The bolero style is repeated in 2 separate pieces with mirror shaping in the second and would be joined at the center back.

The knit gauge is easier to maintain in short or small wearables.  Many garments may be made following the concepts for creating “pies”.

Many garments may be made following the concepts for creating “pies”.

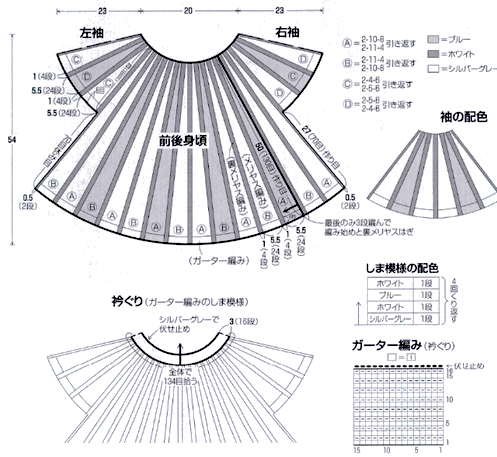

Decades ago batwing sweaters based on a sideways circular knit concept were standard presentations at knit seminars. Short-row diagonal graduated wedges were followed by varying amounts of all knit rows.

This idea for a short sleeve garment is from a Japanese magazine. In creating such illustrations because of the scale of the publication, the aspect ratio is distorted. In the final garment, the bottom circumference can in fact be far narrower than it might appear to the eye in the sketch and may be gathered or left released depending on design goals. The neckline diameter at the end of the project, after joining one shoulder, is gathered with evenly distributed decreases to the desired measurement prior to knitting the collar.  A way to form a long sleeve item, using binding off and casting on stitches in addition to shaped wedges followed by all knit rows.

A way to form a long sleeve item, using binding off and casting on stitches in addition to shaped wedges followed by all knit rows.  Knitting a garment on the bias at 45 degrees will produce a knit fabric that drapes differently.

Knitting a garment on the bias at 45 degrees will produce a knit fabric that drapes differently.

Horizontal patterning can turn into diagonals and chevrons, and fancy decreases may be used in the center shaping of the garment.

Pre-computer programs and knitleaders, an easy way to sort out shaping for garments, was to begin by drawing on large sheets of graph paper. An all-square grid is fine.

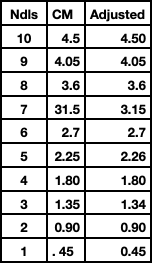

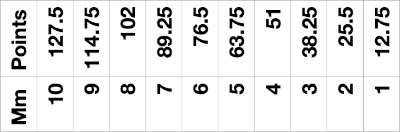

Calculate a 10 cm/4 inch knitting gauge to the second decimal point before any rounding off. For example, if the gauge works out to be 5.728, and the measurement needed is 19.5 inches, the multiplied value result is 111.696, which can be rounded off to a 112-row line on the graph paper.

Working in cm can actually lead to easier calculations and is required when using a charting device.

Each cell in the graph paper grid equals one stitch and one row.

For knitting on the straight grain, based on gauge, draw series dots placing them on the beginning and the ending pots for each measurement, and connect them with straight lines.

Curves such as those necessary for necklines may be composed of short straight-line segments.

When knitting from the bottom up, continue with a colored pencil, filling in squares as they jog in or out, maintaining the new outline as close to the first as possible.

For the bias knit, whether on graph paper, the computer, or a charting device, begin by drawing a 45-degree line.

Rotate and trace the unmodified original straight-line image in place, follow the lines, and mark in and out jogs once more in color for contrast.

This is a very small chart so outline jogs in far larger pieces cannot be reflected. They would produce edges not as straight as in standard knitting, which will need to be considered when joining finished pieces.

As the piece is rotated, a wider grid base is required. Consider that the motif images as they are worked on the purl side will be mirrored horizontally on the knit side, a particular consideration if any text is introduced.

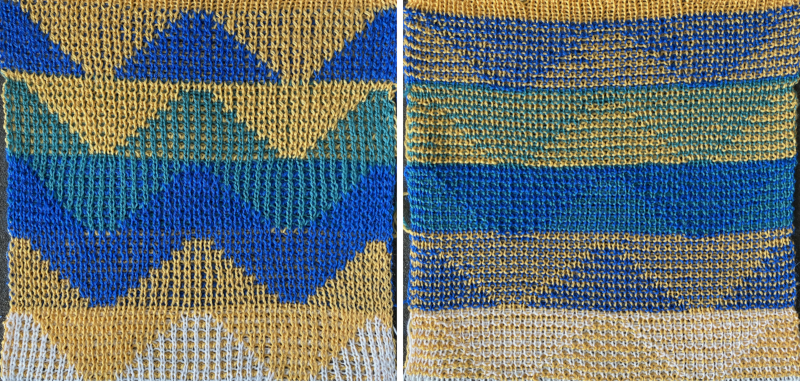

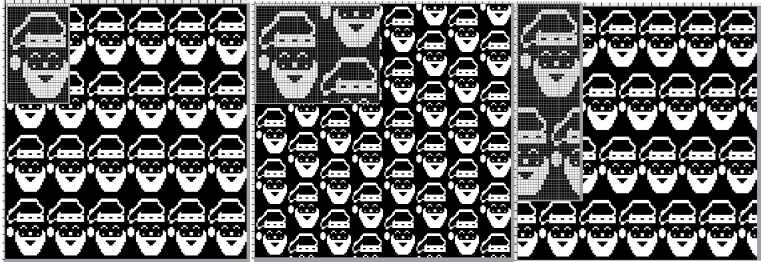

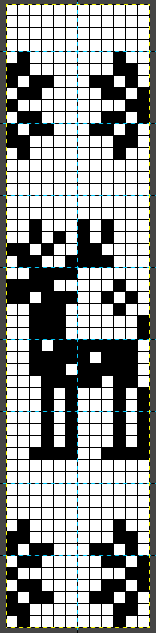

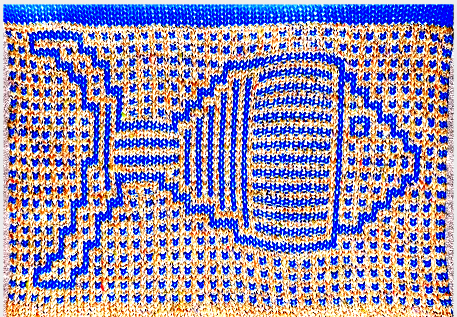

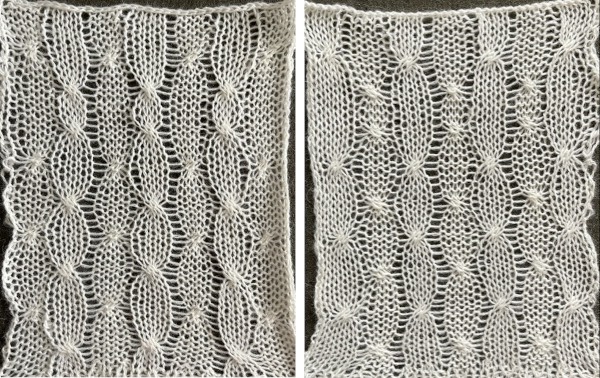

Comparing theoretical purl as opposed to knit views on the left, two purl views on the right.

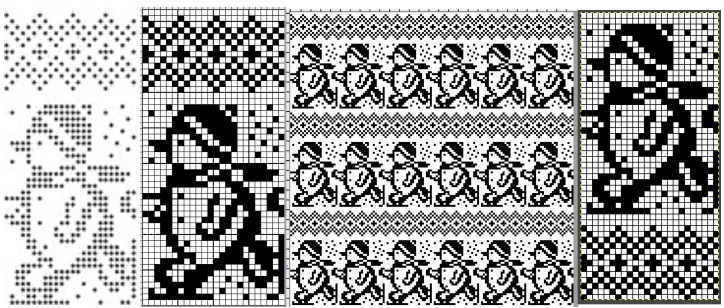

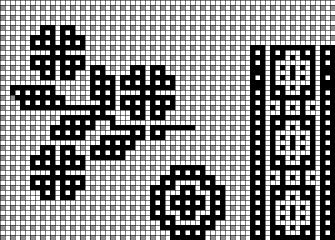

Comparing theoretical purl as opposed to knit views on the left, two purl views on the right.  Fonts in various stitch and row counts are useful when planning knit text.

Fonts in various stitch and row counts are useful when planning knit text.

The point at which the text or pattern is introduced needs to have enough stitches in work on the machine to contain the intended words, ie for the above, a minimum ground, independent of shaping, would need to contain more than 9 rows if solid color stripes are to be added above and below it, and 26 stitches in width in this case.

A proof of concept swatch with arbitrary shaping on every other row illustrates the need for shaping based on a calculated gauge if a square is indeed the aim.

I knit on a 930 where mirroring is automated for programmed designs, so the text was programmed as drawn.

Sometimes less information is more. It became evident very soon that the placement of the text on the left was wrong if the aim was to have it centered in the final shape, and that more rows were needed at the top of the design.

On the right, the purl side as it faces the knitter is shown, with black pixels used to represent increases and decreases. The center red line separates the needle placements on either side of 0, and the text is shown in the default mirroring.  The respective swatches after their rotation preview one of the potential results

The respective swatches after their rotation preview one of the potential results

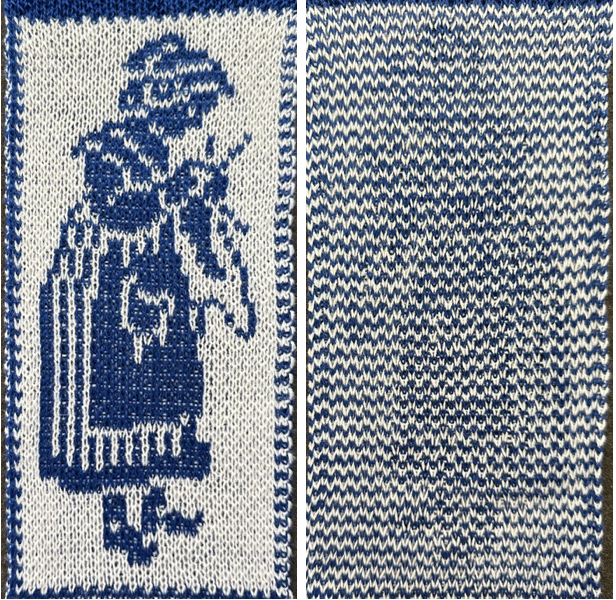

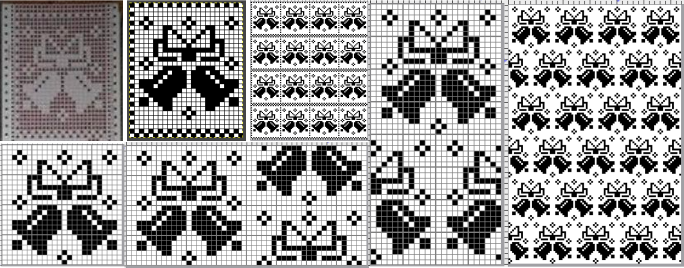

A true diagonal repeat may be planned for motif patterning knit from the bottom up. The drawback is that for executing a fair isle using more than 2 colors or with multiple color changes, partially illustrated on the far right, the 32X32 repeat would need to be rotated and knit as above.

A true diagonal repeat may be planned for motif patterning knit from the bottom up. The drawback is that for executing a fair isle using more than 2 colors or with multiple color changes, partially illustrated on the far right, the 32X32 repeat would need to be rotated and knit as above.

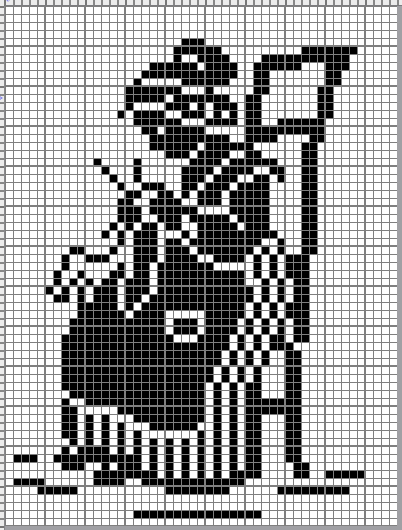

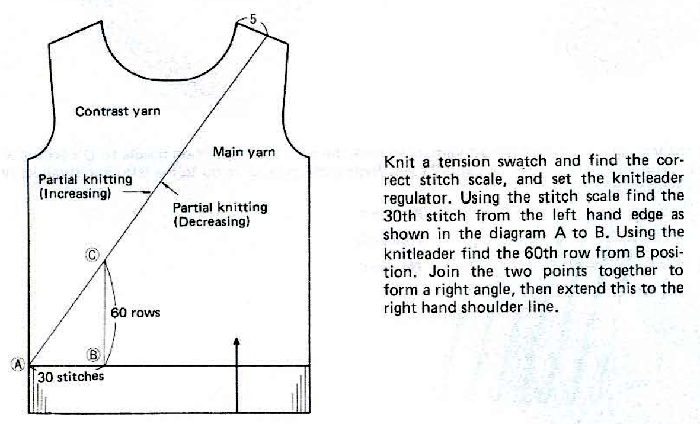

From the Brother machine knitting techniques book, a suggestion for dividing a sweater front into diagonal halves created by using the holding technique

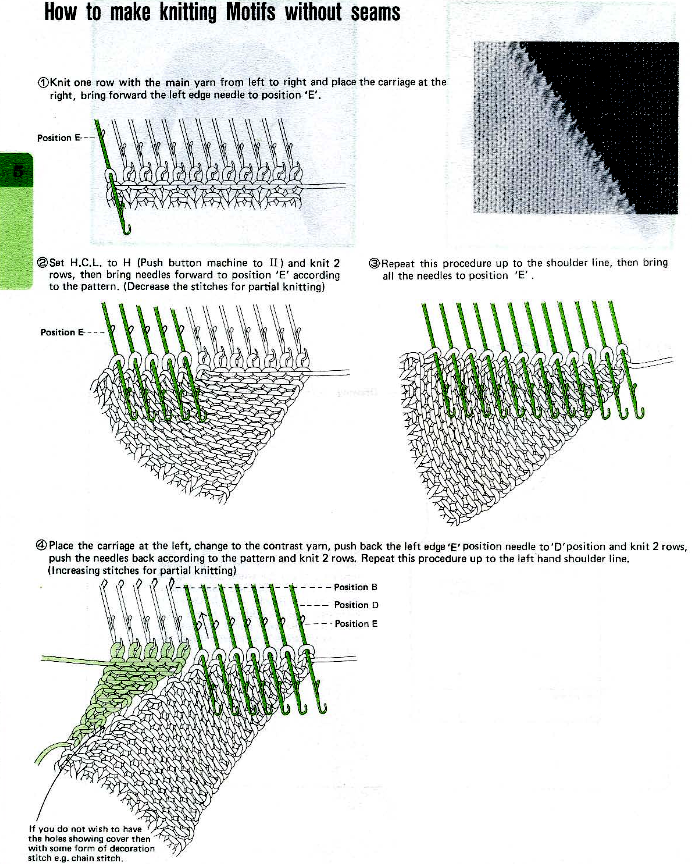

The idea of chaining the eyelet areas to reduce the size of the slits is an interesting one that up to now I have not tested.

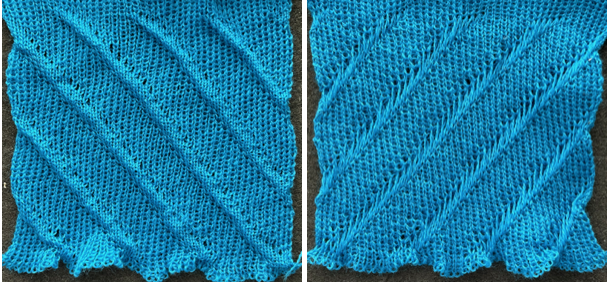

Diagonal pleats

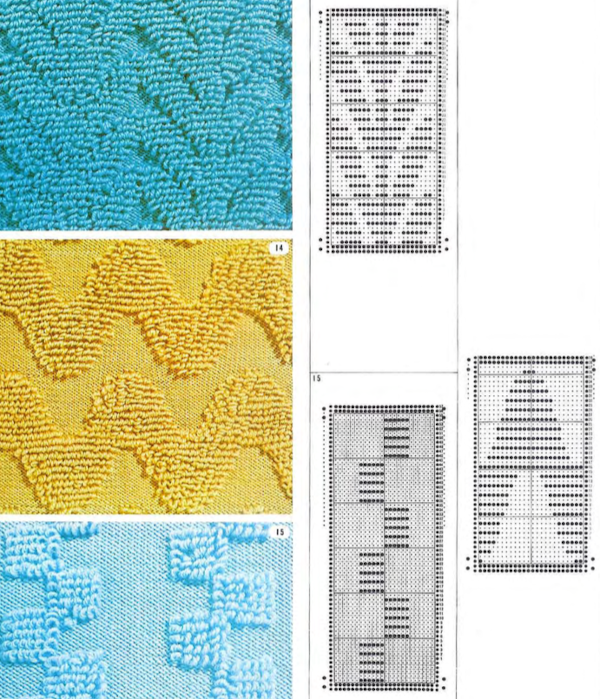

Other explorations of the use of tuck stitch settings in 2-color double-bed every needle rib fabric began with attempting to create a solid color shape on a vertically striped ground in Geometric shapes on ribber fabrics with tuck stitches 1

Other explorations of the use of tuck stitch settings in 2-color double-bed every needle rib fabric began with attempting to create a solid color shape on a vertically striped ground in Geometric shapes on ribber fabrics with tuck stitches 1  Another simple shape was programmed, and varied carriage settings on either or both beds were explored in Geometric shapes on ribber fabrics with tuck stitches 2; knitting with 4 carriages.

Another simple shape was programmed, and varied carriage settings on either or both beds were explored in Geometric shapes on ribber fabrics with tuck stitches 2; knitting with 4 carriages.  Geometric shapes on ribber fabrics with tuck stitches 3 uses self-drawn repeats and multiple colors.

Geometric shapes on ribber fabrics with tuck stitches 3 uses self-drawn repeats and multiple colors.  varying carriage settings while using only 2 colors

varying carriage settings while using only 2 colors  Lace transfers meet fisherman rib in 2 colors on Brother KM 1

Lace transfers meet fisherman rib in 2 colors on Brother KM 1 Lace transfers meet fisherman rib, 2 color ribbed brioche on Brother machines 2 , one of several swatches.

Lace transfers meet fisherman rib, 2 color ribbed brioche on Brother machines 2 , one of several swatches.  These are advanced, complex fabrics. The repeats for 2 colors can grow exponentially in length.

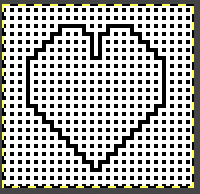

These are advanced, complex fabrics. The repeats for 2 colors can grow exponentially in length. Working toward a repeat for knitting the shapes in a single color, imagining the location of eyelets resulting from stitch transfers,

Working toward a repeat for knitting the shapes in a single color, imagining the location of eyelets resulting from stitch transfers,  I used two repeats, adjusting the first one to vary the resulting shape slightly

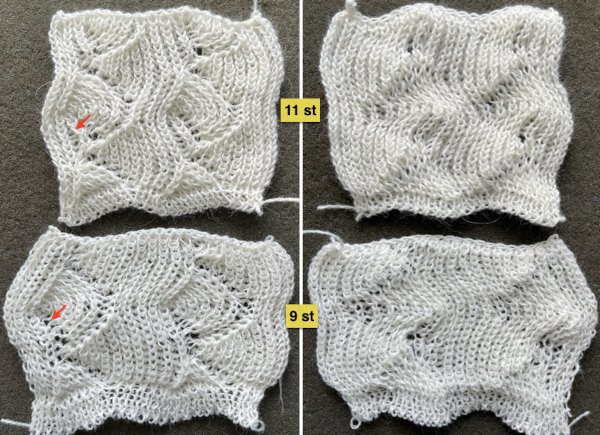

I used two repeats, adjusting the first one to vary the resulting shape slightly  A 11X30 repeat mirrored horizontally for use on my 930, tiled twice horizontally before programming and downloading, used as a 23X30 single motif to obtain a matching border on each side,

A 11X30 repeat mirrored horizontally for use on my 930, tiled twice horizontally before programming and downloading, used as a 23X30 single motif to obtain a matching border on each side, ![]()

A 9X28 repeat, my second try, programmed as a 20X28 single motif,

A 9X28 repeat, my second try, programmed as a 20X28 single motif, ![]()

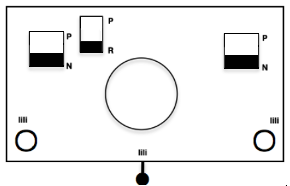

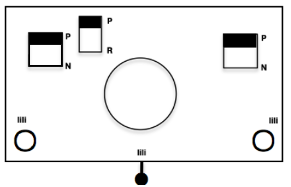

As described in previous posts, in knitting using only one color, the machine is set with the main bed tucking on every needle in one direction, followed by knitting on every needle as it returns to the starting side, the ribber does the same but in the opposite direction. It is a circular tuck, also referred to as fisherman’s rib. A slight shift in patterning may change the outline of the desired shape, requiring introducing or removing stray lines or secondary shapes.

As described in previous posts, in knitting using only one color, the machine is set with the main bed tucking on every needle in one direction, followed by knitting on every needle as it returns to the starting side, the ribber does the same but in the opposite direction. It is a circular tuck, also referred to as fisherman’s rib. A slight shift in patterning may change the outline of the desired shape, requiring introducing or removing stray lines or secondary shapes.

In a two-color brioche, when no needles are selected on the top bed (white squares), the top bed will tuck every needle; the ribber is set to knit.

In a two-color brioche, when no needles are selected on the top bed (white squares), the top bed will tuck every needle; the ribber is set to knit.  When needles are selected on the top bed (black squares), the ribber is set to tuck in both directions.

When needles are selected on the top bed (black squares), the ribber is set to tuck in both directions.  Brother preselects needles for the next row to be knit, on rows with partial selection and some needles in the B rather than the D position, with an appropriate transfer tool, move the stitches on the non-selected needles to the adjacent selected needles to their right after pushing it (them) back to the B position.

Brother preselects needles for the next row to be knit, on rows with partial selection and some needles in the B rather than the D position, with an appropriate transfer tool, move the stitches on the non-selected needles to the adjacent selected needles to their right after pushing it (them) back to the B position.

![]()

Here groups of columns are eliminated to bring the shapes close together

Here groups of columns are eliminated to bring the shapes close together

![]()

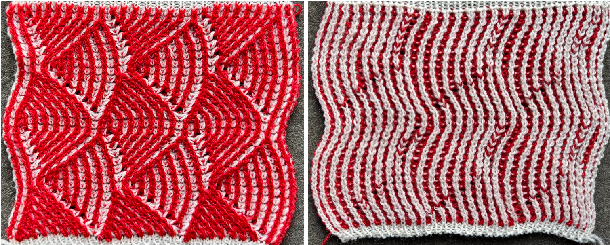

The yarns used are white 2/15 and red 2/10 wool. The latter is coarsely spun and tends to split and occasionally not properly knit off, resulting in the specks on the white columns on the reverse, making it a poor choice for final projects.

The yarns used are white 2/15 and red 2/10 wool. The latter is coarsely spun and tends to split and occasionally not properly knit off, resulting in the specks on the white columns on the reverse, making it a poor choice for final projects.

The #14 24X42 repeat

The #14 24X42 repeat ![]() used in this sample was color-reversed before being downloaded to the 930

used in this sample was color-reversed before being downloaded to the 930 ![]() checking tiling

checking tiling  punchcard machine users would punch all black cells.

punchcard machine users would punch all black cells.  The pattern is worked with end needle selection canceled, the knit carriage is set to tuck in both directions and the ribber carriage to knit in both.

The pattern is worked with end needle selection canceled, the knit carriage is set to tuck in both directions and the ribber carriage to knit in both.

![]() repeated X2

repeated X2 ![]()

![]() was used to knit this slip-stitch double bed fabric

was used to knit this slip-stitch double bed fabric  The 24X16, file color was reversed

The 24X16, file color was reversed ![]() and this 26X32 file added black pixels in width for more definition of the shapes

and this 26X32 file added black pixels in width for more definition of the shapes ![]()

The yarn used is a 2/20 wool, so thin that there is less definition between the two stitch types and enough open space between the stitches to show the surface beneath the swatch, which measures 13.5 inches in width, 7.25 in height

The yarn used is a 2/20 wool, so thin that there is less definition between the two stitch types and enough open space between the stitches to show the surface beneath the swatch, which measures 13.5 inches in width, 7.25 in height  A DIY attempt at a large scale design: the 24X38 was found in Pinterest, published in 2018 and credited to a Russian site.

A DIY attempt at a large scale design: the 24X38 was found in Pinterest, published in 2018 and credited to a Russian site.![]() the tiled repeat results in a horizontal striping

the tiled repeat results in a horizontal striping  24X38 scaled in Gimp X4 to 96X152

24X38 scaled in Gimp X4 to 96X152  Mode >RGB

Mode >RGB![]() copy to clipboard to use it as a brush

copy to clipboard to use it as a brush click on the select by color tool, click on the red, and use the bucket fill tool again, making certain that the background or foreground colors are selected, not pattern fill

click on the select by color tool, click on the red, and use the bucket fill tool again, making certain that the background or foreground colors are selected, not pattern fill  click on the rectangle select tool and back in the work window to fix the layer, Mode >BW indexed, color invert the result for knitting using the tuck double bed setting

click on the rectangle select tool and back in the work window to fix the layer, Mode >BW indexed, color invert the result for knitting using the tuck double bed setting The yarn used in this swatch is a 2/20 coarse and unevenly spun wool, which leads to the variable moiret-like bleed-through of the fabric colors behind it.

The yarn used in this swatch is a 2/20 coarse and unevenly spun wool, which leads to the variable moiret-like bleed-through of the fabric colors behind it.  The same yarn was then used double-stranded. Some spots were harder to knit than others due to changes in ply quality resulting in snags in texture as well. The shapes are more clearly defined, the largest shape measures 7.5 inches of the 11-inch swatch width and 3 3/8 inches in height.

The same yarn was then used double-stranded. Some spots were harder to knit than others due to changes in ply quality resulting in snags in texture as well. The shapes are more clearly defined, the largest shape measures 7.5 inches of the 11-inch swatch width and 3 3/8 inches in height.  This swatch began with a 25X25 pixel file, processed in Arahpaint

This swatch began with a 25X25 pixel file, processed in Arahpaint ![]() drawn in repeat using the random >preview option until a final version was chosen

drawn in repeat using the random >preview option until a final version was chosen  and rendered double-length. Brush fill was used to expose every other row, and the resulting 75X150 file

and rendered double-length. Brush fill was used to expose every other row, and the resulting 75X150 file  was color-inverted for use with the tuck setting

was color-inverted for use with the tuck setting

These knits produce a subtle texture easily on both sides and lie flat.

These knits produce a subtle texture easily on both sides and lie flat.

After a motif has been separated, usually color 1 is represented in row 1, and all odd-numbered rows

After a motif has been separated, usually color 1 is represented in row 1, and all odd-numbered rows

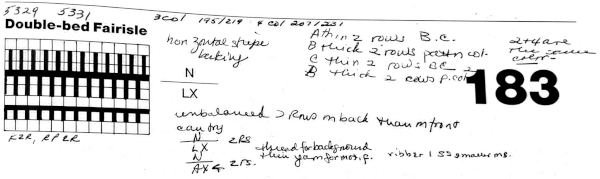

In Fantasy Fairisle knitting using 187 with alternating up and down pushers on the back bed and AX with 2 arrow keys would match Brother ribber knitting with lili buttons used on an even number of needles set to tuck.

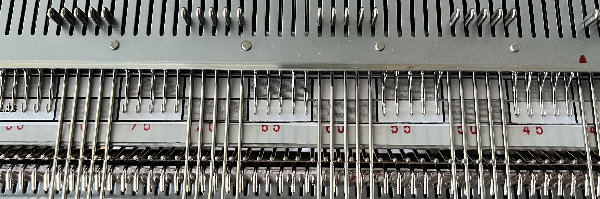

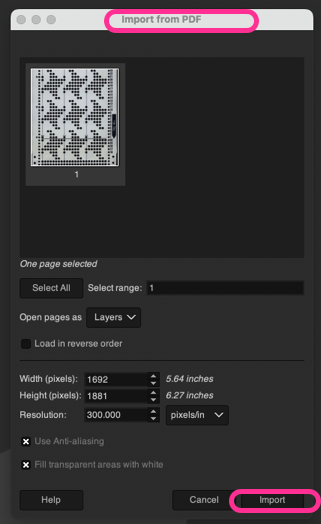

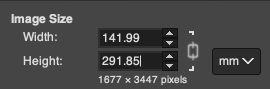

In Fantasy Fairisle knitting using 187 with alternating up and down pushers on the back bed and AX with 2 arrow keys would match Brother ribber knitting with lili buttons used on an even number of needles set to tuck. For the 1-pixel grid in Gimp to be visible on an editable image, a magnification of at least 800 is required. The options offered by default

For the 1-pixel grid in Gimp to be visible on an editable image, a magnification of at least 800 is required. The options offered by default can be changed to suit by simply typing in a new number.

can be changed to suit by simply typing in a new number.

the processed image

the processed image  the trimmed 98X182 png

the trimmed 98X182 png  doubled in length once more to 98X364

doubled in length once more to 98X364  Knitting process on a 930 using img2track:

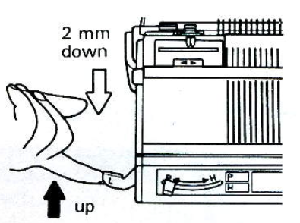

Knitting process on a 930 using img2track: A reminder: in my experience, the Brother cast-on combs are usually chrome-colored, Studio grey, and Passap, and I believe Superba ones were traditionally green. The first 2 were designed for 4.5 mm machines, the latter for 5mm. The different mm spacing does not make the 5 mm combs suitable for casting on on Brother, but they can be poked through the knit in progress. I like to leave the first comb and weights on, insert the new comb closer to the beds, and then move the weight up, and then remove the lower position comb.

A reminder: in my experience, the Brother cast-on combs are usually chrome-colored, Studio grey, and Passap, and I believe Superba ones were traditionally green. The first 2 were designed for 4.5 mm machines, the latter for 5mm. The different mm spacing does not make the 5 mm combs suitable for casting on on Brother, but they can be poked through the knit in progress. I like to leave the first comb and weights on, insert the new comb closer to the beds, and then move the weight up, and then remove the lower position comb.

In the Brother model, sometimes the yarn is left in the wrong place below eye level rather than its own individual one corresponding to its button, and both yarns are picked up with the next color change.

In the Brother model, sometimes the yarn is left in the wrong place below eye level rather than its own individual one corresponding to its button, and both yarns are picked up with the next color change.

a close-up of the texture at an angle

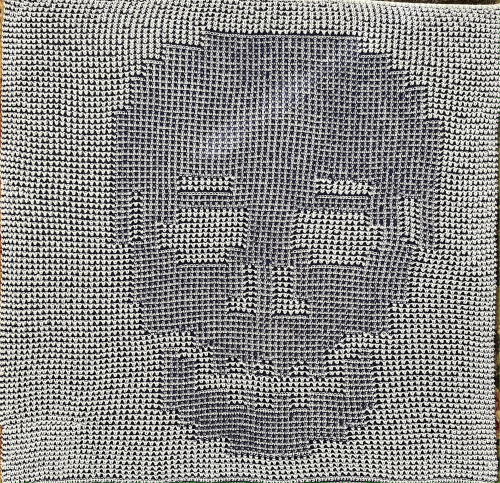

a close-up of the texture at an angle  Claudia Scarpa developed a skull variation using only layers in Gimp

Claudia Scarpa developed a skull variation using only layers in Gimp  and has been kind enough to create a

and has been kind enough to create a

It is possible to work some repeats on some machines with the ribber also set to tuck both ways with EON needle selection.

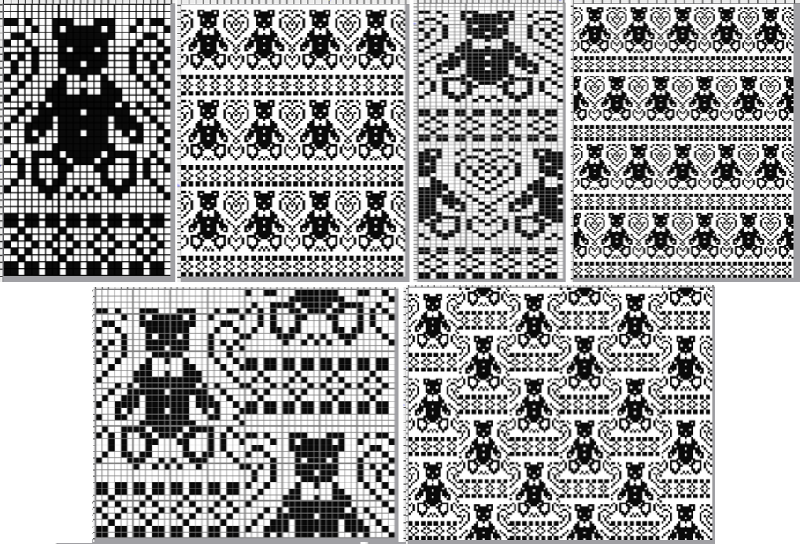

It is possible to work some repeats on some machines with the ribber also set to tuck both ways with EON needle selection. When using the Dak stitch design module, the color separation is automated. Choose any design repeat. This happens to be a 20X20 one, chosen from the thumbnail assortment, so not suitable for punchcard models. “Printing” the template using choosing the option of using dots rather than squares to represent knit stitches makes the resulting print screengrab easier to trace.

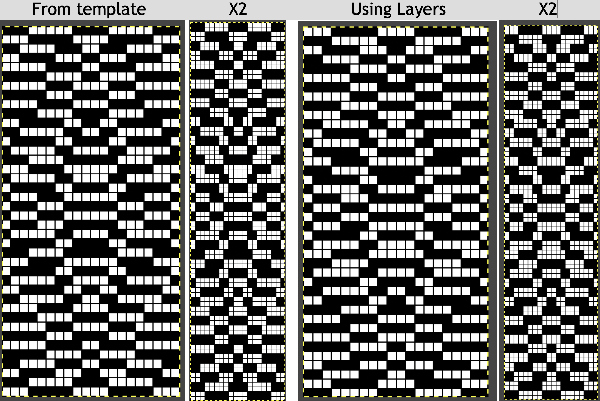

When using the Dak stitch design module, the color separation is automated. Choose any design repeat. This happens to be a 20X20 one, chosen from the thumbnail assortment, so not suitable for punchcard models. “Printing” the template using choosing the option of using dots rather than squares to represent knit stitches makes the resulting print screengrab easier to trace. the 20X20 repeat as a BW png

the 20X20 repeat as a BW png  The result is screengrabbed, opened in Gimp, converted to BW mode, and scaled to the 20X40 expanded design size. Unless the double-length function in the machine is also used, it will need scaling again to double length prior to download.

The result is screengrabbed, opened in Gimp, converted to BW mode, and scaled to the 20X40 expanded design size. Unless the double-length function in the machine is also used, it will need scaling again to double length prior to download. The final image double length, showing the difference between the separation using the template, and that using layers as in Claudia’s video, which appears different but is actually the same repeat, color reversed.

The final image double length, showing the difference between the separation using the template, and that using layers as in Claudia’s video, which appears different but is actually the same repeat, color reversed.  Using bucket fill for the ground in the second layer, as described in the video, the captured clipboard image can be very small

Using bucket fill for the ground in the second layer, as described in the video, the captured clipboard image can be very small

Alternately, the initial design may be scaled X4 to 20 X 80 pixels

Alternately, the initial design may be scaled X4 to 20 X 80 pixels

bring the ribber needles up into work between them

bring the ribber needles up into work between them

drop the ribber

drop the ribber

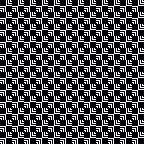

The repeat is 8X8 and the above movement can be seen in the purl view.

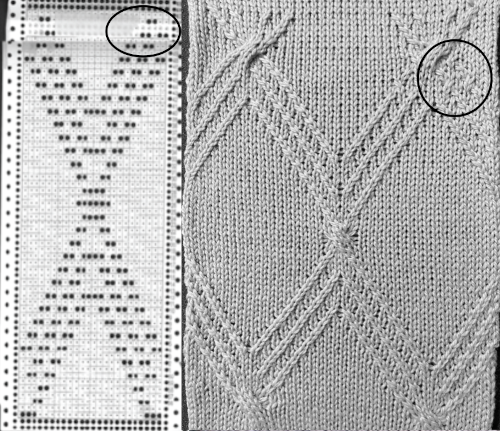

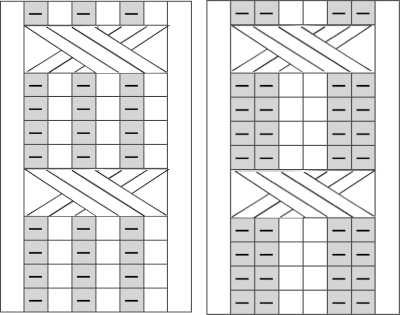

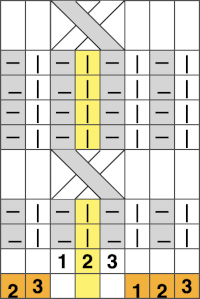

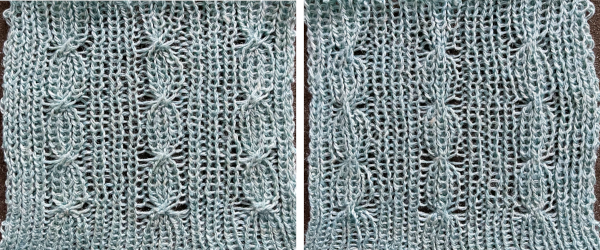

The repeat is 8X8 and the above movement can be seen in the purl view. A spreadsheet table may be created to help with tracking multiple series of cables across a knit and their direction. It can contain as little or as much information as one wishes. Included here: the RC for possible crossings, and their direction on the purl side for machine knitting (reversed for hand knitting). Columns may be added including how many needles are left in or out of work between cable knit spaces or other info.

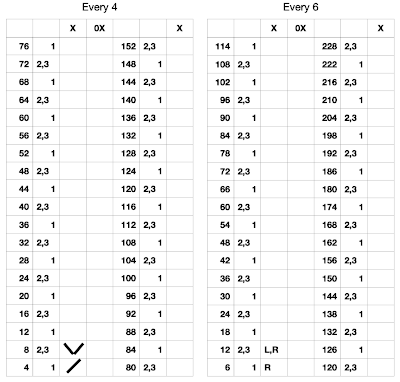

A spreadsheet table may be created to help with tracking multiple series of cables across a knit and their direction. It can contain as little or as much information as one wishes. Included here: the RC for possible crossings, and their direction on the purl side for machine knitting (reversed for hand knitting). Columns may be added including how many needles are left in or out of work between cable knit spaces or other info.

Which leads to the topic of creating shapes by combining the repeats

Which leads to the topic of creating shapes by combining the repeats  A brief effort containing at least 5 errors leads me to wonder about programming needle selection to help track crossings more easily and avoid mistakes. The center ladder here was latched up during knitting.

A brief effort containing at least 5 errors leads me to wonder about programming needle selection to help track crossings more easily and avoid mistakes. The center ladder here was latched up during knitting.

If the start is on the top bed, stitches on the ribber may be created by picking up bars from the top bed

If the start is on the top bed, stitches on the ribber may be created by picking up bars from the top bed  the yarn above was a 2/8 wool, which refused to cable on the ribber, and having the crossing was preferred to not

the yarn above was a 2/8 wool, which refused to cable on the ribber, and having the crossing was preferred to not  changing to a thinner wool-silk solved the problem.

changing to a thinner wool-silk solved the problem.

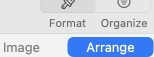

In reviewing the post after linking to it here I realized the now marked punchcard error at its top. The amended longer chart reworked in Numbers is also added to the older post. It is shown here aside from its tiled chart, checking for alignment, a habit developed as my skill and comfort in using spreadsheets grew,

In reviewing the post after linking to it here I realized the now marked punchcard error at its top. The amended longer chart reworked in Numbers is also added to the older post. It is shown here aside from its tiled chart, checking for alignment, a habit developed as my skill and comfort in using spreadsheets grew,

It is possible to use the repeat working 1 X 2 stitch crossings for a very different look.

It is possible to use the repeat working 1 X 2 stitch crossings for a very different look. Assigning colors to crossings in a chart may be helpful or too much info depending on one’s perspective, the bottom of the repeat is on the right.

Assigning colors to crossings in a chart may be helpful or too much info depending on one’s perspective, the bottom of the repeat is on the right.

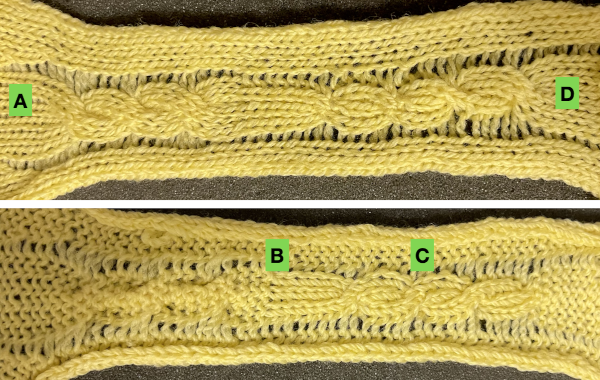

In my first test crossings occur on both beds and on the same row. Even using the thinner blue yarn at maximum tension the transfers were hard to execute. I had more success when I added 2 empty needles between the vertical ribs and brought one on each side of each rib into work on the top bed prior to knitting the last row between transfers, creating a bit of extra yarn to ease the crossings.

In my first test crossings occur on both beds and on the same row. Even using the thinner blue yarn at maximum tension the transfers were hard to execute. I had more success when I added 2 empty needles between the vertical ribs and brought one on each side of each rib into work on the top bed prior to knitting the last row between transfers, creating a bit of extra yarn to ease the crossings.

Trying out a simple repeat in smaller rib configurations will provide some idea as to whether the technique falls into the love of or not something to do simply because one can.

Trying out a simple repeat in smaller rib configurations will provide some idea as to whether the technique falls into the love of or not something to do simply because one can.

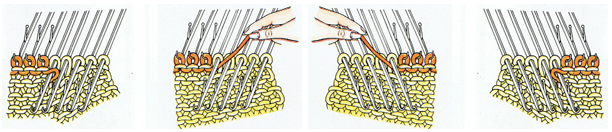

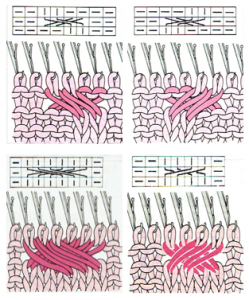

The step-by-step instructions apply to both instances: the chart shows 4 rows knit between crossings, instead, here 6 rows are knit in both tests.

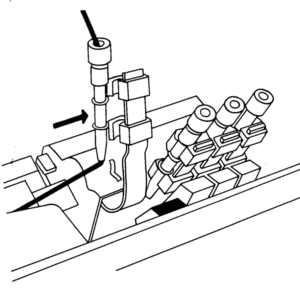

The step-by-step instructions apply to both instances: the chart shows 4 rows knit between crossings, instead, here 6 rows are knit in both tests. the rib configuration set up

the rib configuration set up  1. after 5 rows knit, bring an extra needle in work on the top bed to pick up extra yarn for the cross

1. after 5 rows knit, bring an extra needle in work on the top bed to pick up extra yarn for the cross  2. drop the extra loop, make certain the empty needle returns to A position

2. drop the extra loop, make certain the empty needle returns to A position  3. transfer all cable ribber needles to top bed

3. transfer all cable ribber needles to top bed  4. cross the stitches with two three-prong tools

4. cross the stitches with two three-prong tools  5. transfer stitches back down to the ribber

5. transfer stitches back down to the ribber  knit 5 rows, repeat steps 1 to 5.

knit 5 rows, repeat steps 1 to 5. An attempt at a larger swatch using 1X1 ribs:

An attempt at a larger swatch using 1X1 ribs:

the cable crossings using it were impossible, starting over with a thinner yarn at the same tension

the cable crossings using it were impossible, starting over with a thinner yarn at the same tension  the ribber may be dropped after transfers up to the main bed, keeping stitches and crossings visible, making it possible to make corrections in any cables if they are needed before re-engaging the ribber and transferring stitches back down

the ribber may be dropped after transfers up to the main bed, keeping stitches and crossings visible, making it possible to make corrections in any cables if they are needed before re-engaging the ribber and transferring stitches back down

In the above swatches, when any transfers were made to the top bed, after crossings, a row was knit before returning stitches to the ribber. The extra row may or may not be noticeable, depending on the yarn and colors used.

In the above swatches, when any transfers were made to the top bed, after crossings, a row was knit before returning stitches to the ribber. The extra row may or may not be noticeable, depending on the yarn and colors used.

The number of rows between crossings can vary. When the crossing row is reached:

The number of rows between crossings can vary. When the crossing row is reached:

Assigning colors to columns reveals that stitches are not moved onto the same stitch type when moved over a single, undisturbed, fixed center stitch.

Assigning colors to columns reveals that stitches are not moved onto the same stitch type when moved over a single, undisturbed, fixed center stitch.  Shifting the needle arrangements when cabling, moving across a center column of two stitches that remain fixed on the main bed, the cable direction as it would appear on the purl side on the left, the knit side on the right is straightforward here:

Shifting the needle arrangements when cabling, moving across a center column of two stitches that remain fixed on the main bed, the cable direction as it would appear on the purl side on the left, the knit side on the right is straightforward here:  I found the above impossible to knit, even with ladders for extra slack, and the swatch stopped when the yarn broke

I found the above impossible to knit, even with ladders for extra slack, and the swatch stopped when the yarn broke

There appears to be enough slack produced in the formation of stitches between beds to make the planned crossings possible.

There appears to be enough slack produced in the formation of stitches between beds to make the planned crossings possible.

From a Brother pub, small crossings for a smocked effect

From a Brother pub, small crossings for a smocked effect

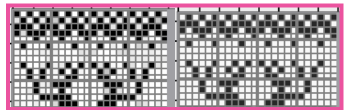

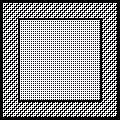

Adding and removing rows in the tables or even changing colors is easy and quick in a spreadsheet, tiling in repeat with scaled screengrabs provides a quick reference for possible improvements/corrections before any actual knitting takes place

Adding and removing rows in the tables or even changing colors is easy and quick in a spreadsheet, tiling in repeat with scaled screengrabs provides a quick reference for possible improvements/corrections before any actual knitting takes place