The latest version Gimp Download site

I am self-taught. As I learn new tools, my workarounds may be convoluted and more complicated than they need to be and evolve with time. I do not delete older posts or their content, but do occasionally add links to later posts or dated notes.

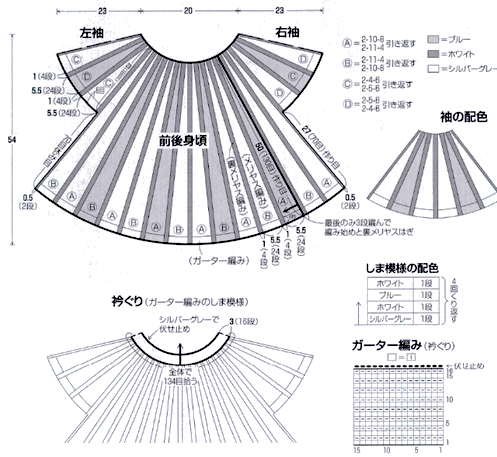

I began designing and charting in the days of having to draw on graph paper and cutting up results to see if the repeats would tile properly when knit, or to place them for alignment variations such as half drop or brick.

Scanning amounted to tracing with a marker onto blank sheets of acetate or tracing paper.

The availability of commercial acetates for purchase at seminars, printed in pairs of matching horizontally striped sheets in lines separated in a variety of widths, offered an advance in scaling designs to a knit aspect ratio.  Copy machines became useful friends.

Copy machines became useful friends.

DBJ designs in the punchcard studio, when I began teaching, were accomplished at first with the use of cards themselves as templates and overlays, involving a series of time-consuming methods for each type of separation ie.  So many such processes are now nearly instantaneous by comparison.

So many such processes are now nearly instantaneous by comparison.

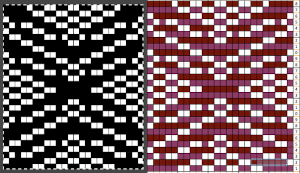

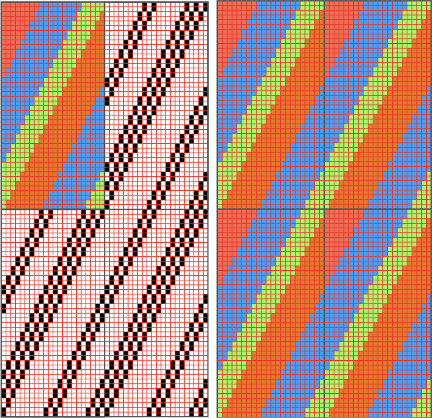

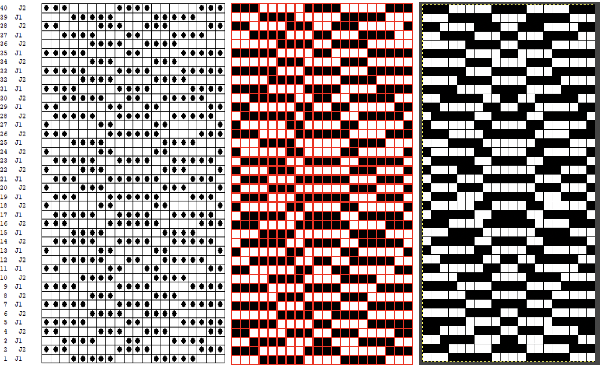

Earlier this year the post Using Layers in Gimp for color separations explored several fabrics beginning with B/W motifs.

Sometimes lightbulbs go off leading to other ideas for achieving results in quicker or easier ways.

This color separation method for mosaics continues to use Layers but in a different approach.

A spreadsheet may still be used if preferred to draw the initial draft of the design, working in black and white only would be fine, and the import could then be processed in Gimp.

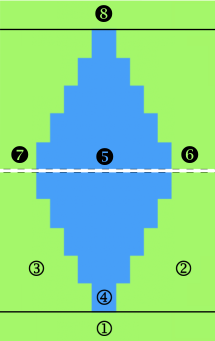

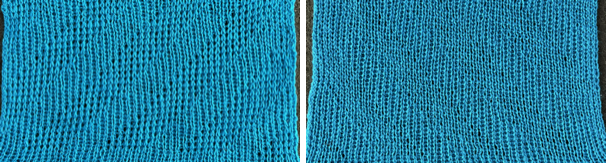

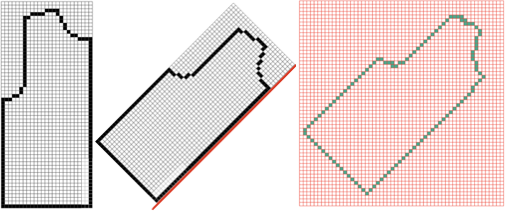

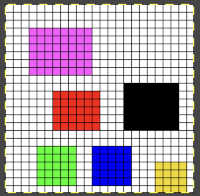

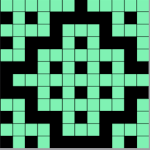

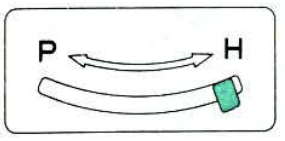

Mosaics and Mazes are generally knit with color changes every 2 rows using either the slip stitch or tuck carriage setting in both directions. Beginning with any DIY or published design, to knit the motif using the tuck setting, there are basic rules to remember.

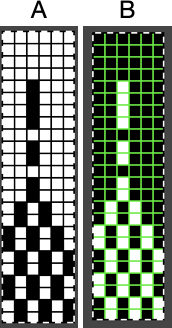

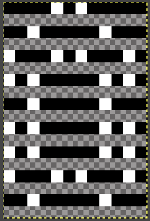

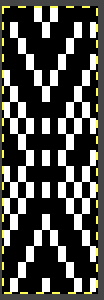

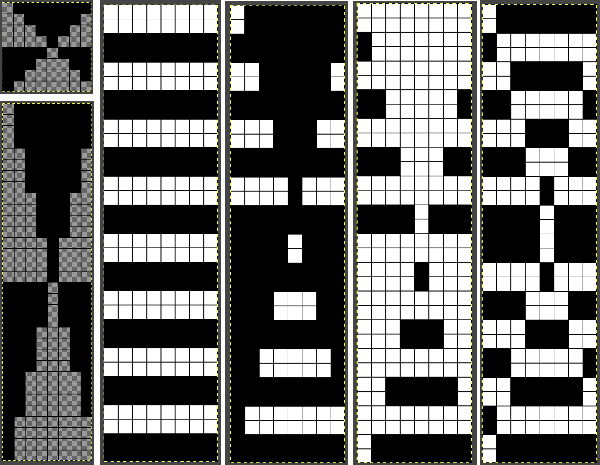

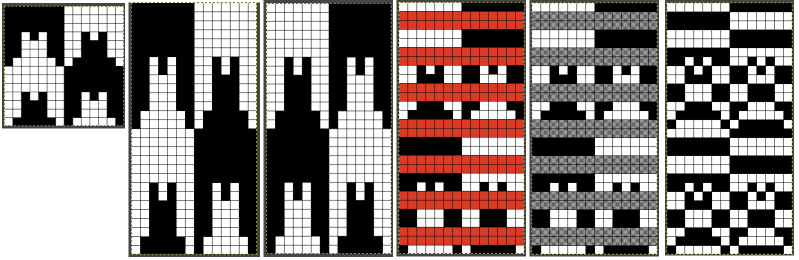

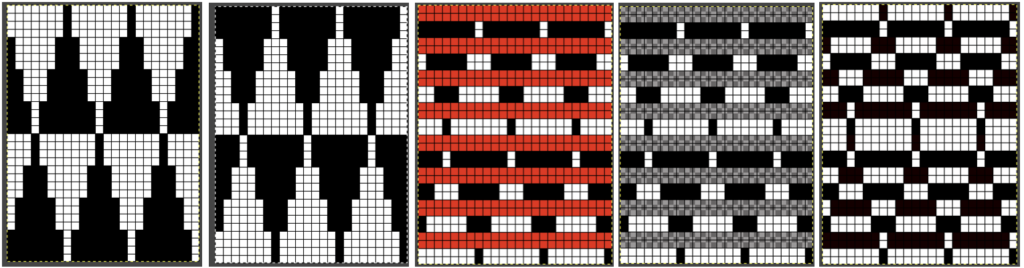

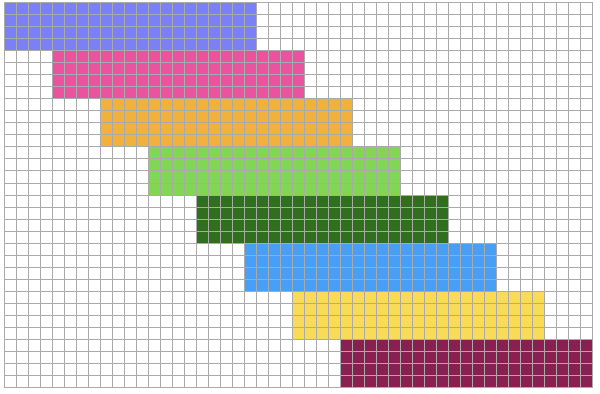

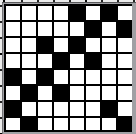

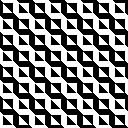

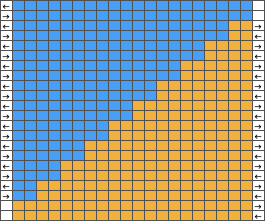

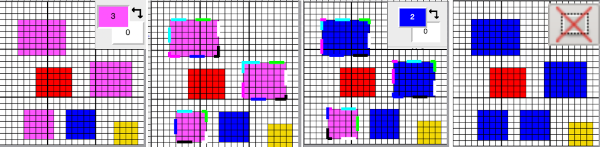

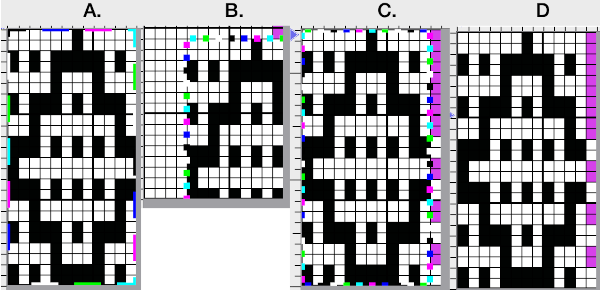

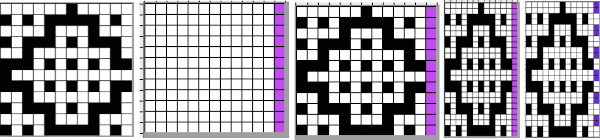

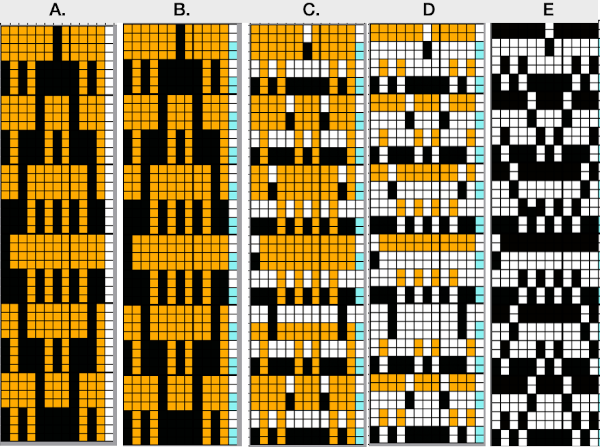

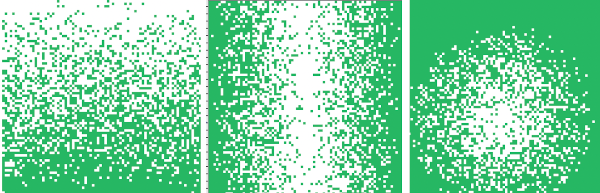

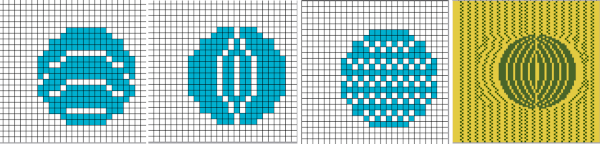

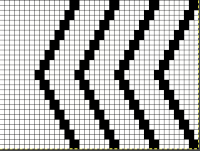

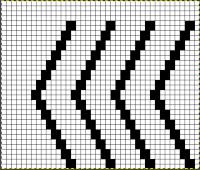

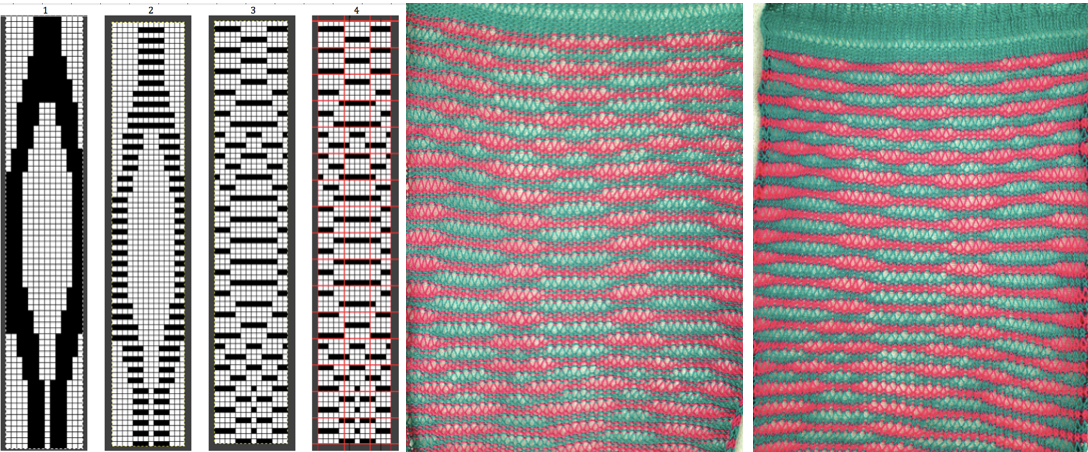

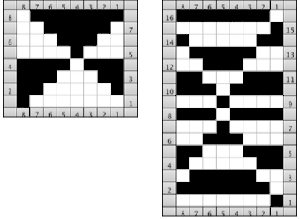

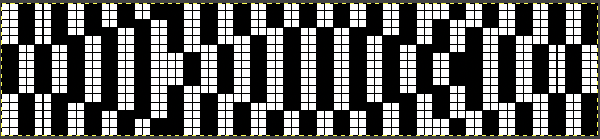

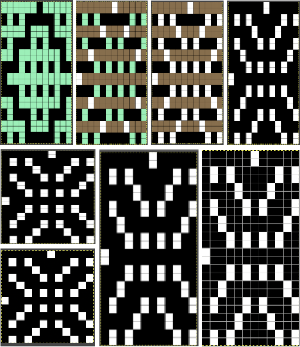

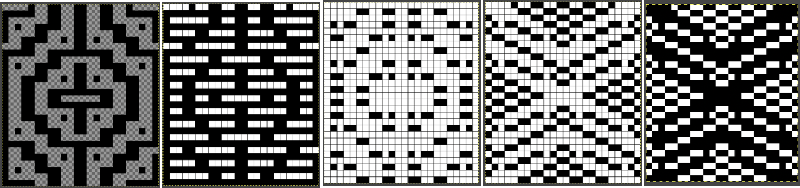

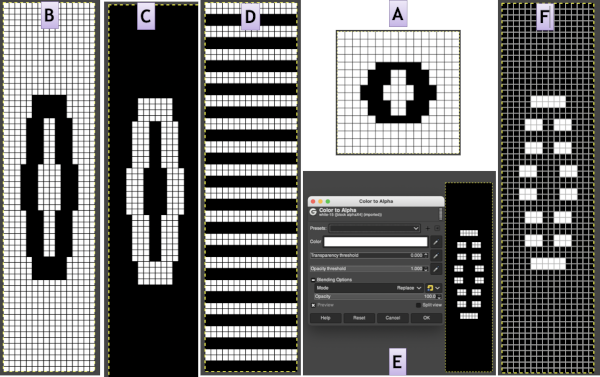

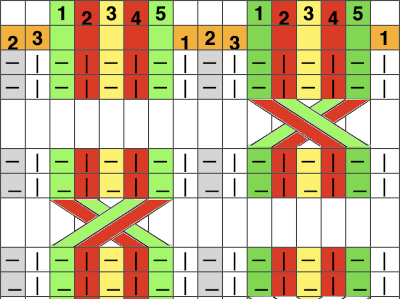

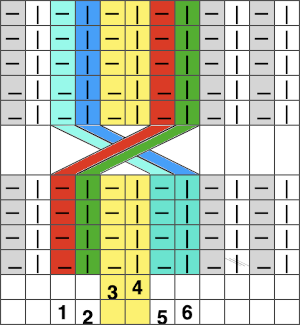

This illustrates possibilities using a random 6-stitch repeat, A.

If the plan is to set the knit carriage to tuck in both directions, the design would need to be color-reversed to B.  The white cells in B represent loops held on corresponding knitting machine needles, the limit in Japanese standard machines is often 4. Black cells represent knit stitches, generally seen in groups or on either side of tuck stitches/ white cells, to anchor the loops down for proper stitch formation. There are some infrequent exceptions to that rule.

The white cells in B represent loops held on corresponding knitting machine needles, the limit in Japanese standard machines is often 4. Black cells represent knit stitches, generally seen in groups or on either side of tuck stitches/ white cells, to anchor the loops down for proper stitch formation. There are some infrequent exceptions to that rule.

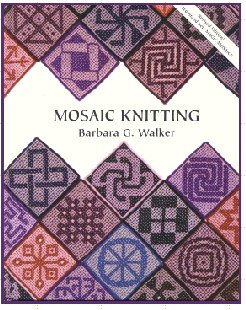

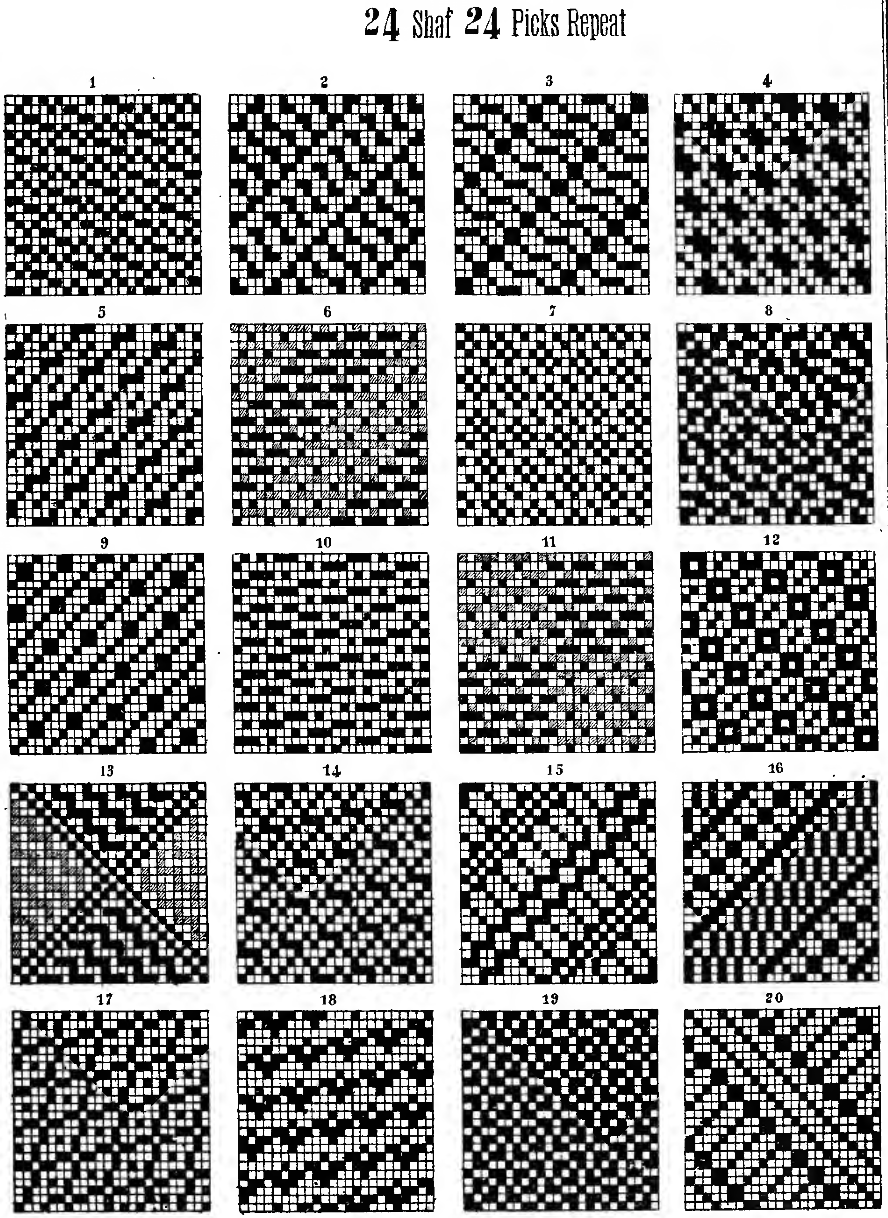

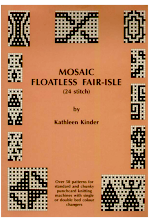

When uncertain as to results in developing DIY designs, begin with a published repeat to build up confidence. This is a hand-knitting resource for endless inspiration, no separations are provided in the book text.  There are always many ways to achieve the same task depending on the specific program used, one’s level of skill, and individual thought process.

There are always many ways to achieve the same task depending on the specific program used, one’s level of skill, and individual thought process.

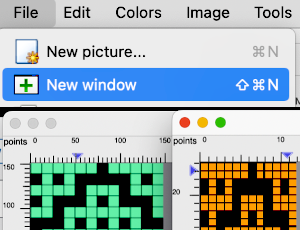

This method uses multiple windows in progression.

When starting out, save the result in each step for added practice or in case any step is accidentally deleted.

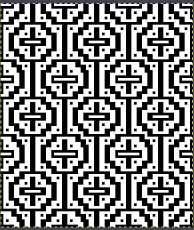

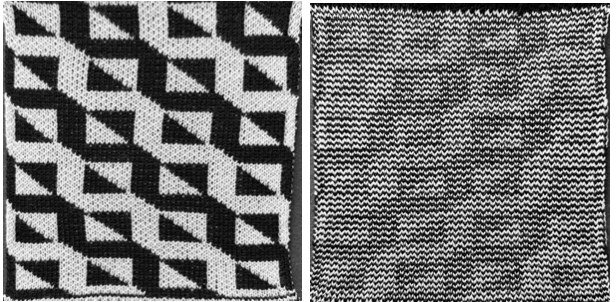

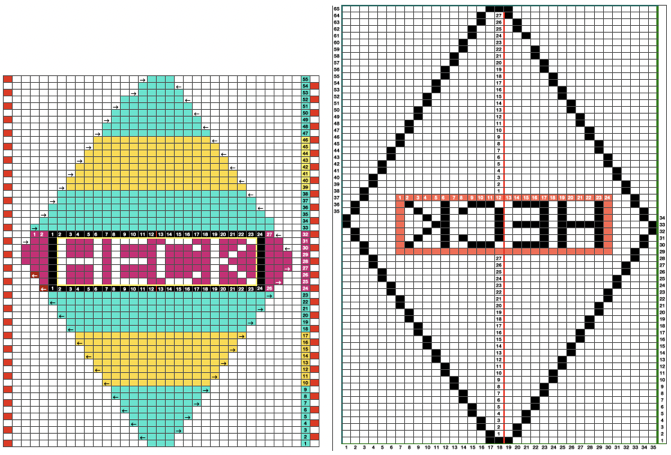

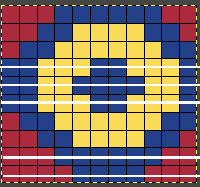

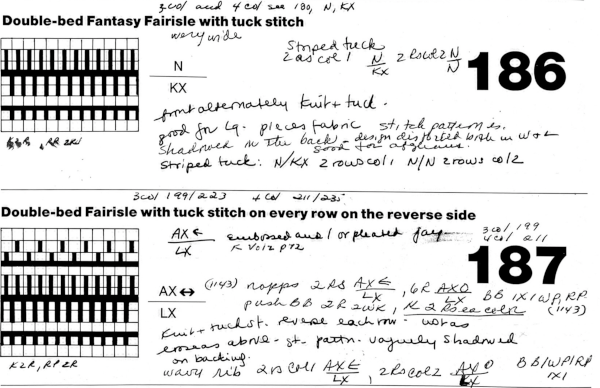

This is by Kathleen Kinder, published in Floatless Fair Isle, p. 87

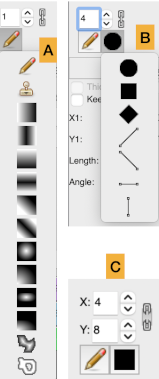

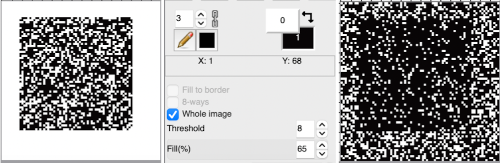

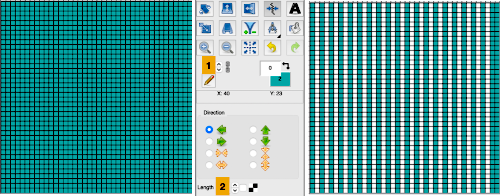

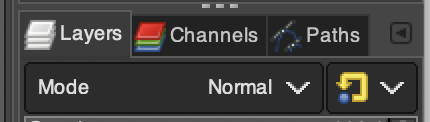

Though the final designs are saved as black and white pngs or bmps, to work using colors in separations, the mode needs to be set to RGB.

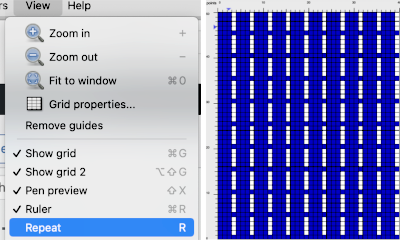

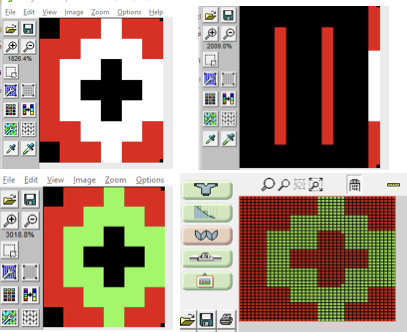

Though the final designs are saved as black and white pngs or bmps, to work using colors in separations, the mode needs to be set to RGB.  For very small repeats, use view, show grid,

For very small repeats, use view, show grid,

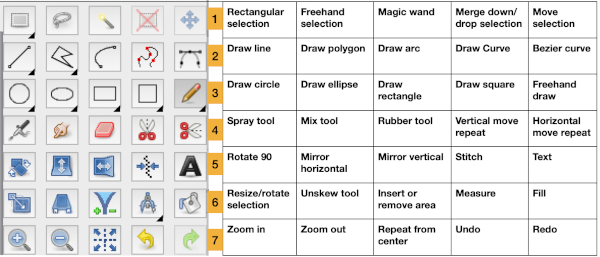

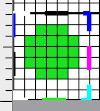

magnify 1800X, type in a number for a preferred value, ![]() or use the command key in Mac and the scroll wheel of your mouse to do so. Using the pencil tool draw the repeat in black and white

or use the command key in Mac and the scroll wheel of your mouse to do so. Using the pencil tool draw the repeat in black and white ![]()

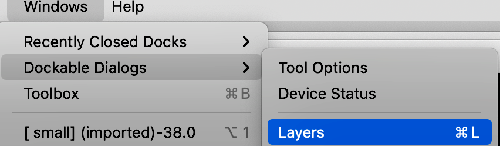

Selecting file, new, open a canvas in the same size and magnification, with each step a new icon appears at the top left of the Gimp window

Selecting file, new, open a canvas in the same size and magnification, with each step a new icon appears at the top left of the Gimp window ![]() to select any file, simply click on the corresponding icon, use Edit Copy or command C, and then edit, paste or command V to place files onto new selections.

to select any file, simply click on the corresponding icon, use Edit Copy or command C, and then edit, paste or command V to place files onto new selections.

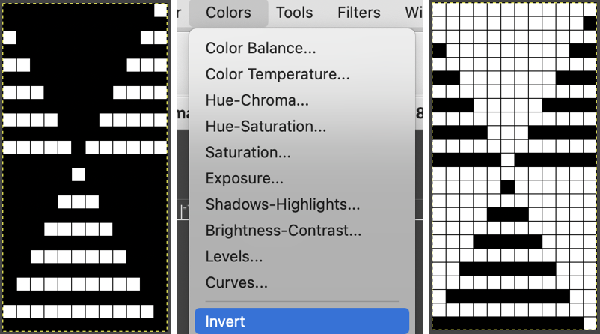

Copy and paste the first image onto the blank canvas and colors-invert the result ![]()

![]()

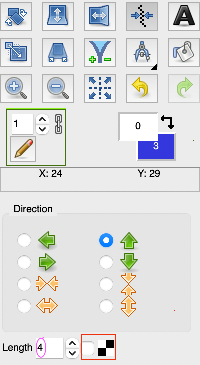

To draw straight lines on a Mac, use the pencil tool to place the starting pixel. Hold and drag the mouse to the desired endpoint. As this is done, a guiding line will appear. When the endpoint is reached and the mouse is released, that line disappears and the selected area will fill with the chosen color.

To draw straight lines on a Mac, use the pencil tool to place the starting pixel. Hold and drag the mouse to the desired endpoint. As this is done, a guiding line will appear. When the endpoint is reached and the mouse is released, that line disappears and the selected area will fill with the chosen color.

When using the 2-pixel brush, the mouse must be placed slightly into the second row of cells before dragging it for the line to remain straight and in the proper rows. If an error is made, choose Edit, Undo, to eliminate any step.  Continue to work on the color inverted file, and beginning with row 1 fill in every other row with a distinctly different color.

Continue to work on the color inverted file, and beginning with row 1 fill in every other row with a distinctly different color. ![]()

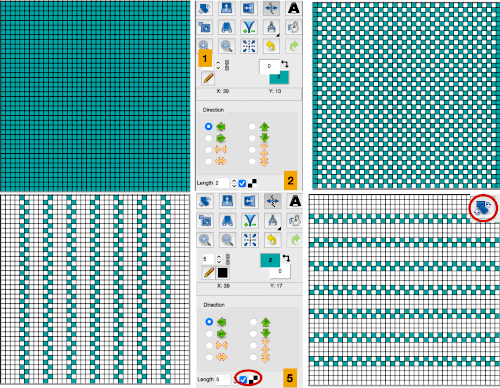

![]() To fix any layer before continuing, click on the rectangle select tool, and then again anywhere in the work window.

To fix any layer before continuing, click on the rectangle select tool, and then again anywhere in the work window.

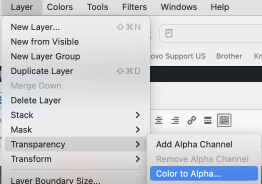

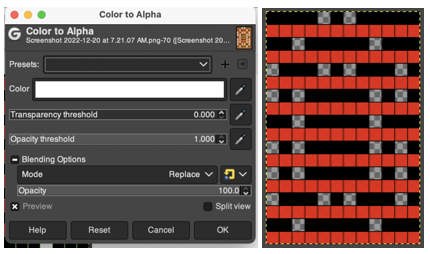

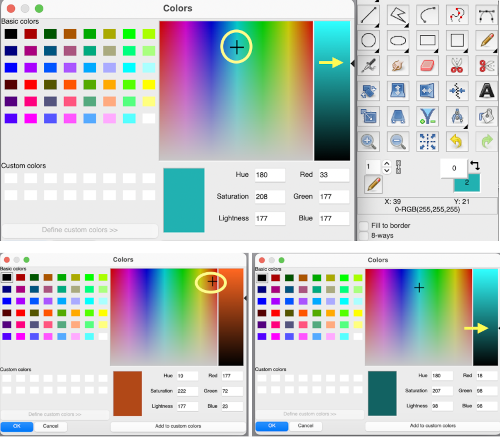

Getting rid of the red:  this will be the immediate appearance of the image in the window, disregard it.

this will be the immediate appearance of the image in the window, disregard it.

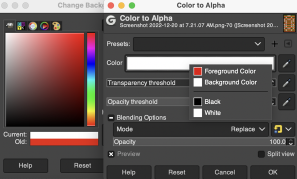

Right-click on Color/white, choose the foreground or background color

Right-click on Color/white, choose the foreground or background color  or left-click on the Color bar, and click again to choose the color from the palette window.

or left-click on the Color bar, and click again to choose the color from the palette window.  Choose rectangle-select cool, click on the result to fix the image, and the color window will disappear. The result:

Choose rectangle-select cool, click on the result to fix the image, and the color window will disappear. The result: ![]()

![]()

Copy and paste the file onto the initial image, there will be dotted lines upon the placement,

Copy and paste the file onto the initial image, there will be dotted lines upon the placement,  Click on the rectangle tool again, and then in the work window for the final png repeat.

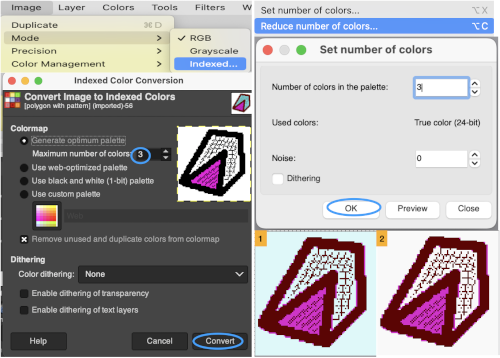

Click on the rectangle tool again, and then in the work window for the final png repeat. ![]() Change the image Mode to Indexed BW if its end use is a download to an electronic machine

Change the image Mode to Indexed BW if its end use is a download to an electronic machine ![]()

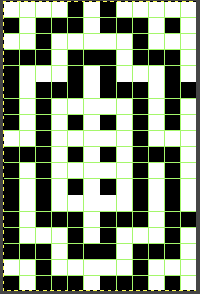

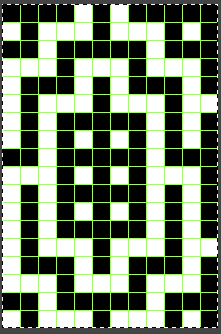

Why is it different than the Kinder repeat? It is easier in drawing to color in white squares as opposed to black, so the repeat in the pub is the above, color reversed.

Why is it different than the Kinder repeat? It is easier in drawing to color in white squares as opposed to black, so the repeat in the pub is the above, color reversed.  Punchcard machine users may mark the black squares and then punch all others.

Punchcard machine users may mark the black squares and then punch all others.

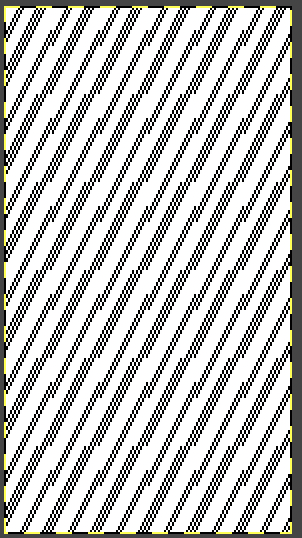

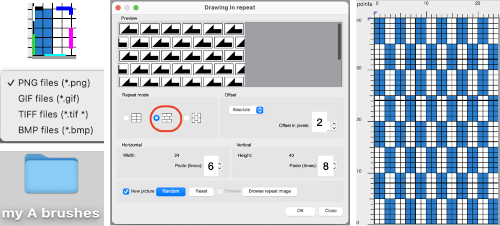

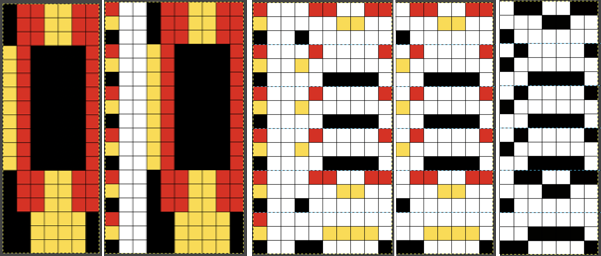

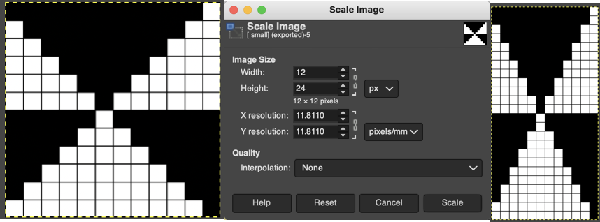

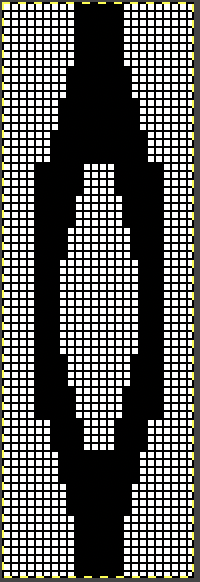

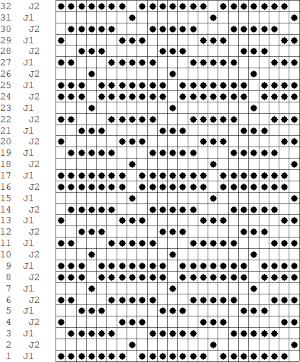

The last step: if colors are to be changed every 2 rows, remember to use double length or to program/punch the last png double length. ![]()

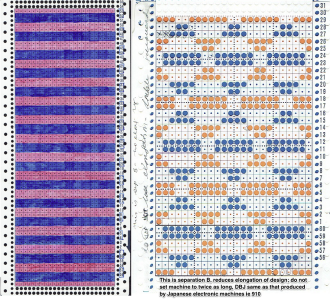

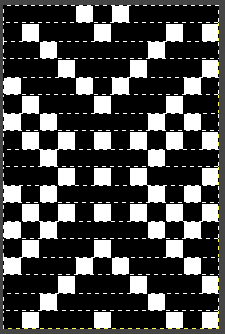

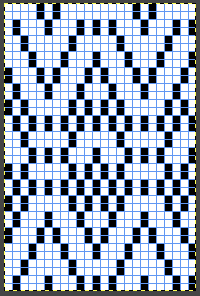

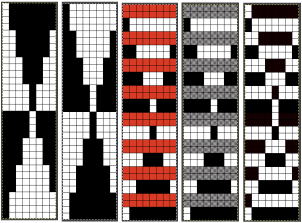

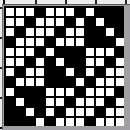

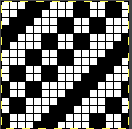

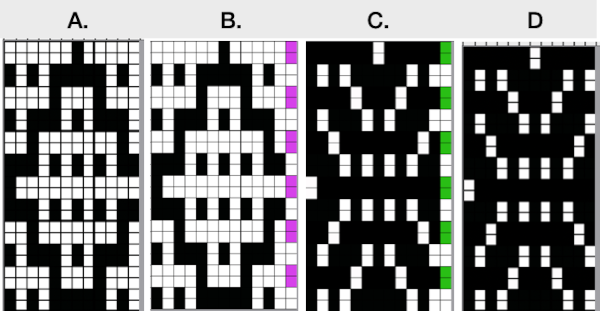

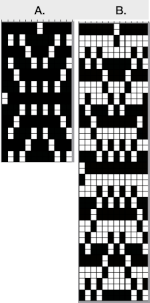

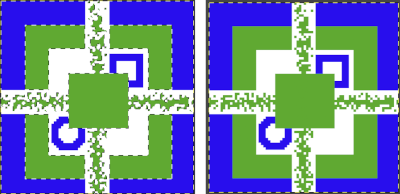

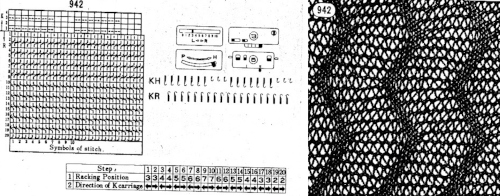

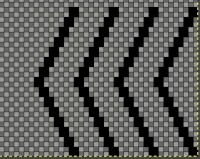

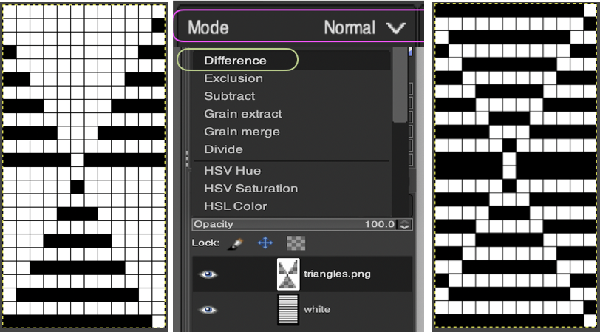

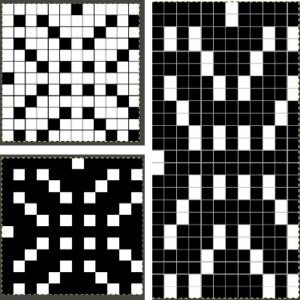

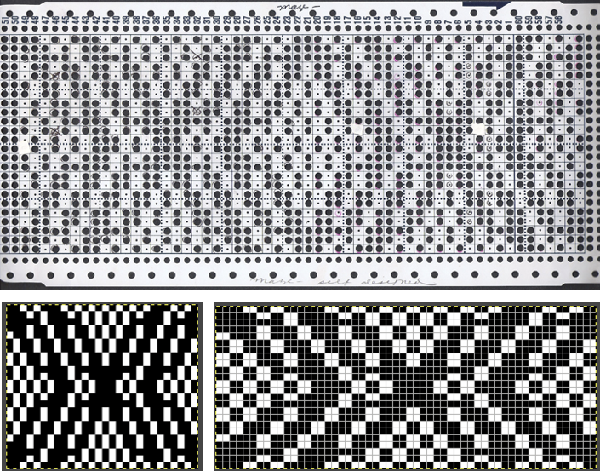

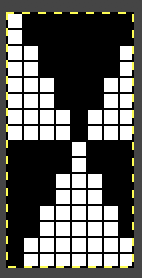

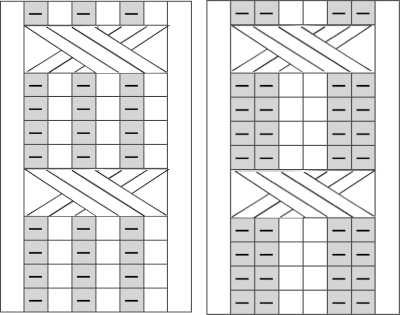

An illustration for the full double-length punchcard repeat. The above, 12X36 repeat was color reversed and tiled twice to meet the 24-stitch width requirement. The 36-row height also meets the minimum height requirement for punchcards to roll in continuous patterning.

An illustration for the full double-length punchcard repeat. The above, 12X36 repeat was color reversed and tiled twice to meet the 24-stitch width requirement. The 36-row height also meets the minimum height requirement for punchcards to roll in continuous patterning.

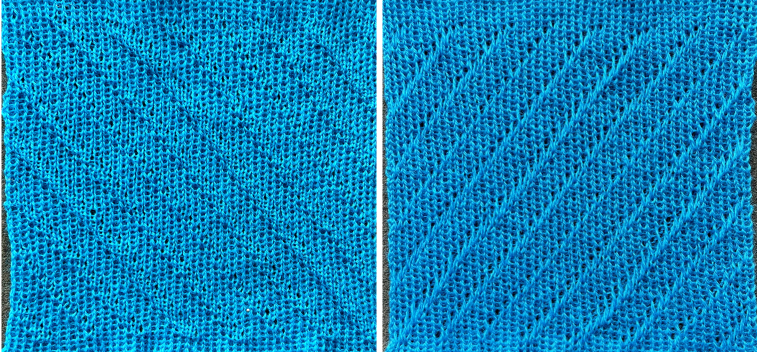

Mark the black cells in the image below on the card, and punch all the white ones.  These fabrics are often more interesting using the tuck setting than the slip stitch one.

These fabrics are often more interesting using the tuck setting than the slip stitch one.

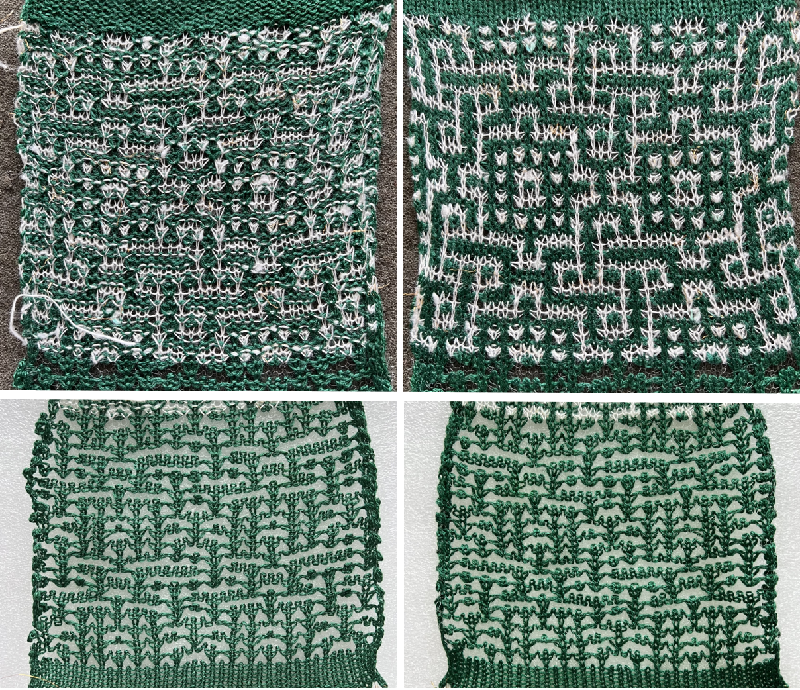

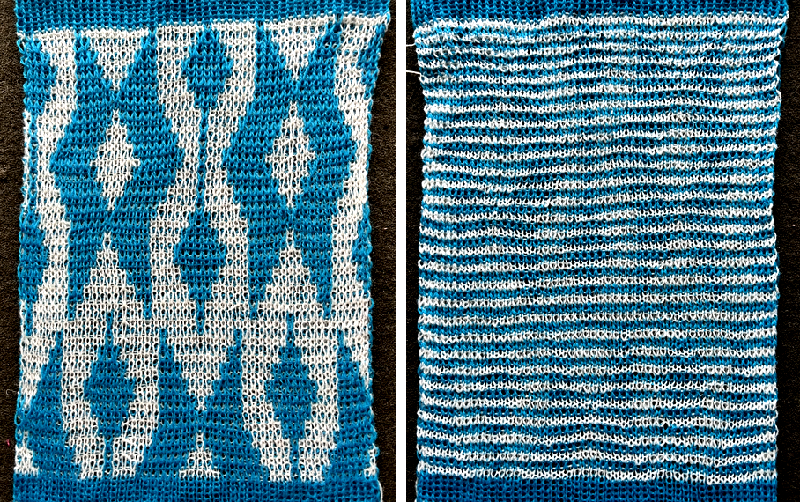

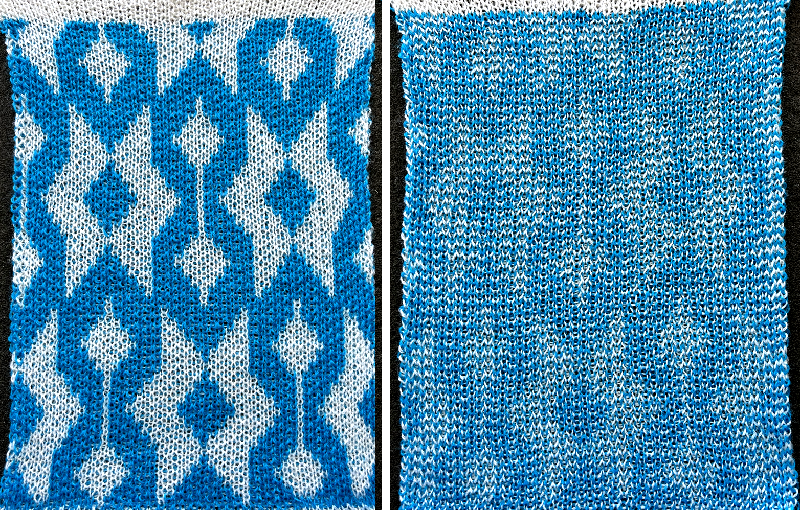

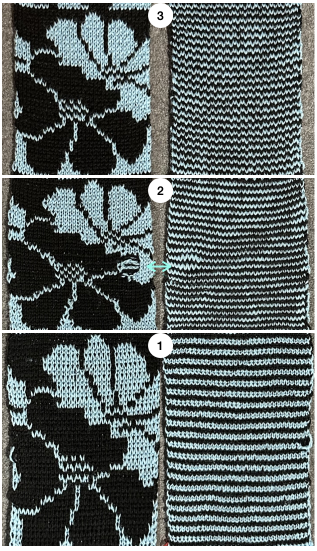

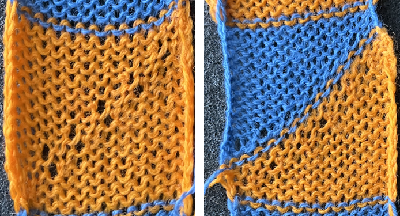

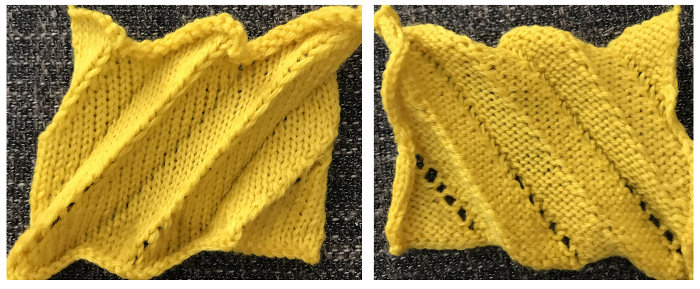

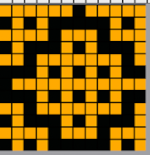

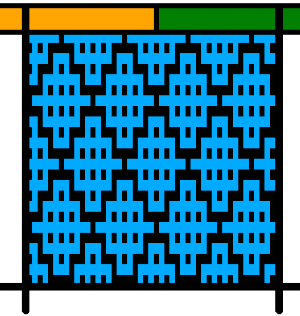

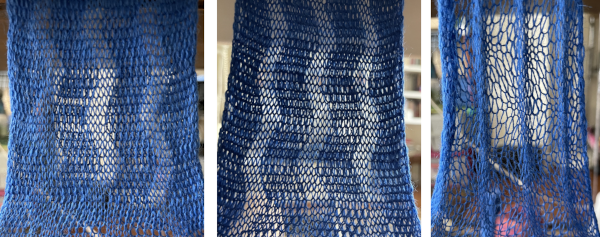

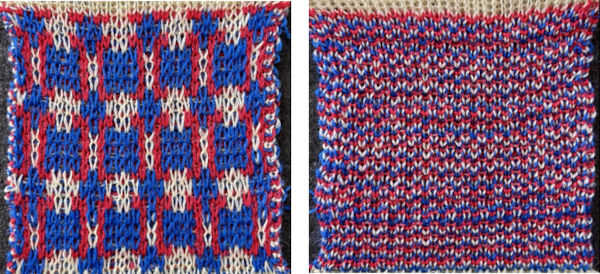

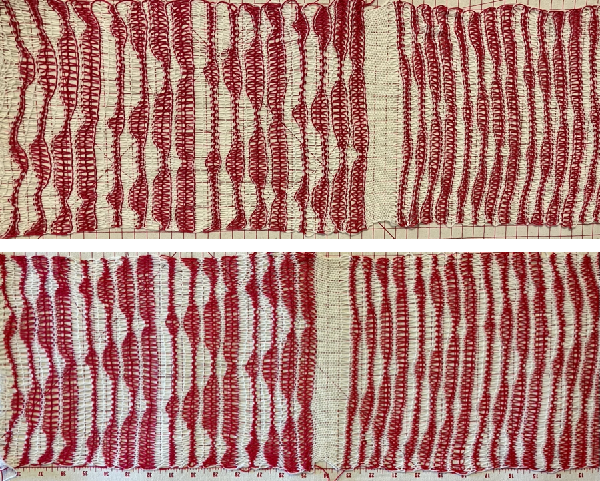

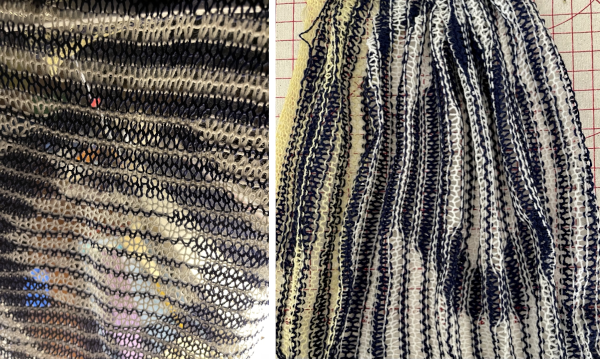

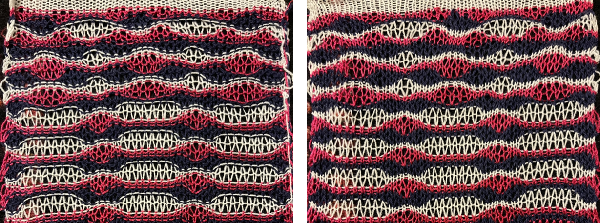

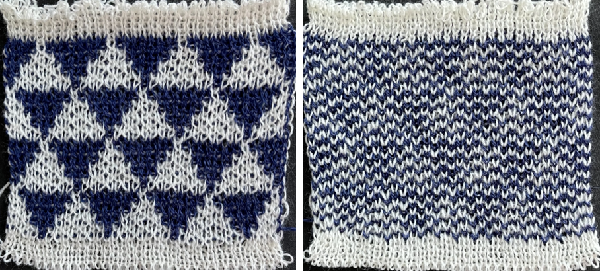

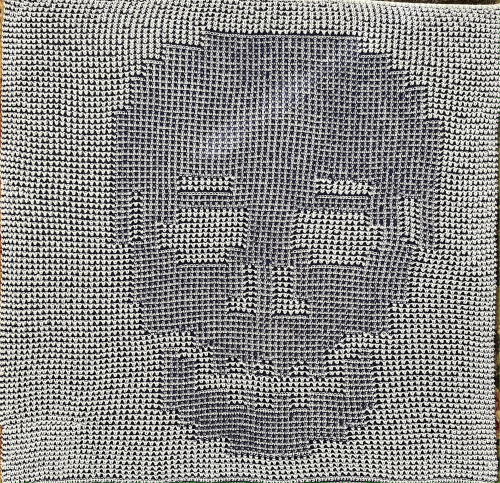

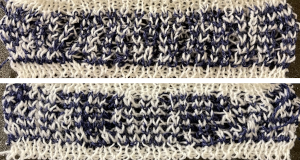

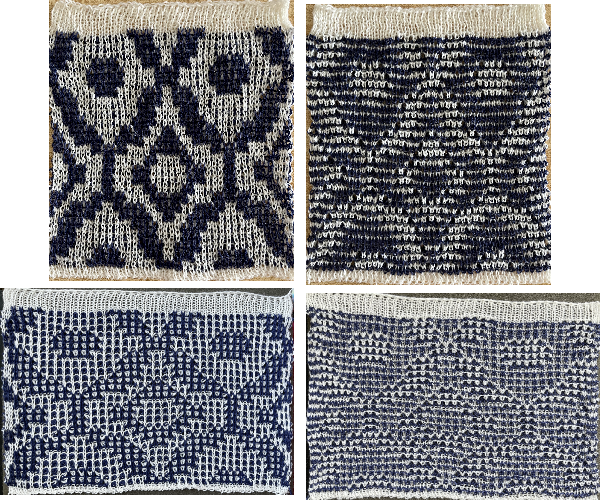

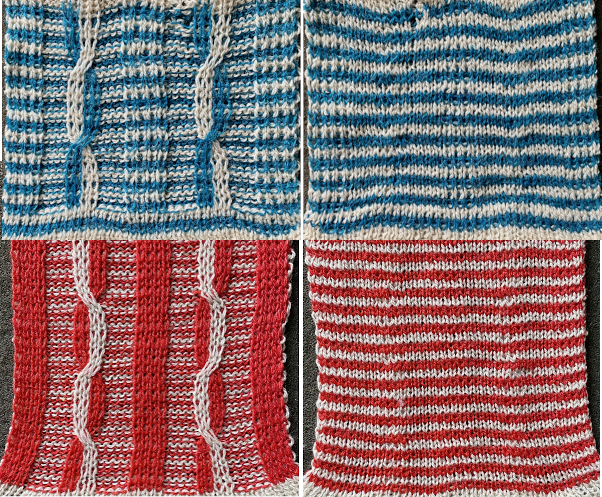

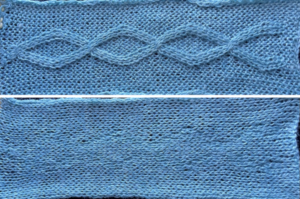

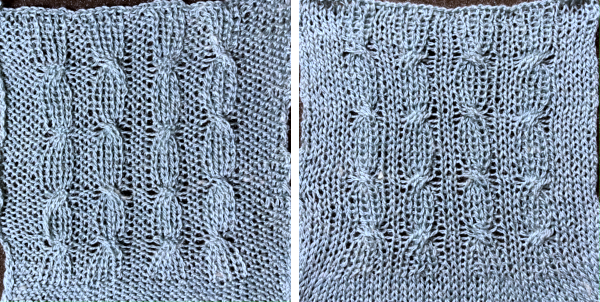

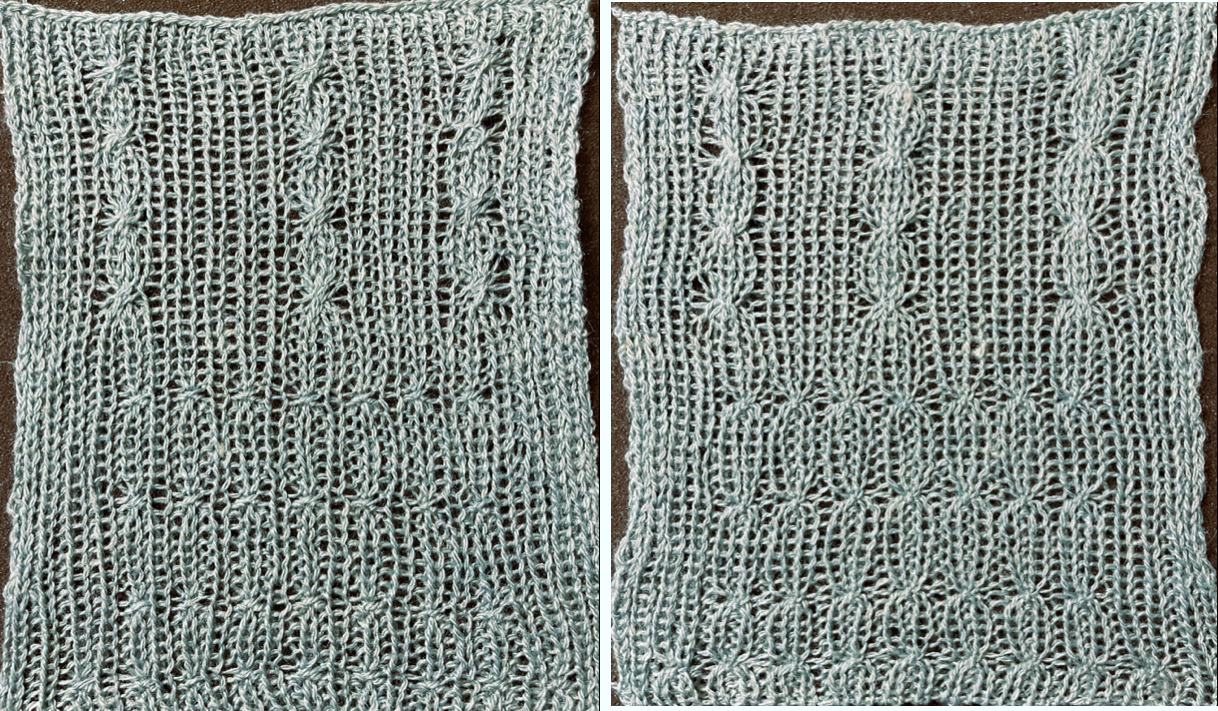

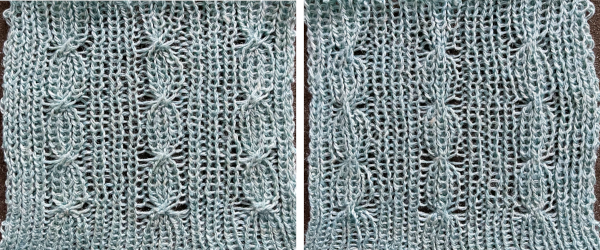

I have a lifetime supply of copper yarns from my jewelry-making days. This repeat is more a maze than a mosaic. Using a fishing line or wire can sometimes also produce interesting effects.

The blue yarn is composed of 3 strands of 2/48 cashmere/ wool.

The wire is a 32 gauge coated copper magnet wire which tends to flatten the final knit. On the machine, it is hard to recognize repeats due to the very short floats, and the unusual fiber rows can appear to be see-through

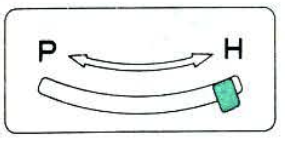

Using a light color wool rayon as the second color.

Using a light color wool rayon as the second color.  Using a separated 16X16 repeat from the 2020 post to knit a swatch for Instagram, I noticed a solid 3X3 block in the center of one of the shapes. Because the wire is see-through to some extent, the white stitch floats behind the blocks are noticeable.

Using a separated 16X16 repeat from the 2020 post to knit a swatch for Instagram, I noticed a solid 3X3 block in the center of one of the shapes. Because the wire is see-through to some extent, the white stitch floats behind the blocks are noticeable.  The copper wire used was 40 gauge, 3 plied. The higher the gauge number the thinner the wire strands, nearly invisible when threaded and while being used. Because the knit tension was as tight as possible, the stitch definition is lost in a few spots.

The copper wire used was 40 gauge, 3 plied. The higher the gauge number the thinner the wire strands, nearly invisible when threaded and while being used. Because the knit tension was as tight as possible, the stitch definition is lost in a few spots.

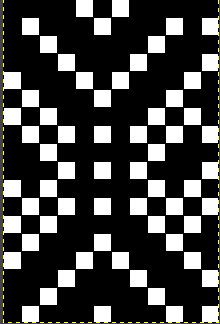

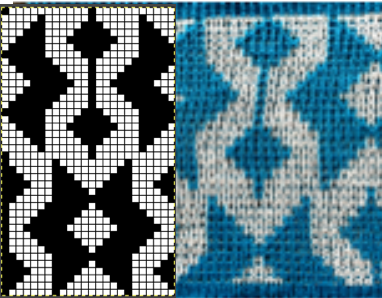

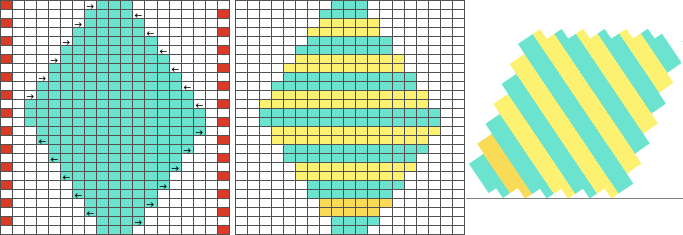

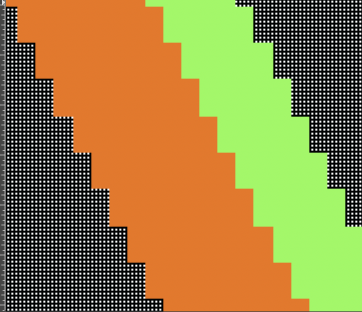

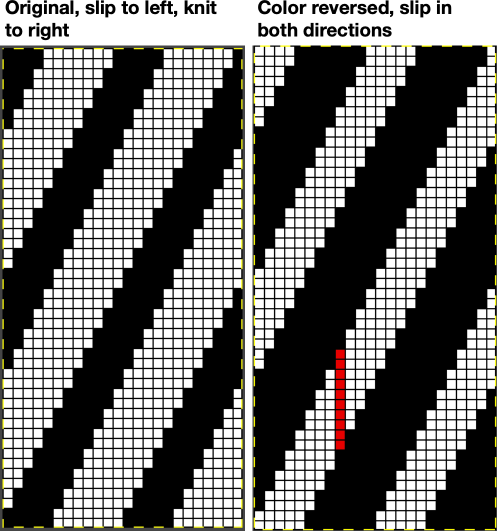

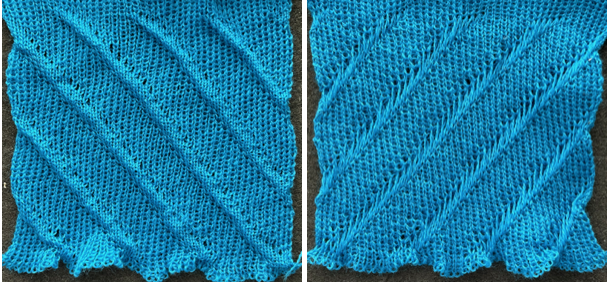

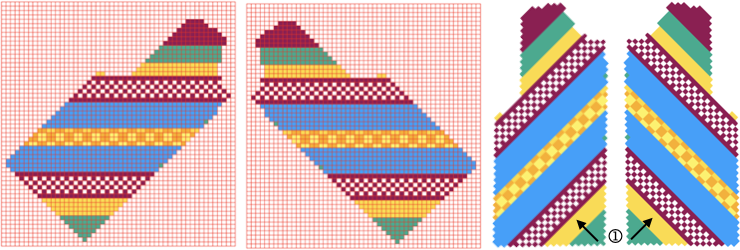

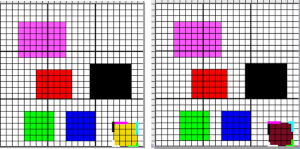

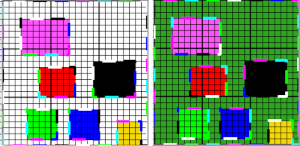

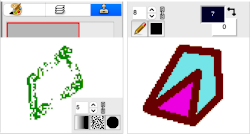

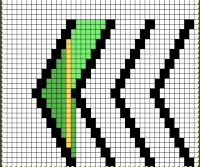

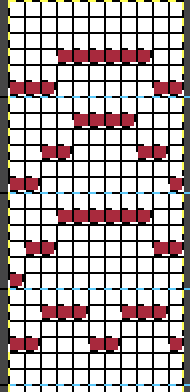

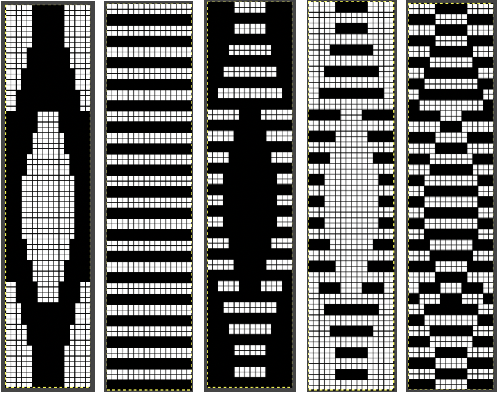

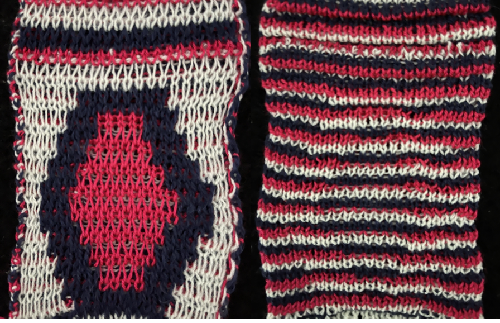

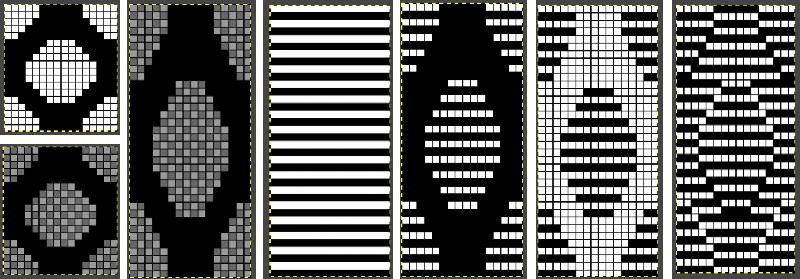

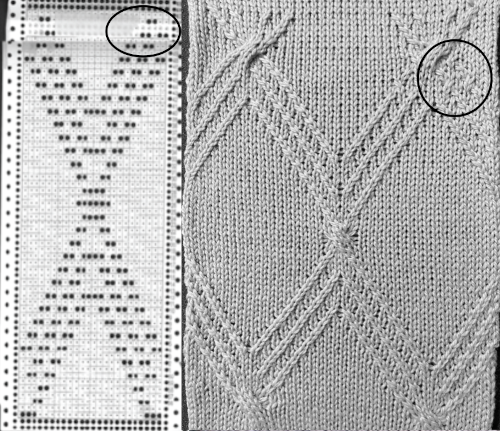

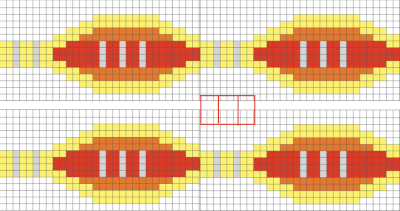

The original design motif, on the left, was missing a white cell in the location of the red cell. It was quickly converted using only Gimp.  Comparing the old repeat to the new, that problem pixel may easily be located.

Comparing the old repeat to the new, that problem pixel may easily be located.  The corrected file before lengthening X2,

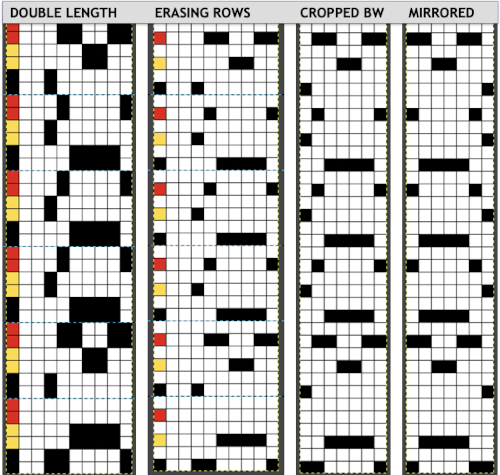

The corrected file before lengthening X2, ![]() double length

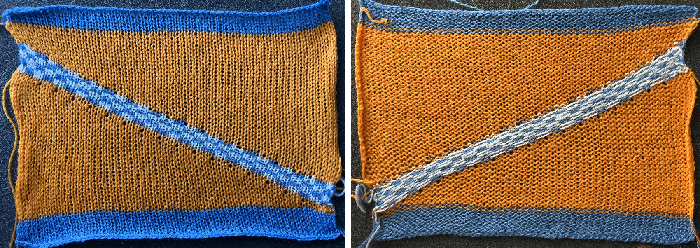

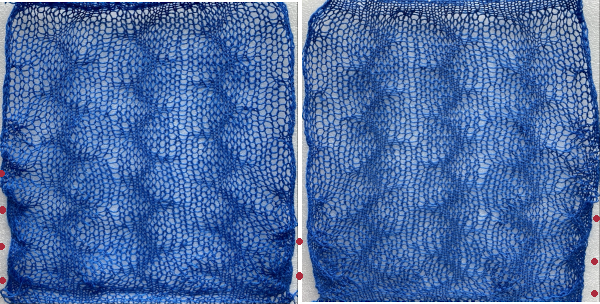

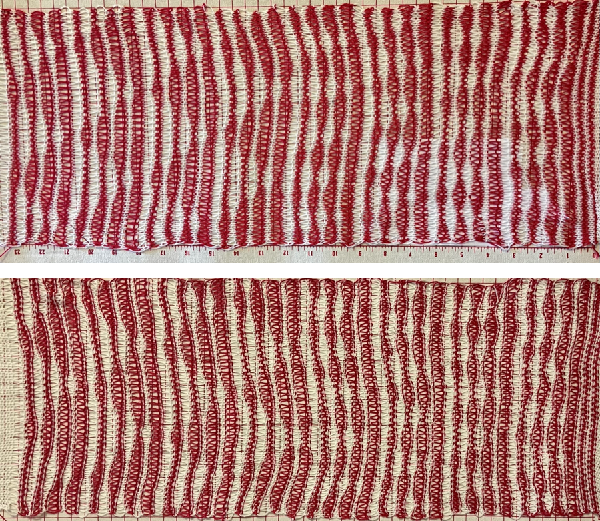

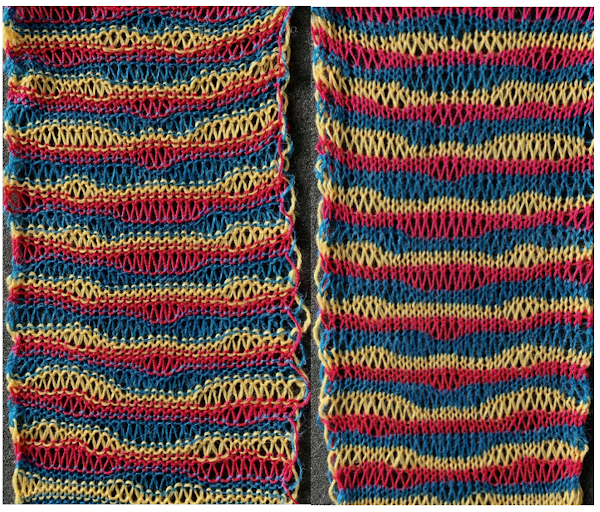

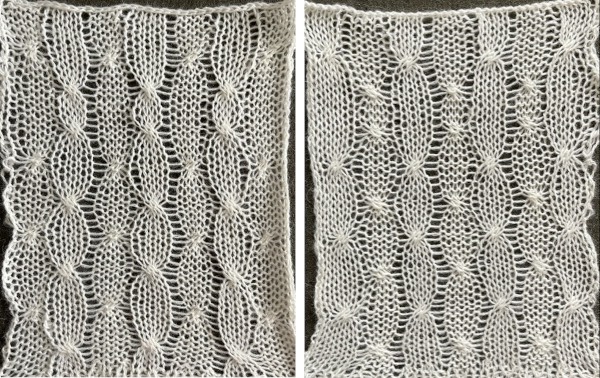

double length ![]() Proofing a pattern is best done using comparable weight, familiar yarns. Here thin poly and 4-pound fishing line are used as the second color

Proofing a pattern is best done using comparable weight, familiar yarns. Here thin poly and 4-pound fishing line are used as the second color  It takes a bit of squinting to see the match.

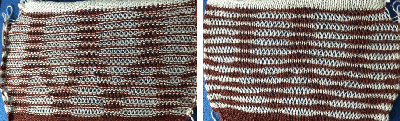

It takes a bit of squinting to see the match.  Testing the same repeat in more “friendly” and equal-thickness yarns

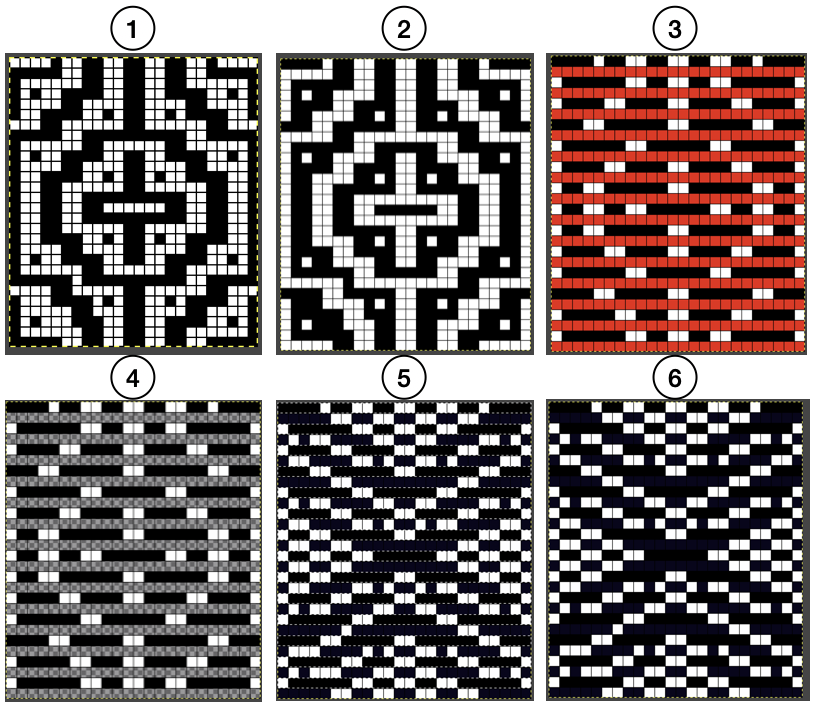

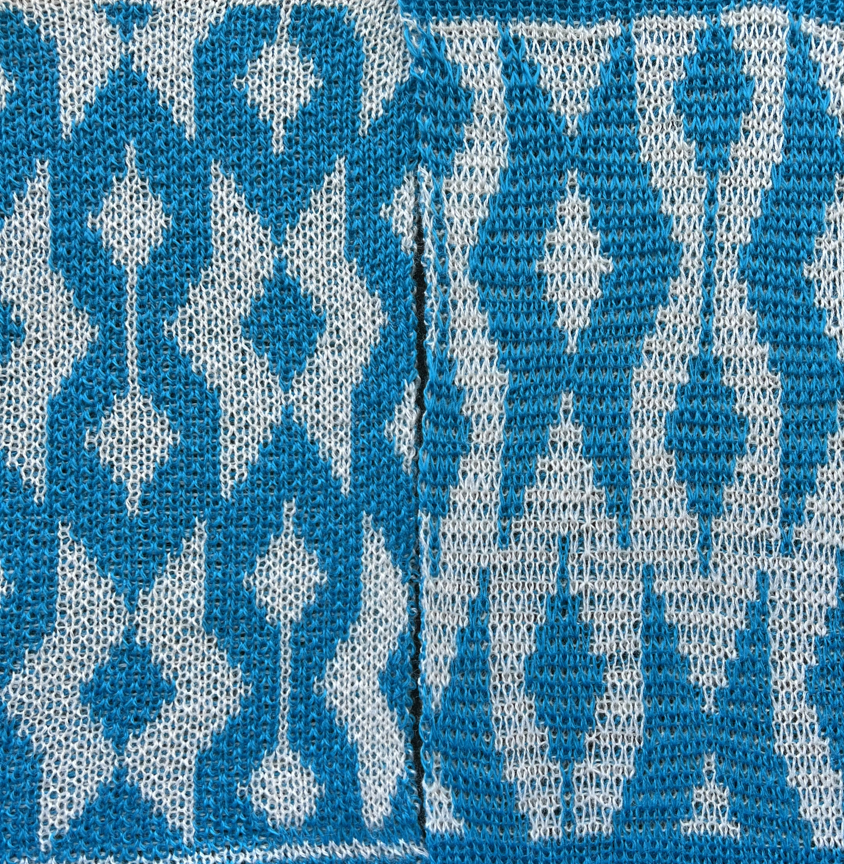

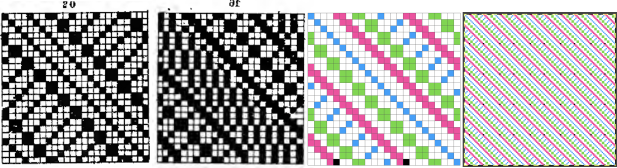

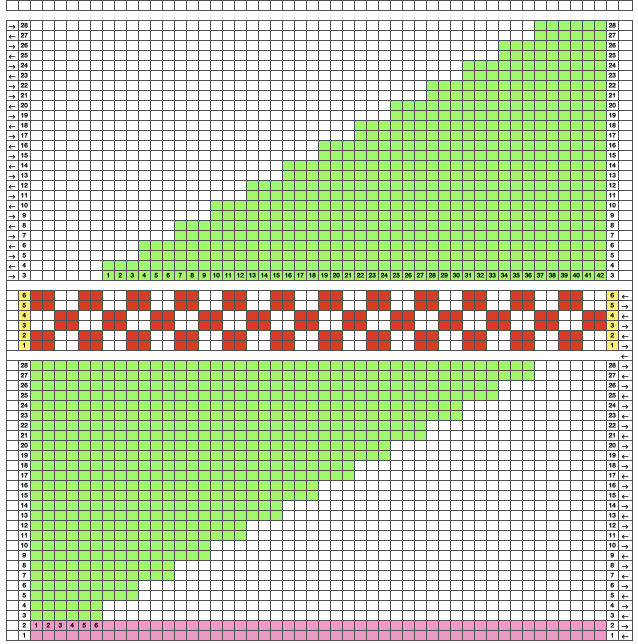

Testing the same repeat in more “friendly” and equal-thickness yarns  This 24X28 repeat from the earlier post is reworked in this method

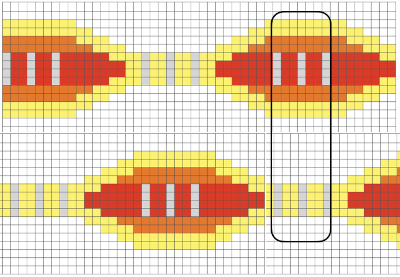

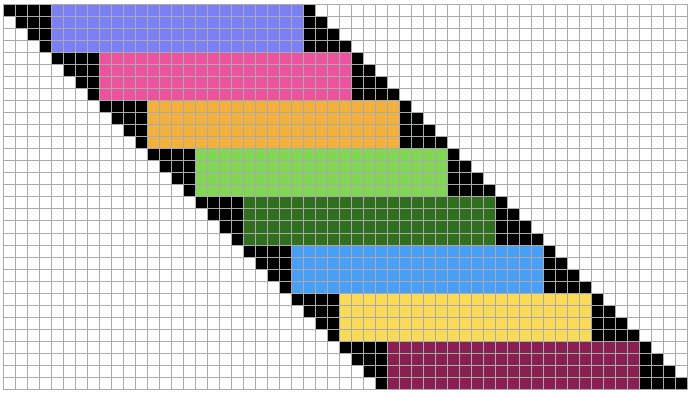

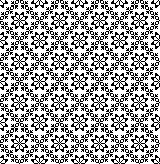

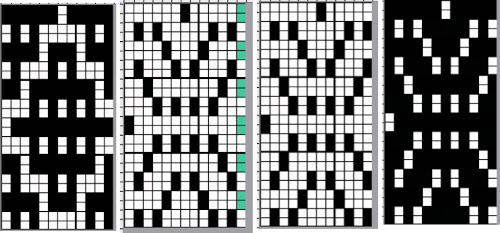

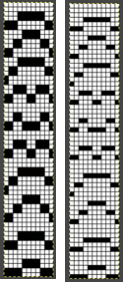

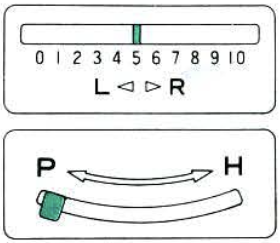

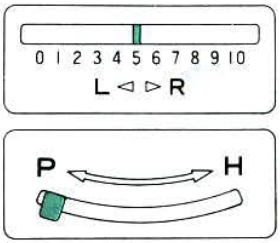

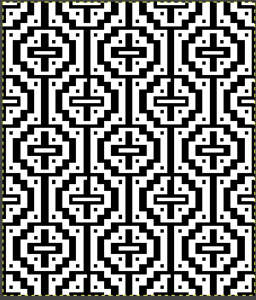

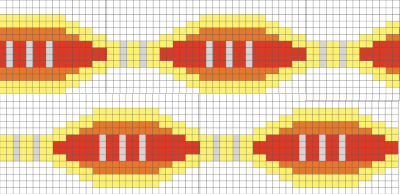

This 24X28 repeat from the earlier post is reworked in this method  repeating the process described here, it took longer to render the repeat than to perform the color separation. The tiled alignment check

repeating the process described here, it took longer to render the repeat than to perform the color separation. The tiled alignment check

The steps are in sequence and produce a result matching that achieved in the previous post.

The steps are in sequence and produce a result matching that achieved in the previous post.  A reminder: step #6 result would need to be doubled in height, whether by altering the file prior to download or by using the built-in functions in the machine after the download. The theoretical color separation to knit the mosaic as DBJ where each color knits twice,

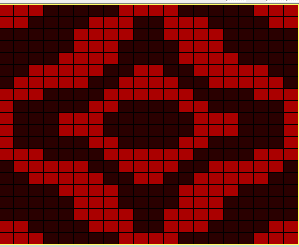

A reminder: step #6 result would need to be doubled in height, whether by altering the file prior to download or by using the built-in functions in the machine after the download. The theoretical color separation to knit the mosaic as DBJ where each color knits twice,  the repeat single length, 24X56

the repeat single length, 24X56 ![]() double length, 24X112

double length, 24X112 ![]()

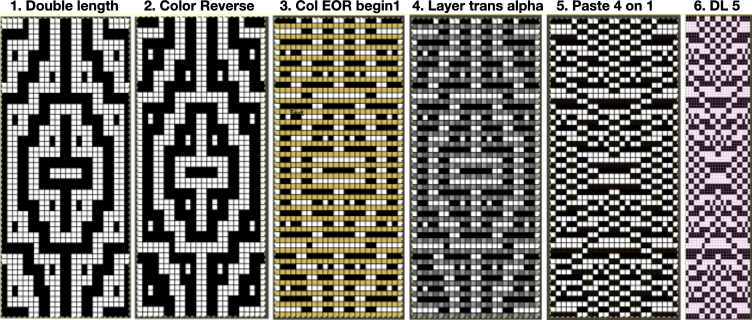

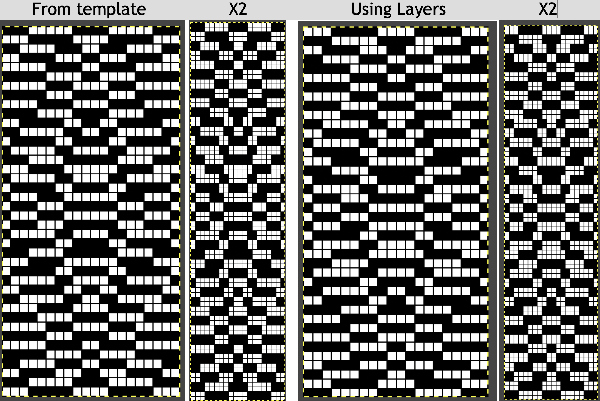

Double jacquard using punchcard machines shared manual methods for including one avoiding the elongation by matching the electronic built-in KRC color separation. Using Layers in Gimp for color separations introduced an approach using only Gimp.

There are times that the 2-color separation for DBJ which knits each color in each design row twice is necessary for the intended knit technique.

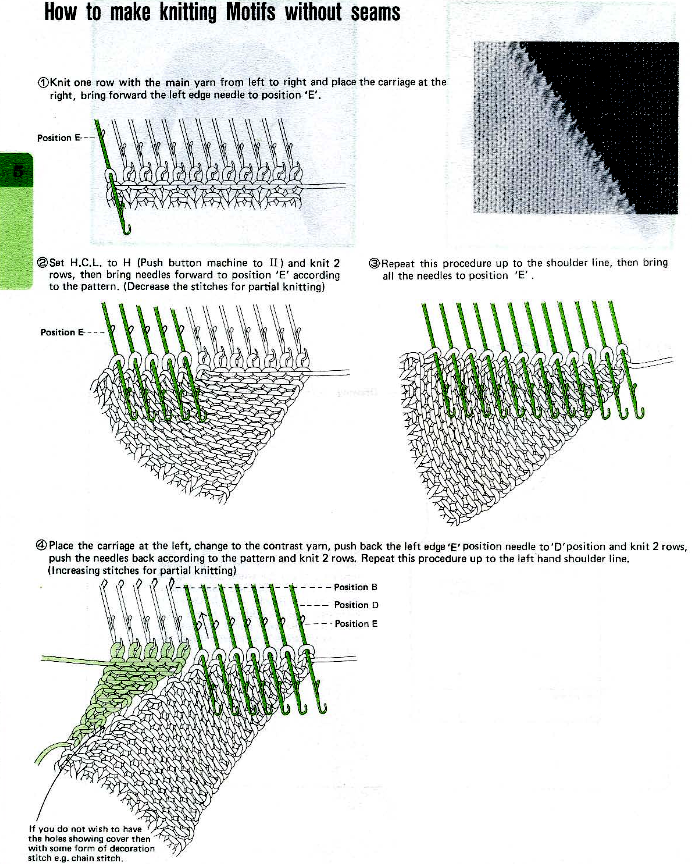

When testing new methods, one may begin with files that have already been proofed. This file is created so no elongation is required, beginning with the shape  elongated X4.

elongated X4.

From the layers post, the double-length separation where each color in each design row knits twice ![]()

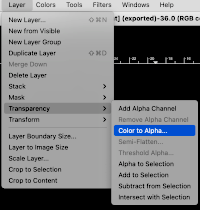

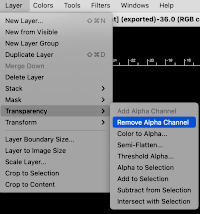

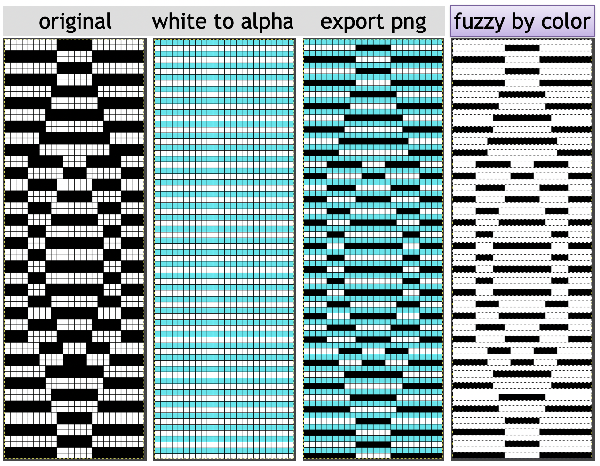

Duplicating the result using layer/ transparency

Duplicating the result using layer/ transparency  Longer repeats can become more complicated to separate. Testing the results by necessity requires larger swatches.

Longer repeats can become more complicated to separate. Testing the results by necessity requires larger swatches.

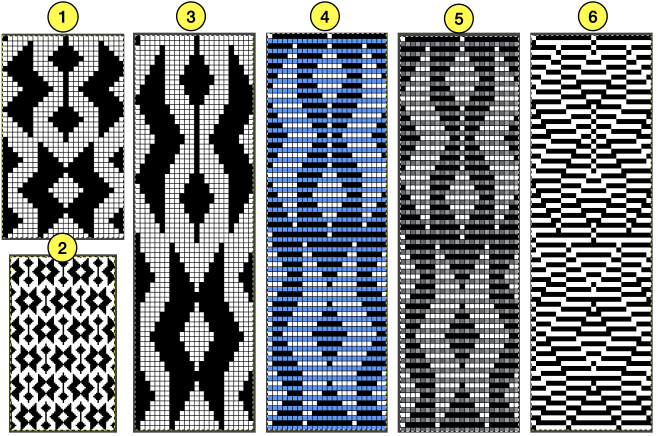

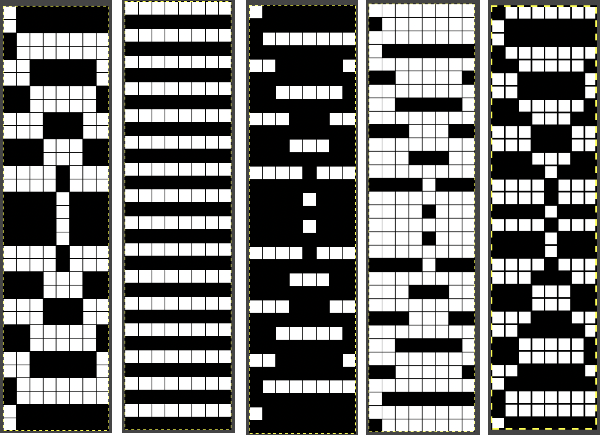

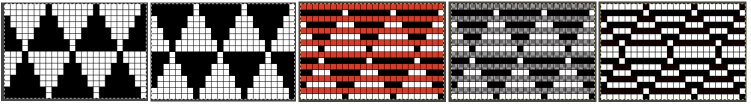

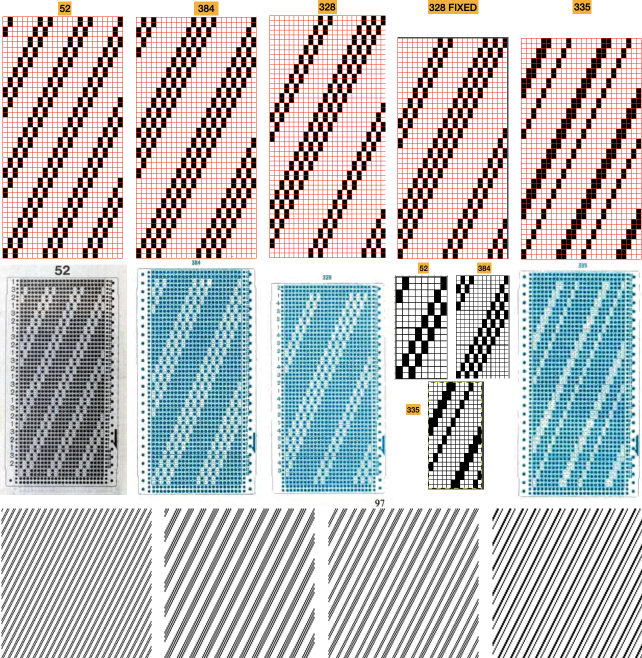

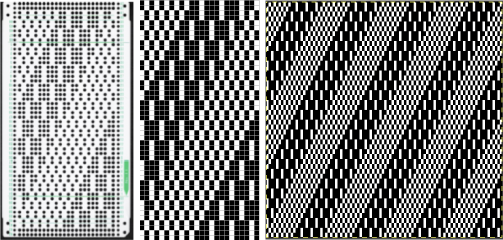

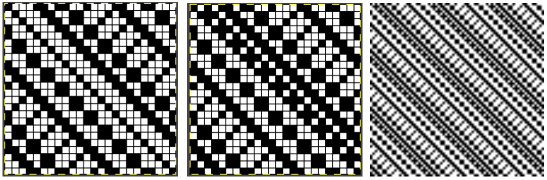

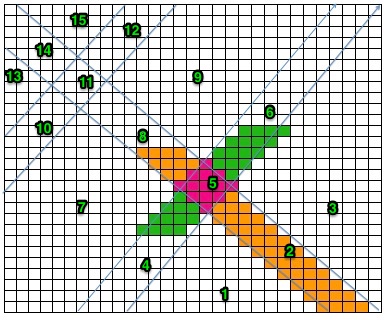

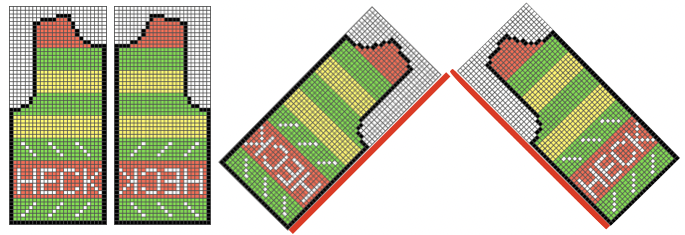

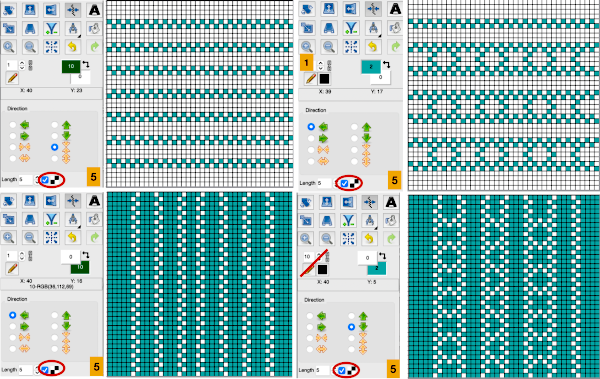

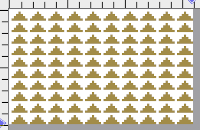

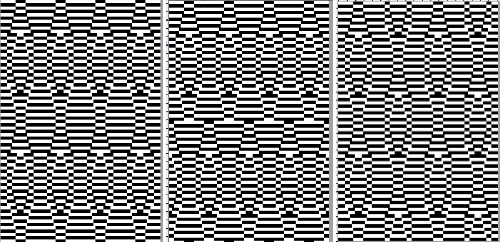

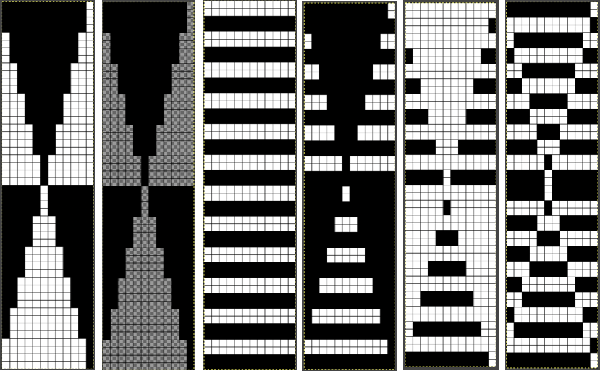

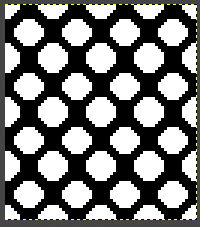

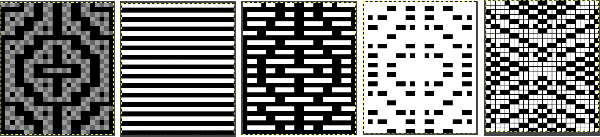

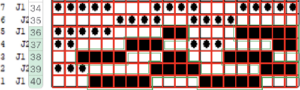

Using Stitchworld #548, a 24X40 repeat, as with mosaics![]() 1: draw the desired repeat in Gimp

1: draw the desired repeat in Gimp

2: when the drawing is completed, tile the repeat to check alignment, save the image if desired, or discard it

3: in the original window, scale the image to double its original height, now 24X80

4: using file, new, open an image on a white ground in the same size and magnification, a minimum of 800X, with grid view, as the first window

color invert

continuing on the same image, changing magnification as needed for ease of visibility ie 1800 X, choose a palette color, and using the pencil tool fill in every other row beginning with design row 1 using it

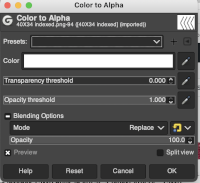

5. using color to alpha will remove the blue color in this case, and the image will change in appearance, the blue is now transparent. Copy the result.

6: use the second image, and paste it directly onto the one in the first work window.

For the repeat to knit successfully as DBJ, the resulting 24X80 file ![]() will need to be lengthened X2 to 160 rows in height for accurate patterning to occur.

will need to be lengthened X2 to 160 rows in height for accurate patterning to occur. ![]()

The design lengthened X4, using a 2-pixel pencil beginning on rows 3 and 4,

The design lengthened X4, using a 2-pixel pencil beginning on rows 3 and 4,

produces a 24X160 file that requires no elongation.  In this DBJ version, the first preselection row is made toward the color changer, followed by color changes every 2 rows.

In this DBJ version, the first preselection row is made toward the color changer, followed by color changes every 2 rows.

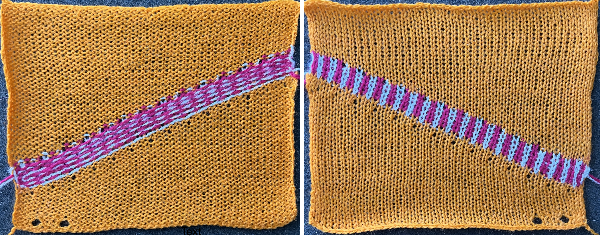

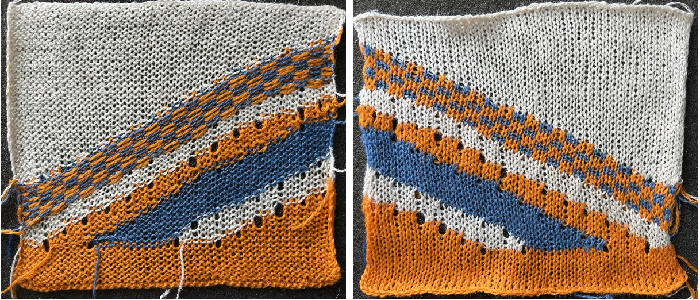

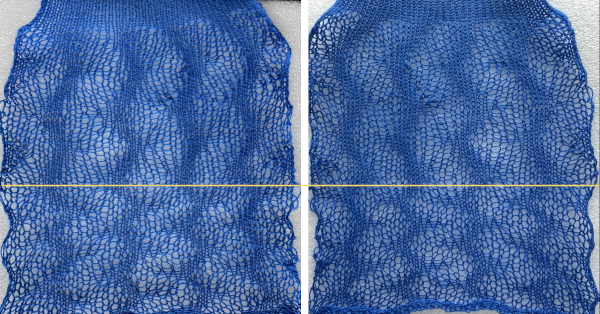

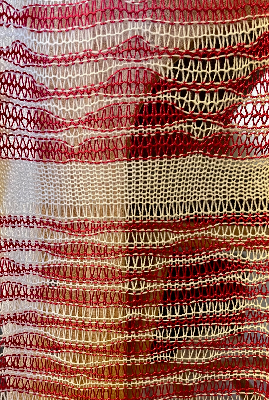

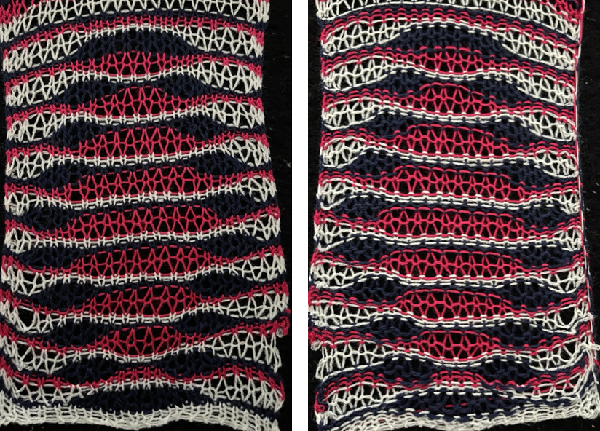

My proof of concept is knit with the knit carriage set to slip/slip and the ribber setting left to N/N, creating long stitches.

The height of the design, any bleed-through, elongation, drape, and stretch, are variables influenced by carriage setting changes on either or both knit and ribber carriages.

By default, DBJ knitting requires many more carriage passes than 2 color patterns knit single bed as fair isle.

My swatch does not begin at design row 1 because I forgot to set the knit carriage to slip after the first preselection row and color changing on the left.  Scaling the knit for a sense of the degree of elongation

Scaling the knit for a sense of the degree of elongation  The above separation is the default one in Passap knitting machines.

The above separation is the default one in Passap knitting machines.

Japanese electronic knitting machines perform the separation where each color in each design row knits only once automatically by engaging the KRC function.

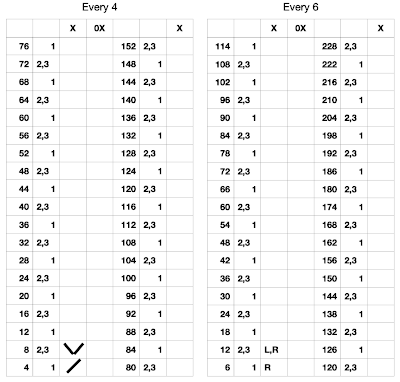

Punchcard users can achieve the same results for repeats that meet the width constraints using a maximum of 24 stitches or factors of 24 in width.

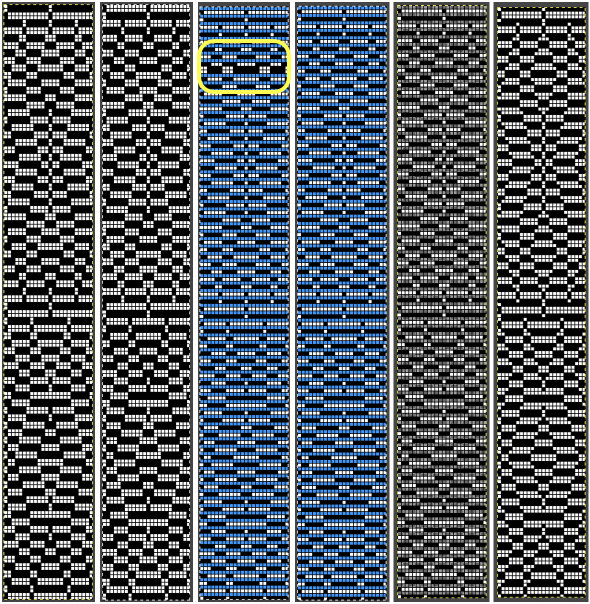

The separation where each color only knits once from the layers post began with the result where each color in each design row knits twice:  My first effort using layer transparency to separate for each design row color knitting only once begins with the double length separation opened in Gimp, not necessary as seen in notes that follow.

My first effort using layer transparency to separate for each design row color knitting only once begins with the double length separation opened in Gimp, not necessary as seen in notes that follow.

Using the pencil tools, marking begins on the second and then even numbered design rows.

When # 5 is color reversed, it matches the separation using layers in the above far right  Using the same concept, the first test began with the separation already completed for the repeat that would knit each color in each row twice.

Using the same concept, the first test began with the separation already completed for the repeat that would knit each color in each row twice.

Toggling magnification helps to make the height of the repeat manageable. Errors are easy to spot and correct if noticed early, a few rows of pencil marks can simply be undone. Save the final png, also 24X160. ![]()

The separated design is suitable for punchcard machines, my swatch is knit on a 930. Since these separated designs are programmed as fair isle designs, there will not be any color change prompts provided by some machine models.

The separated design is suitable for punchcard machines, my swatch is knit on a 930. Since these separated designs are programmed as fair isle designs, there will not be any color change prompts provided by some machine models.

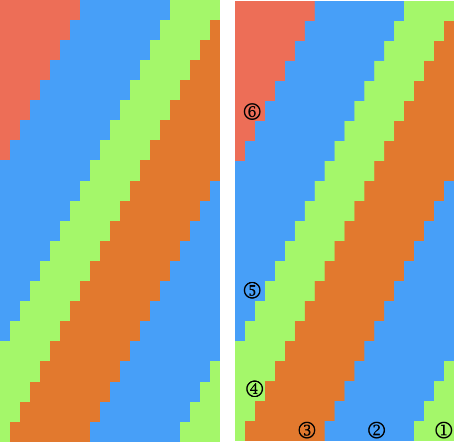

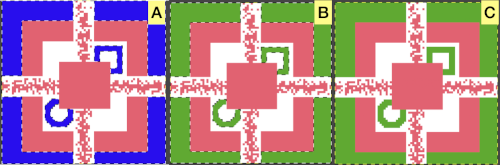

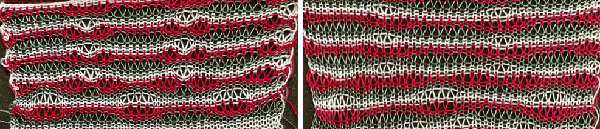

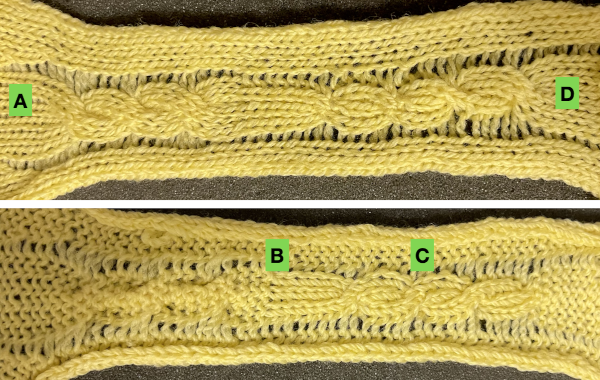

The first preselection row, as when using the KRC function, is made from left to right. The knit carriage is set to slip both ways. The ribber carriage is also set to slip both ways on an even number of needles, and lili buttons are in use.  The visual difference in scale between the two different techniques and color separations.

The visual difference in scale between the two different techniques and color separations.  The simplified method begins with the original design scaled X2 to 24X80. The 2-pixel pencil tool is used to mark the resulting design beginning on rows 2 and 3, skipping the next 2 rows, and repeating the process

The simplified method begins with the original design scaled X2 to 24X80. The 2-pixel pencil tool is used to mark the resulting design beginning on rows 2 and 3, skipping the next 2 rows, and repeating the process

![]()

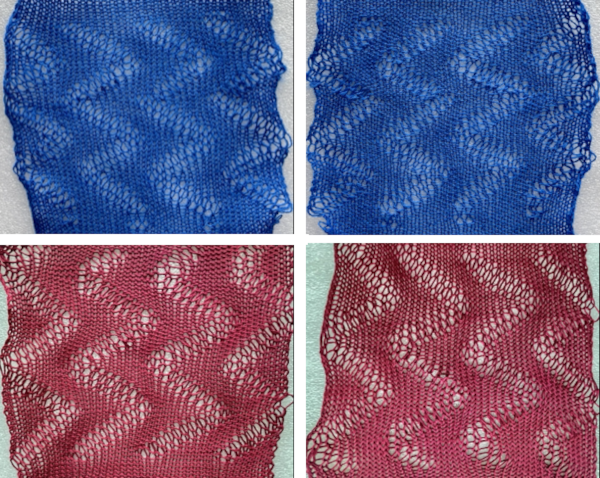

Committing to a larger test swatch:

Committing to a larger test swatch:  The repeat though successful in this case is different from half the first one obtained the long way, the concept merits testing with other motifs.

The repeat though successful in this case is different from half the first one obtained the long way, the concept merits testing with other motifs.

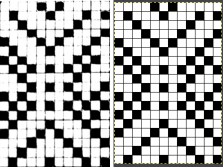

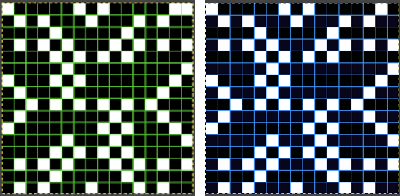

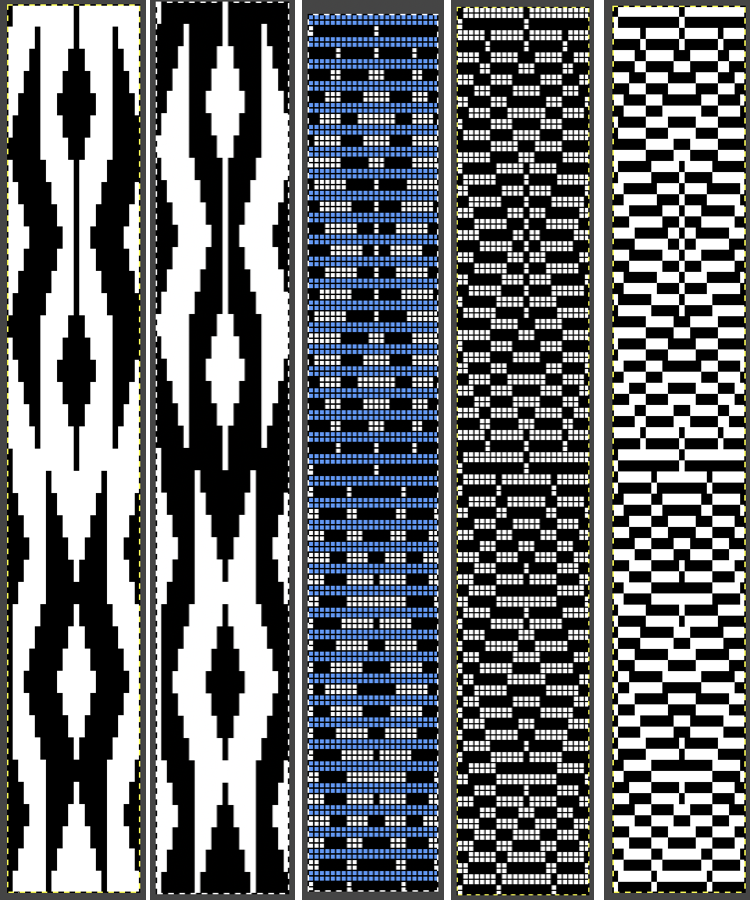

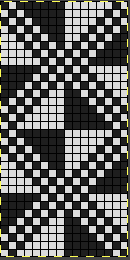

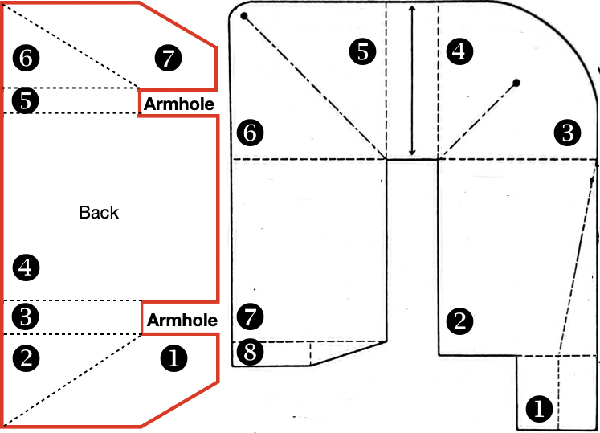

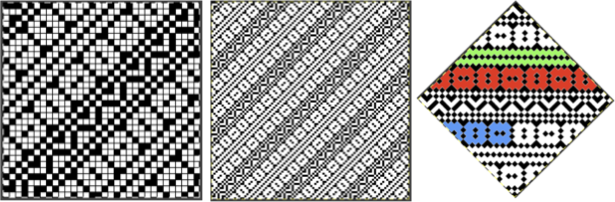

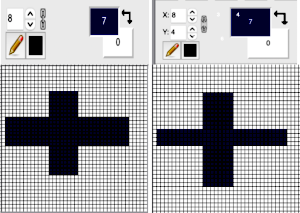

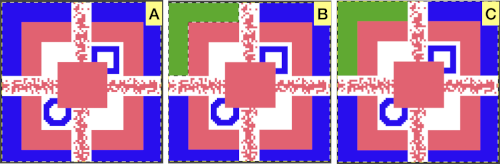

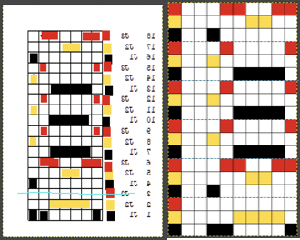

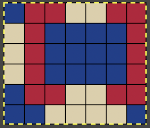

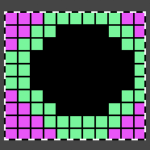

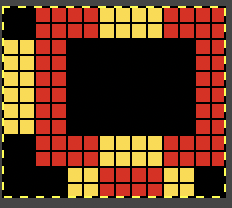

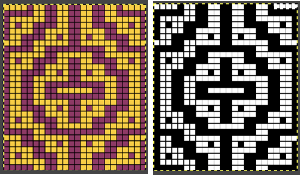

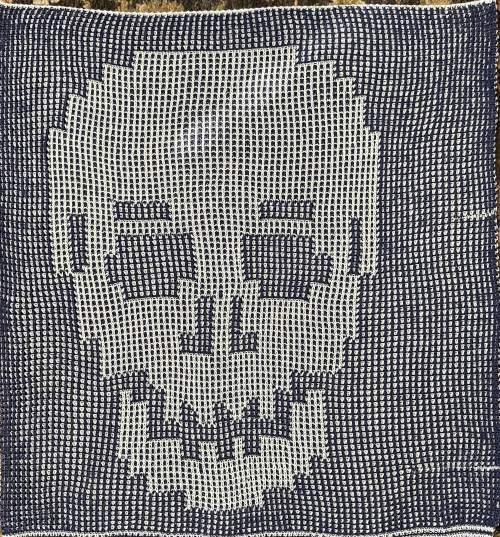

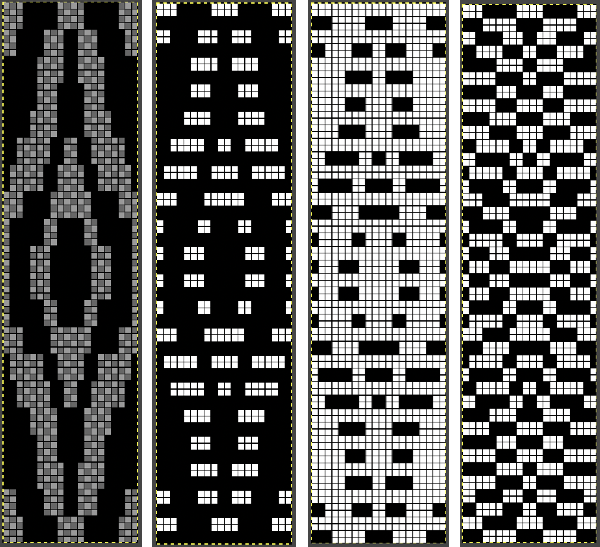

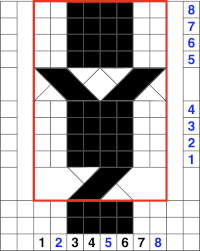

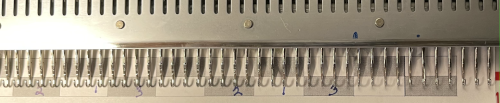

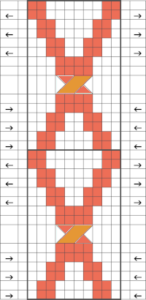

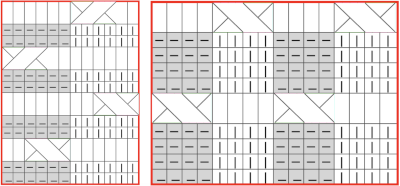

Years ago I shared the way punchcard knitters may create a DBJ card using a series of templates. The starting 8X8 design was often used in my 2 color DBJ posts. On the right, it is repeated across 24 cells, as it would be in a punch card.

Years ago I shared the way punchcard knitters may create a DBJ card using a series of templates. The starting 8X8 design was often used in my 2 color DBJ posts. On the right, it is repeated across 24 cells, as it would be in a punch card.  Using layer/Transparency/Alpha the same results can as when using the card templates may be attained in just minutes. Here each color in each row would be knit only once:

Using layer/Transparency/Alpha the same results can as when using the card templates may be attained in just minutes. Here each color in each row would be knit only once:  In this case, the final result would need to be elongated X2 in order to knit each color in each design row twice.

In this case, the final result would need to be elongated X2 in order to knit each color in each design row twice.  This separation requires no elongation.

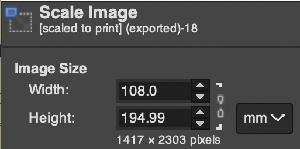

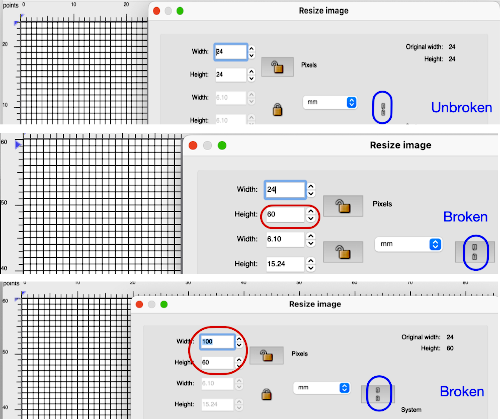

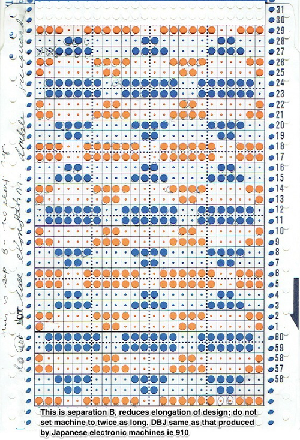

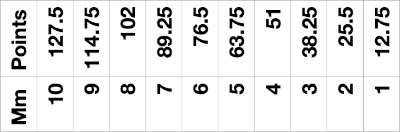

This separation requires no elongation.  If the plan is to print a template to aid in marking a card prior to punching, one way to determine the required template size is to measure a punchcard with a ruler in mm.

If the plan is to print a template to aid in marking a card prior to punching, one way to determine the required template size is to measure a punchcard with a ruler in mm.

The width of the card is fixed to a print width of 108 mm since the card will always be 24 cells wide. No calculation is required.

In height, the 60 rows on the factory blank card measure 300mm, 5mm for each cell.

I cropped the chosen image to the top 39 rows and scaled it to 108X195 mm.

(39X5).

When printing on US letter size, with no adjustments other than to the image, the limit appears to be no more than 45 rows per page.  I was not able to print directly from Gimp.

I was not able to print directly from Gimp.

The file, exported, opened in Preview, and then printed, is shown with a card superimposed on the printout over a makeshift light box, ready for easy punchcard marking even though the printed cells were not all of the same ink density.  2024 the subject of elongation in DBJ designs recently made the rounds in forum again. I was not quite sure where to share this, settled on here

2024 the subject of elongation in DBJ designs recently made the rounds in forum again. I was not quite sure where to share this, settled on here

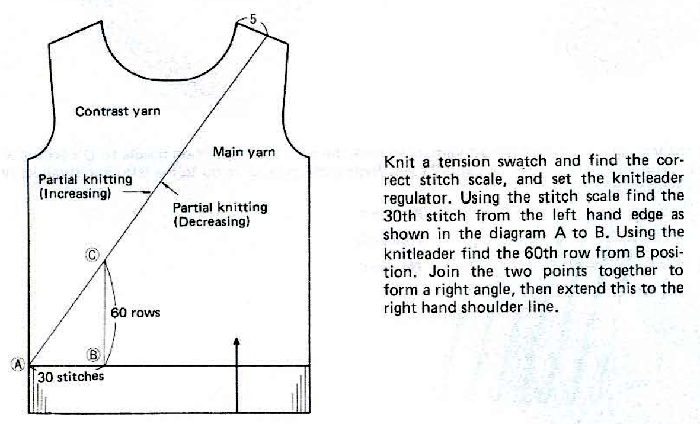

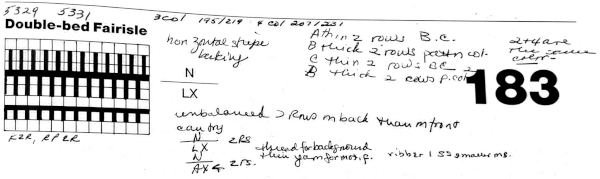

Vertical striper backing on Brother machines is rendered possible by manipulating ribber needles in conjunction with the use of lili buttons.

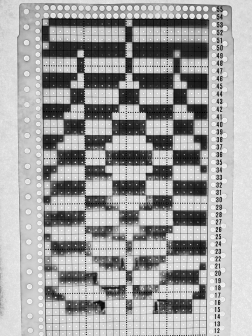

This swatch uses the same 40X44 pixels design ![]() The tension and yarn selection choices remained fixed.

The tension and yarn selection choices remained fixed.

1: conventional striper backing, with the ribber set to knit in both directions

2: half striper backing, with the ribber set to knit from left to right and to slip from right to left. In this technique as the carriages move from right to left, floats will be formed on the top bed. As larger number of needles are knit on either bed, the tension should be adjusted accordingly, here it was not, resulting in those dropped stitches. The floats peek through behind the resulting hole.

3: the traditional birdseye backing, resulting in the narrowest portion of the swatch.

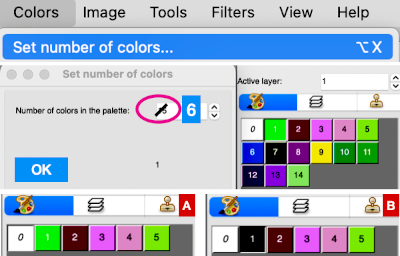

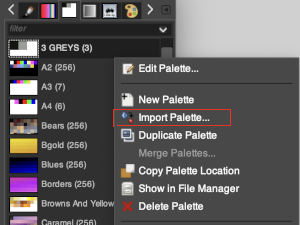

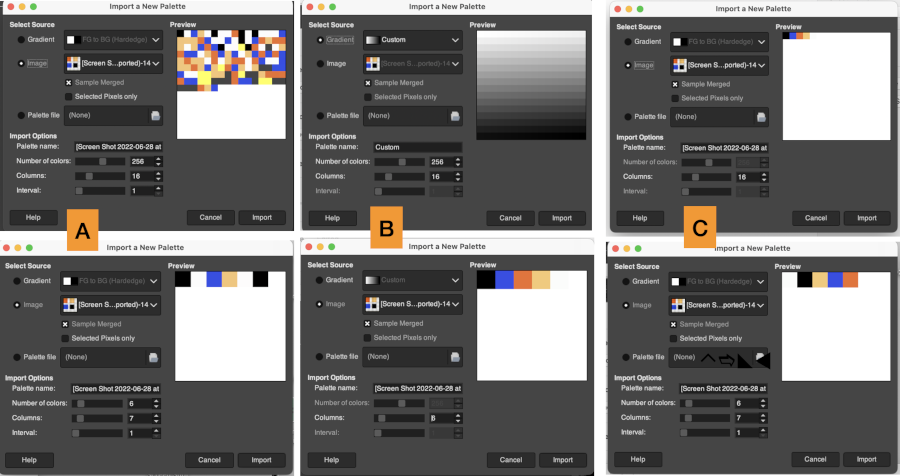

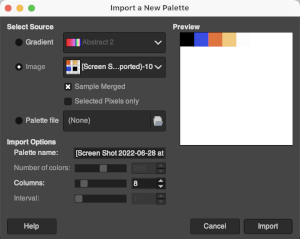

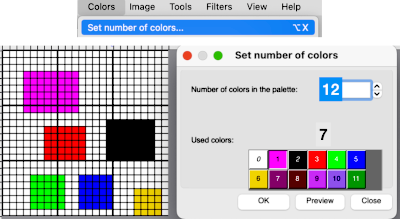

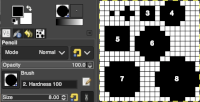

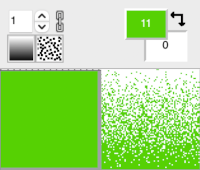

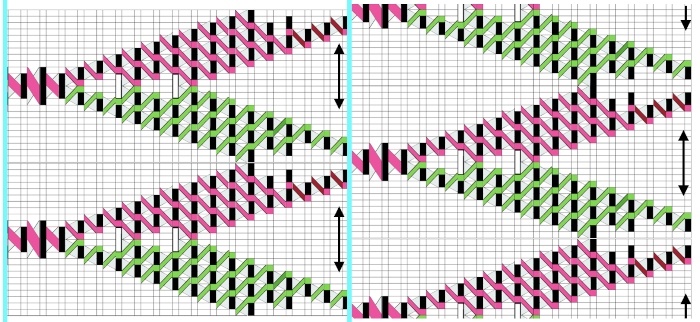

Designing for fair isle, or when attempting to visualize and illustrate slip and tuck fabrics with frequent color changes, more colors may be required even though the final download will be in black and white. There is a quick way to add random colors assigned by the program and based on the initial palette:

Designing for fair isle, or when attempting to visualize and illustrate slip and tuck fabrics with frequent color changes, more colors may be required even though the final download will be in black and white. There is a quick way to add random colors assigned by the program and based on the initial palette:

Here it is shown modified, with rows containing fewer than 3 colors marked.

Here it is shown modified, with rows containing fewer than 3 colors marked.

The repeats for designs may be self-separated to suit.

The repeats for designs may be self-separated to suit.

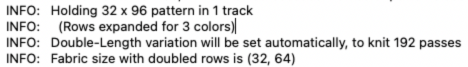

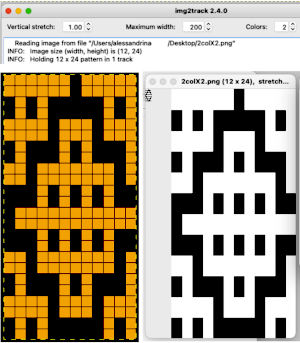

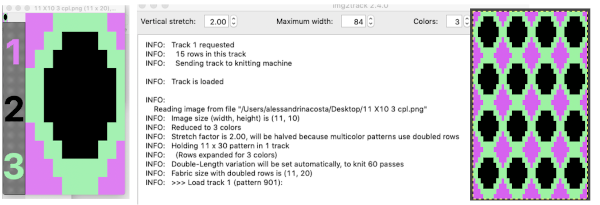

Three variations of the final png files are shared

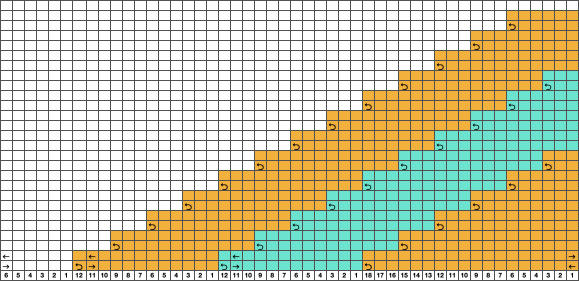

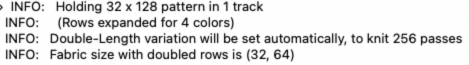

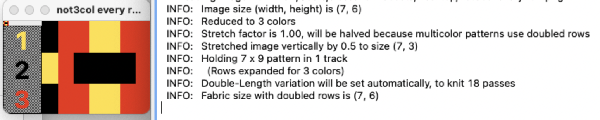

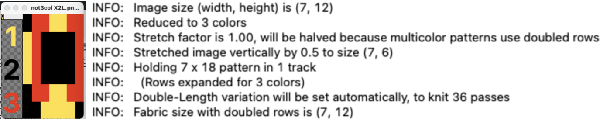

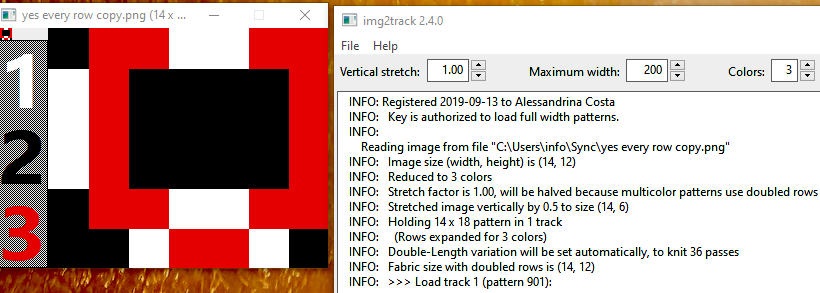

Three variations of the final png files are shared  This is the appearance when a different design was entered in img2track. The separated file 3 color file in BW is not shared.

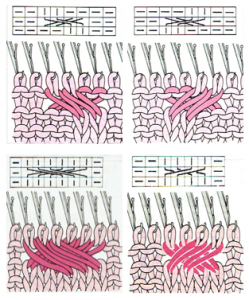

This is the appearance when a different design was entered in img2track. The separated file 3 color file in BW is not shared.  The method for knitting the pattern: the long stitches are formed by loops that are created on the top bed and dropped on the following row.

The method for knitting the pattern: the long stitches are formed by loops that are created on the top bed and dropped on the following row.

The second carriage, C2 is set to KCII as well. It will be advancing the design with each pass as well and will drop loops on the first pass, preselect for the subsequent pattern row on the next

The second carriage, C2 is set to KCII as well. It will be advancing the design with each pass as well and will drop loops on the first pass, preselect for the subsequent pattern row on the next

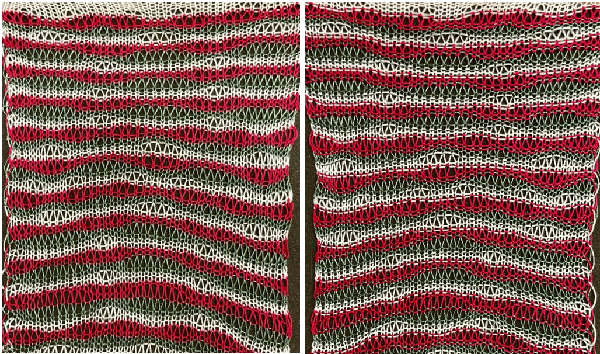

The elongated stitches allow objects behind them to peek through

The elongated stitches allow objects behind them to peek through

Here the goal is to use the img2 track separation, maintaining the same color change rotation in each piece.

Here the goal is to use the img2 track separation, maintaining the same color change rotation in each piece.

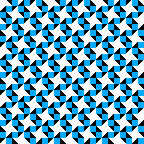

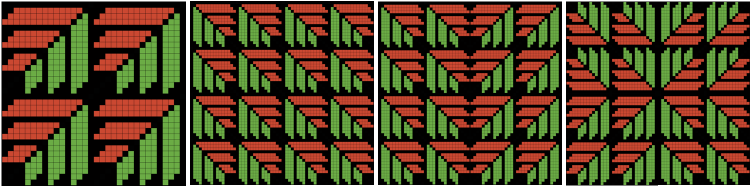

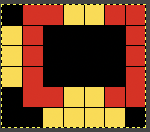

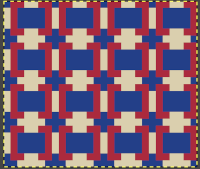

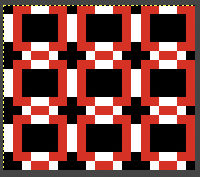

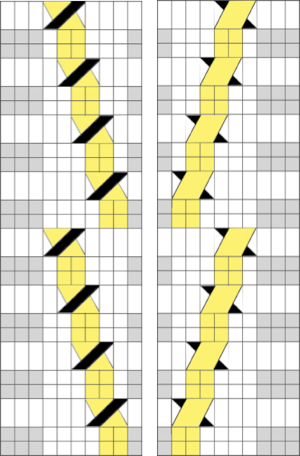

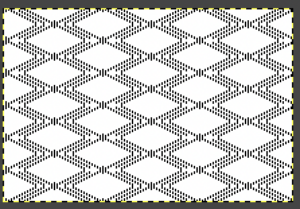

The tiled potential appearance as a dbj fabric:

The tiled potential appearance as a dbj fabric: In the first sample three carriages are used:

In the first sample three carriages are used: What of end release? because all 3 colors are present in every row, the design is suitable. The first preselection row is from right to left.

What of end release? because all 3 colors are present in every row, the design is suitable. The first preselection row is from right to left.

Any published or self-drawn separation for 3 colors per row patterning including every color in every row of the original design may be used, programmed as a single bed design, and knit for end release.

Any published or self-drawn separation for 3 colors per row patterning including every color in every row of the original design may be used, programmed as a single bed design, and knit for end release.

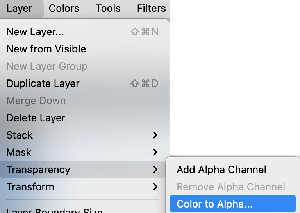

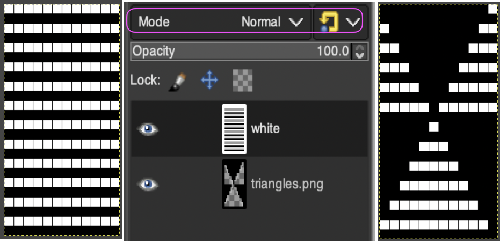

the white ground of the resulting image is rendered transparent by using Color to Alpha

the white ground of the resulting image is rendered transparent by using Color to Alpha

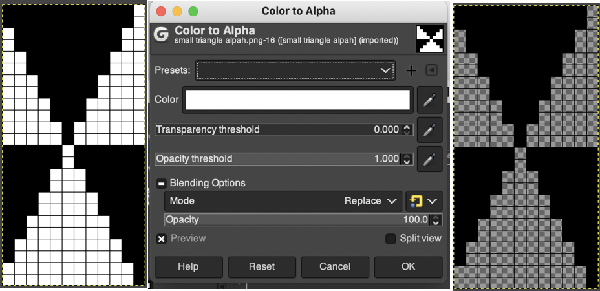

Select New Layer from the Layers menu (see chart), choosing the background or foreground color to have a white screen. It will share properties with the alpha repeat such as pixel count, magnification, and the grid view if used.

Select New Layer from the Layers menu (see chart), choosing the background or foreground color to have a white screen. It will share properties with the alpha repeat such as pixel count, magnification, and the grid view if used. Copy the selection, and it will be saved to the clipboard and remain available for filling with the pattern unless the program is quit. It may also be

Copy the selection, and it will be saved to the clipboard and remain available for filling with the pattern unless the program is quit. It may also be  In the layers dialogue, use the mouse to drag and drop the alpha image icon for the triangle layer onto the newly created one. The selected icon will appear surrounded by a border when chosen, a new icon will appear during the step.

In the layers dialogue, use the mouse to drag and drop the alpha image icon for the triangle layer onto the newly created one. The selected icon will appear surrounded by a border when chosen, a new icon will appear during the step.

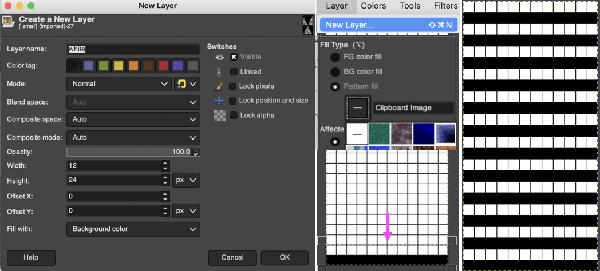

Color invert the new image

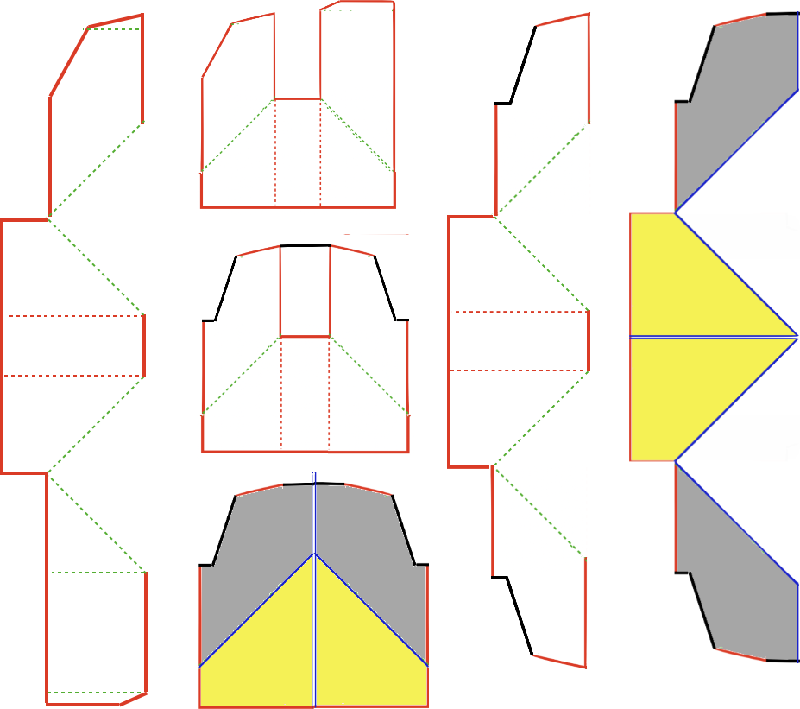

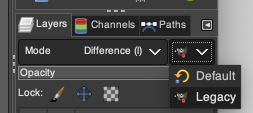

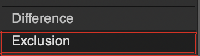

Color invert the new image  Click on the downward pointer to the right of Normal and select Difference. The result is a repeat that may then be saved and used doubled in height to knit DBJ in a variety of settings.

Click on the downward pointer to the right of Normal and select Difference. The result is a repeat that may then be saved and used doubled in height to knit DBJ in a variety of settings. Elongation after download can be avoided by working with the same initial image scaled in height X4 and following the same process, saving and using the repeat on the far right.

Elongation after download can be avoided by working with the same initial image scaled in height X4 and following the same process, saving and using the repeat on the far right.  The same separation was achieved using other methods in the post on fantasy fair isle.

The same separation was achieved using other methods in the post on fantasy fair isle. Are punchcard knitters left out? In the

Are punchcard knitters left out? In the  and the starting design shown with the color reversed repeat of the above.

and the starting design shown with the color reversed repeat of the above.

When a color separation is downloaded it is used as one would a fair isle. If the motif is representational and direction on the knit side matters, any repeats may have to be mirrored horizontally if they are automatically reversed by either your software prior to download or your machine model after it.

When a color separation is downloaded it is used as one would a fair isle. If the motif is representational and direction on the knit side matters, any repeats may have to be mirrored horizontally if they are automatically reversed by either your software prior to download or your machine model after it.

The image is processed as for the previous separation, the final png is exported. Open the saved in Gimp.

The image is processed as for the previous separation, the final png is exported. Open the saved in Gimp. Using the rectangle tool, select a single blue row, after the selection, press and hold down the shift key and repeat selections of multiple rows in the same color. Each selection will be bordered by a dotted line.

Using the rectangle tool, select a single blue row, after the selection, press and hold down the shift key and repeat selections of multiple rows in the same color. Each selection will be bordered by a dotted line.  Release the shift key. Click on the rectangle select tool and then again in the work window outside the image to set it. The dotted lines will disappear. The same action is repeated if working on segments of the full file at a time.

Release the shift key. Click on the rectangle select tool and then again in the work window outside the image to set it. The dotted lines will disappear. The same action is repeated if working on segments of the full file at a time. The 24X72 new png

The 24X72 new png  Both results require scaling X2 before knitting, whether by button setting changes in the repeat after download or in Gimp before.

Both results require scaling X2 before knitting, whether by button setting changes in the repeat after download or in Gimp before.

The process in Layers

The process in Layers The very last file on the right is saved as a PNG. In turn, it is opened again in Gimp, scaled to twice its height

The very last file on the right is saved as a PNG. In turn, it is opened again in Gimp, scaled to twice its height  Exclusion is the alternative Layer mode which when following the same process yields identical results.

Exclusion is the alternative Layer mode which when following the same process yields identical results.

A block slip stitch design from the

A block slip stitch design from the

In Fantasy Fairisle knitting using 187 with alternating up and down pushers on the back bed and AX with 2 arrow keys would match Brother ribber knitting with lili buttons used on an even number of needles set to tuck.

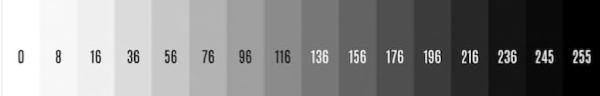

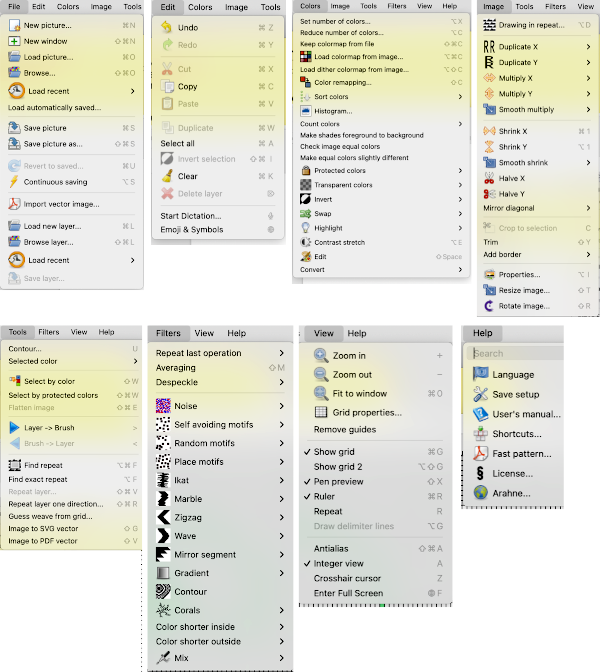

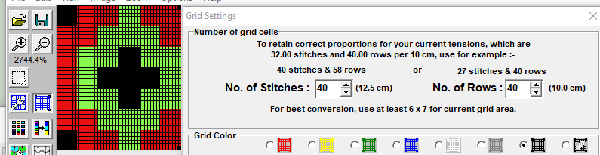

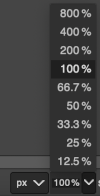

In Fantasy Fairisle knitting using 187 with alternating up and down pushers on the back bed and AX with 2 arrow keys would match Brother ribber knitting with lili buttons used on an even number of needles set to tuck. For the 1-pixel grid in Gimp to be visible on an editable image, a magnification of at least 800 is required. The options offered by default

For the 1-pixel grid in Gimp to be visible on an editable image, a magnification of at least 800 is required. The options offered by default can be changed to suit by simply typing in a new number.

can be changed to suit by simply typing in a new number.

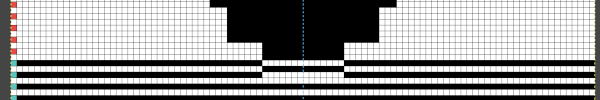

the processed image

the processed image  the trimmed 98X182 png

the trimmed 98X182 png  doubled in length once more to 98X364

doubled in length once more to 98X364  Knitting process on a 930 using img2track:

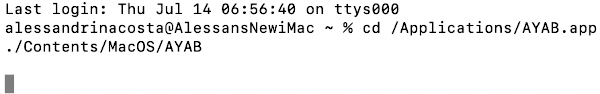

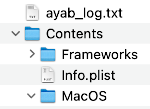

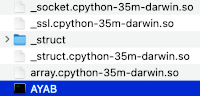

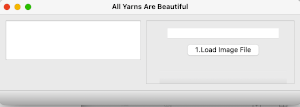

Knitting process on a 930 using img2track: A reminder: in my experience, the Brother cast-on combs are usually chrome-colored, Studio grey, and Passap, and I believe Superba ones were traditionally green. The first 2 were designed for 4.5 mm machines, the latter for 5mm. The different mm spacing does not make the 5 mm combs suitable for casting on on Brother, but they can be poked through the knit in progress. I like to leave the first comb and weights on, insert the new comb closer to the beds, and then move the weight up, and then remove the lower position comb.

A reminder: in my experience, the Brother cast-on combs are usually chrome-colored, Studio grey, and Passap, and I believe Superba ones were traditionally green. The first 2 were designed for 4.5 mm machines, the latter for 5mm. The different mm spacing does not make the 5 mm combs suitable for casting on on Brother, but they can be poked through the knit in progress. I like to leave the first comb and weights on, insert the new comb closer to the beds, and then move the weight up, and then remove the lower position comb.

In the Brother model, sometimes the yarn is left in the wrong place below eye level rather than its own individual one corresponding to its button, and both yarns are picked up with the next color change.

In the Brother model, sometimes the yarn is left in the wrong place below eye level rather than its own individual one corresponding to its button, and both yarns are picked up with the next color change.

a close-up of the texture at an angle

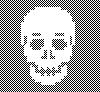

a close-up of the texture at an angle  Claudia Scarpa developed a skull variation using only layers in Gimp

Claudia Scarpa developed a skull variation using only layers in Gimp  and has been kind enough to create a

and has been kind enough to create a

It is possible to work some repeats on some machines with the ribber also set to tuck both ways with EON needle selection.

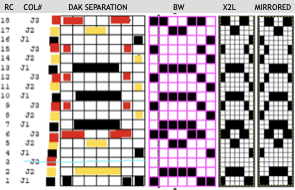

It is possible to work some repeats on some machines with the ribber also set to tuck both ways with EON needle selection. When using the Dak stitch design module, the color separation is automated. Choose any design repeat. This happens to be a 20X20 one, chosen from the thumbnail assortment, so not suitable for punchcard models. “Printing” the template using choosing the option of using dots rather than squares to represent knit stitches makes the resulting print screengrab easier to trace.

When using the Dak stitch design module, the color separation is automated. Choose any design repeat. This happens to be a 20X20 one, chosen from the thumbnail assortment, so not suitable for punchcard models. “Printing” the template using choosing the option of using dots rather than squares to represent knit stitches makes the resulting print screengrab easier to trace. the 20X20 repeat as a BW png

the 20X20 repeat as a BW png  The result is screengrabbed, opened in Gimp, converted to BW mode, and scaled to the 20X40 expanded design size. Unless the double-length function in the machine is also used, it will need scaling again to double length prior to download.

The result is screengrabbed, opened in Gimp, converted to BW mode, and scaled to the 20X40 expanded design size. Unless the double-length function in the machine is also used, it will need scaling again to double length prior to download. The final image double length, showing the difference between the separation using the template, and that using layers as in Claudia’s video, which appears different but is actually the same repeat, color reversed.

The final image double length, showing the difference between the separation using the template, and that using layers as in Claudia’s video, which appears different but is actually the same repeat, color reversed.  Using bucket fill for the ground in the second layer, as described in the video, the captured clipboard image can be very small

Using bucket fill for the ground in the second layer, as described in the video, the captured clipboard image can be very small  Alternately, the initial design may be scaled X4 to 20 X 80 pixels

Alternately, the initial design may be scaled X4 to 20 X 80 pixels

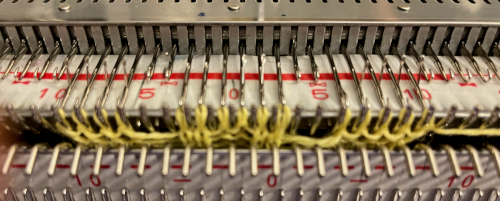

bring the ribber needles up into work between them

bring the ribber needles up into work between them

drop the ribber

drop the ribber

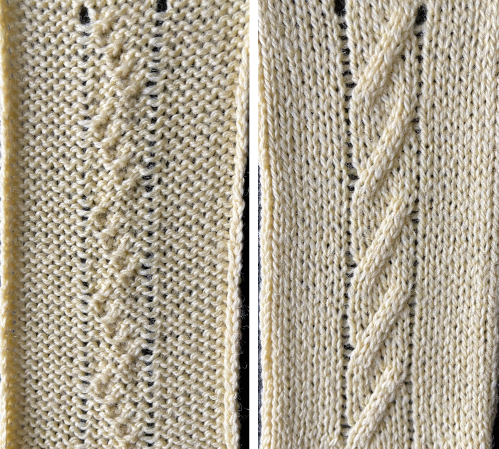

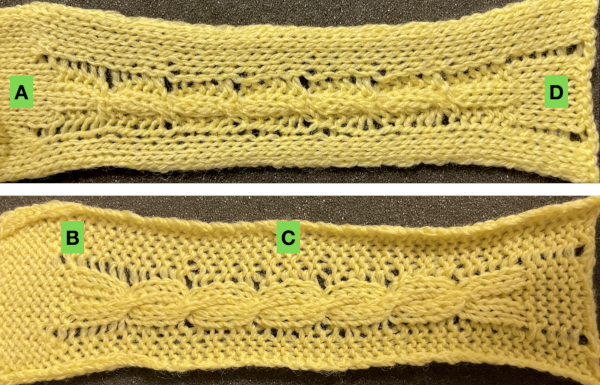

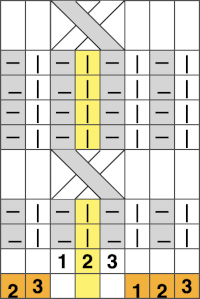

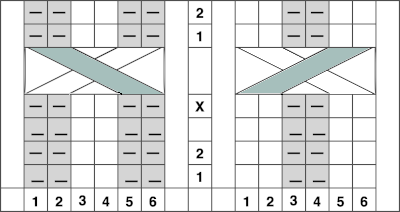

The repeat is 8X8 and the above movement can be seen in the purl view.

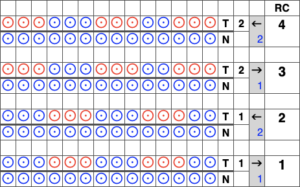

The repeat is 8X8 and the above movement can be seen in the purl view. A spreadsheet table may be created to help with tracking multiple series of cables across a knit and their direction. It can contain as little or as much information as one wishes. Included here: the RC for possible crossings, and their direction on the purl side for machine knitting (reversed for hand knitting). Columns may be added including how many needles are left in or out of work between cable knit spaces or other info.

A spreadsheet table may be created to help with tracking multiple series of cables across a knit and their direction. It can contain as little or as much information as one wishes. Included here: the RC for possible crossings, and their direction on the purl side for machine knitting (reversed for hand knitting). Columns may be added including how many needles are left in or out of work between cable knit spaces or other info.

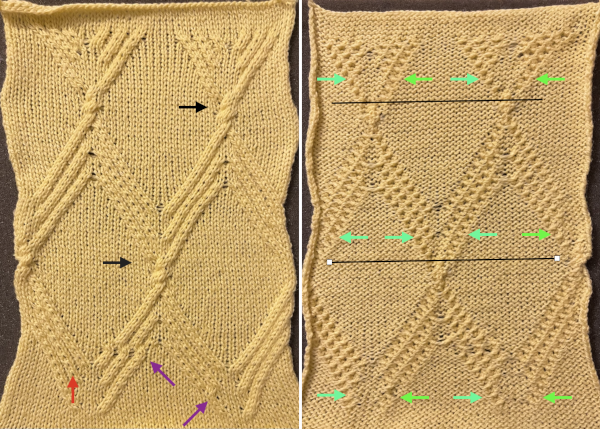

Which leads to the topic of creating shapes by combining the repeats

Which leads to the topic of creating shapes by combining the repeats  A brief effort containing at least 5 errors leads me to wonder about programming needle selection to help track crossings more easily and avoid mistakes. The center ladder here was latched up during knitting.

A brief effort containing at least 5 errors leads me to wonder about programming needle selection to help track crossings more easily and avoid mistakes. The center ladder here was latched up during knitting.

If the start is on the top bed, stitches on the ribber may be created by picking up bars from the top bed

If the start is on the top bed, stitches on the ribber may be created by picking up bars from the top bed  the yarn above was a 2/8 wool, which refused to cable on the ribber, and having the crossing was preferred to not

the yarn above was a 2/8 wool, which refused to cable on the ribber, and having the crossing was preferred to not  changing to a thinner wool-silk solved the problem.

changing to a thinner wool-silk solved the problem.

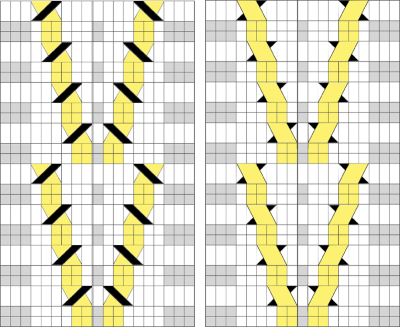

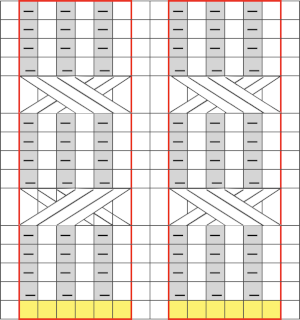

In reviewing the post after linking to it here I realized the now marked punchcard error at its top. The amended longer chart reworked in Numbers is also added to the older post. It is shown here aside from its tiled chart, checking for alignment, a habit developed as my skill and comfort in using spreadsheets grew,

In reviewing the post after linking to it here I realized the now marked punchcard error at its top. The amended longer chart reworked in Numbers is also added to the older post. It is shown here aside from its tiled chart, checking for alignment, a habit developed as my skill and comfort in using spreadsheets grew,

It is possible to use the repeat working 1 X 2 stitch crossings for a very different look.

It is possible to use the repeat working 1 X 2 stitch crossings for a very different look. Assigning colors to crossings in a chart may be helpful or too much info depending on one’s perspective, the bottom of the repeat is on the right.

Assigning colors to crossings in a chart may be helpful or too much info depending on one’s perspective, the bottom of the repeat is on the right.

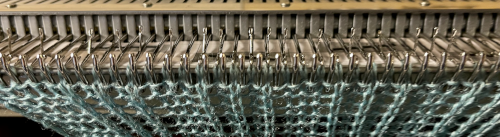

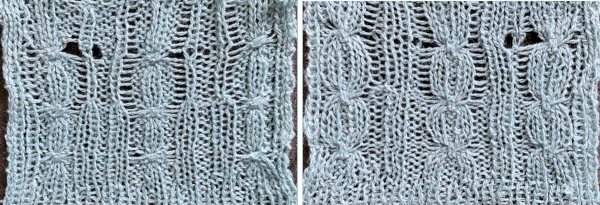

In my first test crossings occur on both beds and on the same row. Even using the thinner blue yarn at maximum tension the transfers were hard to execute. I had more success when I added 2 empty needles between the vertical ribs and brought one on each side of each rib into work on the top bed prior to knitting the last row between transfers, creating a bit of extra yarn to ease the crossings.

In my first test crossings occur on both beds and on the same row. Even using the thinner blue yarn at maximum tension the transfers were hard to execute. I had more success when I added 2 empty needles between the vertical ribs and brought one on each side of each rib into work on the top bed prior to knitting the last row between transfers, creating a bit of extra yarn to ease the crossings.

Trying out a simple repeat in smaller rib configurations will provide some idea as to whether the technique falls into the love of or not something to do simply because one can.

Trying out a simple repeat in smaller rib configurations will provide some idea as to whether the technique falls into the love of or not something to do simply because one can.

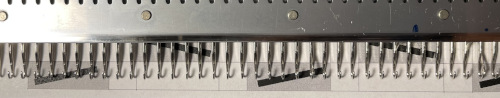

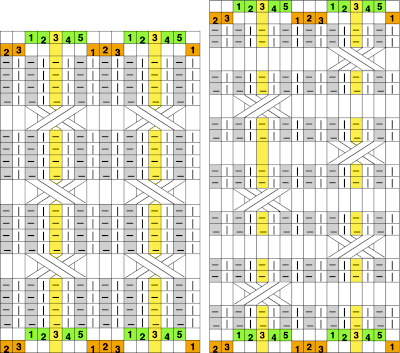

The step-by-step instructions apply to both instances: the chart shows 4 rows knit between crossings, instead, here 6 rows are knit in both tests.

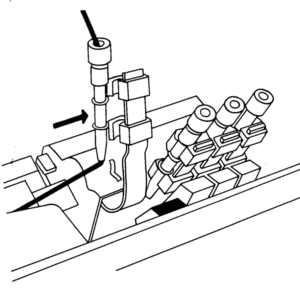

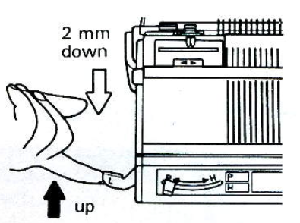

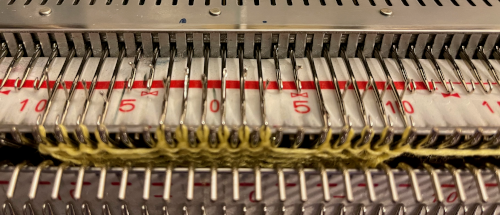

The step-by-step instructions apply to both instances: the chart shows 4 rows knit between crossings, instead, here 6 rows are knit in both tests. the rib configuration set up

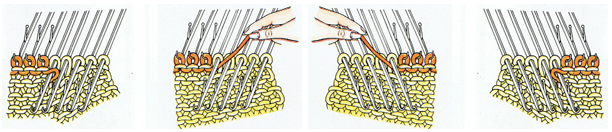

the rib configuration set up  1. after 5 rows knit, bring an extra needle in work on the top bed to pick up extra yarn for the cross

1. after 5 rows knit, bring an extra needle in work on the top bed to pick up extra yarn for the cross  2. drop the extra loop, make certain the empty needle returns to A position

2. drop the extra loop, make certain the empty needle returns to A position  3. transfer all cable ribber needles to top bed

3. transfer all cable ribber needles to top bed  4. cross the stitches with two three-prong tools

4. cross the stitches with two three-prong tools  5. transfer stitches back down to the ribber

5. transfer stitches back down to the ribber  knit 5 rows, repeat steps 1 to 5.

knit 5 rows, repeat steps 1 to 5. An attempt at a larger swatch using 1X1 ribs:

An attempt at a larger swatch using 1X1 ribs:

the cable crossings using it were impossible, starting over with a thinner yarn at the same tension

the cable crossings using it were impossible, starting over with a thinner yarn at the same tension  the ribber may be dropped after transfers up to the main bed, keeping stitches and crossings visible, making it possible to make corrections in any cables if they are needed before re-engaging the ribber and transferring stitches back down

the ribber may be dropped after transfers up to the main bed, keeping stitches and crossings visible, making it possible to make corrections in any cables if they are needed before re-engaging the ribber and transferring stitches back down

In the above swatches, when any transfers were made to the top bed, after crossings, a row was knit before returning stitches to the ribber. The extra row may or may not be noticeable, depending on the yarn and colors used.

In the above swatches, when any transfers were made to the top bed, after crossings, a row was knit before returning stitches to the ribber. The extra row may or may not be noticeable, depending on the yarn and colors used.

The number of rows between crossings can vary. When the crossing row is reached:

The number of rows between crossings can vary. When the crossing row is reached:

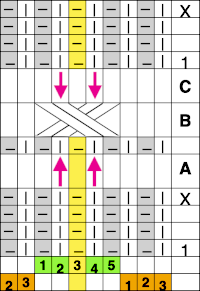

Assigning colors to columns reveals that stitches are not moved onto the same stitch type when moved over a single, undisturbed, fixed center stitch.

Assigning colors to columns reveals that stitches are not moved onto the same stitch type when moved over a single, undisturbed, fixed center stitch.  Shifting the needle arrangements when cabling, moving across a center column of two stitches that remain fixed on the main bed, the cable direction as it would appear on the purl side on the left, the knit side on the right is straightforward here:

Shifting the needle arrangements when cabling, moving across a center column of two stitches that remain fixed on the main bed, the cable direction as it would appear on the purl side on the left, the knit side on the right is straightforward here:  I found the above impossible to knit, even with ladders for extra slack, and the swatch stopped when the yarn broke

I found the above impossible to knit, even with ladders for extra slack, and the swatch stopped when the yarn broke

There appears to be enough slack produced in the formation of stitches between beds to make the planned crossings possible.

There appears to be enough slack produced in the formation of stitches between beds to make the planned crossings possible.

From a Brother pub, small crossings for a smocked effect

From a Brother pub, small crossings for a smocked effect

Adding and removing rows in the tables or even changing colors is easy and quick in a spreadsheet, tiling in repeat with scaled screengrabs provides a quick reference for possible improvements/corrections before any actual knitting takes place

Adding and removing rows in the tables or even changing colors is easy and quick in a spreadsheet, tiling in repeat with scaled screengrabs provides a quick reference for possible improvements/corrections before any actual knitting takes place