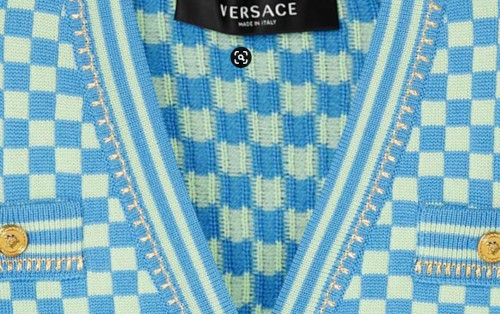

In the past few years, in many runway collections, knit pieces have featured slits that happen either/both horizontally or vertically, with some effects achieved by turning the fabric sideways.

My first post on horizontal slits was written in 2016.

This post will share published references describing additional various methods for creating them.

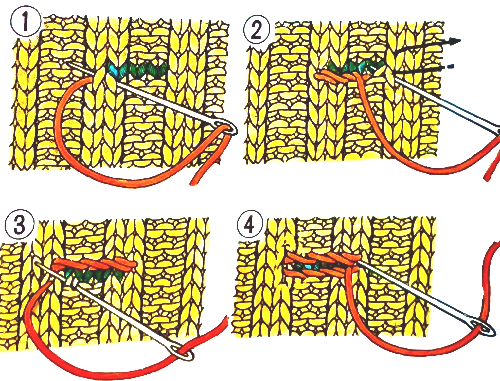

A review of grafting aka Kitchener stitch is illustrated here for hand knitting and used in some of the buttonholes/slits that follow.  Some single-bed buttonholes were illustrated in the post. One of the many resources

Some single-bed buttonholes were illustrated in the post. One of the many resources  Horizontal single-bed: using a ravel cord and tapestry needle

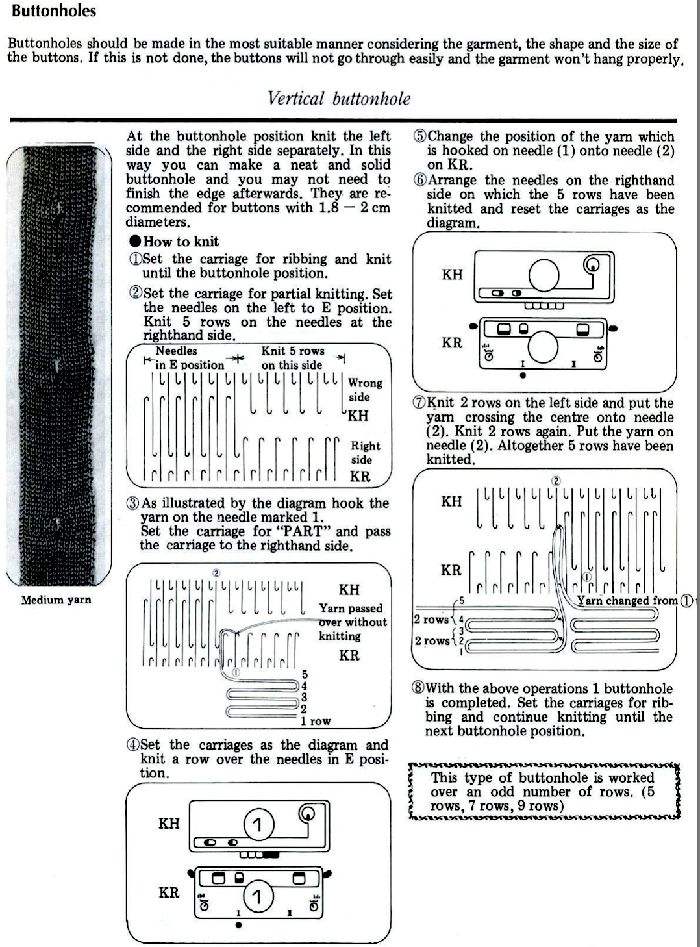

Horizontal single-bed: using a ravel cord and tapestry needle  A vertical option

A vertical option

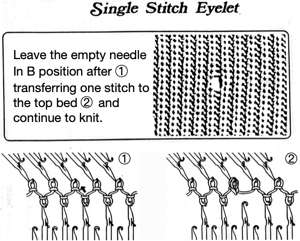

Single stitch eyelet in knit one purl one rib, suitable only for small buttons

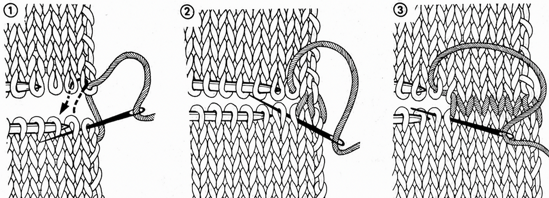

Single stitch eyelet in knit one purl one rib, suitable only for small buttons  Another version: leave the needle in B position out of work for a few rows, slide latch tool under a couple of the resulting floats, pick up the next in the hook, and latch-up as shown.

Another version: leave the needle in B position out of work for a few rows, slide latch tool under a couple of the resulting floats, pick up the next in the hook, and latch-up as shown.  Using waste yarn/ ravel cord followed by sewn bind-off, possible on unfolded fabric bands

Using waste yarn/ ravel cord followed by sewn bind-off, possible on unfolded fabric bands  An interesting translation in the publication of horizontal 😉

An interesting translation in the publication of horizontal 😉

The published reference to waste yarn here implies the use of a contrasting color yarn in a fiber content that allows for it to easily be slipped out when the process indicates. Any smooth yarn that will not break easily and can be knit at the same tension as the knit piece for a comparable gauge may be used, ie crochet cotton or nylon. Although yarns that shed may function for this purpose, they may leave contrasting bits of fiber and color behind in the finished knit that will not be removable.

The published reference to waste yarn here implies the use of a contrasting color yarn in a fiber content that allows for it to easily be slipped out when the process indicates. Any smooth yarn that will not break easily and can be knit at the same tension as the knit piece for a comparable gauge may be used, ie crochet cotton or nylon. Although yarns that shed may function for this purpose, they may leave contrasting bits of fiber and color behind in the finished knit that will not be removable.

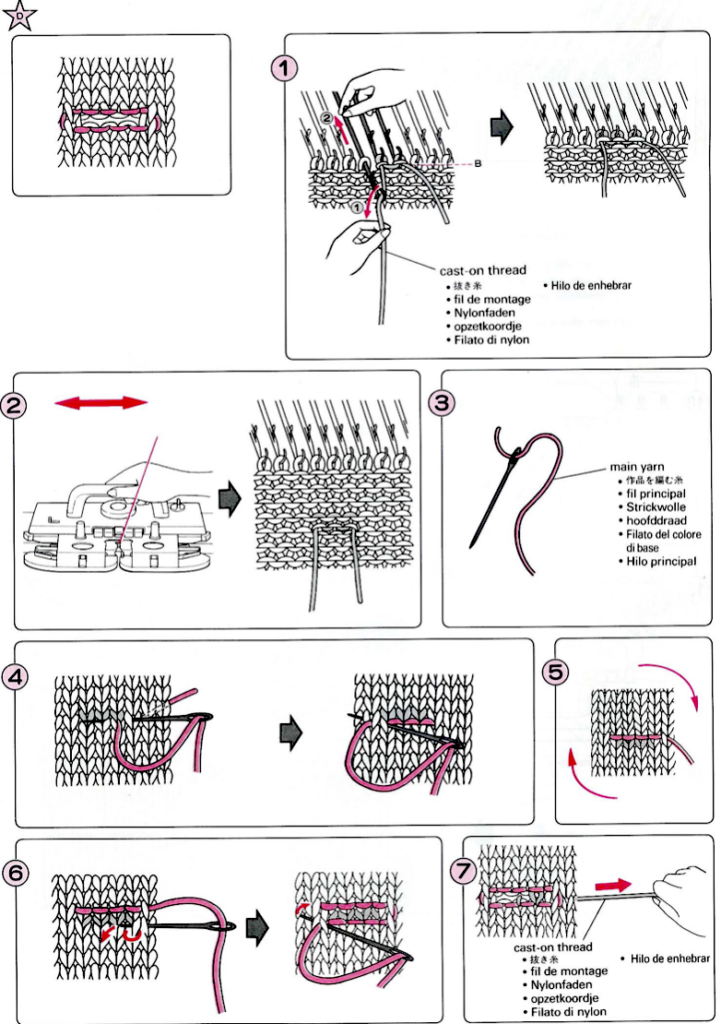

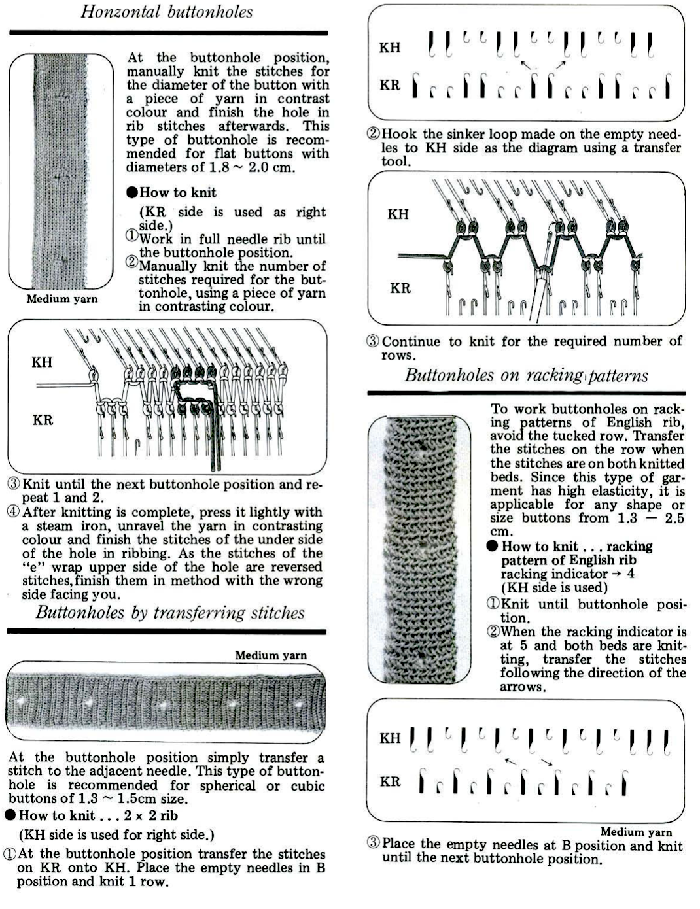

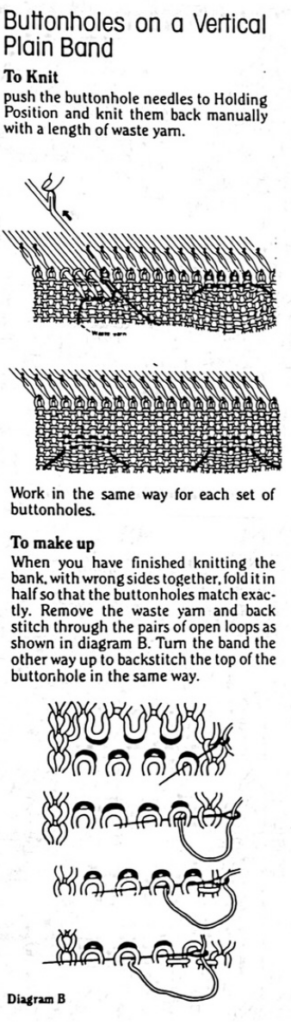

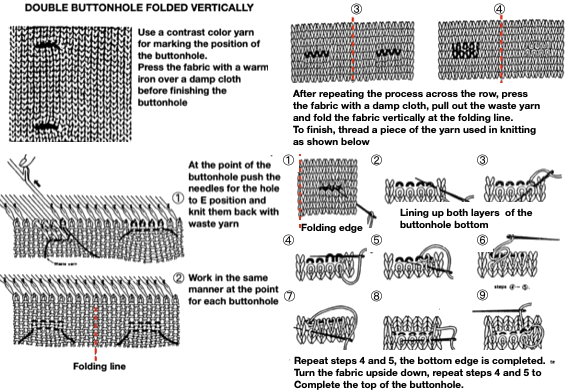

Double-layer buttonholes may be used in stocking stitch bands applied to the side edge of a garment ie cardigans upon completion of the piece or may be planned in hems if the piece is to be turned sideways.  Here they are folded horizontally on a band that will be applied to the finished edge ie of a cardigan’s front

Here they are folded horizontally on a band that will be applied to the finished edge ie of a cardigan’s front

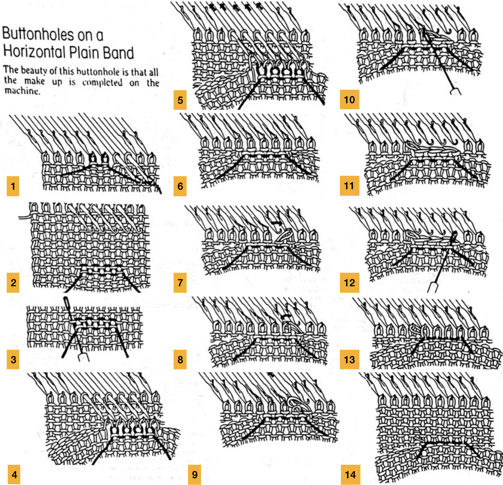

1: push the required needles to hold, knit them back with waste yarn

2: continue to the position for the next slit, and repeat

3: with a transfer-tool pick up the sinker loops of the first slit that were

created with waste yarn

4: place the sinker loops onto the needles in the holding position

5: push the needles back into the working position

6: knit loops through pre-existing stitches

7: to complete the lower edge of the buttonhole transfer the second

stitch to the first stitch of the buttonhole

8: transfer both stitches onto the empty needle

9-11: repeat the process

12: pick up the loop below the waste yarn

13: place the loops on their respective empty needles

14: continue to knit, and pull out waste yarn after a few rows to check for proper formation of the buttonholes  It is possible to work across a whole band, here the joining method uses a tapestry needle and is akin to grafting.

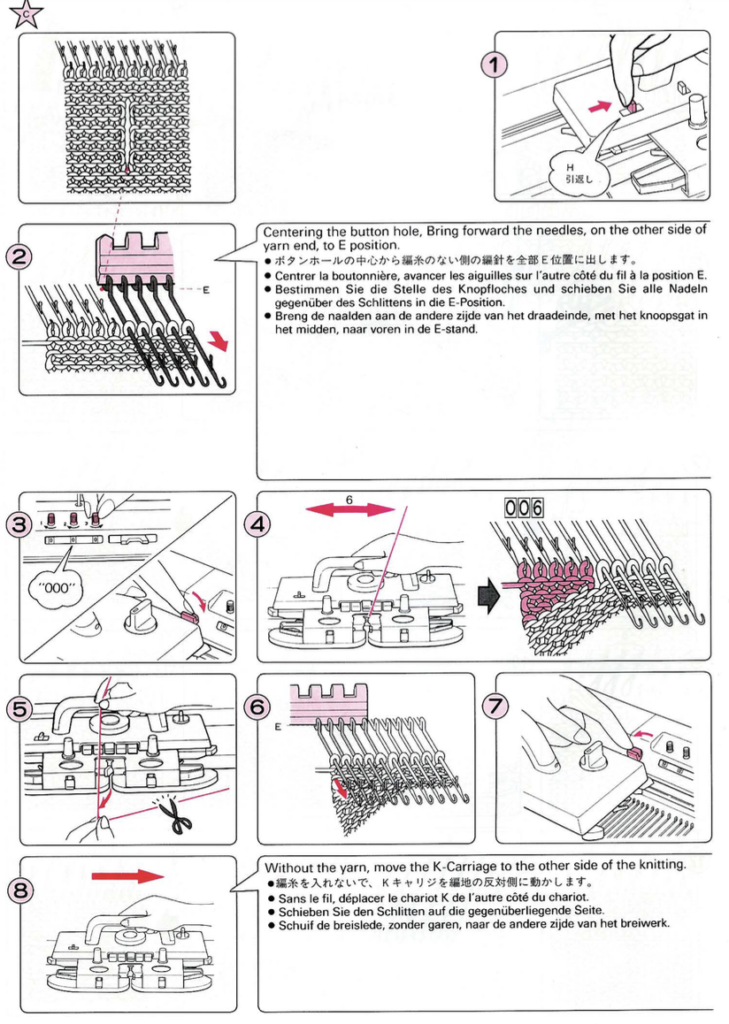

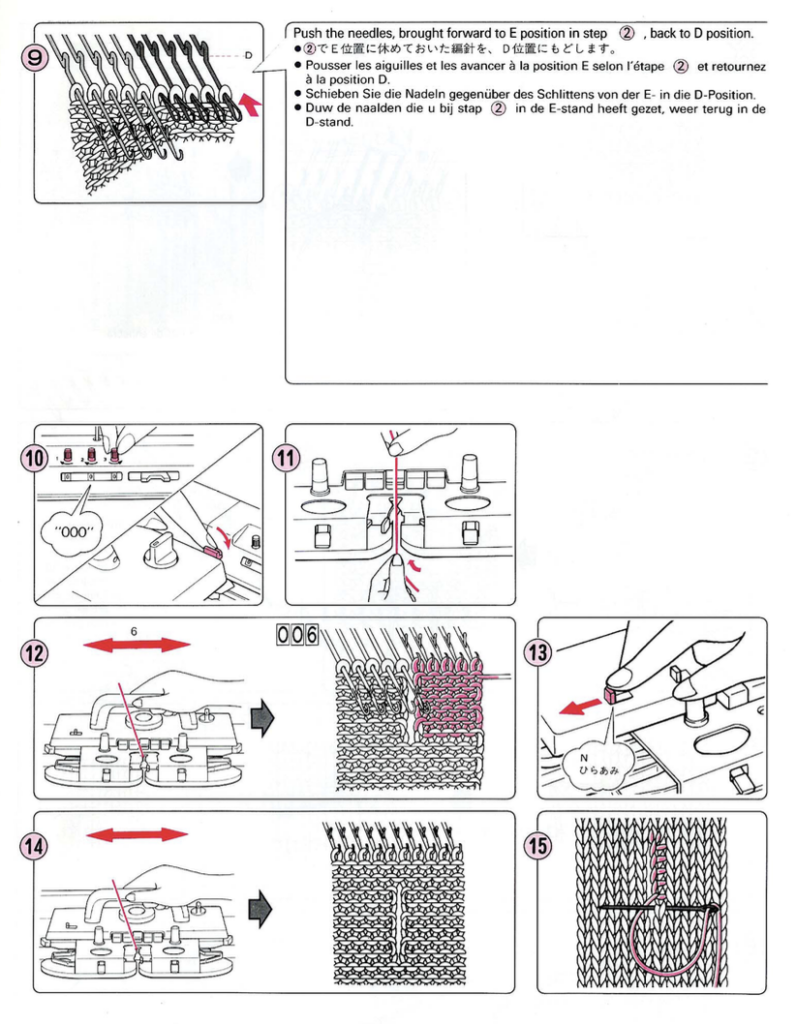

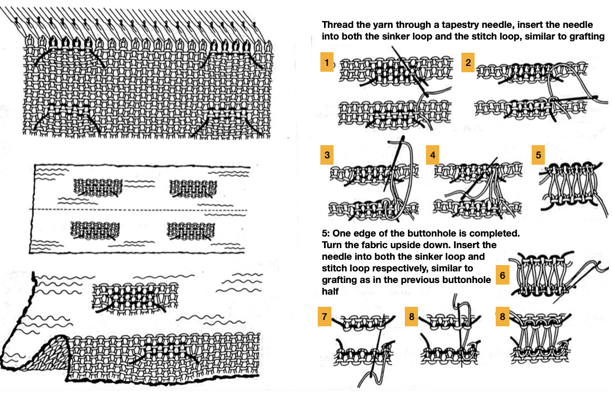

It is possible to work across a whole band, here the joining method uses a tapestry needle and is akin to grafting.  Buttonholes folded vertically are actually worked on live stitches. Pressing the fabric helps to set them.

Buttonholes folded vertically are actually worked on live stitches. Pressing the fabric helps to set them.  Another view:

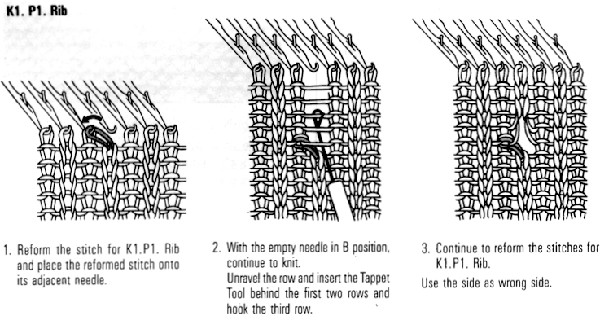

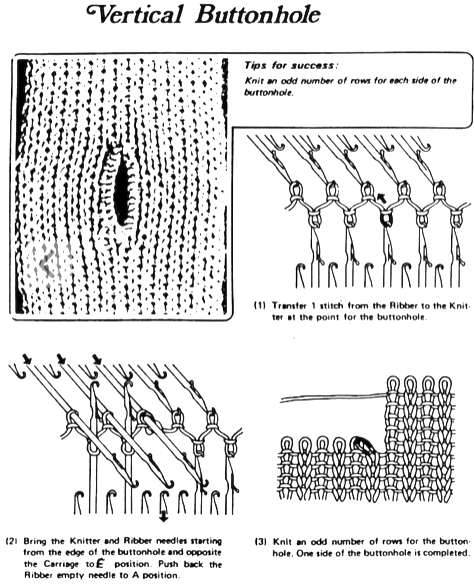

Another view:  This method uses holding on the ribber to create vertical openings tappet tool. The latter is the ancient term used for what has come to be known as a latch tool

This method uses holding on the ribber to create vertical openings tappet tool. The latter is the ancient term used for what has come to be known as a latch tool

Category: Machine knitting (MK)

Building more textures in needles out of work spaces

A collection of previous posts exploring some variations on the topic:

Ladders with lace, (leaf) “making things work” 1 3/15

Ladders with lace, (leaf) “making things work” 2 3/15

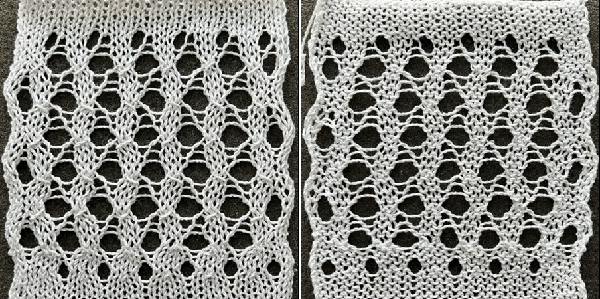

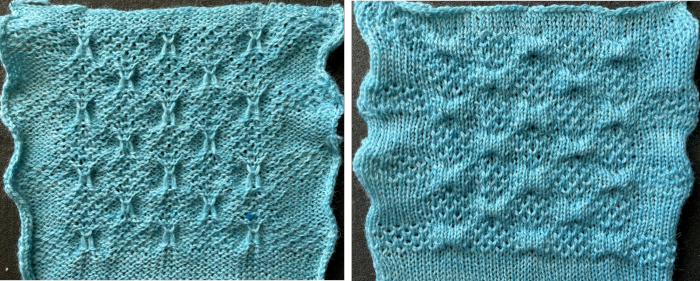

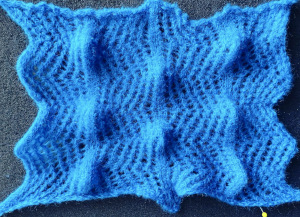

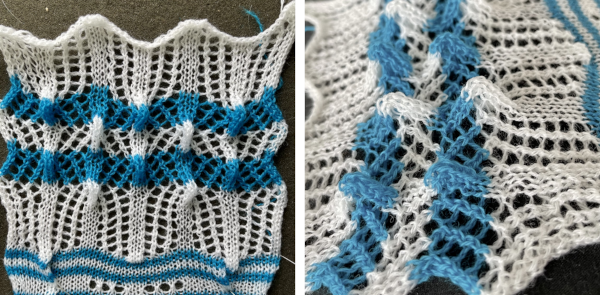

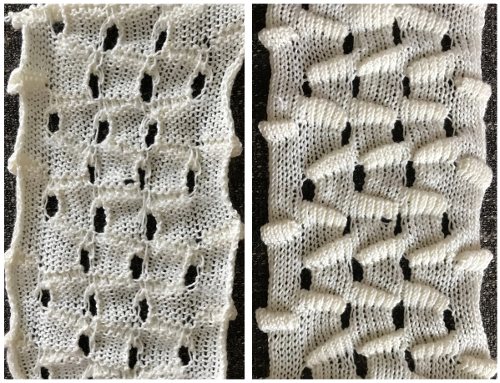

Ladder lace 8/13 Instructions reviewed in 2022, one of the accompanying swatches:  Ladders and Lace 8/13. MK ladders, and a bit of crochet 12/16

Ladders and Lace 8/13. MK ladders, and a bit of crochet 12/16

Tuck “lace” trims (and fabrics 1) 6/17

Tuck “lace” trims (and fabrics 2) 6/17

Tuck “lace” trims or fabrics 312/17

Automating tuck stitches combined with “lace” 2 6/17

Combining tuck stitches with “lace” 1 3/15

Many fabrics other than the traditional ones familiar to hand knitters and machine knitters that create eyelet patterns by transferring and combining stitches with yarnovers often include the term lace in their name, one such is ladder lace.

No matter what machine is in use, charts may be developed and followed that include row-by-row directions for needles out of work and any movement of stitches to alter the look of the floats created in the resulting spaces.

Knitology offers endless video inspiration for lovers of hand techniques including ones relying on patterns including ladders.

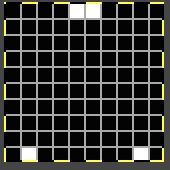

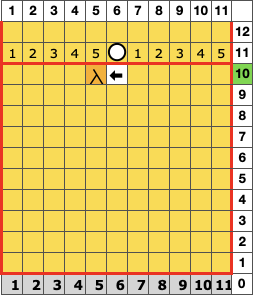

There are several aids in maintaining the desired repeat in NOOW (needles out of work). When establishing the initial needle configuration, punchcard knitters can punch a single row to match the required needle selection if the repeat works within the 24-stitch constraint, and use locked preselection to make transfers in base knitting.

Electronic knitters may use the same concept, I prefer if doing so to plan for programming the width of the stitches in use on the needle bed, adding pixels for knit borders on either side. Punchcard users may need to disregard some needle selections to form them.

Another option for hand technique tracking in addition to marking the needle tape or even the needle bed is to print custom needle tapes created in a spreadsheet.  They can be marked as needed to guide hand technique selections, with colors added if preferred, and are easily swapped out if corrected or additional tapes are needed for different segments of the same technique.

They can be marked as needed to guide hand technique selections, with colors added if preferred, and are easily swapped out if corrected or additional tapes are needed for different segments of the same technique.

A variety of printable tapes for multiple gauge knitting machines is offered by Claudia Scarpa in her blog post.

A series of printable sheets for tracking row counts at even intervals may be found at the bottom of this post.

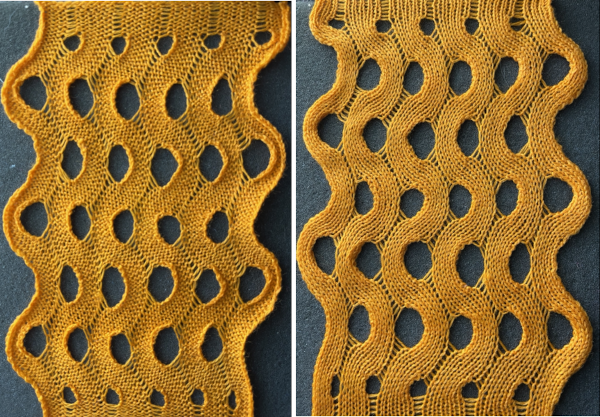

In laddered fabrics, the edge stitch on either side of the float may widen and grow in size over time.

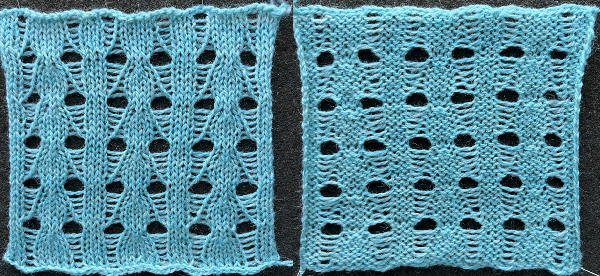

The 8/13 swatch uses lace transfers that produce doubled-up stitches to help with stitch stability.

Adding hand techniques serves a similar purpose in wide or varying ladder space designs created on the knit bed.

The length of the item produced combined with the added weight in the finished piece as it is hung or worn may quicken any lengthening and narrowing of the piece, requiring blocking again or at the very least pressing and steaming.

The fiber used makes a difference in the retention of the blocked shapes, in this case, man-made fibers may serve better than wool with its spring back.

If a needle is emptied, if left forward or brought back to the B position, it will pick up a loop on the next pass, and when followed by a second knit row, an eyelet is formed in the loop location.

If a loop on a previously empty needle is dropped after it is formed, the resulting ladder grows in width.

Latching ladders while on the machine creates knit stitches on the purl ground.

Stitches may be removed and returned to the needle bed, cable crossings may be involved.

Picking up the heels of specific stitches on designated rows below and placing them on the knit stitches to the right or left of the ladder space is a way of adding non-vertical shaping.

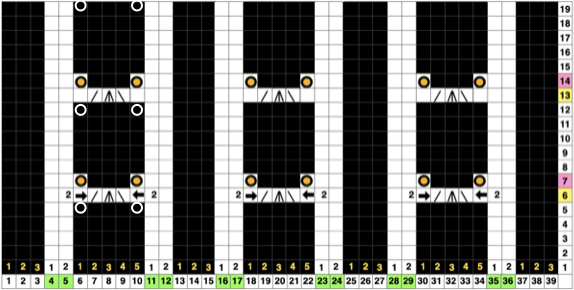

If experimenting with the number of rows knit before adding hand techniques, keep good notes in order to be able to reproduce segments in an all-over pattern. Beginning patterning with simple transfers in stocking stitch ground, here the needle configuration shifts but remains constant throughout. My proof of concept swatch is knit in 2/8 wool.  Visualizing the necessary actions:

Visualizing the necessary actions:

The proof of concept:

The proof of concept:

Adding 2X2 cable crossings: this repeat is 12 stitches wide.

Adding 2X2 cable crossings: this repeat is 12 stitches wide.

A chain cast-on allows for dropping the 2 chains in the location of the starting ladders, with some weight applied to the starting rows one may proceed to the first cable crossing.

On row 6, and then again at 10-row intervals from there, the designated pairs of stitches are crossed consistently in the same direction. The needles aside from the crossing are pushed back to the A position.

Knit 4 rows.

On row 10, and then again at 10-row intervals from there move the left stitch of the pair of the center needles to its left, and the right stitch to its right, restoring the empty column at the center of the chart. Return the remaining empty needles to the B or E position

Knit 6 rows.

Repeat the process, ending with 6 knit rows. ![]()

This variation uses transfer lace stitch crossings to produce larger eyelets than seen in the above swatch. Row counts for specific hand techniques can be tracked in a written or printed document if preferred.

This variation uses transfer lace stitch crossings to produce larger eyelets than seen in the above swatch. Row counts for specific hand techniques can be tracked in a written or printed document if preferred.

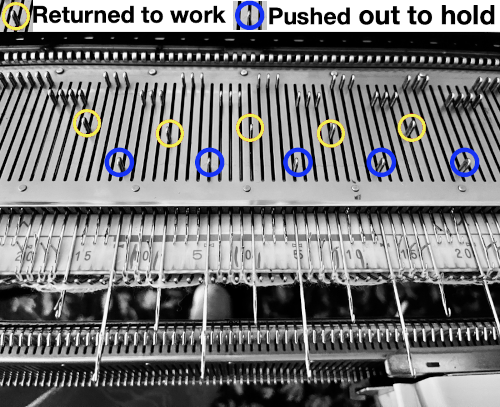

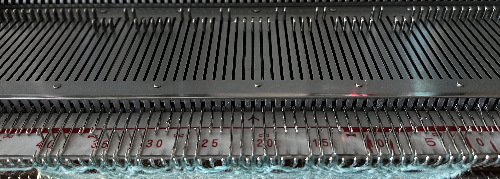

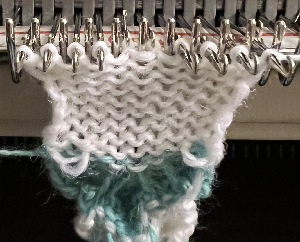

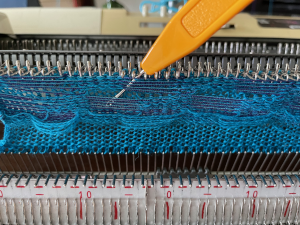

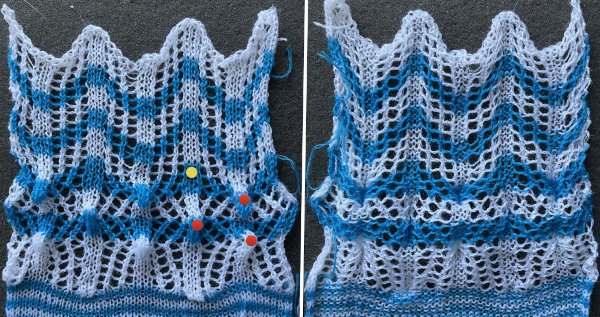

The knitting in progress: the initial needle spacing:

The knitting in progress: the initial needle spacing:  Emptied needles are in the process of being returned to work after the transfers to restore the initial setup, the first knit row will create loops on those needles, and the stitch is completed with the next knit pass from the opposite side

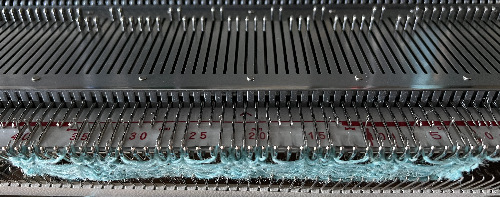

Emptied needles are in the process of being returned to work after the transfers to restore the initial setup, the first knit row will create loops on those needles, and the stitch is completed with the next knit pass from the opposite side  The growing pattern becoming apparent

The growing pattern becoming apparent

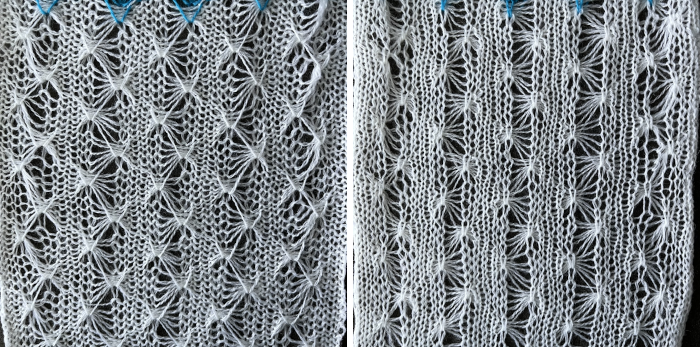

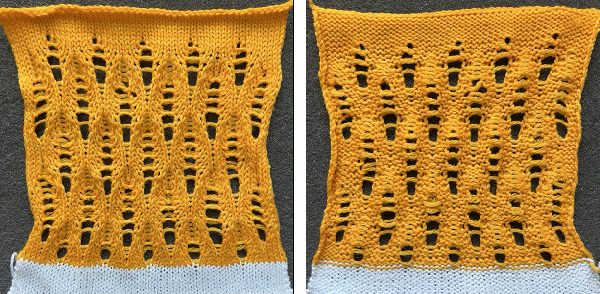

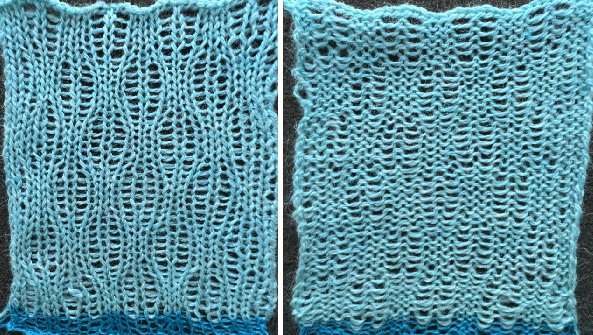

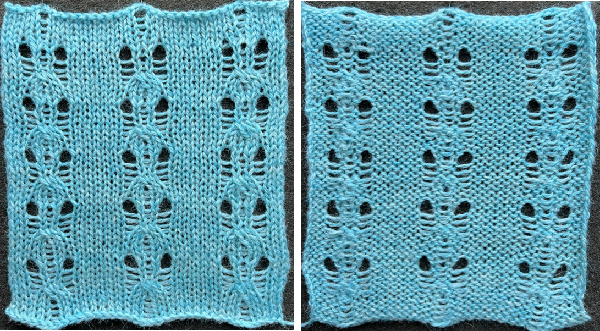

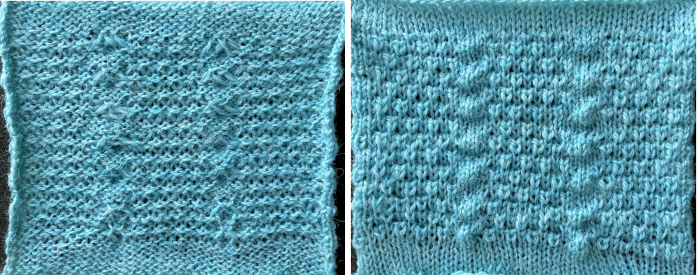

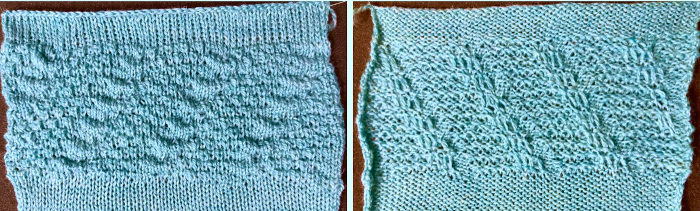

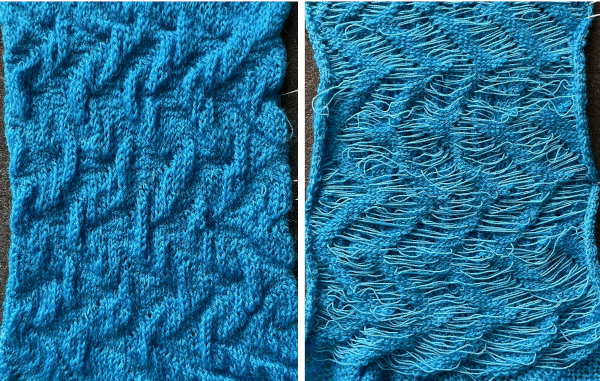

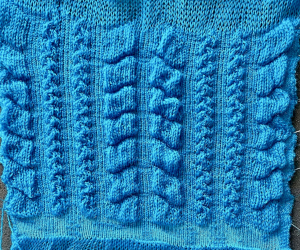

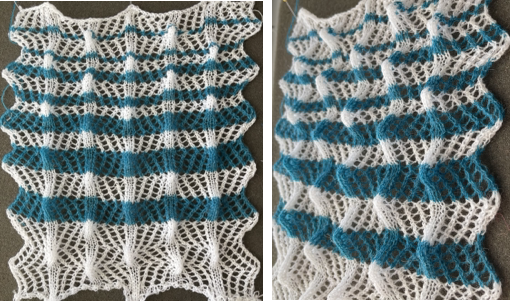

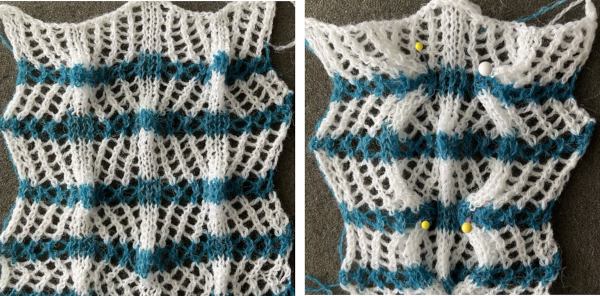

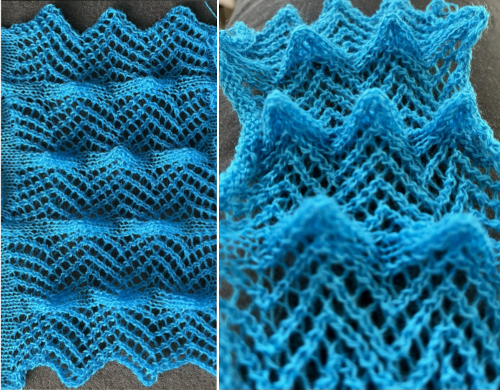

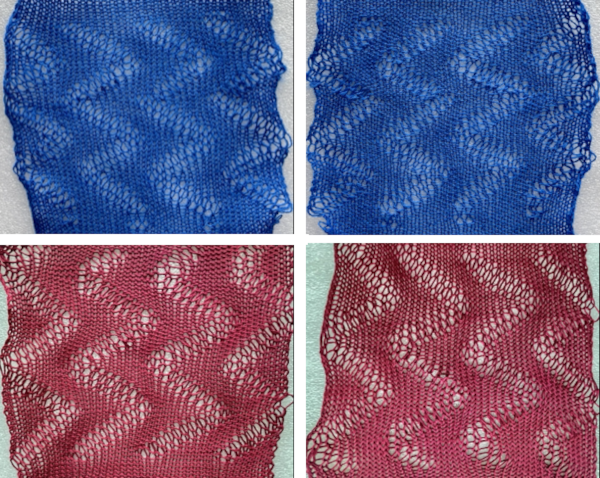

After updating the 8/13 post, these experiments continue exploring the above concept. The yarn now used is a wool rayon, which appeared not to split, and retains blocking if it is used.

After updating the 8/13 post, these experiments continue exploring the above concept. The yarn now used is a wool rayon, which appeared not to split, and retains blocking if it is used.

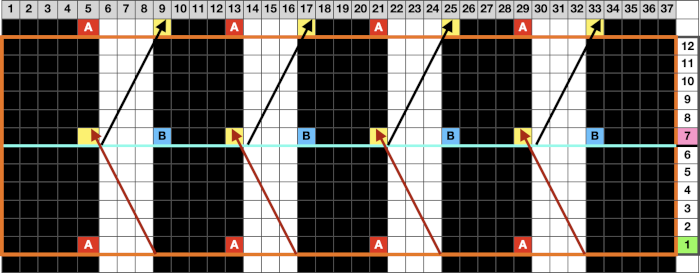

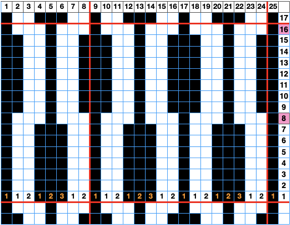

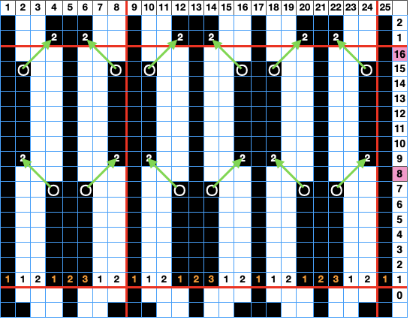

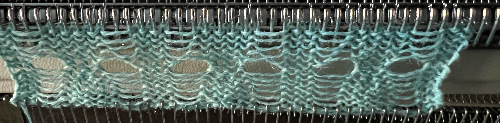

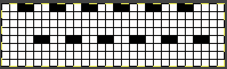

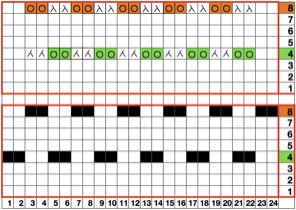

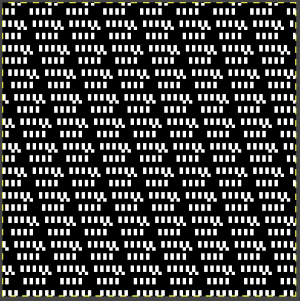

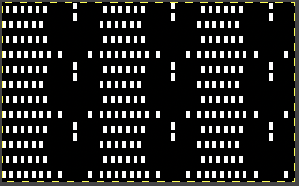

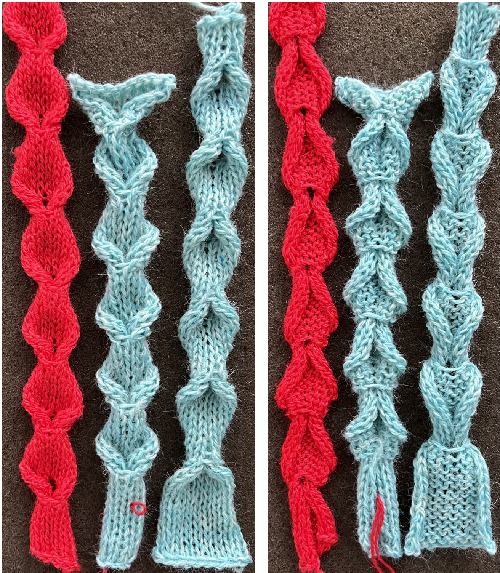

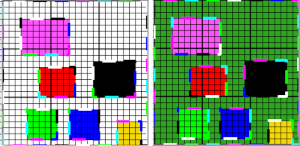

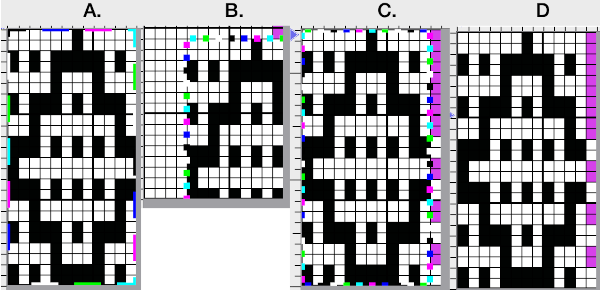

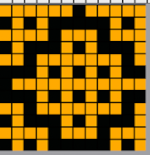

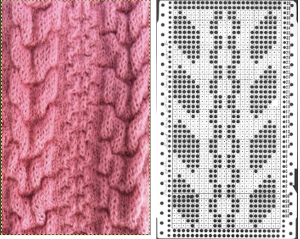

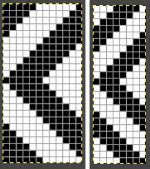

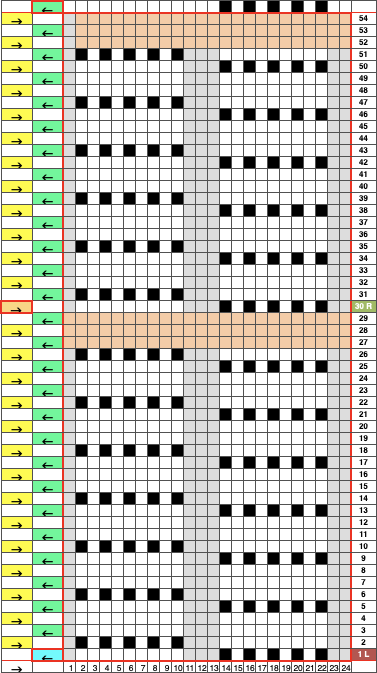

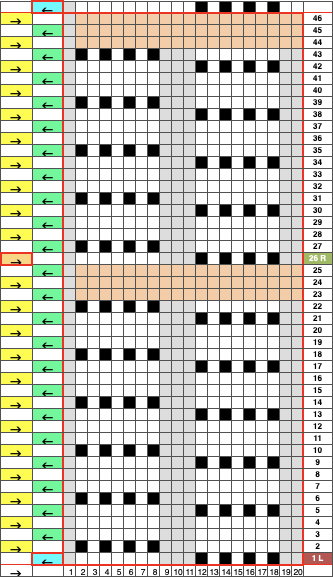

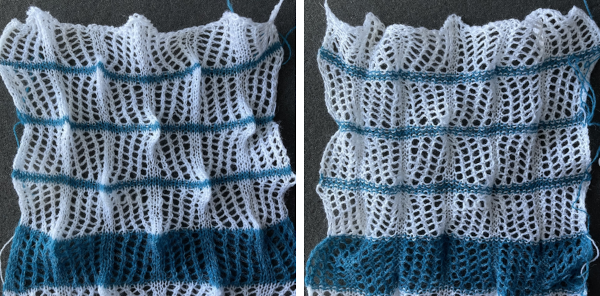

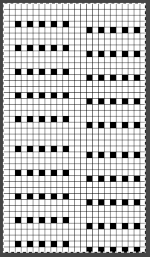

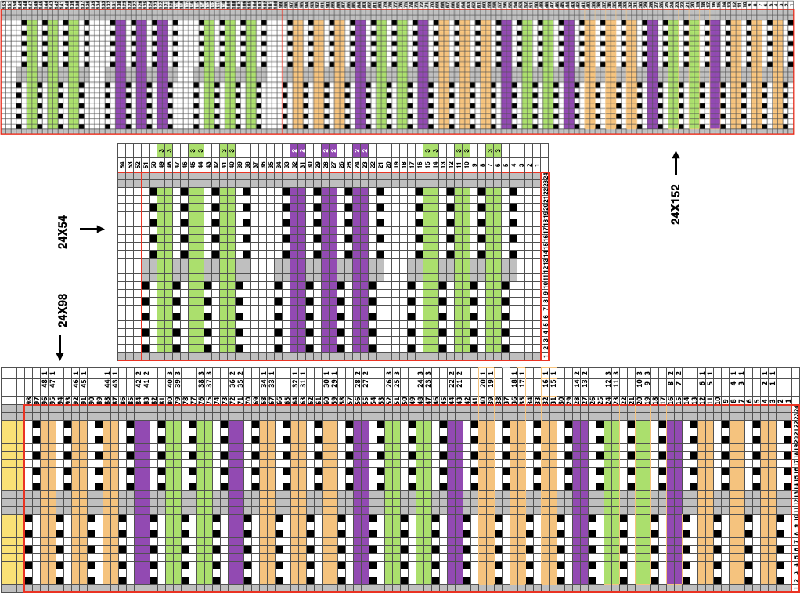

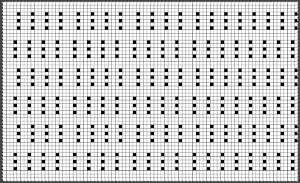

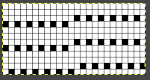

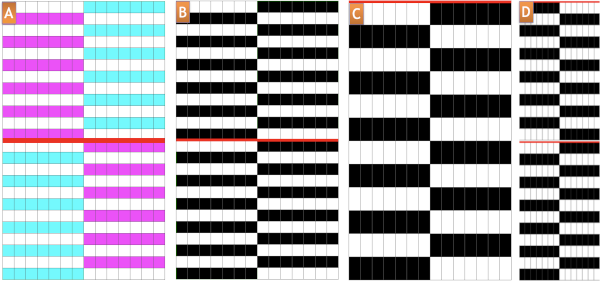

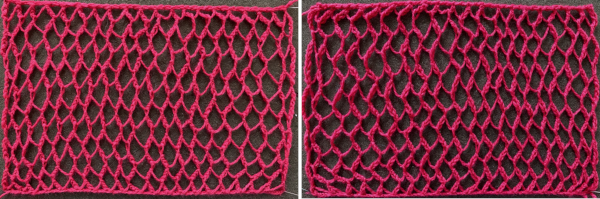

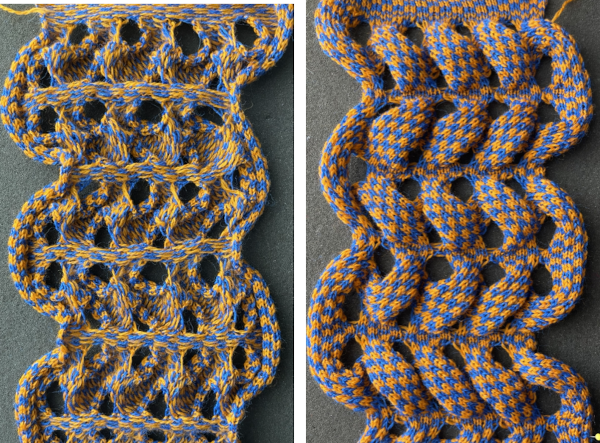

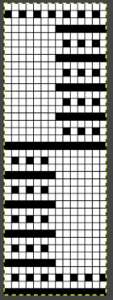

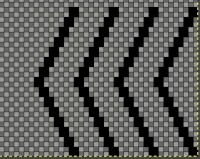

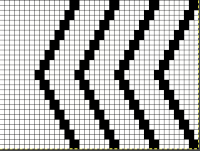

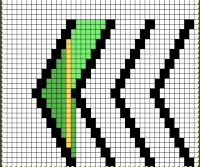

The samples use an 8-row repeat with different transfer methods. The first uses two-stitch transfers. The 24-stitch version is suitable for a punchcard, 48 rows in height.  the smallest electronic repeat

the smallest electronic repeat  tiled to a 28-stitch repeat for the electronic, in the width of my planned swatch, only for the required 8-row height

tiled to a 28-stitch repeat for the electronic, in the width of my planned swatch, only for the required 8-row height

![]()

The now familiar double loops

The now familiar double loops  Beginning ladders

Beginning ladders  A partial row view of stitches moved 2 at a time toward the higher end stitch count, treating the loops as one would stitches

A partial row view of stitches moved 2 at a time toward the higher end stitch count, treating the loops as one would stitches

e-wrapping one of the two loops consistently in the same direction at the top of the piece will form equal eyelets on the next pass

e-wrapping one of the two loops consistently in the same direction at the top of the piece will form equal eyelets on the next pass

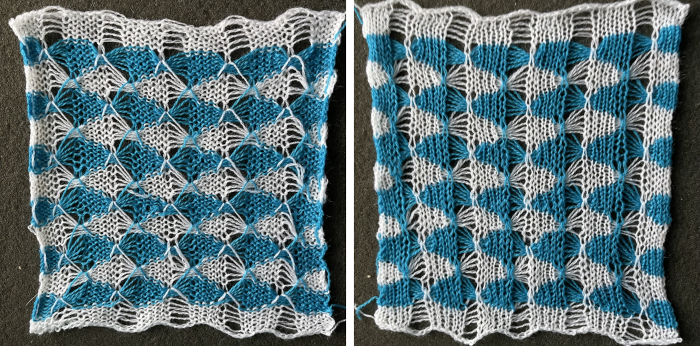

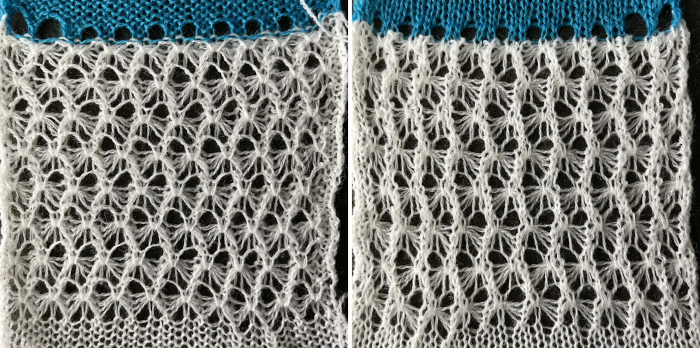

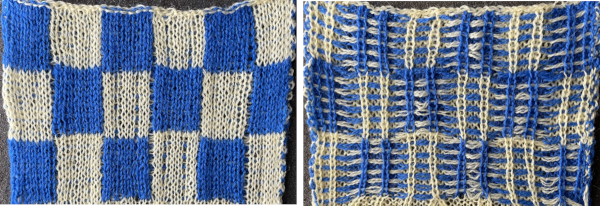

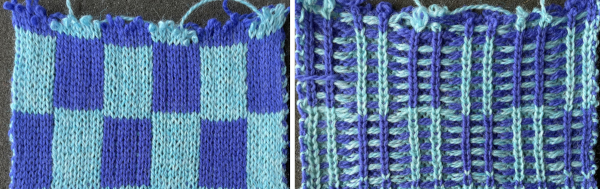

Working with multiple loops held in hooks of specific needles: the following swatches were actually the beginning for what became the above thread

Working with multiple loops held in hooks of specific needles: the following swatches were actually the beginning for what became the above thread

I tend to web surf in the early morning hours. Sometimes that includes coming across YouTube videos where contributors show fantastic dexterity at handling tools while developing complex fabrics using only hand techniques.

This is one example:

https://www.youtube.com/watch?v=IoJbbInlxck.

As usual, I attempted to automate as much as I could and failed to be able to execute a truly similar fabric.

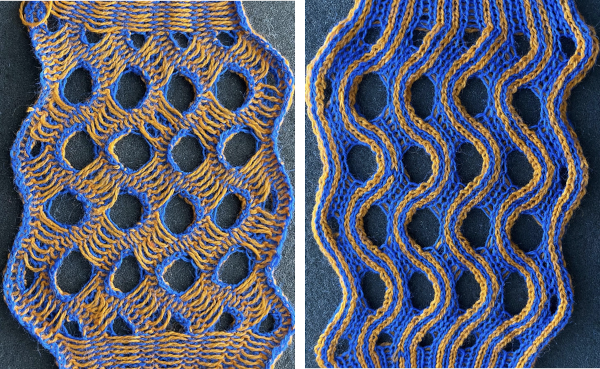

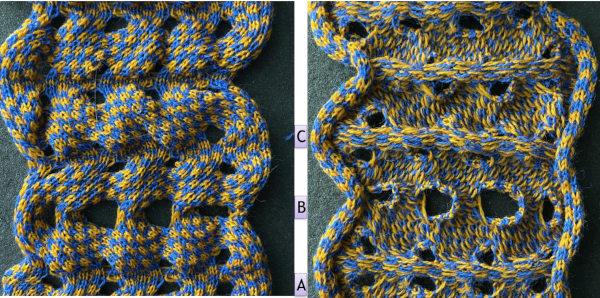

In my first modified version, I introduced knit rows as seen below to make tracking of hand techniques easier and to facilitate knitting stitches/ loops groups.

The result is of course quite different from the swatch in the video.

To knit: begin with a permanent cast on over the planned number of needles. In this case, 2 needles are included to form vertical all-knit borders on both sides.

I knit most of my proof of concept swatches on an electronic machine and download a plain design repeat with a stitch count equal to the entire width of the number of needles in use on the bed.

On a punchcard model, the all-knit border needles would have to be brought out to E on every row for them to knit with each carriage pass.

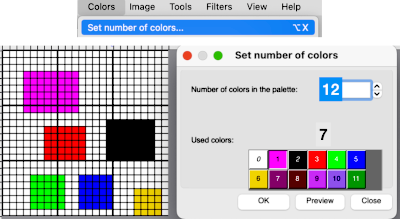

Using provided repeat pngs as shared may require mirroring the repeat horizontally depending on the download program and the knitting machine model used, as well as changing the image mode back to indexed BW since downloaded designs from the posts may be converted to RGB mode as they are copied.

If working on a finished piece, knit several rows of waste yarn, followed by a row of ravel cord and a permanent cast-on, otherwise simply knit enough to hang a comb and some weights, required for most tuck knitting.

I happen to have a 2/20 wool as my go-to for most experiments that result in 4 or more loops building up in the needle hooks.

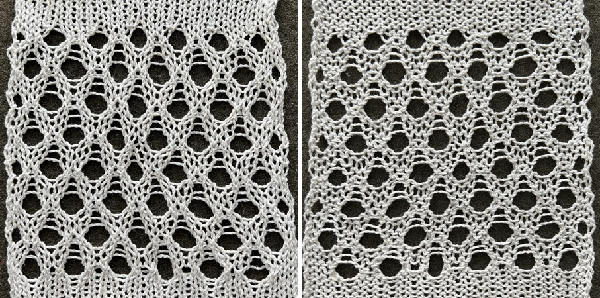

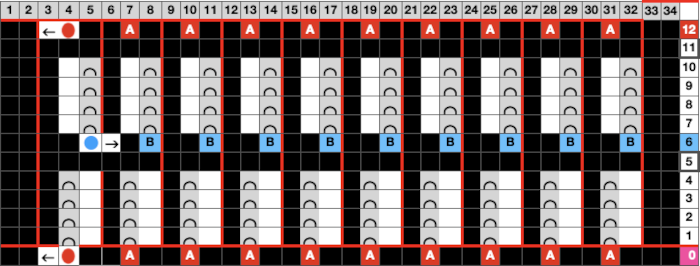

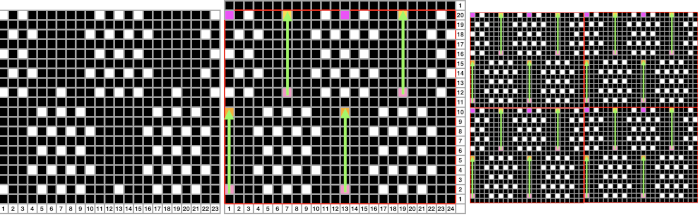

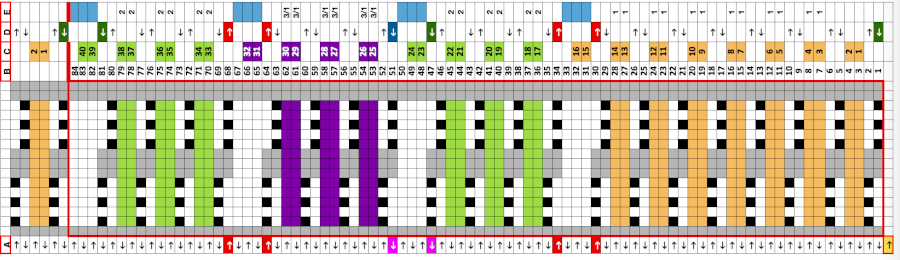

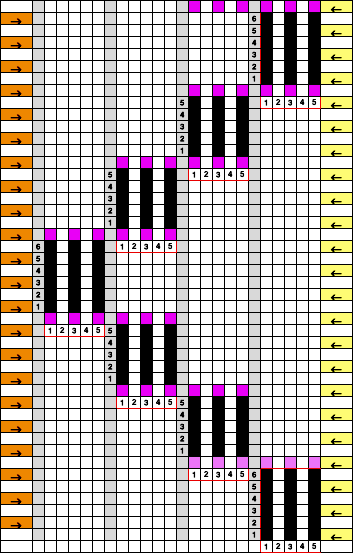

The beginning concept: hand transfers and automated tuck patterning

The programmed repeat is planned for two rows of knit stitches between sets of loops

The programmed repeat is planned for two rows of knit stitches between sets of loops

![]() After the cast-on and base knit rows, program the machine and preselect the first pattern row. The starting side does not matter unless the use of the color changer is planned, in which case, the first preselection row would need to move toward it.

After the cast-on and base knit rows, program the machine and preselect the first pattern row. The starting side does not matter unless the use of the color changer is planned, in which case, the first preselection row would need to move toward it.

Because some needles are taken out of work, end needle selection is canceled.

After the first preselection row, the machine is set to tuck in both directions.

My test repeat was programmed as a single motif on the 930, with the image mirrored horizontally.

Each pattern segment is 6 rows high, the full repeat is 12 rows tall. Color changes could be introduced every 6 rows.

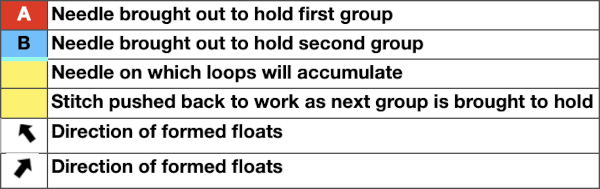

Following the chart for the first segment, transfer the A marked nonselected location needles to the adjacent preselected ones on their left, push the emptied needles out to A position, OOW after each transfer, and its adjacent needle with the combined stitches/loops out to E position.

After 4 tuck stitch rows, push any needles previously placed out of work to A position out to E so they will knit appropriately on the next pass as part of an all-knit row.

As the carriage moves to the opposite side, the second all-knit row will preselect. As the carriage again moves once again to the previous side, it will knit the whole row, while preselecting for the first hand-technique row once more.

Prior to the next carriage pass, transfer each of the marked B location nonselected needles to the adjacent preselected ones on its right, push the emptied needles out to A, OOW after each transfer, and its adjacent needle with the combined stitches out to E.

Form loops for 4 more rows, and push any needles previously placed back to A position out to E so they will knit appropriately on the next pass, forming an all-knit row. As the carriage moves to the opposite side, the next all-knit row will preselect, followed by preselection for loops and transfers again as the carriage moves again to the previous side knitting every stitch.

Repeat the process for the desired length.

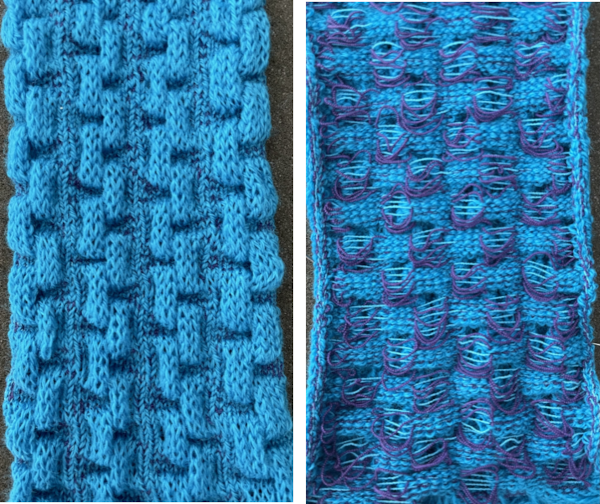

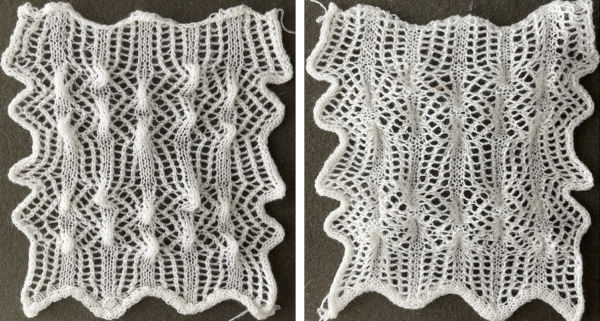

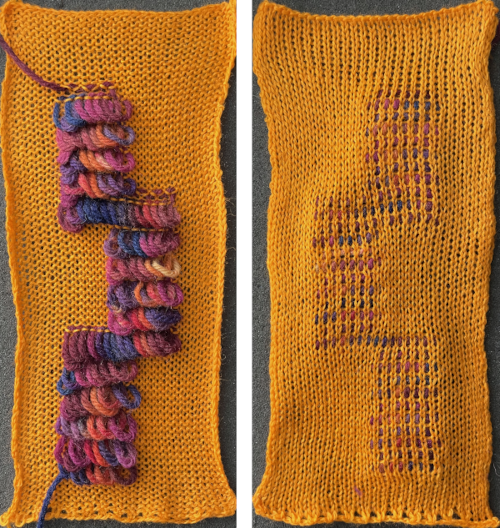

End the piece with at least 2 all-knit rows after a full or half design repeat. Cast off loosely to compensate for the widening due to the type of stitch formation.  This fabric is executed as a hand technique/ short rows with no automated tuck patterning assistance. I have found when using the tuck automated setting in Brother models there is often a limit for accumulating no more than 4 strands in the hooks of the needles, while in using holding, manually pushing needles out to hold and back to work can be far more forgiving.

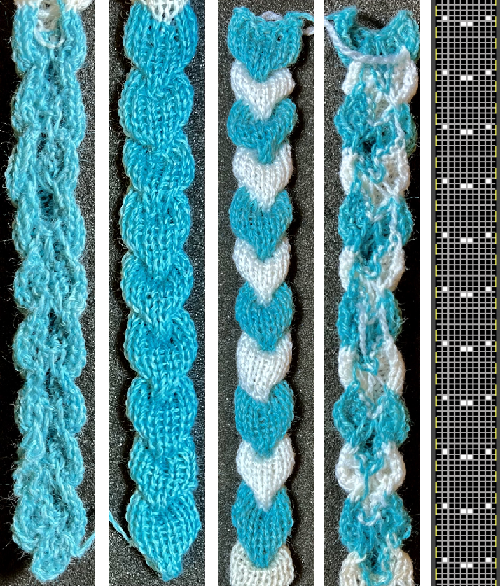

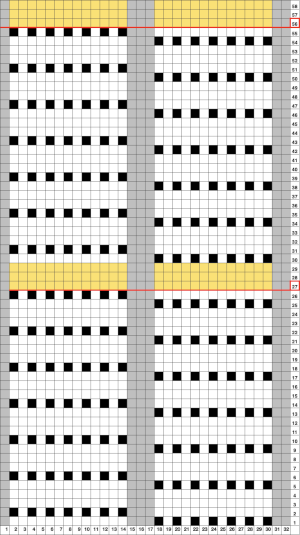

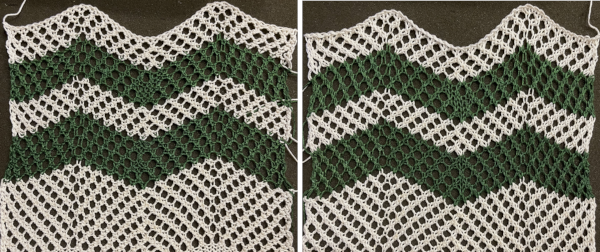

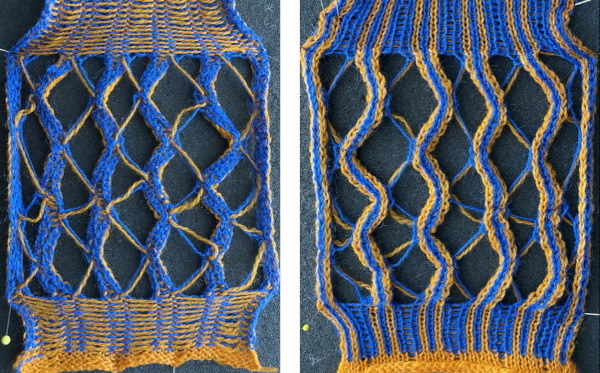

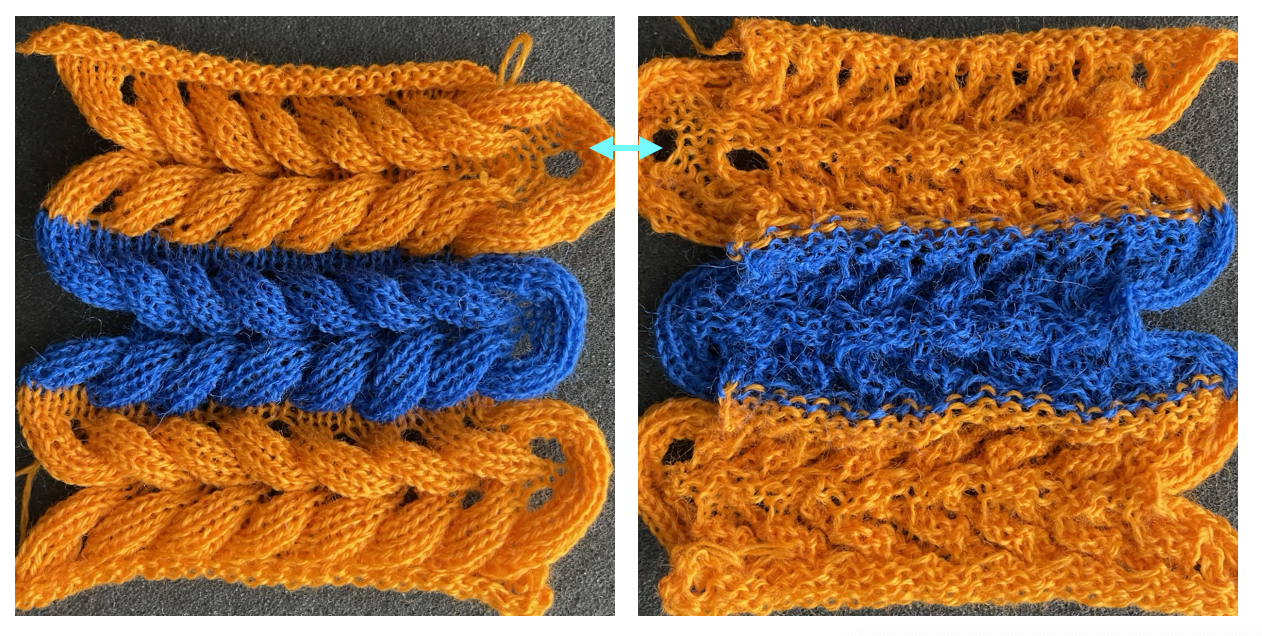

This fabric is executed as a hand technique/ short rows with no automated tuck patterning assistance. I have found when using the tuck automated setting in Brother models there is often a limit for accumulating no more than 4 strands in the hooks of the needles, while in using holding, manually pushing needles out to hold and back to work can be far more forgiving.

In this instance, loops are formed for 6 consecutive rows.

There are no all-knit rows. The color changes were made every 6 rows prior to knitting across the newly adjusted needle positions.

Pretend/ mock cables 4

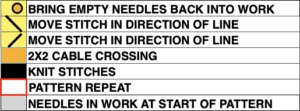

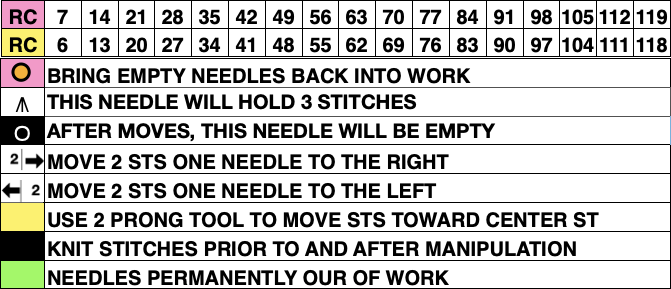

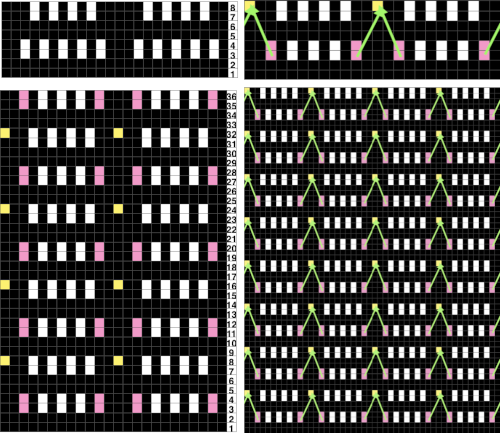

The blog post Pretend/ mock cables 3 presented the concept of using tuck stitch patterning and needle preselection, a Brother feature, as a guide to creating a version of mock cable crossings.

These designs are from an ancient Japanese publication. Technically the results are not very cable-like for these three concepts, but they share the principles behind the technique.  I am offering this information as a way of interpreting and adapting the suggestions in the publication. There has been some editing of the originally shared repeat suggestions after testing them in proof of concept swatches.

I am offering this information as a way of interpreting and adapting the suggestions in the publication. There has been some editing of the originally shared repeat suggestions after testing them in proof of concept swatches.

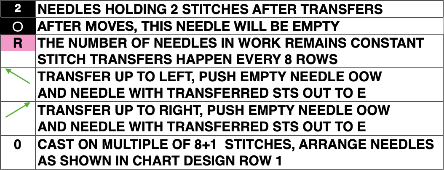

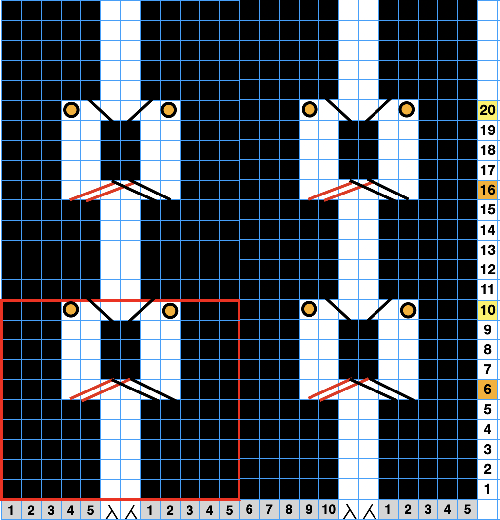

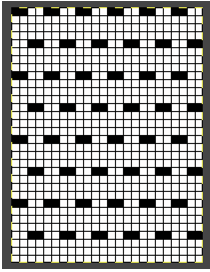

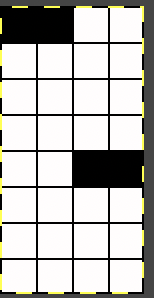

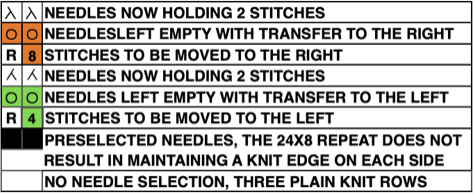

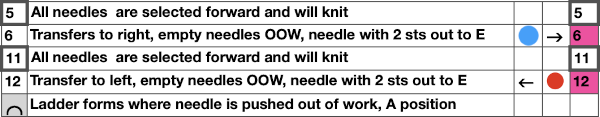

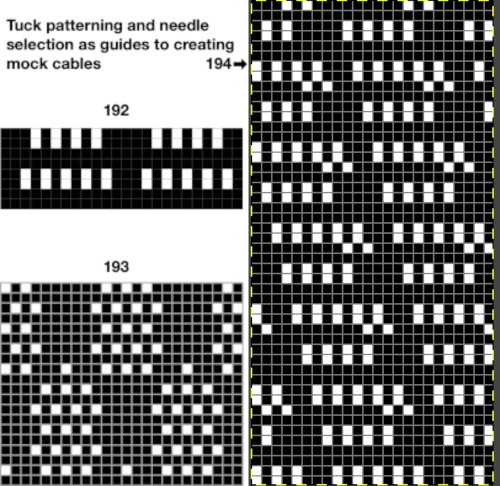

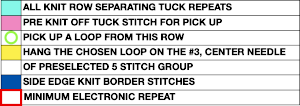

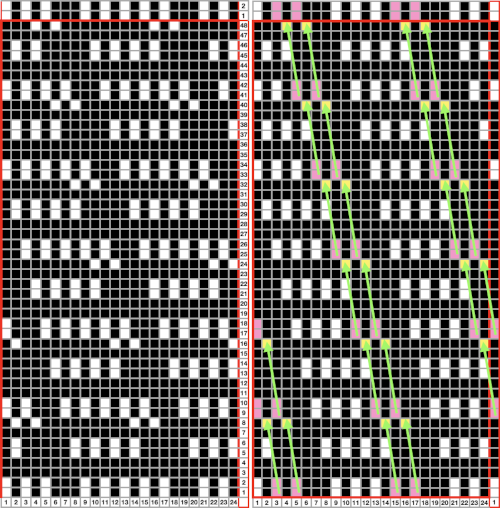

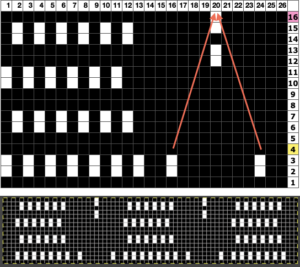

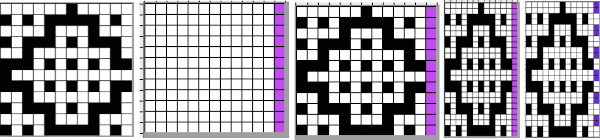

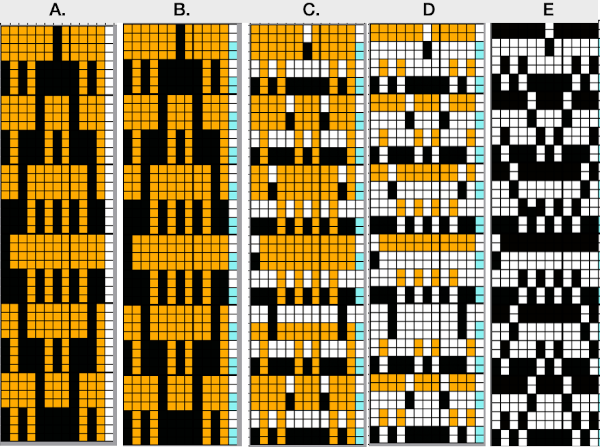

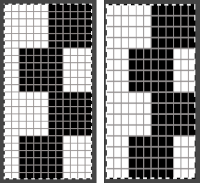

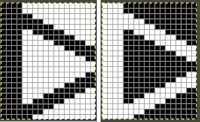

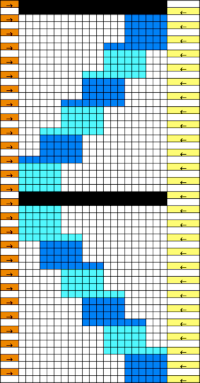

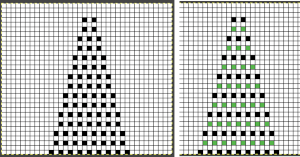

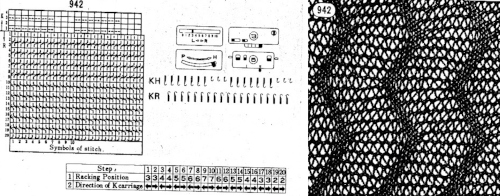

The scanned inspiration source:  The punchcard repeats: symbols are used in the above chart. The elongated short inverted U shapes, with some in bold type, represent the tuck stitch locations and needles that will hold loops in a pattern. The longer, thinner inverted Us suggest which tuck loop(s) will be raised and hooked up on new locations to create the desired textured effects.

The punchcard repeats: symbols are used in the above chart. The elongated short inverted U shapes, with some in bold type, represent the tuck stitch locations and needles that will hold loops in a pattern. The longer, thinner inverted Us suggest which tuck loop(s) will be raised and hooked up on new locations to create the desired textured effects.

Punchcards mirror the design horizontally when in use, so the texture will appear as shown in the swatch photos on the knit side when the design is worked based on the illustrated charts on the right.

When using the tuck setting, unpunched holes will create loops on nonselected needles, punched holes will create knit stitches. Electronic patterns will use black and white pixels to result in the same selections.

Deliberately not punching holes or adding white pixels may be used to provide a marker on all knit unpunched or black pixel rows for hand techniques to take place, ie in the repeat planned for 194.

With the charts as guides, partial punchcard repeats for the three designs:  Punchcards ideally require a minimum of 36 punched pattern rows to roll accurately, the single, smallest repeat segment is adequate for knitting on electronic machines.

Punchcards ideally require a minimum of 36 punched pattern rows to roll accurately, the single, smallest repeat segment is adequate for knitting on electronic machines.

I knit primarily on a 930 and prefer to tile the repeats in width to the number of needles in my samples. The single motif button, default on the 930, need not then be reset and the design will be automatically centered. It is not a necessary step. Centering any single repeat across the needles in use or otherwise placing it may be achieved by programming its position. In punchcard machines, the selection is fixed across the 24 stitch markings on the needle tape, other positioning may be achieved by shifting the knitting in its position on the needle bed.

My illustrations are achieved by using both Mac Numbers and Gimp.

Adding color to help visualize hand techniques, and tiling to check alignments:

192 is 8 rows in height, more than that is needed to indicate the locations for hooking loops up. It appears this happens on white squares in the published original chart, which translate to knit stitch locations, the punched holes in the card.

For some transfer locations, no needle selection clues are provided, and they are made based on visual identification.

If the transfer is to be made onto a preselected needle, push the appropriate needle back to the B position.

Visually follow the rows down to locate the appropriate tuck loop(s),

lift them onto the needle just put it back to B,

and push that same needle out to the E position after the hook up in order to form a knit stitch with the next carriage pass.

The repeat with the most frequent hand technique is 192, with hookups every 8 rows

![]()

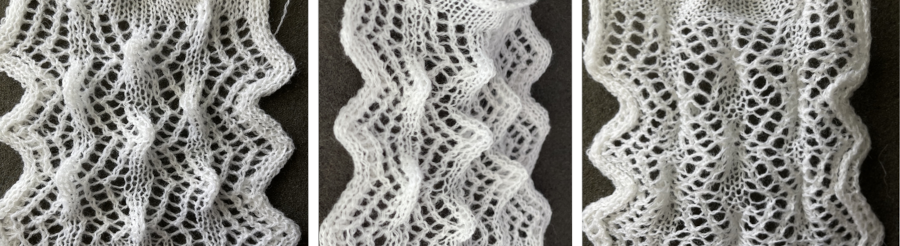

Using light color yarn makes it easier to identify the closely packed stitch structures.

Using light color yarn makes it easier to identify the closely packed stitch structures.

The tool used to pick up and rehang stitches can vary depending on personal preference.

Programming the design as an 8-row pattern allows for easier tracking in a design that requires actions to be taken at that specific interval.

Another view:

I had a hard time finding the proper spot for picking up loops and needed extra magnification in addition to my bifocals to sort that out.

I had a hard time finding the proper spot for picking up loops and needed extra magnification in addition to my bifocals to sort that out.

The wool used for the test swatches is a 2/8 weight.

Because transfers in the scanned publication are made on a tuck stitch row, these designs may be easier to execute on a Studio machine.

As Brother knits that last tuck row, it preselects every needle for the knit row that will happen with the next carriage pass from the opposite side. I found the location easier to track for the hand technique a row early, before the every-needle preselection.

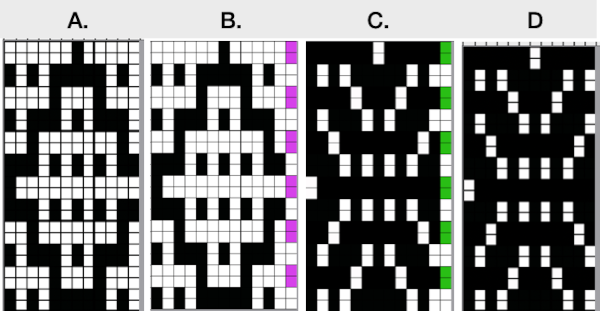

The effect is subtle and time-consuming, a consideration if planning larger pieces of knitting.  193 is 20 rows high, with hookups every 10.

193 is 20 rows high, with hookups every 10. ![]()

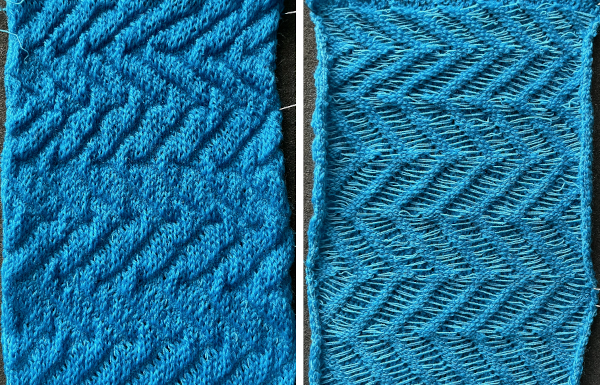

In the concept swatch, some of the tuck stitches were eliminated, seen here in a 48 stitch wide repeat, allowing for a released edge on either side. The tiled X2 in height repeat checks its vertical alignment.

In the concept swatch, some of the tuck stitches were eliminated, seen here in a 48 stitch wide repeat, allowing for a released edge on either side. The tiled X2 in height repeat checks its vertical alignment. ![]()

This time as many of the compounded knit and tuck loops as possible were moved, producing more detailed surface textures on the knit side

This time as many of the compounded knit and tuck loops as possible were moved, producing more detailed surface textures on the knit side  194 is 48 rows high, with hookups also every 8 rows. The single 24X 48 png is followed by the tiled 48 stitches wide version and the tiled Gimp alignment check

194 is 48 rows high, with hookups also every 8 rows. The single 24X 48 png is followed by the tiled 48 stitches wide version and the tiled Gimp alignment check ![]()

![]()

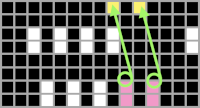

The visualization of stitch/loop movements

The visualization of stitch/loop movements  The hand technique occurs after an all-knit row, which in cards would be all punched, in electronics all black pixels.

The hand technique occurs after an all-knit row, which in cards would be all punched, in electronics all black pixels.

In Brother kms, while the first all-knit row is made, the next with isolated pairs of preselected needles will occur.

Prior to moving the carriage to the opposite side, hook up from highlighted locations, and bring needles out to E after doing so.  As the carriage travels across the bed again, all knit stitches will form while preselecting for the subsequent tuck stitch row. A rhythm will develop eventually.

As the carriage travels across the bed again, all knit stitches will form while preselecting for the subsequent tuck stitch row. A rhythm will develop eventually.

Notes to self:

some days it is not good to be near a knitting machine

cables and intensive hand techniques are still on my avoid if at all possible list

keep an eye on broken ends of yarn in old cones at least periodically before knitting across whole rows

if knitting lengths of this technique, or even a large swatch, removing the ribber if it is in use will facilitate the process. Remember to check its balance when it is recoupled with the main bed

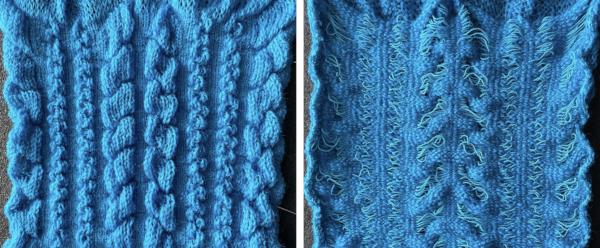

while you are busy keeping an eye out on what to pick up and which stitches did not form properly or are jumping off the main bed, remember to look up at the yarn mast periodically, especially if the tension appears to change suddenly  An improvement, however, over this masterpiece a decade ago when working in my attic supplementary studio space 😉

An improvement, however, over this masterpiece a decade ago when working in my attic supplementary studio space 😉  Although all hooking up aka ruching is in the same direction, there is no apparent biasing. This fabric is quite compressed, not for someone without a lot of focus, patience, and good eyesight.

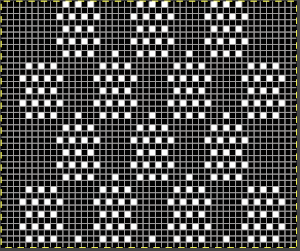

Although all hooking up aka ruching is in the same direction, there is no apparent biasing. This fabric is quite compressed, not for someone without a lot of focus, patience, and good eyesight.  This pattern emulates the wishbone trim familiar to many knitters. It is the easiest in the series to execute, with the most textured result. The knit repeat used in the swatch is 26 stitches wide and can be trimmed easily to 24 stitches wide for use with punchcard machines.

This pattern emulates the wishbone trim familiar to many knitters. It is the easiest in the series to execute, with the most textured result. The knit repeat used in the swatch is 26 stitches wide and can be trimmed easily to 24 stitches wide for use with punchcard machines.

The heels above the designated tucked stitches at the bottom of each repeat are lifted up and onto the single unselected needle of an all-knit row.

End needle selection is on, and the tuck setting in both directions is used after the initial preselection row.

Though initially an all-knit border was planned on each side, several knit stitches were eliminated on one side of the swatch. The difference is seen in the edges of the work, where all-knit stitches are allowed to roll, creating a very different “trim” than where tuck patterning was left uninterrupted. Such rolls can make satisfactory added details along accessories such as scarves, where a few rows of all knit stitches may also be allowed to roll to the purl side at the top and bottom of the piece as a finishing alternative.

The 26X16 single repeat. ![]() Tiled repeat, checking alignment

Tiled repeat, checking alignment  Charted information

Charted information  The proof of concept swatch

The proof of concept swatch  A mock cable trim may be knit separately, in any color or even multiple colors, and applied as you knit on a large piece or stitched on after the fact.

A mock cable trim may be knit separately, in any color or even multiple colors, and applied as you knit on a large piece or stitched on after the fact.

One variation as a hand technique: after a closed cast-on on 10 stitches, knit 10 rows.

Pick up the second stitch from each side of the original cast-on row, and hook up on needles 5 and 6 on each side of the center. Knit 10 rows.

Pick up the second stitch from each side 10 rows below, hang on needles 5 and 6 on each side of the center, and repeat to the desired length.

Color changes may be added every 10 rows when all knit selection is made.

The slip stitch setting in this case is used to track and facilitate the process.

End needle selection is on, with the knit carriage set to slip in both directions, with the first preselection row made after at least one base knit row.

Weight may not be necessary depending on how comfortable one is with managing the knit without them and the yarn being used.

The repeat, in turn, is tiled twice in height in the shared png

![]() A short slip stitch float will form in the location of the white pixels at the bottom of the chart and when the selection is made to match the top row of the repeat, the single float is picked up and hung on the unselected needles,

A short slip stitch float will form in the location of the white pixels at the bottom of the chart and when the selection is made to match the top row of the repeat, the single float is picked up and hung on the unselected needles,  Those needles are brought out to E position after the transfers.

Those needles are brought out to E position after the transfers.

At that point, prior to the next carriage pass, the color may be changed. The short single skipped stitch floats are shown more clearly in this image.  When changing colors it is best to use yarns of the same thickness that will knit easily at the same tension, not done in the first shape in this sample.

When changing colors it is best to use yarns of the same thickness that will knit easily at the same tension, not done in the first shape in this sample.

If using 2 carriages operating from opposite sides to carry different color(s) remember that extension rails will need to be used, as both will be selecting needles and will anchor onto the belt to do so.

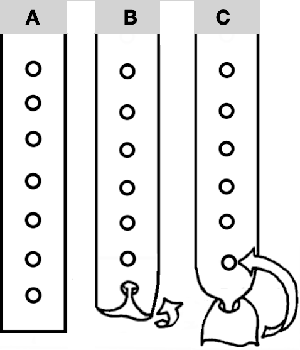

Floats will happen at the side(s) as colors are carried up, but they and cut yarn ends can be hidden when the trim is applied.  Here a fixed number of stitches +1=11 is knit for a fixed number of rows

Here a fixed number of stitches +1=11 is knit for a fixed number of rows

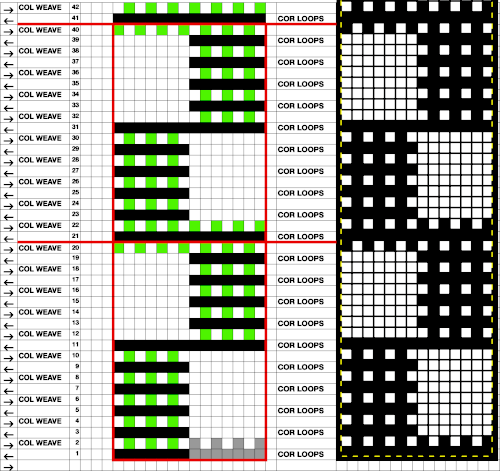

an eyelet is created every 10 rows A

A single eyelet was sufficient to allow for feeding the trim through on the same side and from the bottom up, B and C, upon completion of the planned strip length. The red sample on the left is knit with 2/18 silk/wool, the blue is 2/wool. It is best to avoid any fiber that will pill easily.

The blue samples were knit for 65 rows each.  In DIY, begin a test by casting on an odd number of needles (11, chart row 0)

In DIY, begin a test by casting on an odd number of needles (11, chart row 0)

if all needles are not properly formed after a permanent cast-on, bring all needles out to E for the first 2 or 3 rows

insert a claw weight

knit the same number of rows as cast on -1 (10)

transfer a needle to the left or right so as to maintain an even number of needles on each side after the transfer, making certain the empty needle is in the work position before the next carriage pass (chart row 10)

as you knit to the opposite side a loop will form on the empty needle, the eyelet location (chart row 11)

a carriage pass to the opposite side will form the full stitch in the loop location (chart row 12)

The charted working repeat for the trims below is outlined in red

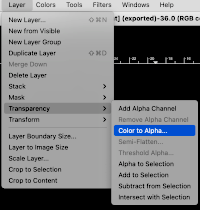

ArahPaint and Gimp in knit design 3

Previously published:

ArahPaint and Gimp in knit design 2

ArahPaint meets Gimp in knit design 1

Subsequent posts on using Gimp Layers to process images:

Using Layers in Gimp for color separations

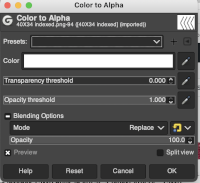

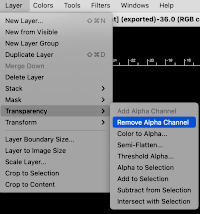

Layer/Transparency/Color to Alpha Gimp Update for Mac 3_more on color separations

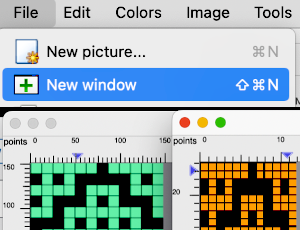

Gimp allows one to work on multiple images with only a single window open, left mouse clicking on any one of the images will bring it into view for editing. In the dark theme, it is hard to see the difference, but a lighter border actually surrounds the active image distinguishing it from the others, outlined here in yellow  In Arah, multiple windows may be opened at any one time, and left-clicking on any one of them will bring it to the front for editing.

In Arah, multiple windows may be opened at any one time, and left-clicking on any one of them will bring it to the front for editing.  When working using the same file in more than one window, the degree of magnification needs to match in each.

When working using the same file in more than one window, the degree of magnification needs to match in each.

Spreadsheets and paint programs may be used to achieve color separations for designs intended for specialty fabrics, many worked on the double bed.

Two places to begin exploring them here are for knitting single-bed mosaics and double-bed jacquard in its form where each color in each design row knits twice.

It is unlikely to happen often in knitting that more than 6 colors are used in any one fabric except perhaps in an elaborate color-changing fair isle.

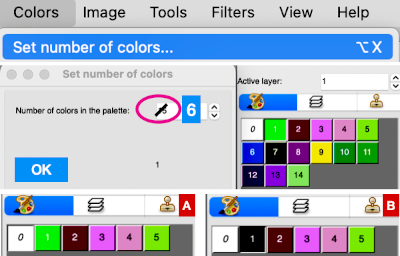

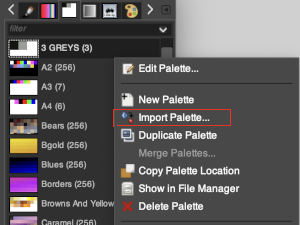

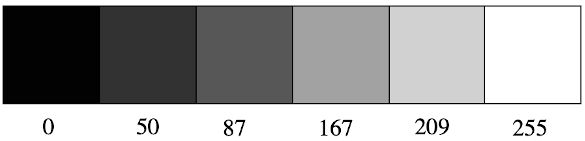

The palette that appears in Arah when opening a new file is random, as seen here when two new files of the same size are loaded  If one’s preference is to reduce the number of colors, the specific number may be set by choosing from the colors menu, editing the number identified as that for the working palette, changing it to the new value, in this case, 6, and the palette reduction occurs as seen in A. For most knit repeats a black color is handy, any one of the 6 colors or more may be adjusted as described in the previous post, seen in B, where black has been added, replacing the color in position 1.

If one’s preference is to reduce the number of colors, the specific number may be set by choosing from the colors menu, editing the number identified as that for the working palette, changing it to the new value, in this case, 6, and the palette reduction occurs as seen in A. For most knit repeats a black color is handy, any one of the 6 colors or more may be adjusted as described in the previous post, seen in B, where black has been added, replacing the color in position 1.  More Gimp information: https://docs.gimp.org/2.10/en/gimp-palette-dialog.html

More Gimp information: https://docs.gimp.org/2.10/en/gimp-palette-dialog.html

Some of the related content in brief: the former versions of GIMP had a “Save palette” command. Palettes were stored in a specific folder via the preferences pane. Easy to do and manage. It no longer exists.

To save the palette of an image, indexed or not, you must now import it from the image.

The “Palettes” dialog is dockable: from the Image menu, select Window, Dockable Dialogues, Palettes.

A few dozen more or less randomly chosen palettes are supplied with GIMP.“Import Palette” allows you to create a new palette from the colors in a gradient, image, or palette file.

Right-click in the space to the right of the illustrated palettes to call up the import option, or for palette editing.  It is not necessary to index the image, this image was used in RGB mode.

It is not necessary to index the image, this image was used in RGB mode.  A palette name can be assigned, and if previously used, a number will be appended by the program.

A palette name can be assigned, and if previously used, a number will be appended by the program.

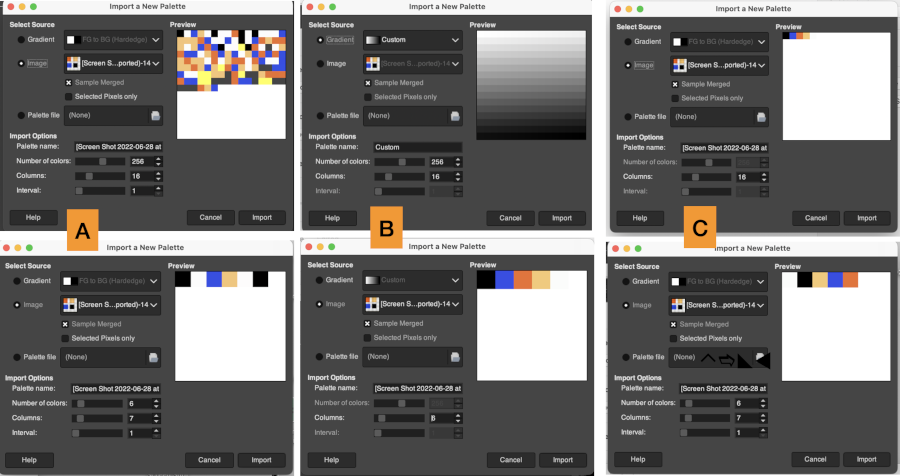

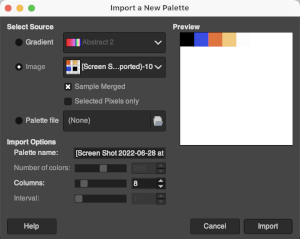

The number of colors: the default is 256, you can set the number to any you choose. Gimp will try to create a palette by spacing the number of colors evenly across the range of the gradient or image. Each screengrab in the top row shows the initial selections for gradient or image, and the second row of screengrabs notes other changes made when choices were available and the results. White dots mark selections as seen while using the program.  Using the same image, indexed to 5 colors, the custom palette is rendered in a one-step process. The gradient seen in the first position on the top left was randomly assigned by the program and does not influence the results.

Using the same image, indexed to 5 colors, the custom palette is rendered in a one-step process. The gradient seen in the first position on the top left was randomly assigned by the program and does not influence the results.  The Columns selection number settings only influence the way the palette is displayed and have no effect on the way the palette is used. The lower the number, the larger the display size of each color unit.

The Columns selection number settings only influence the way the palette is displayed and have no effect on the way the palette is used. The lower the number, the larger the display size of each color unit.

Double-clicking on any palette color will magnify the palette view on the theme color background. Left-clicking on any color makes it available for drawing, the selection will have a dotted bounding line and the selected color will be assigned to the foreground position, ![]()

Right-clicking on a color results in these options.

Right-clicking on a color results in these options.  The imported palette will be added to the Palettes dialog and is automatically saved in your personal palettes folder when you quit GIMP so that it will be available in future sessions.

The imported palette will be added to the Palettes dialog and is automatically saved in your personal palettes folder when you quit GIMP so that it will be available in future sessions.

In Arah, the color palette will always display the colors of the active layer. The working image contains colors intended for use in my designs. In addition, please see the note from the developer in the comment at the end of the post.  The palette tools:

The palette tools:  A: if you press this icon the program will underline the colors actually used in the image, since all colors are used in this case, each color is underlined in either white or black in this instance

A: if you press this icon the program will underline the colors actually used in the image, since all colors are used in this case, each color is underlined in either white or black in this instance  D: adds color(s) to the palette

D: adds color(s) to the palette  B: removes unused colors in the above palette, it would restore the original colors

B: removes unused colors in the above palette, it would restore the original colors

C: removes duplicate colors, not applicable in this instance

E: removes the last unused color, will not work if all colors are used.

Changing color positions in the palette: to switch the position of two colors in the palette, click the chosen color in the palette, move the cursor to the color you want to switch the position with, and press the left mouse button while holding the Ctrl key on the keyboard. In this instance, the color was duplicated in the new position.  Knitters designing for dbj are likely to work with a limited range of colors, often 3 or 4 max, in specific palette ranges to ready images for download.

Knitters designing for dbj are likely to work with a limited range of colors, often 3 or 4 max, in specific palette ranges to ready images for download.

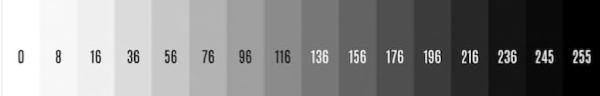

If color separations for 3 or more colors are done in shades of grey in terms of technical details, you need a pattern image that is 8-bit greyscale, with each color in a range of 8-bit values. So for 4 colors, it would be 0-63 color 1; 64-127 color 2; 128-195 color 3; 196-255 color 4.

Binary images have only 2 possible intensity values, normally displayed as black and white with values of either 1 or 255 for white, and often 0 for black.

That convention may have led to the selection of white as color 1 in automatic separations such as the KRC Japanese one, where white is selected first. In a greyscale or color image, a pixel can take on any value between 0 and 255.

Designing for fair isle, or when attempting to visualize and illustrate slip and tuck fabrics with frequent color changes, more colors may be required even though the final download will be in black and white. There is a quick way to add random colors assigned by the program and based on the initial palette:

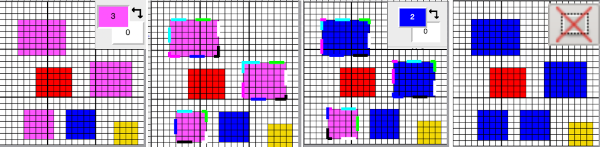

Designing for fair isle, or when attempting to visualize and illustrate slip and tuck fabrics with frequent color changes, more colors may be required even though the final download will be in black and white. There is a quick way to add random colors assigned by the program and based on the initial palette:  The magic wand tool allows you to work on consistently colored areas without having to select and outline each.

The magic wand tool allows you to work on consistently colored areas without having to select and outline each.

To alter a single color using the bucket tool, click on the wand, then on the color single color area you wish to change, it will become outlined by bounding lines.

Click on one of the colors in the expanded palette, and it will automatically appear in the foreground color position, and it may then be used to bucket fill the chosen area.  Flatten the image using the merge-down tool.

Flatten the image using the merge-down tool.

If the foreground color, in this case, white/0, needs to be changed, in order to choose all pixels in the foreground color, click on the wand, and use Tools > Select by color or Shift+W. This function works only on 8-bit pixel images. Click on the color you wish to use to replace the ground, and bucket fill with the newly selected color.  Flatten the image using the merge-down tool.

Flatten the image using the merge-down tool.

Changing multiple color blocks in the same color could be selected by the tool, but filling each of them one at a time was required.  In Gimp a similar tool is the fuzzy select, which also allows for changing the color in a selected area or for selecting and changing all pixels in that color. Selected areas will also be outlined in dashed bounding lines. Bucket fill may then be used to replace color(s). The option is offered to choose either foreground or background for the fill.

In Gimp a similar tool is the fuzzy select, which also allows for changing the color in a selected area or for selecting and changing all pixels in that color. Selected areas will also be outlined in dashed bounding lines. Bucket fill may then be used to replace color(s). The option is offered to choose either foreground or background for the fill.

2023 in Gimp 2.10.34 use and hold the shift key prior to selecting and using the bucket fill tool to change all the areas outlined by dashed lines. The bucket-fill tool itself now works again on any area with a defined boundary, no other, following action is necessary.

2023 in Gimp 2.10.34 use and hold the shift key prior to selecting and using the bucket fill tool to change all the areas outlined by dashed lines. The bucket-fill tool itself now works again on any area with a defined boundary, no other, following action is necessary.

Click on the rectangle select tool and then on any spot in the work area or on the image to set the image. The dashed lines will disappear.

In terms of saving the palette in Arah for future use, I saw no specific directions in the manual.

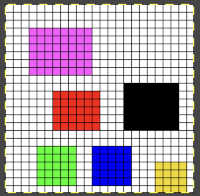

The color palette displayed is always the one used in the active layer. As a workaround: open the image, and the associated palette will be displayed. The repeat begins drawn 24 pixels in width, by 24 in height.

Select clear from the edit menu, or bucket fill area with white

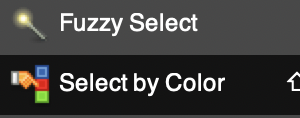

If the size of your intended drawing area is different, choose the option Resize Image from the Image menu. With the chain link intact, the new canvases are created keeping the aspect ratio. Enter a new value for width/height, hit return, or move the cursor to the alternate value, and its number will automatically change to a matching one. Click OK to use the new canvas, or reset if you wish to return to the original 24 by 24 pixel one for a different edit.

With a broken chain link as one of the two values is altered, a preview is available. If both values are to be changed, break the chain link, enter the two values in turn, and a preview appears for each step. Ok is used again prior to saving, or choose reset to return to the previously used setting.

![]() Color separations can make specialty fabrics possible to knit which are outside the possibility of doing so simply by changing cam settings. Two instances are mosaics and DBJ where each color in each design row knits twice. Separating each may be done in two ways. The first method, convenient for longer repeats, requires that the result be elongated X 2, whether in the repeat design software or after download to the machine or using the elongation X2 function in the punchcard models. For illustration purposes here I will be working to create files that do not require elongation.

Color separations can make specialty fabrics possible to knit which are outside the possibility of doing so simply by changing cam settings. Two instances are mosaics and DBJ where each color in each design row knits twice. Separating each may be done in two ways. The first method, convenient for longer repeats, requires that the result be elongated X 2, whether in the repeat design software or after download to the machine or using the elongation X2 function in the punchcard models. For illustration purposes here I will be working to create files that do not require elongation.

Mosaics and Mazes are constructed in similar ways and are sometimes referred to as floatless fair-isle even though technically speaking usually 2 stitch floats do appear on the purl side in the alternate color used with each color change.

Many such repeats may be knit using both the slip and tuck settings, the latter is the more interesting of the two on the purl side.

When learning structures it may be worth beginning with a published design.

Kathleen Kinder decades ago published two books, one with 24 stitch repeats, the other with 40 stitch repeats, with the separations included as well  This, by Barbra Walker and intended for hand knitting, offers a huge library of designs for inspiration and conversion

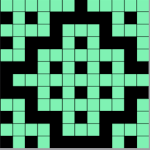

This, by Barbra Walker and intended for hand knitting, offers a huge library of designs for inspiration and conversion  Following specific rules it is also possible to develop DIY repeats from scratch. That said, the repeat used in this blog post happens to have a known value of 12 pixels by 12

Following specific rules it is also possible to develop DIY repeats from scratch. That said, the repeat used in this blog post happens to have a known value of 12 pixels by 12 Magnification in Gimp is achieved by selecting or typing in new percentages at the bottom of the window.

Magnification in Gimp is achieved by selecting or typing in new percentages at the bottom of the window.

Entering and exiting the full screen may be controlled via the view menu

Entering and exiting the full screen may be controlled via the view menu  To exit, it right-click at the very top of the window to expose menu options and select deselect full screen.

To exit, it right-click at the very top of the window to expose menu options and select deselect full screen.  In Arah, if you press any number from 0-9 on the keyboard, you will change the zoom directly to that level (1 means 100%, 6 means 600%, 0 means 1000%). The plus + and minus keys- as well as the magnifying lens icons, will zoom in and out

In Arah, if you press any number from 0-9 on the keyboard, you will change the zoom directly to that level (1 means 100%, 6 means 600%, 0 means 1000%). The plus + and minus keys- as well as the magnifying lens icons, will zoom in and out  To use the entire space available in the window, choose Fit to Window from the view menu or select Ctrl+zero.

To use the entire space available in the window, choose Fit to Window from the view menu or select Ctrl+zero.

If working in more than one window this option makes repeats the most visible, scaling back can be done by counting the number of selections, helping to match the new picture magnification to the first.

Press the escape key on the keyboard to return to the original 100% view.

To work using the full screen, select the option from the view menu. To exit, right-click at the very top of the window to expose menu options, and select exit full screen  Separating the design: ultimately the planned final graphic repeat would be a BW png used for electronic download, programmed as a fair isle one, but knit using tuck or slip settings, it may be drawn initially using only in those 2 colors. Black may need to be added to the palette selections.

Separating the design: ultimately the planned final graphic repeat would be a BW png used for electronic download, programmed as a fair isle one, but knit using tuck or slip settings, it may be drawn initially using only in those 2 colors. Black may need to be added to the palette selections.

One may always draw on a large canvas and then crop as needed, but as a starting point, it may be easier to simply match canvas size to the published repeat being used.

It is handy to have an extra column to help track image processing during the separation, the repeat above is identified as being composed of 12X12 pixels, one could begin with a 13X12 canvas.

A second way to provide the 13th column is to work using 2 windows, matching magnification, and the second with a different, larger pixel measurement than the first. Copy the contents of the original work area and paste them into the larger canvas in the other window. Crop to new size if necessary.

To illustrate the two-window process, here the original BW repeat has already been drawn and elongated X2

A. Use the rectangle-select tool to capture the whole image in the first window, bounding lines in the colors of the palette in use will outline the selected area

B. Use the edit menu or command C to copy the selection, edit paste, or command V in the new window to place it.

When pasting on a different size ground, the bounding lines will also appear in the new image, the contents remain moveable,

C. Place the selection where desired on the new canvas, when satisfied use the X, merge down tool to flatten it.

The quicker method begins with a canvas one pixel wider than the repeat, 13X12.

The quicker method begins with a canvas one pixel wider than the repeat, 13X12.

Adjust magnification, for comfortable viewing in the editing process.

View: show grid 2

Colors: set the number of colors to 6, and adjust the #1 color to black, white is in position 0 in the palette by default

Activate the pencil tool, and draw a vertical line on the far right in an easy-to-see color choice other than white or black

Using black, fill in pixels for your first draft of the pattern repeat

Image multiply YX2, resulting in 13X24

Using the pencil tool fill in the first 2 design rows followed by every other pair with white.  Magnify image A to a comfortable work viewing size.

Magnify image A to a comfortable work viewing size.

B and C: using the rectangle select tool, with the left mouse button, place the pointer on the purple pixel, drag the mouse across each pair of marked rows,  release the mouse, and use Command I to color invert, and merge down

release the mouse, and use Command I to color invert, and merge down to eliminate the bounding box.

to eliminate the bounding box.

The purple pixels will change color as well, making it easier to track what rows have been altered already.

D: crop the image, removing the row with colored cells for the final repeat

If for some reason you are processing an image that is color reversed, the steps are identical, but tuck or slip stitch fabrics, black pixels or punched holes knit, white pixels or unpunched squares tuck or slip. For this reason, the cropped final result would need to be color inverted prior to knitting or punching holes.

If for some reason you are processing an image that is color reversed, the steps are identical, but tuck or slip stitch fabrics, black pixels or punched holes knit, white pixels or unpunched squares tuck or slip. For this reason, the cropped final result would need to be color inverted prior to knitting or punching holes.  This separation for 2-color DBJ results in its potential use in many fabrics other than DBJ and may be performed by some programs used to download multiple color patterns to the machines prior to knitting the fabric. One such fabric is drop-stitch lace.

This separation for 2-color DBJ results in its potential use in many fabrics other than DBJ and may be performed by some programs used to download multiple color patterns to the machines prior to knitting the fabric. One such fabric is drop-stitch lace.

Punchcard machine users would need to separate the colors manually, or if Dak is available, the separation may be done using the program and a corresponding template may be printed as a guide to punching holes.

This method is the automatic default one for any 2-color DBJ knit on the Passap.

Each color in each design row will be knit with each pair of consecutive color passes. Completing one design row containing 3 colors will require 6 carriage passes, 4 colors 8, and so on.

The built-in color separation in electronic machines wherein each of only 2 colors in each design row knits only once does not apply when using more than two colors, though it is possible using Dak or by downloading a special card reader technique to program separately from the design when using the Passap E6000 in addition to the pattern repeat.

This separation of a 2 color pattern results in an elongated version of the design regardless of any dbj backing used.

Begin with a 2 color image,  an extra column of pixels is added here as well:

an extra column of pixels is added here as well:

A: multiply YX4 to 13X48

B: mark alternating pairs of rows in the extra column with a contrasting color

C: following the color cues on the far right column, on rows with no added color use the pencil tool to replace black pixels with white, leaving only the orange cells

D: on rows marked with the third color replace the orange pixels with white, leaving only the black pixels

E: crop the image eliminating the extra column

adjust the remaining orange color to black

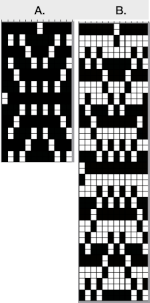

index the result to B/W, and the image is ready to save and use  The difference between single repeats for each type of fabric, no further elongation is required. A: mosaic, B: DBJ

The difference between single repeats for each type of fabric, no further elongation is required. A: mosaic, B: DBJ Using layers in Gimp opens up the possibility of several color separations for fabrics using only 2 colors.

Using layers in Gimp opens up the possibility of several color separations for fabrics using only 2 colors.

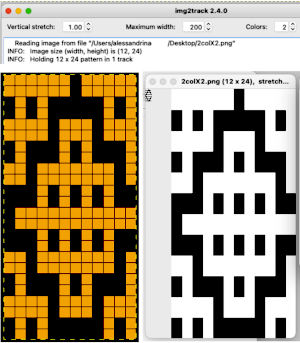

Both img2track and Ayab are capable of opening 2 color images.

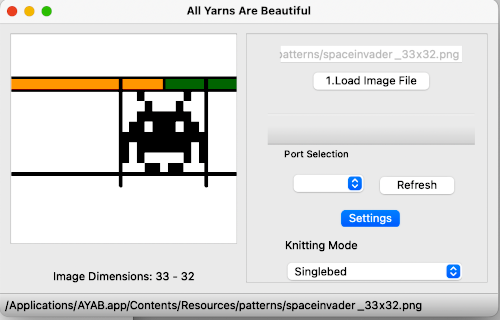

In img2track this is what would appear, after the download the KRC function needs to be activated in the knitting machine.  Ayab: the repeat should be programmed in width equal to the number of needles planned to be in use. The color change happens as the file is loaded into the program, the ribber classic option is used

Ayab: the repeat should be programmed in width equal to the number of needles planned to be in use. The color change happens as the file is loaded into the program, the ribber classic option is used  to render results that would match the KRC knitting machine selection after an img2track download. Here the repeat is also tiled in height.

to render results that would match the KRC knitting machine selection after an img2track download. Here the repeat is also tiled in height.  My personal preference is to work with images designed in black and white. With the 910 presently stored, my blog swatches are knit on a 930 using img2track.

My personal preference is to work with images designed in black and white. With the 910 presently stored, my blog swatches are knit on a 930 using img2track.

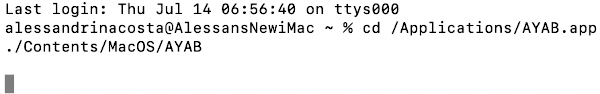

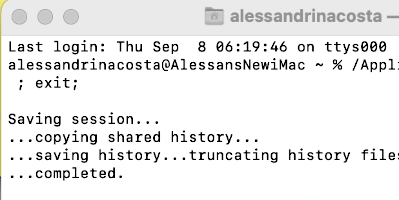

A note for Mac users like myself using desktops with the M1 chip and Mac OS Monterey. Img2 track requires an FTDI driver for its download cable, on June 6 finally released a beta version of a more recent driver, I do not plan to install it at this moment, function in the upcoming Ventura OS would be unknown. ![]() Ayab does not launch automatically. These are the steps necessary to run the program, following suggestions by Adrienne Hunter via the Ayab FB group:

Ayab does not launch automatically. These are the steps necessary to run the program, following suggestions by Adrienne Hunter via the Ayab FB group:

open a Terminal window (Applications/Utilities/Terminal) and type these two lines:

cd /Applications/AYAB.app

./Contents/MacOS/AYAB

The app may also be found and then opened via using Spotlight search if you prefer  Once the program is quit unless you choose to keep the terminal icon

Once the program is quit unless you choose to keep the terminal icon

in your dock, it will disappear and the above process will need to be repeated. Once the text has been entered, and Ayab has been launched, a message similar to this will appear, showing your last log in.

in your dock, it will disappear and the above process will need to be repeated. Once the text has been entered, and Ayab has been launched, a message similar to this will appear, showing your last log in.![]() To launch Ayab again, simply use the up arrow key and hit return to repeat the command

To launch Ayab again, simply use the up arrow key and hit return to repeat the command  Creating an AYAB desktop shortcut for Mac that will work without opening the terminal each time

Creating an AYAB desktop shortcut for Mac that will work without opening the terminal each time

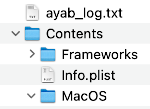

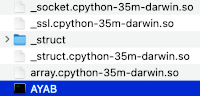

Using Finder, open Applications and find AYAB. Right-click on AYAB and select “Show Package Contents”.

Locate “AYAB” under MacOS.

Locate “AYAB” under MacOS.  While holding down the command and option buttons, click and drag that icon to the desktop. This will create an ayab shortcut that does the terminal stuff for you

While holding down the command and option buttons, click and drag that icon to the desktop. This will create an ayab shortcut that does the terminal stuff for you  you can change the icon by copying and pasting the icon image in “get info” but it works fine without it. These icons will appear in your dock after double clicking on the icon

you can change the icon by copying and pasting the icon image in “get info” but it works fine without it. These icons will appear in your dock after double clicking on the icon  The ayab window opens with only the load image option highlighted

The ayab window opens with only the load image option highlighted  Click on the load image file to open an image, and the remaining features of the program will now be available

Click on the load image file to open an image, and the remaining features of the program will now be available  If you quit ayab, the terminal window remains active

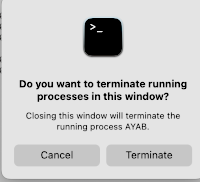

If you quit ayab, the terminal window remains active  Quitting terminal called up this window for me only the first time I did so.

Quitting terminal called up this window for me only the first time I did so.

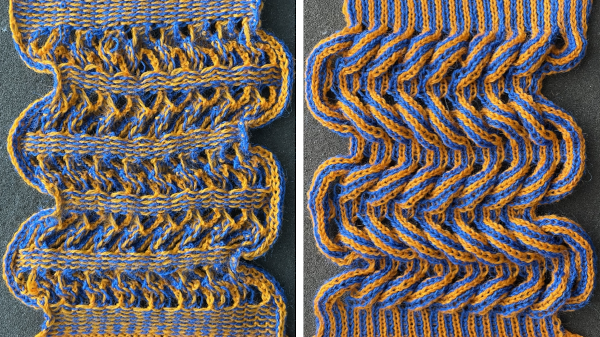

Knitting with “unusual” fibers/ elastic 3

There is always more to explore in any technique.

My blog is a living document, I often add new swatches to previous posts, but sometimes choose as here, to add a new post to a growing collection of information on specific topics.

I shared two previous posts on working with elastic: 1, and 2. Many of the same design repeats may be hand knit or using a G carriage to produce pleated knit and purl knits.

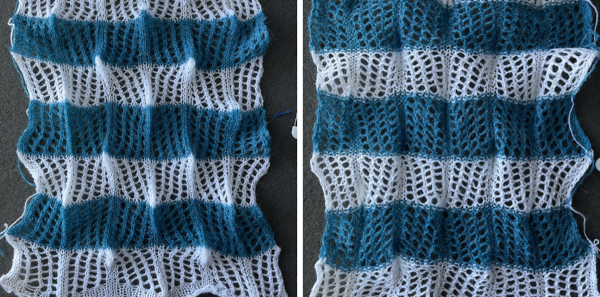

A sample of a pattern similar to the block ones executed below, knit on the machine using hand transfers between beds.

Changing yarns sometimes even simply using a different dye lot, tensions, or elastic manufacturer brands or colors can alter the appearance of the results significantly.

Changing yarns sometimes even simply using a different dye lot, tensions, or elastic manufacturer brands or colors can alter the appearance of the results significantly.

A previous post shared that the traditional yarn positions for the thick and thin yarns in the feeders need to be reversed when using the elastic for 3D effects. At times as I return to previous posts I find that explanations or reasons for the recommended directions are missing, especially if the steps appeared to be obvious at that moment in time.

I recently initially assessed the need for the position swap in thread lace using elastic as an “oddity” on my machine. It took a Ravelry response to remind me of the float formation in this fabric.

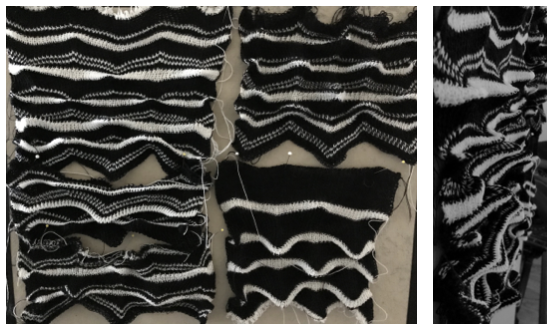

In review: the “lace holes” are formed by knitting a fine thread with a significantly thicker yarn as the “second color”. When the fine yarn knits, a larger stitch in it alone is formed on the knit face of the fabric, with the thicker yarn floating behind it. The thicker yarn goes in Brother’s A feeder, the thinner in B. The resulting effect, shown in a previous post  An ancient elastic sample and the corresponding punchcard using elastic as the “thin” yarn.

An ancient elastic sample and the corresponding punchcard using elastic as the “thin” yarn.  Using the traditional yarn positions: both yarns would knit on needles that are not selected, corresponding to the unpunched squares in the card. The thin yarn alone would knit on needles corresponding to the punched holes, with the thick yarn floating behind it. To create the punched shapes as puckers with the elastic floating behind them, if the yarn positions are switched in the feeders, both yarns still knit together where there are no punched holes (or pixels), and the thin yarn (elastic) will float behind the shapes in the other fiber, creating the resulting 3D textures.

Using the traditional yarn positions: both yarns would knit on needles that are not selected, corresponding to the unpunched squares in the card. The thin yarn alone would knit on needles corresponding to the punched holes, with the thick yarn floating behind it. To create the punched shapes as puckers with the elastic floating behind them, if the yarn positions are switched in the feeders, both yarns still knit together where there are no punched holes (or pixels), and the thin yarn (elastic) will float behind the shapes in the other fiber, creating the resulting 3D textures.

My present elastic stash includes a small supply of 2 colors of recently purchased elastic and a purple cone of equal weight from my teaching days (UKI, no longer manufactured).

Another UK source for 2 thicknesses sold in varied size cones https://airedaleyarns.co.uk/index.php/yarns-fibres-for/knitting-machine/boomerang-2ply-3ply-lycra-yarn.html also lists international shipping rates https://airedaleyarns.co.uk/index.php/postage.html.

The blue yarn in these beginning tests is a 2/20 wool, the elastic a combination of the purple and blue threaded together in the tension unit.

When elastic is old, it loses the ability to spring back when used in knits though when tugged on manually it may appear to have a good recovery response to stretching. The result can be seen on the purl side of the swatches. When on the machine both threads appeared to be feeding evenly and smoothly with no contrast, while when off the machine, the purple does not recover and its floats are loose and droopy compared to the blue.

End needle selection is canceled. If for some reason end needles come out to the patterning position, they should be pushed back manually. The amount of weight used, if any, depends on the yarn and tension but also on the knitter’s preference.

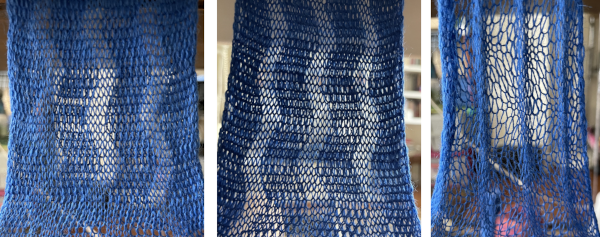

The fabric shrinks considerably in width when off the machine. Any plain knitting above or below the rows worked in the pattern will ruffle, making end-use suitable in bands for that purpose.

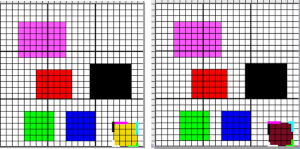

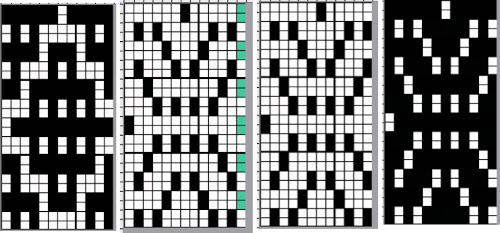

These first tests explore evenly distributed black/white pixels planned first for a 50X24 repeat, A, with borders of white pixels on each side where both yarns will knit together. ![]() A shorter repeat, B, with smaller blocks, 51X16

A shorter repeat, B, with smaller blocks, 51X16 ![]() The charted repeats are shown in a single width, repeated twice in height, and are also suitable for punchcard machines.

The charted repeats are shown in a single width, repeated twice in height, and are also suitable for punchcard machines.  On the machine: when using the thread lace setting for these fabrics, generally the pattern is programmed so that the floats on the back of the fabric are created by the elastic yarns being used, intended to gather the results for the 3D texture on the knit side. The tool here is inserted beneath the elastic floats, the wrong yarn selection is shown below it, with the wool rather than the elastic forming the floats, the result if using standard yarn positions.

On the machine: when using the thread lace setting for these fabrics, generally the pattern is programmed so that the floats on the back of the fabric are created by the elastic yarns being used, intended to gather the results for the 3D texture on the knit side. The tool here is inserted beneath the elastic floats, the wrong yarn selection is shown below it, with the wool rather than the elastic forming the floats, the result if using standard yarn positions.

In patterns where positive and negative design spaces are equal, this is less of a factor.

In patterns where positive and negative design spaces are equal, this is less of a factor.

Comparing results: A  B:

B:  Notice the purple elastic droop. The fabric is similar to some of my racked samples such as this one, but it is knit single bed, far quicker and easier to produce, but the floats on the purl side are merit consideration when planning end-use.

Notice the purple elastic droop. The fabric is similar to some of my racked samples such as this one, but it is knit single bed, far quicker and easier to produce, but the floats on the purl side are merit consideration when planning end-use.  These zig-zag variations are equal in height but with balanced numbers of black and white pixels in each row, a single repeat of 12 stitches in width is charted on the left, for 8 stitches in width on the right, making them usable in punchcard machines as well. The fabric produced does not create crisp and immediately identifiable shapes on the knit side.

These zig-zag variations are equal in height but with balanced numbers of black and white pixels in each row, a single repeat of 12 stitches in width is charted on the left, for 8 stitches in width on the right, making them usable in punchcard machines as well. The fabric produced does not create crisp and immediately identifiable shapes on the knit side.  A 60X24 repeat including a 2 stitch border using the 12X24 repeat, one of the elastic strands was not feeding as evenly as the other

A 60X24 repeat including a 2 stitch border using the 12X24 repeat, one of the elastic strands was not feeding as evenly as the other ![]()

![]()

A 60X24 repeat including a 2 stitch border using the 8X24 repeat

A 60X24 repeat including a 2 stitch border using the 8X24 repeat ![]()

![]()

When working with larger repeats the floats for the elastic get proportionately wider. A 18X22 pixel repeat ![]() Color is reversed, so white pixels will knit both yarns together, and black pixels will pull on the white areas thus creating the 3D effect

Color is reversed, so white pixels will knit both yarns together, and black pixels will pull on the white areas thus creating the 3D effect  planned for knitting on a test on 58 stitches, with both yarns knitting a border on each side,

planned for knitting on a test on 58 stitches, with both yarns knitting a border on each side, ![]()

Combining shapes of different sizes, and mirroring them ![]()

![]() The sample was knit on 75 stitches, off the machine, and relaxed it measured 5.25 inches in width, with pinning and the effort to stretch it, it reached an 8.5-inch width. A single strand of the elastic was not enough to obtain the desired effect, it was used double strand again in this final swatch.

The sample was knit on 75 stitches, off the machine, and relaxed it measured 5.25 inches in width, with pinning and the effort to stretch it, it reached an 8.5-inch width. A single strand of the elastic was not enough to obtain the desired effect, it was used double strand again in this final swatch.

The knit on the machine: the elastic is pulled tight across the fixed width between the needles, droops slightly as knitting progresses and it relaxes.

How it might begin to appear when stretched on the body or a form.

How it might begin to appear when stretched on the body or a form.

Some fair isle variations knit using one fiber that felts, the other that does not, achieve similar effects, but with far more recognizable shapes.

Here a leaf pattern is knit with UKI 3M elastic using the thread lace setting as in the above swatches.  The same repeat now knit using the fair isle setting, exchanging yarn positions with wool forming the long floats on the left, rayon chainette on the right, and followed by felting.

The same repeat now knit using the fair isle setting, exchanging yarn positions with wool forming the long floats on the left, rayon chainette on the right, and followed by felting.

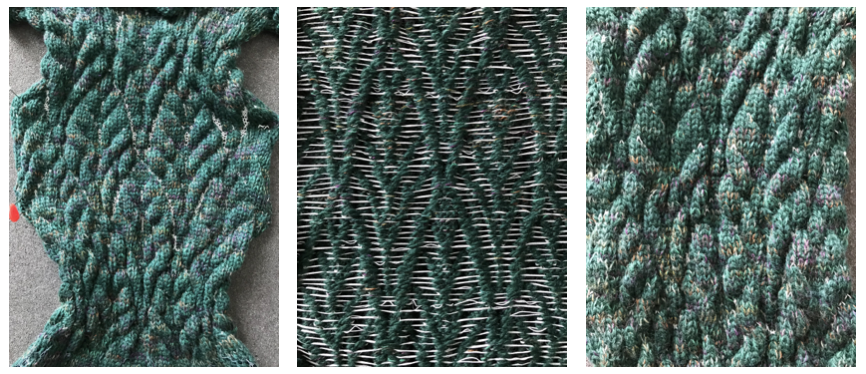

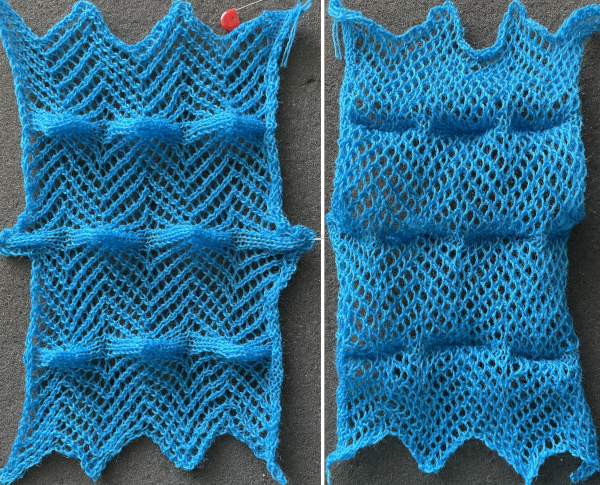

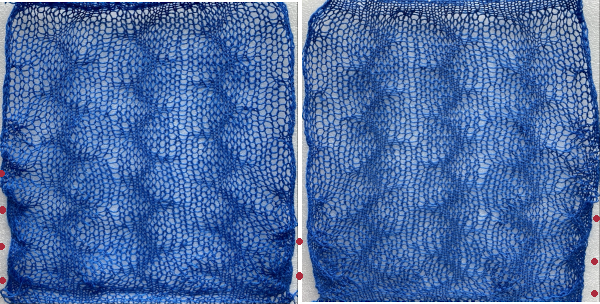

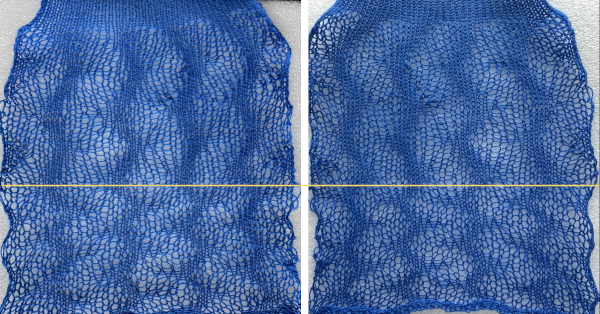

More mesh dragon scales, some striped and some not

A first look at Single bed scales made with stitch transfers:  Another look at the repeat, here it is mirrored for use on my 930, and shown in for working over 72 needles knit border stitches on both sides.

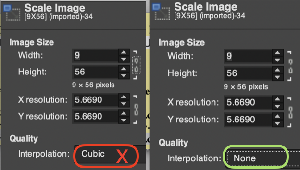

Another look at the repeat, here it is mirrored for use on my 930, and shown in for working over 72 needles knit border stitches on both sides.  A reminder: when transitioning from spreadsheet-generated repeats to indexing and then scaling them in Gimp, check that the interpolation has not been changed in the program since the last time you used it, it needs to be set to none for good results with minimal if any cleanup required.

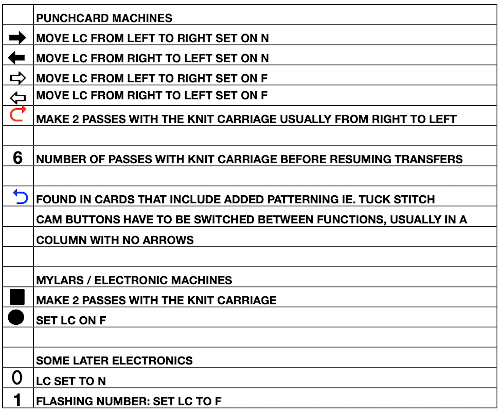

A reminder: when transitioning from spreadsheet-generated repeats to indexing and then scaling them in Gimp, check that the interpolation has not been changed in the program since the last time you used it, it needs to be set to none for good results with minimal if any cleanup required.  Analyzing what is happening: arrows on the left indicate the direction of the lace carriage moments. The LC makes 4 passes followed by two rows knit throughout with the exception when extra passes are required to place the lace carriage in the correct position for reversing the direction of the transfers.

Analyzing what is happening: arrows on the left indicate the direction of the lace carriage moments. The LC makes 4 passes followed by two rows knit throughout with the exception when extra passes are required to place the lace carriage in the correct position for reversing the direction of the transfers.

The grey columns represent all knit vertical areas.

The 3 blank rows as opposed to the usual 2 in RC 27-29 and 52-54 respectively place the LC in position to reverse transfer directions, which begin to the left on the bottom half of the pattern, to to the right after the pattern midpoint is reached. The reversal helps to create a fabric that is not flat and produces scale-like projections.  A reduced repeat before any mirroring or tiling:

A reduced repeat before any mirroring or tiling: ![]()

Whether the repeat requires mirroring or not depends on the machine used and the software used for downloads. The intention is to have the first row of transfers from left to right. Punchcard users, if the repeat is suitable, may punch and use it as given. The LC preselects on the first pass to the right, and transfers selected needles producing eyelets to the left with its second pass. In many electronic machine models, the pattern is actually opened as a FI repeat and the machine itself will automatically mirror the pattern horizontally so as to have lettering, motifs, etc. appear as drawn on the knit side. For lace and tuck patterns with needles out of work, the image may require mirroring horizontally, true on my 930.

Whether the repeat requires mirroring or not depends on the machine used and the software used for downloads. The intention is to have the first row of transfers from left to right. Punchcard users, if the repeat is suitable, may punch and use it as given. The LC preselects on the first pass to the right, and transfers selected needles producing eyelets to the left with its second pass. In many electronic machine models, the pattern is actually opened as a FI repeat and the machine itself will automatically mirror the pattern horizontally so as to have lettering, motifs, etc. appear as drawn on the knit side. For lace and tuck patterns with needles out of work, the image may require mirroring horizontally, true on my 930.

My tests with thicker yarn resulted in a flatter knit, and the LC kept having difficulty making proper transfers. Having the width of each set of transfers set at 4 means that if necessary with the specific yarn, the 7 prong tool may be used to move each group of needles in turn.

The results with easy transfers using 2/20 wool at tension 4.2, meriting further consideration for color change placements Another attempt, also shown after a light pressing and folding, pleats could be stitched to create other effects,

Another attempt, also shown after a light pressing and folding, pleats could be stitched to create other effects,  and then, seeking symmetry, finally realizing each of the above repeats has a missing pair of transfers in the top half, which may account for some of the color placements being “off”. This chart now, now 58 rows in height, appears to contain the correct number of pairs of transfers in each half repeat.

and then, seeking symmetry, finally realizing each of the above repeats has a missing pair of transfers in the top half, which may account for some of the color placements being “off”. This chart now, now 58 rows in height, appears to contain the correct number of pairs of transfers in each half repeat.

![]() Adding knit rows where transfers reverse directions, here 2 rows are knit in the base color at the end of each segment and prior to changing colors. At or immediately after design rows 28 and 56, the color in use knits for 2 rows. Color 2 follows and in turn knits for two rows, then LC use begins to select and transfer again.

Adding knit rows where transfers reverse directions, here 2 rows are knit in the base color at the end of each segment and prior to changing colors. At or immediately after design rows 28 and 56, the color in use knits for 2 rows. Color 2 follows and in turn knits for two rows, then LC use begins to select and transfer again.  At the top of this swatch, two rows are knit in the white, followed by two in the blue, and two in the white again before continuing with transfers.

At the top of this swatch, two rows are knit in the white, followed by two in the blue, and two in the white again before continuing with transfers.  The white yarn is a 2/20 wool, knit at just under tension 5, which was the tightest possible for successful transfers on my machine. The blue is an acrylic of similar thickness, which, if pressing was planned for the scales, is a bad idea since it lacked the tolerance for adequate heat and steam.

The white yarn is a 2/20 wool, knit at just under tension 5, which was the tightest possible for successful transfers on my machine. The blue is an acrylic of similar thickness, which, if pressing was planned for the scales, is a bad idea since it lacked the tolerance for adequate heat and steam.

The zig-zag effect may be enhanced by adding to the number of transfers in each half in the repeat’s length and on each row in width, but not necessarily in the stitch count in the knit columns. One is then committed to knitting broader test samples.

Extending the experiment to a broader repeat, 32X58![]()

Both yarns used in the samples that follow are 2/20 wool.

Both yarns used in the samples that follow are 2/20 wool.

Here this swatch is shown as it came off the machine, oriented sideways  a change in perspective

a change in perspective  An attempt to shrink the size of the eyelets, this swatch was lightly hand felted. The issue with felting very open knits is having enough control to retain some of the openness in the structure, here the projections became rounder and flatter as well.