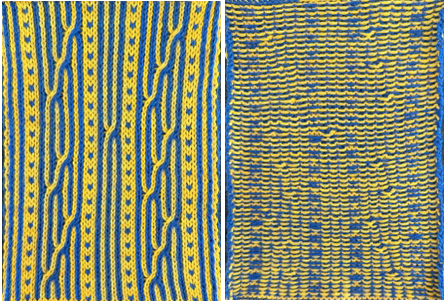

Fringes, loops, and pile/carpet knits are populating Fall knitwear runways.

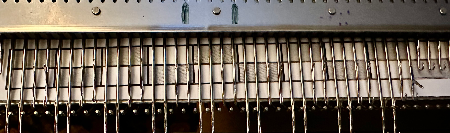

Pile knitting is best executed on Studio knitting machines. Love the knit structure? find a Studio KM to borrow for the project.

Fringes are essentially long loops, and share principles with knitweaving.

Previous posts

Pile knitting on Passap and Brother KMs 4

Pile_carpet stitch knitting on Passap and Brother KMs 3

Pile knitting on Passap and Brother KMs 2

Pile knitting on Passap, Brother, and Studio KMs 1

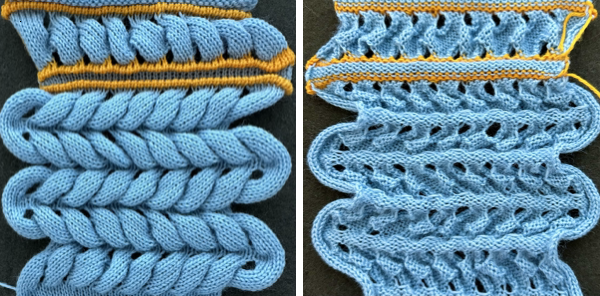

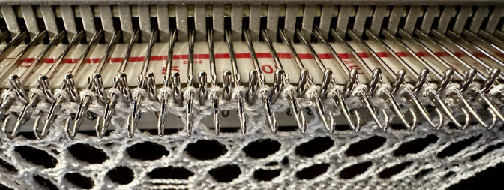

With Studio KMs outside the range of possible use, there are loop techniques that can be executed manually on any gauge machine

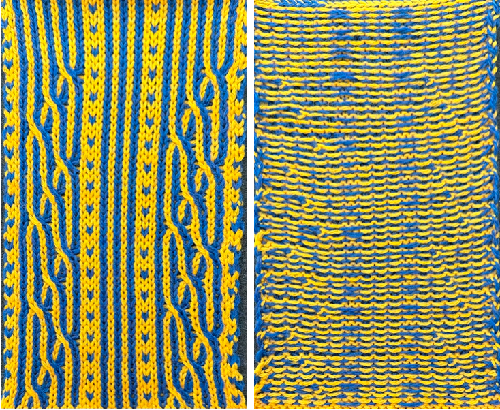

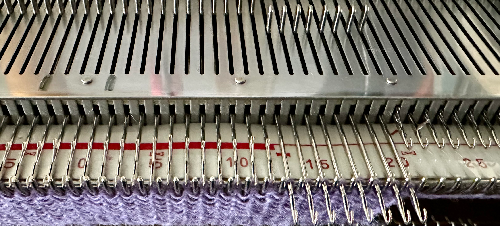

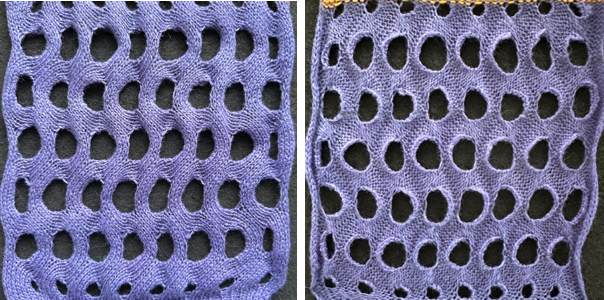

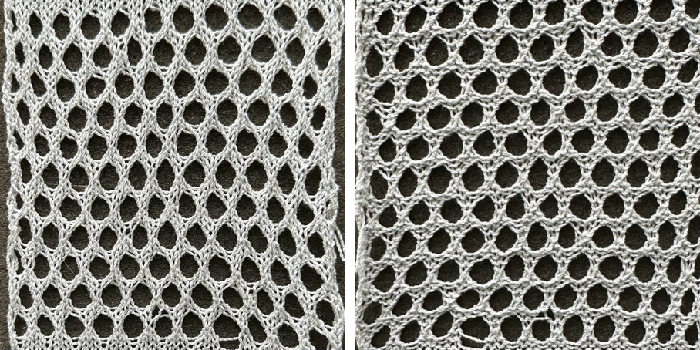

The first sample is knit on a 4.5 mm 930.

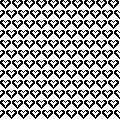

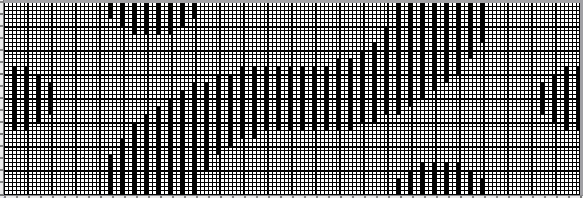

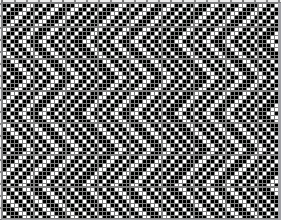

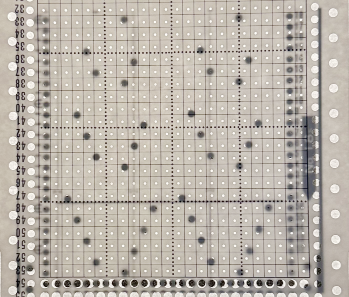

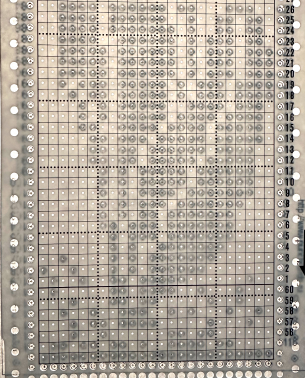

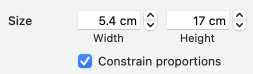

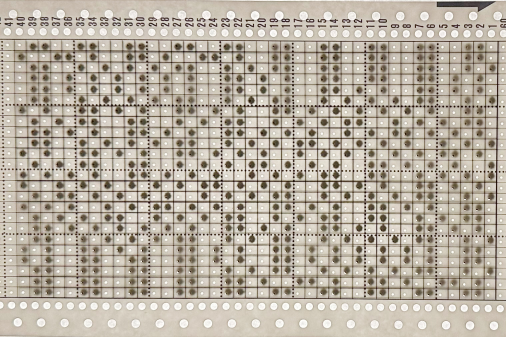

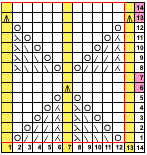

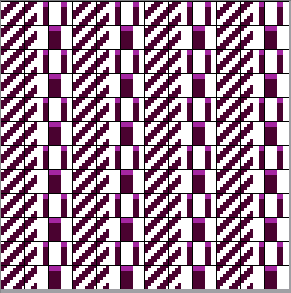

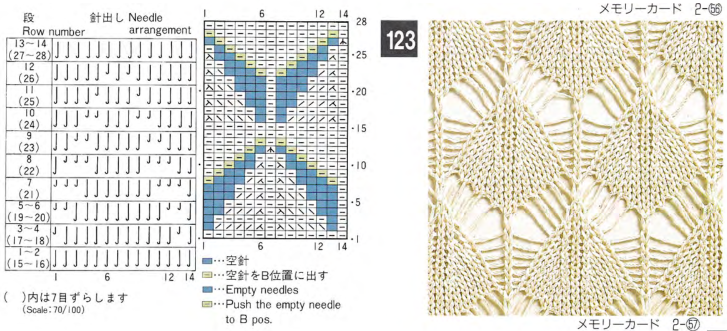

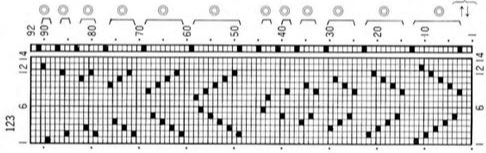

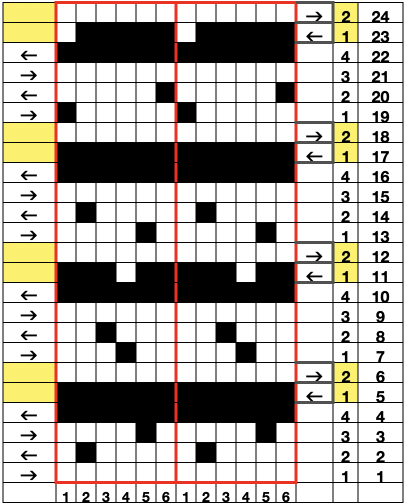

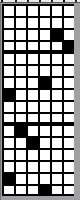

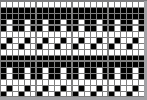

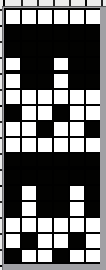

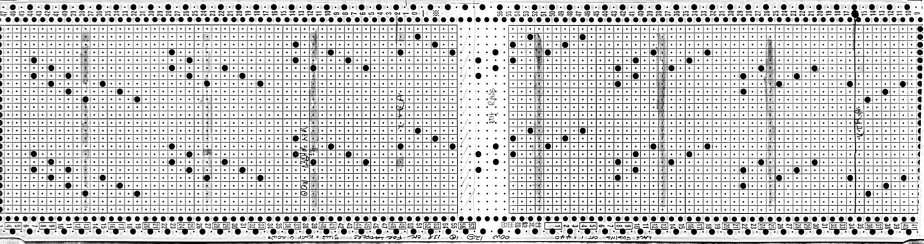

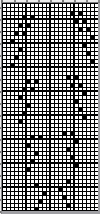

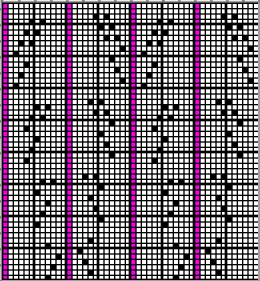

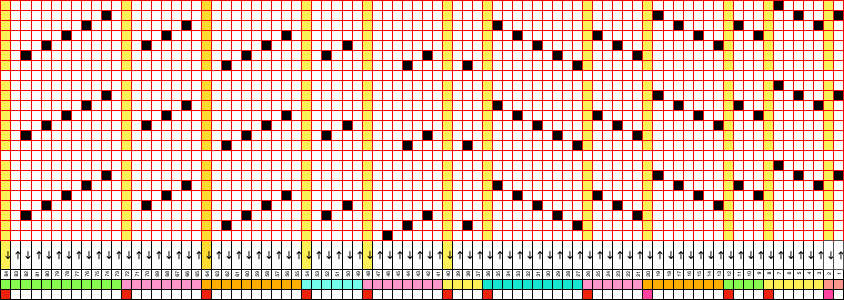

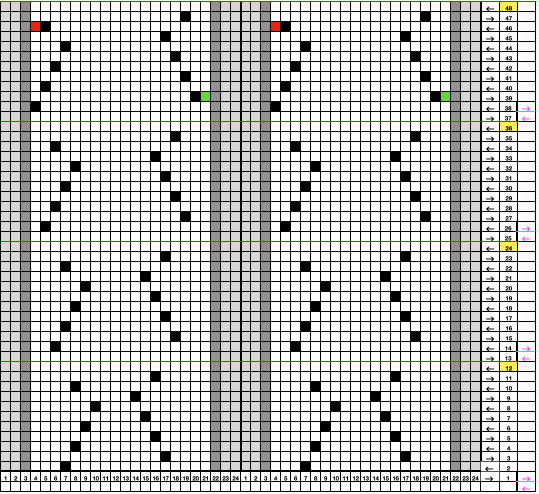

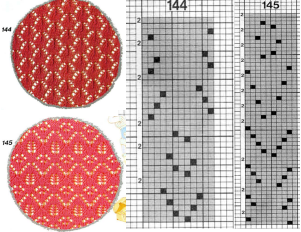

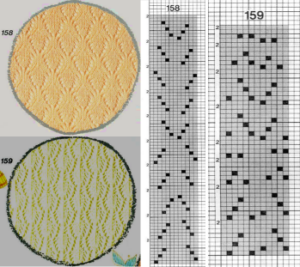

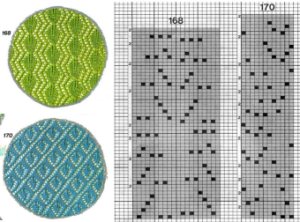

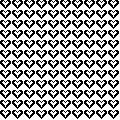

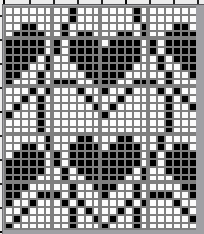

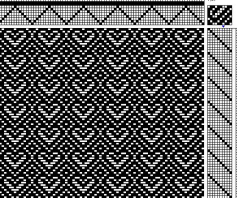

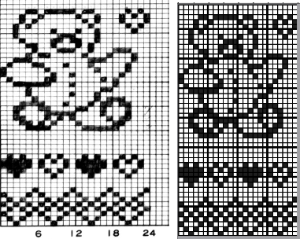

A downloadable punchcard volume for Studio aka Silver Reed machines  offers punchcards for the double bed technique referred to as punch pile

offers punchcards for the double bed technique referred to as punch pile  In analyzing the repeats, the black cell rows represent loops picked up on the main bed, the blank rows the carriage passes knitting every stitch on the ribber alone holding the loops down.

In analyzing the repeats, the black cell rows represent loops picked up on the main bed, the blank rows the carriage passes knitting every stitch on the ribber alone holding the loops down.

Applying permanent loops to the surface of a knit using Brother knitting machines falls into the knit weaving family.

The knitter can choose color placement and changes, as one might in intarsia.

Previous related posts:

Machine knit fringes 4, long loop patterning , my first use of straws,  bulky loop yarn, the main bed programmed repeat:

bulky loop yarn, the main bed programmed repeat:  Long loops: a bit on method includes instructions on the use of single bed cast on comb, rulers, ribber gate pegs.

Long loops: a bit on method includes instructions on the use of single bed cast on comb, rulers, ribber gate pegs.

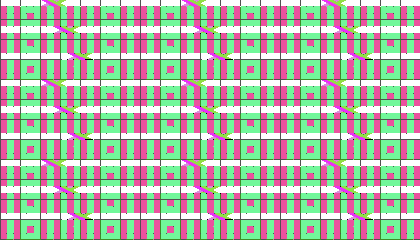

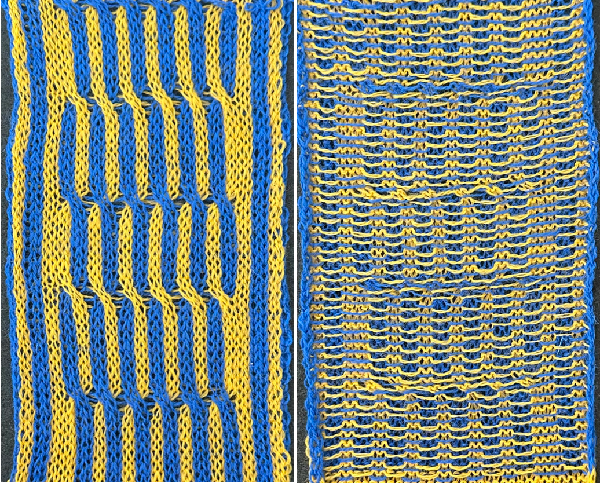

As usual, my swatches begin with random yarn choices from my stash, using colors that will help identify proper stitch formation, and just as a random return to designs intended for other fabrics in previous shares.

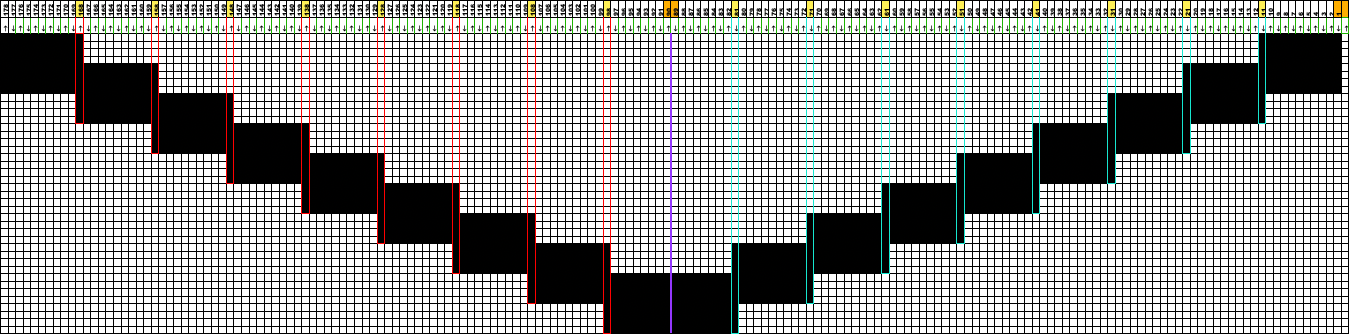

Developing a repeat: since the loops are created by hand, the goal is to work with larger loops than those in automated punch pile designs.

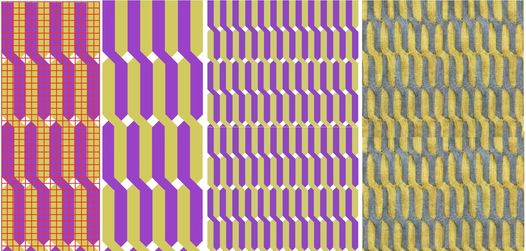

In the past, I was drawn to and explored truchet tilings

Truchet tiling design inspiration 1

Truchet/Smith inspired designs 2 meet ArahPaint

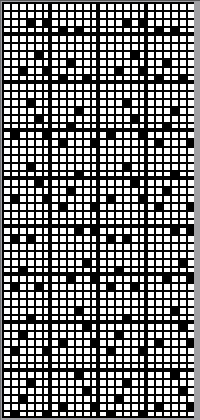

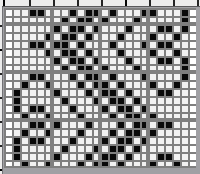

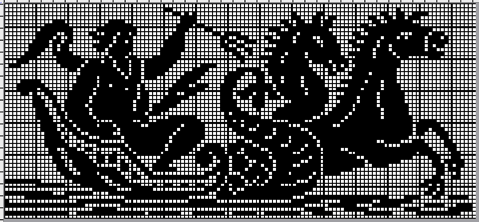

More Truchet inspired tiles, a brief look at gradient filter use included this 3-color knit sample resulting from an img2track color-separated DBJ repeat  Aiming to form large loops and a larger scale motif with more than one knit row between rows of them, the original 24X48 repeat,

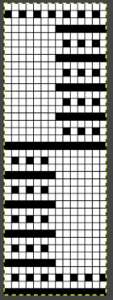

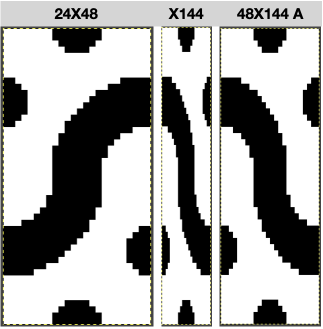

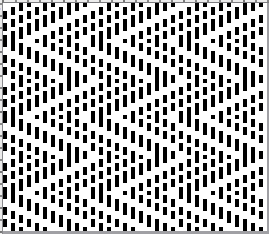

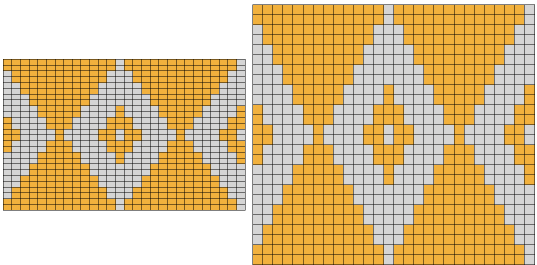

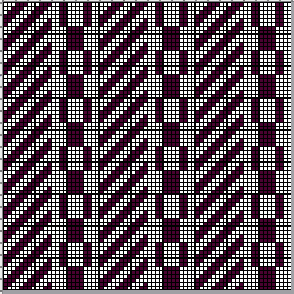

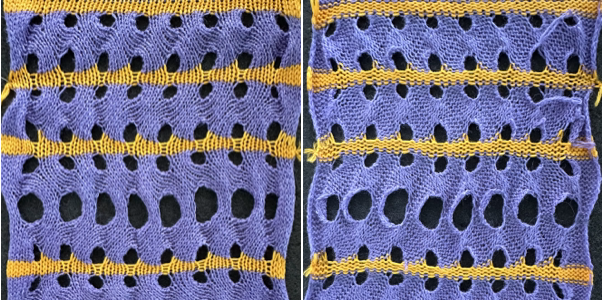

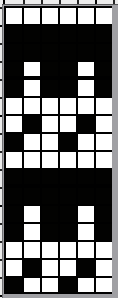

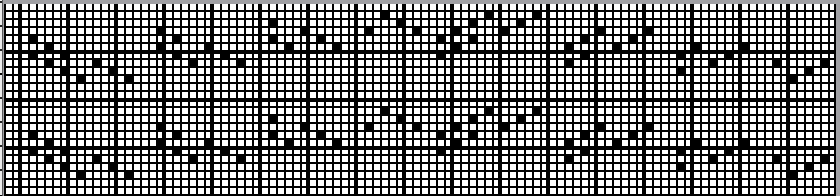

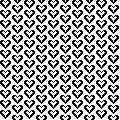

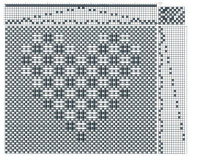

Aiming to form large loops and a larger scale motif with more than one knit row between rows of them, the original 24X48 repeat, ![]() evolved into a very different 48X48 repeat.

evolved into a very different 48X48 repeat. ![]() The full design in gridded view:

The full design in gridded view:  The process used to attain it: the original repeat was scaled x3 in height, and then again in width X2 for visual balance

The process used to attain it: the original repeat was scaled x3 in height, and then again in width X2 for visual balance  Working in RGB mode the 48X144 image was opened in Gimp, and a new image file in the same size was added with a white ground, and then a third 48X3 image with rows 2 and 3 colored in red.

Working in RGB mode the 48X144 image was opened in Gimp, and a new image file in the same size was added with a white ground, and then a third 48X3 image with rows 2 and 3 colored in red. ![]() The latter saved to the clipboard, may be used to bucket-fill the all-white second image.

The latter saved to the clipboard, may be used to bucket-fill the all-white second image.

The white is rendered clear using layer, transparency, and color to alpha.

The result is copied and pasted on the original.

The red is selected by color, filled with white, and fixed by clicking on the rectangle tool.

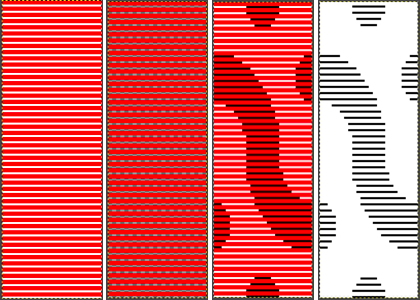

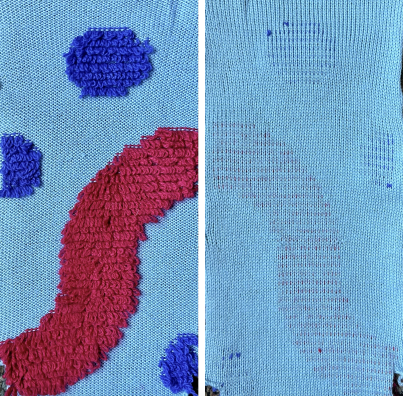

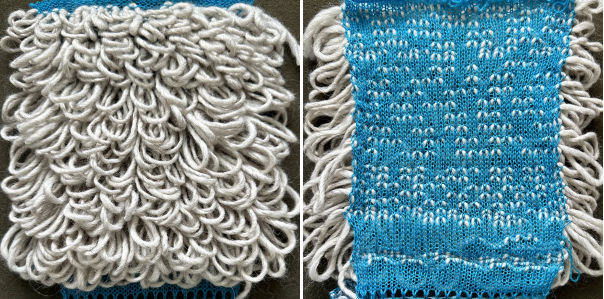

The mode is changed to BW indexed, and the image is saved for knitting.  I grabbed yarns for color visibility and thickness, not fiber content, and in the resulting knit the loops flattened permanently in the red acrylic and the blue acrylic blend. The technique might be better served using a 3/8 wool for the loops.

I grabbed yarns for color visibility and thickness, not fiber content, and in the resulting knit the loops flattened permanently in the red acrylic and the blue acrylic blend. The technique might be better served using a 3/8 wool for the loops.

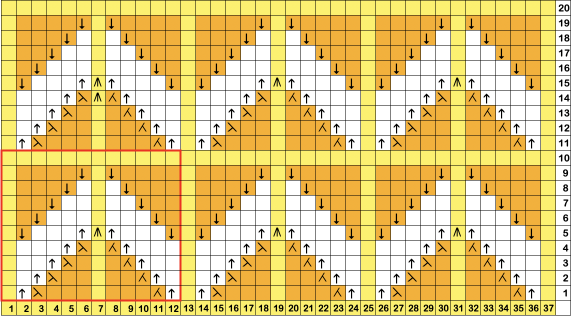

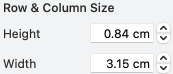

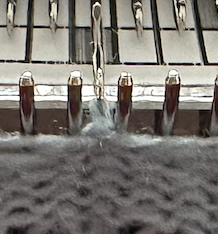

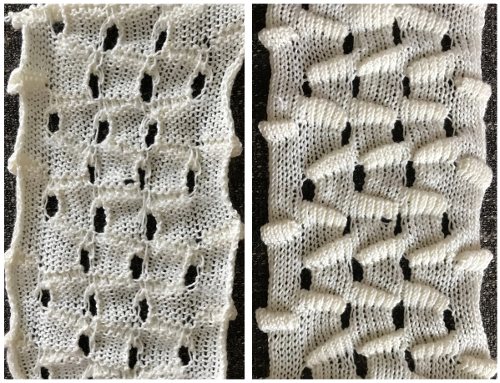

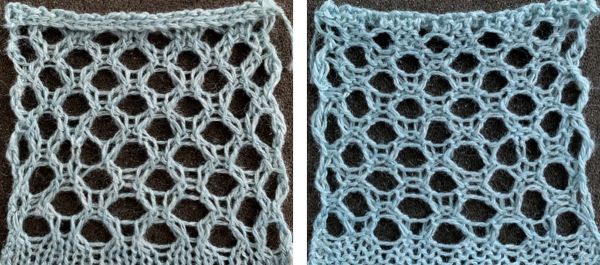

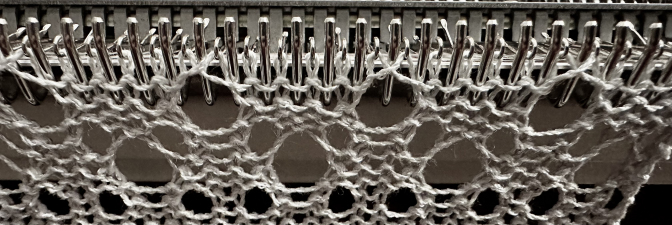

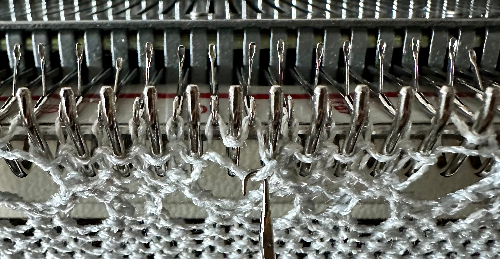

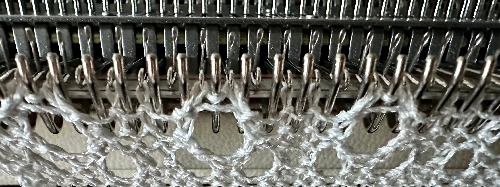

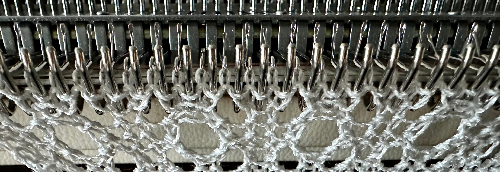

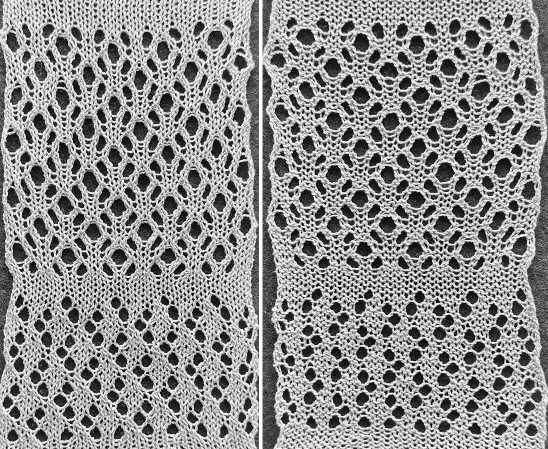

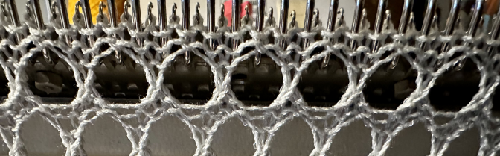

The work in progress:  The full repeat in the final swatch measures 6X11.5 inches

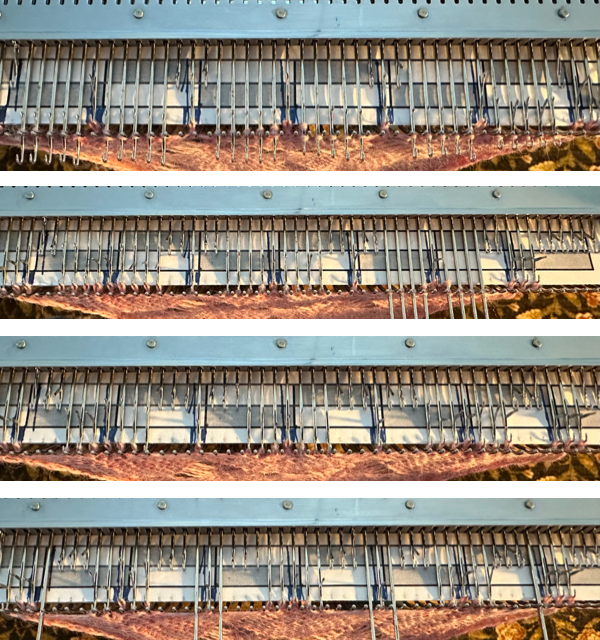

The full repeat in the final swatch measures 6X11.5 inches  The same repeat was used again, and the red acrylic yarn was switched to the background for a result that would steam flatter permanently, while the loops were formed with triple yarn strands.

The same repeat was used again, and the red acrylic yarn was switched to the background for a result that would steam flatter permanently, while the loops were formed with triple yarn strands.

It took testing adjustments in tension and loop length, noticeable at the bottom of the swatch images, to achieve consistent coverage and a new tool to form them.

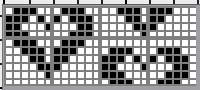

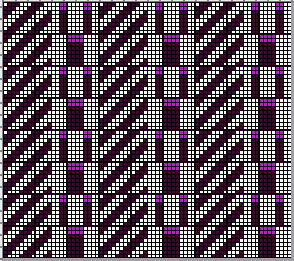

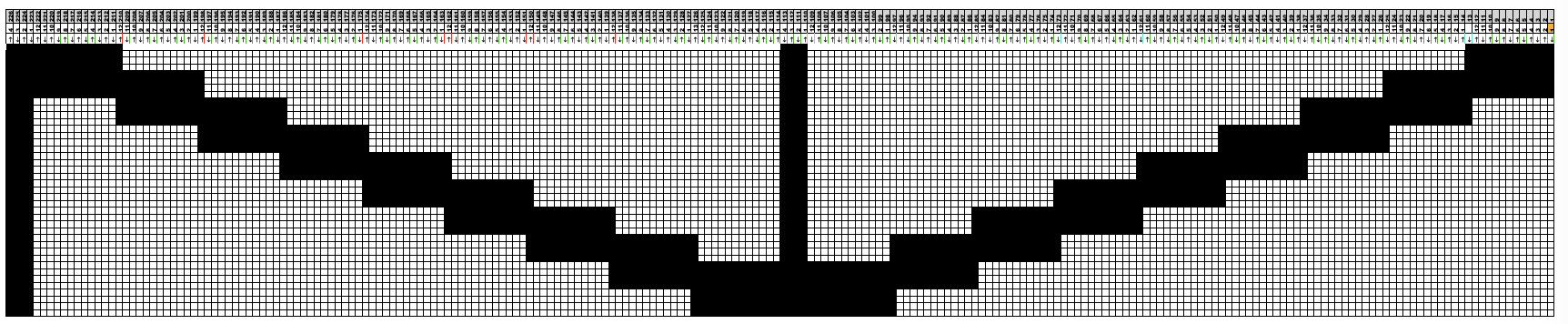

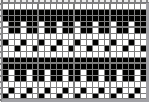

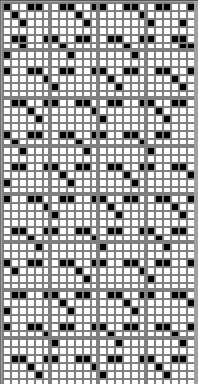

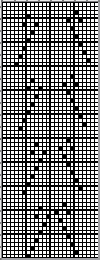

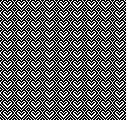

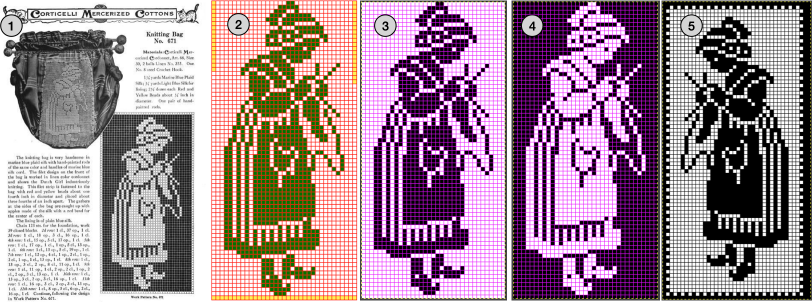

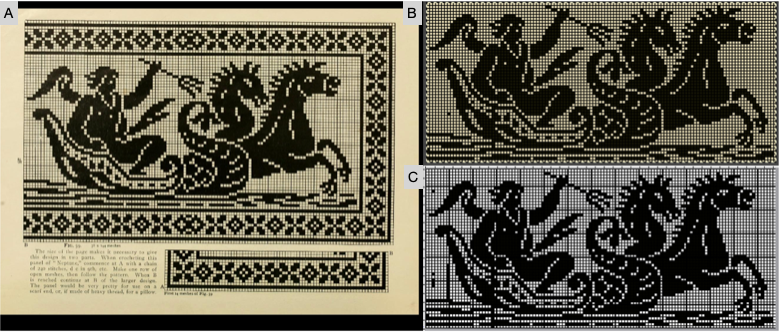

When searching through published sources and adapting them, results can be random or outright failures. Pondering patterning on every other needle, with end needle selection off, this design from:

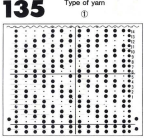

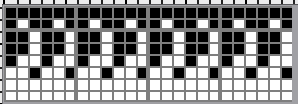

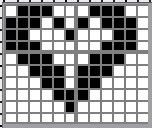

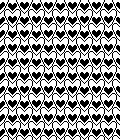

When searching through published sources and adapting them, results can be random or outright failures. Pondering patterning on every other needle, with end needle selection off, this design from:  for 12 stitch punchcard models came to mind, including this chunky machine design

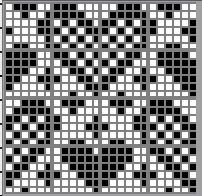

for 12 stitch punchcard models came to mind, including this chunky machine design  The what if repeat, expanding it to a 22 stitch version with every other column blank and checking for proper tiling

The what if repeat, expanding it to a 22 stitch version with every other column blank and checking for proper tiling ![]()

was not useful as a knit woven pattern, but when used to form loops on preselected needles and graduating the height of the loops the result proved interesting.

was not useful as a knit woven pattern, but when used to form loops on preselected needles and graduating the height of the loops the result proved interesting.

Rulers of different widths and thicknesses were used as tools used to form the loops including but not shown, the metric ruler supplied with Brother knit leaders.

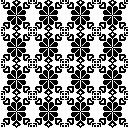

Diagonal designs, in particular, can be hard to force into 12 or 24-stitch conventions. With further editing, the published repeat is adjusted to larger 23X18 pixel dimensions,

Diagonal designs, in particular, can be hard to force into 12 or 24-stitch conventions. With further editing, the published repeat is adjusted to larger 23X18 pixel dimensions, ![]() appears to align correctly, and will be returned to in a post containing more knitwoven samples.

appears to align correctly, and will be returned to in a post containing more knitwoven samples.  This test begins with caution, then produces a dense pile testing the limits on yarn thickness using the repeat:

This test begins with caution, then produces a dense pile testing the limits on yarn thickness using the repeat:

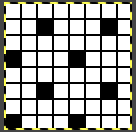

Pony beads were threaded on a double strand of cotton from an unmarked cone, and loops were formed with beads advanced and placed between and below preselected needles.

Pony beads were threaded on a double strand of cotton from an unmarked cone, and loops were formed with beads advanced and placed between and below preselected needles.

Spacing was tested before committing to the final choice, the same repeat as in the above swatch.

The bead-carrying yarn was pulled to tighten it across the previous woven row just before laying it in place for the next patterned row.

Bead addition was also tested between chains in bind-off.

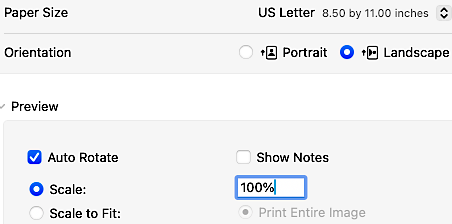

Mac experiments on printing needle tapes and punchcard templates to scale and other tips

Periodically the question of printing blank templates for DIY drawings or images from published sources to scale to produce traceable images used to mark cards for punching is asked in forums and very recently in Ravelry.

I primarily use Apple and open-source free software in my work.

Creating knit graph paper on Mac, using Excel and Numbers began with Working in Excel 2008 and Mac Numbers 3.2.

The topic was revisited by me here.

A far more recent variety of printable tapes for multiple gauge knitting machines is offered by Claudia Scarpa in her 2022 blog post.

With some exploration, trial, effort, and good note keeping goals can often be achieved with tools on hand.

The concepts for retaining aspect ratio can be applied to other platforms, programs, and printers.

Suggestions exclude using banner paper or legal size sheets.

The assumption is made that only 8.5 X 11 inches stock is available for use.

Acrobat Reader free downloads provide limited functions.

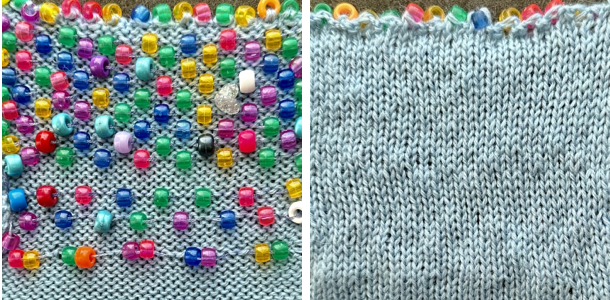

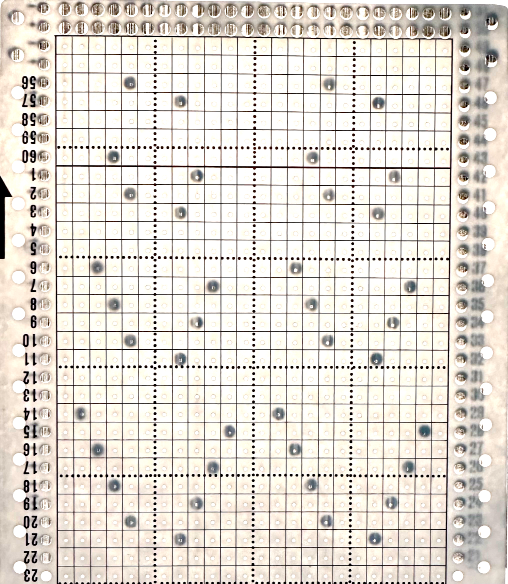

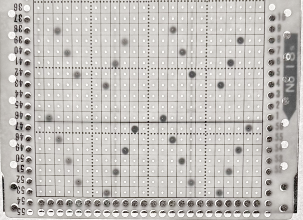

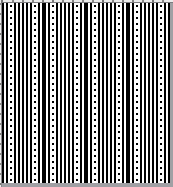

Factory punchcards are marked in what appears visually to be a square grid.

Using a ruler measuring in mm, the blank 24X60 punching content measures 108 mm in width and 300 mm in length.

The 300 mm content length will be adjusted depending on the height of the design repeat and whether the 4 rows of all-punched squares need to be considered in the printout.

The individual squares on the factory blanks measure 4.5 mm in width and 5 mm in height.

Cards can be joined together with snaps for longer repeats, and the additional pieces ought to be a minimum of 20 rows in height for the card to feed smoothly and accurately. Some added taping will further ensure it continues to do so if the card will be used often or in very long projects.

Two editable spreadsheets to download:

Traceable punchcard templates for DIY designs

1. Numbers 13, the greyed-out rows represent the first two all-squares-punched rows

Depending on the program used to process the file, there may be some juggling between the use of cm and mm values, a matter of a decimal point.

The shared table without numbers measures 10.8X22 cm.

The shared numbered table includes an extra column border marked needed to match the full blank card width markings, 14.2 cm in width, and the same length as the first table, 22cm.

2. A test PDF for a template including row numbers: punchcard-blank 35.

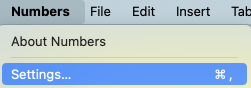

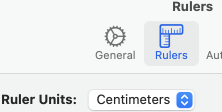

To print to scale using Acrobat Reader, select ![]() Matching results for both templates with a superimposed factory card segment.

Matching results for both templates with a superimposed factory card segment.  Custom needle tapes

Custom needle tapes

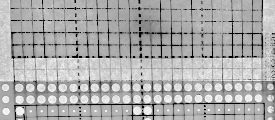

Working in cm, considering that needles are 4.5 mm, 0.45cm apart, eliminates the need for conversion to points, the format used when planning to use the resulting charts for conversion to pixels per stitch PNGs.

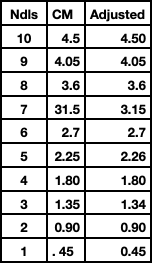

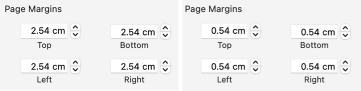

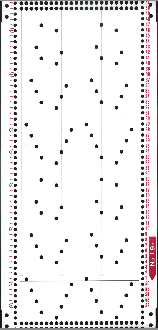

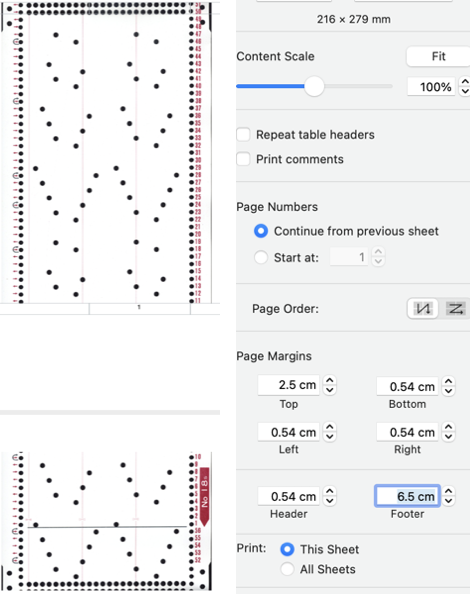

Both Gimp and Numbers alter some of the values by default very slightly, as seen here in Numbers for 1-10 cm needle spacings for designing blocks for needle tapes.  To maximize the available printing space, under print, setup, change all margin values from any preset default, seen on the left, to 0.54

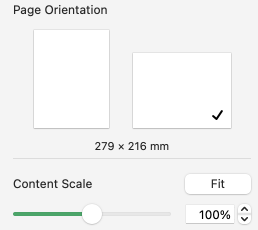

To maximize the available printing space, under print, setup, change all margin values from any preset default, seen on the left, to 0.54  Although the print setup shows page numbers in cm, the page orientation measures are given in mm

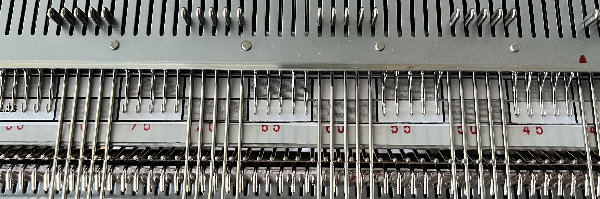

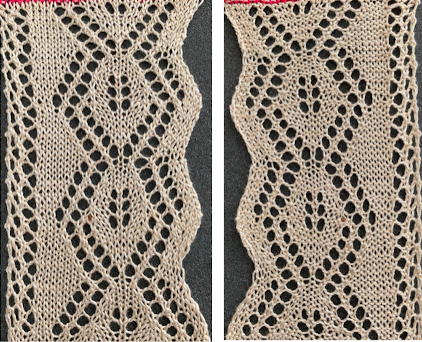

Although the print setup shows page numbers in cm, the page orientation measures are given in mm  The 2.26 mm, 5 stitch cell unit tape in place on the machine

The 2.26 mm, 5 stitch cell unit tape in place on the machine  To change rulers in Numbers 13.2 to the Centimeter setting, and thus avoid the need for any conversions of the values to points, from the Numbers Menu at the top of the screen Choose Numbers >Settings, click and scroll on Ruler Units from the pop-up menu, then choose an increment, in this case, centimeters.

To change rulers in Numbers 13.2 to the Centimeter setting, and thus avoid the need for any conversions of the values to points, from the Numbers Menu at the top of the screen Choose Numbers >Settings, click and scroll on Ruler Units from the pop-up menu, then choose an increment, in this case, centimeters.

When returning to drafting for pixel charts, repeat the process for changing rulers back to points.

The math in calculating table cell size is simple.

The math in calculating table cell size is simple.

This export is a revised copy for use in Numbers 09 using cm rulers: needle-tapes-only.

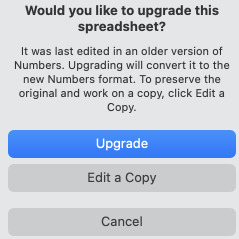

If working in a later OS, this prompt may appear  The matching document created in Numbers 13.2:

The matching document created in Numbers 13.2:

needle tapes only_numbers 2

Tapes printed in single blank units may be colored in or scribbled on easily, depending on end use  The same concept could be used to generate printed blank graph paper for intarsia and/or to obtain a sense of changes in aspect ratio resulting from knit stitches forming a rectangular grid while designing using pixels per stitch is commonly on a square one.

The same concept could be used to generate printed blank graph paper for intarsia and/or to obtain a sense of changes in aspect ratio resulting from knit stitches forming a rectangular grid while designing using pixels per stitch is commonly on a square one.

The mm ruler settings allow entering the values from the swatch gauge measured in mm and calculated to include decimal points.

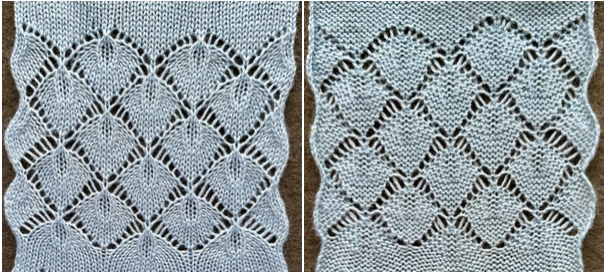

The chart grid on the left is shown in 6/4 proportion, a common width-to-height knit stitch ratio, while on the right it is in equal units.  The elongation in most knitting is often reduced by the choice of technique or if working in DBJ, by choosing ribber settings such as slip stitch with lili buttons.

The elongation in most knitting is often reduced by the choice of technique or if working in DBJ, by choosing ribber settings such as slip stitch with lili buttons.

Online published repeats converted to traceable printouts for punching cards

It is possible to produce print-to-size copies of punchcards to trace in a variety of ways.

One alternative is to use Mac Numbers to ready the image for doing so.

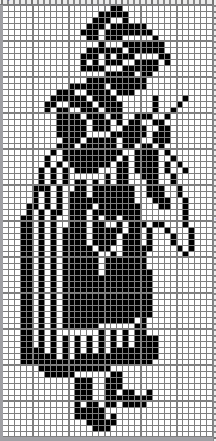

Two jacquard tests began with images from a source for massive punchcard repeat collections regularly mentioned in forums (translated to English link ), and at times in my previous posts.

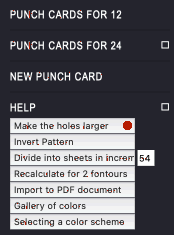

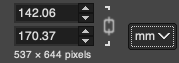

The first is for a border design, #4245 shown here with the holes made larger.  The second design is a far longer one, number 4937

The second design is a far longer one, number 4937  In the help menu on the right, select the first option, make the holes larger

In the help menu on the right, select the first option, make the holes larger

Save the image or simply drag and drop it into a new sheet in an existing Numbers document or create a new blank doc removing the default table.

Save the image or simply drag and drop it into a new sheet in an existing Numbers document or create a new blank doc removing the default table.

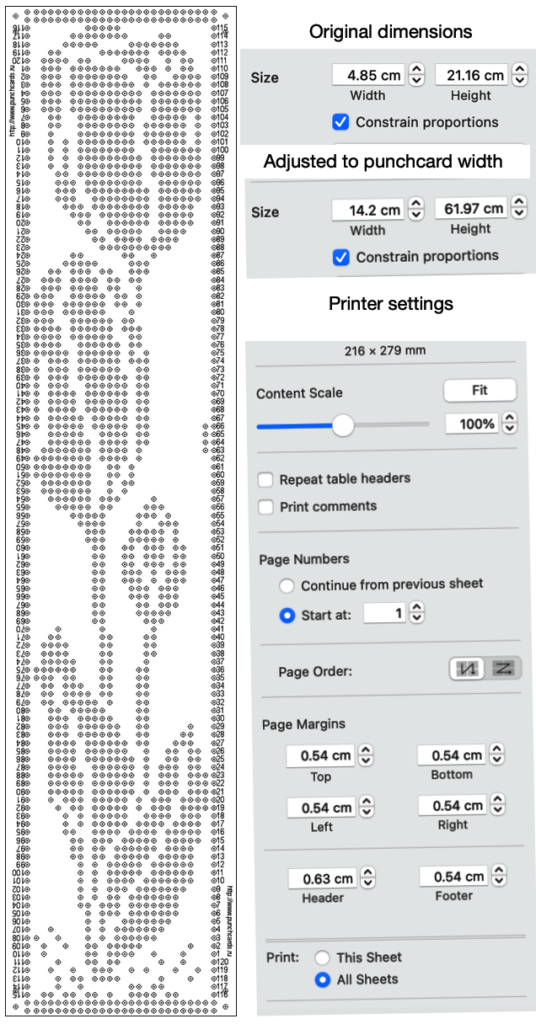

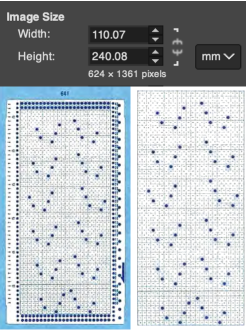

Click on the image, and in the top menu right, choose image arrange.  With Constrain Proportions left checked, change the image width to 14.2 cm punchcard full standard width. The height will be adjusted automatically.

With Constrain Proportions left checked, change the image width to 14.2 cm punchcard full standard width. The height will be adjusted automatically.

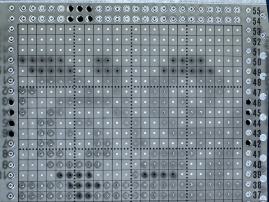

The first printout test. Some of the dots were also marked with a pen, not necessary if tracing over a light source.  Numbers will split far longer images into segments/sheets, in this case, 3.

Numbers will split far longer images into segments/sheets, in this case, 3.

The top of the image is displayed on the first sheet, moving down rows to the start of the design in the following “sheets”.

Page margins are all set at .54 cm. Adjusting header and footer values changes and shifts the position of the segments to obtain full dots on each printout.

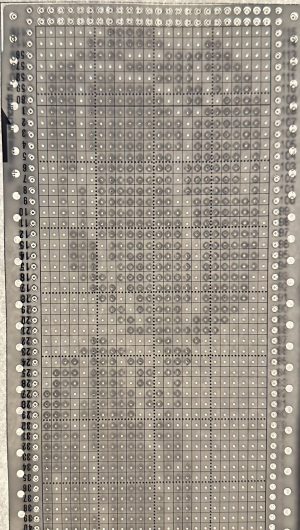

Scale contents to 100%, choose to print all sheets or any single one.  The printout is shown with a card laid over it, placed over a lightbox of sorts.

The printout is shown with a card laid over it, placed over a lightbox of sorts.  If a spreadsheet is not your preference, the same can be achieved with published cards using Gimp and Mac Preview. Printing from Gimp, even if the display is set to 100% appears not to appear to offer an option for dividing the file in scale automatically on more than one page.

If a spreadsheet is not your preference, the same can be achieved with published cards using Gimp and Mac Preview. Printing from Gimp, even if the display is set to 100% appears not to appear to offer an option for dividing the file in scale automatically on more than one page.

A recent Ravelry query asked about printing individual cards from downloaded PDF sets for Brother machines, including this card for Brother Lace 18, from the set S  Open the full downloaded document, display the thumbnails by selecting the view button in the toolbar, and pick Thumbnails.

Open the full downloaded document, display the thumbnails by selecting the view button in the toolbar, and pick Thumbnails.

Select the thumbnail to print, it will be highlighted, and drag and drop the thumbnail for the punchcard to the desktop, it will be in PDF format as well.

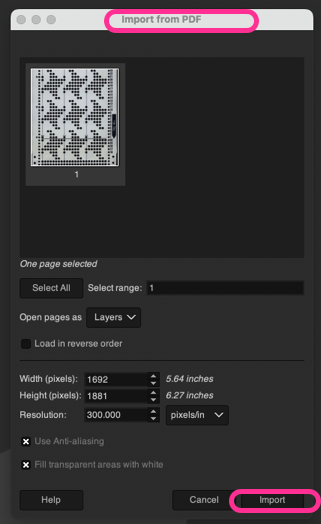

Click on the chosen file, select open with Gimp, and an import PDF window will appear, as seen for this Fair Isle Design  Because transfer lace cards have so few holes to punch and the placement is critical, the lace card 18s was chosen for testing.

Because transfer lace cards have so few holes to punch and the placement is critical, the lace card 18s was chosen for testing.

Select Import and an image composed of 2550X3300 pixels will open, surrounded by white space.

Using Crop to Content will reduce it to 1485X3052.

Scale it by choosing mm values, and type in the 142 mm card desired width, reduced automatically to 141.99 mm.  The value for the full, scaled image will still be displayed in pixels at the top of the work window, now 1677X3447 pixels.

The value for the full, scaled image will still be displayed in pixels at the top of the work window, now 1677X3447 pixels.

Since the repeat is longer than 40 rows, it can be divided into two segments using the mm value. These are the cm and pixel values for my cropped top segment, exported as a PNG. The saved PNG was opened in Preview and with the option for scaling to 100% ![]() produced a good traceable result despite the printer needing a new ink cartridge.

produced a good traceable result despite the printer needing a new ink cartridge.  Letting Preview split the image into large enough segments can be achieved by altering page margins.

Letting Preview split the image into large enough segments can be achieved by altering page margins.  The bottom of the above split printed is good enough considering the starting image was a tad rotated to the left and incomplete.

The bottom of the above split printed is good enough considering the starting image was a tad rotated to the left and incomplete.  A fail, a screengrab from the PDF full page, working with a PNG and printing from Gimp: the grab, 910X1522, cropped to content 694X1526, scaled to the same mm values,

A fail, a screengrab from the PDF full page, working with a PNG and printing from Gimp: the grab, 910X1522, cropped to content 694X1526, scaled to the same mm values,  yields an image with a very different pixel count from the PDF converted values,

yields an image with a very different pixel count from the PDF converted values,  and cropped to a segment 694X642 pixels and printed from Gimp was not to scale,

and cropped to a segment 694X642 pixels and printed from Gimp was not to scale,  In the downloadable PDF for that fair isle design #4 from the R series, the punchcard is presented in the two segments required to meet the full punched height for knitting.

In the downloadable PDF for that fair isle design #4 from the R series, the punchcard is presented in the two segments required to meet the full punched height for knitting.

The bottom segment opened and scaled in Gimp first as a PDF Import and then as a screengrab PNG, resulted in the same failure in maintaining equal pixel aspect values with scaling for printing as seen with 18S  The process was followed on the tulip file PNG: a segment was cropped from the bottom of the saved “larger hole” image, scaled to cm value, and printed in proper aspect ratio,

The process was followed on the tulip file PNG: a segment was cropped from the bottom of the saved “larger hole” image, scaled to cm value, and printed in proper aspect ratio,

What of images from Brother Punchcard Volume 5, especially for those lace cards with so few dots?

What of images from Brother Punchcard Volume 5, especially for those lace cards with so few dots?

Choose an image, open it in Gimp, crop it to the edges of the punchcard design

scale the image by multiplying both the number of stitches and the number of rows by 5  The result printing from Preview (and more ink)

The result printing from Preview (and more ink) Dak is a Windows-only program. There are multiple volumes of stp files usable only in DAK, downloadable for free, including those for Brother Punchcard Volume 5.

Dak is a Windows-only program. There are multiple volumes of stp files usable only in DAK, downloadable for free, including those for Brother Punchcard Volume 5.

The stp format is only read by the program, and stitch designs cannot be exported in other formats ie. PNGs.

Other posts have suggested hacks for converting screengrabs from DAK to PNGs for use in electronic machines.

I use InSync to move files between my Mac and PC and download to the 930 from there, using img2track.

There are many related ways to achieve the same task using only the PC.

If the goal is to use punchcard templates generated in DAK for traceable printouts to mark cards for punching, both Mac Preview and Numbers may once again be used.

The fixed full width for 24 stitches on a blank card is 108 mm.

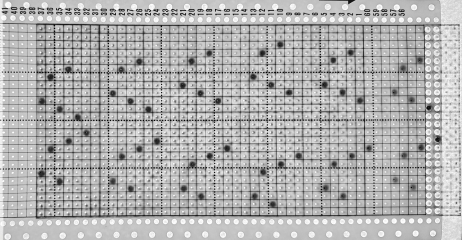

Dak loads the files from the punchcard book in the smallest repeat for correct tiling when available, so lace #771 stp opens as a 12X34 stitch repeat.

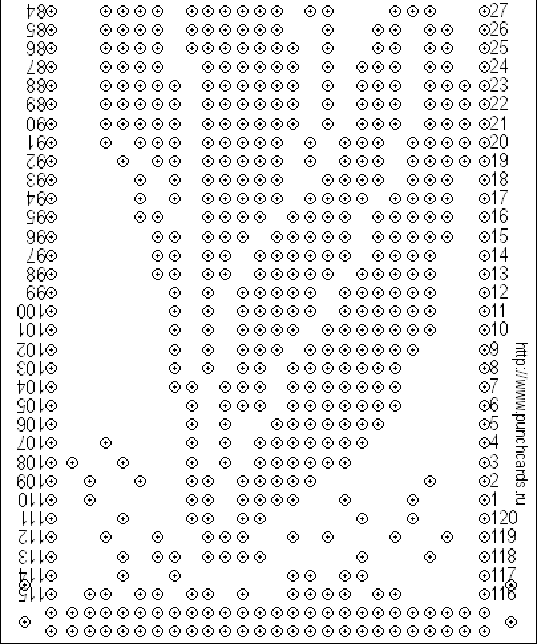

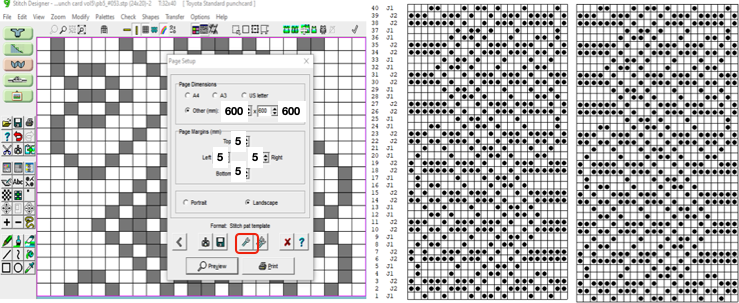

A screengrab segment of the DAK window.  With the repeat isolated and cropped in Gimp, the entered values of 54X170 were adjusted to these by the program, the PNG was saved.

With the repeat isolated and cropped in Gimp, the entered values of 54X170 were adjusted to these by the program, the PNG was saved.  If Numbers is used for printing, under Image/Arrange, adjust the image size

If Numbers is used for printing, under Image/Arrange, adjust the image size  Or if opened in Preview, set the print scale to 100%

Or if opened in Preview, set the print scale to 100% ![]() The results for both matched

The results for both matched  Analyzing the repeat, note the blank first row, not usually seen in a Brother transfer lace design.

Analyzing the repeat, note the blank first row, not usually seen in a Brother transfer lace design.

Checking the Volume 5 source after the fact identifies the repeat as intended for lace combined with knit weaving, a different knit structure.

DBJ color separations other than the KRC built-in function in Japanese electronic machines require other software or manual color separations.

DAK performs a variety of separations easily and quickly.

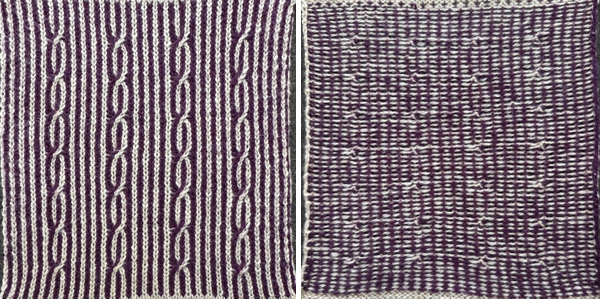

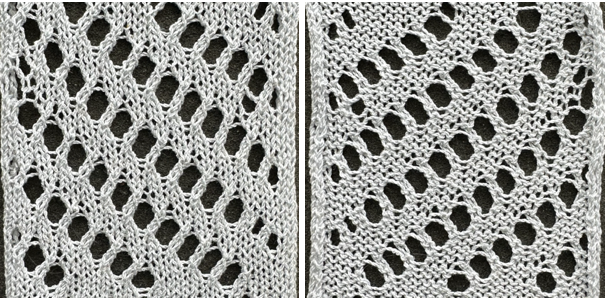

In Volume 5, pattern #53 is shown as punched for fair on the left, and separated for DBJ on the right.  If the # stp is opened in DAK as the 2-color jacquard design.

If the # stp is opened in DAK as the 2-color jacquard design.

To knit a traceable punchcard template for the DBJ, the print option generates usable images.

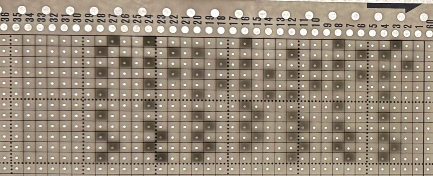

This screen grab of the DAK window shows the jacquard design in the background.

The Page Dimensions window icon outlined in red when selected offers 3 ways to mark the black cells including as dots.

Choosing other (mm) and entering 600 for both values will produce results in a size that allows their being grabbed and saved in full.

The program will conveniently split the design into pages if needed.

The center image shows the generated template for the specific stp, the right one, the image opened in Gimp on the Mac with the content cropped to the dotted chart,  and scaled,

and scaled,  saved, and, in this case, printed using Preview. The punchcard is superimposed beginning with #1 only for an added visual check, punching always begins immediately above the first two all-punched rows

saved, and, in this case, printed using Preview. The punchcard is superimposed beginning with #1 only for an added visual check, punching always begins immediately above the first two all-punched rows

Inspiration for varied stitches from a single chart

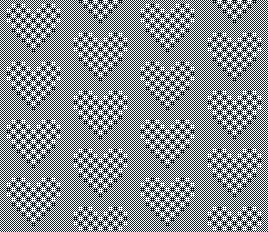

Nearly 9 years ago, I began exploring scale designs. At the time, my charts were generated using Excel  and a program called Intwined Pattern Studio, which soon became inoperative

and a program called Intwined Pattern Studio, which soon became inoperative  The above repeat, visualized tiled.

The above repeat, visualized tiled.  At present, using custom-printed needle tapes has proven useful in tracking actions required in hand-manipulated stitches.

At present, using custom-printed needle tapes has proven useful in tracking actions required in hand-manipulated stitches.

The attached PDFs have been printed in the proper aspect ratio with the following changes from default settings using Mac Preview,  and Acrobat Reader

and Acrobat Reader  7 needles

7 needles

single 4.5

Whether the knit tests are worth pursuing in large pieces with or without modifications is subject to end-use and personal preferences.

To begin with, stitches were transferred, the empty needles were pushed back to the A position, Out Of Work, and returned to the work, B position, for reversing or shifting the shapes.

Forming ladders: the chevron shapes are created by single stitch transfers, and bringing needles in and out of work.

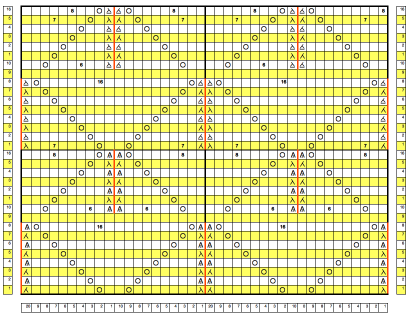

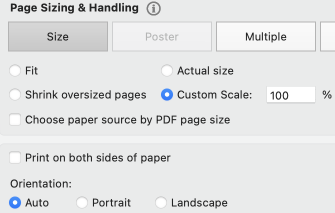

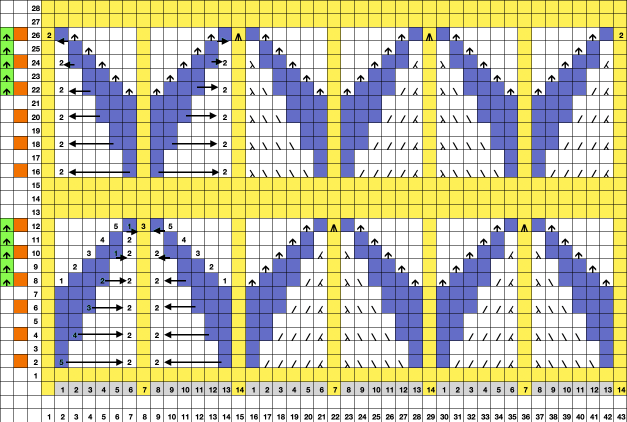

A starting chart:  Keeping the same palette as in previous charts, yellow cells represent needle positions where stitches are not disturbed, and the white cells where needles are taken OOW. The up-arrow needles mobed to A/OOW, and the down-arrow needles returned to B.

Keeping the same palette as in previous charts, yellow cells represent needle positions where stitches are not disturbed, and the white cells where needles are taken OOW. The up-arrow needles mobed to A/OOW, and the down-arrow needles returned to B.

The work in progress:

1: to reduce the line length formed by the single stitches, the point at which needles are returned to work can be varied

2: in this instance, as 5 empty needles side by side are reached, bring needles into work for the next shape on each side of the single stitch decreasing the number of empty needles to four. As the knit carriage returns to the opposite side, loops are formed on each of the needles returned to work

3: continue to bring an empty needle into work aside each pre-existing loop

4: after the last 2 empty needles are returned to work and are followed by a knit row the last two loops are formed

5: knit one last row across all the needles, and begin transfers for the alternate shape.  This yarn is a 2/8 wool, which worked nicely for holding ladder edge stitches in the leaf swatches but yielded a stiff knit in this case, and the elongated single stitches fold over at the top, creating extra nubs on the surface of the knit.

This yarn is a 2/8 wool, which worked nicely for holding ladder edge stitches in the leaf swatches but yielded a stiff knit in this case, and the elongated single stitches fold over at the top, creating extra nubs on the surface of the knit.  Continuing designs with similarly shaped outlines but leaving the emptied needles in work, B position, produces different shapes. All needles remain in B throughout.

Continuing designs with similarly shaped outlines but leaving the emptied needles in work, B position, produces different shapes. All needles remain in B throughout.

The yellow columns in the chart indicate the locations on the needle bed where stitches are never moved.

Visualizing the tiled repeat and the direction of the transfers: the initial experiment is also a 12-row repeat. The magenta cells indicate spots where extra all-knit rows may be added in DIY.

The work in progress:

A 7-prong tool is handy in making the 5 and 4-stitch transfers.

After each transfer, loops will form on the empty needles with the next carriage pass

3: the loop becomes part of the subsequent transfer, and the newly emptied needle remains in work

The first swatch began with a 12-row repeat and an all-knit row before transfers began for the alternate shape.  Visualized in larger BW tiling

Visualized in larger BW tiling  The transfers are made away from the circles in the chart using multiple transfer tools.

The transfers are made away from the circles in the chart using multiple transfer tools.

After each transfer, the empty needles are left in B or pushed out to E.

As the knit carriage moves to the opposite side, loops are formed on the empty needles.

Each loop becomes part of the next transfer.

Setting up the first design row using a 7-prong tool with 5 prongs selected: the numbers in the lower image indicate the number of stitches on each of those needles as the setup row is completed.  The second group moves 4 stitches at a time. Loops are treated as stitches.

The second group moves 4 stitches at a time. Loops are treated as stitches.

After the transfers, there will be groups of 2 stitches adjacent to those holding 3 in the previous row.

The outline in the lower image points to one pair of transfers in the process of being completed.

1: When this configuration is reached, knit one more row to the opposite side,

1: When this configuration is reached, knit one more row to the opposite side,

2: begin transfers away from the midpoint between the shapes to form the brick repeat.  The result forms a bump once more due to the length of the single knit stitch columns.

The result forms a bump once more due to the length of the single knit stitch columns.  The above yarn is a 2/8 wool, the swatch was quite stiff. A second swatch was knit using a softer, thinner, alpaca-silk blend.

The above yarn is a 2/8 wool, the swatch was quite stiff. A second swatch was knit using a softer, thinner, alpaca-silk blend.

The relaxed knit after removal from the machine was very textured and narrow,  this result followed some light pressing and steaming.

this result followed some light pressing and steaming.

Traditional wet blocking would be required to maintain the shapes in a final piece.  Eliminating the all-knit row to reduce the extra lengths of those single-stitch columns did not produce what to my eye was an improved knit.

Eliminating the all-knit row to reduce the extra lengths of those single-stitch columns did not produce what to my eye was an improved knit.

In a last what-if test, the chart was turned 180 degrees, with transfers beginning with a single stitch, and ending with moving five.  The results, knit in 2/15 wool and lightly steamed and pressed, appeared more successful to my eye.

The results, knit in 2/15 wool and lightly steamed and pressed, appeared more successful to my eye.  relaxed overnight, the surface is a bit more 3D

relaxed overnight, the surface is a bit more 3D  Using a similar technique for multiple transfer lace designs: a 14-row repeat, magenta cells mark all knit rows, and all transfers are made toward stitches aside every 7 stitches except for on rows 6 and 13,

Using a similar technique for multiple transfer lace designs: a 14-row repeat, magenta cells mark all knit rows, and all transfers are made toward stitches aside every 7 stitches except for on rows 6 and 13,  circles in the chart now indicate eyelets, transfers are made every row.

circles in the chart now indicate eyelets, transfers are made every row.  1: the setup row.

1: the setup row.

Empty needles are left in work, B. Cyan dots mark needles holding 2 stitches after the beginning transfers

2: the next knit carriage pass forms loops on the empty needles

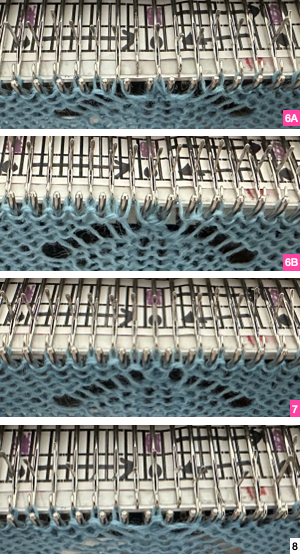

3: with the next transfer, an empty needle results adjacent to each loop, the start of the next eyelet  On Row 6 the last transfer results in 3 stitches on the normally undisturbed vertical stitch columns, 6A as the next carriage pass is made, 6B, loops are formed on the empty needles. A second row is knit on every needle, 7, and transfers begin to be reversed for the top half of the shape, 8.

On Row 6 the last transfer results in 3 stitches on the normally undisturbed vertical stitch columns, 6A as the next carriage pass is made, 6B, loops are formed on the empty needles. A second row is knit on every needle, 7, and transfers begin to be reversed for the top half of the shape, 8.

The result shares some similarities with another hand technique .

The result shares some similarities with another hand technique .

Cables meet fair isle

This sweater by Namesake, in the Fall 2024 collection, led to a FB query as to how to produce a cable version inspired by its color movement on home knitting machines.  The discussion leads back to how to produce cables in 2 colors on home knitting machines best and accurately.

The discussion leads back to how to produce cables in 2 colors on home knitting machines best and accurately.

One way to achieve color movement is to begin with using and modifying vertical lines.

Due to the fixed width between machine needles, it is best to use a fiber with a bit of stretch such as wool, and often 2X2 crossings appear to be the limit for designs containing them in frequent, all-over patterns.

When working in single colors there are ways to obtain extra slack to make the crossings easier, but using the FI settings makes the knit tighter as in any slip stitch, limiting the use of such measures. In addition, returning the needles to the proper preselection position in pattern after the transfers needs to be performed manually.

A starting best-guess rule is to knit a minimum number of rows between crossings matching the number of stitches moved ie. for a 3X5 cable, knit at least 8 rows before repeating.

Tracking transfers can be achieved in several ways. The needle bed or tape can be marked with water-soluble ink, custom paper needle tapes may be printed to size, or paper strips simply marked and slid under needles in work.

In machines such as Brother, where needles are preselected, that fact can be used to advantage in establishing guides for the cable locations within the programmed design.

This swatch can be knit using a 1X1 locked needle selection.

While hand knitters have the advantage of seeing the color movement clearly on the knit side, machine knitters can find it harder to follow their locations with only the purl side facing them.  The vertical stripes can be interrupted at intervals by additional patterns or shifting cable locations.

The vertical stripes can be interrupted at intervals by additional patterns or shifting cable locations.

My charts begin in a spreadsheet, Mac Numbers. The first trial effort:  To begin with, the goal was to avoid the 2 by 3-pixel blocks that occur with tiling, which upon later consideration, might aid in avoiding placing cables in the wrong columns,

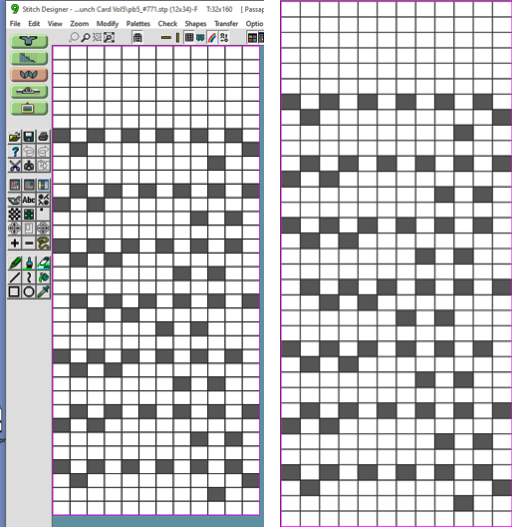

To begin with, the goal was to avoid the 2 by 3-pixel blocks that occur with tiling, which upon later consideration, might aid in avoiding placing cables in the wrong columns,  resulting in a 20X18 design. Black pixels represent the dark color, or simply the color in the B feeder.

resulting in a 20X18 design. Black pixels represent the dark color, or simply the color in the B feeder.

![]()

The alternate repeat to yield those double-width blocks, 21X18

The alternate repeat to yield those double-width blocks, 21X18 ![]()

When matching hand-knit designs such as in complex arans, the direction of the crossings matters and may need to be reversed throughout.

When matching hand-knit designs such as in complex arans, the direction of the crossings matters and may need to be reversed throughout.  In these instances, it is enough to be consistent, and their direction can be a personal choice. I prefer cabling right over left.

In these instances, it is enough to be consistent, and their direction can be a personal choice. I prefer cabling right over left. ![]()

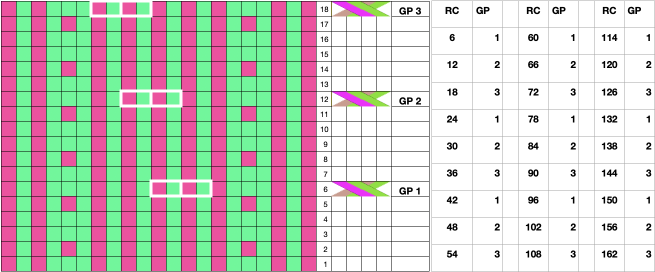

![]() In the first test, using the 20-stitch repeat, I marked up a paper strip placed under needles in work and followed markings for Row Counts and needle GrouP shared in the table on the right.

In the first test, using the 20-stitch repeat, I marked up a paper strip placed under needles in work and followed markings for Row Counts and needle GrouP shared in the table on the right.  The result begs the question of how to avoid cables in the wrong columns and the possibility of repeating them more frequently than every six rows. Occasional stitches in the wrong color may be duplicate-stitched to mask them, but small cables in the wrong place or the wrong direction are problematic.

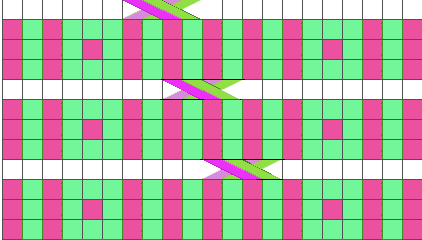

The result begs the question of how to avoid cables in the wrong columns and the possibility of repeating them more frequently than every six rows. Occasional stitches in the wrong color may be duplicate-stitched to mask them, but small cables in the wrong place or the wrong direction are problematic.  This repeat is 20X12 pixels, and it includes areas missing needle selection that will serve as visual cues on the needle bed for where stitches need to be crossed, now every 4 rows. Using the repeat on the 930 required mirroring horizontally to achieve the desired direction

This repeat is 20X12 pixels, and it includes areas missing needle selection that will serve as visual cues on the needle bed for where stitches need to be crossed, now every 4 rows. Using the repeat on the 930 required mirroring horizontally to achieve the desired direction

![]()

Returning to the inspiration sweater, imagining a possible repeat keeping in mind cable crossings no wider than 2X2,

Returning to the inspiration sweater, imagining a possible repeat keeping in mind cable crossings no wider than 2X2,  The knit tests were knit using 2/13 wools at T10+.

The knit tests were knit using 2/13 wools at T10+.

It proved impossible to use a tighter tension or to across more than 24 stitches along any single row without stitches dropping from becoming too small or the yarn breaking. The solution was to place the cabled details in a center panel. Using similar panels between undisturbed plain or patterned columns could become planned design features.

The full swatch repeat, 40X20 pixels, reversed on the 930.

![]() The end needle selection is canceled, and cable crossings are all made in the same direction. The left pair moves under the right pair to the right, and the right pair moves to the front and behind them onto the two empty needles every 10 rows, immediately after the change in needle preselection and before the following knit carriage passes.

The end needle selection is canceled, and cable crossings are all made in the same direction. The left pair moves under the right pair to the right, and the right pair moves to the front and behind them onto the two empty needles every 10 rows, immediately after the change in needle preselection and before the following knit carriage passes.

A printed needle tape can help track their locations.  It is placed on the proper preselected needles, bring those needles out to the E position, check that transfers have been made properly, and knit the next 10 rows, repeating the process.

It is placed on the proper preselected needles, bring those needles out to the E position, check that transfers have been made properly, and knit the next 10 rows, repeating the process.  Maintaining diagonal details requires planning a repeat that works as an all over design, then choosing a panel to add to cable details. One such repeat, 12X12

Maintaining diagonal details requires planning a repeat that works as an all over design, then choosing a panel to add to cable details. One such repeat, 12X12 ![]() the smallest repeat, 6X6,

the smallest repeat, 6X6,  could be used for bucket filling parts of designs with pattern in Gimp

could be used for bucket filling parts of designs with pattern in Gimp

tiled alignment test: maintaining diagonals with cable crossing blocks,

maintaining diagonals with cable crossing blocks,

The proof of concept after testing yarn tolerance for crossings, using the 24 stitch repeat suitable for punchcard model machines as well:

The proof of concept after testing yarn tolerance for crossings, using the 24 stitch repeat suitable for punchcard model machines as well: ![]()

Fails are easily predicted in a paint or image processing program when rows are added keeping the repeat at 24 wide, the diagonal is not changed, but the spacing between cables is increased ie by 2 more rows:

Fails are easily predicted in a paint or image processing program when rows are added keeping the repeat at 24 wide, the diagonal is not changed, but the spacing between cables is increased ie by 2 more rows:  Making it work: 24X48 rows

Making it work: 24X48 rows ![]()

More on developing DIY cable charts:

Visualizing knit cables 3_ using Numbers and Gimp

Visualizing knit cables in color 2_ using Numbers and Gimp , includes cumulative links

ArahPaint is often a part of the process now as well

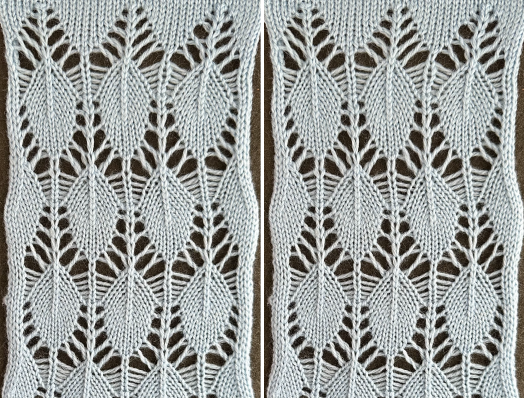

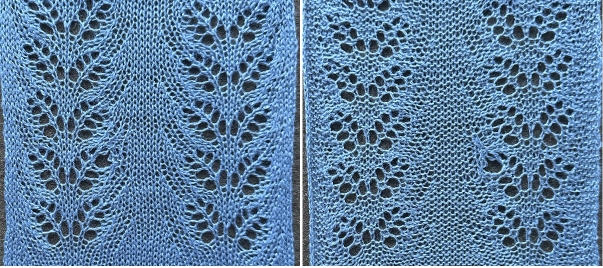

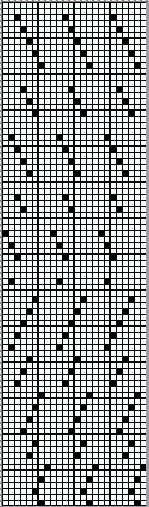

Revisiting lace leaf design repeats 2

I am constantly drawn into multiple knitting rabbit holes. Along with my revisiting 3D surfaces, more leaves are still in my line of sight for further exploration.

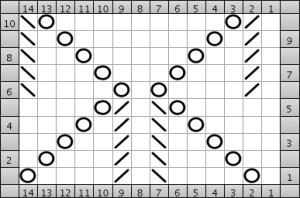

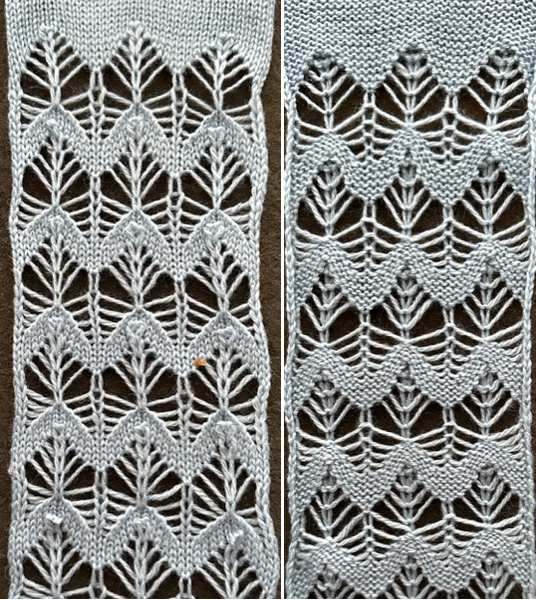

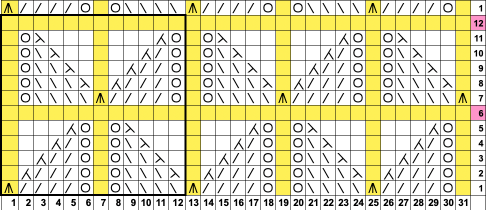

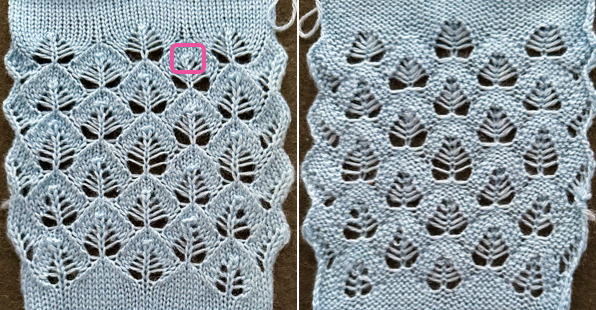

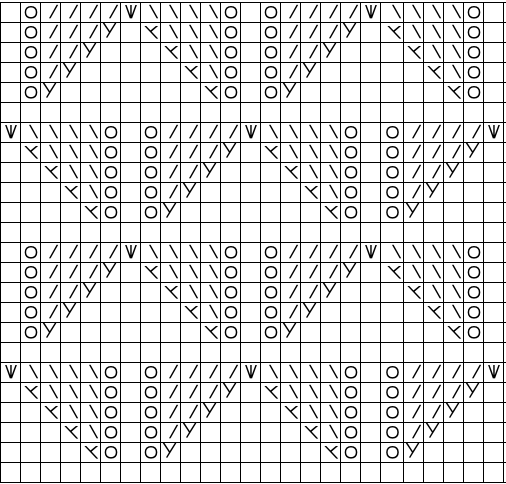

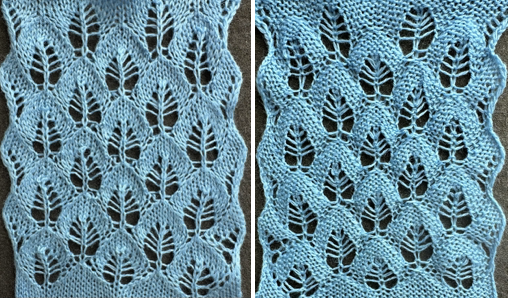

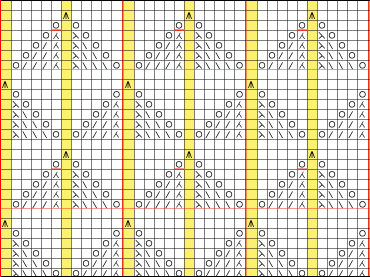

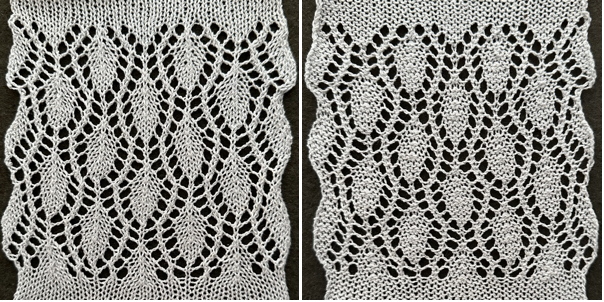

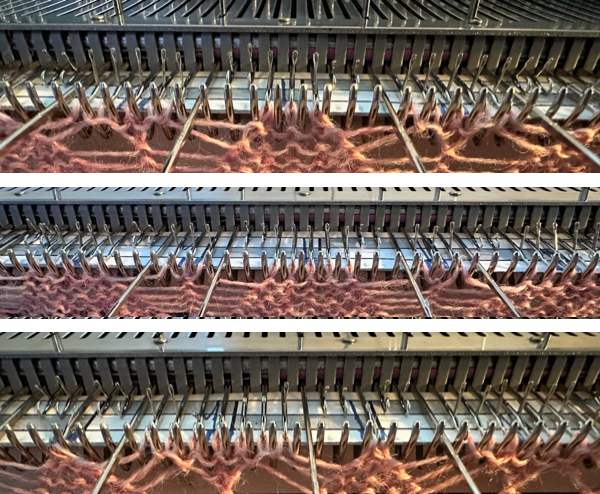

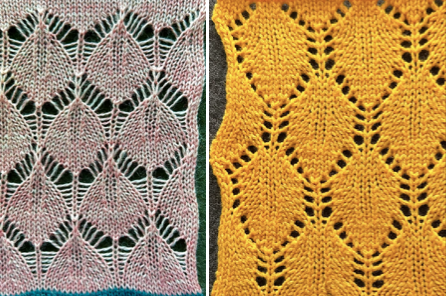

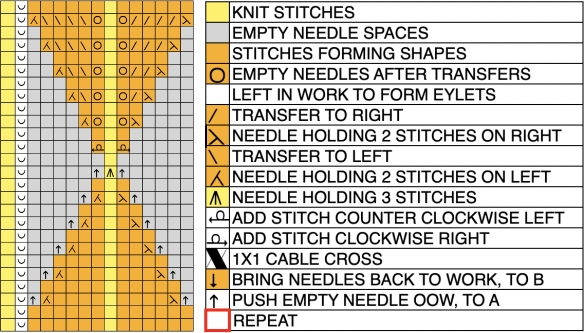

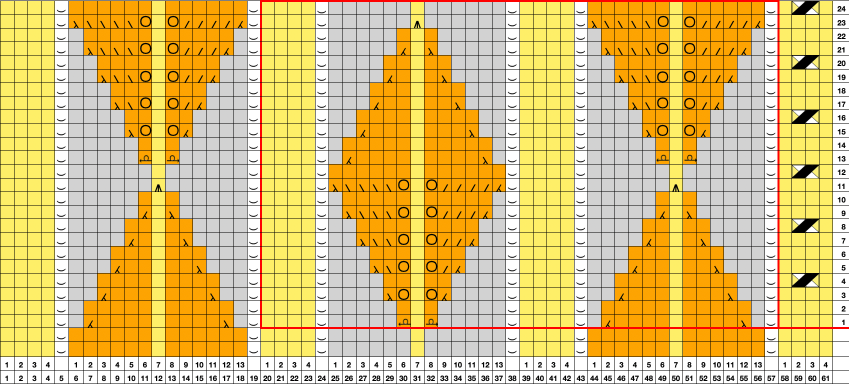

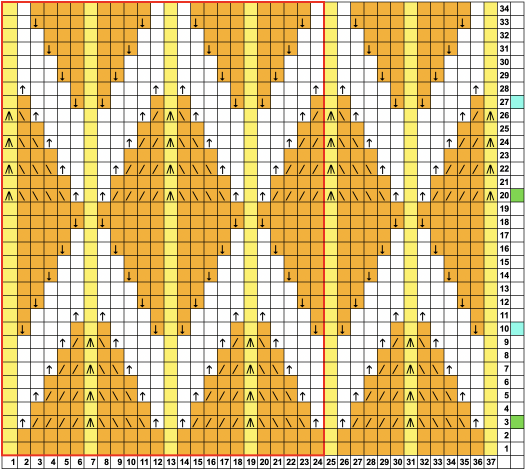

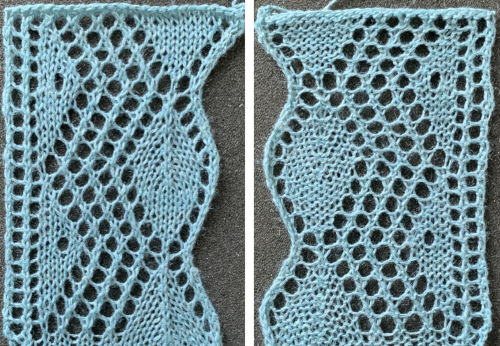

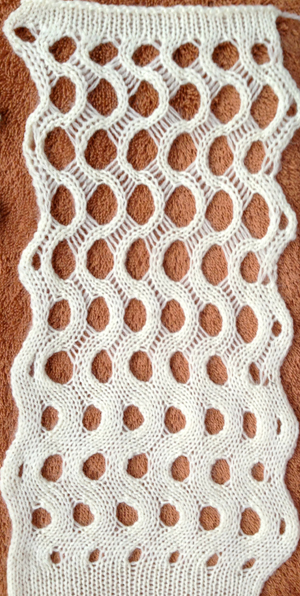

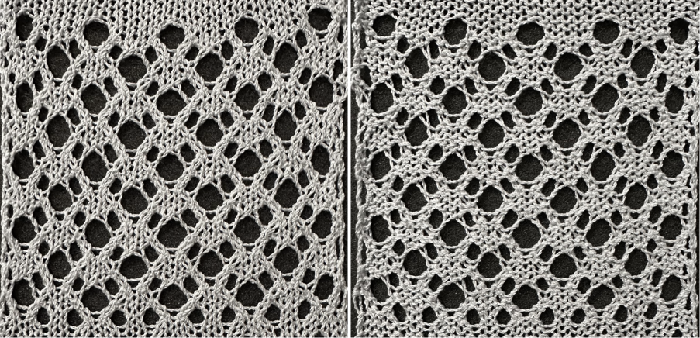

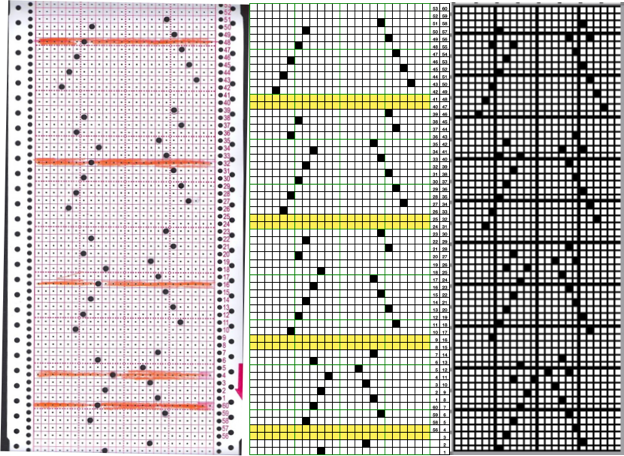

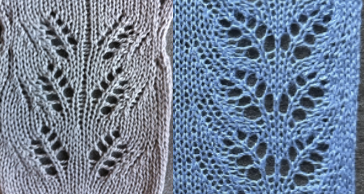

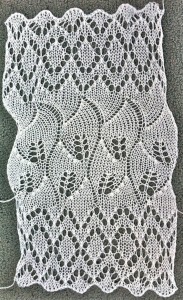

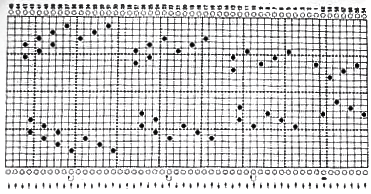

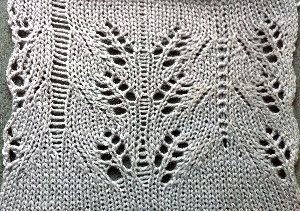

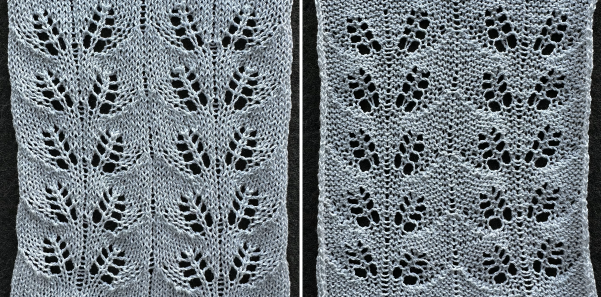

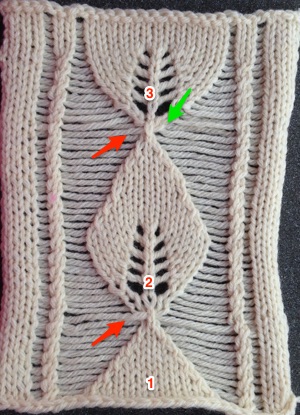

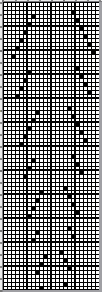

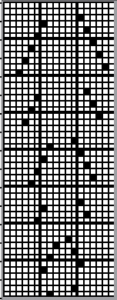

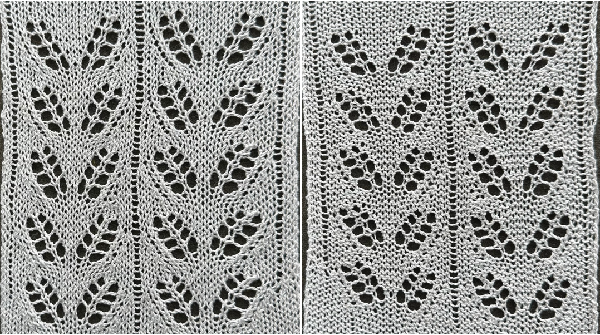

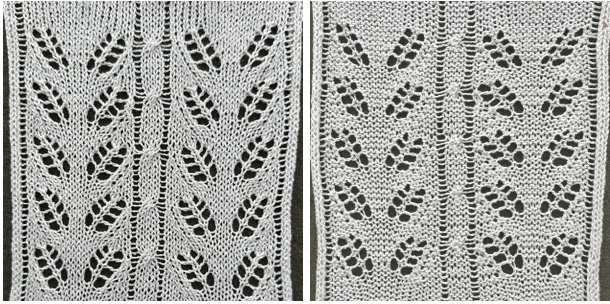

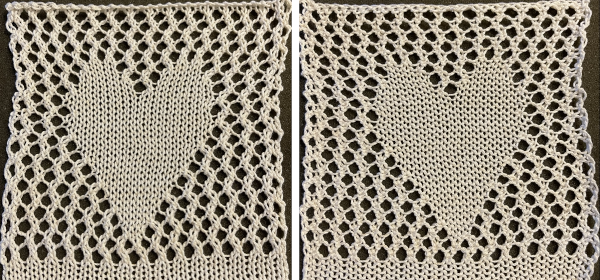

Here they are surrounded by a traveling mesh ground: a 12X52 repeat, marked for punchcard use:

the associated PNG

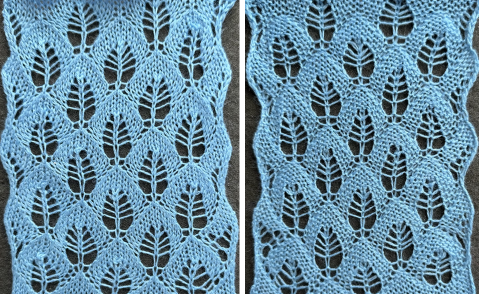

the associated PNG ![]() The test swatch knit on 38 stitches:

The test swatch knit on 38 stitches:  This design was shared as an stp file for use with DAK by Claudia Scarpa.

This design was shared as an stp file for use with DAK by Claudia Scarpa.

Her blog post includes downloadable files with clear markings for knit row locations, a punchcard version, a schematic for working it as a possible hand technique, and more.

DAK does not allow for exports in other file formats ie PNG.

Charts for the designs can be screengrabbed and processed with other programs ie Gimp and ArahPaint to make them usable in other ways including download options.

This electronic repeat is 20X136 pixels.

Horizontal mirroring was not required when using it in my 930.

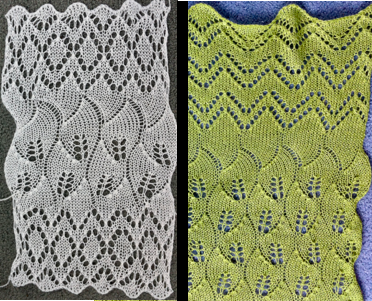

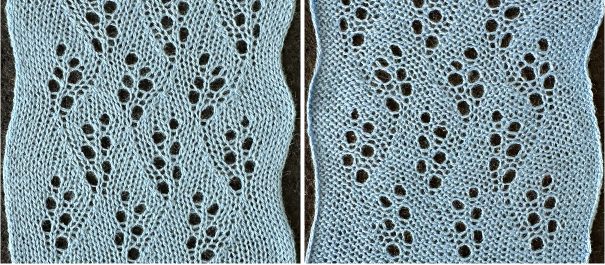

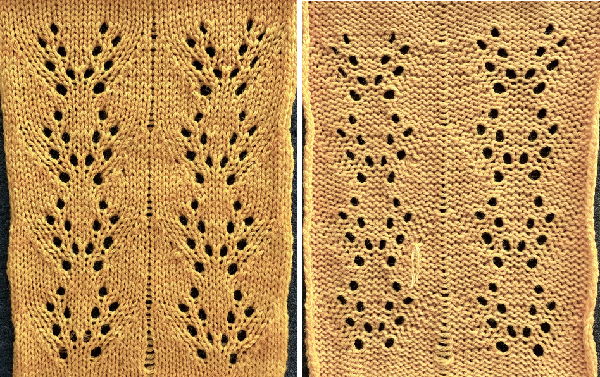

![]() Knit on 40 stitches, using the same wool-rayon yarn as in the first sample, there is a considerable change in the size of the resulting leaf shapes

Knit on 40 stitches, using the same wool-rayon yarn as in the first sample, there is a considerable change in the size of the resulting leaf shapes  This is my chart for Claudia’s punchcard version, marked in 6X6 squares blocks as found in Brother factory punchcards,

This is my chart for Claudia’s punchcard version, marked in 6X6 squares blocks as found in Brother factory punchcards,  the result is a longer repeat resulting in larger leaf shapes, 24X228 pixels

the result is a longer repeat resulting in larger leaf shapes, 24X228 pixels ![]() And then there is the world of leaves formed with hand techniques and surrounded by ladder spaces.

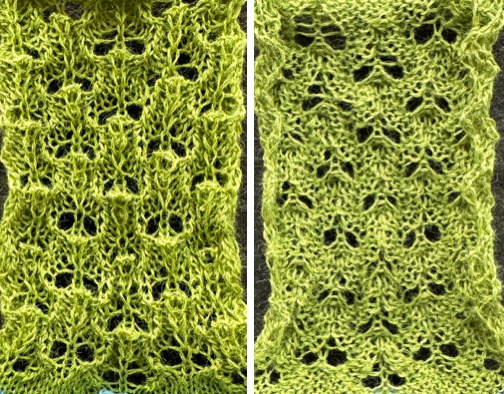

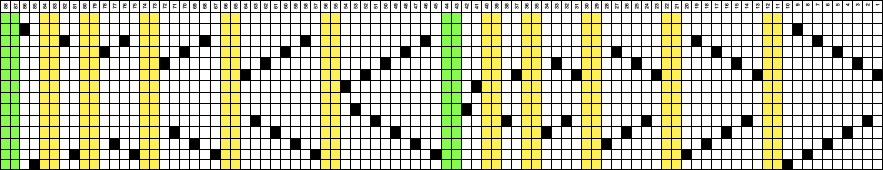

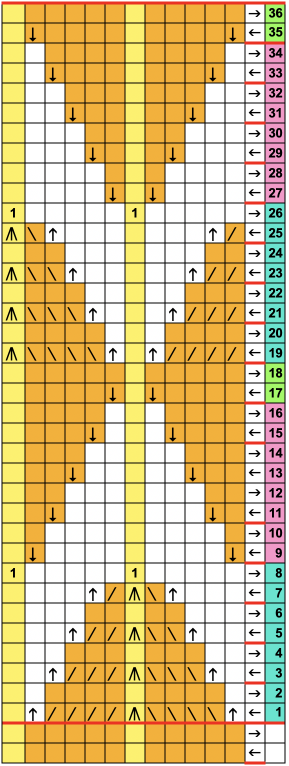

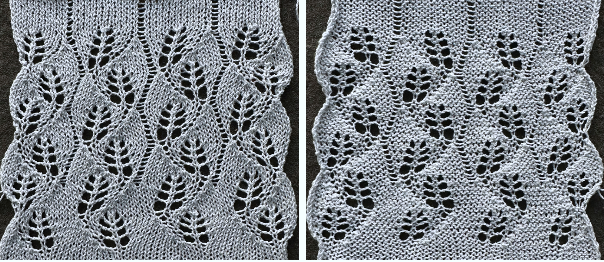

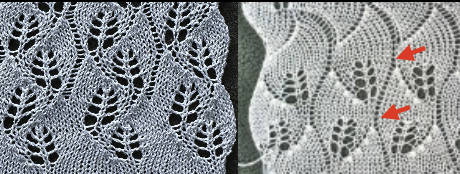

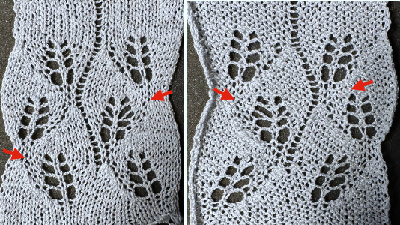

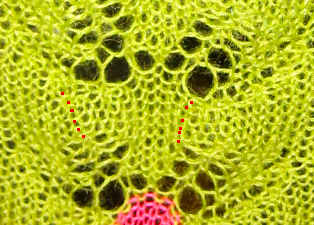

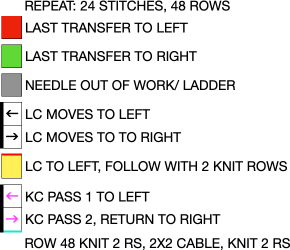

And then there is the world of leaves formed with hand techniques and surrounded by ladder spaces.

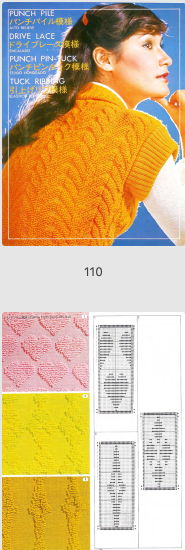

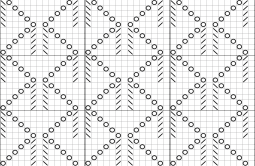

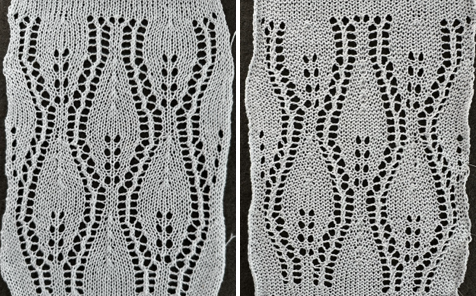

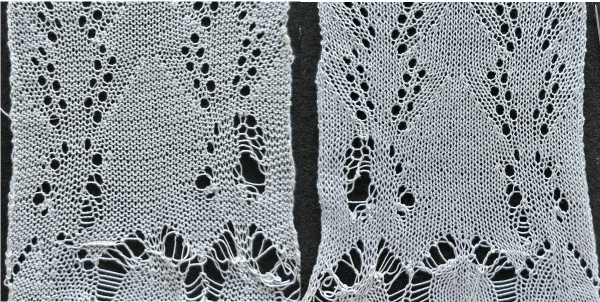

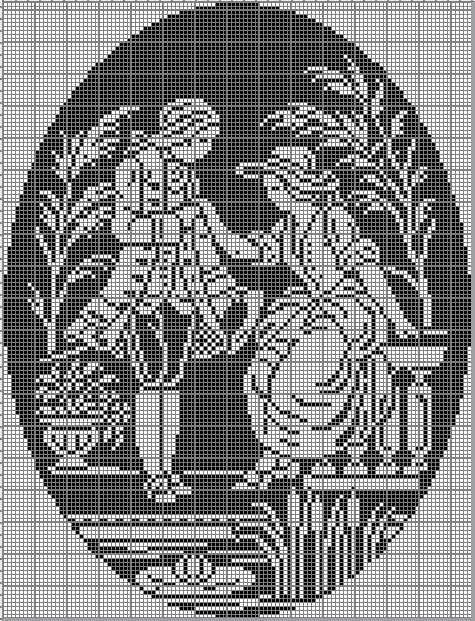

This was published in an early Silver Reed/ Studio pub eons ago and got filed in my “someday” image folder.  Visualizing repeats and necessary actions in spreadsheets before any actual knitting is useful.

Visualizing repeats and necessary actions in spreadsheets before any actual knitting is useful.

With practice, we develop a personal library of choices regarding symbols and any additional information.

This was my initial draft taking into consideration:

the direction of the transfers

the location of single-stitch columns that are left undisturbed throughout

the needles on which stitches are doubled after transfers

where stitches are decreased, every 2 rows, marked with orange cells in the second column from the left

where stitches are brought back into work on every row, marked with green cells and arrows that point up in the first column on the left

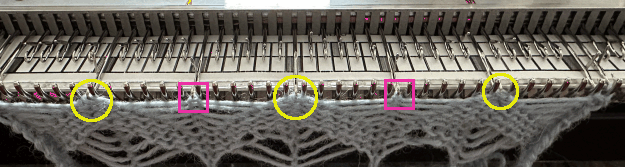

Printing custom needle tapes is an alternative to marking the needle beds or needle tapes to offer guides that help avoid errors or lots of needle counting in many hand techniques.

Printing custom needle tapes is an alternative to marking the needle beds or needle tapes to offer guides that help avoid errors or lots of needle counting in many hand techniques.

Mac Numbers version at present: 13.2. Its rulers can be set to centimeters for easy calculation of needle space cells with Japanese machine needles set 4.5 mm apart.

This PDF printed to the correct size for me when set to 100% landscape: 7 needles

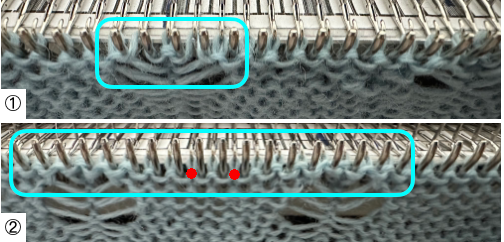

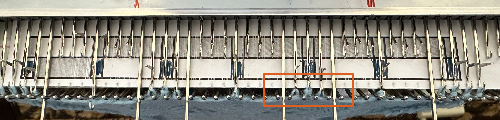

4.5X7=31.5 mm: to convert the mm to cm in DIY move the decimal point one number to the left. Row height can vary with the limit being about 2 cm. The specs from the shared file:  The work in progress on the machine as transfers are being made and the empty needles are taken out of work back to the A position.

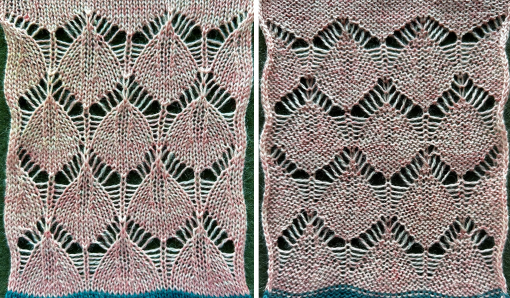

The work in progress on the machine as transfers are being made and the empty needles are taken out of work back to the A position.  The end of transfers approach and needles are returned to work before each carriage pass, forming loops on them.

The end of transfers approach and needles are returned to work before each carriage pass, forming loops on them.  The test swatch, knit in 2/8 wool at tension 9, the color chosen randomly for weight and easy visibility

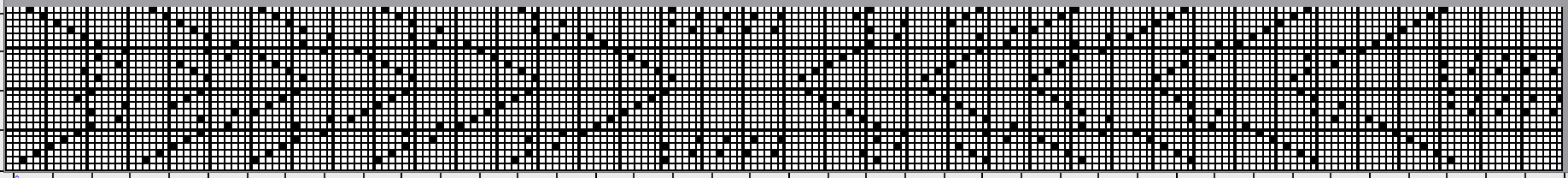

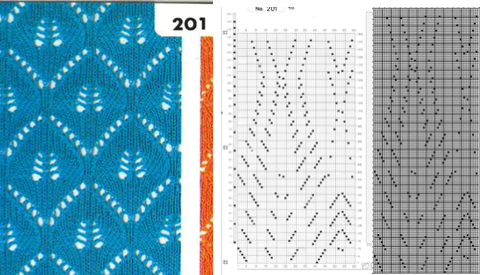

The test swatch, knit in 2/8 wool at tension 9, the color chosen randomly for weight and easy visibility  The pattern is evocative of another Studio transfer lace #112, 12X104

The pattern is evocative of another Studio transfer lace #112, 12X104 ![]() a smaller design without the missing stitches and empty spaces.

a smaller design without the missing stitches and empty spaces.  Following some research, the chart for Studio punch card 123:

Following some research, the chart for Studio punch card 123:  The electronic equivalent, 14X92 cells

The electronic equivalent, 14X92 cells ![]() The file adjusted for knitting on Brother is now reduced to 14X88 cells, and the cyan is marking areas where the knit carriage makes 4 passes rather than the usual 2

The file adjusted for knitting on Brother is now reduced to 14X88 cells, and the cyan is marking areas where the knit carriage makes 4 passes rather than the usual 2

![]() The result is a 14-stitch leaf in traditional transfer lace.

The result is a 14-stitch leaf in traditional transfer lace.  And then, the general shape begins to “appear” in other, older post swatches such as in this, part of the development of very different 12-24 stitch designs.

And then, the general shape begins to “appear” in other, older post swatches such as in this, part of the development of very different 12-24 stitch designs.  More leaves combined with open spaces, returning to hand techniques:

More leaves combined with open spaces, returning to hand techniques:

in DIY charts symbols can be developed to suit and included or eliminated in final directions. Convention matters if directions are to be published with patterns for general use, and matters less when for personal use.

Examples:

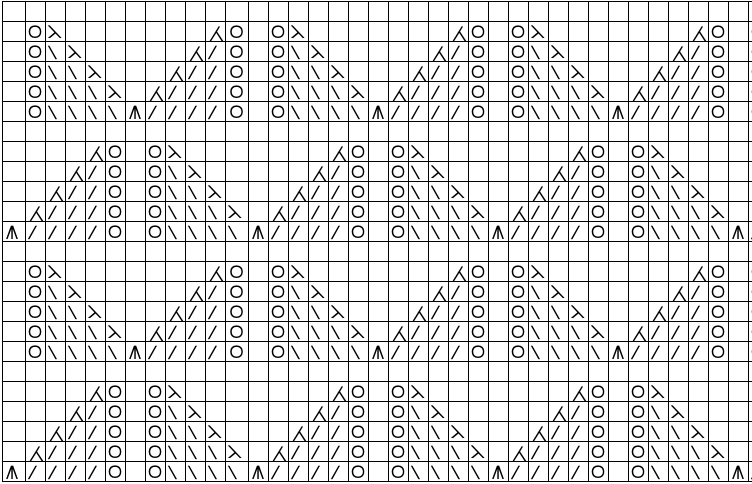

the starting diagram:

the starting diagram:

The test swatch was begun on 2/8 wool, then switched to a 4/10 alpaca and silk because it was green, and the guess that the resulting looser stitches using it might make cable crossings and transfers easier, As can be seen in the work that follows, the size and definition of knit stitches at the edge of the vertical columns and the leaves are sharper and better retained in the thicker yarn.

The test swatch was begun on 2/8 wool, then switched to a 4/10 alpaca and silk because it was green, and the guess that the resulting looser stitches using it might make cable crossings and transfers easier, As can be seen in the work that follows, the size and definition of knit stitches at the edge of the vertical columns and the leaves are sharper and better retained in the thicker yarn.  A chain cast-on was performed on the number of needles as shown above, and chains were dropped to achieve the proper setup

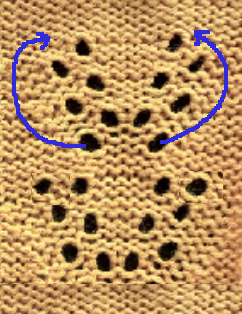

A chain cast-on was performed on the number of needles as shown above, and chains were dropped to achieve the proper setup  To make a visually balanced increase from one to three stitches, the tool is inserted from back to front of the ladder on each side of the stitch, twisted clockwise on the right, counter-clockwise on the left, with the twisted loops lifted and placed on the empty needles each side of that center stitch.

To make a visually balanced increase from one to three stitches, the tool is inserted from back to front of the ladder on each side of the stitch, twisted clockwise on the right, counter-clockwise on the left, with the twisted loops lifted and placed on the empty needles each side of that center stitch.  An illustration from one of my earlier posts on leaf shapes surrounded by ladders

An illustration from one of my earlier posts on leaf shapes surrounded by ladders  It is helpful to have a couple of 7-prong transfer tools to speed transfers along, with one set to move 4 stitches, the other 5, or simply use a combination of the standard ones.

It is helpful to have a couple of 7-prong transfer tools to speed transfers along, with one set to move 4 stitches, the other 5, or simply use a combination of the standard ones.  Another variation:

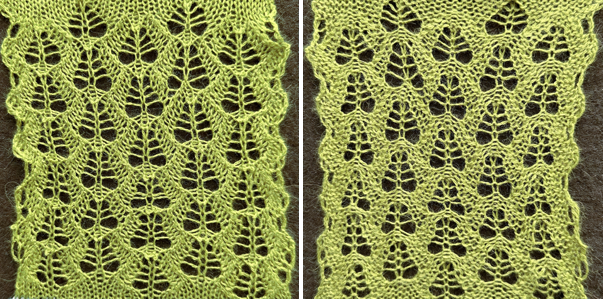

Another variation:  The slightly revised repeat

The slightly revised repeat

A few images of the work in progress: in this design, actions take place every 2 rows.

A few images of the work in progress: in this design, actions take place every 2 rows.

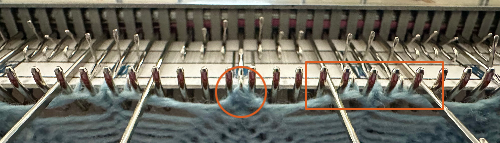

The dark segments on the custom-printed needle tape mark the needle positions for stitches that are never transferred, ie rows # 1, 7, 13, 19, etc. in the chart.

At this point in the work, there are 3 stitches on the needles holding the last transfers, marked with circles, and single stitches on the alternate needle locations, marked with squares.  After a row is knit to the opposite side, the groups of 3 stitches are reduced to a single stitch.

After a row is knit to the opposite side, the groups of 3 stitches are reduced to a single stitch.  and it is time to begin to reduce the width of the floats.

and it is time to begin to reduce the width of the floats.

Empty needles are brought to B position/work on each side of the single stitches.  Loops will form on each of those needles as the knit carriage moves to the opposite side.

Loops will form on each of those needles as the knit carriage moves to the opposite side.  Moving forward, empty needles are brought into work adjacent to each loop every 2 rows.

Moving forward, empty needles are brought into work adjacent to each loop every 2 rows.

A closer look at the twist in the floats as the action continues and the number of needles out of work is reduced:

A closer look at the twist in the floats as the action continues and the number of needles out of work is reduced:  The locations in which stitches are taken out of work form straight floats, where needles are returned to work, the floats form the familiar twists seen in transfer lace patterns.

The locations in which stitches are taken out of work form straight floats, where needles are returned to work, the floats form the familiar twists seen in transfer lace patterns.

Not to be forgotten, fully automated lace edgings such as here

and this, with both patterns shared in the same blog post

and this, with both patterns shared in the same blog post

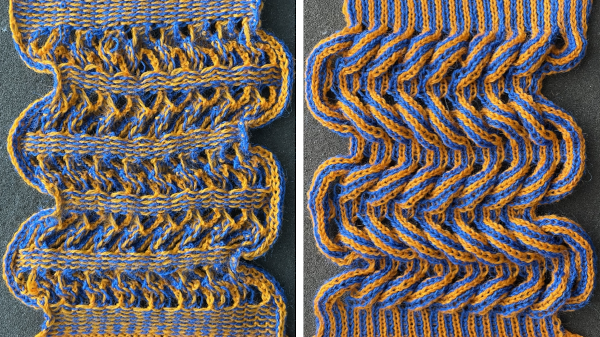

Revisiting “wisteria” 3D shapes and their possible automation

Present software makes automating textured designs in these families easier to plan and execute.

This method is limited to single colors being used at any one time and does not allow for additional patterning through fair isle or end needle selection.

Slip stitch in both directions results in black cells being knit sequentially, and the limit in width for the total design is limited to the width of the knitting machine and how the program is read and implemented.

End needle selection is canceled.

All needles in work need to be cleared with each carriage pass.

My electronic km samples are now knit on a 930, which automatically mirrors any downloaded repeats, an advantage for lettering, but not for many other situations. These designs require mirroring when using any machine or software that does so if the holding is to begin with the knit carriage on the right.  The direction of movement for the knit carriage is illustrated by arrows in the charts, which serve as guides in planning sequences.

The direction of movement for the knit carriage is illustrated by arrows in the charts, which serve as guides in planning sequences.

The original charts were executed using Mac Numbers, the table was converted and scaled to size using Gimp as described in other posts, downloaded using img2track, and mirrored horizontally before test knitting on the 930.

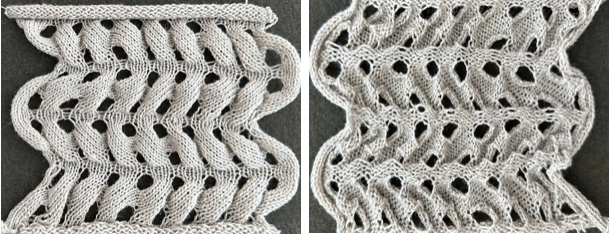

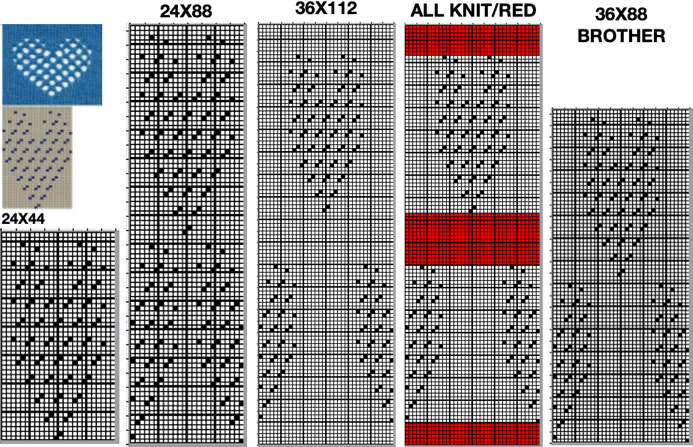

Both swatches are 40 stitches wide, planned in blocks 8 stitches in width and height, the first repeat 40X178 pixels

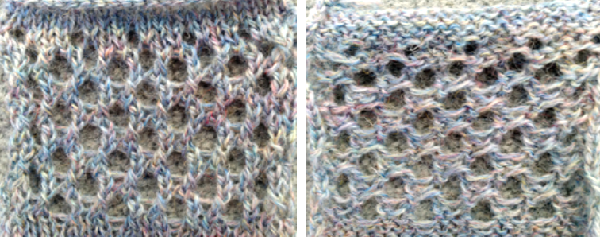

The first test: the knit carriage is set to slip in both directions. A wool yarn was used, retaining spring-back for more of a 3D texture. The design can be interrupted with all knit rows breaking up the shapes at varied intervals, with added colors if preferred.

The second repeat, 40X 226 pixels.

The second repeat, 40X 226 pixels.  A PDF for larger views of both files pdf

A PDF for larger views of both files pdf

A quick test in a 2/18 wool produced a soft, loose, drapey knit.  The same swatch was photographed 48 hours later, in a relaxed state.

The same swatch was photographed 48 hours later, in a relaxed state.  A 2/10 wool knit on the same number of stitches produced a firmer and more clearly 3D effect which remains unaltered with time.

A 2/10 wool knit on the same number of stitches produced a firmer and more clearly 3D effect which remains unaltered with time.

Hems and a knit stripe were tested as a way of breaking up the shapes  Possibilities with hand selection of needles: some samples from Adding fair isle patterning to short row patterns creating eyelets.

Possibilities with hand selection of needles: some samples from Adding fair isle patterning to short row patterns creating eyelets.

“Wisteria” meets hems

“Wisteria” meets hems  “Wisteria” cousin 2, also called fern leaf, hand technique

“Wisteria” cousin 2, also called fern leaf, hand technique  “Wisteria” cousin revisited (“holding” using slip stitch), the first programmed repeat, drawn on mylar. The 910 knit the image as drawn on the purl side, with no mirroring necessary

“Wisteria” cousin revisited (“holding” using slip stitch), the first programmed repeat, drawn on mylar. The 910 knit the image as drawn on the purl side, with no mirroring necessary

“Wisteria” 2  Horizontal “cable”

Horizontal “cable”

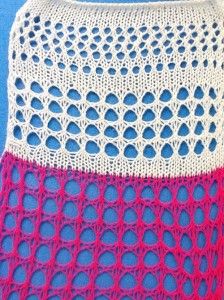

To mesh or not to mesh 10: more large eyelet variations

Some of the relevant previous posts and a few of the associated test swatches for quick comparisons:

Large scale mesh, a punchcard repeat adapted for electronic 4/21 Tuck setting used in both directions, one of 3 variations

Revisiting large eyelet lace, hand transferred (or not) 7/20

Revisiting large eyelet lace, hand transferred (or not) 7/20  Large diagonal eyelet lace 6/12, electronic sample follows at the bottom of this post:

Large diagonal eyelet lace 6/12, electronic sample follows at the bottom of this post:  Large eyelet lace, hand transferred (or not) 9/13

Large eyelet lace, hand transferred (or not) 9/13  Large scale mesh, breaking the rules, the start of the explorations 4/11

Large scale mesh, breaking the rules, the start of the explorations 4/11 Single bed slits aka horizontal “button holes” 11/16

Single bed slits aka horizontal “button holes” 11/16  “Buttonholes” and “make many – increase” “lace” 5/15

“Buttonholes” and “make many – increase” “lace” 5/15  2024

2024

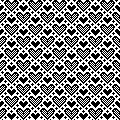

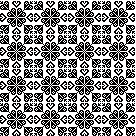

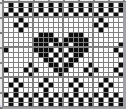

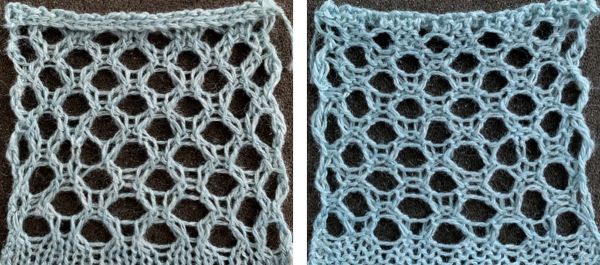

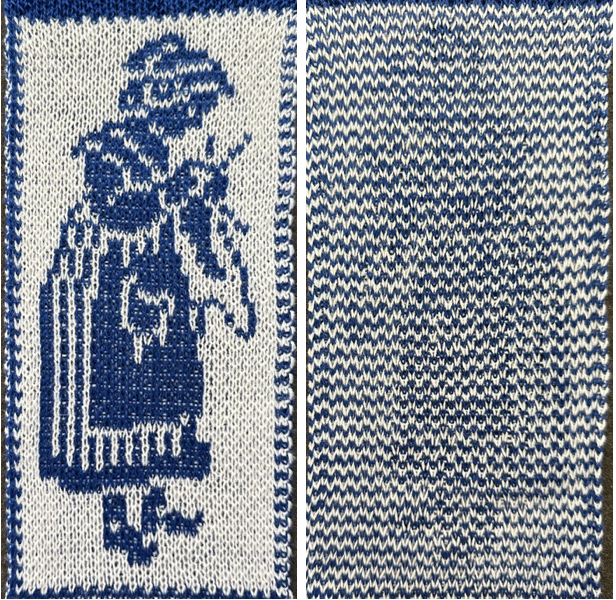

Seasonal knits inspired by published repeats 2_hearts

36X88 ![]()

introduced a combination of standard and large eyelets along the edges of the shape for a better definition of the design.

introduced a combination of standard and large eyelets along the edges of the shape for a better definition of the design.

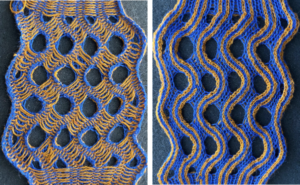

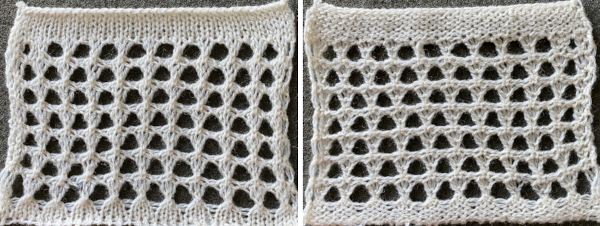

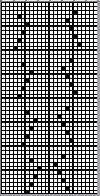

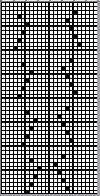

A recent FB share prompted a discussion of a different fabric combining selections by both the LC operating from the left, and the KC operating from the right, using the slip setting to secure the extra loops that result after a knit pass when side-by-side transfers are made in opposing directions.

When two carriages are selecting needles from opposite sides, each needs to clear past the respective set lines on the needle bed so as not to engage the belt while the other carriage is selecting and transferring or knitting, extension rails are a must.

Although this design repeat is 6 stitches in width, and in theory, it could be reproduced on a punchcard, it is not suitable for doing so.

On electronic machine models, each carriage pass advances the design by a single row.

When the alternate carriage is brought into action from the opposite side, punchcard models do not advance the card, repeating the last preselection, so the same stitch type is repeated for a second time. Some illustrations of the differences and contrasts can be found in the posts on doilies and edgings.

Planning the repeat in a spreadsheet helps to ensure that the direction of the lace carriage passes is kept accurate when the LC returns to selecting and transferring, as marked with the arrows on the left of the chart. The yellow cells and the arrows on the right reflect KC passes.  To knit: cancel end needle selection, KCII.

To knit: cancel end needle selection, KCII.

If any end needle is selected before a LC pass, manually push it back to the B position. If any end needle is not selected before a KC pass, push it out to D or E

position.

The LC, set to N, consistently makes 4 passes starting from and returning to the left, followed by 2 passes of the KC set to slip in both directions starting from and returning to the right.

On the 4th LC pass, as it moves from right to left all needles will be preselected forward, a clear marker that the next pass will be with the KC.

The repeat is 6 stitches in width by 24 rows in height. The empty cells on rows 12 and 22 will produce slip-stitch floats below skipped needles that secure the second loop formed by the side-to-side transfers.

This is the pixel or punched-hole configuration that produces the side-by-side transfers.

The 6X24 png

The 6X24 png ![]()

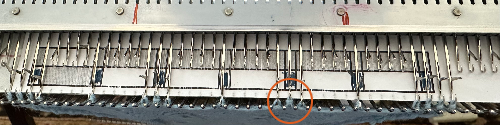

The side-by-side empty needles  after the first pass with the KC to the left, with needles not selected, in B position, matching white cell placements in otherwise all black cell rows

after the first pass with the KC to the left, with needles not selected, in B position, matching white cell placements in otherwise all black cell rows  with slip-stitch floats holding down the first loop after the second KC pass as it returns to the right

with slip-stitch floats holding down the first loop after the second KC pass as it returns to the right  The proof of concept

The proof of concept  Pamela Cruse devised and shared another similarly mixed eyelet size knit. Her repeat is 6X16, with only the LC selecting needles, the KC remains set to knit, making it suitable for punchcard machines as well. The full card,

Pamela Cruse devised and shared another similarly mixed eyelet size knit. Her repeat is 6X16, with only the LC selecting needles, the KC remains set to knit, making it suitable for punchcard machines as well. The full card,  a single repeat,

a single repeat,  and the tiny PNG

and the tiny PNG ![]() The knit in progress: after the two side-by-side needles are emptied, the next KC passes produce two consecutive loops, the first does not stay on the needles, but rather, gets dropped, forming a float

The knit in progress: after the two side-by-side needles are emptied, the next KC passes produce two consecutive loops, the first does not stay on the needles, but rather, gets dropped, forming a float  Needles will be preselected on each side of them, followed by transfers.

Needles will be preselected on each side of them, followed by transfers.  As those transfers are completed to the left and then to the right, it is those moved stitches that anchor down each loop.

As those transfers are completed to the left and then to the right, it is those moved stitches that anchor down each loop.  The first KC pass to the left forms single loops on the now empty needles,

The first KC pass to the left forms single loops on the now empty needles,  and the second KC pass to the right completes an all-knit row.

and the second KC pass to the right completes an all-knit row.  The process is repeated in brick configuration.

The process is repeated in brick configuration.

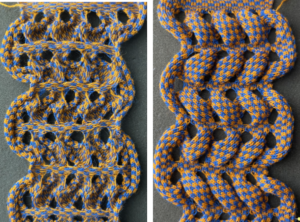

Mirroring horizontally was not required on the 930. When it was tested, an all-over single eyelet was produced, seen a the bottom of the swatch.  This large eyelet variation was developed by Claudia Scarpa, who shared these repeats for Brother machines which use opposite tuck/part buttons

This large eyelet variation was developed by Claudia Scarpa, who shared these repeats for Brother machines which use opposite tuck/part buttons  to form stitches properly after the side-by-side empty needle transfers have been performed.

to form stitches properly after the side-by-side empty needle transfers have been performed.

There are 2 versions, each beginning with 6 stitches X 16 rows design.

Aligning eyelets vertically

![]() and in a brick arrangement

and in a brick arrangement

![]() To knit: cancel end needle selection, KCII.

To knit: cancel end needle selection, KCII.

If any end needle is selected before an LC pass, manually push it back to the B position. If any end needle is not selected before a KC pass, push it out to the D or E position. The LC, set to N, consistently makes 4 passes starting from and returning to the left, followed by 4 passes of the KC set to tuck to the left, slip to the right, starting from and returning to the right of the needle bed.

After the LC transfers have formed the double eyelets, when rows for the formation of tuck loops followed by slip stitch floats have been preselected, there will be pairs of needles brought forward to the D position.

The first KC tuck pass to the left forms tuck loops on the non-selected needles  the second slip pass to the right anchors the tuck loop as all needles are preselected for the pair of all knit rows that follow

the second slip pass to the right anchors the tuck loop as all needles are preselected for the pair of all knit rows that follow  The process is repeated with the eyelets forming in either orientation

The process is repeated with the eyelets forming in either orientation  As the KC makes its last pass to the right there is no needle preselection, a sign that it is time to return to the use of the LC operating from the left

As the KC makes its last pass to the right there is no needle preselection, a sign that it is time to return to the use of the LC operating from the left  The vertically aligned repeat test swatch

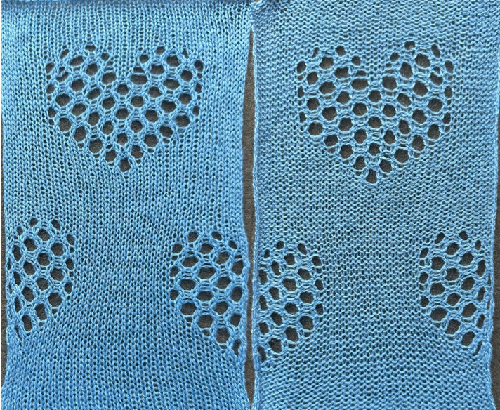

The vertically aligned repeat test swatch  and the brick repeat test

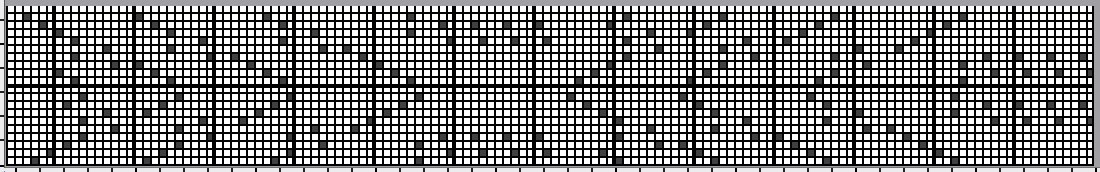

and the brick repeat test  The 24X48 repeat for the diagonal mesh

The 24X48 repeat for the diagonal mesh

![]() The lace carriage makes 4 passes left to right followed by 2 passes of the knit carriage from right to left for the full repeat.

The lace carriage makes 4 passes left to right followed by 2 passes of the knit carriage from right to left for the full repeat.

The first KC pass creates double loops on the side-by-side empty needles  as it returns to the right, the first double loop is dropped, and a second double loop is formed

as it returns to the right, the first double loop is dropped, and a second double loop is formed  the next series of transfers will double up a single stitch on one of the two loops

the next series of transfers will double up a single stitch on one of the two loops  and the process is repeated as knitting progresses. The yarn used is knit wool rayon again, and the side edges were allowed to curl. There is one stitch that got away from me on the left.

and the process is repeated as knitting progresses. The yarn used is knit wool rayon again, and the side edges were allowed to curl. There is one stitch that got away from me on the left.

Revisiting lace leaf design repeats 1

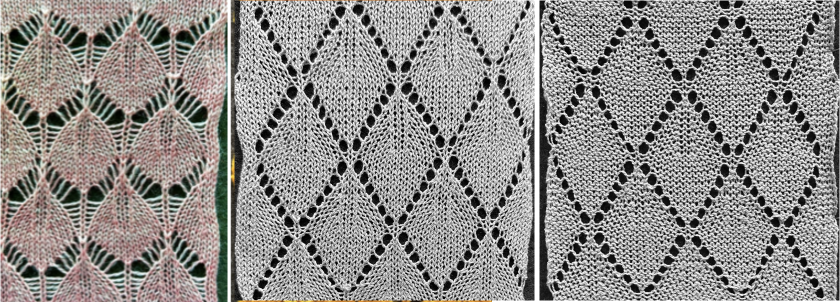

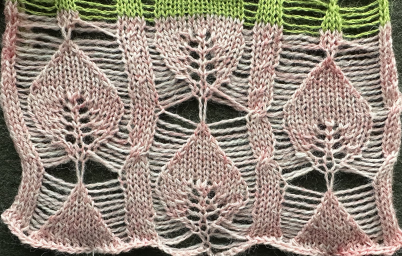

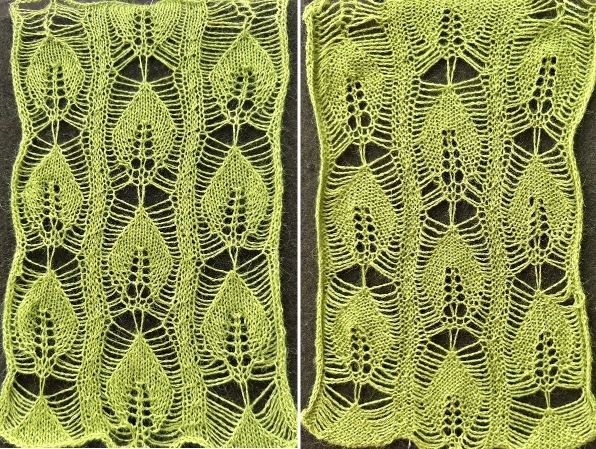

Just about a decade ago, I began one of my many temporary technique obsessions by finally attempting transfer lace knitting, and it continued for a few years during which I produced scarves and shawls for gifts and sale in galleries and craft shows.

Leaf shapes held a particular attraction for me.

That long ago I was not sharing the pattern repeats used in my production items, and my note-keeping was not what could be defined as consistent or compulsive, so in looking at yet another pin sharing a lace leaf pattern in the present time, I went looking for some of my early repeats and let us say I did not immediately locate them.

My lace production pieces were worked on a 910 with mylar or a Brother 892 punchcard model, long before I entered the world of spreadsheet tables, downloads from Mac with Ayab to the 910, and later owning and favoring to a 930 with img2track.

A review of previous shares:

Beginnings, 2/11, adapted from a design published by Susanna Lewis

In progress, 2/11

In progress, 2/11  On the blocking board 2/11

On the blocking board 2/11 Back to lace/ 2/12, hand knit

Back to lace/ 2/12, hand knit  More on those slanting lace leaves 2/12 hand knit, pattern graph available for download

More on those slanting lace leaves 2/12 hand knit, pattern graph available for download  Back to leaf lace, add rib, and take it to the Passap, hand transfer, E6000 with console assist 3/12, added punchcard unrelated design

Back to leaf lace, add rib, and take it to the Passap, hand transfer, E6000 with console assist 3/12, added punchcard unrelated design

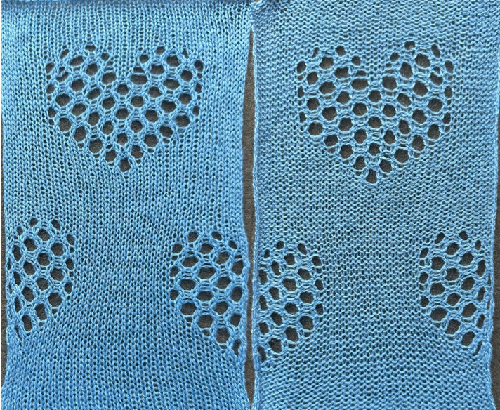

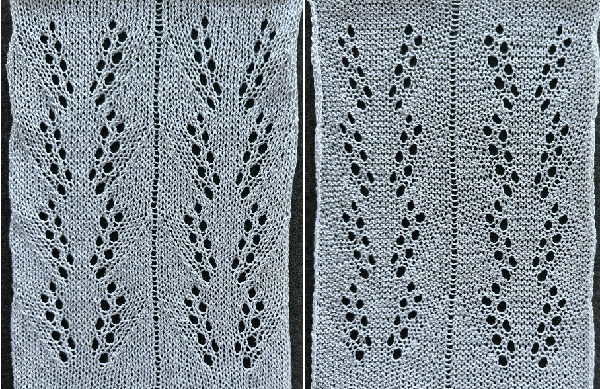

The post punchcard, reconstructed in 2024 using Mac Numbers, Gimp, and ArahPaint, with similarities to the design that evolved in later explorations producing the more successful 24X64 repeat reproduced on the right.

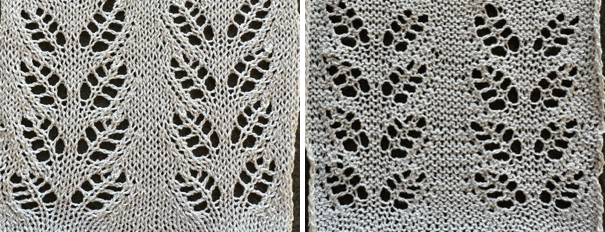

The post punchcard, reconstructed in 2024 using Mac Numbers, Gimp, and ArahPaint, with similarities to the design that evolved in later explorations producing the more successful 24X64 repeat reproduced on the right.  Comparing the knitted results:

Comparing the knitted results:  Getting there hand transfer tech with card assist 3/12

Getting there hand transfer tech with card assist 3/12  The joys of lace on the KM 3/12, dropped knitting, or too many dropped stitches can happen.

The joys of lace on the KM 3/12, dropped knitting, or too many dropped stitches can happen.  Getting there leaf motifs, adding borders 3/12, goal: find the related punchcard

Getting there leaf motifs, adding borders 3/12, goal: find the related punchcard

2024 the punchcard was located.

2024 the punchcard was located.

A punch card roll was used. When purchased, it was advertised for Brother but factory number markings on the right are for Studio machines, with row 1 on row 5 from the bottom all punched rows as opposed to row 7 for Brother. Keeping the use of the roll continuous, the factory markings become irrelevant in such DIY long repeats.

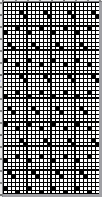

In this instance, the card is 104 rows in length.  Using Mac Numbers, Gimp, and ArahPaint, for easier reproduction, here it is shown with 6X6 grid block markings typical of Brother factory cards

Using Mac Numbers, Gimp, and ArahPaint, for easier reproduction, here it is shown with 6X6 grid block markings typical of Brother factory cards  The card begins with a blank row, and the first transfers will be made to the right rather than to the typical left

The card begins with a blank row, and the first transfers will be made to the right rather than to the typical left

In the swatch, only two knit rows were knit after each series of transfers occurring after 19, 22, 36, 52, 62,74, 88, 104.

Needles were taken out of work beginning with needle 1 on the right of 0, and 13 on the left, continuing every 12 stitches on wider knits.

The earlier swatch has extra rows knit between shapes

The earlier swatch has extra rows knit between shapes  A quick test on 24 stitches with 4 rows knit after 52 and 104 passes of the LC respectively

A quick test on 24 stitches with 4 rows knit after 52 and 104 passes of the LC respectively  Yes, a punchcard is possible leaf motifs 3/12, card, find repeat

Yes, a punchcard is possible leaf motifs 3/12, card, find repeat  the card, also finally found

the card, also finally found  exploring detail options ie adding knit rows, where to place the repeat for side edge variations, using ladders between motifs, latching the ladder to reproduce single row tuck stitches, applying the choices to a long-ago final shawl.

exploring detail options ie adding knit rows, where to place the repeat for side edge variations, using ladders between motifs, latching the ladder to reproduce single row tuck stitches, applying the choices to a long-ago final shawl.

The repeat shortened for swatching 2024: 24X52

The repeat shortened for swatching 2024: 24X52  needles out of work help define the leaf shapes

needles out of work help define the leaf shapes  the png

the png ![]() proof of concept with 4 rows knit after the 52 LC passes that complete one pair of leaves.

proof of concept with 4 rows knit after the 52 LC passes that complete one pair of leaves.  With so many transfers between knit rows on a long piece like a shawl or scarf, knitting 4, 6, or more rows upon completion of each full repeat is an option. Six appears to have been my choice in that work on the machine

With so many transfers between knit rows on a long piece like a shawl or scarf, knitting 4, 6, or more rows upon completion of each full repeat is an option. Six appears to have been my choice in that work on the machine

This repeat is composed of 24X64 cells, there are 16 rows of LC transfers followed by 2 rows of knit stitches throughout, after 64 LC passes only 8 rows of actual knitting have taken place.

This repeat is composed of 24X64 cells, there are 16 rows of LC transfers followed by 2 rows of knit stitches throughout, after 64 LC passes only 8 rows of actual knitting have taken place.

Remember to oil the LC as well as the KC, and look out for dropped stitches, like the one in the swatch followed by a lazy “repair” that is particularly noticeable on the purl side.

![]()

The evolution of a simpler and easier-to-execute pattern with similar movement can be found at the bottom of this post.

The evolution of a simpler and easier-to-execute pattern with similar movement can be found at the bottom of this post.

Ladders with lace, (leaf) “making things work” 1 3/15

Ladders with lace, (leaf) “making things work” 2 3/15

A new “leaf” lace 4/17, chart provided

A new “leaf” lace 4/17, chart provided  The start of a new series aiming for DIY: this repeat is 24 stitches wide, suitable for punchcard models, but tested on a 930 where it was necessary to mirror it horizontally, and is knit using 2/18 wool.

The start of a new series aiming for DIY: this repeat is 24 stitches wide, suitable for punchcard models, but tested on a 930 where it was necessary to mirror it horizontally, and is knit using 2/18 wool.

Plotted on a spreadsheet with LC passes and direction of movement marked on the left side, knit rows after LC passes 2, 8, 12, 20, 26, 36, 40, 48, 54, 64, 72, 84

the 24X84 png

the 24X84 png ![]()

Playing with more variations does not always lead to results worth pursuing, but they provide learning experiences that inform future choices. Anyone familiar with lace knitting, particularly where so many transfer rows occur between knit rows, has experienced a lot of this from time to time.

Playing with more variations does not always lead to results worth pursuing, but they provide learning experiences that inform future choices. Anyone familiar with lace knitting, particularly where so many transfer rows occur between knit rows, has experienced a lot of this from time to time.  Lace can only be described as temperamental.

Lace can only be described as temperamental.

I am perennially in awe of videos where some knitters appear able to knit lace yardage with a motor with no dropped stitches to be seen anywhere. That has not been my experience, though for a while I did manage to produce a line of one-off scarves and shawls knit in a variety of lace patterns. I got good at unraveling down to knit rows and rehanging.

Avoiding dropped stitches, and managing dropped ones have avid advocates for different methods, a topic for a different discussion.

It helps to have a needle retainer bar that is in really good condition, needles with latches that operate properly, tension and suitable weight of yarn based on the number of needles used, and begin testing with yarn colors that make it easy to identify transfer issues as they are happening as opposed to after the fact when large holes seem to magically appear.

Unless the goal is to create a large mesh, if side-by-side needles are preselected in most designs including these, the causes may be punching or drawing errors, or simply that in the specific machine model, or software used, the pattern needs to be mirrored horizontally, as in my 930.

New to me now: the assumption is made that the LC will be slipped off the belt when the other carriage is in use. That is not necessary if the knit carriage does not also select needles, locking onto the belt.

Generally, the patterns are advanced by any carriage set to select needles as it moves past the center of the needle bed.

If the lace carriage does not clear the set mark on the left side of the machine, the pattern may not advance sporadically, which is evocative of needle selection fails, but it will resume doing so when the LC is moved far enough to the left before making its next pass to the right.

In this repeat, the knit rows are easy to track. They happen after there is no needle preselection as the LC moves from right to left, ie. after 4, 8, 6, 10 carriage passes, etc.

The blank number of rows between black pixels is not always even and can be odd when a reversal of the direction of transfers is required with a Lace Carriage that operates only from the left.

If needles out of work are used, care should be taken not to accidentally bring them back into work during knitting. If several rows have been knit, the stitch is dropped, and the needle is brought out of work again, the resulting ladder will be wider than the one in the space below it.

Maintaining the goal of producing a design suitable for punchcard models as well, this new repeat is composed of 24X72 cells  the png.

the png. ![]() adding needles out of work helps define the shapes which can also change appearance depending on yarn and color choices.

adding needles out of work helps define the shapes which can also change appearance depending on yarn and color choices. ![]() A more successful swatch, knit in wool rayon:

A more successful swatch, knit in wool rayon:  Modifying the design for use on electronic models only, an 18X48 repeat, knit in a 2/8 wool that really wanted to split upon being transferred, adding a ladder between repeats as above, and 4 knit rows rather than 2 upon the completion of each design segment

Modifying the design for use on electronic models only, an 18X48 repeat, knit in a 2/8 wool that really wanted to split upon being transferred, adding a ladder between repeats as above, and 4 knit rows rather than 2 upon the completion of each design segment

![]() Three would-be runaway stitch spots are visible.

Three would-be runaway stitch spots are visible.  Wanting to shift eyelets, changing the repeat:

Wanting to shift eyelets, changing the repeat:  The first try, 20X48 pixels repeat proved to be quicker and easier to knit, with only single transfers at any one time, two rows were knit after every 12 LC passes.

The first try, 20X48 pixels repeat proved to be quicker and easier to knit, with only single transfers at any one time, two rows were knit after every 12 LC passes. ![]()

A shift to a 19X48 row repeat, planning to add ladders between each of the repeats

A shift to a 19X48 row repeat, planning to add ladders between each of the repeats

![]() I like to program repeats taking into consideration the number of stitches required for the project, which offers the opportunity of adding extra blank columns for knit borders on either side and avoids any confusion with positioning when returning to the design at some future time.