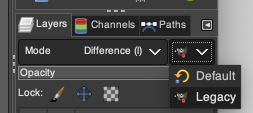

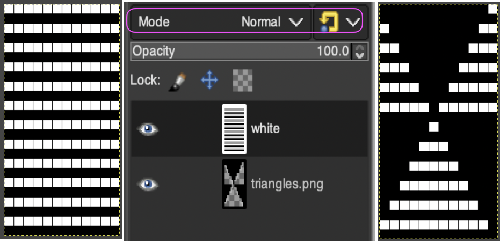

2023 The layers menu in Gimp 2.10.34 no longer offers the difference mode.

From the manual: “If you need to stay compatible with older GIMP versions or you need to use the legacy layer modes for other reasons, look for the icon to the right of the layer modes selection.

This drop-down menu will let you choose between Default and Legacy. If you choose the latter, the layer modes list will only show the legacy layer modes and all modes will have “(legacy)” behind their name (the selected mode will use the short version (l). ”

To make the dialog available:  click on Legacy to switch mode selections.

click on Legacy to switch mode selections.  In December 2022 I began to experiment with layer transparency please see the post Gimp Update for Mac 3.

In December 2022 I began to experiment with layer transparency please see the post Gimp Update for Mac 3.  Over the years I have developed personal methods for creating color separations for many types of knit fabrics, born from lots of experimentation when published resources were absent or extremely limited.

Over the years I have developed personal methods for creating color separations for many types of knit fabrics, born from lots of experimentation when published resources were absent or extremely limited.

I continued to share methods as they evolved from increasing familiarity with specific programs or as I was introduced to new ones.

Since I began to use paint programs including Gimp I had very limited experience using layers and did not consider how they might be used in color separations for BW knit repeats.

In my last post on fantasy fair isle ribber fabrics, Claudia Scarpa shared her layers method and subsequently published a Youtube video for obtaining a separation for a very similar fabric to the one I developed beginning with a large design motif that in her instance was also placed specifically on a larger ground.

Her method for separations in 2 color work sparked my interest in using the steps to yield knitting patterns for varied textures and stitch types, beginning with dbj.

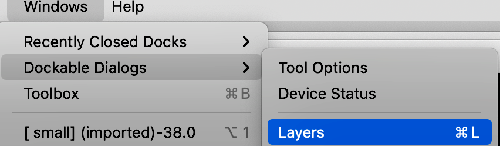

Using

will display layer options in my Mac on the bottom right side of the screen

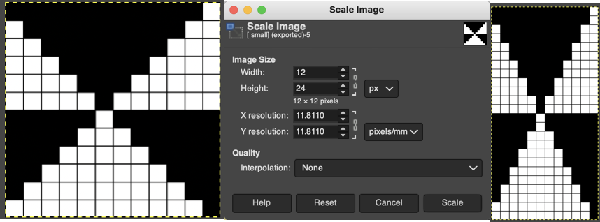

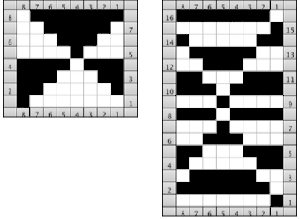

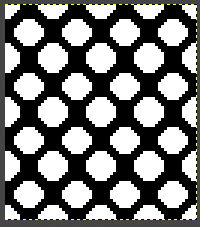

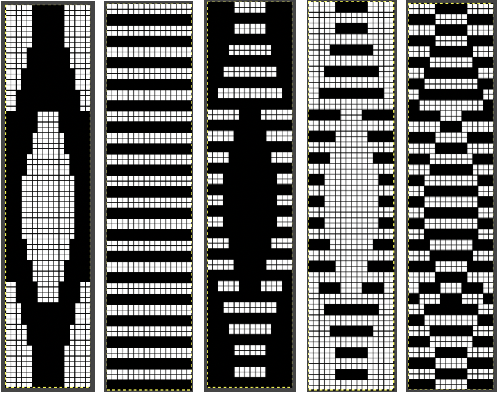

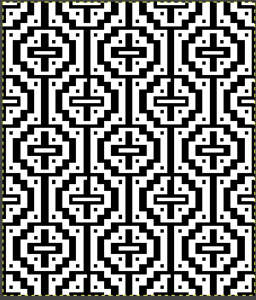

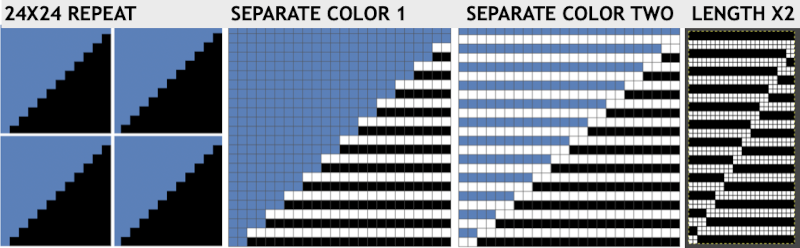

will display layer options in my Mac on the bottom right side of the screen  A simple geometric shape

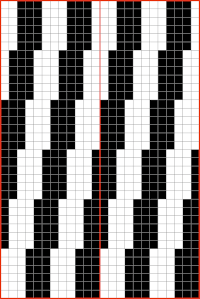

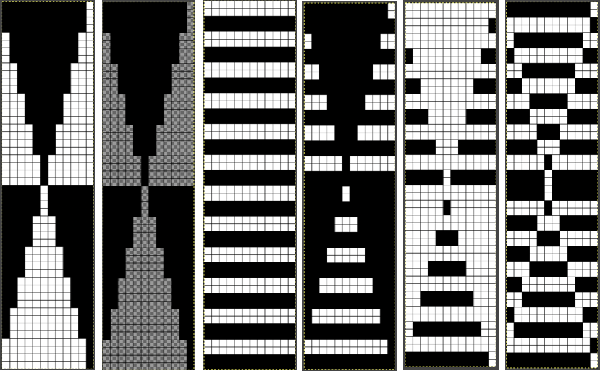

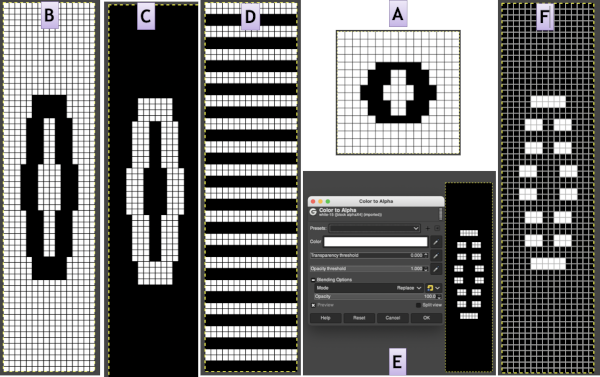

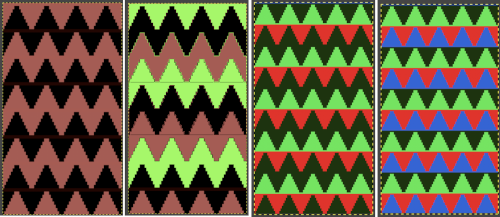

A simple geometric shape ![]() is scaled in Gimp to twice its height, check that Quality Interpolation is set to None. I have sometimes had issues with scaling in Gimp, particularly when working with small repeats. The cause appears to have been that the Quality, Interpolation, needs to be set to None and may randomly change while working through several steps in processing any image or after a program restart. Arahpaint scaling is still an excellent option for knitters who have it available.

is scaled in Gimp to twice its height, check that Quality Interpolation is set to None. I have sometimes had issues with scaling in Gimp, particularly when working with small repeats. The cause appears to have been that the Quality, Interpolation, needs to be set to None and may randomly change while working through several steps in processing any image or after a program restart. Arahpaint scaling is still an excellent option for knitters who have it available.

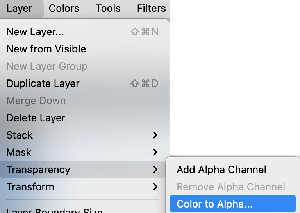

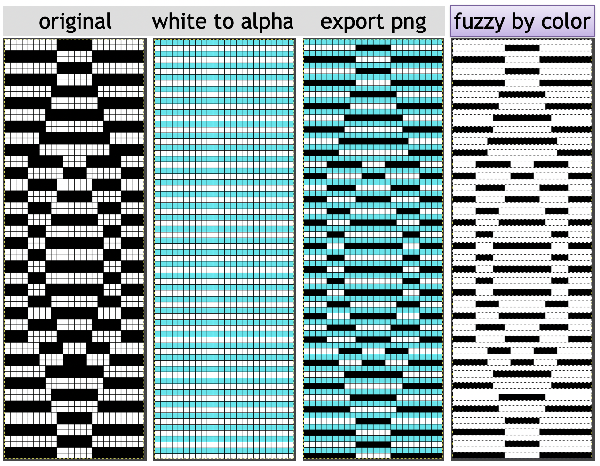

the white ground of the resulting image is rendered transparent by using Color to Alpha

the white ground of the resulting image is rendered transparent by using Color to Alpha  and will constitute the first layer for the separation process

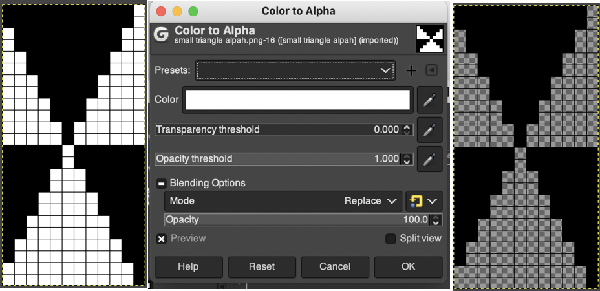

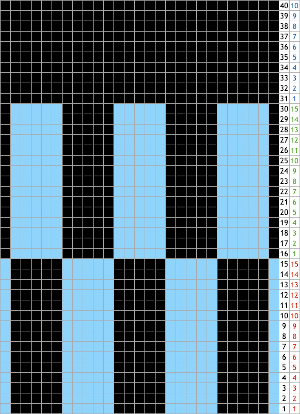

and will constitute the first layer for the separation process  Select New Layer from the Layers menu (see chart), choosing the background or foreground color to have a white screen. It will share properties with the alpha repeat such as pixel count, magnification, and the grid view if used.

Select New Layer from the Layers menu (see chart), choosing the background or foreground color to have a white screen. It will share properties with the alpha repeat such as pixel count, magnification, and the grid view if used.

Use the pencil tool to draw a repeat that will be used to fill the new layer, followed by using the rectangle tool to select what will become the pattern used to bucket fill the whole layer.

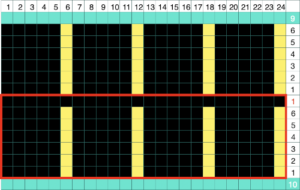

The latter may be the smallest possible selection or even that of complete rows as in my chart.  Copy the selection, and it will be saved to the clipboard and remain available for filling with the pattern unless the program is quit. It may also be saved as a pattern for future use.

Copy the selection, and it will be saved to the clipboard and remain available for filling with the pattern unless the program is quit. It may also be saved as a pattern for future use.

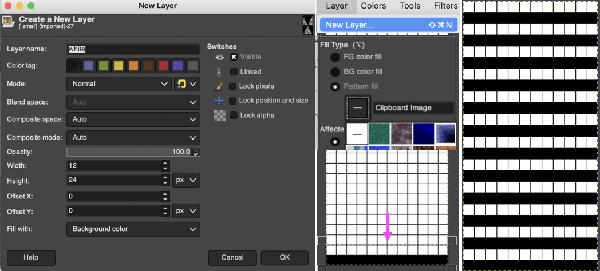

After using the rectangle select tool, remember to click in the window outside the image to set the layer before using the bucket fill tool in the pattern fill setting, or the whole layer will simply fill in with a single color.  In the layers dialogue, use the mouse to drag and drop the alpha image icon for the triangle layer onto the newly created one. The selected icon will appear surrounded by a border when chosen, a new icon will appear during the step.

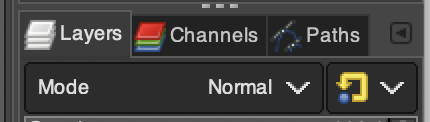

In the layers dialogue, use the mouse to drag and drop the alpha image icon for the triangle layer onto the newly created one. The selected icon will appear surrounded by a border when chosen, a new icon will appear during the step.  Both layers measure the same pixel dimensions, no placement adjustments are necessary. The mode, highlighted here is changed in a later step.

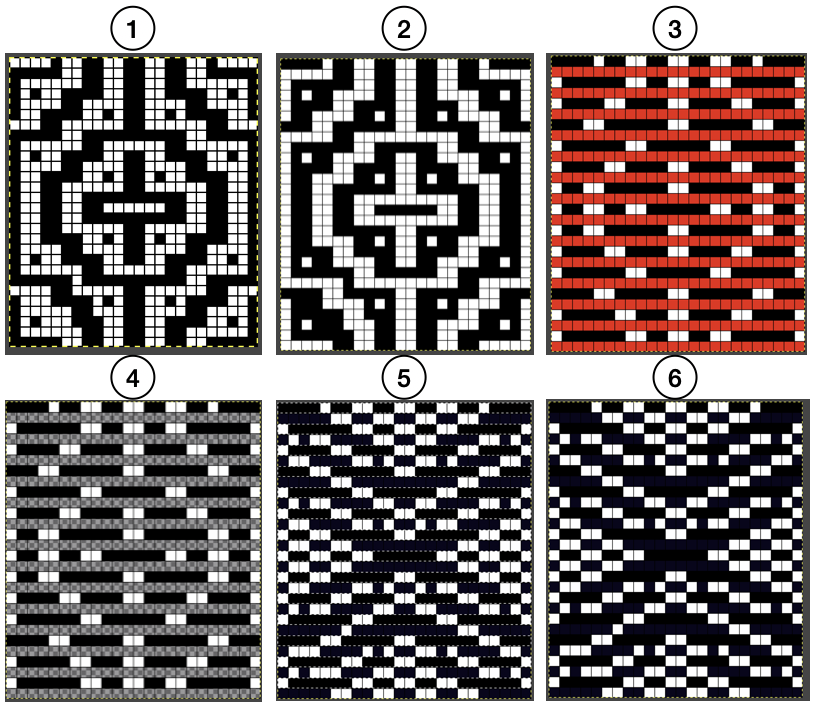

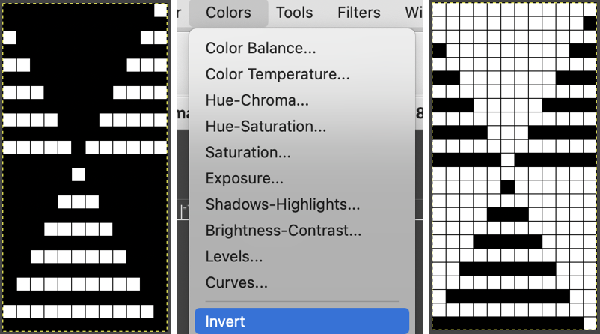

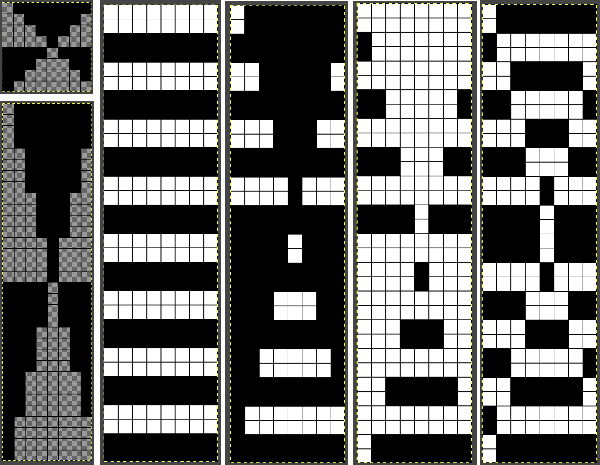

Both layers measure the same pixel dimensions, no placement adjustments are necessary. The mode, highlighted here is changed in a later step.  Color invert the new image

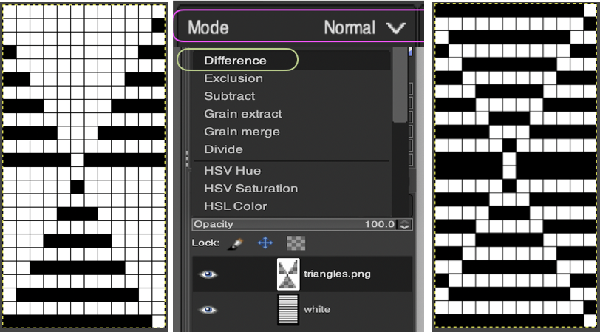

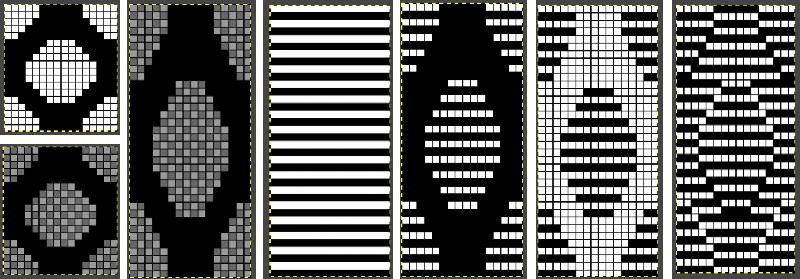

Color invert the new image  Click on the downward pointer to the right of Normal and select Difference. The result is a repeat that may then be saved and used doubled in height to knit DBJ in a variety of settings.

Click on the downward pointer to the right of Normal and select Difference. The result is a repeat that may then be saved and used doubled in height to knit DBJ in a variety of settings.

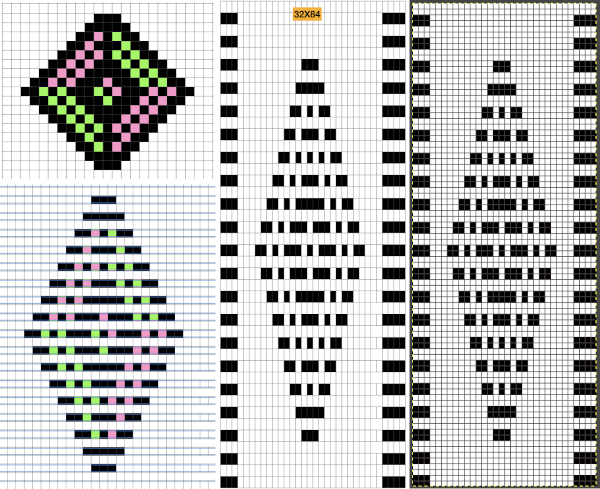

Elongation after download can be avoided by working with the same initial image scaled in height X4 and following the same process, saving and using the repeat on the far right.

Elongation after download can be avoided by working with the same initial image scaled in height X4 and following the same process, saving and using the repeat on the far right.  The same separation was achieved using other methods in the post on fantasy fair isle.

The same separation was achieved using other methods in the post on fantasy fair isle.

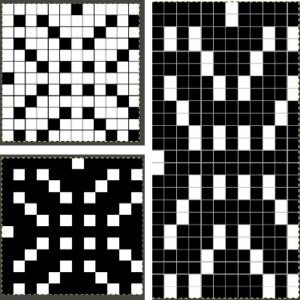

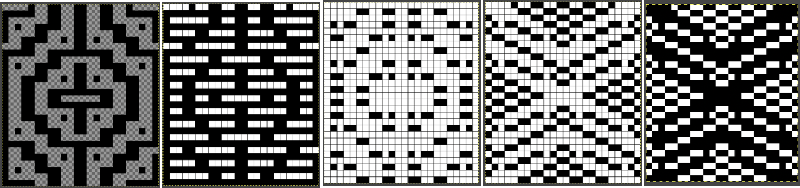

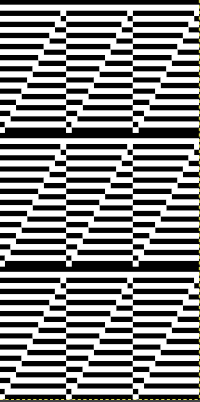

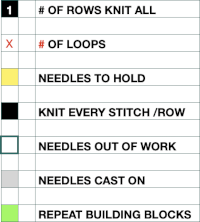

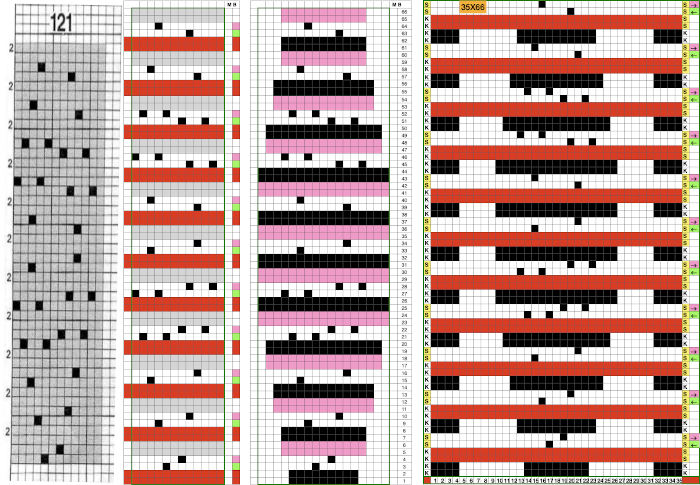

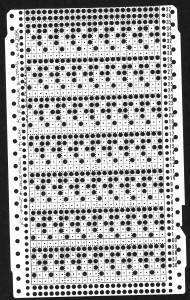

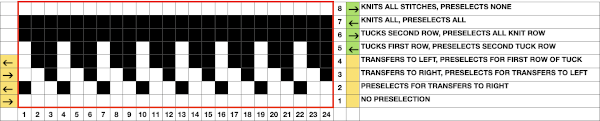

Possible DBJ settings on Brother machines using the elongated final repeat are shown in this grab, part of the post. EOR refers to a repeat that would require double length after the download, the same machine settings apply to any image created in a double-length format prior to download.  Are punchcard knitters left out? In the post on the color separation used for the KRC equivalent separation for a punchcard two results were presented, the full card

Are punchcard knitters left out? In the post on the color separation used for the KRC equivalent separation for a punchcard two results were presented, the full card  and the starting design shown with the color reversed repeat of the above.

and the starting design shown with the color reversed repeat of the above.  The process begins with obtaining the double-length separation

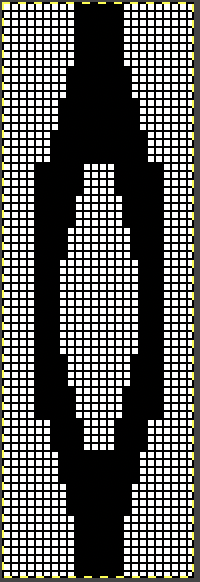

The process begins with obtaining the double-length separation ![]()

after saving the last file on the right as PNG

after saving the last file on the right as PNG ![]() discard any files still open. Open the saved png and process it the same way, changing the ground

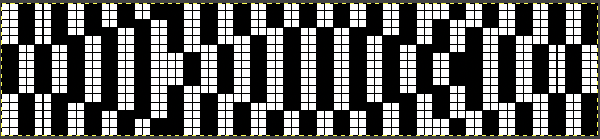

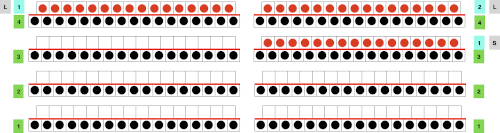

discard any files still open. Open the saved png and process it the same way, changing the ground  Save the last file as png. Punchcard knitters would need to tile the fileX4 in width and height X2 but the final repeat appears different than that in the punchcard post, the proof of success or failure is in the knitting. If the swatch is knit on electronic models, the first preselection row is made from left to right, as it would be if using the built-in color separation. The main bed for this fabric after the preselection row is set to slip in both directions, the ribber, using an even number of needles, is also set to slip in both directions with lili buttons. The 8X32 png

Save the last file as png. Punchcard knitters would need to tile the fileX4 in width and height X2 but the final repeat appears different than that in the punchcard post, the proof of success or failure is in the knitting. If the swatch is knit on electronic models, the first preselection row is made from left to right, as it would be if using the built-in color separation. The main bed for this fabric after the preselection row is set to slip in both directions, the ribber, using an even number of needles, is also set to slip in both directions with lili buttons. The 8X32 png ![]() The result from repeating it twice indicates the separation indeed works.

The result from repeating it twice indicates the separation indeed works.  When a color separation is downloaded it is used as one would a fair isle. If the motif is representational and direction on the knit side matters, any repeats may have to be mirrored horizontally if they are automatically reversed by either your software prior to download or your machine model after it.

When a color separation is downloaded it is used as one would a fair isle. If the motif is representational and direction on the knit side matters, any repeats may have to be mirrored horizontally if they are automatically reversed by either your software prior to download or your machine model after it.

There has been renewed interest in the MK FB group on drop stitch lace recently. I plan to address using this repeat in a future post on knitting the fabric using img2track. ![]()

The 16X72 double-length PNG

The 16X72 double-length PNG ![]() A quicker matching result:

A quicker matching result:

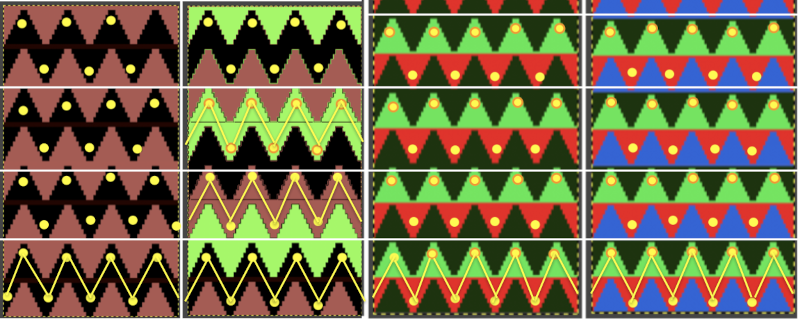

begin with the motif lengthened X4

open a new layer, bucket fill a striped ground and use transparency to change the white in the result to alpha. The layers are immediately combined into a new image

color invert the resulting file

change layer mode by selecting difference from the menu, save the resulting PNG

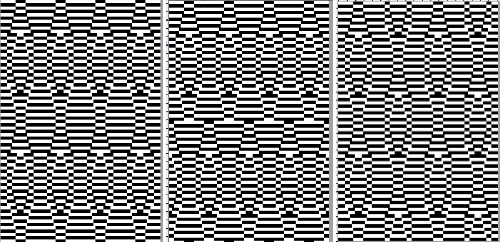

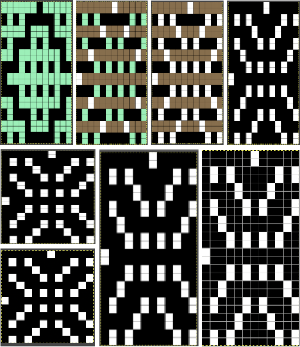

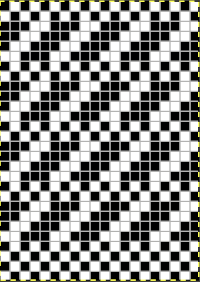

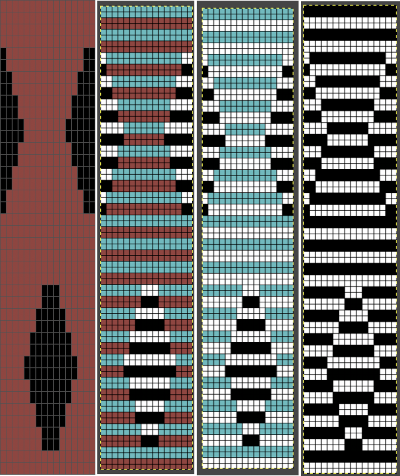

Tiling to visualize alternative repeats, beginning with the 24X72 pixel file

Tiling to visualize alternative repeats, beginning with the 24X72 pixel file![]()

The file for the image in the center, modified to 24X144 pixels file for the image on the right, modified to 48X144 pixels

The file for the image in the center, modified to 24X144 pixels file for the image on the right, modified to 48X144 pixels ![]() Removing the color on every other row for use in specialty fabrics ie drop stitch lace using a modified stitch dropping tool with a now edited 24 stitch repeat, suitable for punchcard models:

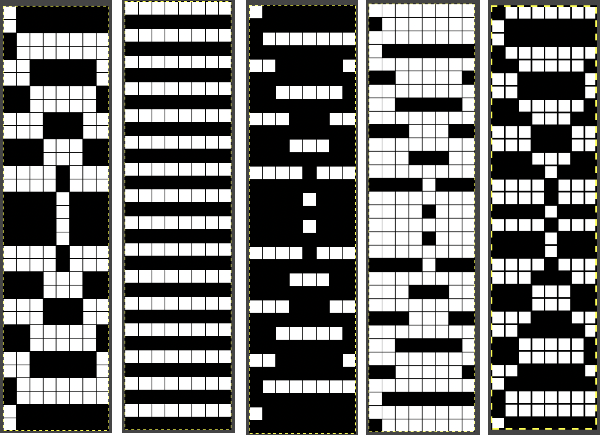

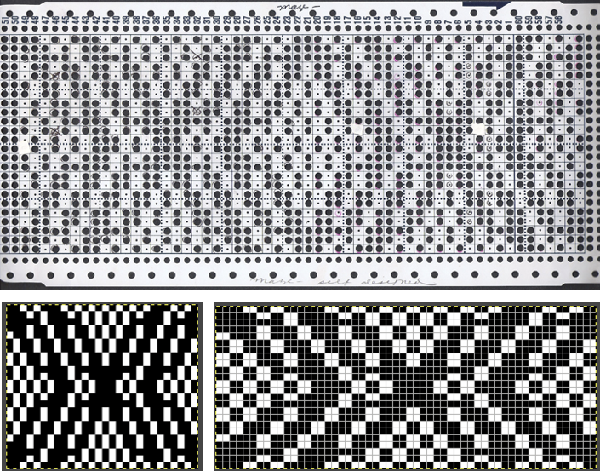

Removing the color on every other row for use in specialty fabrics ie drop stitch lace using a modified stitch dropping tool with a now edited 24 stitch repeat, suitable for punchcard models:  The image is processed as for the previous separation, the final png is exported. Open the saved in Gimp.

The image is processed as for the previous separation, the final png is exported. Open the saved in Gimp.

From the Layer menu choose new.

Create a pattern for bucket-fill in pattern using color, in this case, blue.

A new image immediately appears, export it as a PNG.

Open the saved 3-color PNG.

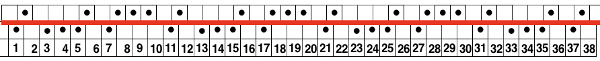

In the tools menu choose the second option for fuzzy select by color, the icon will change.  Using the rectangle tool, select a single blue row, after the selection, press and hold down the shift key and repeat selections of multiple rows in the same color. Each selection will be bordered by a dotted line.

Using the rectangle tool, select a single blue row, after the selection, press and hold down the shift key and repeat selections of multiple rows in the same color. Each selection will be bordered by a dotted line.  Release the shift key. Click on the rectangle select tool and then again in the work window outside the image to set it. The dotted lines will disappear. The same action is repeated if working on segments of the full file at a time.

Release the shift key. Click on the rectangle select tool and then again in the work window outside the image to set it. The dotted lines will disappear. The same action is repeated if working on segments of the full file at a time.

Export the fully altered file as PNG ready for download, or print a gridded version to follow in punching a card.  The 24X72 new png

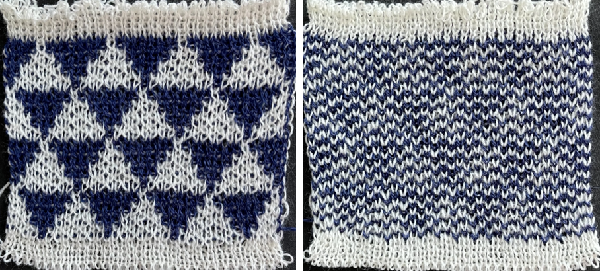

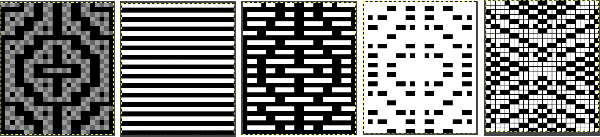

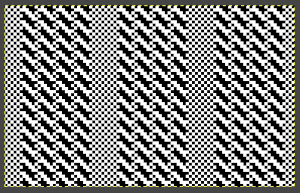

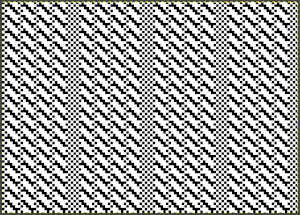

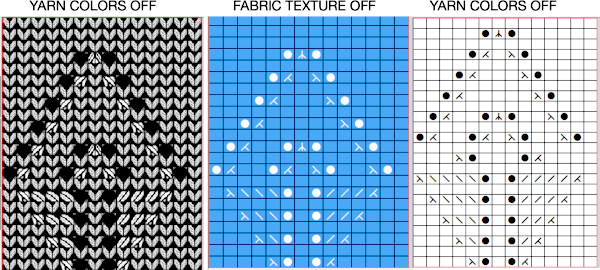

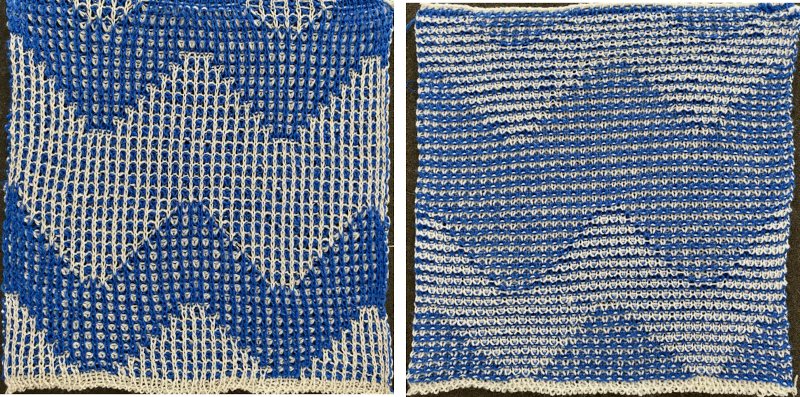

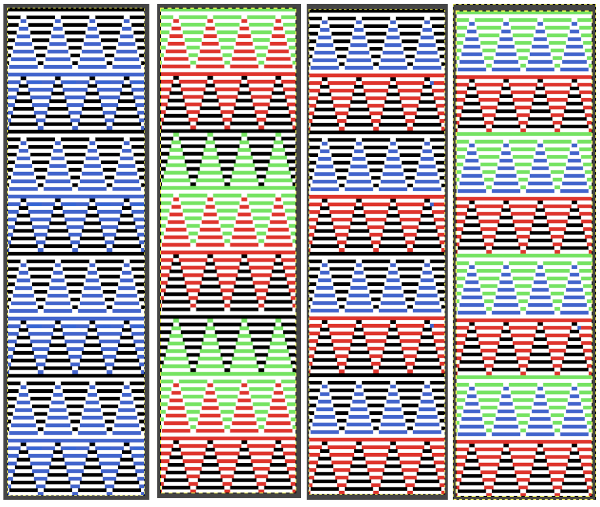

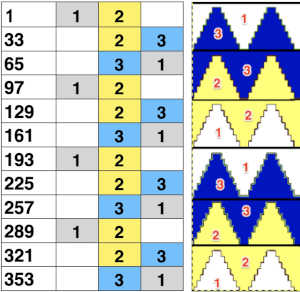

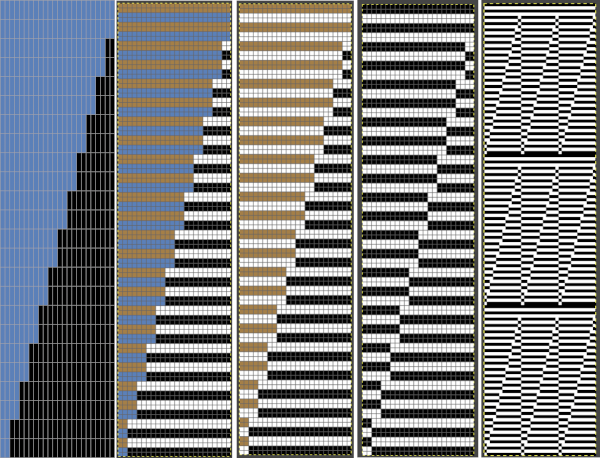

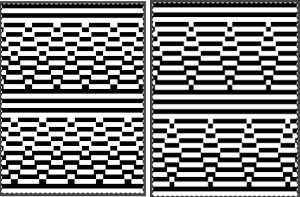

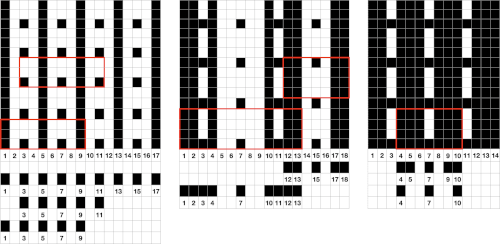

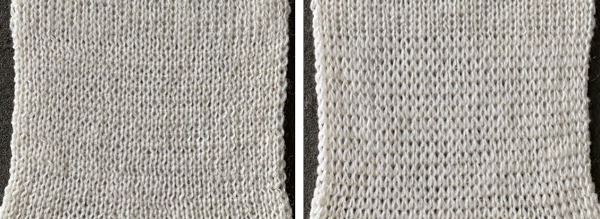

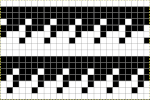

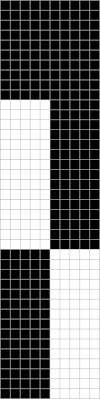

The 24X72 new png ![]() MOSAICS: For proof of concept, I intend to use separations for fabrics accompanied by knit samples in previous posts, beginning with a mosaic one, achieved in the post. The images shown are for the final repeat as separated there are shown at the top of this new image. Below comparisons are made between the original download file and its companion elongated repeat alongside the same developed using Layers

MOSAICS: For proof of concept, I intend to use separations for fabrics accompanied by knit samples in previous posts, beginning with a mosaic one, achieved in the post. The images shown are for the final repeat as separated there are shown at the top of this new image. Below comparisons are made between the original download file and its companion elongated repeat alongside the same developed using Layers Both results require scaling X2 before knitting, whether by button setting changes in the repeat after download or in Gimp before.

Both results require scaling X2 before knitting, whether by button setting changes in the repeat after download or in Gimp before. ![]() After reaching the step where the layer mode is changed to Difference (or Exclusion), stop and save the png, using color reverse at this point will revert to previous a previous layers view

After reaching the step where the layer mode is changed to Difference (or Exclusion), stop and save the png, using color reverse at this point will revert to previous a previous layers view

![]() open the saved png in Gimp, use color reverse, then scale the result doubling its height, save the png for download and knitting without changes in any machine settings.

open the saved png in Gimp, use color reverse, then scale the result doubling its height, save the png for download and knitting without changes in any machine settings.

![]() Testing another image separated in a previous post: the original charted image is now rendered in black and white

Testing another image separated in a previous post: the original charted image is now rendered in black and white  the repeat as a PNG

the repeat as a PNG ![]() tile check

tile check  The process in Layers

The process in Layers The very last file on the right is saved as a PNG. In turn, it is opened again in Gimp, scaled to twice its height

The very last file on the right is saved as a PNG. In turn, it is opened again in Gimp, scaled to twice its height ![]() The non-elongated repeat matches that in the punchcard, which was knit with the machine set to double length

The non-elongated repeat matches that in the punchcard, which was knit with the machine set to double length  Exclusion is the alternative Layer mode which when following the same process yields identical results.

Exclusion is the alternative Layer mode which when following the same process yields identical results.

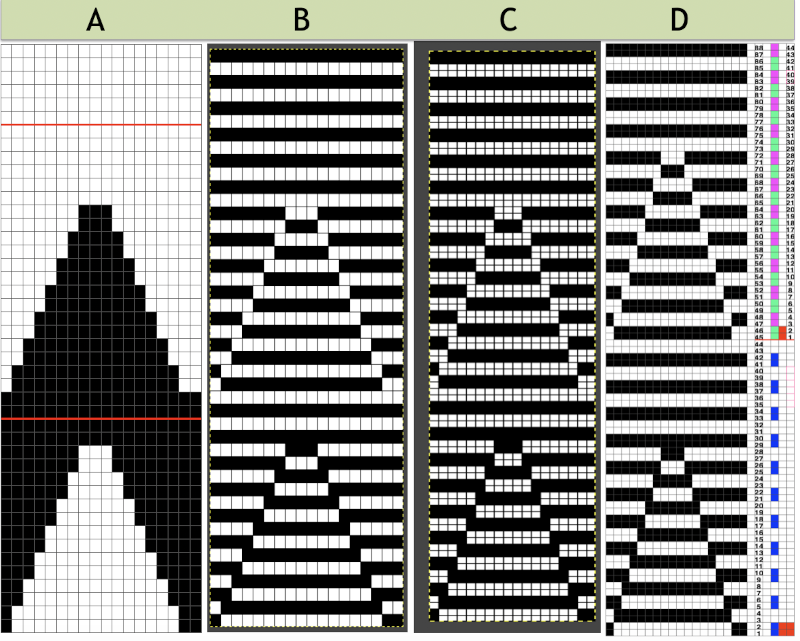

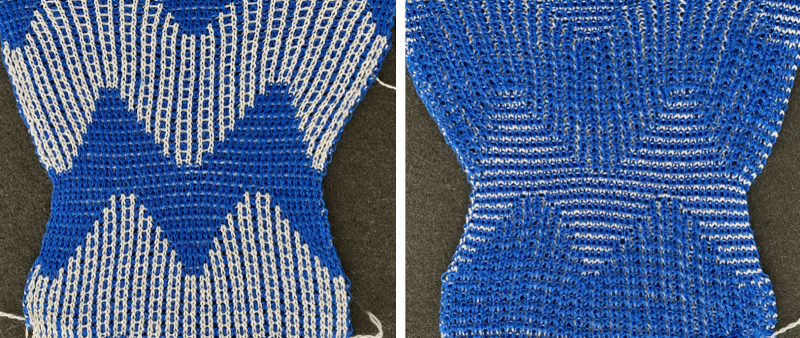

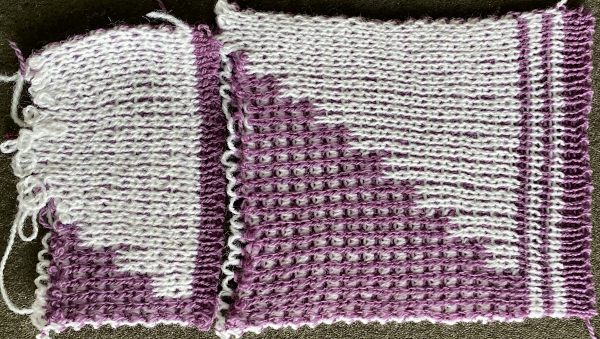

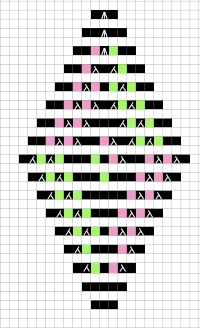

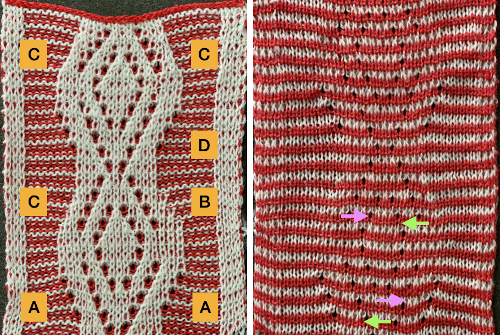

A block slip stitch design from the post requires color inversion and doubling the length.

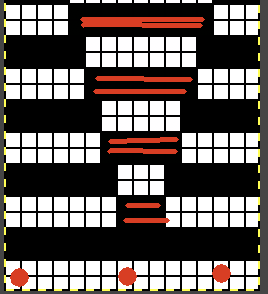

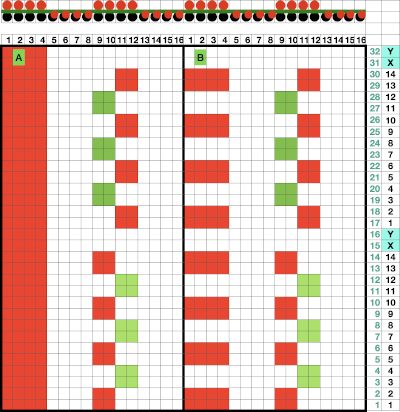

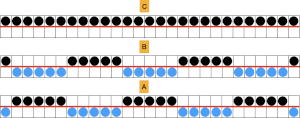

A block slip stitch design from the post requires color inversion and doubling the length.  A: design motif

A: design motif

B: lengthen X 4

C: color reverse

D: new layer filled with pattern

E: color to alpha immediately results in F

F: save the PNG for download

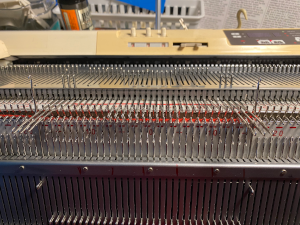

What may be firing in one piece could provide a tube for insertions on either side of the knit.

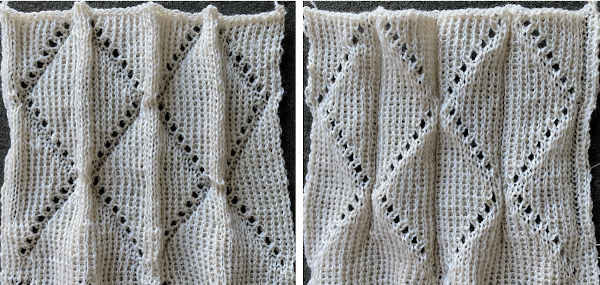

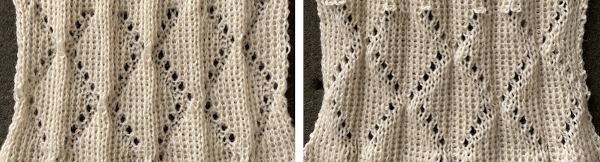

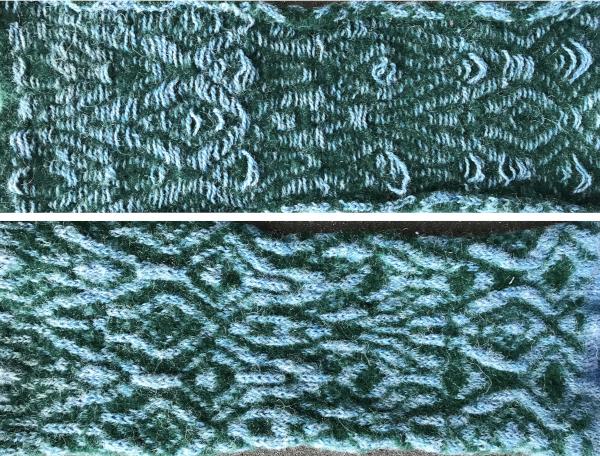

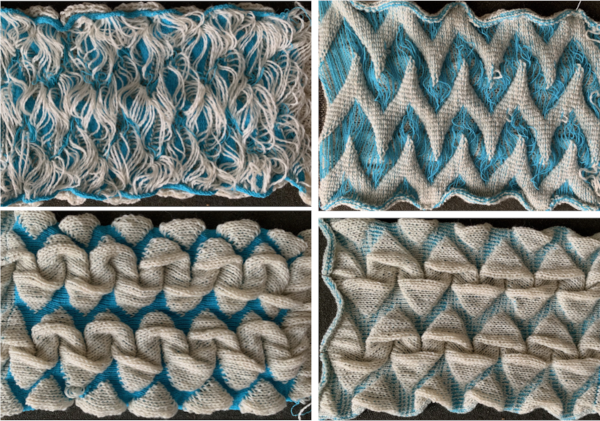

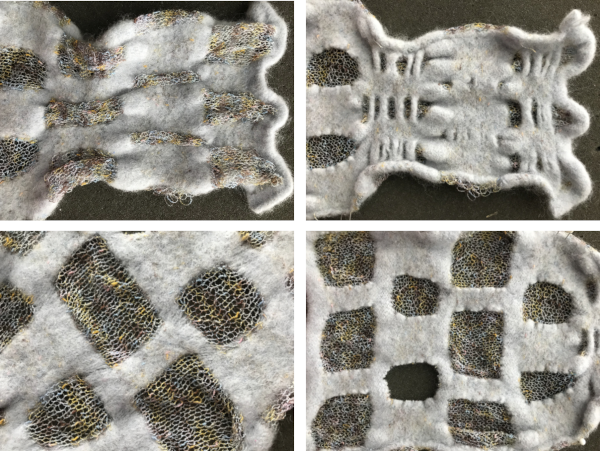

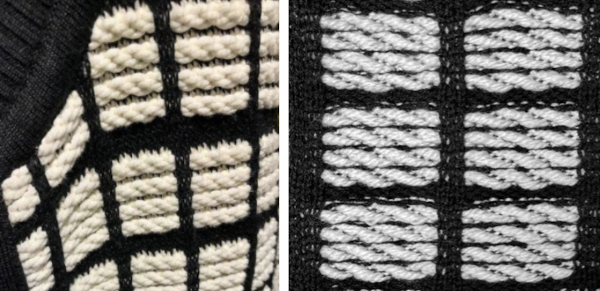

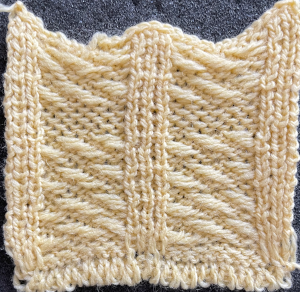

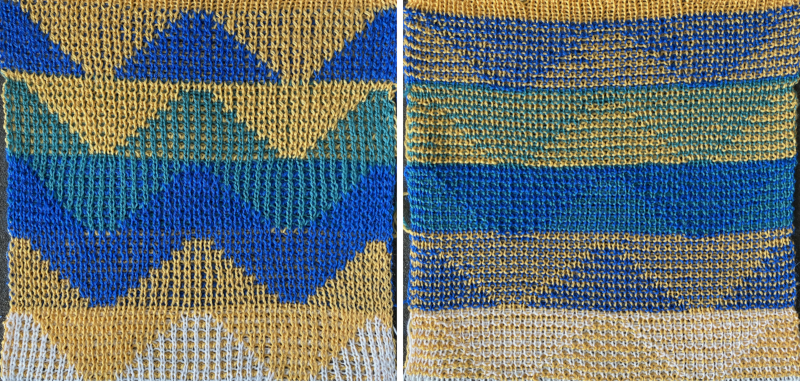

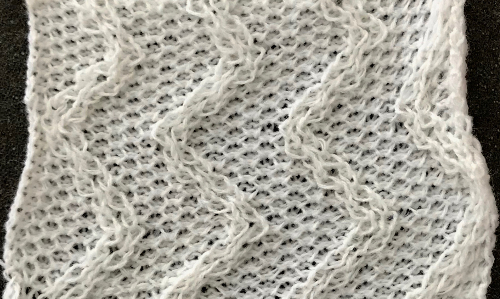

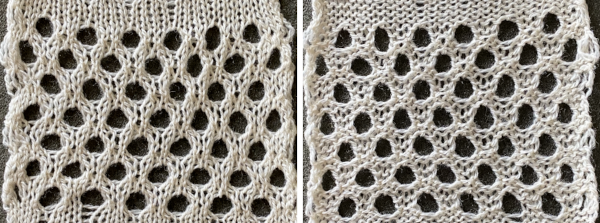

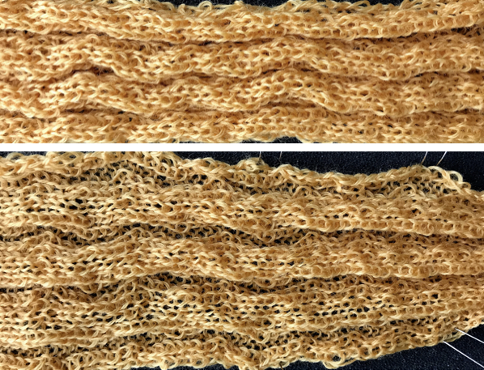

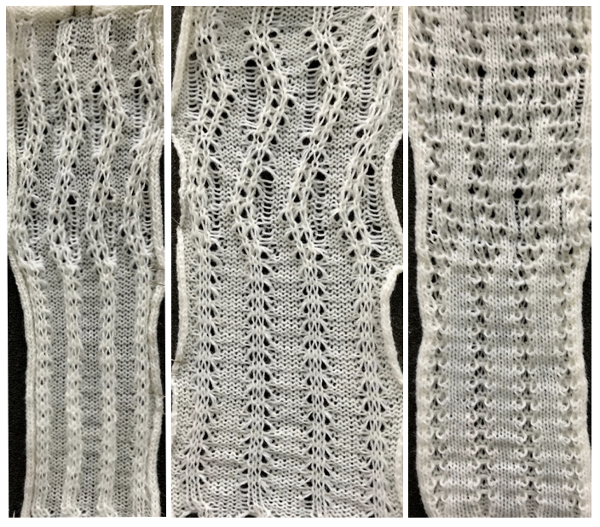

What may be firing in one piece could provide a tube for insertions on either side of the knit. Creating blistered surfaces the easy way, leaf pattern variations: poly-cotton and raffia on the bottom, fishing line as the second yarn line on top. I have found the line for 6lb or fewer works best. The knit is flat.

Creating blistered surfaces the easy way, leaf pattern variations: poly-cotton and raffia on the bottom, fishing line as the second yarn line on top. I have found the line for 6lb or fewer works best. The knit is flat.  Felted rayon chainette and wool; when the main color is wool and the rayon renders the floats there is minimal blistering

Felted rayon chainette and wool; when the main color is wool and the rayon renders the floats there is minimal blistering  the result from reversing the yarn positions creates more bubbling

the result from reversing the yarn positions creates more bubbling Here elastic is used as the second color in the thread lace setting.

Here elastic is used as the second color in the thread lace setting.

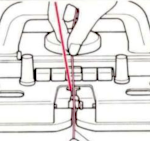

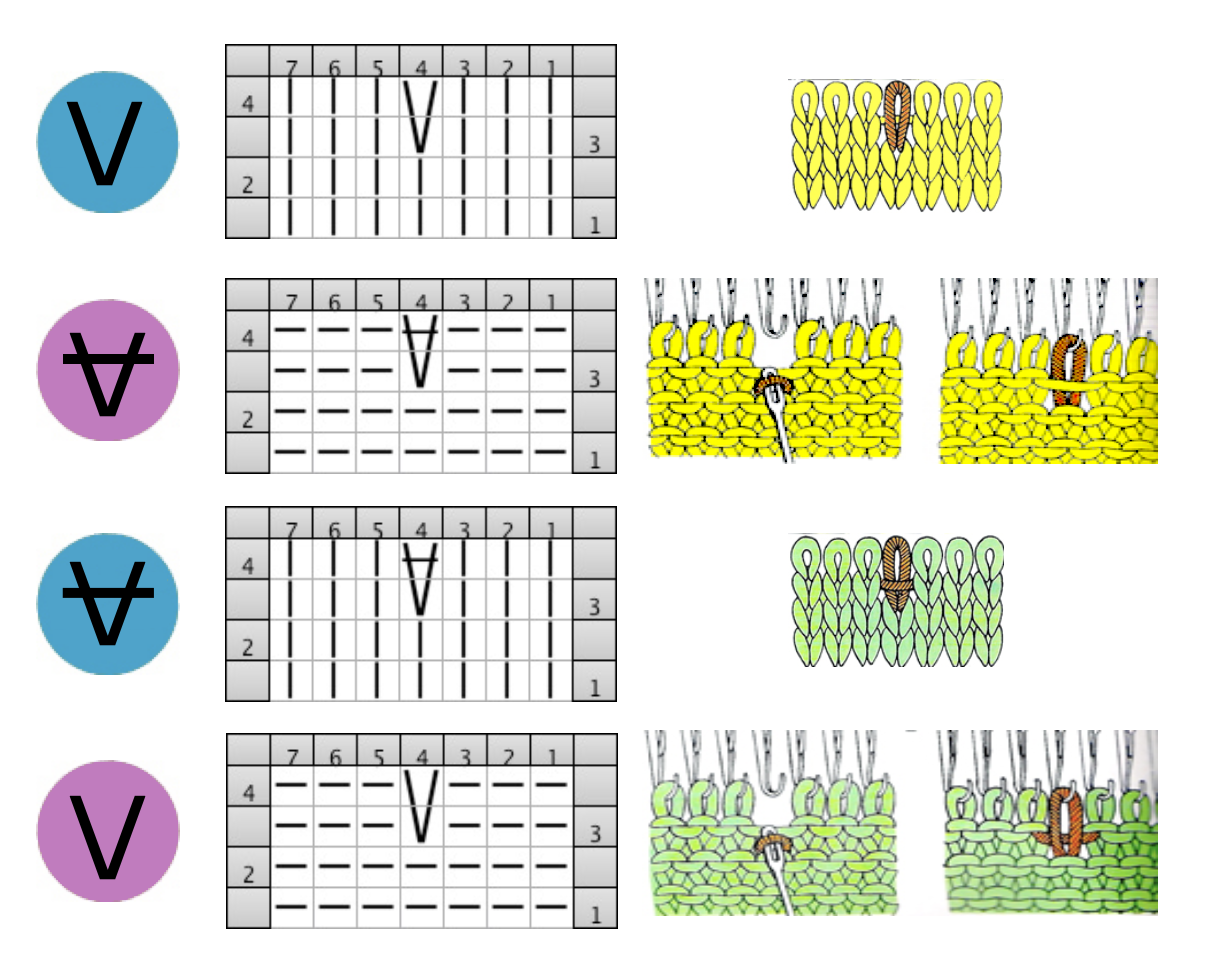

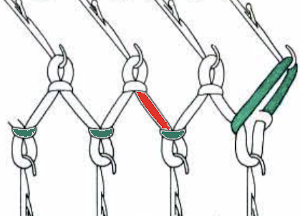

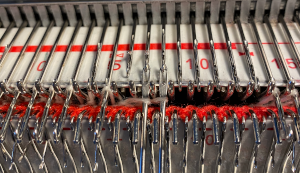

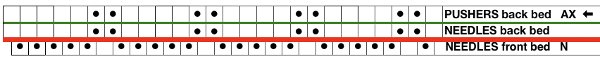

The yarn positions in two color single-pass knitting, remain fixed in their relationship to punched holes. In fair isle patterning, the back feeder, usually labeled A, knits the ground on non-selected needles in the B position. The yarn (red) in the forward, B feeder, knits the stitches on needles selected to the D position which correspond to punched holes or black squares in a mylar, black pixels in a computer file for download. In thread lace, the back A position yarn knit both yarns together, while the forward B position yarn, red thread, knits the forward yarn/color, with the other yarn creating the single set of floats behind it.

The yarn positions in two color single-pass knitting, remain fixed in their relationship to punched holes. In fair isle patterning, the back feeder, usually labeled A, knits the ground on non-selected needles in the B position. The yarn (red) in the forward, B feeder, knits the stitches on needles selected to the D position which correspond to punched holes or black squares in a mylar, black pixels in a computer file for download. In thread lace, the back A position yarn knit both yarns together, while the forward B position yarn, red thread, knits the forward yarn/color, with the other yarn creating the single set of floats behind it.

In addition, large thin fabric shapes can be stiffened over enclosures to create permanent effects in sculptural pieces.

In addition, large thin fabric shapes can be stiffened over enclosures to create permanent effects in sculptural pieces.

A comparison to the mirrored original inspiration, likely knit in thicker yarns

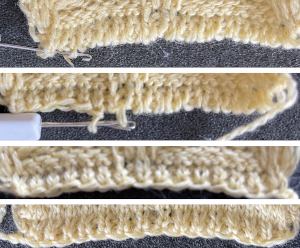

A comparison to the mirrored original inspiration, likely knit in thicker yarns  The knitting process: with any textured or very lacy knits casting on and binding off require special consideration.

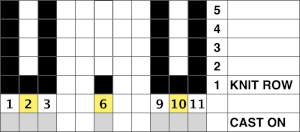

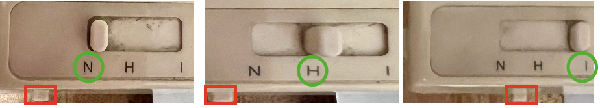

The knitting process: with any textured or very lacy knits casting on and binding off require special consideration. Read the first row of the pattern, cam set to KC1 to ensure end stitches are knit when patterning occurs only on the top bed.

Read the first row of the pattern, cam set to KC1 to ensure end stitches are knit when patterning occurs only on the top bed.

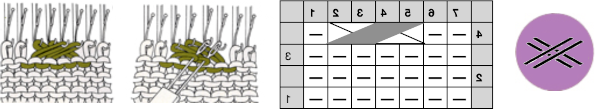

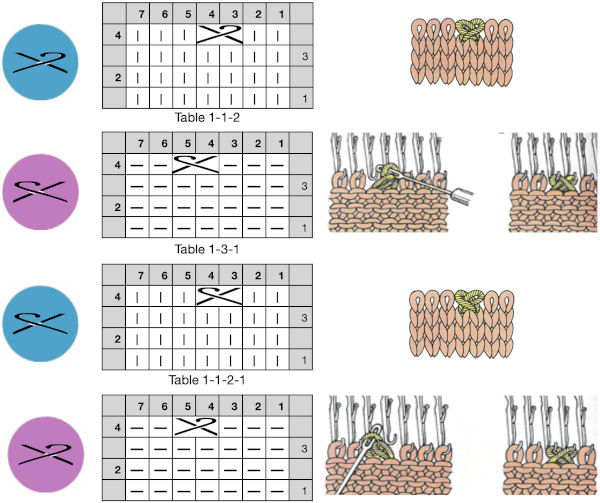

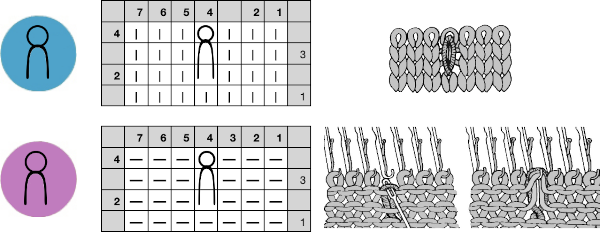

an alternative symbol for the same technique.

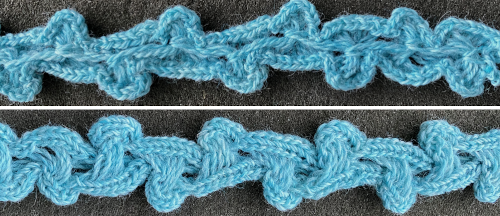

an alternative symbol for the same technique.  The techniques may be used in variations, using 3 or 4 stitches. Yarn and tension are significant factors when any number of stitches are moved across a fixed span on a metal bed machine.

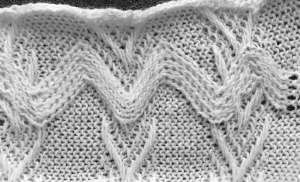

The techniques may be used in variations, using 3 or 4 stitches. Yarn and tension are significant factors when any number of stitches are moved across a fixed span on a metal bed machine. Tuck stitch groups of stitches are gathered in needle hooks, commonly with knit stitches on either side of the gathers.

Tuck stitch groups of stitches are gathered in needle hooks, commonly with knit stitches on either side of the gathers.

More on tuck and slip stitch

More on tuck and slip stitch

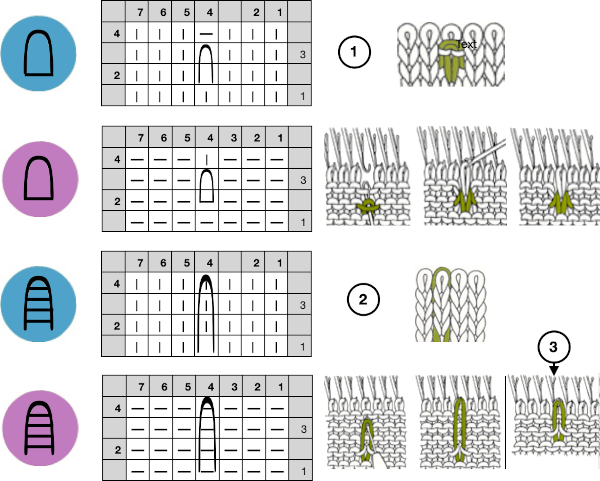

Stitches may be twisted in the body of a knit on the machine by inserting a tool front to back through the stitch, twisting it to the right or left, rehanging the stitch in the same location.

Stitches may be twisted in the body of a knit on the machine by inserting a tool front to back through the stitch, twisting it to the right or left, rehanging the stitch in the same location.

When a ladder needs to be eliminated, there are several ways to deal with returning any empty needles to work. If an empty needle is brought back into work, the first pass to the opposite side will create a loop on the empty needle, the second pass will complete the stitch on that needle, and an eyelet is created. If one wishes to minimize the eyelet, one method is to pick up the purl ridge from the row below on either the right or the left of the empty needle, as illustrated in the fully fashioned increase chart, another is to twist the last ladder and rehang the twisted loop. If multiple needles are out of work, then an e wrap cast on by twisting stitches on every other needle is needed unless needles are brought back into work one at a time, creating secondary eyelet patterns.

When a ladder needs to be eliminated, there are several ways to deal with returning any empty needles to work. If an empty needle is brought back into work, the first pass to the opposite side will create a loop on the empty needle, the second pass will complete the stitch on that needle, and an eyelet is created. If one wishes to minimize the eyelet, one method is to pick up the purl ridge from the row below on either the right or the left of the empty needle, as illustrated in the fully fashioned increase chart, another is to twist the last ladder and rehang the twisted loop. If multiple needles are out of work, then an e wrap cast on by twisting stitches on every other needle is needed unless needles are brought back into work one at a time, creating secondary eyelet patterns.

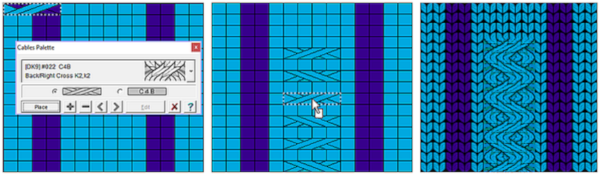

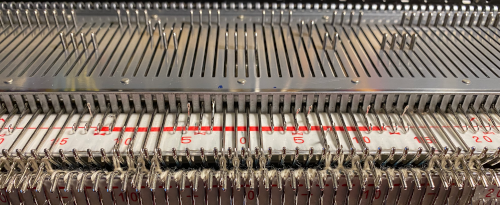

Many cables that can be created in hand knitting are not executable on the knitting machine because the yarn needs to move across fixed widths on a metal bed and the moved stitches need to be large enough to allow the knit carriage to form new stitches properly as it travels back to the opposite side on the following pass. Some techniques can help to make wider cables possible, it is best to test crossing tolerance before planning or following full repeats whether published or self-drawn.

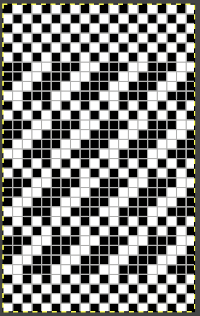

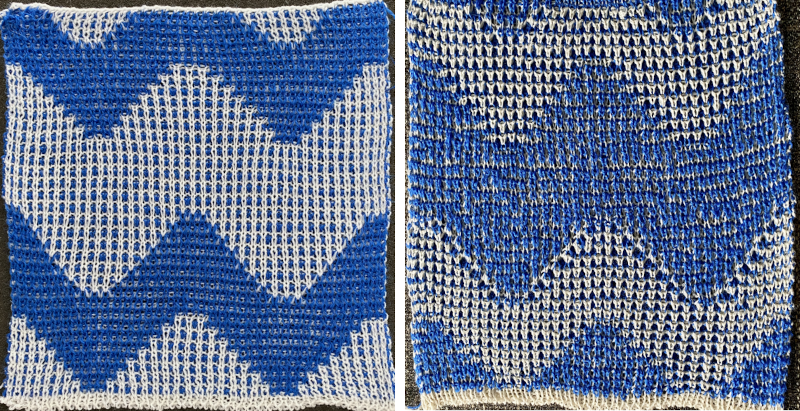

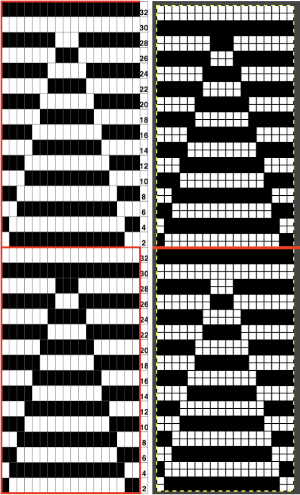

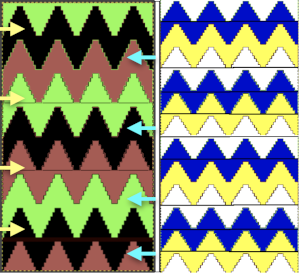

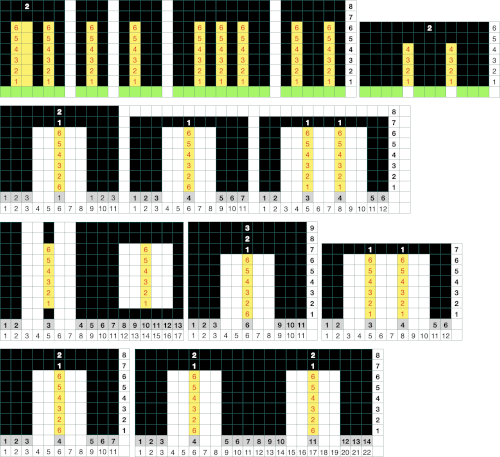

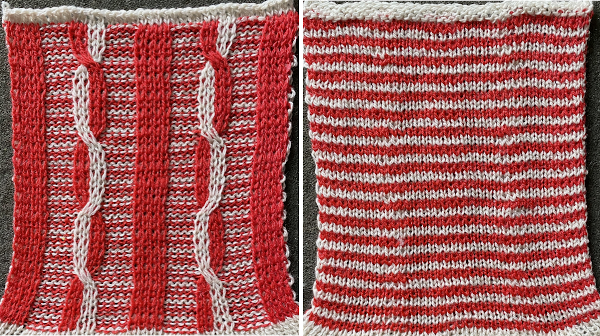

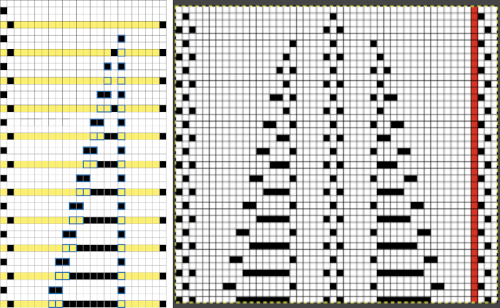

Many cables that can be created in hand knitting are not executable on the knitting machine because the yarn needs to move across fixed widths on a metal bed and the moved stitches need to be large enough to allow the knit carriage to form new stitches properly as it travels back to the opposite side on the following pass. Some techniques can help to make wider cables possible, it is best to test crossing tolerance before planning or following full repeats whether published or self-drawn. The plan is to create a repeat which may be knit using color changes every 2 rows. Each design row knits each color twice, so the standard built-in KRC separation is not a consideration, though the same cam settings may be used in those fabrics as well.

The plan is to create a repeat which may be knit using color changes every 2 rows. Each design row knits each color twice, so the standard built-in KRC separation is not a consideration, though the same cam settings may be used in those fabrics as well.

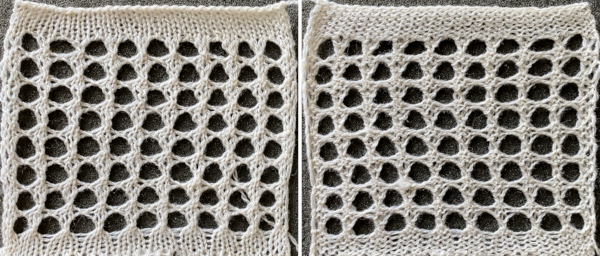

Lock settings are easier to achieve on the Passap than switching out cam buttons in Brother machines. This was knit using 4 carriages. Color one knits with the main bed set to tuck both ways, color two knits with the main bed set to slip both ways. The slip stitch reduces the width of the fabric considerably

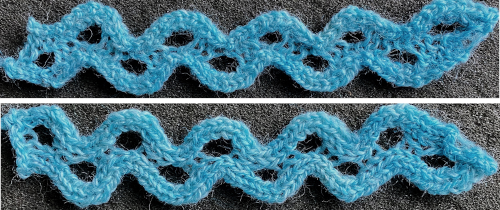

Lock settings are easier to achieve on the Passap than switching out cam buttons in Brother machines. This was knit using 4 carriages. Color one knits with the main bed set to tuck both ways, color two knits with the main bed set to slip both ways. The slip stitch reduces the width of the fabric considerably  Here each color alternately tucks and slips. The choice of cam buttons matters, tucking first from left to right, slipping from right to left, with cam buttons set COL after the first preselection row

Here each color alternately tucks and slips. The choice of cam buttons matters, tucking first from left to right, slipping from right to left, with cam buttons set COL after the first preselection row

This last cam setting appears to my eye to produce a texture “close enough” to the inspiration fabric. Attempting to add more colors: the repeat, D, is still 18 X 88 but is now shifted slightly.

This last cam setting appears to my eye to produce a texture “close enough” to the inspiration fabric. Attempting to add more colors: the repeat, D, is still 18 X 88 but is now shifted slightly.

The existing repeat may be reduced further to 18 X 64, eliminating some of those extra rows in the center of the chevron shape

The existing repeat may be reduced further to 18 X 64, eliminating some of those extra rows in the center of the chevron shape  Whether or not the design is intended to retain chevron shapes in alternating textures, actions may be plotted pre knitting in any way that visually makes sense to the person designing the pattern and tools available to them.

Whether or not the design is intended to retain chevron shapes in alternating textures, actions may be plotted pre knitting in any way that visually makes sense to the person designing the pattern and tools available to them.

Reversing the png so that the more textured stitches will begin with the color in yarn position 1

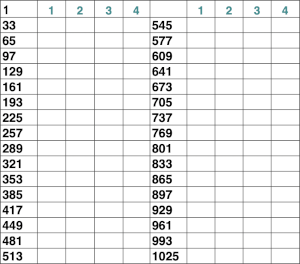

Reversing the png so that the more textured stitches will begin with the color in yarn position 1 Adding colors can be planned cautiously or allowed to happen randomly depending on the preferences of the designer and end-use. Ribber fabric designs are not visible until several inches have been knit, too late to catch color sequence errors. Some machines allow for memo placements or sounds to help track color changes, but only within the initially programmed repeats. A quick spreadsheet can provide customizable checkboxes or added information. For an attempt to retain chevron shapes in different textures:

Adding colors can be planned cautiously or allowed to happen randomly depending on the preferences of the designer and end-use. Ribber fabric designs are not visible until several inches have been knit, too late to catch color sequence errors. Some machines allow for memo placements or sounds to help track color changes, but only within the initially programmed repeats. A quick spreadsheet can provide customizable checkboxes or added information. For an attempt to retain chevron shapes in different textures:

A PDF including row numbers and space for notations

A PDF including row numbers and space for notations

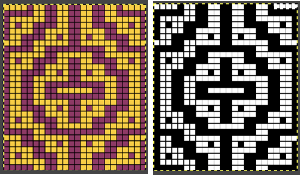

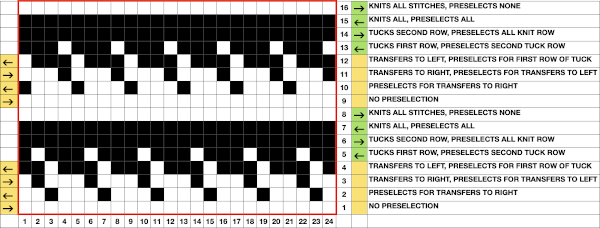

Continuing on a 24 stitch repeat, the original design may be rendered at double height and separated once more, doubling the separation height to 96 rows

Continuing on a 24 stitch repeat, the original design may be rendered at double height and separated once more, doubling the separation height to 96 rows

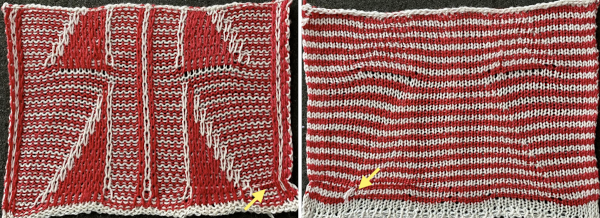

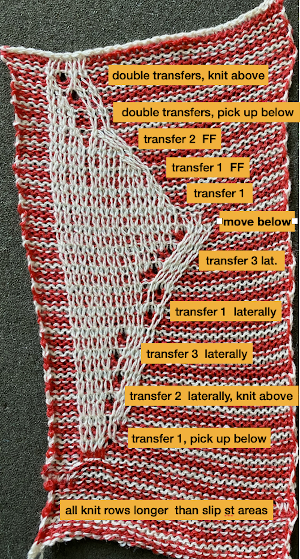

Another even more complex inspiration from a sweater attributed to Falke, Spring 20 collection, using similar stitch structures, but in addition, also transferring stitches between beds exposing a purl striped ground.

Another even more complex inspiration from a sweater attributed to Falke, Spring 20 collection, using similar stitch structures, but in addition, also transferring stitches between beds exposing a purl striped ground.

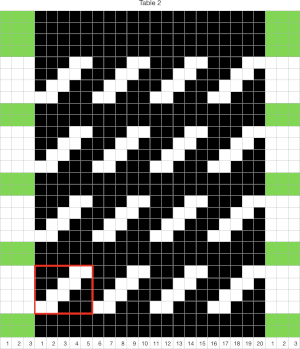

Segments marked with green cells may be grouped in a variety of ways to create repeats in different widths, asymmetrical ones are also a possible consideration

Segments marked with green cells may be grouped in a variety of ways to create repeats in different widths, asymmetrical ones are also a possible consideration

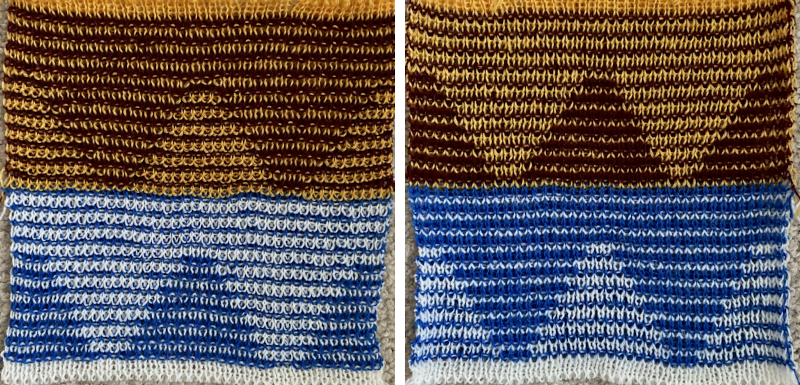

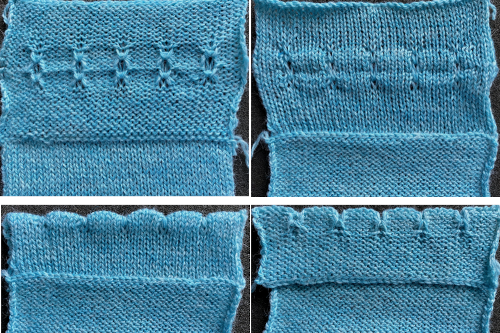

The usual single bed tension for this yarn might be 7 or 8, depending on stitch type. The greater the number of knit stitches on either bed, the closer the tension will have to be adjusted to that used in stocking stitch for the same yarn. Wool also has memory, will want to roll to knit side at the top and bottom, to the purl side along vertical edges, steps often need to be taken to reduce the rolls. Using this repeat

The usual single bed tension for this yarn might be 7 or 8, depending on stitch type. The greater the number of knit stitches on either bed, the closer the tension will have to be adjusted to that used in stocking stitch for the same yarn. Wool also has memory, will want to roll to knit side at the top and bottom, to the purl side along vertical edges, steps often need to be taken to reduce the rolls. Using this repeat

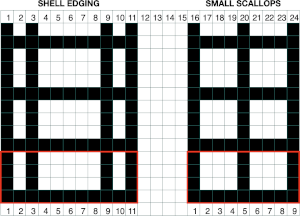

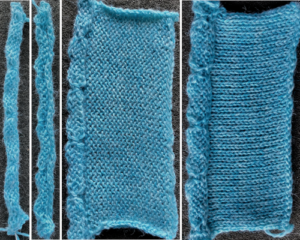

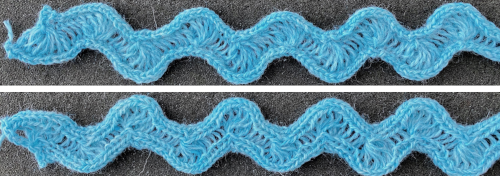

A variety of edgings may be produced by simply hooking up ladder floats created by leaving needles out of work after X number of rows. In this instance chain cast on over 11 needles, dropping the center 5 chains and taking the corresponding needles out of work.

A variety of edgings may be produced by simply hooking up ladder floats created by leaving needles out of work after X number of rows. In this instance chain cast on over 11 needles, dropping the center 5 chains and taking the corresponding needles out of work.

This variation uses the thicker blue yarn, knit at tension 4; 12 rows are knit before hooking up the lower groups of six ladders, which makes the floats easier to pick up or count using a single eye tool. Repeating selection on the same side allows the trim to be easily bent around corners

This variation uses the thicker blue yarn, knit at tension 4; 12 rows are knit before hooking up the lower groups of six ladders, which makes the floats easier to pick up or count using a single eye tool. Repeating selection on the same side allows the trim to be easily bent around corners

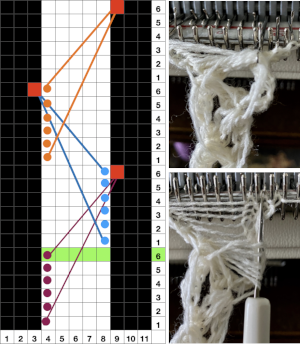

Trims using holding alone border on the possibility of automation using slip stitch programming. A simple one to start: cast on 7 stitches, with the center needle out of work. Knit a few rows, set knit carriage to hold.

Trims using holding alone border on the possibility of automation using slip stitch programming. A simple one to start: cast on 7 stitches, with the center needle out of work. Knit a few rows, set knit carriage to hold.

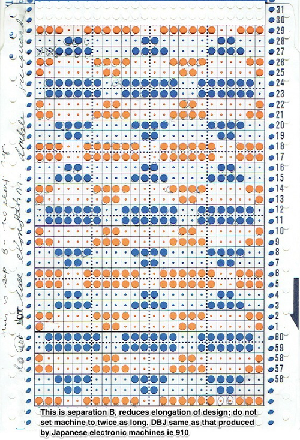

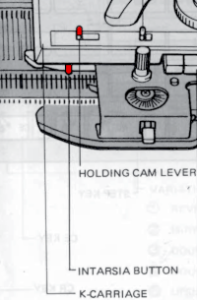

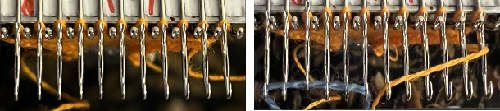

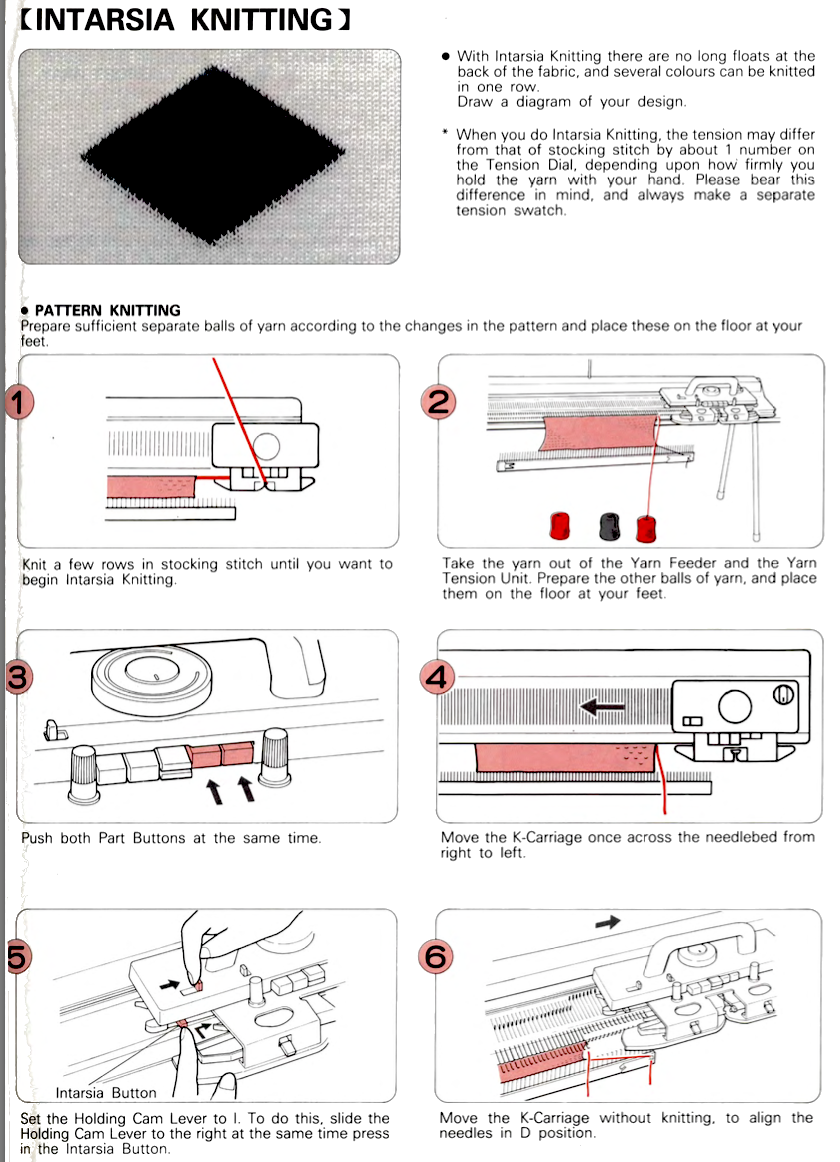

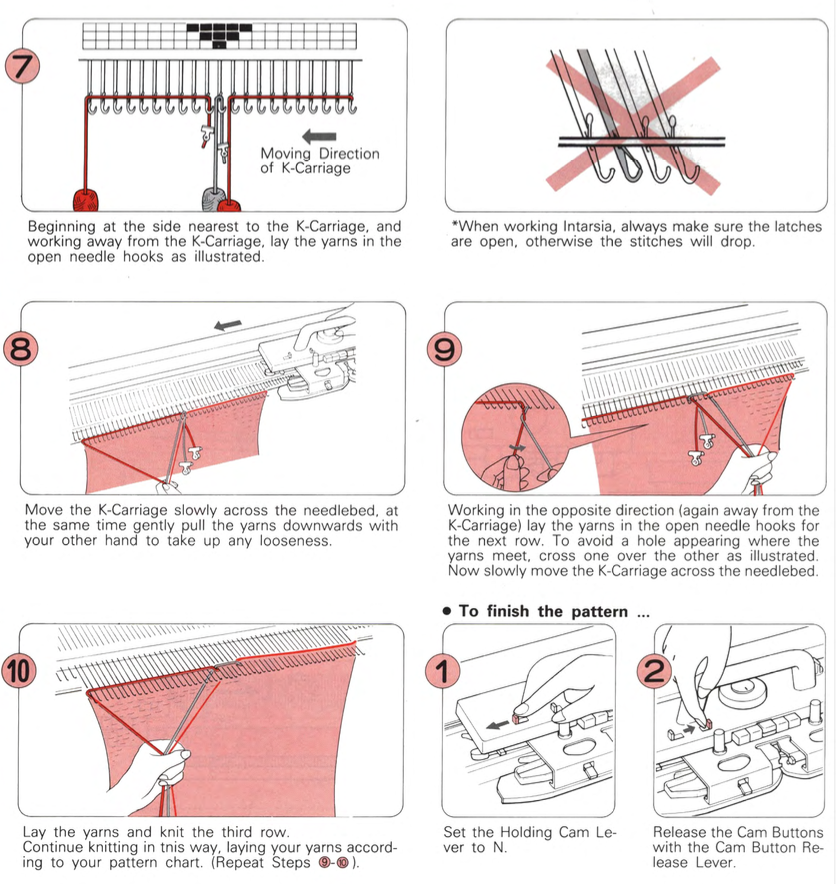

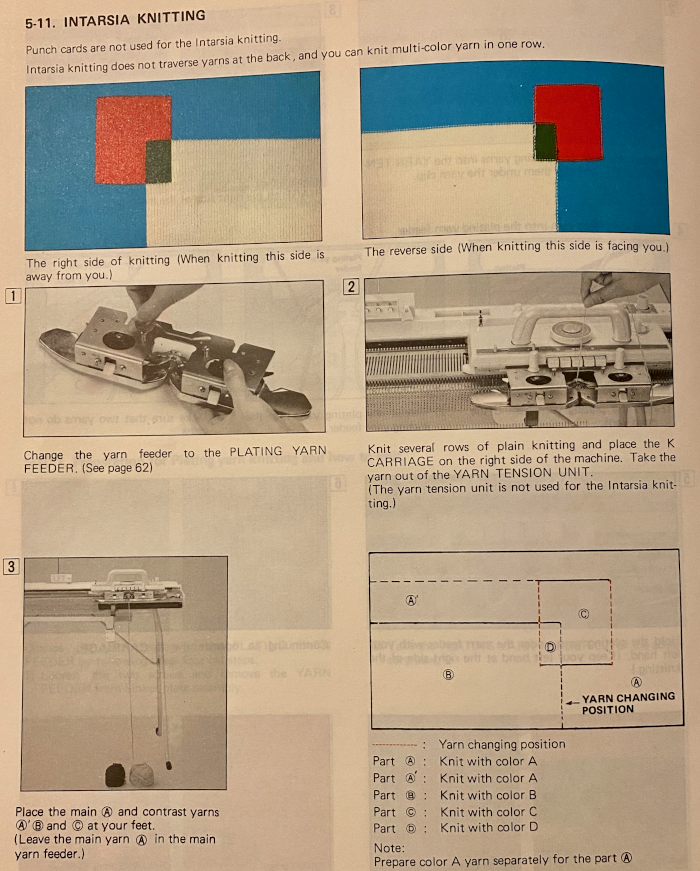

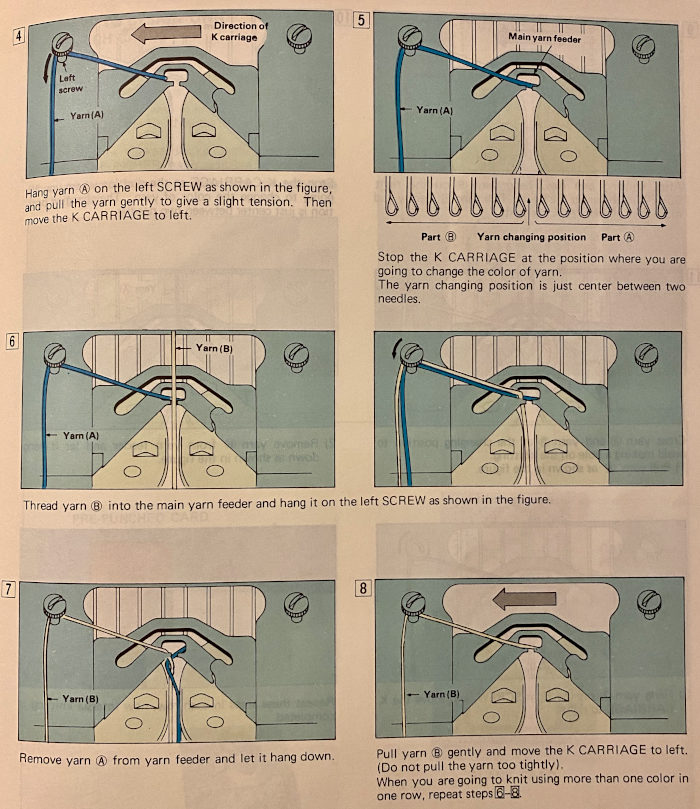

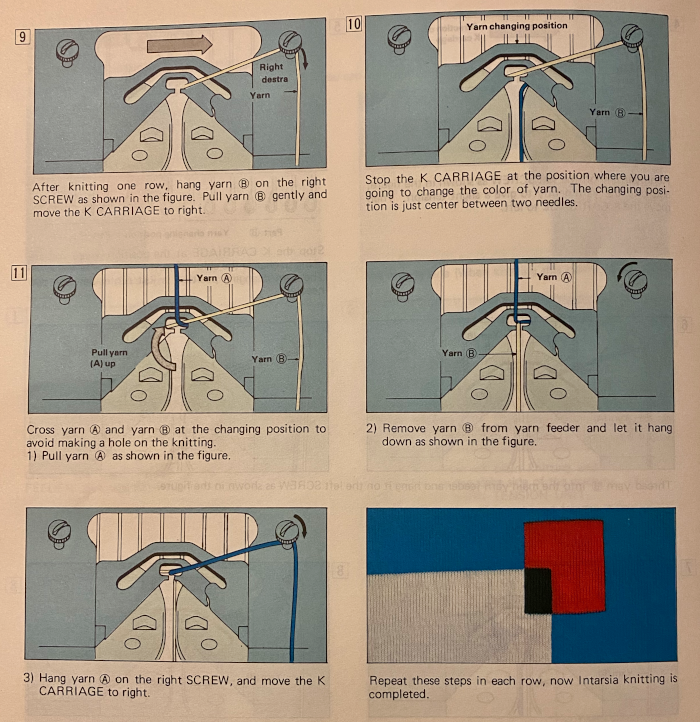

This is from a Japanese language manual for the 891(1987-89) punchcard machine, which appears to introduce the idea of replacing the use of the knit carriage and plaiting feeder with one specifically designed for intarsia

This is from a Japanese language manual for the 891(1987-89) punchcard machine, which appears to introduce the idea of replacing the use of the knit carriage and plaiting feeder with one specifically designed for intarsia

If the intent is to have solid vertical columns of color, those areas as in column marked A, need to be adjusted for using alternating colors as well. Using the repeat on the left of the chart

If the intent is to have solid vertical columns of color, those areas as in column marked A, need to be adjusted for using alternating colors as well. Using the repeat on the left of the chart

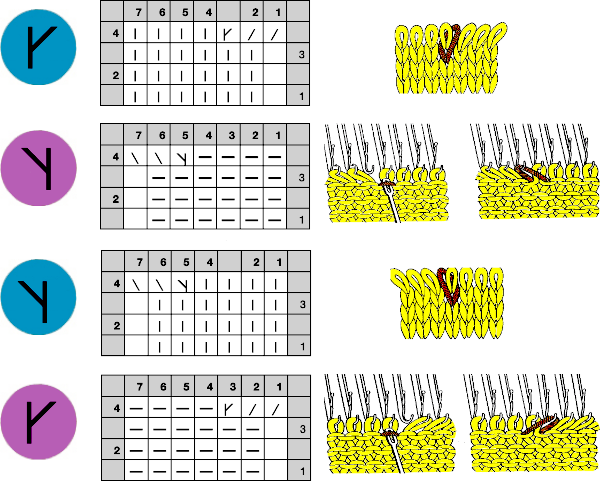

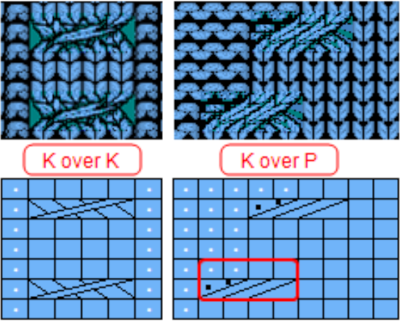

Half Milano stitch formation on the left, full on the right

Half Milano stitch formation on the left, full on the right

In executing the fabric as a hand technique, the main bed is still set to slip in both directions, the ribber to knit every row

In executing the fabric as a hand technique, the main bed is still set to slip in both directions, the ribber to knit every row Begin with simple shapes, examining the quality of increases and decreases, whether single or multiple, eyelet formation. Picking up from the row below before the next pass with the contrast color eliminates eyelets

Begin with simple shapes, examining the quality of increases and decreases, whether single or multiple, eyelet formation. Picking up from the row below before the next pass with the contrast color eliminates eyelets picking up from row below at any point during knitting

picking up from row below at any point during knitting

Simple increases or decreases are made by moving stitches laterally in either or both directions. Increases may be made by moving contrast color stitches laterally, followed by the choice as to whether to fill in the empty needle or allow it to create an eyelet.

Simple increases or decreases are made by moving stitches laterally in either or both directions. Increases may be made by moving contrast color stitches laterally, followed by the choice as to whether to fill in the empty needle or allow it to create an eyelet.

Fully fashioned increases or decreases are made by moving a stitch or a group of them to the adjacent needle/s to the left or the right and then taking the double stitches back to the original position, leaving a single empty needle for the planned eyelet formation. There should not be multiple needles with no stitches on them unless the goal is to expose a stripe of ground

Fully fashioned increases or decreases are made by moving a stitch or a group of them to the adjacent needle/s to the left or the right and then taking the double stitches back to the original position, leaving a single empty needle for the planned eyelet formation. There should not be multiple needles with no stitches on them unless the goal is to expose a stripe of ground  typically, in these exercises, there should be single empty needles after transfers, making certain proper needle selection for the pattern group is maintained

typically, in these exercises, there should be single empty needles after transfers, making certain proper needle selection for the pattern group is maintained  Combining eyelets with lateral increases

Combining eyelets with lateral increases

When transferring stitches, watch for any loops getting caught on gate pegs, as seen on the left below, increases and decreases may be pre-formed on more than single stitches

When transferring stitches, watch for any loops getting caught on gate pegs, as seen on the left below, increases and decreases may be pre-formed on more than single stitches

At the top of the single medallion, the stitches were transferred to the ribber prior to knitting with the same color once there was no needle preselection for it on the top bed.

At the top of the single medallion, the stitches were transferred to the ribber prior to knitting with the same color once there was no needle preselection for it on the top bed. The first preselection row after the chosen cast on is from right to left with end needle selection canceled and the knit carriage already set to slip in both directions, with all required needles on the top bed in the B position.

The first preselection row after the chosen cast on is from right to left with end needle selection canceled and the knit carriage already set to slip in both directions, with all required needles on the top bed in the B position.

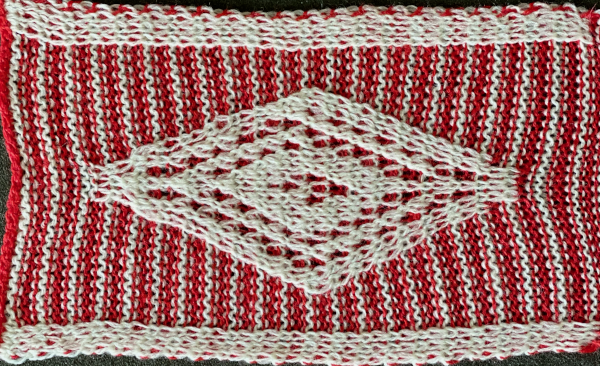

To eliminate the extra white rows, the main bed stays set to slip every row, the ribber settings alternate. It is set to slip for two rows immediately after knitting with the red yarn, then will be reset and knits for 4 consecutive rows. Transfers to create eyelets are made on selected needles on each of those two rows, always toward the carriage, even as the transfers themselves change directions as the angles of the shape decrease toward its center on the top half of the design. After the first transfer and the carriages travel to the right, a long float will be evident, will “disappear” on the return to the left.

To eliminate the extra white rows, the main bed stays set to slip every row, the ribber settings alternate. It is set to slip for two rows immediately after knitting with the red yarn, then will be reset and knits for 4 consecutive rows. Transfers to create eyelets are made on selected needles on each of those two rows, always toward the carriage, even as the transfers themselves change directions as the angles of the shape decrease toward its center on the top half of the design. After the first transfer and the carriages travel to the right, a long float will be evident, will “disappear” on the return to the left.  Patterning selection will reappear as the carriages return to the left.

Patterning selection will reappear as the carriages return to the left.

As with single bed lace, the first pass after transfers creates loops on empty needles, which here need to be kept in upper work, D position after transfers. For non Brother knitters, Brother positions are A, B, D, E, skipping C.

As with single bed lace, the first pass after transfers creates loops on empty needles, which here need to be kept in upper work, D position after transfers. For non Brother knitters, Brother positions are A, B, D, E, skipping C.

Knitting over the loops on the next pass on that bed completes the stitch. This design is knit as continuous, the striping at the bottom is wrong because the red was not picked up after the first 2 rows knit in pattern with white, most sequences for the remaining fabric are 4 passes with white in the feeder, followed by 2 in the red. All eyelets here are reduced in size by picking up from the row below, all transfers for decreases are made laterally, the border is set to a width of 4 stitches, the pivot point for the repeat has been narrowed

Knitting over the loops on the next pass on that bed completes the stitch. This design is knit as continuous, the striping at the bottom is wrong because the red was not picked up after the first 2 rows knit in pattern with white, most sequences for the remaining fabric are 4 passes with white in the feeder, followed by 2 in the red. All eyelets here are reduced in size by picking up from the row below, all transfers for decreases are made laterally, the border is set to a width of 4 stitches, the pivot point for the repeat has been narrowed

Many of the same principles may be applied to designs using tuck stitch settings, where the striping will appear vertically rather than horizontally

Many of the same principles may be applied to designs using tuck stitch settings, where the striping will appear vertically rather than horizontally Brother punchcard machines do not advance pattern rows when two carriages are used for needle selection as each carriage begins to move from the opposite side, the same preselection is repeated. This means editing is required at times if the same designs are to be used on electronic machines, particularly true in lace combination fabrics. The process has been discussed in posts on automating lace edgings with slip stitch settings.

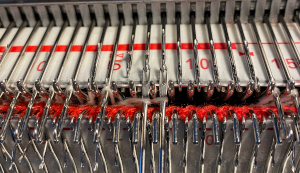

Brother punchcard machines do not advance pattern rows when two carriages are used for needle selection as each carriage begins to move from the opposite side, the same preselection is repeated. This means editing is required at times if the same designs are to be used on electronic machines, particularly true in lace combination fabrics. The process has been discussed in posts on automating lace edgings with slip stitch settings. this is how the yarn is laid over those 2 needles after the first tuck row is completed,

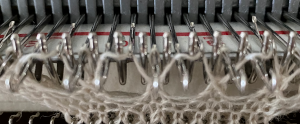

this is how the yarn is laid over those 2 needles after the first tuck row is completed,  and both when using the card and in the first electronic repeat there will be a third tuck loop that is laid over the needle holding the 3 stitches. This is the appearance of the stitch formations just prior to an all-knit row

and both when using the card and in the first electronic repeat there will be a third tuck loop that is laid over the needle holding the 3 stitches. This is the appearance of the stitch formations just prior to an all-knit row  Here analyzing the actions of the punchcard, marking rows according to card actions, the repeat is expanded to include the extra duplicate rows. Though the repeat remains 24 stitches wide, it is no longer usable for use on a punchcard machine.

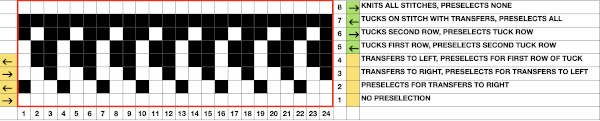

Here analyzing the actions of the punchcard, marking rows according to card actions, the repeat is expanded to include the extra duplicate rows. Though the repeat remains 24 stitches wide, it is no longer usable for use on a punchcard machine.

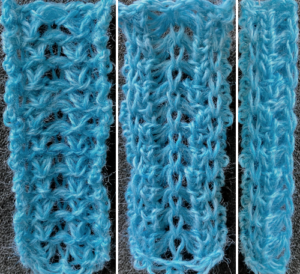

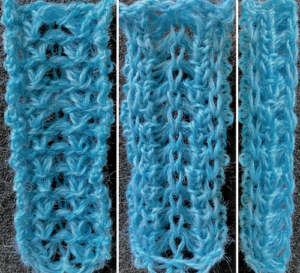

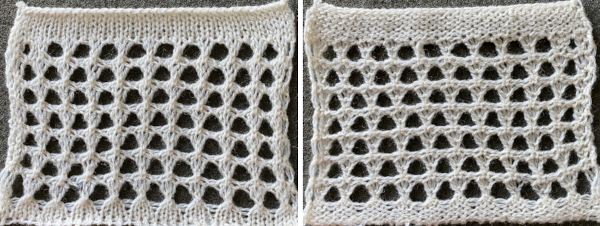

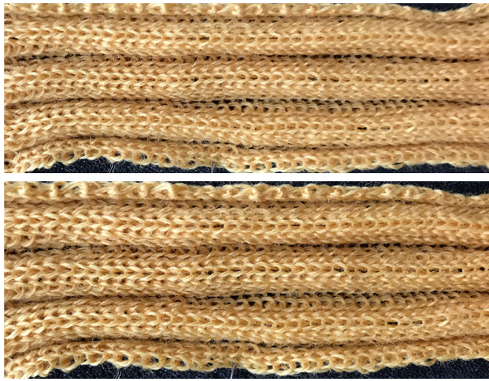

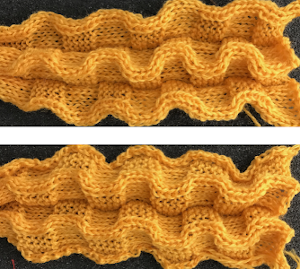

Here the fold is created by 2 stitches tucking for 2 consecutive, then knitting on the same needles for 2 rows on regularly spaced pairs of needles on either bed. Most knitting is on a single bed. A lacey series of eyelets begin to appear, and in some random racking at the top of the swatch, the possibility of developing a secondary pattern due to the combination of racking and tucking begins to show. The middle image is of the fabric slightly stretched. Passap

Here the fold is created by 2 stitches tucking for 2 consecutive, then knitting on the same needles for 2 rows on regularly spaced pairs of needles on either bed. Most knitting is on a single bed. A lacey series of eyelets begin to appear, and in some random racking at the top of the swatch, the possibility of developing a secondary pattern due to the combination of racking and tucking begins to show. The middle image is of the fabric slightly stretched. Passap

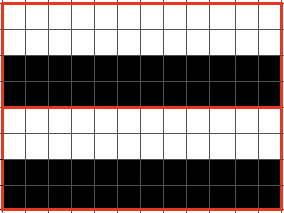

Brother: the ribber can do the stocking stitch background, every needle in work, carriage set to knit. The setup is the same as the Passap diagram. A repeat with 2 black rows of squares followed by 2 white can be programmed on the top bed. On every needle selected rows, pairs of needles will knit, on the white, no selection rows the same pairs of needles will tuck for 2 rows.

Brother: the ribber can do the stocking stitch background, every needle in work, carriage set to knit. The setup is the same as the Passap diagram. A repeat with 2 black rows of squares followed by 2 white can be programmed on the top bed. On every needle selected rows, pairs of needles will knit, on the white, no selection rows the same pairs of needles will tuck for 2 rows.  Moving away from vertical ribs becomes significantly easier if one has a G carriage. The alternative option is to create geometric folds that require transferring between beds. Any of these fabrics are best knit in a yarn that has memory and can spring back. Yarns such as acrylic can be permanently flattened by pressing, resulting in loss of texture. A quick experiment: black cells represent knit stitches, blue purl ones

Moving away from vertical ribs becomes significantly easier if one has a G carriage. The alternative option is to create geometric folds that require transferring between beds. Any of these fabrics are best knit in a yarn that has memory and can spring back. Yarns such as acrylic can be permanently flattened by pressing, resulting in loss of texture. A quick experiment: black cells represent knit stitches, blue purl ones  The needle setups: after casting on, transfer for a stitch configuration based in this case, of blocks that are 5 stitches wide. A single needle on the opposite bed is used on each outside edge of all needles in work.

The needle setups: after casting on, transfer for a stitch configuration based in this case, of blocks that are 5 stitches wide. A single needle on the opposite bed is used on each outside edge of all needles in work.

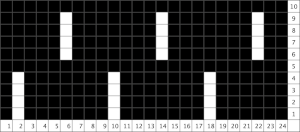

The repeat, 10 stitches by 40 rows.

The repeat, 10 stitches by 40 rows.

Pleated one color “shadow lace” in

Pleated one color “shadow lace” in